Analysis and Optimization of Seeding Depth Control Parameters for Wide-Row Uniform Seeding Machines for Wheat

Abstract

1. Introduction

2. Materials and Methods

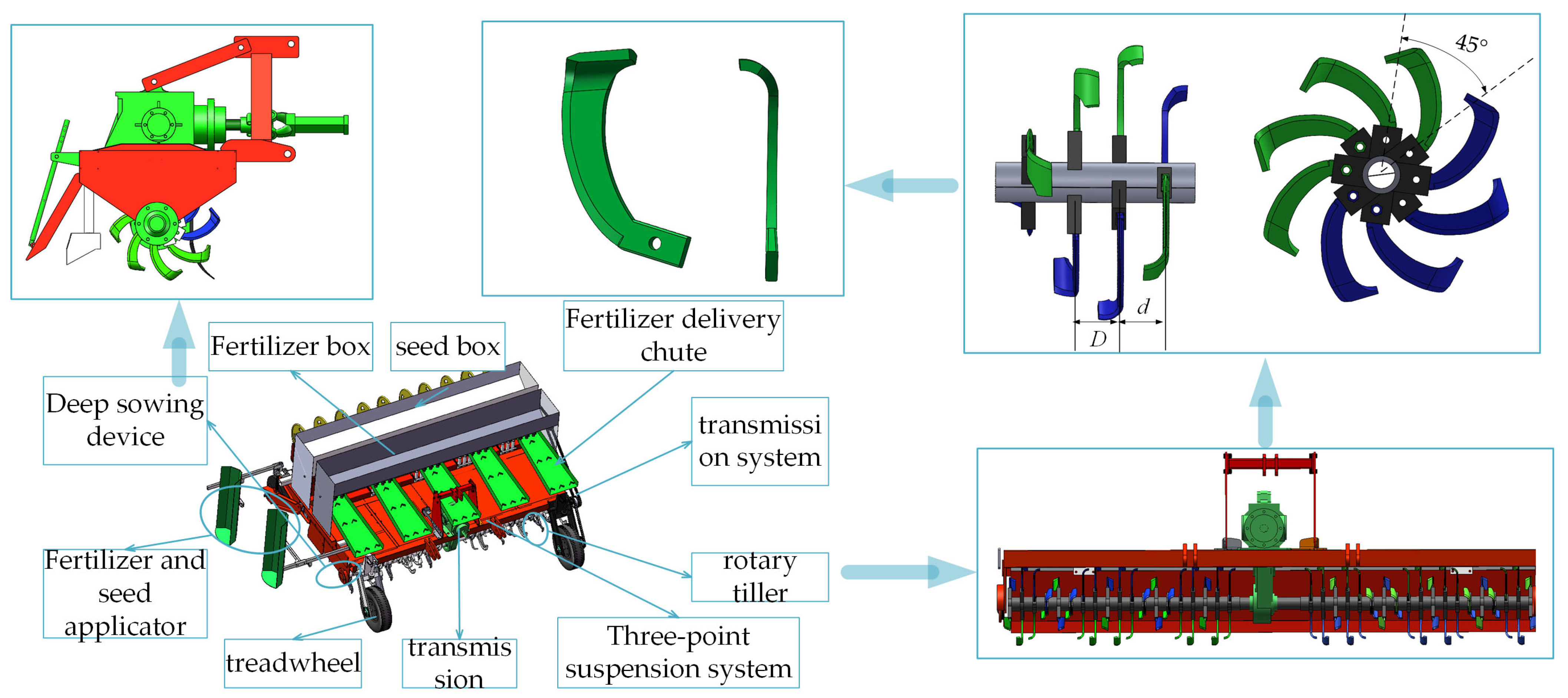

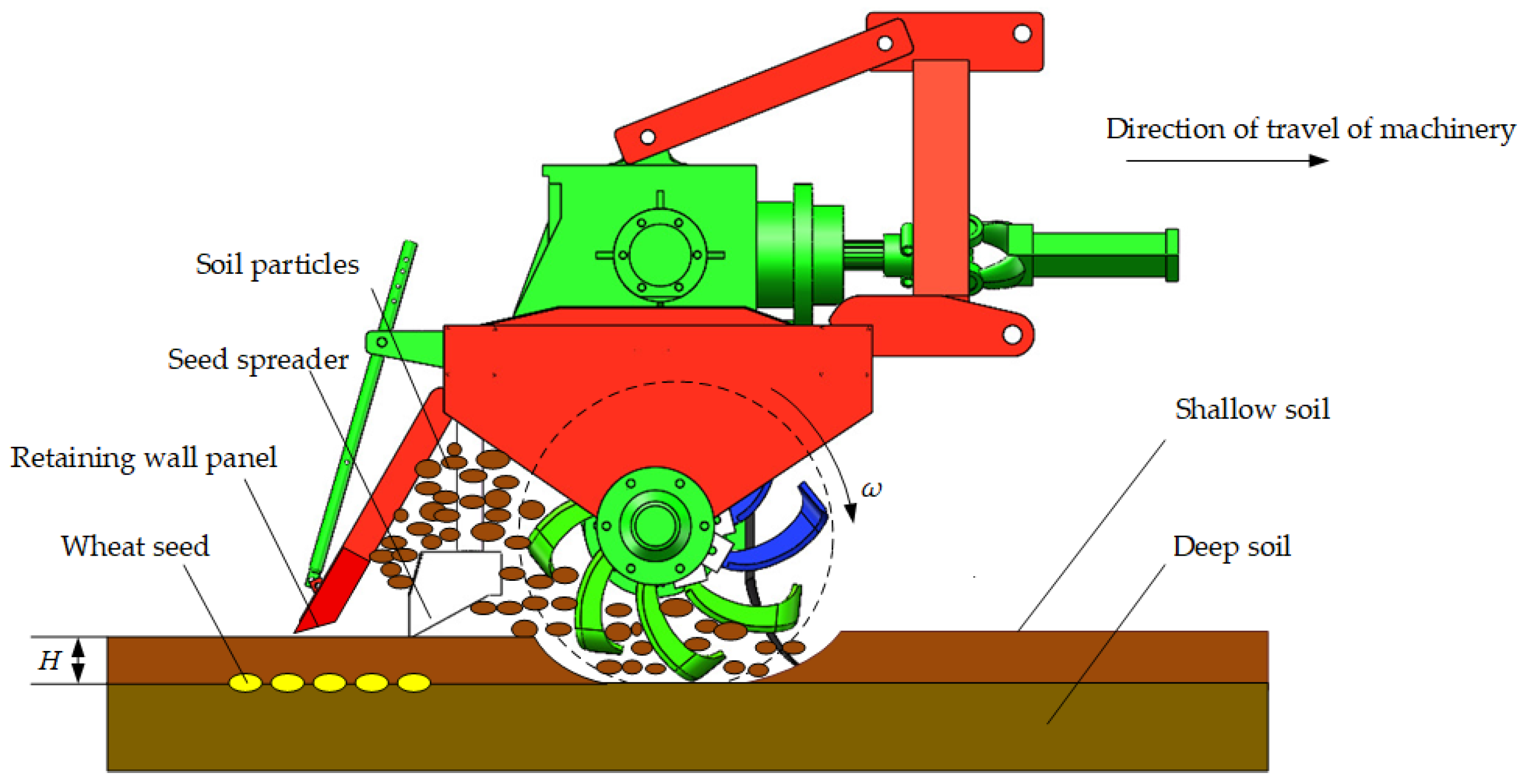

2.1. Structure and Working Principle of the Whole Machine

2.2. Structure and Motion Analysis of the Rotary Tillage Soil Throwing Device

