Progress in Mechanized Harvesting Technologies and Equipment for Minor Cereals: A Review

Abstract

1. Introduction

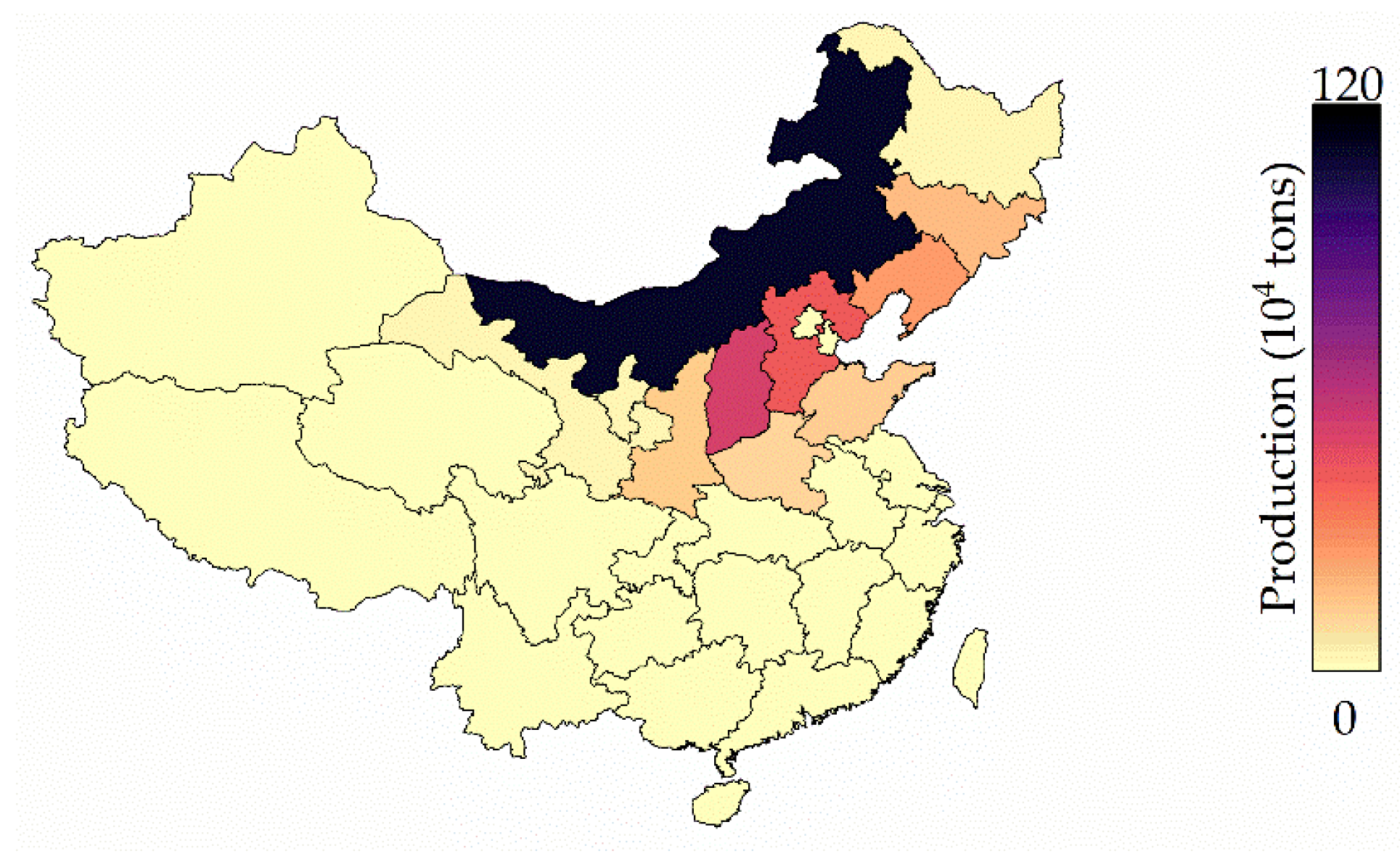

2. Status of the Minor Cereal Industry in China

2.1. Distribution and Scale of Minor Cereal Cultivation

2.2. Status of Mechanized Harvesting of Minor Cereals

3. Key Technologies for Mechanized Harvesting of Minor Cereals

3.1. Crop Cutter Equipment and Key Technologies

3.1.1. Efficient Separating Crop Organization

3.1.2. Low-Loss Feeding Technology for Crop-Supporting Devices

3.1.3. Cutter

3.1.4. High-Efficiency, Low-Loss Flexible Header

3.2. Key Technologies for Mechanized Threshing of Minor Cereals

3.2.1. Combined Threshing Drum Unit

3.2.2. Multi-Drum Combination Threshing Unit

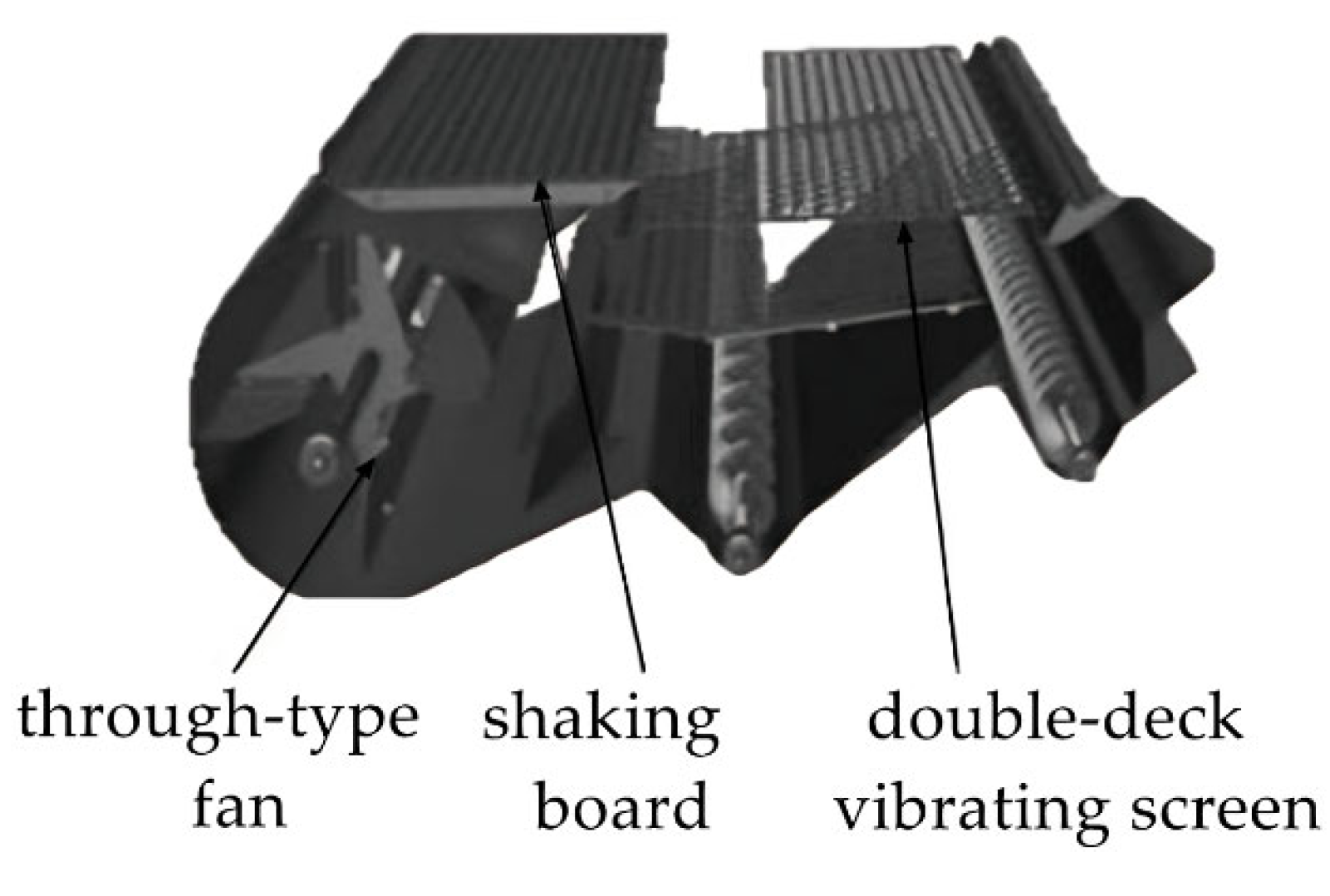

3.3. Mechanized Sorting Technology for Minor Cereals

3.4. Multi-Functional Chassis Travel System

3.5. Intelligent Technologies

4. Worldwide Equipment for Minor Cereal Harvesting

4.1. Small and Medium-Sized Minor Cereals Combine Harvester

4.2. Large Combined Harvester for Minor Cereals

4.3. Characteristics of Harvesting Equipment for Minor Cereals in Various Countries

- The development is mainly focused on small and medium-sized minor cereal harvesters. The cultivation of minor cereals is mostly concentrated in regions such as the Loess Plateau, Inner Mongolia Plateau, Yunnan–Guizhou Plateau, and Tibetan Plateau, which are predominantly hilly areas not suitable for large combine harvesters to operate. Therefore, at the current stage, the majority of the minor cereal combine harvesters put into use are of small and medium sizes.

- There are more general-purpose grain harvesters than specialized minor cereal harvesters. The planting area of minor cereals in China accounts for 8% to 10% of the national grain crop sowing area, and the proportion of its output in the total grain output is less than 5%. To save development costs and improve economic efficiency, general-purpose grain harvesters are often used to harvest some minor cereals by replacing the cutterbar and adjusting equipment parameters. At present, there are only a few specialized minor cereal harvesters.

