1. Introduction

As a key link in hybrid rice seed production, the pollination process requires strict timeliness. However, at present, the country mainly relies on artificial pollination, which presents significant limitations in actual effectiveness [

1,

2,

3,

4]. Remote sensing technologies are an advanced support tool for agricultural operations, providing timely, non-destructive, and spatial information about plants to help farmers’ decision-making [

5,

6].

Furthermore, with the rapid development of agricultural UAV-assisted hybrid rice seed pollination technology in China, the pollination advantages of high efficiency, uniformity, and low damage have significantly improved seed production [

7,

8,

9,

10,

11,

12,

13]. Liu Aimin et al. [

1] found that the best effect of UAV-assisted pollination occurred when the parent-row ratio was 6:(40–60). Wang Pei et al. [

14] used a wind-field measurement system to analyze the flow field of a single-rotor UAV and determined that the Z3 model could achieve a balance of efficiency, safety, and agronomic requirements at an operating altitude of 7 m. Wu Hui et al. [

2] further innovated traditional planting patterns, confirming that the parent-compartment width could be extended to 1.2–2 m, and the mother-compartment width could reach 7–12 m. However, existing studies are mostly focused on the optimization of field parameters, and there is a lack of systematic research on the spatiotemporal distribution characteristics of UAV flow fields and pollen diffusion dynamics, which restricts the fine control and large-scale application of this technology

Numerical modeling and simulation techniques are effective methods to study flow-field distribution characteristics, and computational fluid dynamics (CFD) technology provides a new path to break through the above bottleneck [