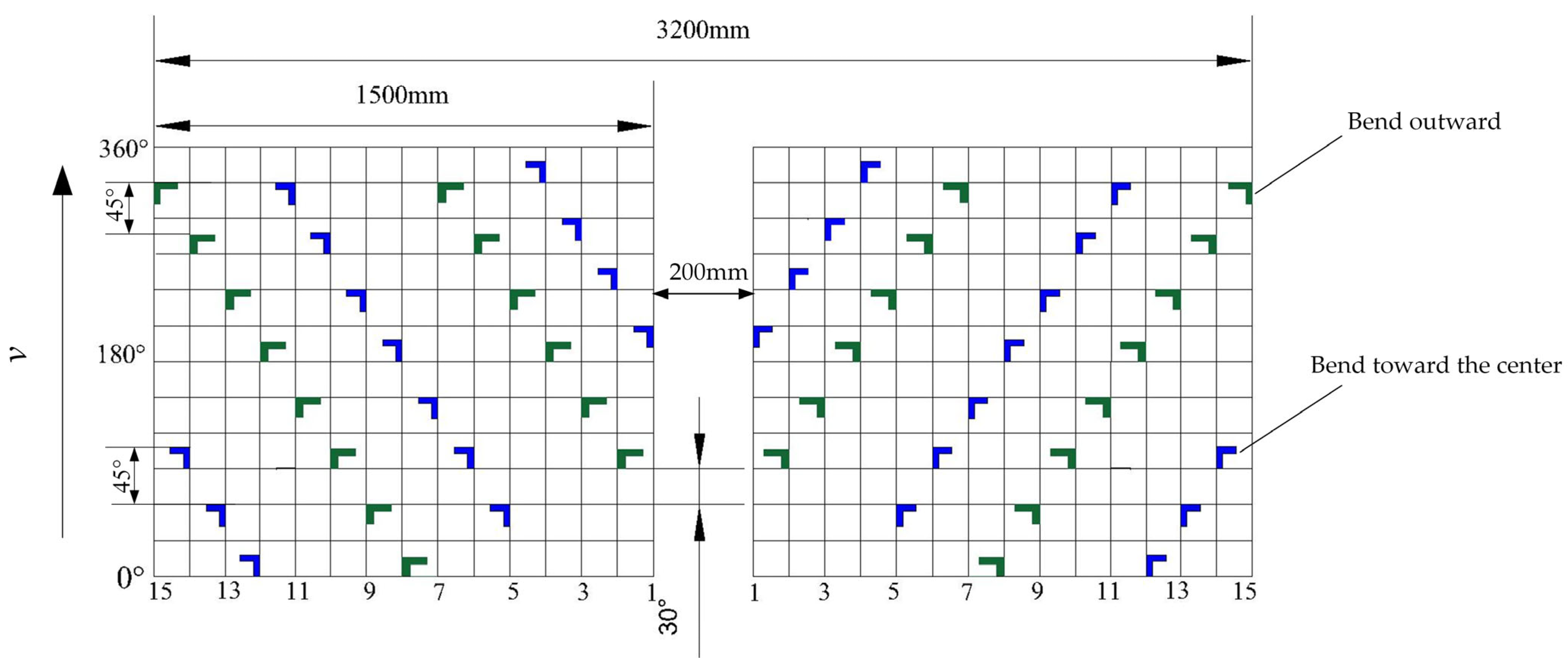

2.2.1. Structure of the Rotary Plowing Device

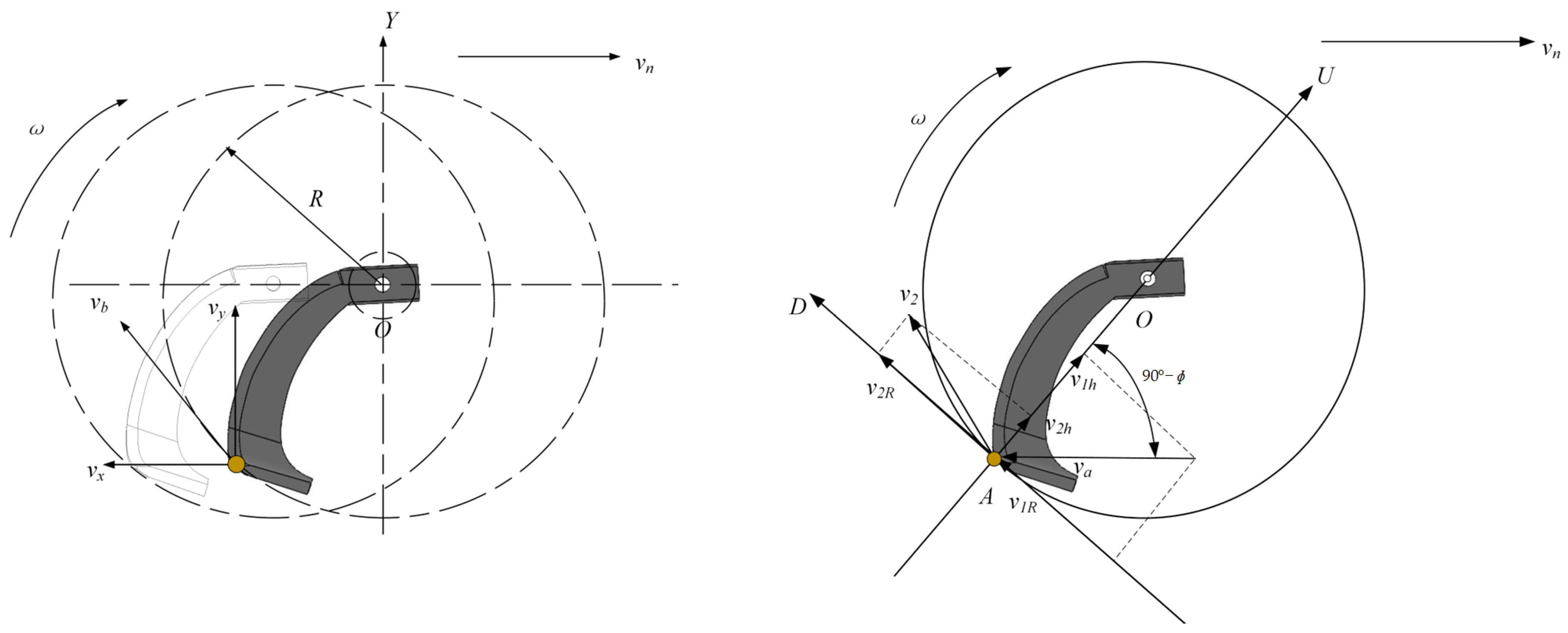

2.2.2. Motion Analysis of Rotary Plowing Devices

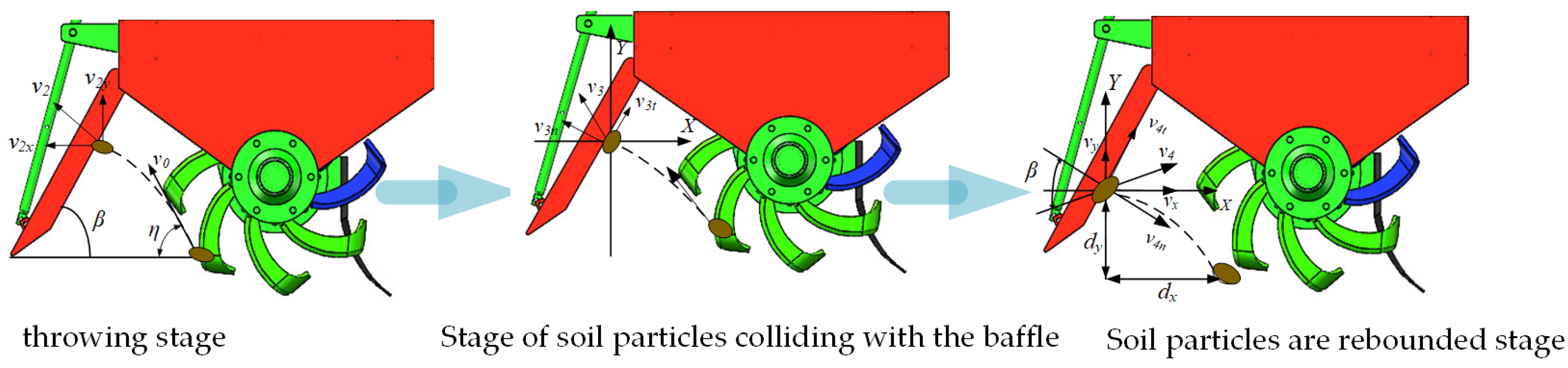

2.2.3. Trajectory Analysis of Thrown Soil Particles and Retaining Plates

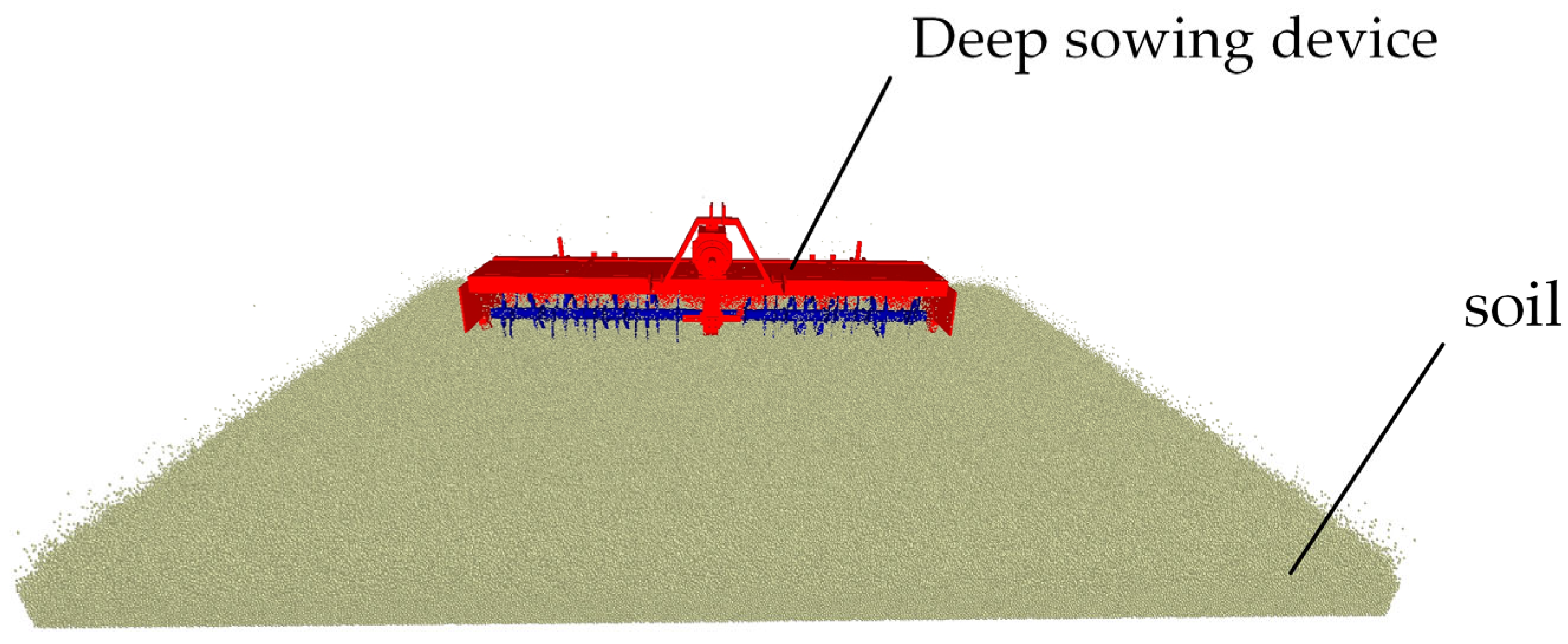

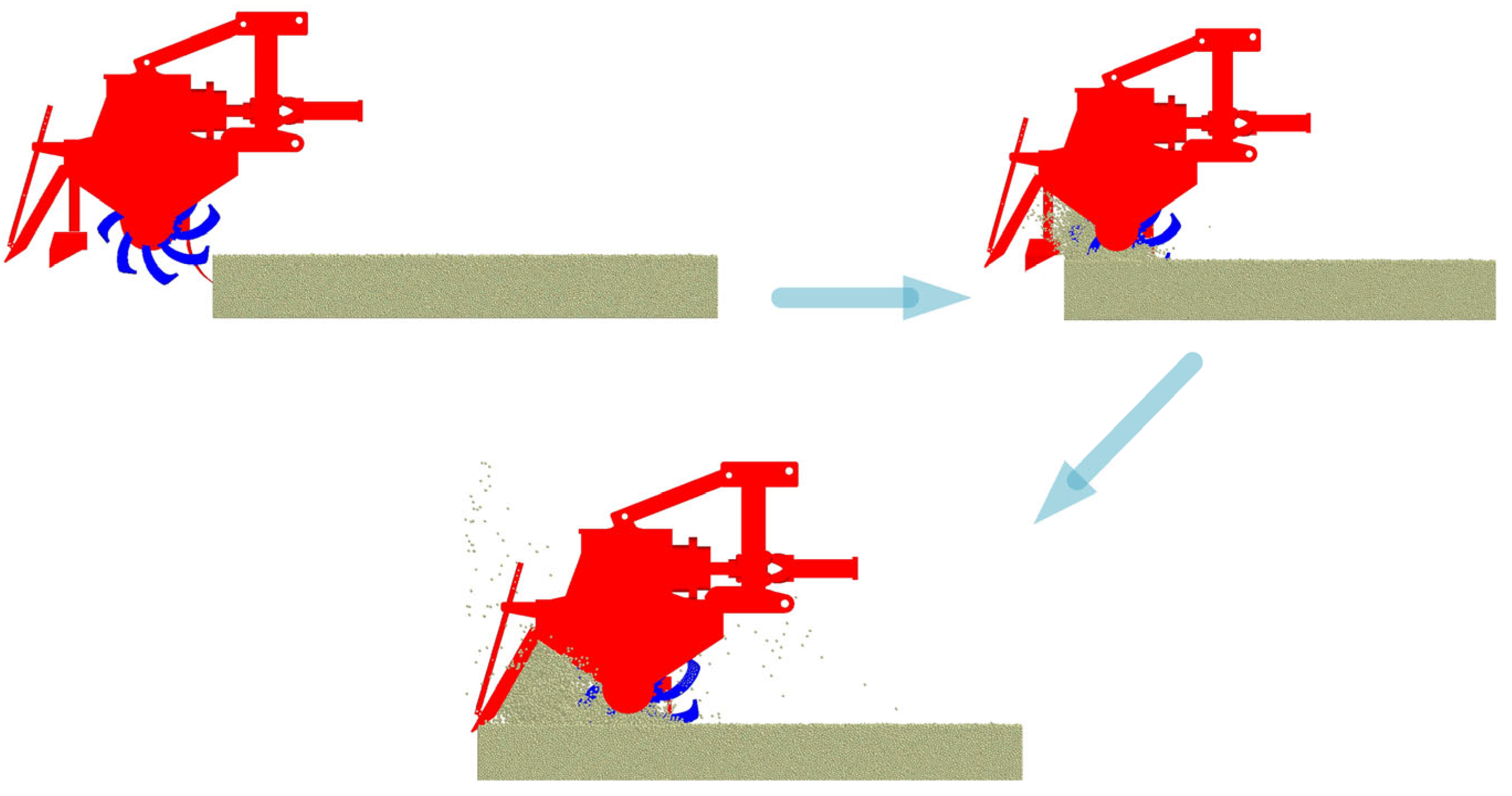

