Structural Improvement of Sugarcane Harvester for Reducing Field Loss When Harvesting Lodged Canes

Abstract

1. Introduction

2. Materials and Methods

2.1. Experiment on the Friction Coefficient Between Sugarcane and Soil as Well as Between Sugarcane and Steel Plates

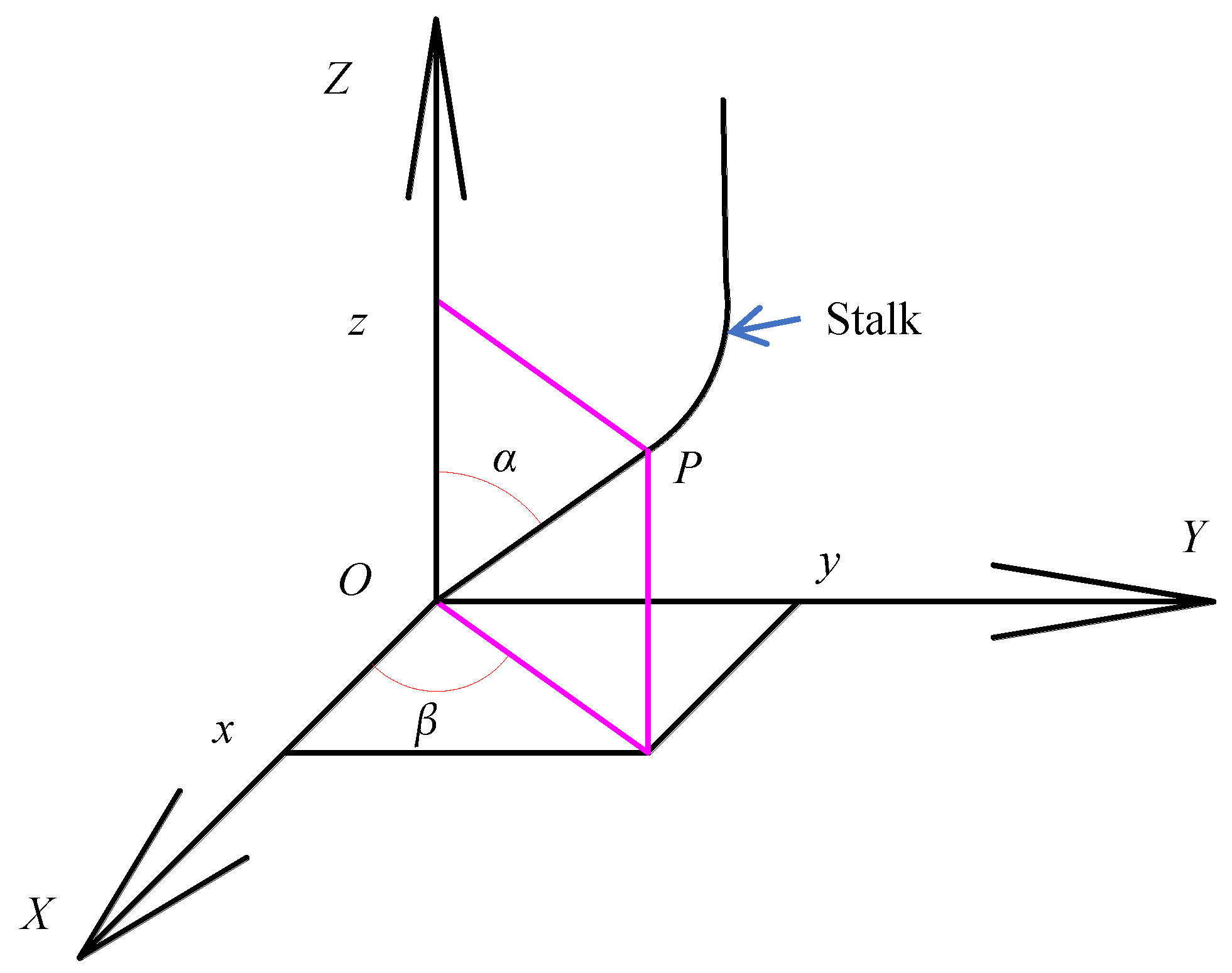

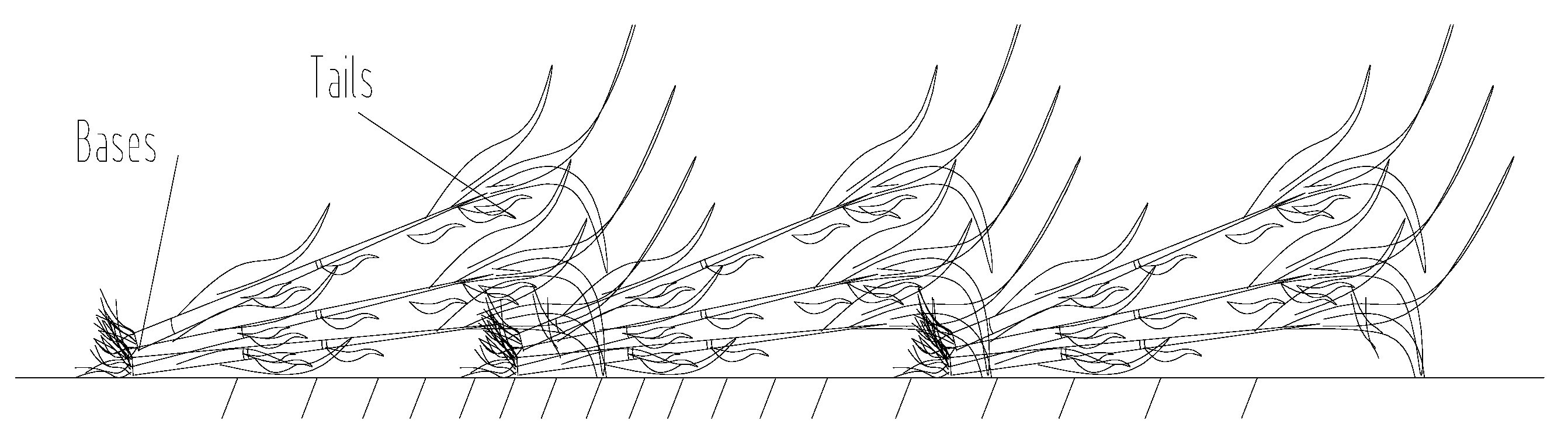

2.2. Measurement of Lodged Sugarcane and Definition of Lodging Angle

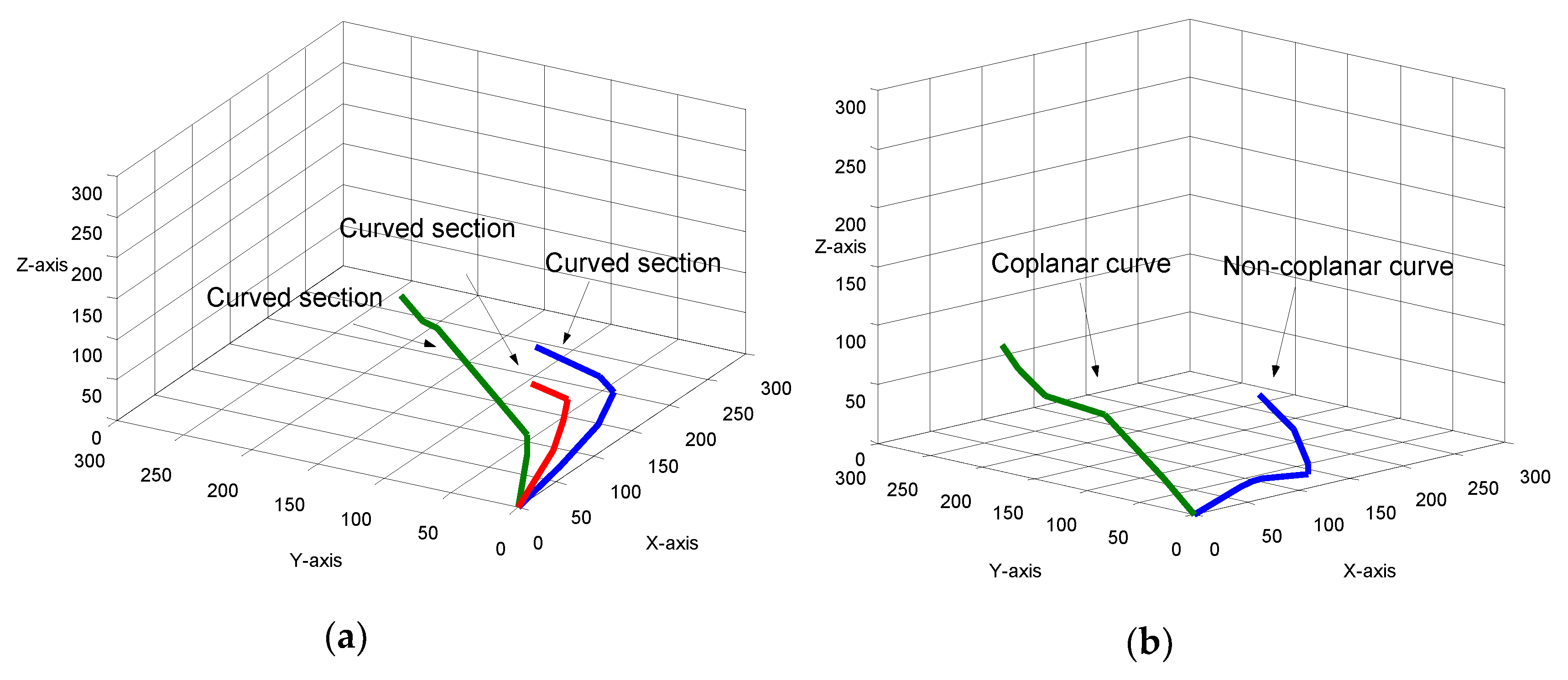

2.2.1. Measurement of the Spatial Posture of Lodged Sugarcane