- It is difficult to achieve multi-purpose use of a single machine for minor cereals, resulting in low equipment utilization rates. Minor cereals mainly include millet, Panicum miliaceum, and buckwheat, among others. The shapes of these different crops vary significantly, and the harvesting conditions also differ greatly across regions. At the current stage, the developed minor cereal harvesters can only harvest a single type of crop and are unable to serve multiple purposes with one machine.

- The level of intelligence is low. At present, most of the minor cereal harvesting machinery studied in China is still in the pure mechanical design stage. Currently, some research institutes and enterprises have achieved certain intelligent research results in a few key components, but there are few product applications. There is still a gap to achieve control intelligence, operation automation, and comfortable driving.

5. Issues and Development Suggestions

6. Conclusions

- This paper provides a comprehensive and systematic review and analysis of the mechanized harvesting industry for minor cereals, covering the current status, key technologies, advanced equipment, existing problems, and suggestions.

- A comprehensive analysis of the current research status of key technologies for minor cereal combine harvesters in terms of the header, threshing, cleaning, mobility, and intelligentization was conducted.

- A comparative analysis of the characteristics of global minor cereal mechanized harvesting equipment was performed. Existing minor cereal harvesters are mostly assembled from grain harvesters by adjusting certain parameters, resulting in low harvesting efficiency and high loss rates.