2.3. Simulation Test

2.3.1. Simulation Test Parameter Setting

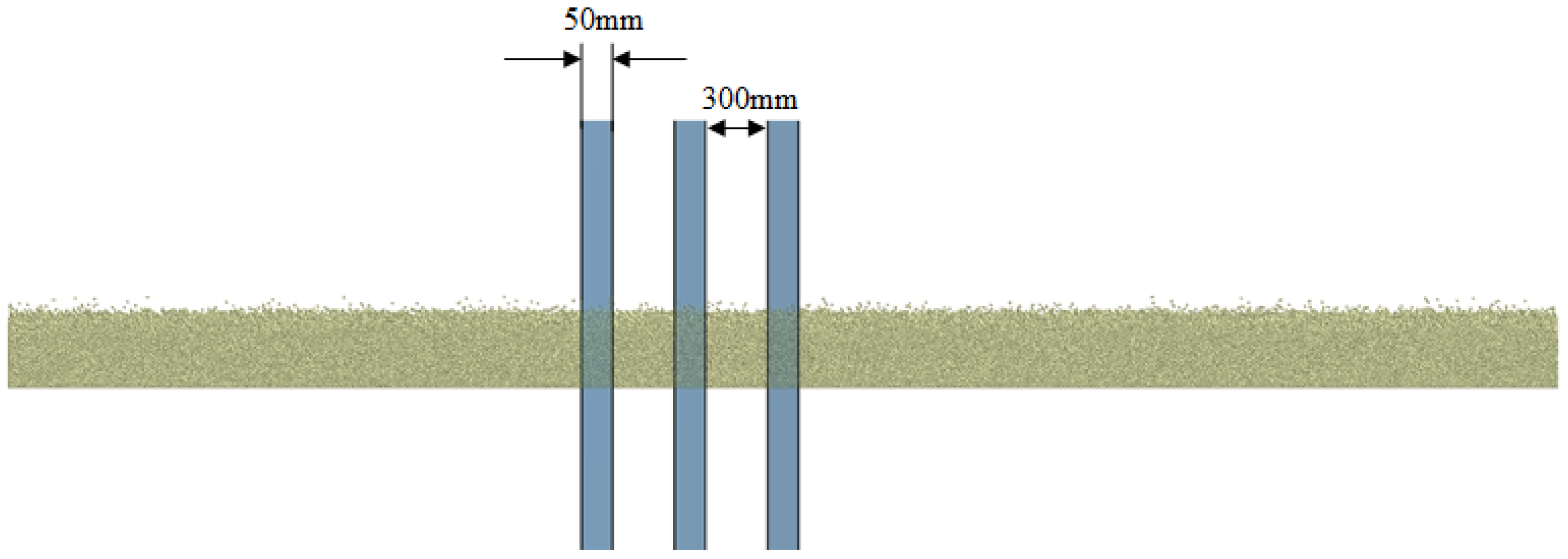

2.3.2. Simulation and Measurement Methods

2.4. One-Way Test

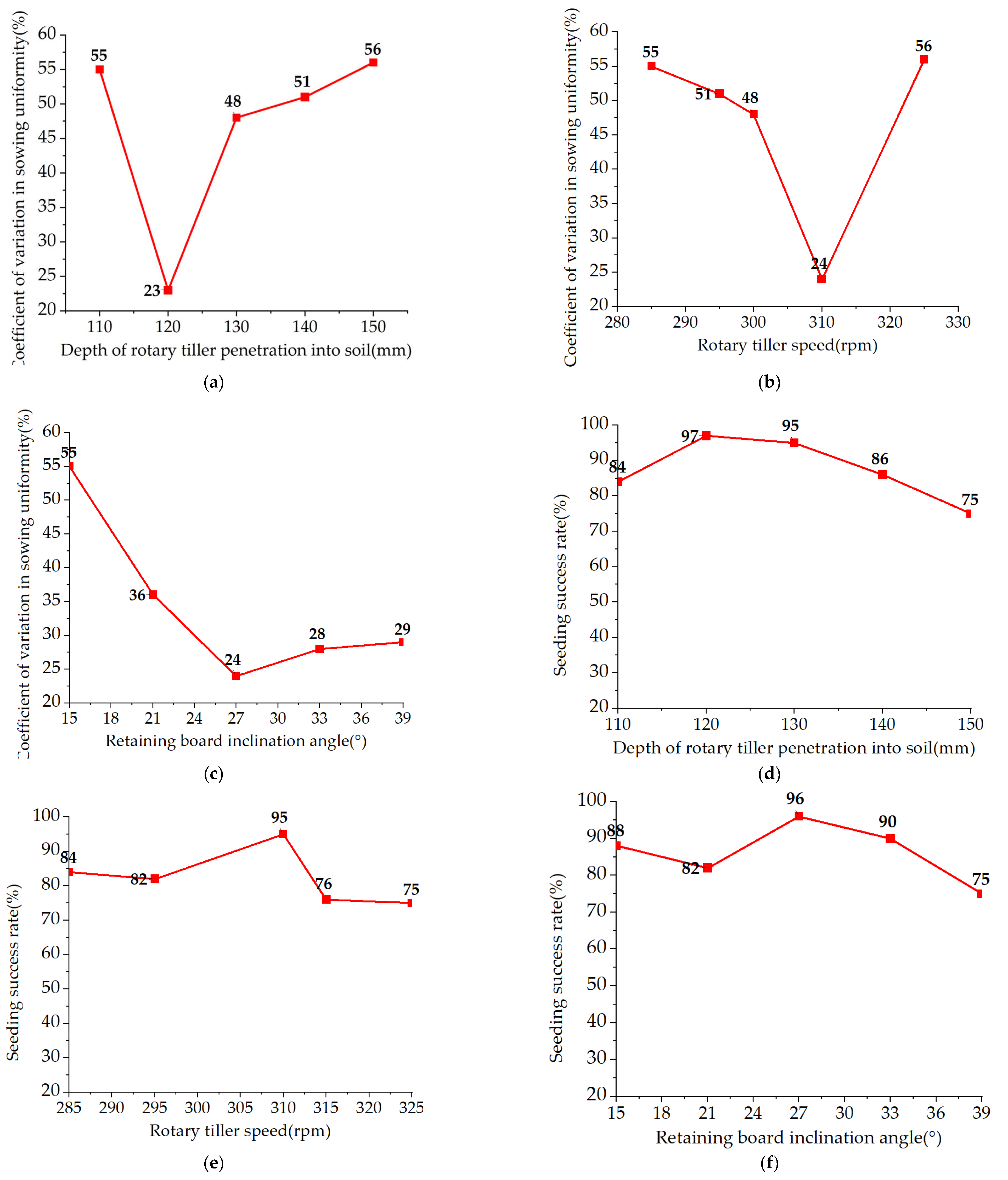

2.4.1. Relationship Between the Depth of Entry of Rotary Tillage Devices and Evaluation Indicators

2.4.2. Relationship Between Rotary Speed and Evaluation Indicators

