Design and Experimental Validation of Stem-Clamping-and-Pull-Out-Type Pepper Plug Seedling-Picking Mechanism

Abstract

1. Introduction

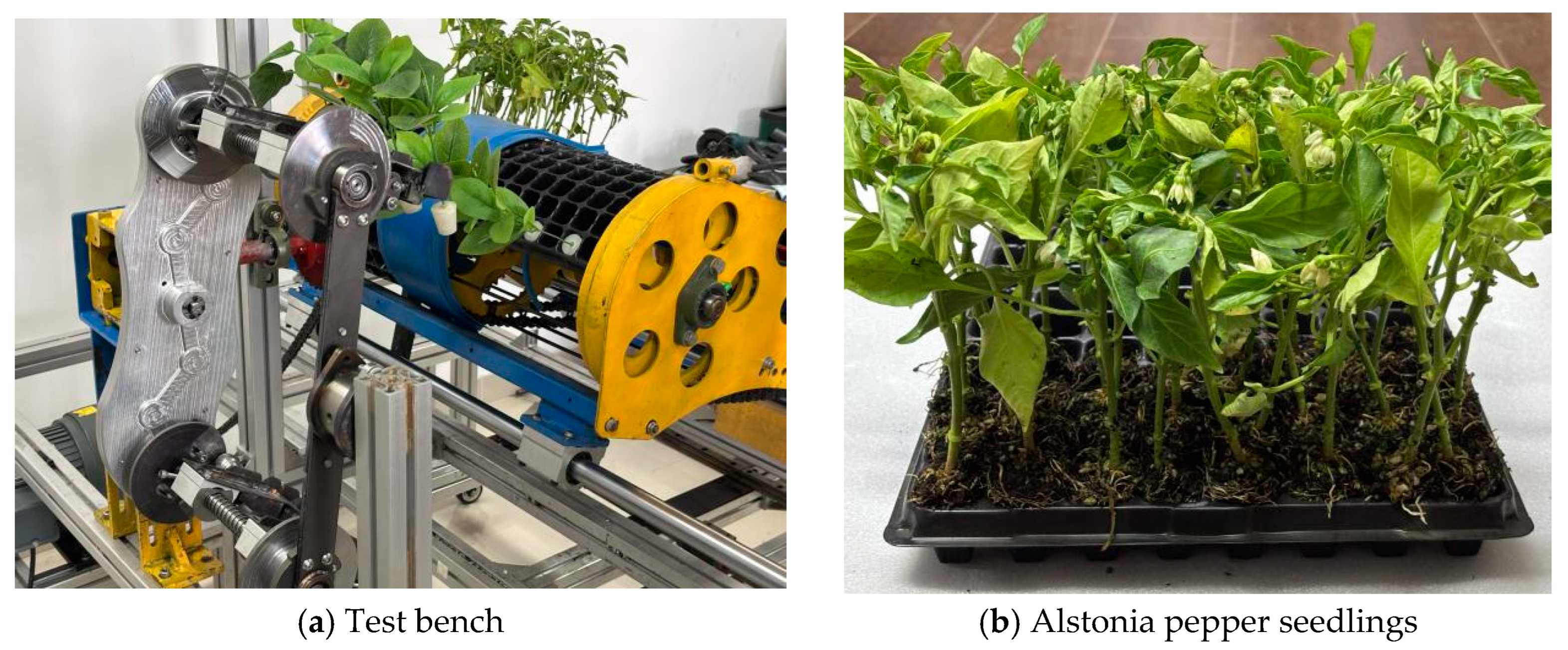

2. Materials and Methods

2.1. Design Requirements for the Seedling-Picking Mechanism

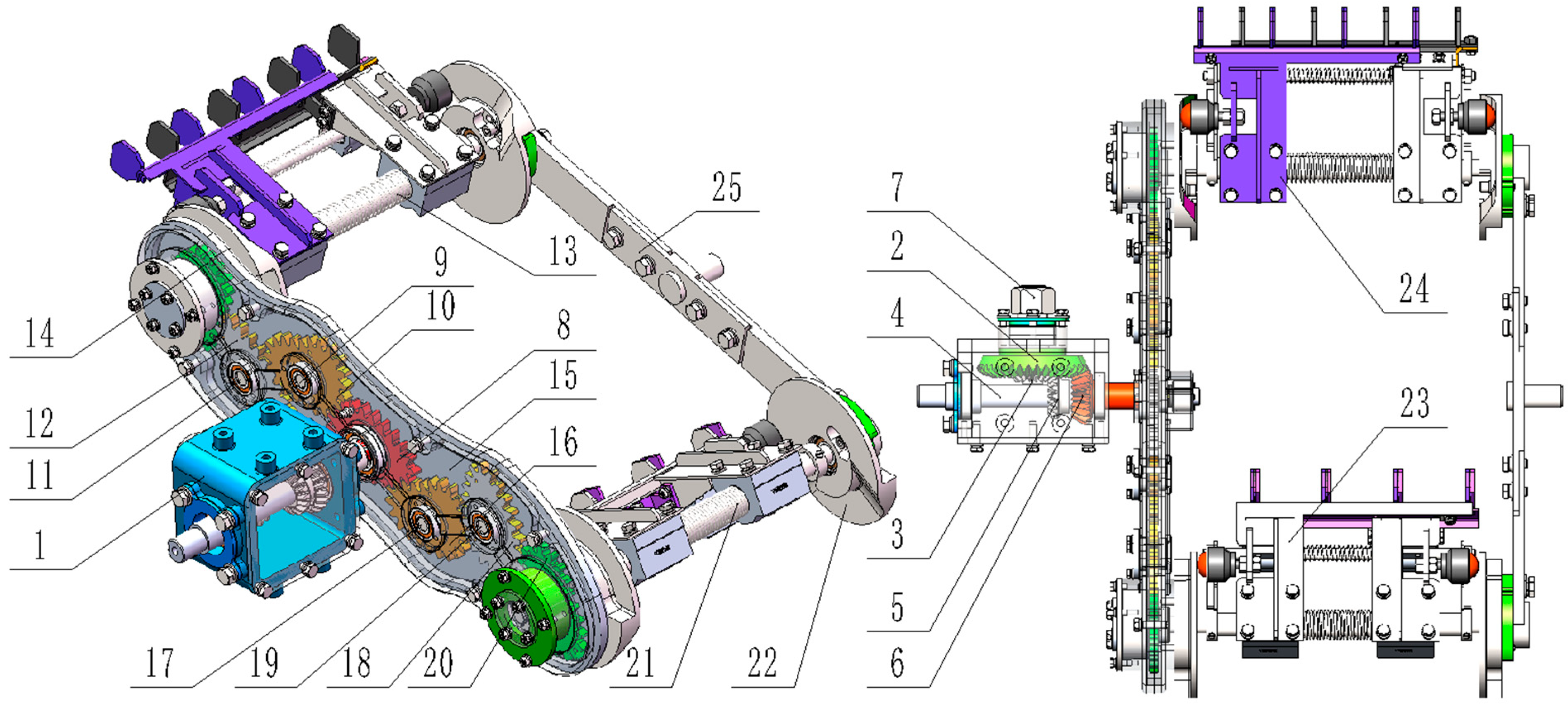