2.2.2. Definition of Lodging Angle (α)

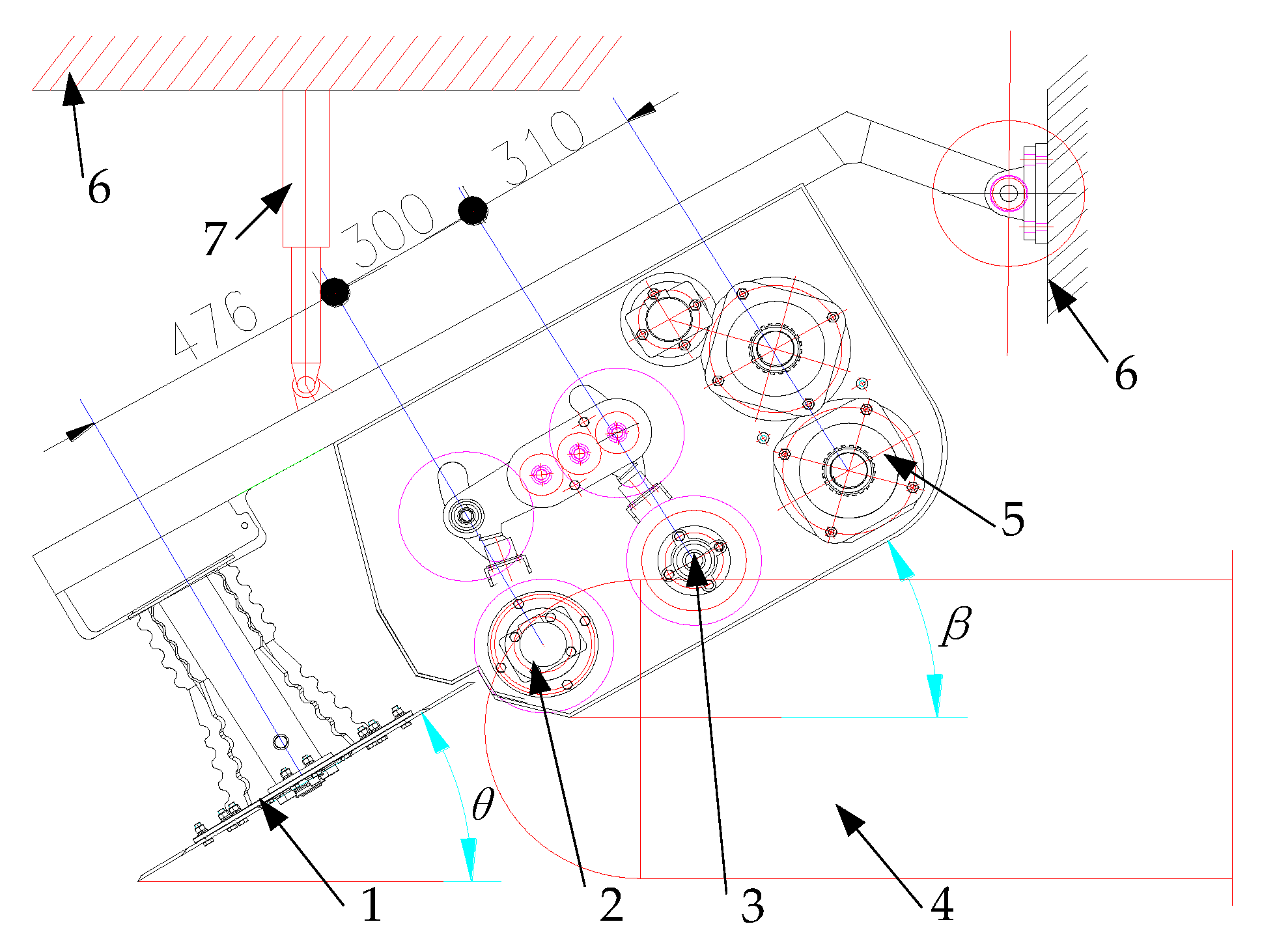

2.3. Analysis of the Causes of High Field Loss Ratio During Lodged Sugarcane Harvesting

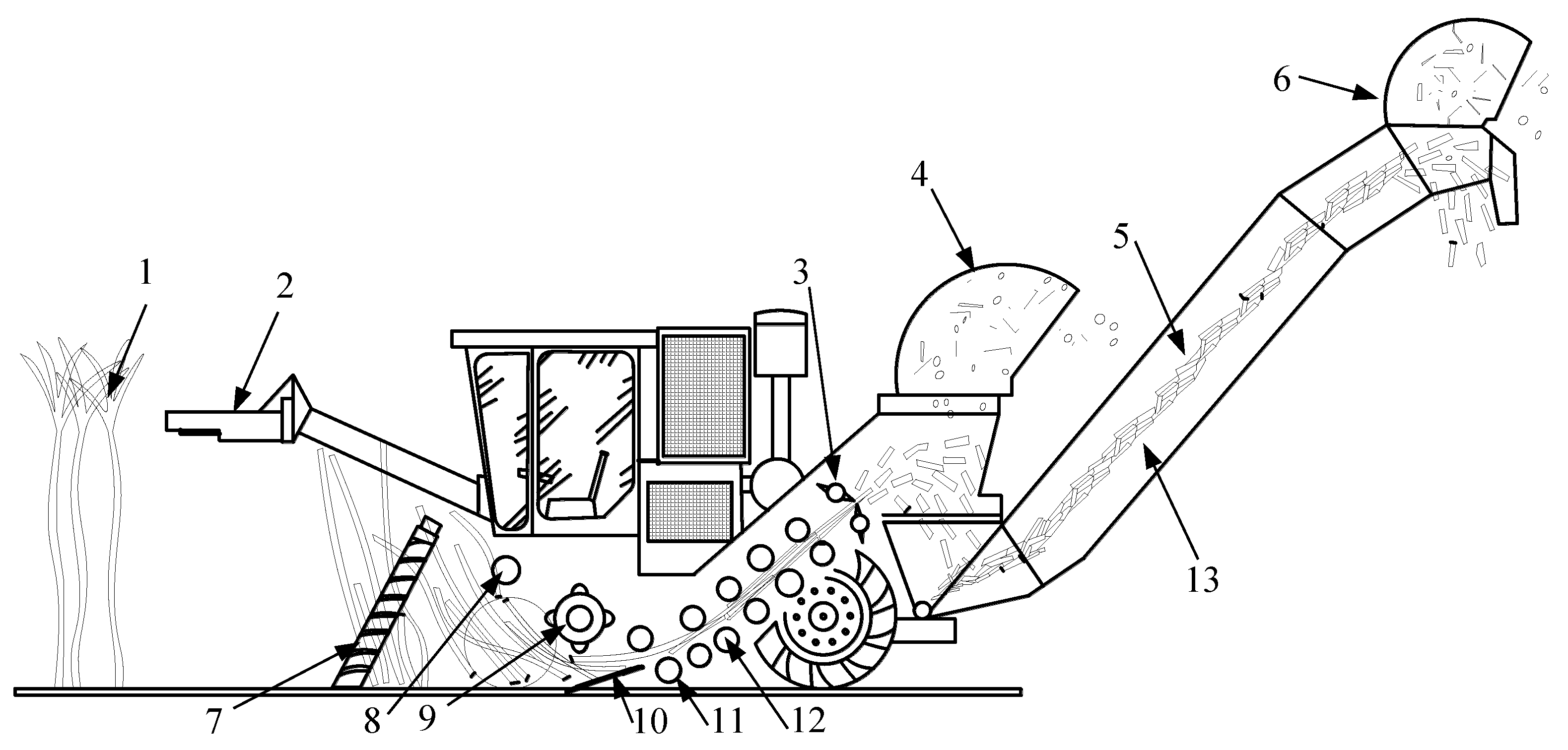

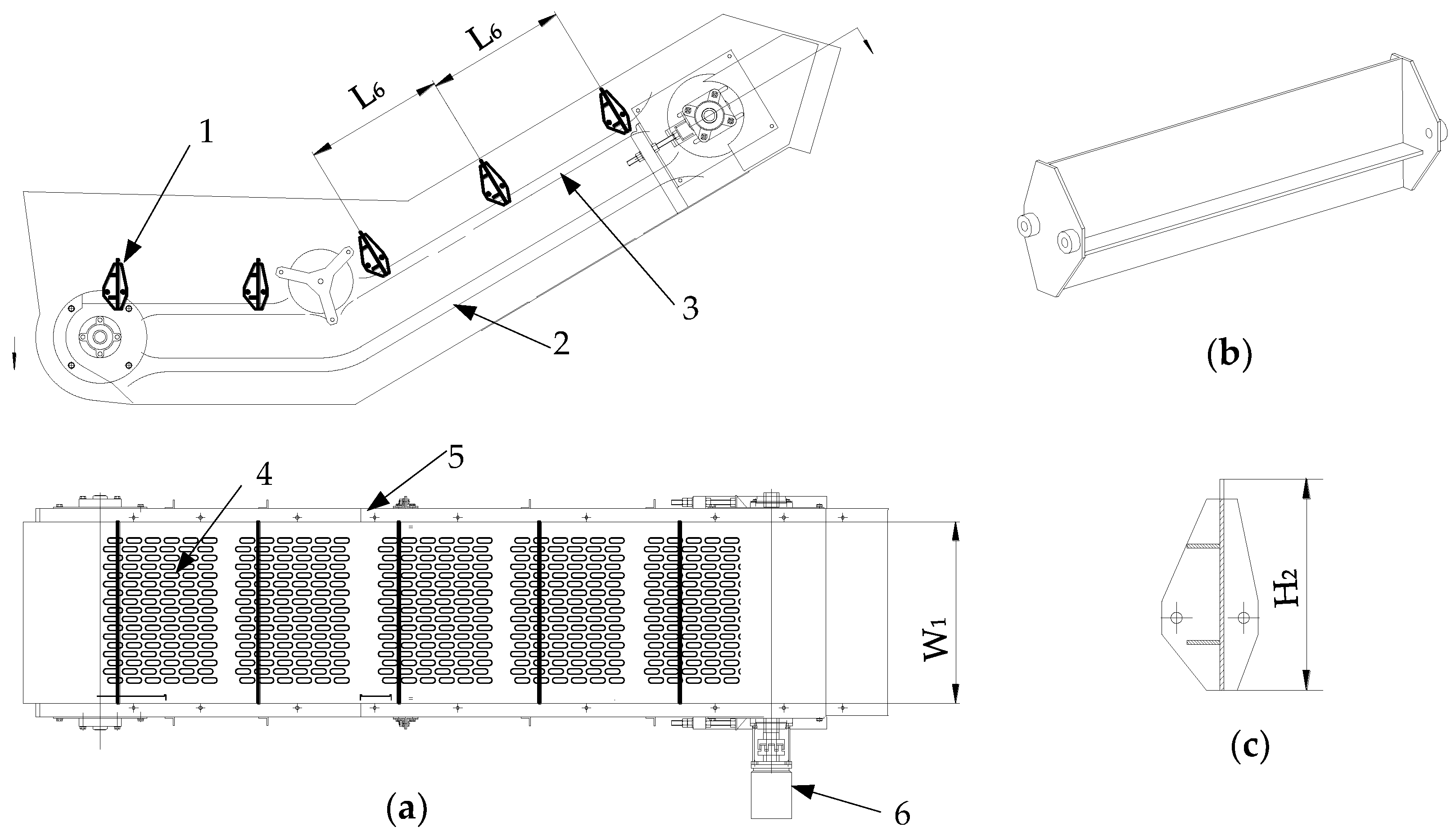

2.3.1. Understanding Sugarcane Chopper Harvester and Its Field Losses During Harvesting

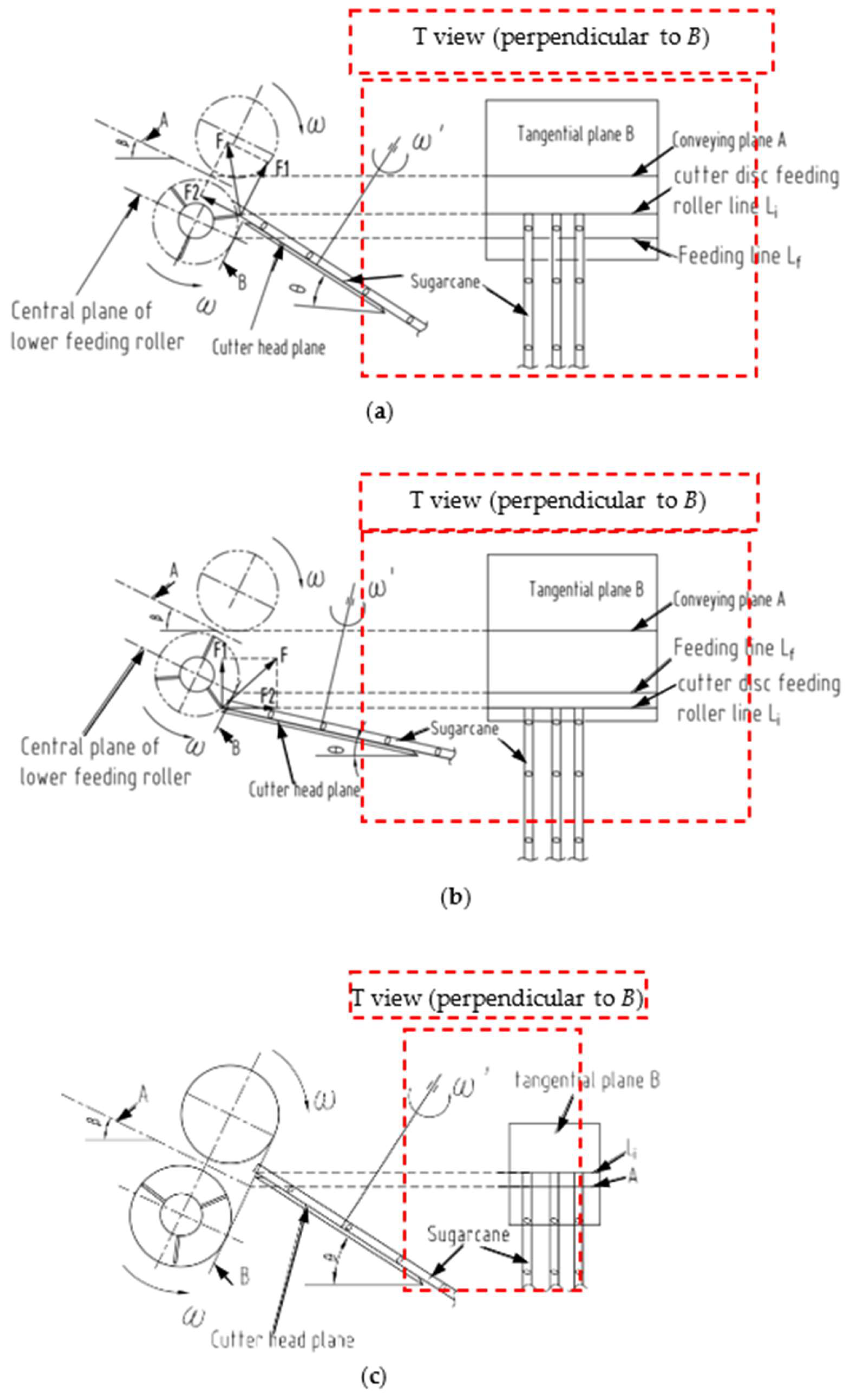

2.3.2. Harvest Losses During Sugarcane Pickup by Basecutter

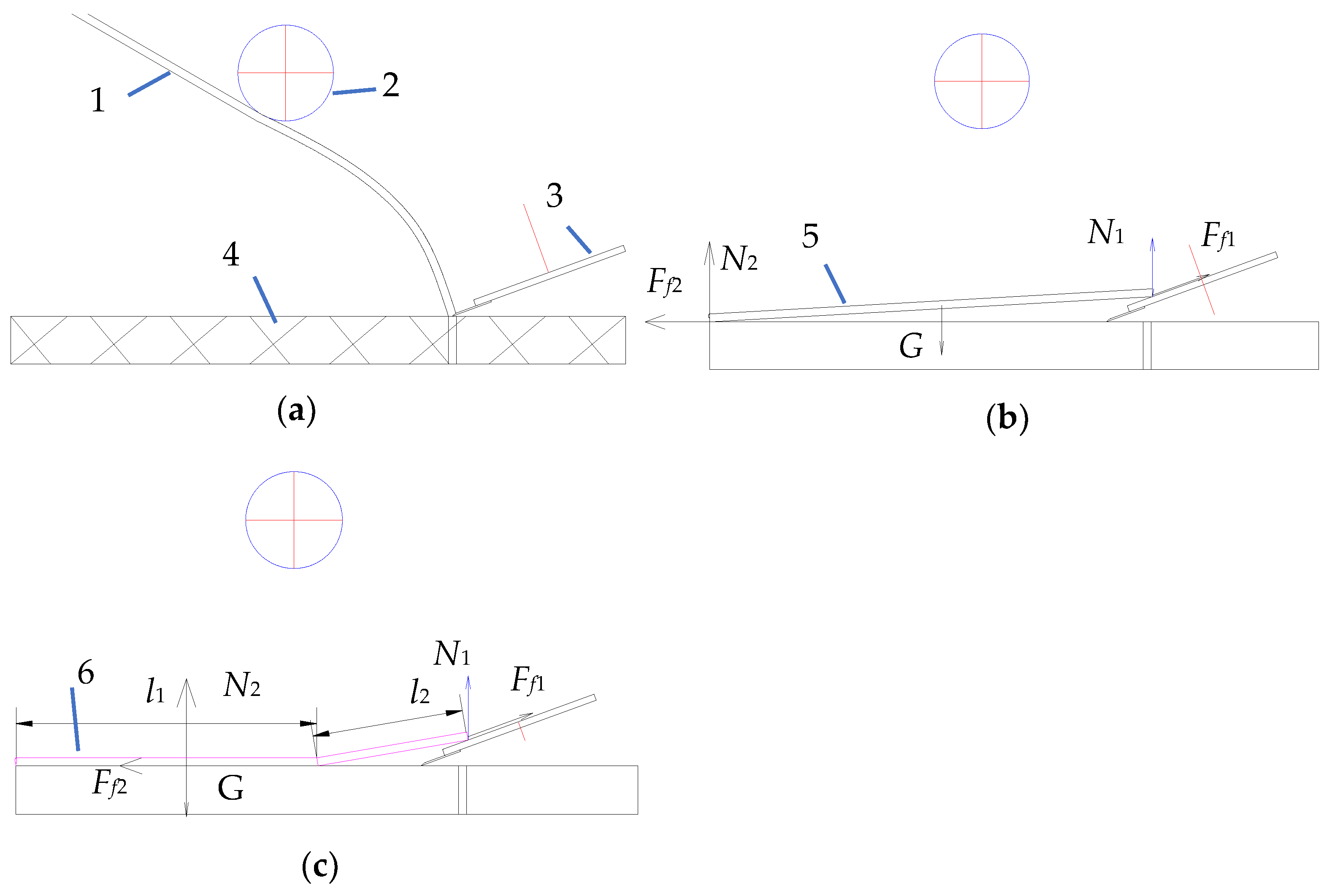