2.4.3. Relationship Between Baffle Inclination and Evaluation Indicators

2.5. Orthogonal Test

2.5.1. Orthogonal Experimental Design

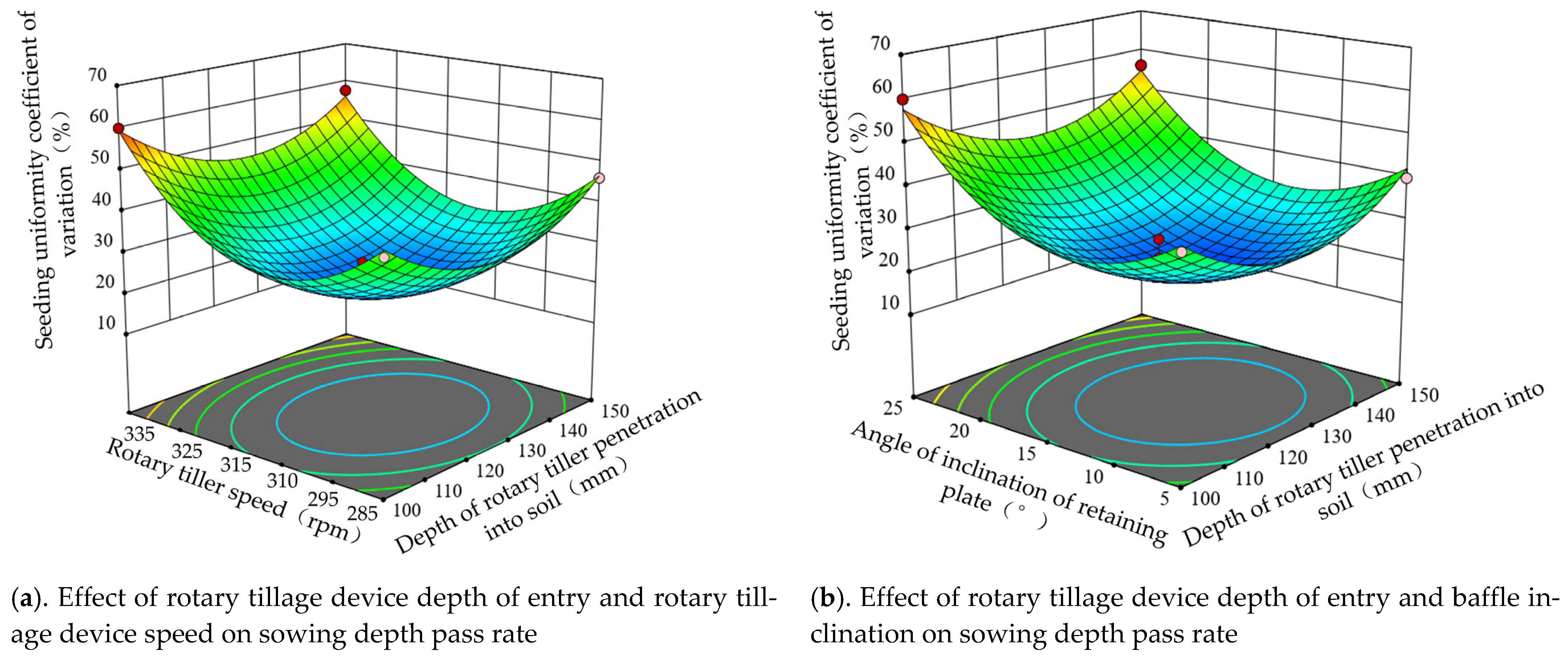

2.5.2. Results and Analysis of Orthogonal Tests for Sowing Depth Qualification

| Serial Number | A. Depth of Entry/mm | B. Rotary Speed/rpm | C. Baffle Inclination/(°) |