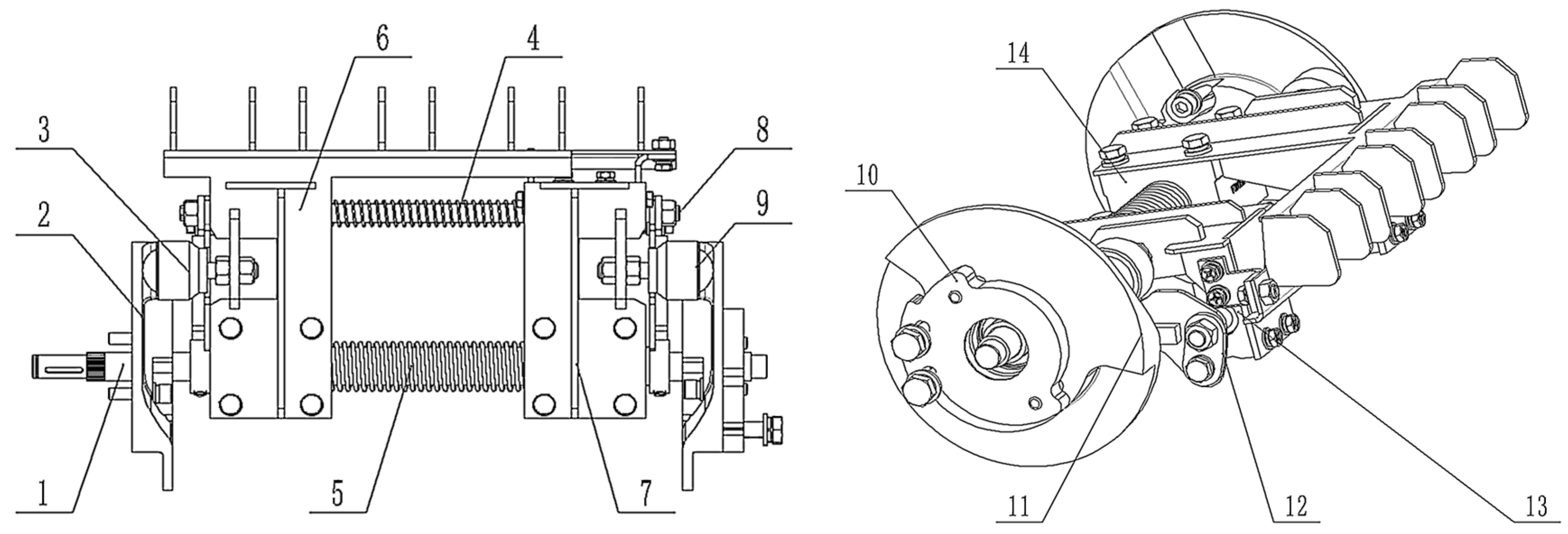

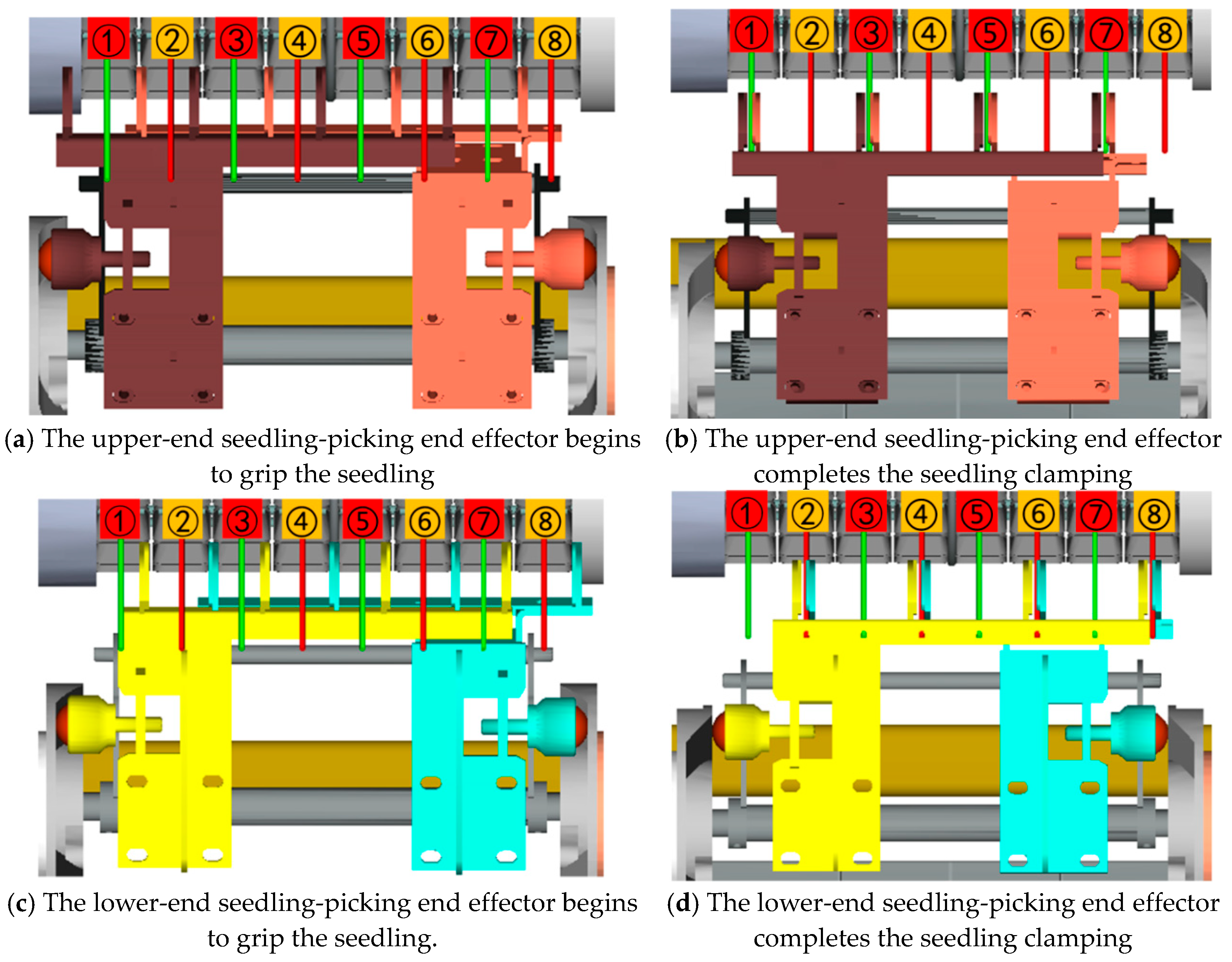

2.2. Composition and Working Principle of the Mechanism

2.3. Kinematic Analysis

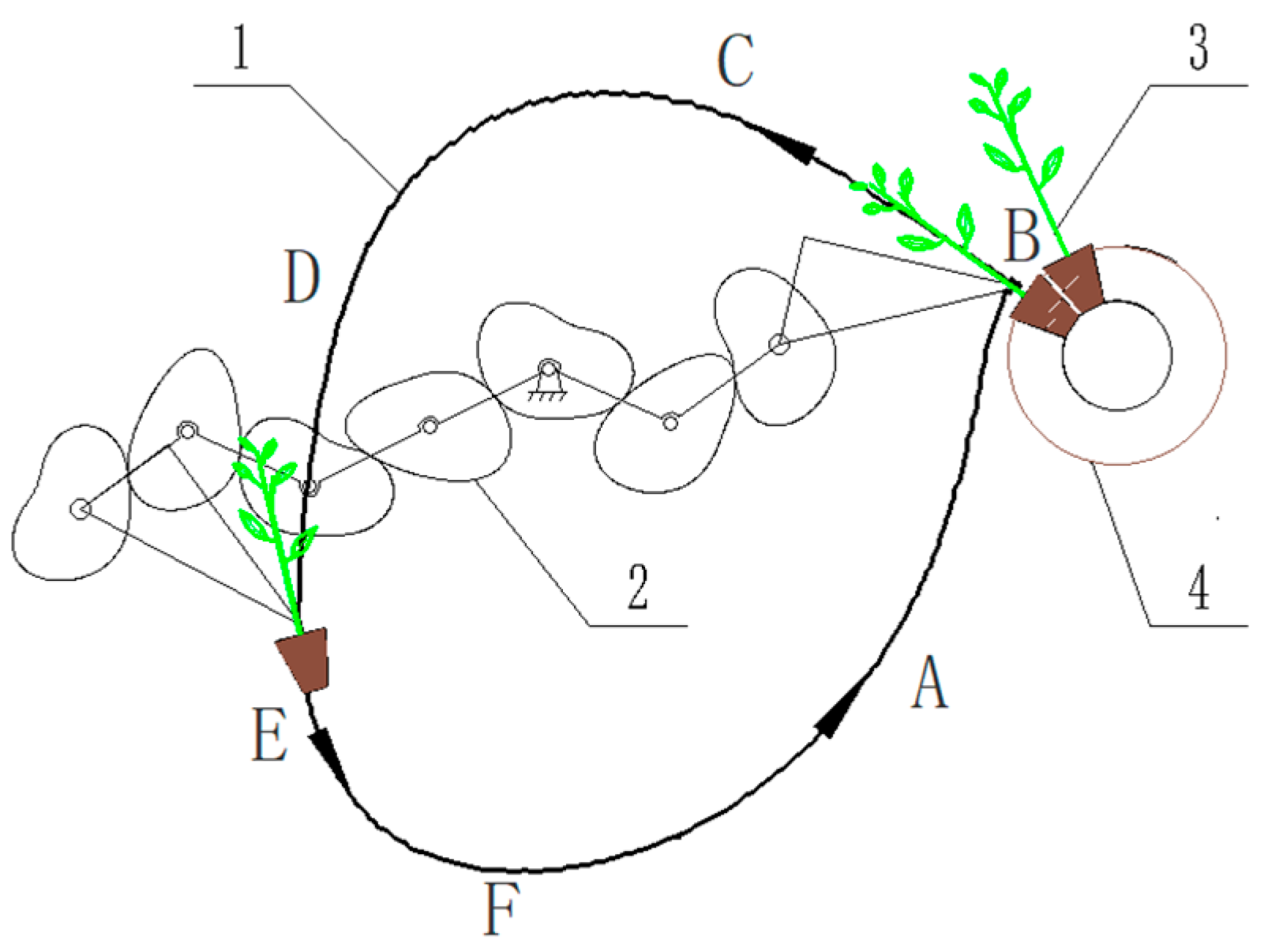

2.4. Trajectory and Posture Analysis

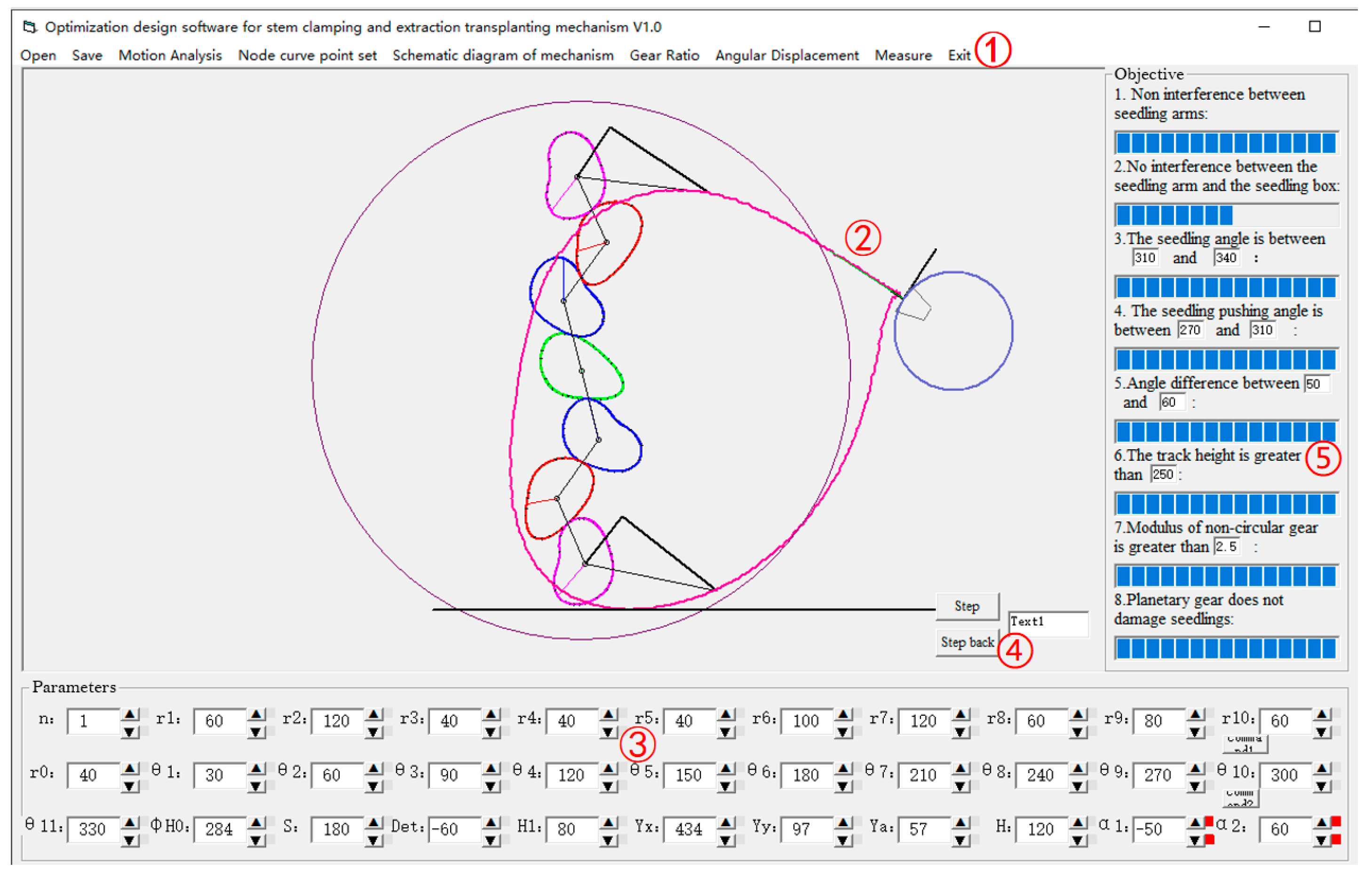

2.5. Optimization Design Software Development and Parameter Optimization

- (1)

- The actuator components at the end of the seedling picking do not interfere with each other;

- (2)

- The end effector for picking seedlings does not interfere with the seedling box;

- (3)

- Seedling-picking angle ;

- (4)

- Seedling-throwing angle ;

- (5)

- Angle difference ;

- (6)

- The height of the picking trajectory is greater than 250 mm;

- (7)

- The non-circular gear module is greater than 2.5 mm;

- (8)

- The planetary gear does not damage the seedlings.