2.3.3. Harvest Loss During the Transfer of Canes Backwards to Butt Lift Roller by Basecutter

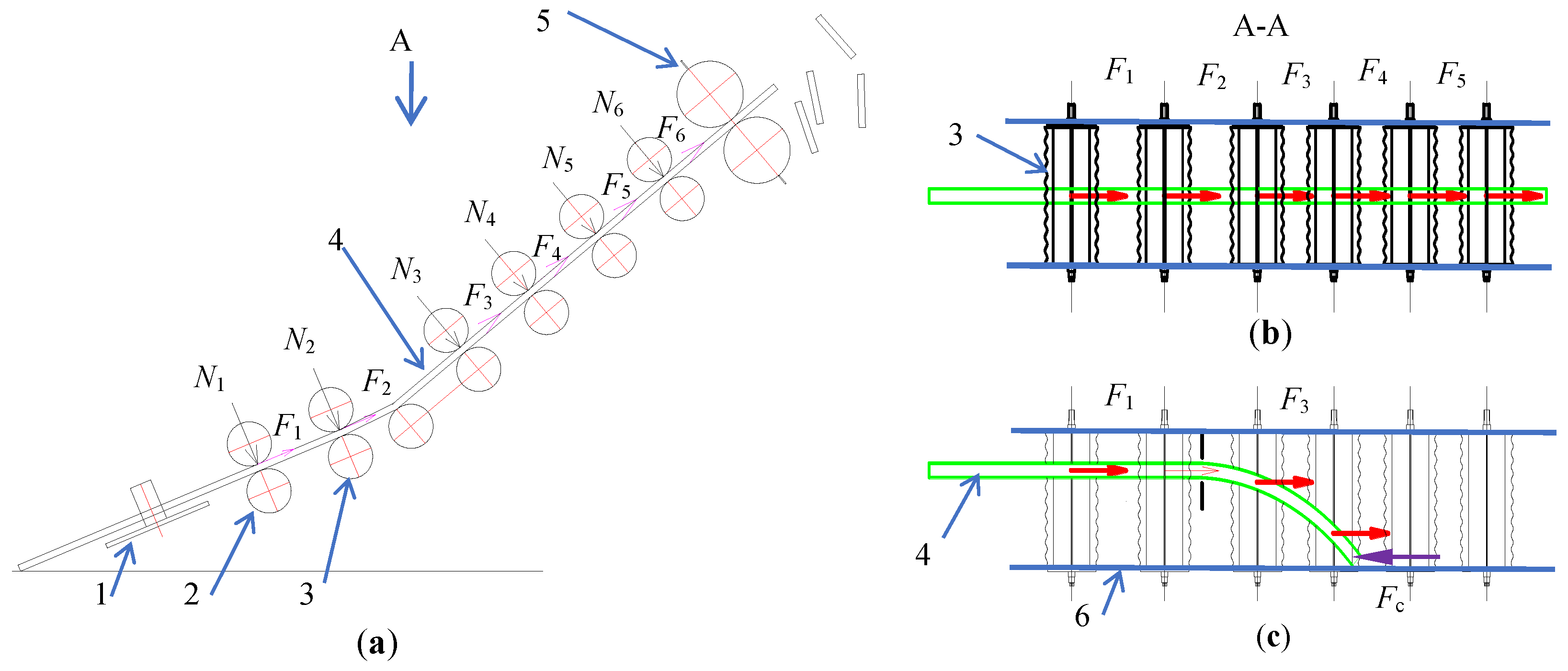

2.3.4. Harvest Losses During Sugarcane Conveyance in the Roller Train

2.4. Performance Enhancement of Chopper Harvesters: Structural Improvements and Field Loss Mitigation Mechanisms

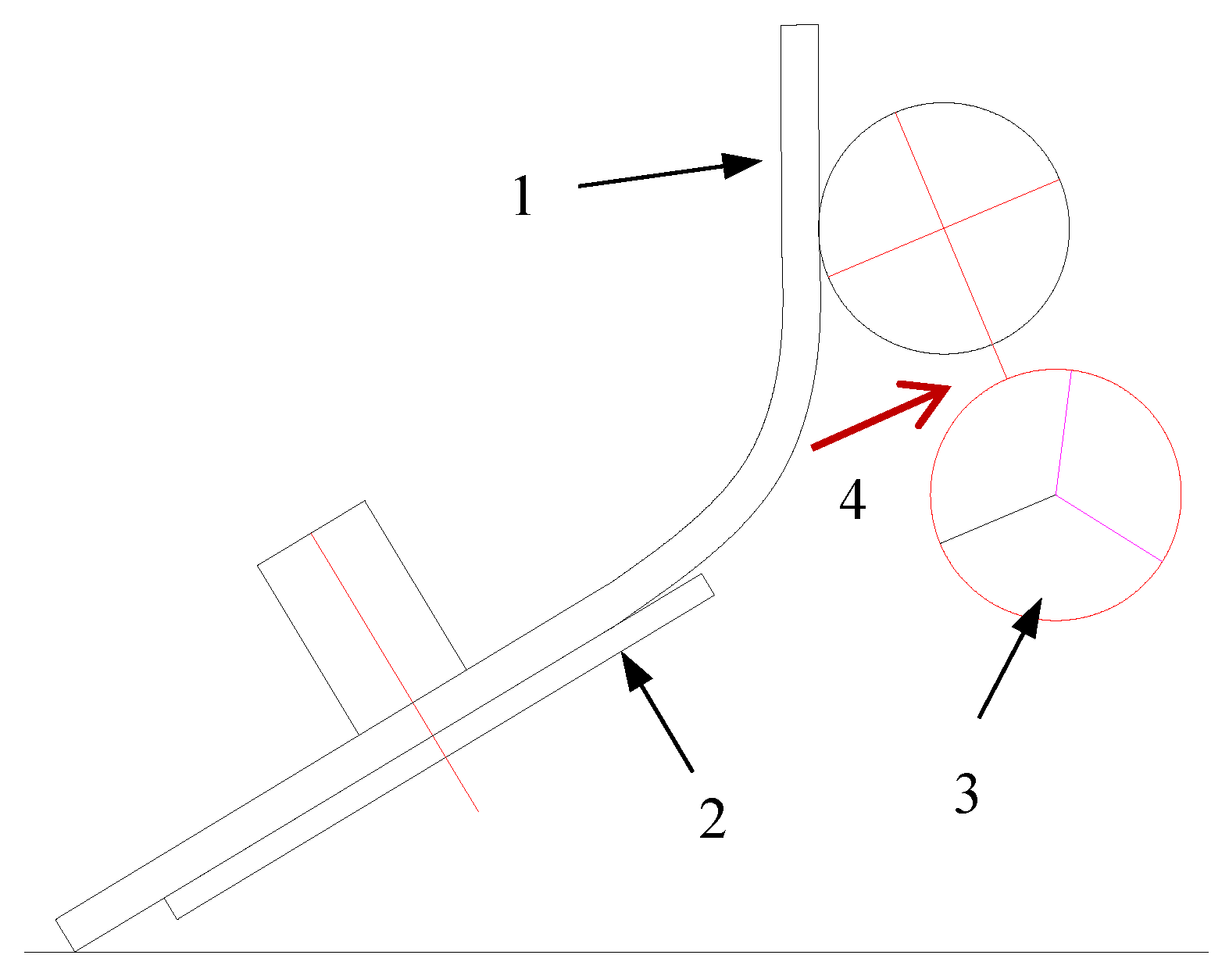

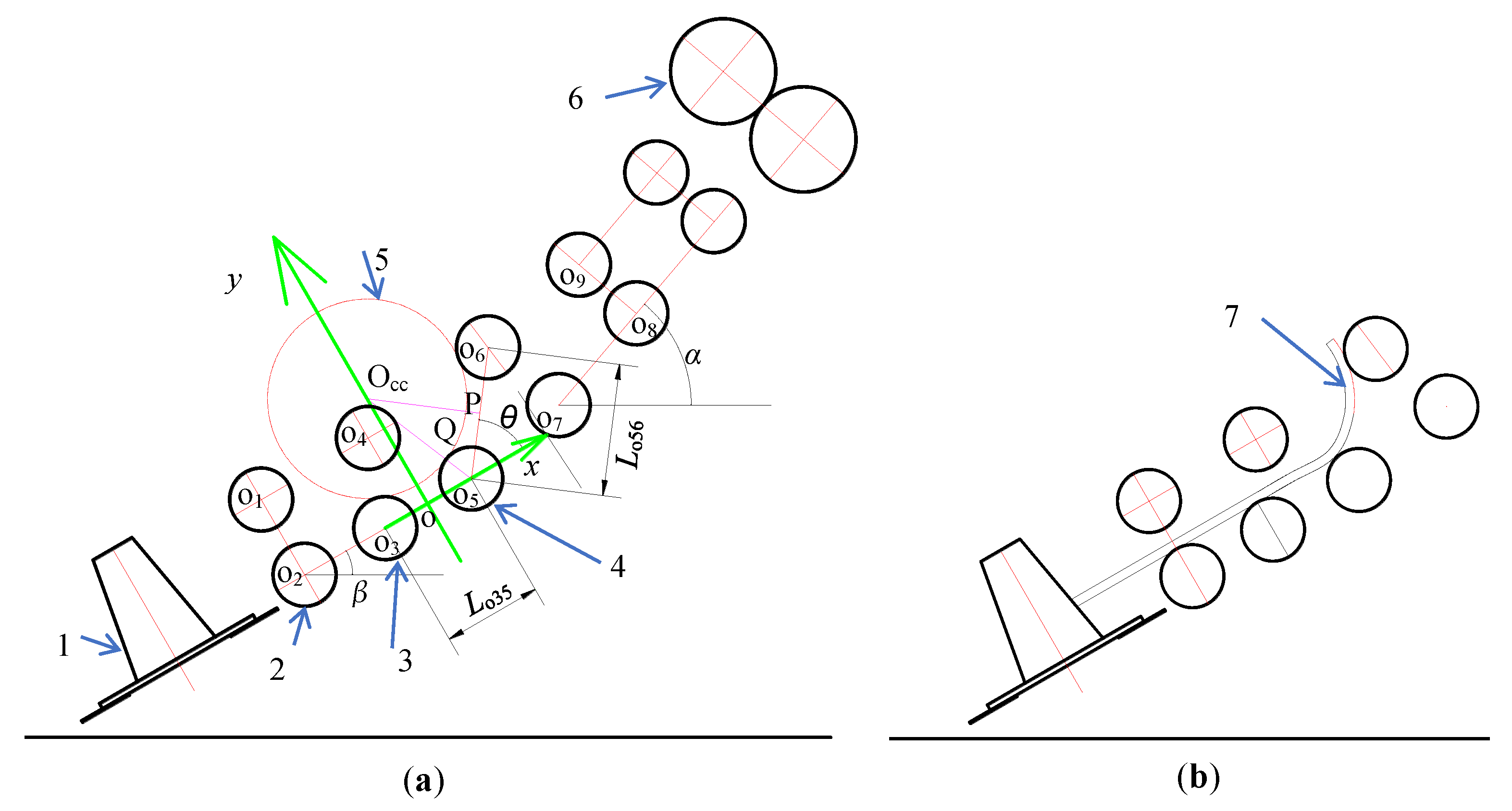

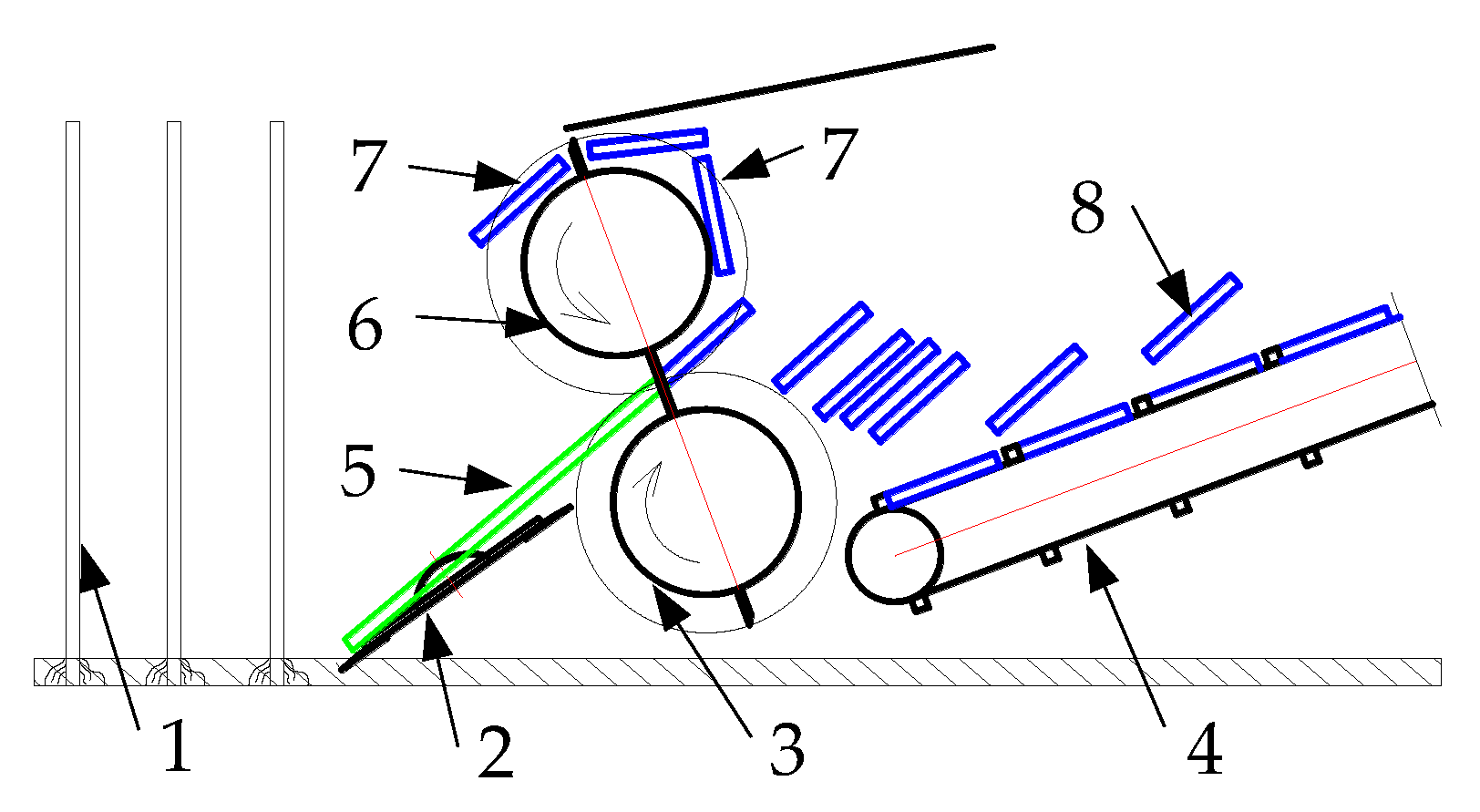

2.4.1. Basecutter Structural Modifications and Stalk Pickup Mechanism