- To address the existing problems, such as low efficiency, high losses, and poor adaptability of current equipment, it is proposed that improvements can be made in the selection of suitable minor cereal varieties for mechanical harvesting, flexible headers, and the design of the roll threshing device. The impact of intelligentization technology and equipment modularization on the development of minor cereal mechanized harvesting is emphasized.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bian, X.; Li, H.; Chen, Y. Overview of the Funding and Implementation for Miscellaneous Grains in “Economic Crops” Special-Purpose Project of the National Key R & D Program during the 13th Five-Year Plan. Crops 2023, 39, 1–6. [Google Scholar]

- Xu, Q. National People’s Congress Representative Li Qiang: Moderately Developing Crops Such as Sweet Potatoes and Other Coarse Grains to Ensure National Food Security. China County Times, 14 March 2024. [Google Scholar]

- Qu, J.; Zhang, H.; Ma, J. Prospect of Production and Trade of China’s Miscellaneous Grains. Agric. Outlook 2021, 17, 78–85. [Google Scholar]

- Pang, W. Discussion on the Development of Chinese Coarse Grain Processing Industry under the New Normal. Grain Process. 2022, 47, 6–8. [Google Scholar]

- Lui, Z. Study on Harvesting Mechanization of Millet in Hilly Areas. Agric. Technol. Equip. 2020, 76–77. [Google Scholar] [CrossRef]

- Cui, Y.; Qin, Y.; Wang, H.; Jiao, Z.; Wang, L.; Han, K.; Ni, G. A Discourse on Mechanized Grain Harvesting Technology Is Hereby Initiated. Farm Mach. 2020, 108–110. [Google Scholar] [CrossRef]

- Chai, Y.; Feng, B. Present Situation and Developing Strategies of Minor Grain Crops in China. Agric. Res. Arid. Areas 2003, 3, 145–151. [Google Scholar]

- Cui, Y. Studies on the Advantages and Existing Problems of Minor Cereal Crop Production in Midwestern China and Countermeasures. J. Agric. Sci. Technol. 2008, 10, 54–57. [Google Scholar] [CrossRef]

- Bao, X.; Wen, F.; Jin, X.; Hu, R.; Huang, Q.; Zhang, G.; Qi, J.; Bai, Y.; Wu, Y.; Bai, Y. Adaptability Analysis of Different Millet Varieties in the Main Grain-Producing Areas of Eastern Inner Mongolia. Crops 2024, 40, 201–206. [Google Scholar] [CrossRef]

- Jia, G.; Diao, X. Current Status and Perspectives of Innovation Studies Related to Foxtail Millet Seed Industry in China. Sci. Agric. Sin. 2022, 55, 653–665. [Google Scholar]

- Feng, B.; Yao, A.; Gao, J.; Gao, X.; Chai, Y. Study on Regional Distribution and Development of Buckwheat in China. Chin. Agric. Sci. Bull. 2005, 21, 375–377. [Google Scholar] [CrossRef]

- Zhao, X.; Han, Y.; Jiang, L.; Ma, H.; Yang, C.; Wang, L. Research and Analysis Reports of Market and Industry of Fagopyrum Tataricum. Agric. Prod. Mark. Wkly. 2021, 42–44. Available online: https://d.wanfangdata.com.cn/periodical/ChVQZXJpb2RpY2FsQ0hJMjAyNTA2MjISEG5jcHNjemsyMDIxMTUwMTgaCDZpMXFjcmc3 (accessed on 30 May 2025).

- Zhao, G.; Zou, L. Buckwheat Nutrition and Function; Science Publishers Ltd.: Beijing, China, 2012. [Google Scholar]

- Zhao, Y.; Lui, M.; Lui, F.; Xia, X.; Nan, C.; Li, S.; Wang, H. Development Trend and Suggestions of China’s Foxtail Milletand Broomcorn Millet Industry. Agric. Outlook 2015, 11, 41–44. [Google Scholar]

- Lui, F.; Lui, M.; Zhao, Y.; Nan, C.; Xia, X.; Li, S.; Xu, L. Development Trends of China’s Foxtail Millet and Broomcorn Millet Industries in 2017. Agric. Outlook 2017, 13, 40–43. [Google Scholar]

- Yang, M.; Bai, R. Regional Comparison of the Development of Agricultural Mechanization in China. Trans. Chin. Soc. Agric. Eng. 2000, 16, 68–72. [Google Scholar] [CrossRef]

- General Office of the Ministry of Agriculture and Rural Development of China. National Agricultural Mechanisation Development Plan for the Fourteenth Five-Year Plan. Anim. Agric. 2022; 5–18.

- Wang, Y.; Shanxi Province Datong Agricultural Machinery Extension Station. Small Grain Mechanised Production Status and Development Countermeasures. Agric. Mach. Technol. Ext. 2010, 31–32. [Google Scholar]

- Yang, Y.; Zhang, X.; Liu, J.; Dong, X. Design and Experiments of Key Components of Fresh Corn Earpicking Platform. J. Hainan Univ. (Nat. Sci.) 2023, 41, 191–198. [Google Scholar]

- Geng, D.; Ni, L.; He, Q.; Luo, H.; Ma, J.; Wang, B.; Bian, D.; Wang, Y.; Li, D.; Cao, L. A Kind of Sorghum Harvester Grain Separating and Supporting. Device. Patent CN218218371U, 6 January 2023. [Google Scholar]

- Luo, H.; Tang, C.; Guan, C.; Wu, M.; Xie, F. Experiment Using Stalk Separator Designed for the Header of Rape Harvester. J. Hunan Agric. Univ. (Nat. Sci.) 2012, 38, 548–550. [Google Scholar] [CrossRef]

- Zhen, G. Structural Design and Experimental Study of Millet Header with Low Loss Rate. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2022. [Google Scholar]

- Wang, X. Agricultural Mechanics; China Agricultural Press: Beijing, China, 2023. [Google Scholar]

- Yan, X. The Design of Small Wheat and Cereal Grain Combine Harvester and Baler. Agric. Technol. Equip. 2021, 5, 13–14+17. [Google Scholar]

- Zhang, M.; Wu, C.; Mu, S.; Wang, G.; Jin, M.; Wu, J.; Tang, Q. A Kind of Eccentric Tilting Harvester Rasp. Wheel. Patent CN201810627613, 19 December 2023. [Google Scholar]

- Remillard, R.G.; Snider, G.U. Crop Harvesting Header with Cam Controlled Movement of the Reel Fingers; MacDon Industries Ltd.: Winnipeg, MB, Canada, 2003. [Google Scholar]

- Hu, J.; Wang, Y.; Wang, J. Analysis on the Lifting Capability of Star Wheel Grain-Lifter. J. Agric. Mech. Res. 2006, 10, 73–75. [Google Scholar] [CrossRef]