- (1)

- The radial component of the sun gear pitch curve in the polar coordinate system is denoted as –;

- (2)

- The corresponding polar angle parameter of the sun gear pitch curve in the polar coordinate system is marked as ;

- (3)

- The initial assembly azimuth angle of the planetary carrier assembly in the seedling-picking device is defined as ;

- (4)

- The initial phase angle of the end effector unit is denoted as Det;

- (5)

- The spatial distance from the center of planetary rotation to the tip of the clamp is characterized as S;

- (6)

- The distance between the inflection point of the terminal picking mechanism and the axis of the planetary gear is described by the parameter ;

- (7)

- The abscissa of the seedling box in the rectangular coordinate system is denoted as YX;

- (8)

- The ordinate of the seedling box in the rectangular coordinate system is denoted as Yy;

- (9)

- The inclination angle of the seedling box is denoted as Ya;

- (10)

- The single-row spacing indicator for plug seedling-planting operations is determined by the H parameter;

- (11)

- The first corner of the planet carrier is denoted as ɑ1;

- (12)

- The second corner of the planet carrier is denoted as ɑ2.

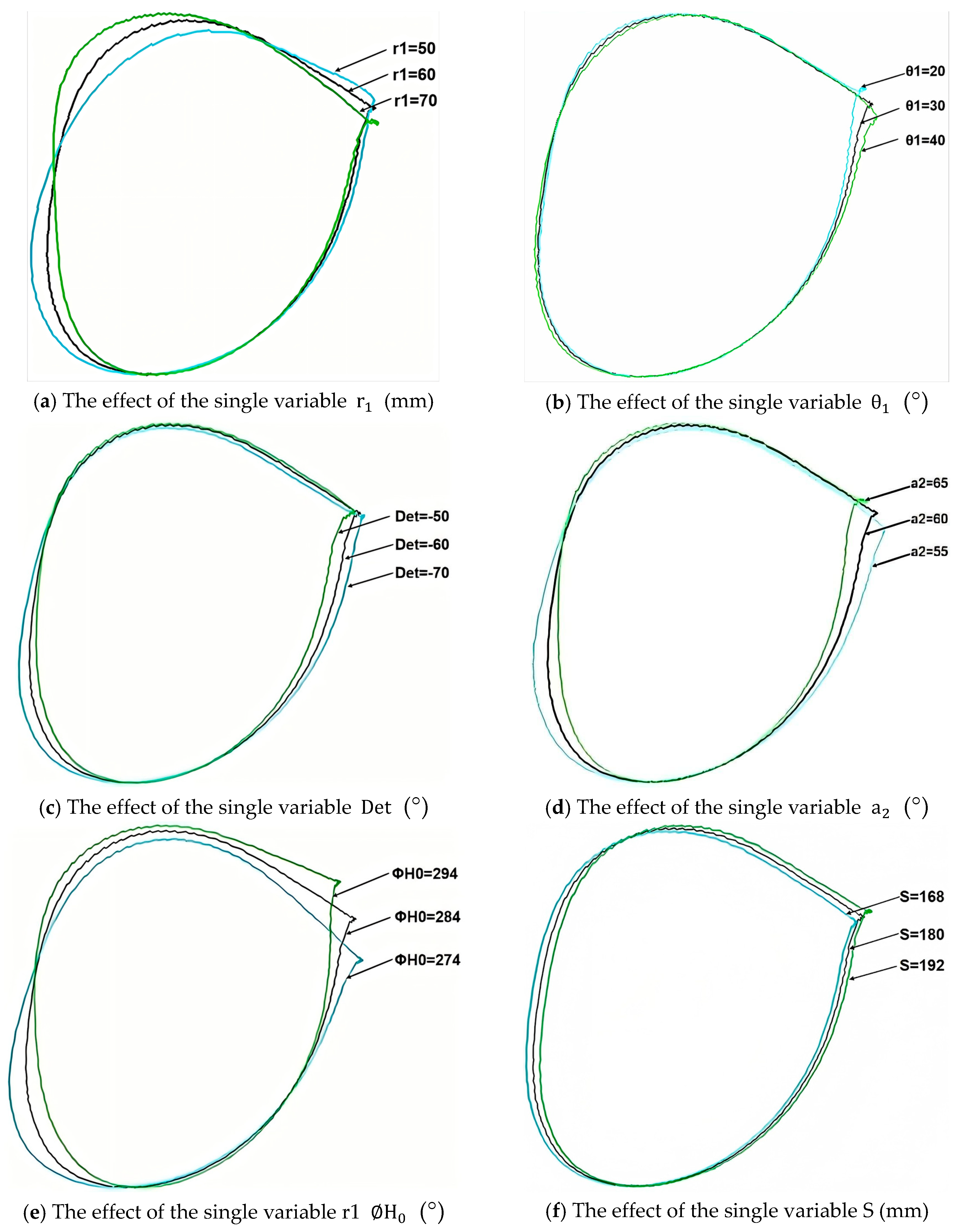

2.6. The Influence of the Main Parameters on the Trajectory of the Seedling-Picking Mechanism

- (1)

- The response relationship of to the optimization objective of the seedling-picking mechanism

- (2)

- The response relationship of to the optimization objective of the seedling-picking mechanism

- (3)

- The response relationship of to the optimization objective of the seedling-picking mechanism

- (4)