2.4.2. Position Relationship Between the Disc and Butt Lift Rollers

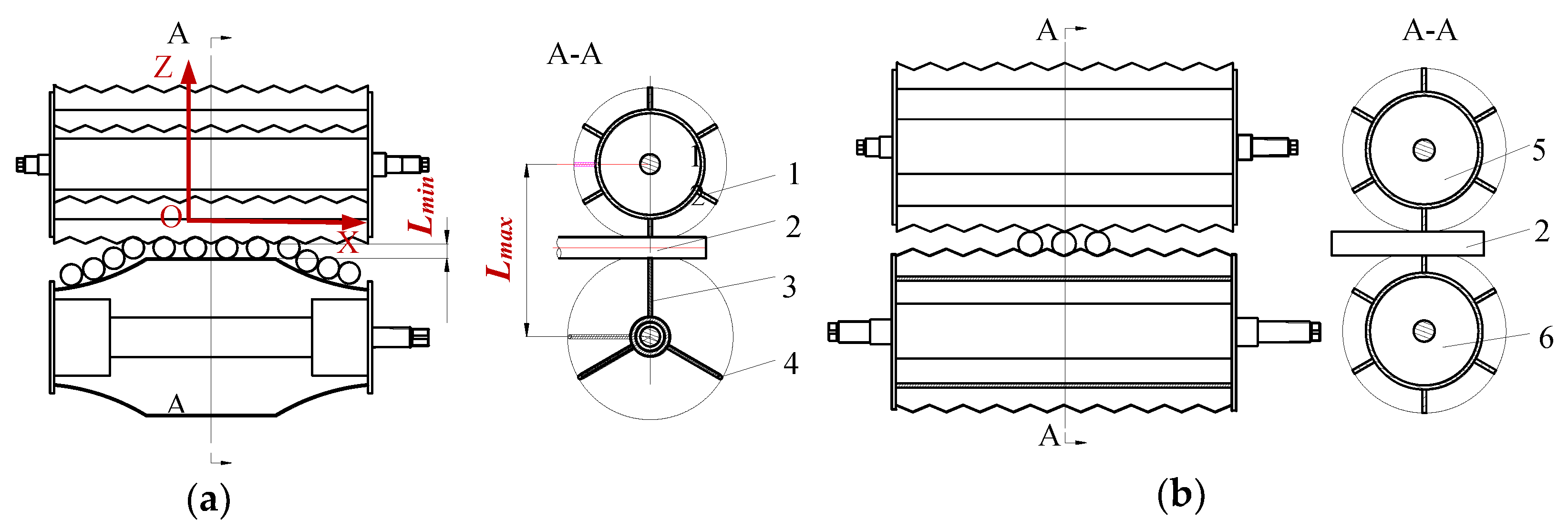

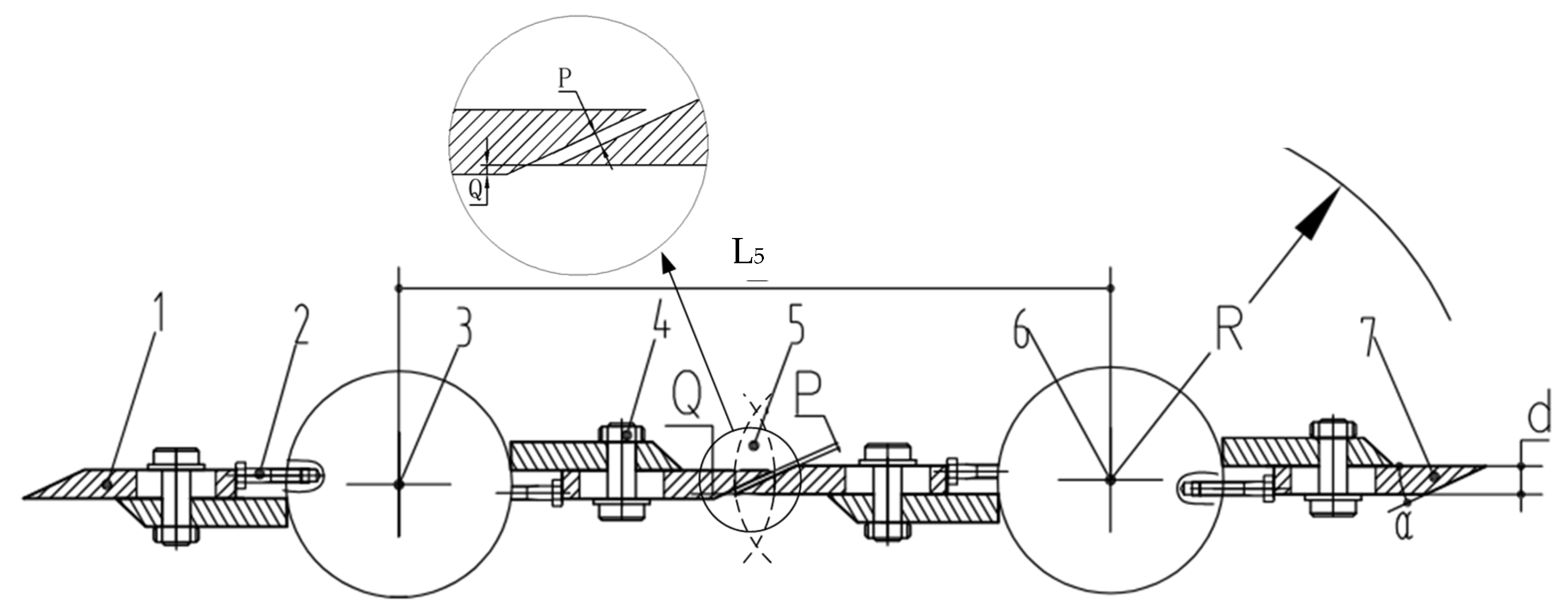

2.4.3. Structural of Roller Train

Analysis of the Structure Without Roller Train Between Basecutter and Chopper

Structural Improvements of Roller Train

2.5. Development of Improved Sugarcane Harvester

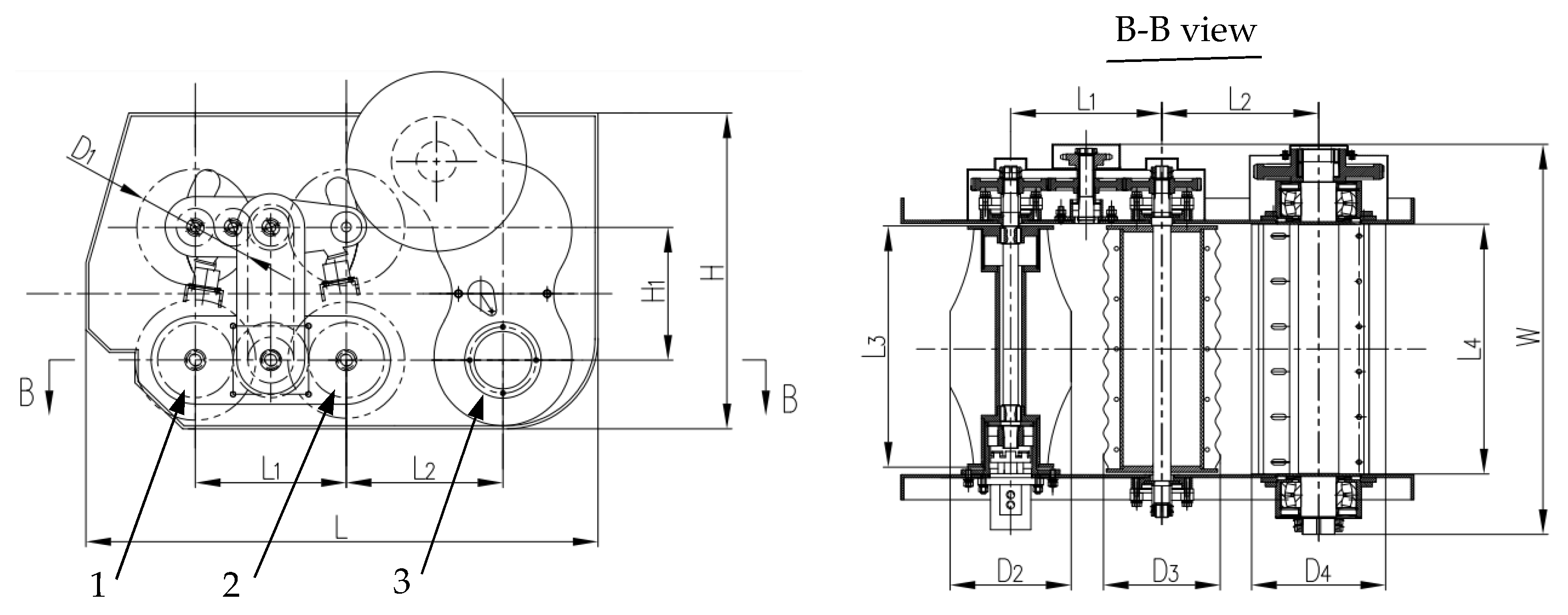

2.5.1. Design of Improved Harvester

Basecutter Structural Configuration

Structural Dimension of the Roller Train

Dimensional Configuration of the Chopper Assembly

Structural Dimension of Billet Conveyor System

2.5.2. Structural Dimensions and Parameters of the Improved Harvester Prototype

2.6. Performance and Field Test of the Harvester

2.6.1. Experimental Instruments and Equipment

2.6.2. Field Testing Conditions and Experimental Setup

2.6.3. Experiment Methods

Field Sampling Methodology

Performance Evaluation Methodology

Billet Qualification Ratio (Cdh)