15,

16,

17,

18]. Yang Shenghui [

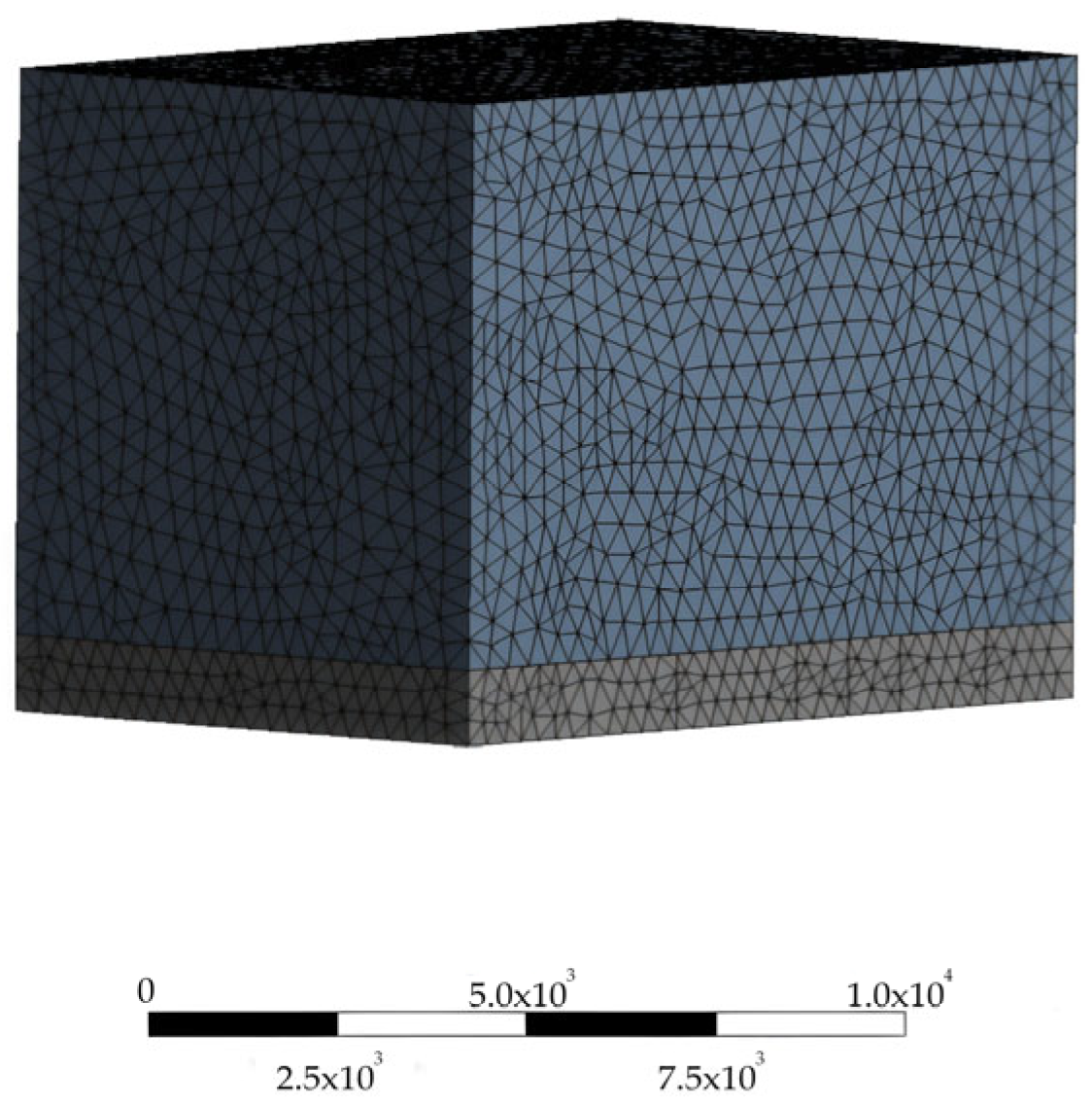

19] established a CFD system for the hexacopter UAV JF01-10 and its 1:10 scaled model based on the ANSYS platform and found that experimental validation confirmed a full-size model validation error of <34%. Zhang Songchao et al. [

20] confirmed, through experiments on fog droplet deposition in the N-3 UAV, that the spatial distribution consistency between CFD simulation results and measured data reached 89%. Yang Fengbo’s team [

21] developed a UAV simulation model, achieving a simulation error of ≤9% compared to the actual model. Guo’s team [

22] achieved a simulation error breakthrough of <10% for hovering conditions of the ZHKU-0404-01 UAV. These studies show that the reasonable construction of CFD models can effectively predict real test scenarios.

The particle size of rice pollen is extremely small, but the strength of the wind field under the rotor of the UAV is significant [

23]. Since the interaction between the two involves complex coupling effects between gas and solid phases, the mechanism must be analyzed with the help of gas–solid coupling theory. In this context, the coupling method based on CFD–DPM (discrete phase model) shows significant advantages due to its accurate modeling ability in the study of the interaction between the flow field and small particulate matter. Luke [

24] simulated the particle settling of horizontal airflow through CFD–DPM coupling to establish an experimentally validated calibration method for improving simulation reliability under complex working conditions; Paula [

25] utilized the CFD–DPM model to reveal the particle settlement characteristics of wheat, which has a very small particle size, and to analyze the explosion characteristics of wheat starch pyrolysis gas mixtures, finding that the turbulent dissipation rate is positively correlated with explosion intensity. Xiao Fenfang [

26] applied the CFD–DPM model to optimize the design of the rice pollen collection device, achieving a 23% efficiency increase. Te et al. [

17] used CFD–DPM coupling to simulate hybrid rice pollen diffusion, and others employed a coupled CFD–DPM method to predict the entire process of hybrid rice pollen dispersal, with a deposition distribution prediction error of <15%, further verifying the method’s feasibility.