- The response relationship of to the optimization objective of the seedling-picking mechanism

- (5)

- The response relationship of to the optimization objective of the seedling-picking mechanism

- (6)

- The response relationship of to the optimization objective of the seedling-picking mechanism

3. Results

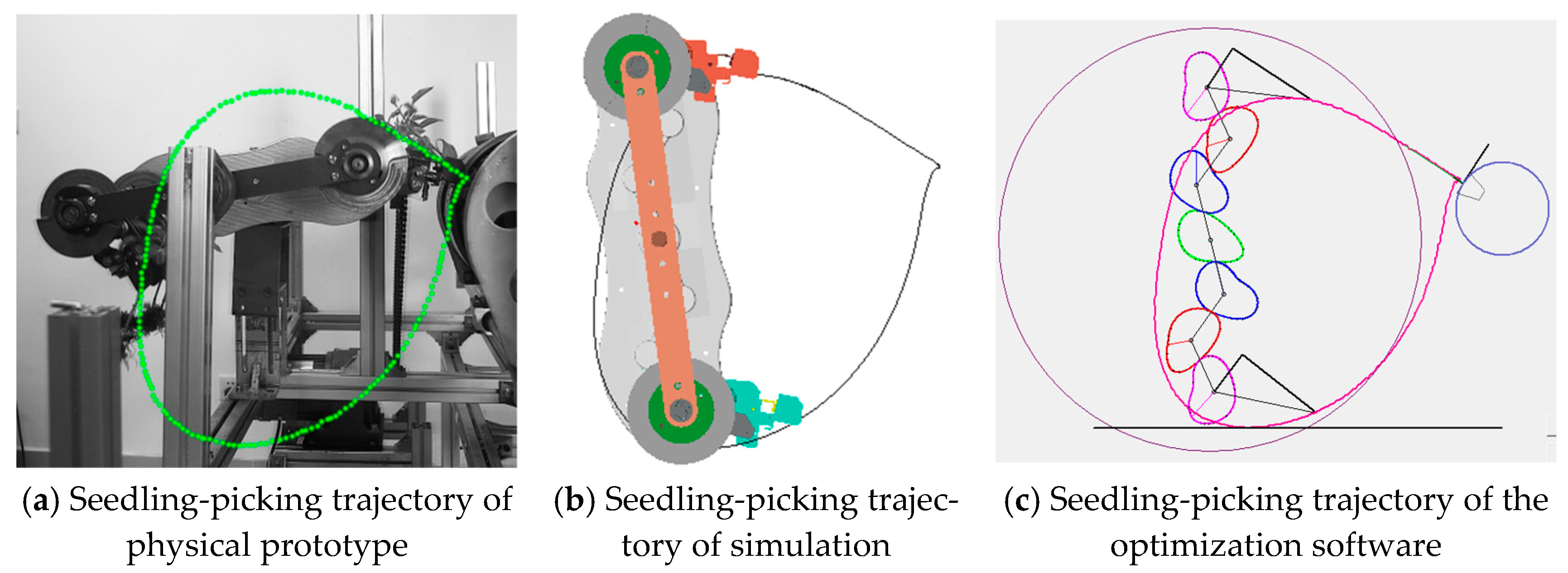

3.1. Virtual Simulation Experiment