- Mechanisation, China Academy of Agricultural; Foton Leiwo International Heavy Industry Co.; Zhejiang Liulin Machinery Co.; China South Machinery Co. Agricultural Machinery-Cutter Bar-Part 3: Knife Sections, Ledger Plates and Knife Backs. 12: General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Standardization Administration of the People’s Republic of China: Beijing, China, 2009. [Google Scholar]

- Tian, K.; Li, X.; Shen, C.; Zhang, B.; Huang, J.; Wang, J.; Zhou, Y. Design and Test of Cutting Blade of Cannabis Harvester Based Onlongicorn Bionic Principle. Trans. Chin. Soc. Agric. Eng. 2017, 33, 56–61. [Google Scholar]

- Yan, X.; Li, Z.; Chen, L. Comparative Morphology of the Mouthparts of Adults in 5 Subfamilies of Cerambycidae (Coleoptera). J. Environ. Entomol. 2018, 40, 1058–1070. [Google Scholar]

- Jia, H.; Guo, M.; Guo, C.; Zheng, J.; Zhang, C.; Zhao, J. Design of Dynamic Bionic Stubble Cutting Device and Optimization Test of Parameters. Trans. Chin. Soc. Agric. Mach. 2018, 49, 103–114. [Google Scholar]

- Zhao, J.; Guo, M.; Lu, Y.; Huang, D.; Zhuang, J. Design of Bionic Locust Mouthparts Stubble Cutting Device. Int. J. Agric. Biol. Eng. 2020, 13, 20–28. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, S.; Ma, L.; Yang, W.; Jin, Z.; Yan, Y.; Zhu, L. Design and Experiment of Bionic Cutting Blades for Panax Notoginseng Stem and Leaf Harvesting Machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 117–126. [Google Scholar]

- Du, Z. Research on Biomimetic Design of Cutting Blade for Tea Stem and Its Cutting Performance. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2020. [Google Scholar]

- Liu, Z.; Wang, T.; Liu, S.; Yan, X.; Zhao, H.; Wu, X.; Zhang, X. Design and Experimental Study of a Bionic Blade for Harvesting the Wild Chrysanthemum Stem. Agriculture 2023, 13, 190. [Google Scholar] [CrossRef]

- Wei, W.; Dai, F.; Zhang, F.; Zhao, W.; Zhang, S.; Shi, R. Design of Bionic Harvest Cutting Table of Flax in Dry Area. J. Chin. Agric. Mech. 2018, 39, 44–48+57. [Google Scholar]

- Liu, H.; Zhang, P.; Yang, X.; Deng, Y.; Li, K.; Zhang, G. Research on the Status and Development of Grain Combine Harvester Cutting Table Intelligence in China. J. Chin. Agric. Mech. 2022, 43, 189–197. [Google Scholar]

- Wang, J.; Gou, F.; Qian, Z.; Ni, Y.; Jin, C. A Review of Intelligent Header Technology for Grain Combine Harvester. INMATEH-Agric. Eng. 2024, 73. [Google Scholar] [CrossRef]

- Zhao, J. Design and Test of 4lzg-1.5 Small Self-Propelled Millet Harvester. Agric. Eng. 2022, 12, 109–112. [Google Scholar]

- Kang, D. Research and Design of Threshing Device for Grain Combine Harvester. Master’s Thesis, Anhui Agricultural University, Hefei, China, 2016. [Google Scholar]

- Xu, H. Current Situation and Development Trend of Mechanised Production of Cereals. Agric. Technol. Equip. 2014, 38–39. [Google Scholar] [CrossRef]

- Kang, D.; Wu, C.; Liang, S.; Tang, Q. Design and Test of the Threshing Device of Millet Combine Harvester. J. China Agric. Univ. 2017, 22, 135–143. [Google Scholar]

- Zhao, R.; Mao, X.; Yi, S.; Tao, G.; Ma, Y. Comparative Experimental Study on Two Threshing Rollers of Bare Oats Threshing and Separating Device. J. Chin. Agric. Mech. 2020, 41, 7–12. [Google Scholar]

- Di, Z.; Cui, Z.; Zhang, H.; Zhou, J.; Zhang, M.; Bu, L. Design and Experiment of Rasp Bar and Nail Tooth Combined Axial Flowcorn Threshing Cylinder. Trans. Chin. Soc. Agric. Eng. 2018, 34, 28–34. [Google Scholar]

- Tang, H.; Chen, X.; Xue, Z.; Li, D.; Xing, X. Development of Grain Harvester Threshing and Cleaning System. China Agric. Inform. 2018, 30, 32–39. [Google Scholar]

- Jin, C.; Kang, Y.; Guo, H.; Wang, T.; Yin, X. Experimental Research on the Influence of Threshing Roller Structures Onthe Quality of Mechanically-Harvested Soybeans. Trans. Chin. Soc. Agric. Eng. 2021, 37, 49–58. [Google Scholar]

- Yu, X.; Wang, J.; Zheng, D. Development of Retractable Rod Tooth Buckwheat Threshing Device and Parameter Optimization. Agric. Eng. 2022, 12, 117–121. [Google Scholar]

- Li, Y.; Li, H.; Xu, L.; Zhao, Z. Performance Test of Short-Rasp-Bar of Axial Flow Threshing and Separating Unit. Trans. Chin. Soc. Agric. Mach. 2009, 40, 88–92. [Google Scholar]

- Xu, C.; Liu, J.; Li, Y.; Zhang, P.; Huang, X. A Combined Axial Threshing Drum for Reducing Seed Entrainment Losses; Southwest University: Chongqing, China, 2024. [Google Scholar]

- Wen, C.; Xu, Y.; Chen, F.; Chen, Y.; He, Y. Simulation Study on Threshing Device of Broad Bean Harvester Based on Discrete Element Method. J. Hubei Univ. Technol. 2024, 39, 24–30+36. [Google Scholar]