|---|---|---|---|

| 1 | 125 | 310 | 27 |

| 2 | 125 | 285 | 40 |

| 3 | 100 | 310 | 40 |

| 4 | 100 | 310 | 15 |

| 5 | 125 | 310 | 27 |

| 6 | 125 | 285 | 15 |

| 7 | 100 | 285 | 27 |

| 8 | 150 | 310 | 15 |

| 9 | 125 | 310 | 27 |

| 10 | 150 | 325 | 27 |

| 11 | 125 | 325 | 40 |

| 12 | 125 | 325 | 15 |

| 13 | 125 | 325 | 27 |

| 14 | 150 | 325 | 40 |

| 15 | 150 | 285 | 27 |

| 16 | 100 | 285 | 27 |

| 17 | 125 | 310 | 27 |

| Target | Source of Variance | Sum of Squares | Degrees of Freedom | Mean Square | F | Significant Level, p |

|---|---|---|---|---|---|---|

| H | A | 156.64 | 1 | 156.64 | 7.96 | 0.0257 |

| B | 13.52 | 1 | 13.52 | 0.6870 | 0.4345 | |

| C | 283.22 | 1 | 283.22 | 14.39 | 0.0068 | |

| A2 | 3168.60 | 1 | 3168.60 | 161.00 | <0.0001 | |

| B2 | 1622.88 | 1 | 1622.88 | 82.46 | <0.0001 | |

| C2 | 2034.65 | 1 | 2034.65 | 103.39 | <0.0001 | |

| AB | 16.40 | 1 | 16.40 | 0.8334 | 0.3916 | |

| AC | 44.72 | 1 | 44.22 | 2.25 | 0.1775 | |

| BC | 6.00 | 1 | 6 | 0.3050 | 0.5979 | |

| Model | 8126.62 | 9 | 902.96 | 45.88 | <0.0001 | |

| Residuals | 137.76 | 7 | 19.68 | |||

| Misfits | 105.27 | 3 | 35.09 | 4.32 | 0.0957 | |

| Errors | 32.49 | 4 | 8.12 | |||

| Sums | 8284.38 | 16 |

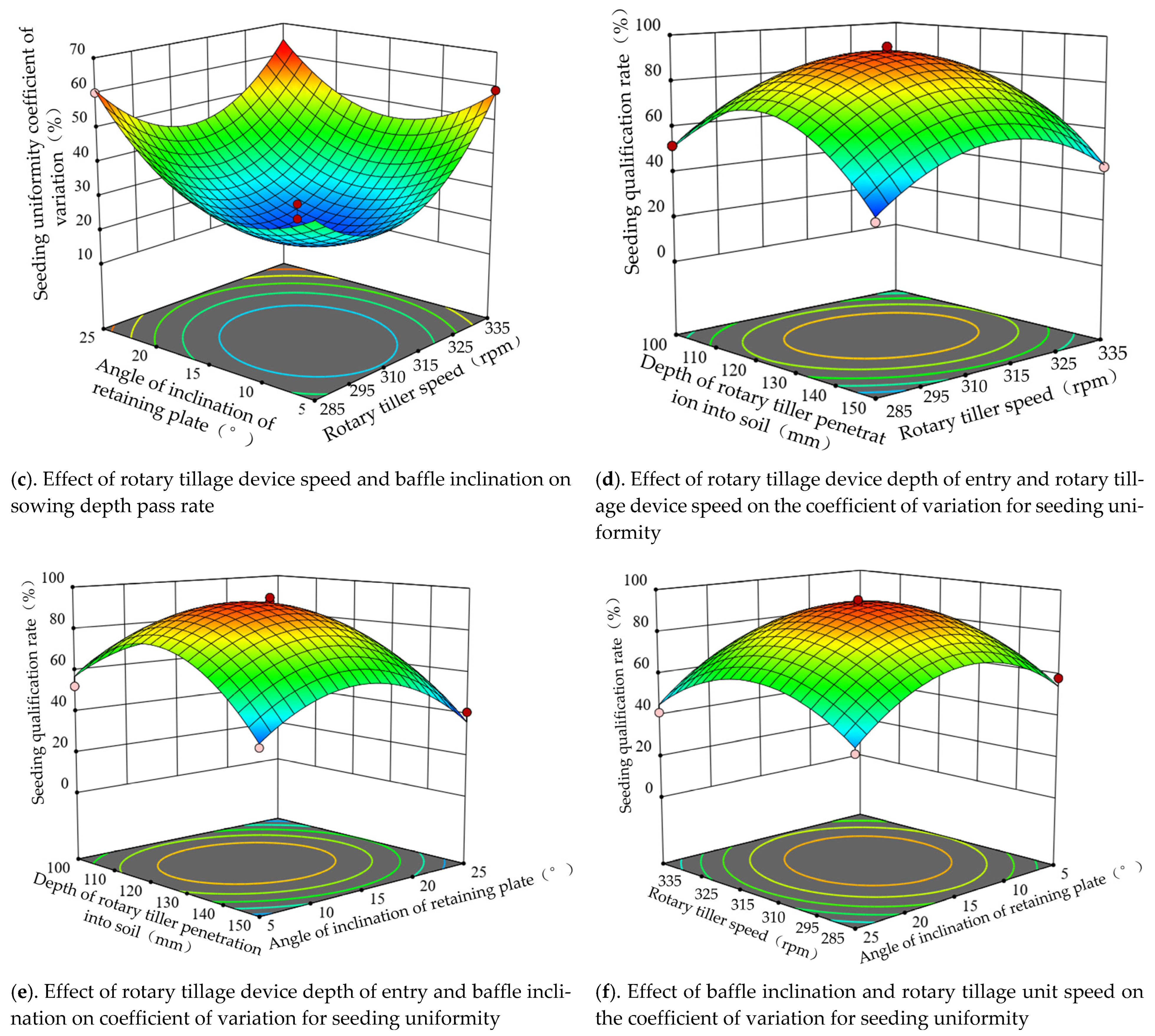

2.5.3. Results and Analysis of the Orthogonal Test of the Coefficient of Variation for Sowing Uniformity

| Target | Source of Variance | Sum of Squares | Degrees of Freedom | Mean Square | F | Significant Level p |