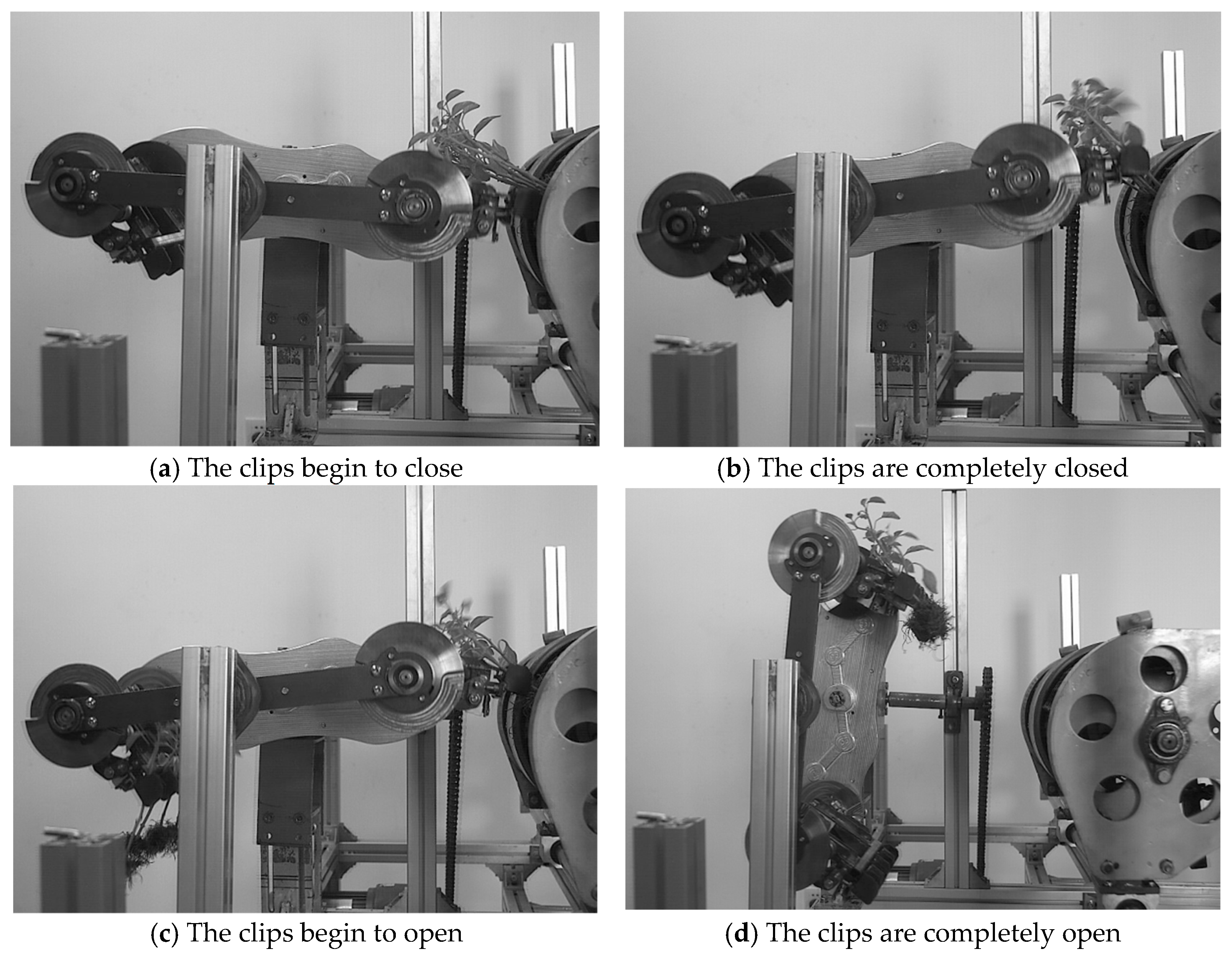

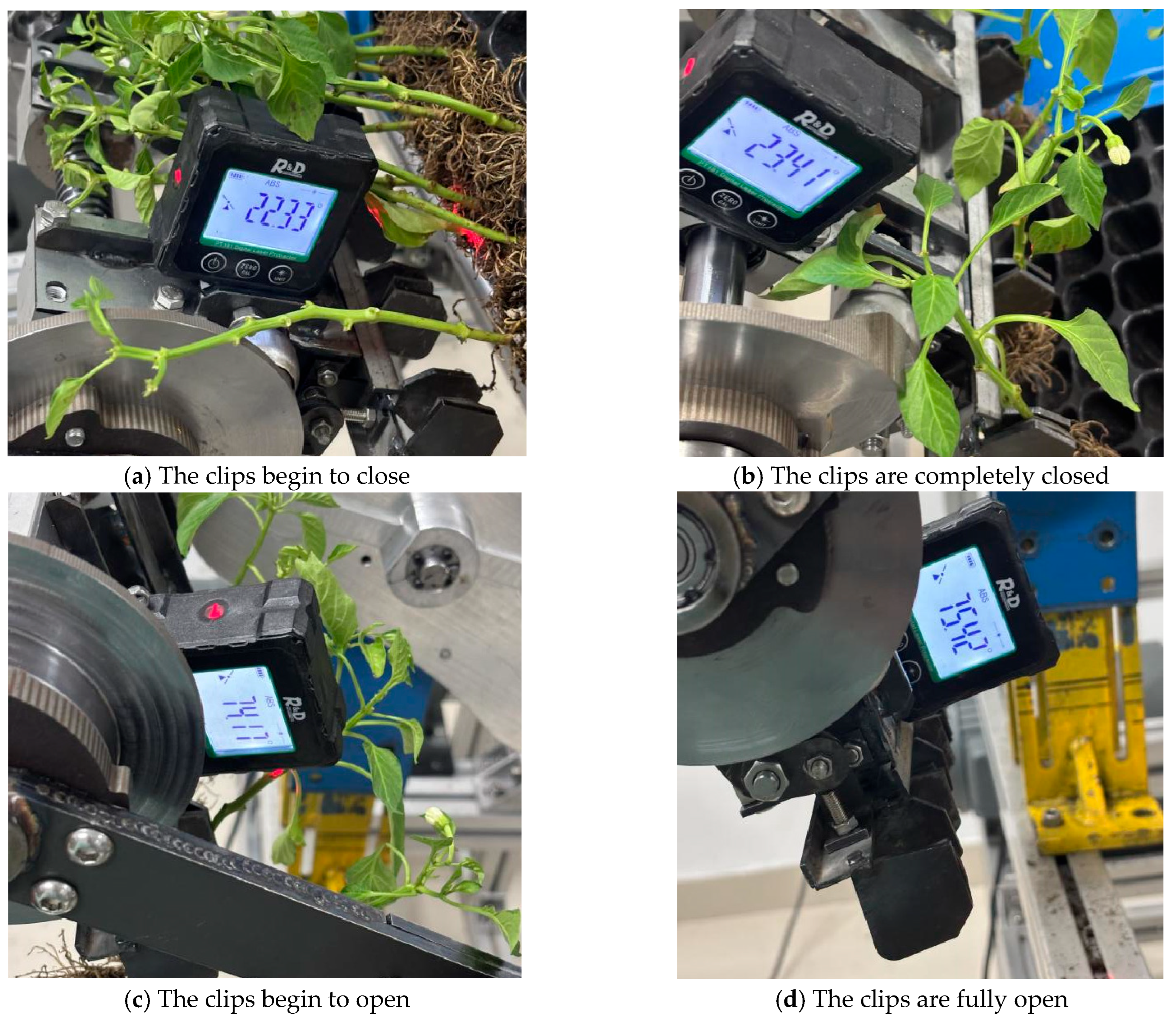

3.2. Pose Verification Experiment

3.3. Seedling-Picking Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.; Han, C.; Zhao, Z.; Guo, H.; Yang, W.; Zhang, J. Present Situation and Development Trend of Chilli and Tomato Transplanter in Xinjiang. Agric. Sci. Technol. Equip. 2015, 41–43. [Google Scholar] [CrossRef]