- Tang, P.; Ma, K.; Xi, Z.; Liu, Z.; Lv, X. Key Technology Analysis and Suggestions of Soybean Combined Harvester. Hans J. Agric. Sci. 2021, 11, 644. [Google Scholar] [CrossRef]

- Dai, F.; Han, Z.; Zhao, W.; Zhang, F.; Gao, A.; Wei, L. Design and Experiment on Threshing and Separating Unit of Plot Breeding Wheat with Doublelongitudinal Axial Cylinder. Res. Agric. Mod. 2016, 37, 1015–1020. [Google Scholar]

- Xu, L.; Li, Y.; Wang, C.; Xue, Z. A Combinational Threshing and Separating Unit of Combine Harvester with a Transverse Tangential Cylinder and an Axial Rotor. Trans. Chin. Soc. Agric. Mach. 2014, 45, 105–108+35. [Google Scholar]

- Guo, Y.; Zhang, H.; Jin, X. Structural Forms of Longitudinal Flow Threshing and Separating Systems for Large Combines. Farm Mach. 2012, 73–74. [Google Scholar] [CrossRef]

- Li, Y.; Sun, T.; Xu, L. Performance Test and Analysis of Rape Multi Cylinder Threshing Andseparating Device. Trans. Chin. Soc. Agric. Eng. 2013, 29, 36–43. [Google Scholar]

- Wan, X. Design and Working Mechanical Study on the Cyclone Separation Cleaning System for Rapeseed Combine Harvester. Ph.D. Thesis, Chengdu Polytechnic University, Chengdu, China, 2019. [Google Scholar]

- Li, Y. Study on Separation of Rethreshed Stripped Mixtures and Their Cleaning Characteristics for Rice. Ph.D. Thesis, Anhui Agricultural University, Hefei, China, 2004. [Google Scholar]

- Zhang, Y.; Yi, S. Experiment Research on Multi Factors of Air-and-Screencleaning Device of Vertical Axial Flow. Mach. Des. Manuf. 2012, 2, 30–32. [Google Scholar]

- Yang, J. Improved Design and Experiment on the Cyclone Separation and Cleaning System for Rapeseed Combine Harvester. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2023. [Google Scholar]

- Zhang, F.; Ji, J. Discussion on the Main Structure and Parameters of Grain Combine Harvester. South China Agric. 2020, 14, 77–83. [Google Scholar]

- Zhao, L.; Wang, X. Experimental Study of Electric Travelling Chassis for Self-Propelled Corn Harvester. Contemp. Farm Mach. 2024, 38–40+42. [Google Scholar] [CrossRef]

- Gao, Q.; Pan, D.; Zhang, X.; Deng, F.; Huang, D.; Wang, L. Design and Simulation of Entire Track Modular Unmanned Agricultural Power Chassis. Trans. Chin. Soc. Agric. Mach. 2020, 51, 561–570. [Google Scholar]

- Jin, C.; Yang, T.; Liu, G.; Wang, T.; Chen, M.; Liu, Z. Design and Test of Posture Controlled Chassis for Caterpillar Combine. Trans. Chin. Soc. Agric. Mach. 2020, 51, 393–402. [Google Scholar]

- Li, Y.; Guo, K.; Chen, W.; Qu, J.; Gao, H. Effects of Attitude Switching Parameters on Switching Precision and Time Offlexible Chassis of Agricultural Vehicles and Its Optimization. Trans. Chin. Soc. Agric. Eng. 2019, 35, 51–61. [Google Scholar]

- Liu, P.; Ke, C.; Ke, T.; Li, H.; Wei, W.; Zhao, C. Design and Experiment of Pre-Detection Active Leveling Agricultural Chassis for Hilly Area. Trans. Chin. Soc. Agric. Mach. 2020, 51, 371–378. [Google Scholar]

- Qu, J.; Guo, K.; Song, S.; Cuong, T.V.; Li, Y. Coupling Control Strategy and Test for Off-Centered Shaft Steeringmechanisms of Agricultural Flexible Chassis. Trans. Chin. Soc. Agric. Eng. 2019, 35, 55–65. [Google Scholar]

- Han, J.; Zhu, W.; Zhang, B.; Zhao, C.; Yang, X. Equipment and Information Collaboration to Promote Development of Modern Smart Agriculture. Strateg. Study CAE 2022, 24, 55–63. [Google Scholar] [CrossRef]

- OuYang, A.; Cui, T.; Lin, L. Development Status and Countermeasures of Intelligent Agriculturalmachinery Equipment Industry. Sci. Technol. Rev. 2022, 40, 55–66. [Google Scholar]

- Chen, X.; Wen, H.; Zhang, W.; Pan, F.; Zhao, Y. Advances and Progress of Agricultural Machinery and Sensing Technology Fusion. Smart Agric. 2020, 2, 1. [Google Scholar]

- Cui, K.; Feng, X. The Application Logic, Practice Scenarios, and Promotion Suggestions of Intelligent Agriculturalmachinery Equipment Towards Agriculture 4.0. Res. Agric. Mod. 2022, 43, 578–586. [Google Scholar]

- Hu, X.; Xia, X.; Zhen, X. Development and Outlook of Intelligent Agricultural Machinery in China. China Rural. Sci. Technol. 2022, 16–19. [Google Scholar] [CrossRef]

- Zhang, H. Intelligent Development of Agricultural Machinery Bottlenecks Need to Be Broken Through. Agric. Mach. Mark. 2022, 27–28. [Google Scholar]

- Liang, Z. Study on Designing Method of Multi-Duct Air-and-Screen Cleaning Unit and Grain Sieve Loss Monitoring and Controlling Technology. Ph.D. Thesis, Chengdu University of Technology, Chengdu, China, 2018. [Google Scholar]

- Mao, H.; Ni, J. Finite Element Analysis and Measurement for Array Piezocrystals Grain Losses Sensor. Trans. Chin. Soc. Agric. Mach. 2008, 39, 123–126. [Google Scholar]