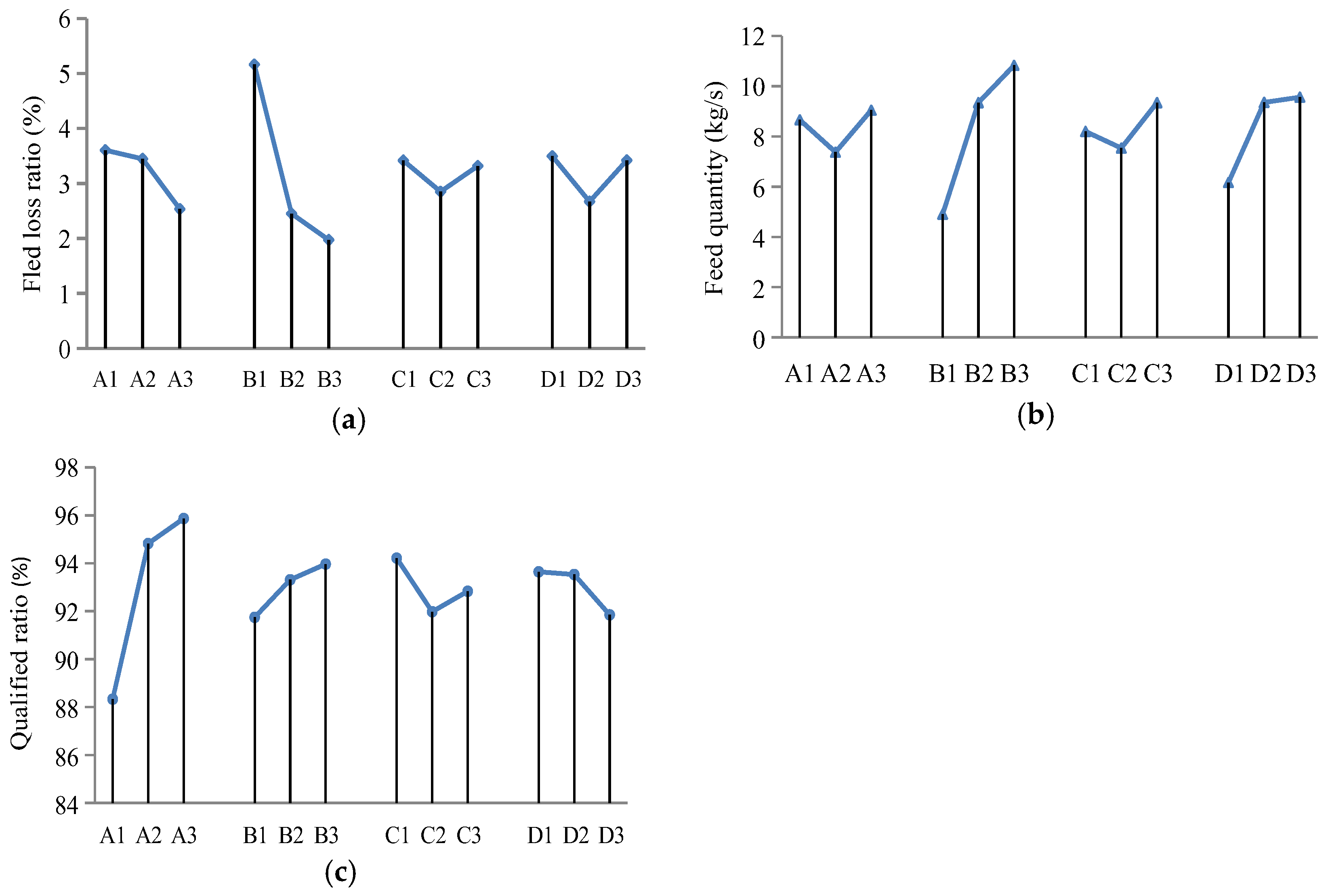

Performance Test Methods

Field Test Methods of the Harvester

3. Results and Analysis

3.1. The Results and Analysis of the SFC Tests

3.2. Sugarcane Field Lodging Severity

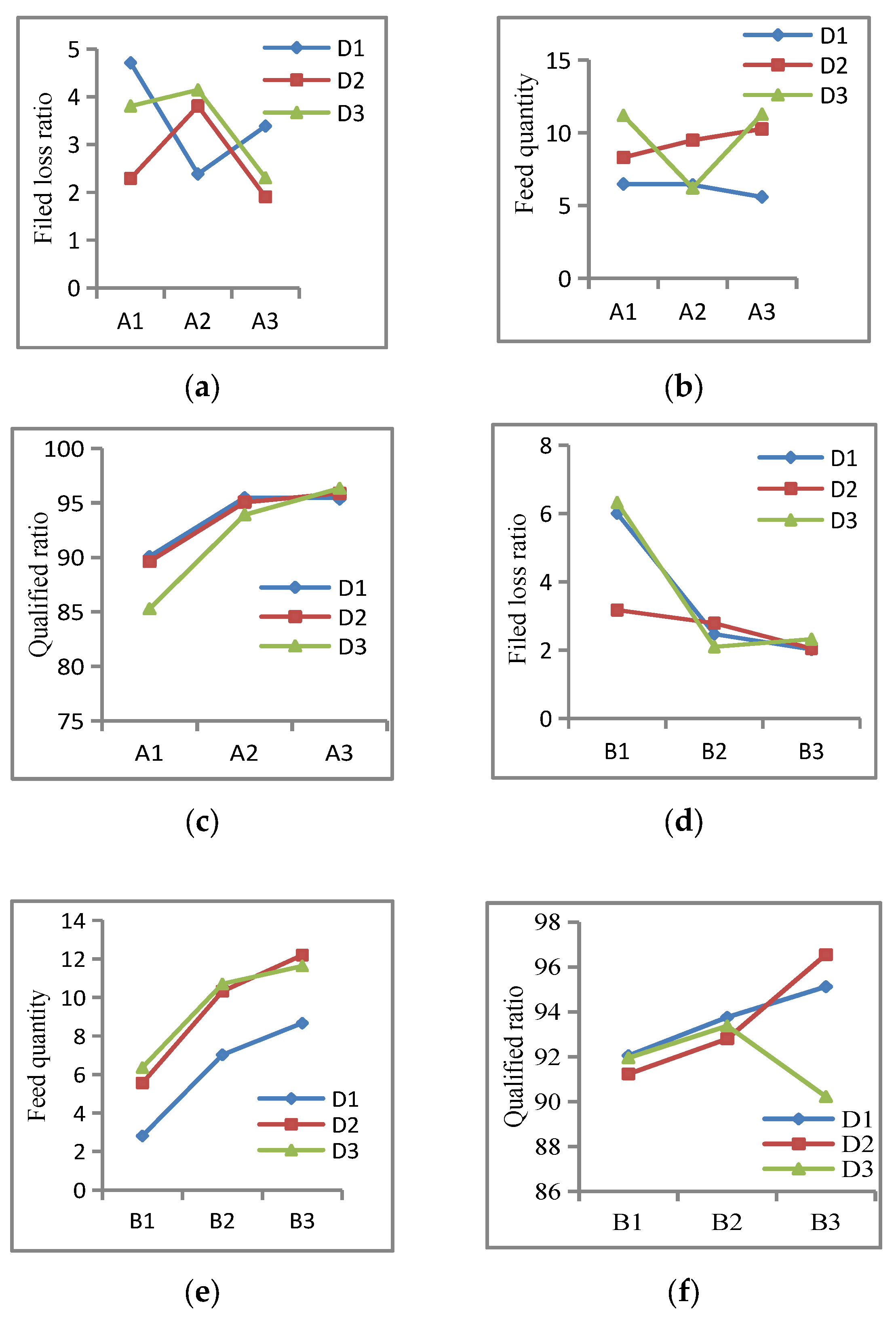

3.3. Results and Analysis of the Performance Test

3.4. Results and Analysis of the Field Test

4. Discussion and Conclusions

4.1. Discussion

4.2. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Younos, M.A.; Embaby, E.M. Natural occurrence of fungi and aflatoxins associated sugarcane plant and sugarcane juice and their Control. Indian J. Microbiol. 2024, 64, 500–510. [Google Scholar] [CrossRef] [PubMed]

- Wen, C.; Yan, Y.; Wu, W.; Li, J.; Hou, B.; Cui, W.; Huang, Y.; Li, K.; Long, X.; Nong, H. Height detection of crop divider toes of sugarcane harvester based on Kalman adaptive adjustment. Sci. Rep. 2023, 13, 16817. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.; Ma, S.; Wang, F.; Xing, H.; Ma, J.; Wang, M. Performance of crop dividers with reference to harvesting lodged sugarcane. Sugar Tech 2020, 22, 812–819. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, J.; Ou, Y. Spatial attitude of lodged sugarcane stalk in field. In Proceedings of the ASABE’s Annual International Meeting 2012, Dallas, TX, USA, 29 July–1 August 2012. [Google Scholar]

- Bai, J.; Ma, S.; Wang, F.; Xing, H.; Ding, Z.; Hu, J. Lifting performance of crop dividers with variable pitch spiral scrolls. Sugar Tech. 2022, 24, 1877–1886. [Google Scholar] [CrossRef]

- Wu, T.; Ren, J.; Liu, Q.; Zou, X.; Zhang, Z.; Zhou, S.; Feng, J.; He, L. Development of the 4GDZ-132 sugarcane chopper combine harvester. Trans. Chin. Soc. Agric. Eng. 2022, 38, 30–38. (In Chinese) [Google Scholar]

- Ma, S.; Scharf, P.A.; Karkee, M.; Zhang, Q. Performance evaluation of a chopper harvester in Hawaii sugarcane fields. In Proceedings of the 2014 ASABE International Annual Meeting, Montreal, Canada, 13–16 July 2014; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2014; p. 1. [Google Scholar]

- Lu, H.; Wu, T. Reflection on development status of mechanized sugarcane harvesting in Guangxi. Sugarcane Canesugar 2023, 52, 53–59. [Google Scholar]

- Jiang, J.; Yang, Y.; Wu, C.Y.; Liu, Q.T.; Ou, Y.G.; Mo, Q.G.; Xia, M.; Wu, T.; Liang, S. Analysis on reasons for the slow advance of sugarcane harvesting mechanization in China. Sugarcane Canesugar 2022, 51, 1–5. [Google Scholar]

- Gary, S.; John, A. The Harvesting Best Practice Manual for Chopper-Extractor Harvester; Bureau of Sugar Experiment Station: Brisbane, Australia, 2002. [Google Scholar]

- Kerr, B.; Blyth, K. 100 Years of Mechanical Cane Harvesting; Canegrowers: Ingham, Australia, 1993. [Google Scholar]