|---|---|---|---|---|---|---|

| v | A | 2.10 | 1 | 2.10 | 0.2024 | 0.6664 |

| B | 280.85 | 1 | 280.85 | 27.06 | 0.0013 | |

| C | 421.95 | 1 | 421.85 | 40.65 | 0.0004 | |

| A2 | 579.09 | 1 | 579.09 | 55.79 | <0.0001 | |

| B2 | 1410.45 | 1 | 1410.45 | 135.89 | <0.0001 | |

| C2 | 1008.64 | 1 | 1008.64 | 97.18 | <0.0001 | |

| AB | 5.76 | 1 | 5.76 | 0.5549 | 0.4806 | |

| AC | 3.06 | 1 | 3.06 | 0.2951 | 0.6039 | |

| BC | 62.41 | 1 | 62.41 | 6.01 | 0.0440 | |

| Model | 4111.68 | 9 | 456.85 | 44.02 | <0.0001 | |

| Residuals | 72.66 | 7 | 10.38 | |||

| Misfits | 36.79 | 3 | 12.21 | 1.37 | 0.3729 | |

| Errors | 35.87 | 4 | 8.97 | |||

| Sums | 4184.34 | 16 |

2.5.4. Test Conditions and Sites

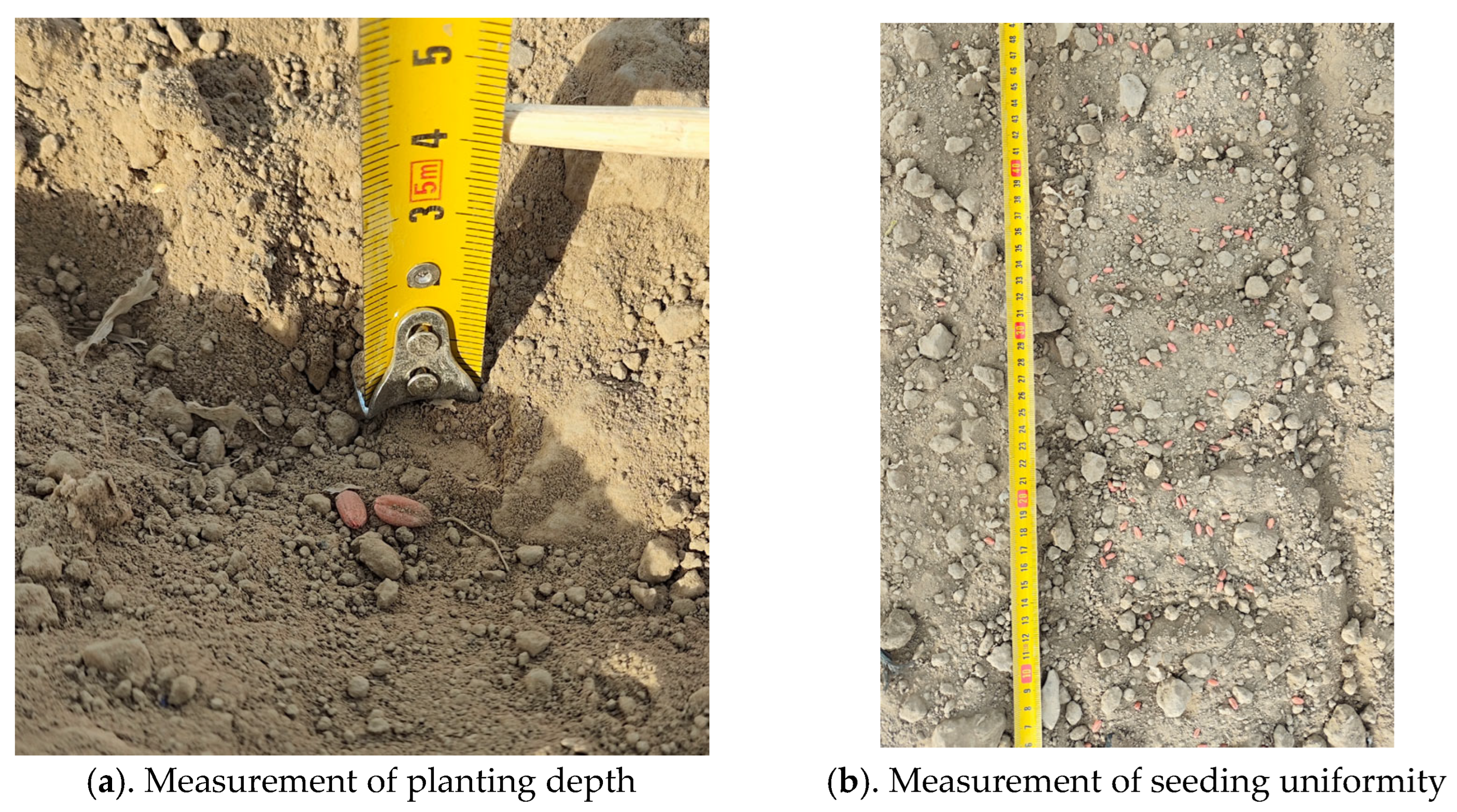

2.5.5. Test Indicators and Methods

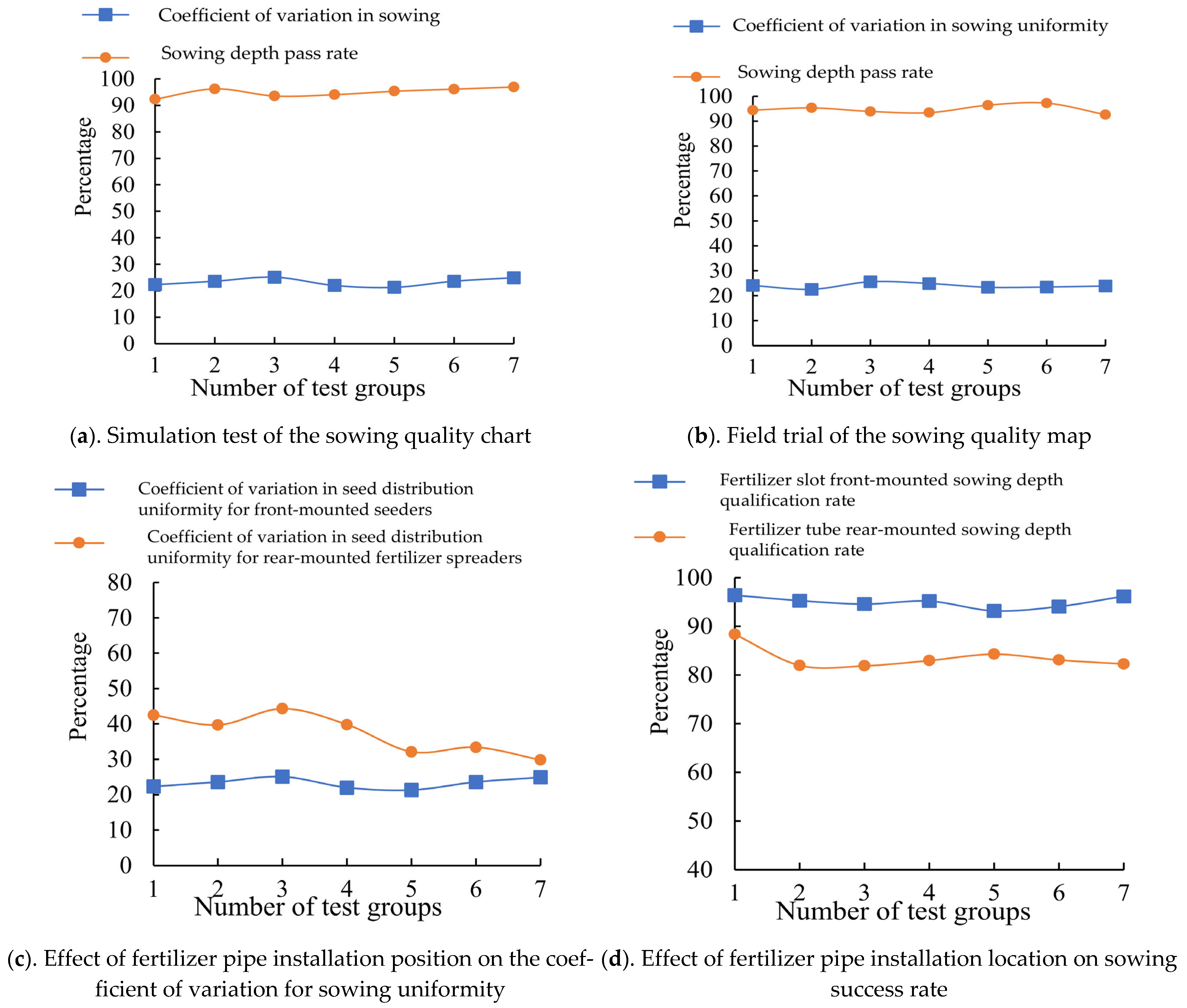

3. Results

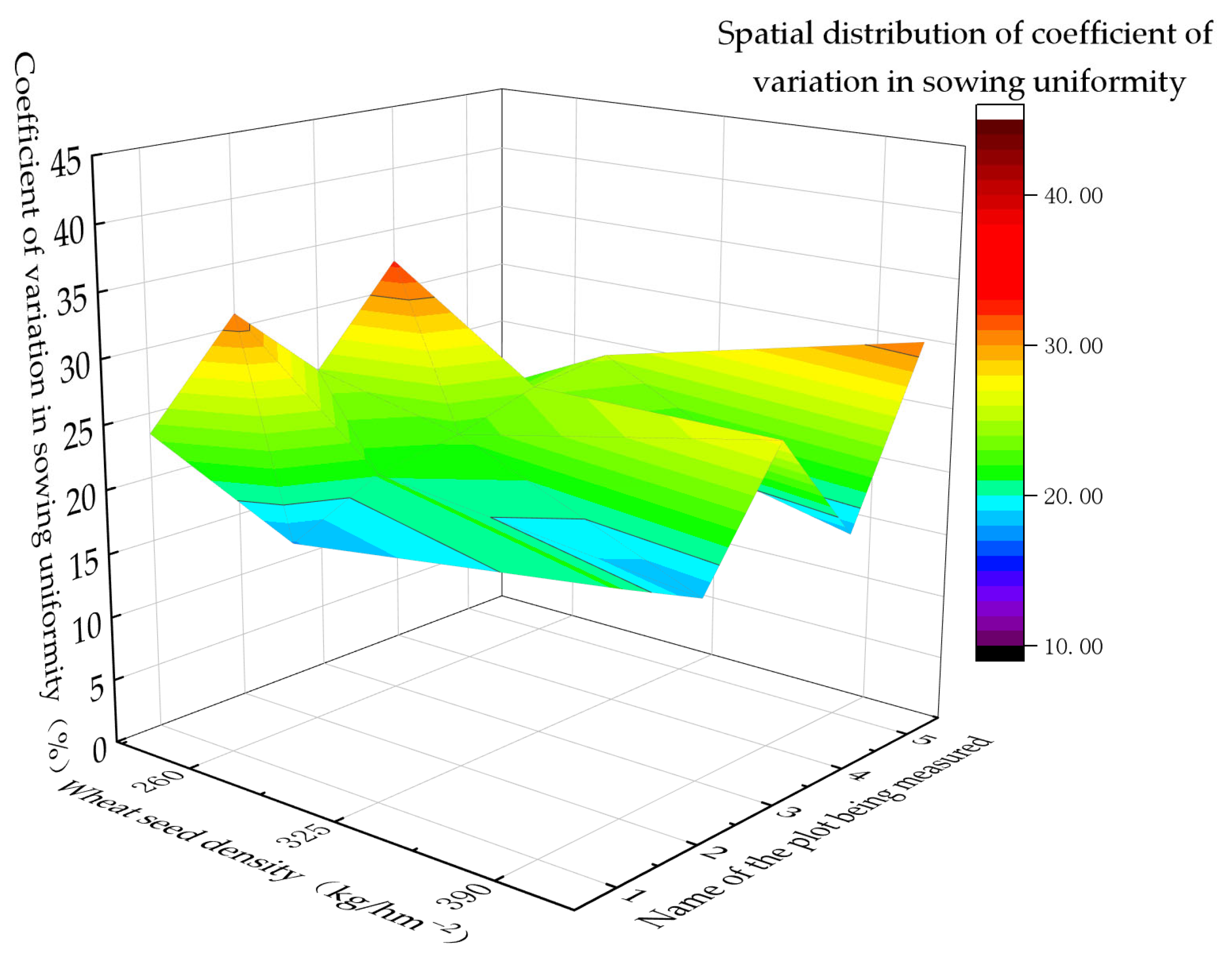

3.1. Measurements of the Coefficient of Variation for Sowing Uniformity

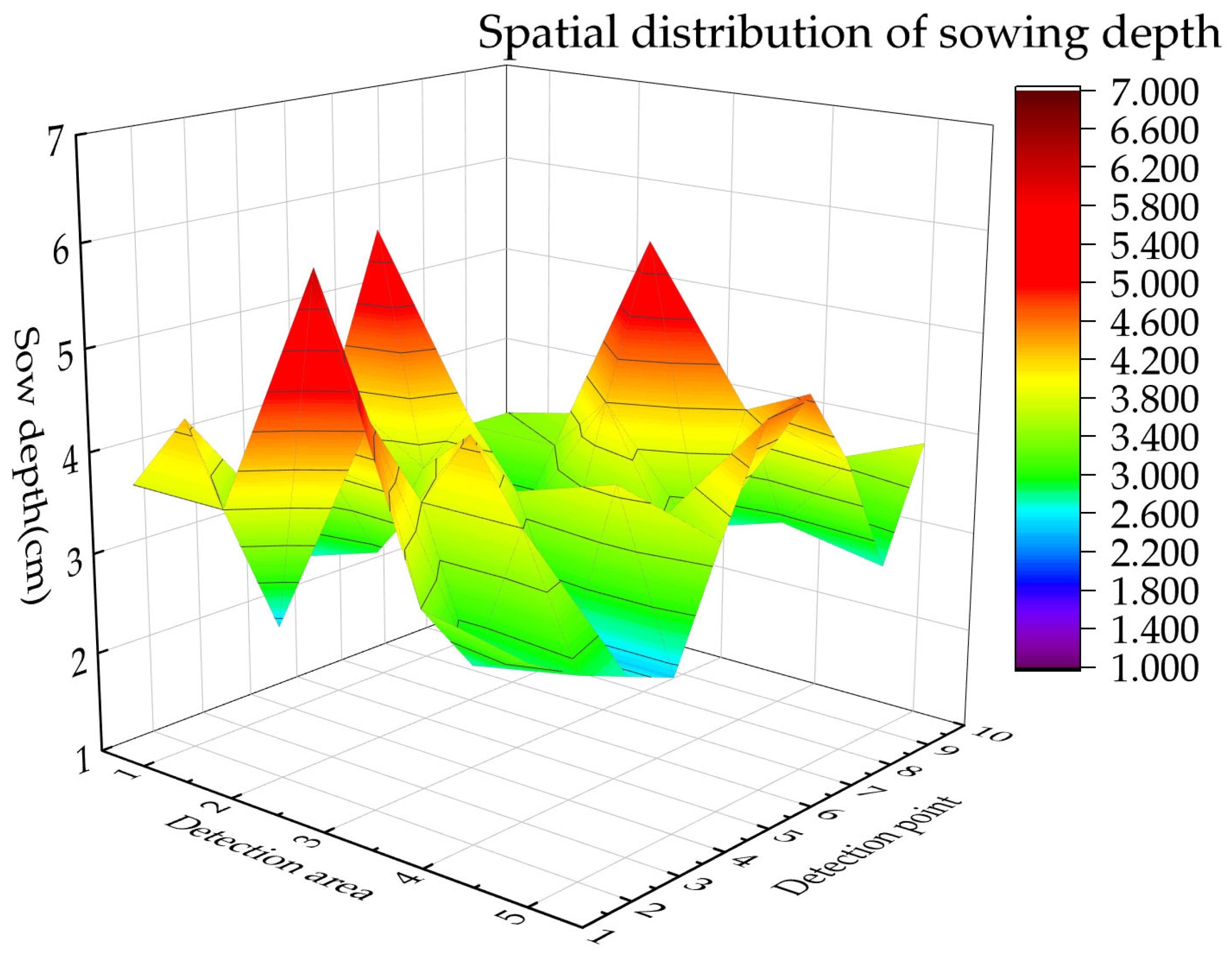

3.2. Measurement Results of Sowing Depth Pass Rate

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, L. Current Status and Outlook for Scientific and Technological Innovation in China’s Wheat Industry. J. Cold-Arid Agric. Sci. 2024, 3, 491–494. [Google Scholar]