- Ni, J.; Mao, H.; Li, P. Design of Intelligent Grain Cleaning Losses Monitor Based on Array Piezocrystals. Trans. Chin. Soc. Agric. Mach. 2010, 41, 175–177. [Google Scholar]

- Li, Y.; Liang, Z.; Zhao, Z.; Chen, Y. Real-Time Monitoring System of Grain Loss in Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2011, 42, 99–102. [Google Scholar]

- Shirinov, A.V.; Schomburg, W.K. Pressure Sensor from a Pvdf Film. Sens. Actuators A Phys. 2007, 142, 48–55. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, Z.; Bai, J. Design and Implementation of the Three-Point Pvdf Piezo-Film Sphygmo-Transducer. Chin. J. Sens. Actuators 2004, 688–692. [Google Scholar] [CrossRef]

- Mao, H.; Liu, W.; Han, L.; Zhang, X. Design of Intelligent Monitoring System for Grain Cleaning Losses Based Onsymmetry Sensors. Trans. Chin. Soc. Agric. Eng. 2012, 28, 34–39. [Google Scholar]

- Zhao, N.; Jin, C.; Wang, C.; Tang, X.; Guo, Z. Research Progress on Intelligent Technology of Grain Combined Harvester Cleaning System. J. Chin. Agric. Mech. 2023, 44, 163–170. [Google Scholar] [CrossRef]

- Li, S.; Liu, F.; Liu, M.; Zhao, Y.; Wang, H. The Current Industry Situation, Development Trend, and Suggestions for the Futureof Foxtail Millet in China. Res. Agric. Mod. 2014, 35, 531–535. [Google Scholar]

- Wu, H.; Liu, H.; Yang, Z.; Li, X.; Jiao, H.; Wang, C.; Zhang, G. Analysis of the Current Situation and Development Trend of Mechanisation of Cereal Production. Agric. Technol. Equip. 2012, 14–17. [Google Scholar] [CrossRef]

- Zhang, X. Grain Harvesting Machinery Status and Problems. Agric. Technol. Equip. 2012, 32–34. [Google Scholar]

- Ji, J.; Li, X.; Jin, X.; Geng, L.; He, Z.; Li, S.; Pang, J. Present Situation, Technical Analysis and Equipment Demand of Harvesting Mechanization for Characteristic Coarse Cereals. Agric. Eng. 2016, 6, 1–3. [Google Scholar]

- Gao, H.; Guo, Y.; Cao, J.; Shen, X. Test and Improvement of 4l Zg-2 Grain Harvester. Agric. Technol. Equip. 2013, 76–77. [Google Scholar]

- Ministry of Agriculture and Rural Development of the People’s Republic of China. Outline for the Promotion and Certification of Agricultural Machinery-Grain Combine Harvester; Ministry of Agriculture and Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Liang, S.; Jin, C.; Zhang, F.; Kang, D.; Hu, M. Design and Experiment of 4lzg-3.0 Millet Combine Harvester. Trans. Chin. Soc. Agric. Eng. 2015, 31, 31–38. [Google Scholar]

- Li, Y. Design and Test on a Kind of Sorghum Combined Harvesting Device. Agric. Eng. 2017, 7, 118–121. [Google Scholar]

- Sha, M.; Wu, L. Status Quo and Trend of Coarse Grains Research. Agric. Outlook 2015, 11, 53–56+60. [Google Scholar]

- Wei, L. Problems of Mechanised Production of Small Grains and Development Countermeasures. Contemp. Farm Mach. 2022, 53–54. [Google Scholar]

- Gu, X.; Liu, J.; Yi, S.; Yang, L. Design of Large and Medium Self-Propelled Millet Combine Harvester. Agric. Mach. Using Maint. 2020, 1–6. [Google Scholar] [CrossRef]

| Name | Bionic Design Process | Characteristics | ||

|---|---|---|---|---|

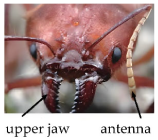

| Tenebrae Upper Jaw Reciprocating Bionic Cutter [19,29,30] |  |  |  | The extraction of the tooth profile curve of the upper jaw cutting tooth part of the aspen revealed a stalk leakage rate of 2.5% in the field test. This reduction in leakage rate, coupled with a decrease in cutting resistance and an enhancement in cutting efficacy, was observed in comparison to the conventional cutter. |

| Locust Bionic Cutter [31,32] |  |  |  | The bionic disc cutter demonstrated an 18.49% reduction in power consumption when evaluated for its effectiveness in cutting corn stover. |

| Leaf cutter ant bionic cutter [33] |  |  |  | The experimental findings demonstrated that the maximum shear force of the bionic blade was reduced by 7.74%, in comparison with the conventional blades. Furthermore, the maximum shear force was reduced by 8.84%. |

| Cricket mouthparts maxillary bionic cutter [34,35] |  |  |  | The two bionic cutters were utilized in cutting experiments on stalks. The former exhibited robust cutting performance, exhibiting an 18% reduction in maximum shear force and a 15.8% reduction in cutting power consumption. The latter demonstrated superior cutting efficacy, exhibiting an average cutting force of 9.193 N and a cutting power of 1.215 J. The latter exhibited superior cutting performance. |

| Chewing Mouthpiece Upper Jaw of Korean Golden Turtle [36] |  |  |  | The bionic cutting device has been demonstrated to reduce the blanking zone by 50% and the re-cutting zone by 80%, which is significantly better than the traditional standard-type cutter. |

| Type | Features | Schematic Diagram of Structure | Applicable Scope | |

|---|---|---|---|---|

| Ribbed rod-nail tooth threshing drum | Standard type | The material enters the drum axially and subsequently passes through the ribbed rod section and the nail tooth section. In comparison with the full nail tooth drum, the striking capacity is weaker, the loss rate is higher, and the power consumption is higher; however, the impurity content is lower [43]. |  | The implement is generally suitable for the threshing and separation of grains. |