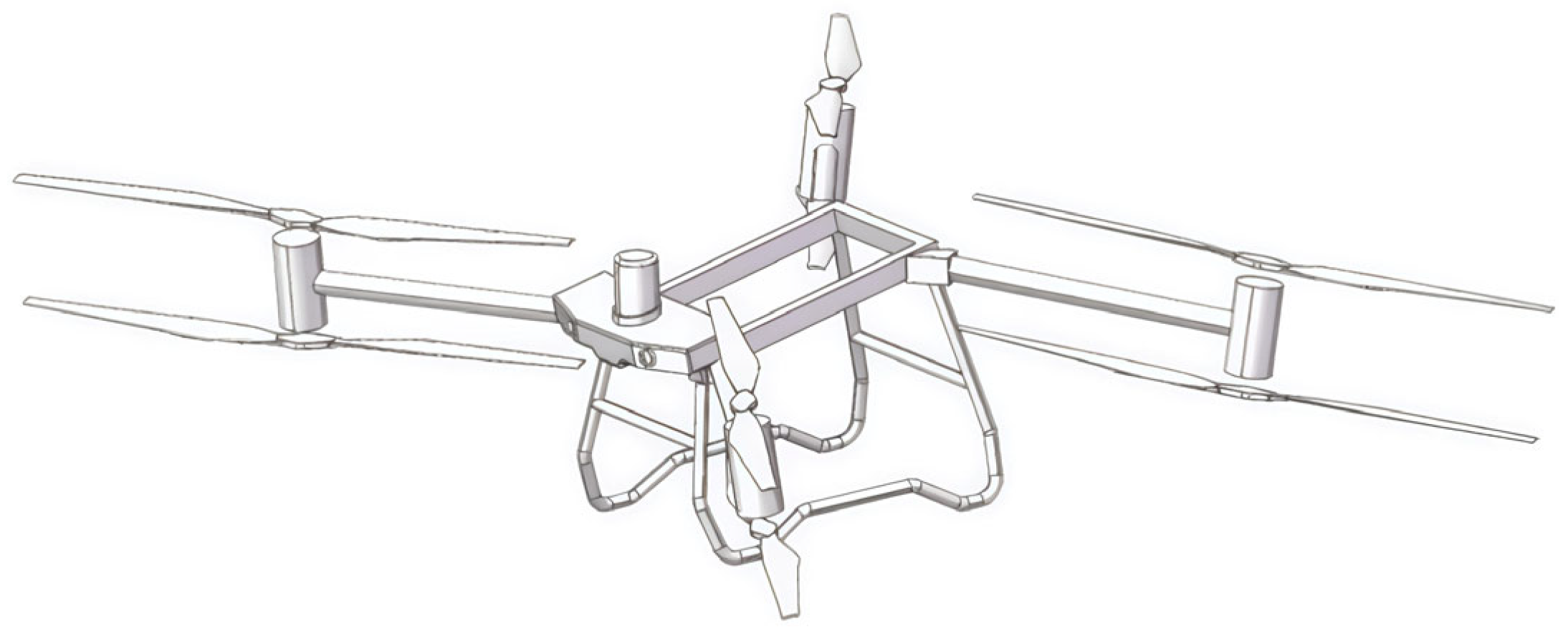

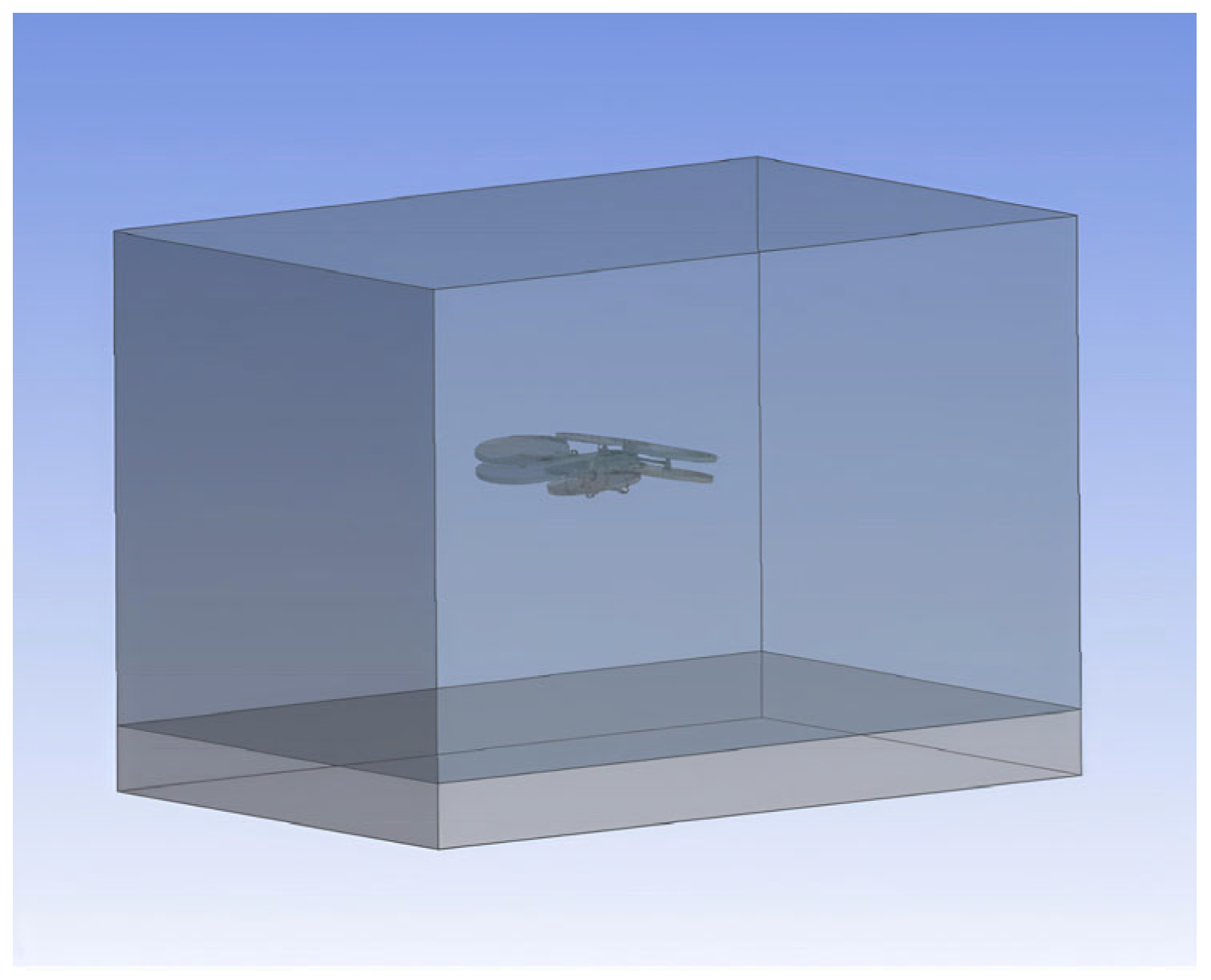

This study implemented a coupled CFD–DPM method to investigate the interaction mechanism between UAV wind-field and pollen particles, quantify the model accuracy by comparing numerical simulation with field measurement data, and construct a pollination-parameter optimization framework that could be transferred to multi-rotor UAVs, avoiding model-dependent limitations. This study is expected to solve the problem of the insufficient validation of the current UAV pollination technology and provide important theoretical support and tools to promote its standardization and intelligent development.