- Lu, C. The Current Status of Wheat Production in China and Considerations for Improving Wheat Production Capacity. J. South. Agric. 2021, 15, 177–178. [Google Scholar]

- Wang, H.; Cao, R.; Huang, X. Study on the physiological indicators and yield of different varieties of spring wheat in response to moisture. J. Irrig. Drain. 2024, 43, 1–10. [Google Scholar]

- Shi, F. Analysis of the high yield, stable yield, and adaptability of the dryland winter wheat variety Jinmai 100. Mod. Agric. Sci. Technol. 2024, 19, 1–4. [Google Scholar]

- Zhao, S.; Yang, X.; Li, L. Hyperspectral monitoring of nitrogen nutritional indices in wheat leaves under water-nitrogen coupling effect. J. Hebei Agric. Univ. 2025, 1–11. [Google Scholar]

- Xi, T.; Zhao, H.; Liang, Z.; Xie, S.; Liu, Q.; Xue, J. The effect of combined sowing methods on wheat population and yield formation. Chin. Agric. Sci. Bull. 2014, 30, 185–188. [Google Scholar]

- Pei, Y. Advantages and Key Points of High-Yield Wheat Wide-Row Uniform Seeding Technology. Agric. Sci. Eng. China 2024, 36, 93–96. [Google Scholar]

- Chen, G.; Cheng, H.; Fan, H.; Fan, Z.; Hu, F.; Yin, W. Study on the Adaptability of Spring Wheat Yields in Oasis Irrigation Areas to Reduced Water and Nitrogen Use under Wide-Row Uniform Seeding and Traditional Row Seeding. Sci. Agric. Sin. 2023, 56, 2461–2473. [Google Scholar]