- Dias Neto, A.F.; Albiero, D.; Rossetto, R.; Biagi, J.D. Modeling of Mechanized Sugarcane Harvesting to Support Decision-Making on Asset Management. Sugar Tech. Int. J. Sugar Crops Relat. Ind. 2022, 24, 798–812. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, G.; Huang, X.; Song, J.; Xie, D.; Chen, L. Experimental research on the effect of sugarcane stalk lifting height on the cutting breakage mechanism based on the sugarcane lifting-cutting system (SLS). Agriculture 2022, 12, 2078. [Google Scholar] [CrossRef]

- Qiu, M.; Meng, Y.; Li, Y.; Shen, X. Sugarcane stem cut quality investigated by finite element simulation and experiment. Biosyst. Eng. 2021, 206, 135–149. [Google Scholar] [CrossRef]

- Qian, J.; Ma, S.; Xu, Y.; Liang, W.; Zhou, B.; Li, W. Analysis of crack stress intensity factor of sugarcane cutting based on fracture mechanics. Trans. Chin. Soc. Agric. Mach. 2023, 54, 101–109. (In Chinese) [Google Scholar]

- Ding, Z.; Ma, S.; Zhang, X.; Liang, W.; Li, L.; Su, C. Ultrasonic sensor-based basecutter height control system of sugarcane harvester. Sugar Tech 2023, 25, 453–459. [Google Scholar] [CrossRef]

- Li, H.; Yang, J.; Song, J.; Sun, M.; Wei, W.; Zhang, S.; Wu, T.; Li, Y. Stem base detection in sugarcane plants using improved YOLOv5m model. Sugar Tech 2025, 1–11. [Google Scholar] [CrossRef]

- Davis, R.J.; Norris, C.P. Improving the feeding ability of sugarcane harvesters. In Proceedings of the 2002 Conference of the Australian Society of Sugar Cane Technologists, Cairns, Australia, 29 April–2 May 2002; pp. 190–198. [Google Scholar]

- Wang, M.; Liu, Q.; Ou, Y.; Zou, X. Determination of physical and mechanical properties of sugarcane single-bud billets. J. ASABE 2022, 65, 1029–1038. [Google Scholar] [CrossRef]

- Ma, L.; Huang, W.; Li, S.; Huang, Z.; Teng, X. Parameters calibration of discrete element model for latosolicred soil of sugarcane in Guangxi Autonomous Region. J. Agric. Mech. Res. 2023, 45, 18–26. [Google Scholar]

- JB/T 6275-2019; Sugarcane Combine Harvester. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2019.

- CASE A8000 and A8800 Cane Harvesters Operator’s Manual, 84158982-01; Case IH: Sydney, Australia, 2009.

- Available online: https://www.deere.com/en/search/?term=Sugar+Cane+Harvester (accessed on 10 April 2025).

- Wang, F.; Ma, S.; Xing, H.; Bai, J.; Ma, J.; Hu, J.; Yang, Y. High-speed photography analysis on sugarcane base cutting process of contra-rotating basecutters. Sugar Tech 2021, 23, 1118–1125. [Google Scholar] [CrossRef]

- Qiu, C.; Mo, H.; Li, S.; He, G.; Zeng, B.; Yang, D. Experimental research on influence factors of the sugarcane ratoon cutting quality undervibration conditions. In Proceeding of the IncoMe-VI and Tepen 2021, Tianjin, China, 20–23 October 2021; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Wang, F.L.; Ma, S.C.; Xing, H.N.; Bai, J.; Ma, J.-Z.; Wang, M.-L. Effect of contra-rotating basecutter parameters on basecutting losses. Sugar Tech Int. J. Sugar Crops Relat. Ind. 2021, 23, 278–285. [Google Scholar] [CrossRef]

- Xie, L.; Wang, J.; Cheng, S.; Zeng, B.; Yang, Z. Performance evaluation of a chopper system for sugarcane harvester. Sugar Tech. 2019, 21, 825–837. [Google Scholar] [CrossRef]