| Short ribbed rod-nail tooth type | The anterior portion of the drum is equipped with ribbed rod blocks, which primarily function as threshing mechanisms, while the posterior section is fitted with nail teeth that facilitate churning and separation processes, in addition to threshing functions [44]. The integration of these two distinct tooth types, in conjunction with spiral rows, enhances the conveying capacity, increases the axial size, and optimizes the separation efficiency. |  | It is particularly well-suited for crops with high moisture content and is characterized by its ease of breakage, a trait that is advantageous in the processing of corn. | |

| Ribbed rod-rod tooth threshing drum | Standard type | The initial segment corresponds to the ribbed rod portion, which constitutes the primary phase of threshing. The subsequent segment, known as the rod-tooth portion, functions to facilitate the separation of kernels ensconced within the stem layer [45]. |  | It has been demonstrated to be suitable for legumes with low water content [46]. |

| Ribbed rod-telescopic rod tooth type | The ribbed rod constitutes the primary component responsible for the threshing process. During the rotational movement, it propels the rod teeth, which are articulated with it, to execute a reciprocating telescopic movement. This movement subsequently exerts an impact on the material, causing it to be knocked. As the rod teeth rotate and expand, the material undergoes a tumbling and backward propulsion to prevent material blockage [47]. |  | This implement is particularly well-suited for buckwheat and other crops that pose significant challenges during the threshing process. | |

| Short ribbed rod-plate tooth type | The short ribbed rod and plate teeth are integrated into a unified threshing unit, which is meticulously arranged on the threshing drum in an even and linear fashion. This configuration effectively reduces the debris content of the threshed material, thereby ensuring a uniform distribution [48]. |  | The implement is generally suitable for the threshing and separation of grains. | |

| Short ribbed rod-bow tooth type | The configuration of the ribbed rod blocks and bow teeth is such that the first half of the ribbed rod blocks and bow teeth are staggered in rows, and the second half consists of bow teeth and a separating plate. This configuration has been shown to result in a reduction in the crushing rate, an increase in the stripping rate, and a reduction in entrainment loss. |  | The cultivation of sorghum is well-suited for this purpose. | |

| Main and auxiliary nail tooth type | The combined axial flow threshing drum is characterized by its integration of a fixedly mounted main nail tooth on the cylinder shaft, a type of main tooth seat, and a secondary nail tooth that is inserted and fitted into a limiting slot [49]. This configuration is notable for its simplicity and effectiveness in reducing seed entrainment losses. |  | The machine is designed for the efficient threshing and separation of grains with high moisture content, as well as for addressing issues of significant sticky entrainment of seeds. | |

| Type | Characteristics | Schematic Diagram of Structure | Application Scenario |

|---|---|---|---|

| Tangential flow-type double drum threshing device | The configuration of the drums is such that they are arranged parallel to each other from front to back. The drum at the front is typically a peg-tooth drum, which possesses a high threshing capacity. In contrast, the drum at the rear is of a ripple-type design [51]. |  | This configuration is frequently utilized in harvesters that process substantial feed volumes. |

| Longitudinal flow double drum threshing device | The machine consists of two threshing drums with different structures and motion parameters at the front and rear [52]. It features an axial flow of grain and a long threshing stroke, as well as a long threshing time and good separation performance. |  | The utilization of this technique is particularly recommended for miscellaneous crops that are more challenging to thresh and separate. |

| Tangential flow + double longitudinal flow threshing device | The integration of tangential and longitudinal axial flow technologies is a recent development in agricultural machinery. The design consists of a tangential drum at the front and two axial flow drums at the rear, arranged side by side. This configuration allows for the effective separation of high-yield crops that are difficult to thresh [53]. The result is an improvement in crop harvesting efficiency and threshing quality. |  | A representative model of this structure is the John Deere C230 combine [54]. |

| Tangential flow + double transverse axial flow threshing device | The system under consideration utilizes a configuration of three threshing drums, comprising one tangential flow and two axial flows. In comparison with the tangential axial flow two-drum structure, this configuration has been demonstrated to exhibit superior operational efficacy [55]. |  | It is suitable for harvesting oilseed rape as well as other miscellaneous crops. |

| Multi-stage tangential feed threshing drum + double longitudinal flow threshing device | The apparatus under consideration is composed of two tangential flow feeding drums and one tangential flow threshing drum. The latter is situated centrally between the two feeding wheels. In the posterior section, two longitudinal axial flow threshing and separating drums are arranged laterally. |  | As indicated in [54], this element is typically identified in substantial longitudinal flow harvesters of the CLASS category. |

| Monitoring Device | Schematic Diagram | Principle | Features |

|---|---|---|---|

| YT-5L-type piezoelectric ceramic piezoelectric element [73] |  | The YT-5L-type piezoelectric ceramic has been utilized as a sensitive element, while a stainless steel 304 thin plate has been employed as a sensitive plate. The electrodes and shielded wire lead into the signal modulation circuit have been fabricated using double-conducting copper foil tape developed by Harbin Institute of Technology Bosheng Precision Company in Heilongjiang, China. The detection unit and seeds, stalks collision test, and measurement of collision signal characteristics have been constructed. | The multivariate fuzzy controller is employed for loss clearance, with the monitoring amount of the loss detection sensor serving as the input to facilitate the automatic adjustment of the parameters of the working parts. This process is capable of achieving an effective reduction in seed-clearing loss with high sensitivity. |

| Austenitic Stainless Steel No. 304 Array Piezoelectric Crystal Sensor [74,75] |  | The output port transmits the signal of seed-clearing loss to the microcontroller. Subsequently, the monitoring program carries out the counting process and displays the result on the LCD in real time. This completes the online monitoring of the clearing loss. If the result exceeds the preset limit value, the instrument will trigger an alarm. | The reduction in uncertainty in the information is accompanied by the enhancement of the reliability of the system, as well as the extension of the performance of individual sensors, a phenomenon that is facilitated by redundant and complementary data between sensors. |