- Li, S. Key Technologies for Wide-Row Uniform Seeding of Wheat. Henan Agric. 2021, 13, 46. [Google Scholar]

- Zhao, P.; Ju, X.; Yang, P.; Zheng, Z.; Huang, Y.; Gao, X.; Shi, J. Design and Experiment of a Pre-placed Fertilizer Pipe Wheat Wide Seedling Rotary Tiller Fertilization Seeding Machine. Trans. Chin. Soc. Agric. Eng. 2024, 40, 12–21. [Google Scholar]

- Ye, R.; Ma, X.; Zhao, J.; Liao, J.; Liu, X.; Xi, L.; Su, G. Optimization and Design of Disc-Type Furrow Opener of No-Till Seeder for Green Manure Crops in South Xinjiang Orchards. Agriculture 2023, 13, 1474. [Google Scholar] [CrossRef]

- Aikins, K.A.; Ucgul, M.; Barr, J.B.; Awuah, E.; Antille, D.L.; Jensen, T.A.; Desbiolles, J.M.A. Review of Discrete Element Method Simulations of Soil Tillage and Furrow Opening. Agriculture 2023, 13, 541. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, Z.; Gu, F.; Ding, Q. Simulation and Experimental Study of the Tillage Mechanism for the Optimal Design of Wheat Rotary Strip–Tiller Blades. Agriculture 2023, 13, 632. [Google Scholar] [CrossRef]

- Li, Y.; Qi, B.; Bao, E.; Tang, Z.; Lian, Y.; Sun, M. Design and Analysis of Sowing Depth Detection and Control Device for MultiRow Wheat Seeders Adapted to Different Terrain Variations. Agriculture 2025, 15, 290. [Google Scholar] [CrossRef]

- Luo, J. Design and Experimental Study of a Wheat Uniform Seeder. Master’s thesis, Jiangsu University, Zhenjiang, China, 2019. [Google Scholar]

- Liu, C.; Liu, J.; Sang, Y.; Feng, X.; Zhou, X. Design and Testing of a Rotary Tillage and Soil Covering Device for Wheat Planting Based on Uniform Broadcasting. J. Agric. Mech. Res. 2025, 47, 185–190. [Google Scholar]

- Xue, B.; Zhou, L.; Niu, K.; Zheng, Y.; Bai, S.; Xi, L. Research of Sowing Depth Based on Adaptive Fuzzy PID Control System of Wheat Planter. Trans. Chin. Soc. Agric. Mach. 2023, 54, 93–102. [Google Scholar]

- Kang, Y.; Liao, Q.; Lin, J.; Han, J.; Wan, X.; Zhang, Q. Development of the rapeseed direct seeding machine with stubble covering based on combined harvesting machine platform. Trans. Chin. Soc. Agric. Eng. 2024, 40, 15–25. [Google Scholar]

- Zhang, X.; Zhang, L.; Hu, X.; Wang, H.; Shi, X.; Ma, X. Simulation of soil cutting and power consumption optimization of a typical rotary tillage soil blade. Appl. Sci. 2022, 12, 8177. [Google Scholar] [CrossRef]

- Yang, Y.; Fielke, J.; Ding, Q.; He, R. Field experimental study on optimal design of the rotary strip-till tools applied in rice-wheat rotation croping system. IJABE 2018, 11, 88–94. [Google Scholar]

- Mandal, S.K.; Bhattacharya, B.; Mukherjee, S. Optimization of design parameters for rotary tiller’s blade. Power 2013, 4. [Google Scholar]

- Chen, X.; Xu, G.; Zhang, X.; Tan, W.; Ding, Q.; Tagar, A.A. Performance Evaluation of Biomimetic-Designed Rotary Blades for Straw Incorporation in an Intensive Tillage System. Agriculture 2024, 14, 1426. [Google Scholar] [CrossRef]

- Qin, Y.; Gao, Y.; Xie, C.; Tong, J.; Wang, Q.; Feng, X. Design and Test of an Energy-Saving Bionic-Inspired Rotary Blade: A Study on Power Consumption and Soil Surface Quality. Agriculture 2025, 15, 938. [Google Scholar] [CrossRef]

- Salokhe, V.M.; Ramalingam, N. Effects of direction of rotation of a rotary tiller on properties of Bangkok clay soil. Soil Till. Res. 2001, 63, 65–74. [Google Scholar] [CrossRef]

- Gao, J.; Qi, H. Soil throwing experiments for reverse rotary tillage at various depths, travel speeds, and rotational speeds. Trans. ASABE 2017, 60, 1113–1121. [Google Scholar] [CrossRef]

- Ma, F.; Wang, L.; Wang, C.; Wang, Q.; Lu, C. Study on Impact Soil Movement Experiments on Wheat Seeds Based on EDEM. Agriculture 2025, 15, 400. [Google Scholar] [CrossRef]

- Niu, Y.; Zhang, J.; Qi, J.; Meng, H.; Peng, H.; Li, J. Design and Test of Soil–Fertilizer Collision Mixing and Mulching Device for Manure Deep Application Machine. Agriculture 2023, 13, 709. [Google Scholar] [CrossRef]

- Sugirbay, A.; Hu, G.R.; Chen, J.; Mustafin, Z.; Muratkhan, M.; Iskakov, R.; Chen, Y.; Zhang, S.; Bu, L.; Dulatbay, Y.; et al. A study on the calibration of wheat seed interaction properties based on the discrete element method. Agriculture 2022, 12, 1497. [Google Scholar] [CrossRef]

- Sun, K.; Yu, J.; Liang, L.; Wang, Y.; Yan, D.; Zhou, L.; Yu, Y. A DEM-based general modelling method and experimental verification for wheat seeds. Powder Technol. 2022, 401, 117353. [Google Scholar] [CrossRef]

- Patidar, P.; Soni, P.; Jain, A.; Mahore, V. Modelling soil-rotor blade interaction of vertical axis rotary tiller using discrete element method (DEM). J. Terramech. 2024, 112, 59–68. [Google Scholar] [CrossRef]

- GB/T 9478-2005; Testing Methods for Grain Strip Seeders, General Administration of Quality Supervision. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2005.

- NY/T 1143-2006; Operational Quality of Rotary Tillage, Fertilization, and Seeding Combination Machines. Ministry of Agriculture of the People’s Republic of China: Beijing, China, 2006.

| Material Contact Parameters Parameter | Values |

|---|---|

| Soil–soil coefficient of recovery | 0.38 |

| Soil–soil static friction factor | 0.48 |

| Soil–soil kinetic friction factor | 0.28 |

| Soil–steel coefficient of recovery | 0.42 |

| Soil–steel static friction factor | 0.48 |

| Soil–steel kinetic friction factor | 0.22 |

| Soil–wheat coefficient of recovery | 0.02 |

| Soil–wheat static friction factor | 1.25 |

| Soil–wheat kinetic friction factor | 1.24 |

| Wheat–steel recovery factor | 0.41 |

| Wheat–steel static friction factor | 0.32 |

| Wheat–steel kinetic friction factor | 0.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Shi, Z.; Xue, Y.; Zhang, X.; Bai, S.; Zhang, J.; Jin, Y. Analysis and Optimization of Seeding Depth Control Parameters for Wide-Row Uniform Seeding Machines for Wheat. Agriculture 2025, 15, 1800. https://doi.org/10.3390/agriculture15171800

Yang L, Shi Z, Xue Y, Zhang X, Bai S, Zhang J, Jin Y. Analysis and Optimization of Seeding Depth Control Parameters for Wide-Row Uniform Seeding Machines for Wheat. Agriculture. 2025; 15(17):1800. https://doi.org/10.3390/agriculture15171800

Chicago/Turabian StyleYang, Longfei, Zenglu Shi, Yingxue Xue, Xuejun Zhang, Shenghe Bai, Jinshan Zhang, and Yufei Jin. 2025. "Analysis and Optimization of Seeding Depth Control Parameters for Wide-Row Uniform Seeding Machines for Wheat" Agriculture 15, no. 17: 1800. https://doi.org/10.3390/agriculture15171800

APA StyleYang, L., Shi, Z., Xue, Y., Zhang, X., Bai, S., Zhang, J., & Jin, Y. (2025). Analysis and Optimization of Seeding Depth Control Parameters for Wide-Row Uniform Seeding Machines for Wheat. Agriculture, 15(17), 1800. https://doi.org/10.3390/agriculture15171800