4. Discussion

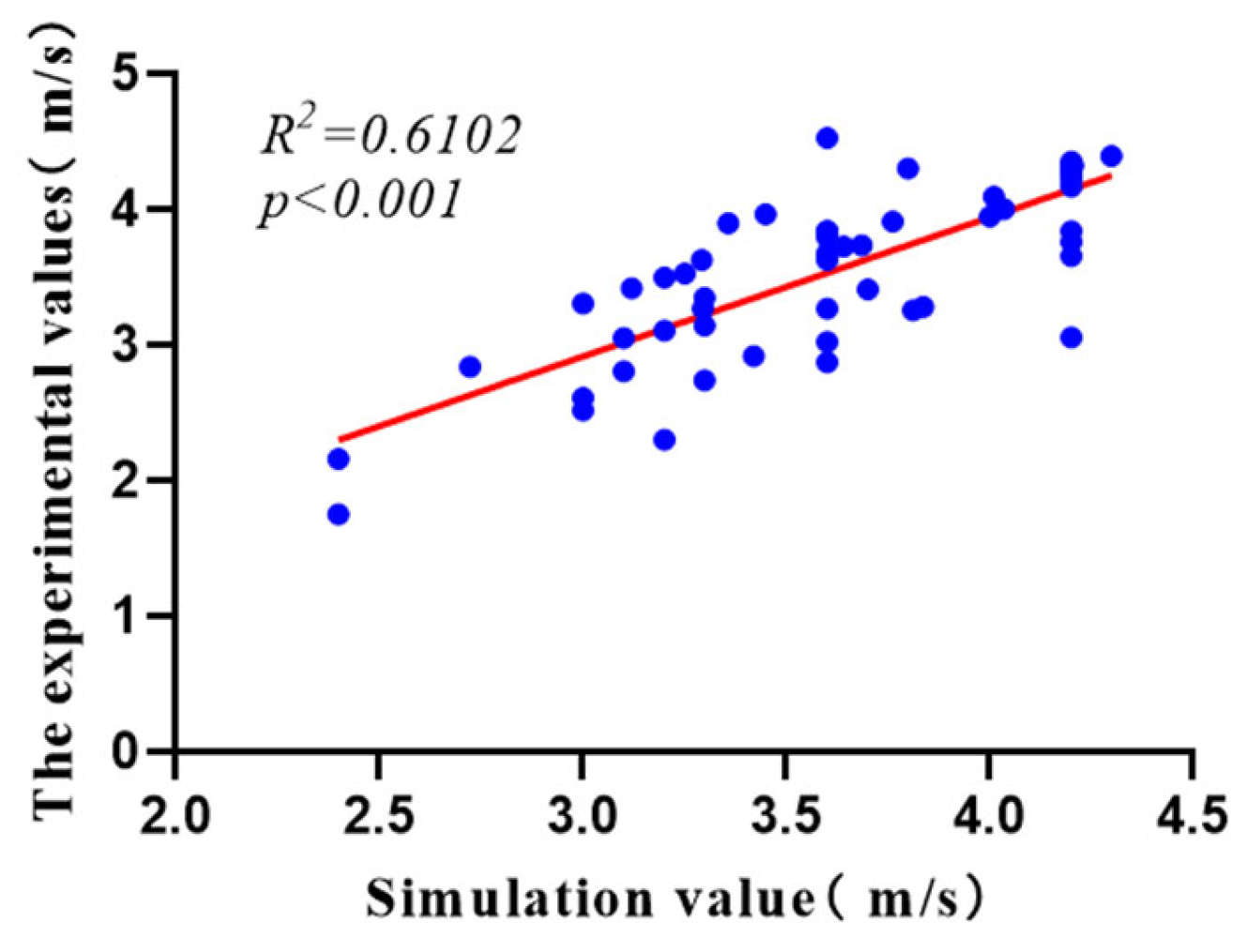

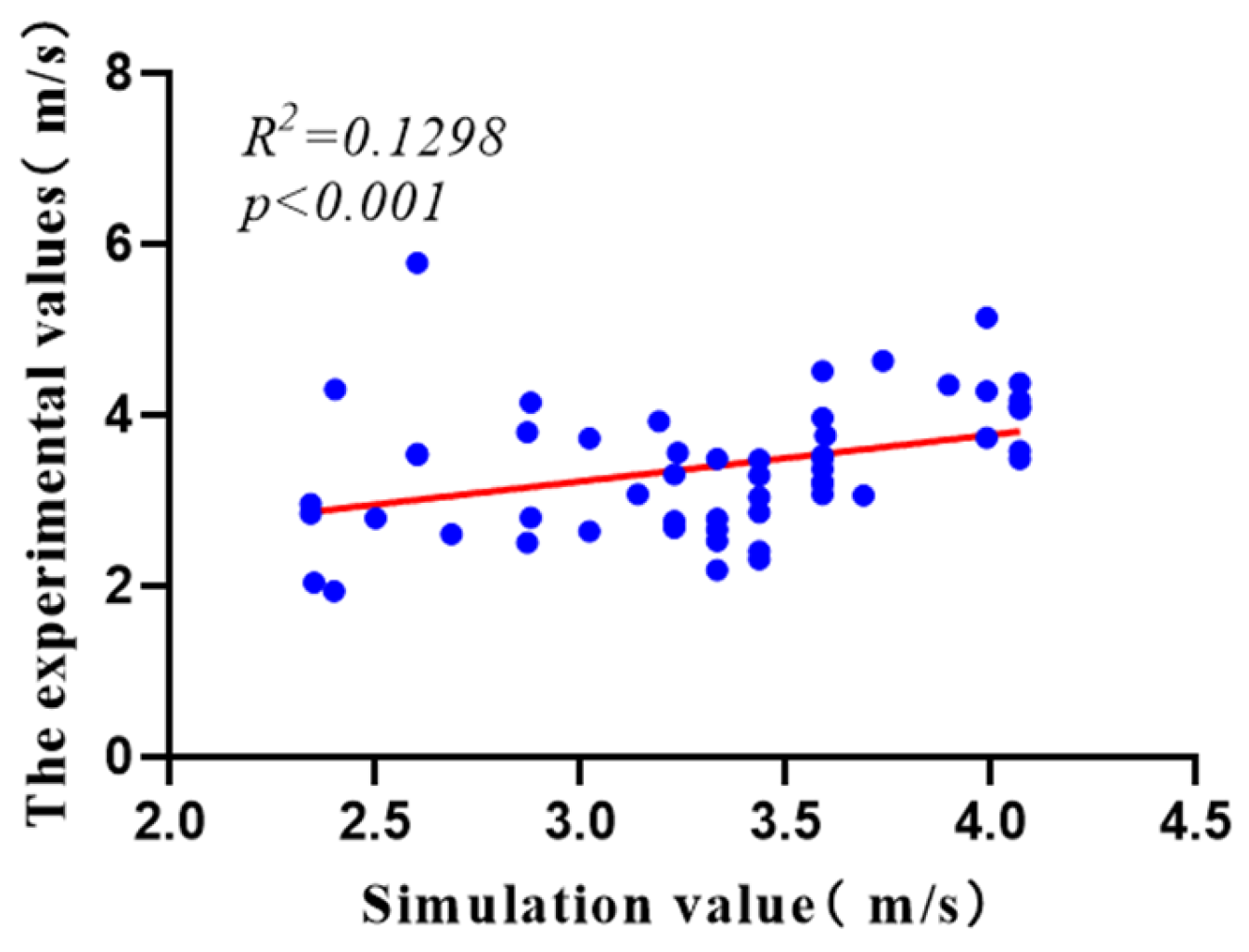

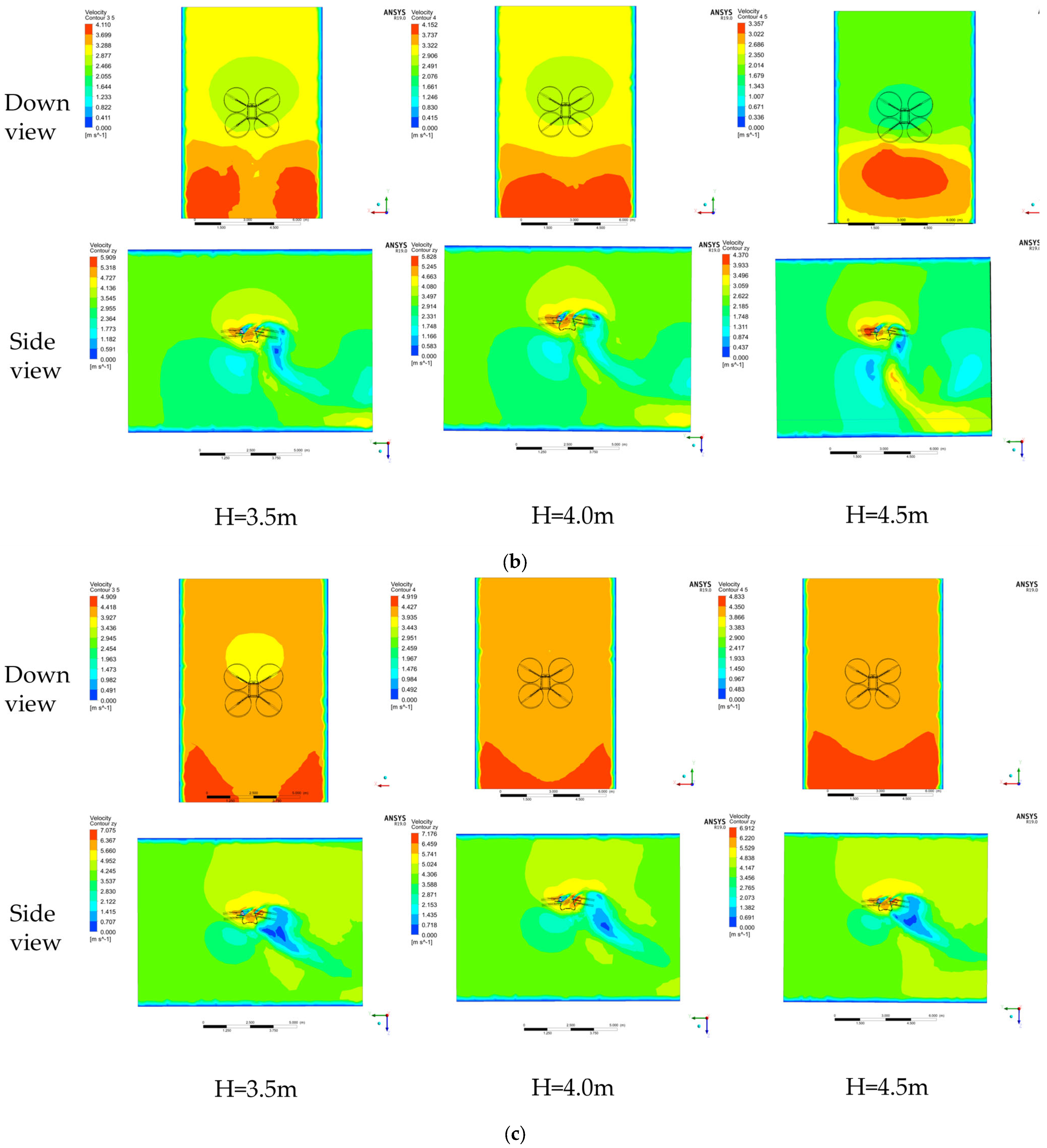

This study established a three-tier verification system comprising “numerical simulation—wind-field verification—field verification” to systematically elucidate the coupling mechanism between airflow fields and pollen movement in the context of multi-rotor UAV-assisted pollination. By establishing a coupled CFD–DPM model, the study achieved visual analysis and quantitative assessment of airflow patterns and pollen transport dynamics at different flight altitudes and speeds.

At the model validation level, the CFD model of the drone wind field constructed in this study reflected a simulation error of 10.92%. This error value is significantly lower than the 34% model error reported by Yang Shenghui et al. [

19] and is highly consistent with the <10% simulation error range reported by Guo et al. [

22] under drone-hovering conditions. These comparison results fully validate the high reliability of this model in predicting the near-ground flow-field distribution of agricultural UAVs. However, during the validation process, it was found that environmental wind speed (as shown in

Table 4 for the T3, T6, and T9 experimental groups) has a potential impact on measurement accuracy. To further improve the accuracy of experimental data, future studies may consider using ultrasonic wind speed and direction meters with higher precision and sensitivity. Additionally, this study involved certain limitations: Experimental verification was primarily conducted under Level 1 wind speed conditions (0.3–1.5 m/s). As shown in

Appendix A Table A2, under higher wind speed conditions, the simulation error in the