| PVDF Piezoelectric Film Sensors [76] |  | The analog circuit, with its core composed of the AT89C52 microcontroller and its sensitive element constituted by PVDF piezoelectric film, functions by outputting the signals of entrainment and scavenging loss charge to the microcontroller. There, the microcontroller performs the calculation of the loss rate. | PVDF, a recently developed polymer material, finds application in the domain of weak impact and acceleration measurements due to its high piezoelectric constant, sensitivity, wide frequency response, low acoustic impedance, and aptitude for utilization in harsh environments [77,78] |

| TS1100 Symmetrical Sensor Structure [79] |  | The system under consideration comprises three components: a symmetrical structure sensor, a signal conditioning unit, and a monitoring and control unit. It has been demonstrated that compensating for sense disturbance signals and implementing band-pass filtering circuits effectively extracts the loss signal of grain. Ultimately, real-time monitoring and counting are carried out by the microcontroller [80]. | In comparison with the asymmetric structure, the monitoring accuracy and reliability of the seed loss signal are significantly enhanced. |

| Machine Type | Wheel Type | Rated Intake Capacity (a, kg/s) |

|---|---|---|

| Large | Wheeled | a ≥ 5 |

| Tracked | a ≥ 4 | |

| Medium | Wheeled | 5 > a ≥ 2 |

| Tracked | 4 > a > 1.5 | |

| Small | Wheeled | a < 2 |

| Tracked | a ≤ 1.5 |

| Name/Model | Schematic Diagram of Structure | Technical Features |

|---|---|---|

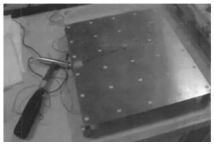

| The 4LZG-3.0 Self-Propelled Track Millet Combine Harvester was developed by Xingguang Agricultural Machinery Company in Henan, China |  | The external dimensions of the machine are as follows: length, 5080 mm; width, 2685 mm; height, 2605 mm. The machine’s weight is 2570 kg. The working width is 2000 mm. The machine’s productivity ranges from 0.23 to 0.45 hectares per hour. The machine’s feeding capacity is 3.3 kg/s, and its minimum ground clearance is 240 mm. It is equipped with a double-drum transverse-axial flow threshing-type grid-type concave plate sieve, a reciprocating double-decker vibrating sieve, and an agricultural centrifugal fan [87]. |

| The 4LZ-2 Self-Propelled Full-Feed Sorghum Combine Harvester was developed by Futian Lovol GuShen Company in Shandong, China |  | The engine power is 66 kW. The cutting width is 2360 mm. The feeding capacity is 2 kg/s. The productivity is 0.33–0.53 m2/h. The total weight is 3650 kg. The equipment includes eccentric elastic tooth paddle wheels, a wheeled front-drive walking system, and a ripple block-bow tooth combination threshing drum and wind-screening drum [88]. |

| The 4LZB-4GA Self-Propelled Track Full-Feed Combine Harvester was developed by Futian Lovol GuShen Company in Shandong, China |  | The dimensions of the machine are as follows: length 6080 mm, width 2780 mm, and height 2060 mm. The length of the header is 2300 mm. The weight of the machine is 3490 kg. The feeding volume is 4 kg/s. The engine power is 74 KW. The machine is equipped with a 900-mm diameter cutting knife of the 2nd type, an eccentric elastic tooth-type paddle sheave, and a longitudinal axial flow threshing drum. The minimum ground clearance is 280 mm, and a re-thresher with an impeller-toothed plate is employed to minimize loss. |

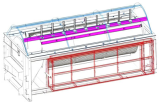

| The W70 Combine Harvester was developed by John Deere Company in Illinois, USA |  | The machine’s dimensions are as follows: length, 7400 mm; width, 3660 mm; height, 3400 mm. The header width is 3280 mm. The machine weighs 5200 kg. The feeding volume is 3.5 kg/s (wheat). The engine power is 80 KW, and the machine adopts a ripple-type threshing drum, a four-key-type manuscript-by-drawer, a front-drive wheeled walking system, a minimum ground clearance of 440 mm, and a driving tire spacing of 2150 mm. |

| The 4LZY-1.8 (PRO688Q) Tracked Full-Feed Combine Harvester was developed by Kubota Corporation in Osaka, Japan |  | The dimensions of the machine are as follows: length 5150 mm, width 2810 mm, and height 2815 mm. The width of the header is 2000 mm. The weight of the machine is 2930 kg. The feeding volume is 2.5 kg/s. The engine is a vertical water-cooled 4-cylinder turbo diesel engine with a power output of 49.2 KW. The detachment part adopts a longitudinal axial-flow type, and the track spacing is 1150 mm. The eccentric paddle-toothed paddle wheel is also noteworthy. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, X.; Dai, F.; Zhao, W.; Shi, R.; Chen, J.; Chang, L. Progress in Mechanized Harvesting Technologies and Equipment for Minor Cereals: A Review. Agriculture 2025, 15, 1576. https://doi.org/10.3390/agriculture15151576

Ren X, Dai F, Zhao W, Shi R, Chen J, Chang L. Progress in Mechanized Harvesting Technologies and Equipment for Minor Cereals: A Review. Agriculture. 2025; 15(15):1576. https://doi.org/10.3390/agriculture15151576

Chicago/Turabian StyleRen, Xiaojing, Fei Dai, Wuyun Zhao, Ruijie Shi, Junzhi Chen, and Leilei Chang. 2025. "Progress in Mechanized Harvesting Technologies and Equipment for Minor Cereals: A Review" Agriculture 15, no. 15: 1576. https://doi.org/10.3390/agriculture15151576

APA StyleRen, X., Dai, F., Zhao, W., Shi, R., Chen, J., & Chang, L. (2025). Progress in Mechanized Harvesting Technologies and Equipment for Minor Cereals: A Review. Agriculture, 15(15), 1576. https://doi.org/10.3390/agriculture15151576