- Hogarth, D.M.; Allsopp, P.G. Manual of Canegrowing; Sugar Research Australia: Brisbane, Australia, 2000. [Google Scholar]

| Parameters | Values |

|---|---|

| Overall size L × W × H (mm) | 6355 × 1780 × 2940 |

| Track length L1/track gauge L2 (mm) | 3480/1230 |

| Engine rated power (kW) | 91 |

| Displacement of the motor of knockdown roller (mL/r) | 160 |

| Displacement of the motor of basecutter (mL/r) | 80 |

| Displacement of the motor of butt lift/feed roller (mL/r) | 200 |

| Displacement of the motor of chopper (mL/r) | 200 |

| Displacement of the motor of billet conveying device (mL/r) | 125 |

| A: Rotational Speed of Chopper (r/min) | B: Numbers of Stalks in a Group | C: Rotational Speed of Butt Lift/Feed Rollers (r/min) | D: Ground Speed (m/s) | |

|---|---|---|---|---|

| 1 | 230 | 5 | 150 | slow (0.65) |

| 2 | 310 | 10 | 190 | medium (1.09) |

| 3 | 390 | 15 | 230 | fast (1.41) |

| Orientation | Sample | MC | 1 | 2 | 3 | Mean | Standard Error | |

|---|---|---|---|---|---|---|---|---|

| Soil | Vertical | DL | 5% | 0.7 | 0.79 | 0.71 | 0.73 | 0.03 |

| 10% | 0.8 | 0.8 | 0.91 | 0.84 | 0.04 | |||

| 15% | 0.59 | 0.62 | 0.56 | 0.59 | 0.02 | |||

| WL | 5% | 0.74 | 0.73 | 0.85 | 0.77 | 0.04 | ||

| 10% | 0.79 | 0.88 | 0.82 | 0.83 | 0.03 | |||

| 15% | 0.41 | 0.51 | 0.56 | 0.5 | 0.04 | |||

| Horizontal | DL | 5% | 0.72 | 0.76 | 0.8 | 0.76 | 0.02 | |

| 10% | 0.69 | 0.79 | 0.93 | 0.8 | 0.07 | |||

| 15% | 0.4 | 0.56 | 0.53 | 0.5 | 0.05 | |||

| WL | 5% | 0.92 | 0.93 | 0.84 | 0.9 | 0.03 | ||

| 10% | 0.62 | 0.71 | 0.59 | 0.64 | 0.03 | |||

| 15% | 0.75 | 0.73 | 0.72 | 0.73 | 0.01 | |||

| Steel | Vertical | DL | 0.48 | 0.46 | 0.49 | 0.48 | 0.01 | |

| WL | 0.4 | 0.39 | 0.42 | 0.4 | 0.01 | |||

| Horizontal | DL | 0.51 | 0.44 | 0.49 | 0.48 | 0.02 | ||

| WL | 0.47 | 0.49 | 0.47 | 0.48 | 0.01 |

| No. | A | B | A×B | C | A×C | B×C | D | A×D | B×D | C×D | Sz/% | Qw/kg/s | Cdh/% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 9.00 | 2.30 | 89.90 |

| 2 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 1.76 | 6.02 | 87.21 |

| 3 | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 6.30 | 5.65 | 90.66 |

| 4 | 1 | 2 | 2 | 2 | 1 | 1 | 2 | 2 | 2 | 3 | 2.55 | 9.50 | 86.29 |

| 5 | 1 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 1 | 2.95 | 9.17 | 86.48 |

| 6 | 1 | 2 | 2 | 2 | 3 | 3 | 1 | 1 | 1 | 2 | 3.30 | 7.61 | 87.57 |

| 7 | 1 | 3 | 3 | 3 | 1 | 1 | 3 | 3 | 3 | 2 | 2.18 | 18.77 | 78.71 |

| 8 | 1 | 3 | 3 | 3 | 2 | 2 | 1 | 1 | 1 | 3 | 1.84 | 9.54 | 92.78 |

| 9 | 1 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 1 | 2.57 | 9.40 | 95.39 |

| 10 | 2 | 1 | 2 | 3 | 1 | 2 | 1 | 3 | 3 | 1 | 3.44 | 3.12 | 95.24 |

| 11 | 2 | 1 | 2 | 3 | 2 | 3 | 2 | 1 | 1 | 2 | 6.11 | 5.41 | 92.20 |

| 12 | 2 | 1 | 2 | 3 | 3 | 1 | 3 | 2 | 2 | 3 | 8.32 | 6.00 | 90.24 |

| 13 | 2 | 2 | 3 | 1 | 1 | 2 | 2 | 1 | 1 | 3 | 3.81 | 9.41 | 96.10 |

| 14 | 2 | 2 | 3 | 1 | 2 | 3 | 3 | 2 | 2 | 1 | 2.12 | 9.85 | 95.99 |

| 15 | 2 | 2 | 3 | 1 | 3 | 1 | 1 | 3 | 3 | 2 | 1.92 | 6.69 | 96.45 |

| 16 | 2 | 3 | 1 | 2 | 1 | 2 | 3 | 2 | 2 | 2 | 2.00 | 2.79 | 95.53 |

| 17 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 3 | 3 | 3 | 1.80 | 9.44 | 94.76 |

| 18 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 1 | 1 | 1 | 1.51 | 13.67 | 96.91 |

| 19 | 3 | 1 | 3 | 2 | 1 | 3 | 1 | 2 | 2 | 1 | 5.57 | 3.00 | 91.01 |

| 20 | 3 | 1 | 3 | 2 | 2 | 1 | 2 | 3 | 3 | 2 | 1.64 | 5.24 | 94.30 |

| 21 | 3 | 1 | 3 | 2 | 3 | 2 | 3 | 1 | 1 | 3 | 4.34 | 7.42 | 94.95 |

| 22 | 3 | 2 | 1 | 3 | 1 | 3 | 2 | 3 | 3 | 3 | 2.01 | 12.04 | 96.02 |

| 23 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 1 | 1 | 1 | 1.21 | 13.09 | 97.65 |

| 24 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 2 | 2 | 2 | 2.19 | 6.76 | 97.26 |

| 25 | 3 | 3 | 2 | 1 | 1 | 3 | 3 | 1 | 1 | 2 | 1.37 | 13.34 | 96.43 |

| 26 | 3 | 3 | 2 | 1 | 2 | 1 | 1 | 2 | 2 | 3 | 2.41 | 7.02 | 97.83 |

| 27 | 3 | 3 | 2 | 1 | 3 | 2 | 2 | 3 | 3 | 1 | 2.07 | 13.52 | 97.36 |

| Performance Indicators | Sz, % | Qw, kg/s | Cdh,% |

|---|---|---|---|

| Source | sig | sig | sig |

| A | 0.421 | 0.540 | 0.004 ** |

| B | 0.010 * | 0.011 * | 0.435 |

| A×B | 0.679 | 0.858 | 0.575 |

| C | 0.774 | 0.512 | 0.442 |

| A×C | 0.328 | 0.982 | 0.394 |

| B×C | 0.618 | 0.588 | 0.610 |

| D | 0.57 | 0.098 | 0.516 |

| A×D | 0.0 ** | 0.0 ** | 0.0 ** |

| B×D | 0.0 ** | 0.0 ** | 0.0 ** |

| C×D | 0.367 | 0.943 | 0.428 |

| Sz, % | Qw, kg/s | Cdh,% | ||

|---|---|---|---|---|

| A3B3C2D2 | 1 | 1.81, | 13.41 | 97.81 |

| 2 | 1.74 | 14.5 | 98.28 | |

| 3 | 1.58 | 12.92 | 96.85 | |

| Mean | 1.71 | 13.61 | 97.65 | |

| Standard error | 0.065 | 0.467 | 0.421 | |

| A3B2C3D3 | 1 | 1.26 | 13.29 | 95.62 |

| 2 | 1.15 | 13.65 | 97.41 | |

| 3 | 1.22 | 12.34 | 94.42 | |

| Mean | 1.21 | 13.09 | 95.82 | |

| Standard error | 0.032 | 0.391 | 0.869 | |

| t-test value | 6.6421 | 0.8486 | −1.8958 | |

| Parameters | 1 | 2 | 3 | Mean | Standard Error |

|---|---|---|---|---|---|

| Feed quantity, kg/s | 10.1 | 11.2 | 10.2 | 10.5 | 0.287 |

| Ratio of stubble broken, % | 12.9 | 13.2 | 12.3 | 12.8 | 0.215 |

| Ratio of trash content, % | 5.9 | 4.2 | 4 | 4.7 | 0.492 |

| Field loss ratio, % | 2.1 | 1.7 | 2.2 | 2.0 | 0.125 |

| Qualification rate of the billets, % | 92.9 | 95.1 | 94.6 | 94.2 | 0.544 |

| Unit diesel consumption ratio, kg/ha | 125.8 | 127.2 | 127.4 | 126.8 | 0.411 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; Han, X.; Liu, Q.; Xu, H.; Wu, T.; Feng, J.; Zou, X.; Li, Y. Structural Improvement of Sugarcane Harvester for Reducing Field Loss When Harvesting Lodged Canes. Agriculture 2025, 15, 1759. https://doi.org/10.3390/agriculture15161759

Jiang J, Han X, Liu Q, Xu H, Wu T, Feng J, Zou X, Li Y. Structural Improvement of Sugarcane Harvester for Reducing Field Loss When Harvesting Lodged Canes. Agriculture. 2025; 15(16):1759. https://doi.org/10.3390/agriculture15161759

Chicago/Turabian StyleJiang, Jiaoli, Xueting Han, Qingting Liu, Hai Xu, Tao Wu, Jiamo Feng, Xiaoping Zou, and Yuejin Li. 2025. "Structural Improvement of Sugarcane Harvester for Reducing Field Loss When Harvesting Lodged Canes" Agriculture 15, no. 16: 1759. https://doi.org/10.3390/agriculture15161759

APA StyleJiang, J., Han, X., Liu, Q., Xu, H., Wu, T., Feng, J., Zou, X., & Li, Y. (2025). Structural Improvement of Sugarcane Harvester for Reducing Field Loss When Harvesting Lodged Canes. Agriculture, 15(16), 1759. https://doi.org/10.3390/agriculture15161759