Z-axis direction may increase. Therefore, future simulation studies should incorporate comparison experimental data under different environmental wind speeds to clarify the model’s applicability and boundary conditions.

Based on a validated and reliable CFD model, this study further developed a wind field–pollen coupling (CFD–DPM) model aimed at systematically optimizing the operational parameters of drone pollination. A simulation analysis identified a flight speed of 3 m/s and a flight altitude of 4 m as the optimal parameter combination. This combination meets the critical threshold requirement that the pollen suspension velocity must reach 2–3 times its natural settling velocity [

13,

27,

31]; on the other hand, by synergistically regulating the horizontal coverage width of the wind field and the vertical settling range of pollen, this parameter combination can optimally match the area of airflow disturbance on pollen with the effective settling area of pollen on the stigma. This provides an innovative solution to the lack of systematic theoretical support for optimizing drone pollination parameters in existing research.

The results of the field validation trials further confirm the practical value of this study. Compared to traditional manual pollination, drone-assisted pollination achieved a 21.4% increase in yield [

29]. Most importantly, the optimized pollination parameters (speed and altitude) obtained from the field trials were highly consistent with the simulation predictions of the CFD–DPM coupled model. This consistency strongly validates the effectiveness of the established coupled simulation method in guiding agricultural drone pollination practices and provides a solid theoretical basis for the parameterization design of precision agricultural technologies.

5. Conclusions

In this study, the intrinsic correlation between pollination parameters and pollen distribution patterns of multi-rotor UAVs was systematically revealed through combined numerical simulations and field experiments. The results show that the constructed CFD simulation model for UAV wind-field distribution enables the simulation and prediction of wind-field characteristics, with a 10.92% error between model predictions and field-measured data. Furthermore, the developed CFD–DPM coupled pollen–wind field model simulates pollen transport dynamics and distribution patterns, identifying optimal UAV pollination parameters as a 3 m/s flight speed and a 4 m flight height based on operational requirements. Field production trials demonstrated that UAV-assisted pollination achieved an average production of 2.61 t/hm2, compared to 2.35 t/hm2 for artificially assisted pollination. Future research will further integrate the flow-field characteristics of multi-rotor drones with the complexity of field production environments, focusing on analyzing the impact of different flight path patterns on pollination assistance effectiveness to achieve in-depth optimization of operational parameters. Additionally, given the complexity of rice plant structures, the research team is currently working on developing a wind field–stem interaction model that integrates the actual morphology of rice plants. This model aims to more accurately simulate the interaction between wind fields and crops in real agricultural environments, thereby providing a more practical theoretical basis for optimizing the aforementioned flight path patterns and operational parameters.