- Ma, G.; Shi, Q.; Wu, Y.; Liu, Y.; Han, L.; Hu, J.; Mao, H.; Zuo, Z. Effects of Biochar on the Growth and Physiological and Mechanical Properties of Cucumber Plug Seedlings Before and After Transplanting. Agriculture 2024, 14, 2012. [Google Scholar] [CrossRef]

- Ma, G.; Chen, X.; Liu, Y.; Hu, J.; Han, L.; Mao, H. Effects of Compound Biochar Substrate Coupled with Water and Nitrogen on the Growth of Cucumber Plug Seedlings. Agronomy 2022, 12, 2855. [Google Scholar] [CrossRef]

- Sun, Z.; Xue, L.; He, L.; Liu, M.; Li, J.; Zheng, J. Design and experiments of automatic taking and throwing device for chili pepper plug seedlings. J. Chin. Agric. Mech. 2023, 44, 48–54. [Google Scholar]

- Han, L.; Mo, M.; Gao, Y.; Ma, H.; Xiang, D.; Ma, G.; Mao, H. Effects of New Compounds into Substrates on Seedling Qualities for Efficient Transplanting. Agronomy 2022, 12, 983. [Google Scholar] [CrossRef]

- Wen, Y.S.; Zhang, J.X.; Yuan, T.; Tan, Y. Current situation and analysis of automatic pick-up technology for vegetable plug seedlings. J. China Agric. Univ. 2021, 26, 128–142. [Google Scholar]

- Yao, M.; Hu, J.; Liu, W.; Shi, J.; Jin, Y.; Lv, J.; Sun, Z.; Wang, C. Precise Servo-Control System of a Dual-Axis Positioning Tray Conveying Device for Automatic Transplanting Machine. Agriculture 2024, 14, 1431. [Google Scholar] [CrossRef]

- Han, L.; Mao, H.; Hu, J.; Kumi, F. Development of a riding-type fully automatic transplanter for vegetable plug seedlings. Span. J. Agric. Res. 2019, 17, e0205. [Google Scholar] [CrossRef]

- Dong, A.; Liu, Z.; Zhou, M.; Tian, H.; Huang, H.; Yuan, Z. Optimization design and experiment of seedling conveying device of automatic transplanter. J. Henan Agric. Univ. 2025, 59, 112–121. [Google Scholar]

- Jin, X.; Li, M.; Li, D.; Ji, J.; Pang, J.; Wang, J.; Peng, L. Development of automatic conveying system for vegetable seedlings. EURASIP J. Wirel. Commun. Netw. 2018, 11, 2–9. [Google Scholar] [CrossRef]

- Yue, R.; Hu, J.; Liu, Y.; Yao, M.; Zhang, T.; Shi, J. Design and Working Parameter Optimization of Pneumatic Reciprocating Seedling-Picking Device of Automatic Transplanter. Agriculture 2022, 12, 1989. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, J.; Jin, Y.; Bai, Z.; Liu, J.; Zhou, X. Design and Testing of an Intelligent Multi-Functional Seedling Transplanting System. Agronomy 2022, 12, 2683. [Google Scholar] [CrossRef]

- Yang, X.; Ma, Y. Current Situation and Development Trend of Vegetable Mechanized Seedling Transplanting in Facilities. J. Agric. Mech. Res. 2022, 44, 8–13. [Google Scholar]

- Choi, W.C.; Kim, D.C.; Ryu, I.H.; Kim, K.U. Development of a seedling pick-up device for vegetable transplanters. Trans. ASME 2002, 45, 13–19. [Google Scholar]

- Kang, D.-H.; Kim, D.-E.; Lee, G.-I.; Kim, Y.-H.; Lee, H.-J.; Min, Y.-B. Development of a Vegetable Transplanting Robot. J. Biosyst. Eng. 2012, 37, 201–208. [Google Scholar] [CrossRef][Green Version]

- Hu, Q. Design and Working Mechanism of Transplanter for Rape Substrate Block Seedling. Ph.D. Thesis, Huazhong Agricultural University, Wuhan, China, 2022. [Google Scholar]

- Min, Y.-B.; Han, C.-W.; Kweon, G.-Y. Study on optimum operating conditions of a pushing unit for onion plug seedlings. J. Agric. Life Sci. 2014, 48, 435–445. [Google Scholar] [CrossRef]

- Islam, M.N.; Iqbal, M.Z.; Ali, M.; Chowdhury, M.; Kabir, M.S.N.; Park, T.; Kim, Y.-J.; Chung, S.-O. Kinematic analysis of a clamp-type picking device for an automatic pepper transplanter. Agriculture 2020, 10, 627. [Google Scholar] [CrossRef]

- Iqbal, M.Z.; Islam, M.N.; Chowdhury, M.; Islam, S.; Park, T.; Kim, Y.-J.; Chung, S.-O. Working speed analysis of the gear-driven dibbling mechanism of a 2.6 kw walking-type automatic pepper transplanter. Machines 2021, 9, 6. [Google Scholar] [CrossRef]

- Iqbal, M.Z.; Islam, M.N.; Ali, M.; Kabir, M.S.N.; Park, T.; Kang, T.-G.; Park, K.-S.; Chung, S.-O. Kinematic analysis of a hopper-type dibbling mechanism for a 2.6 kW two-row pepper transplanter. J. Mech. Sci. Technol. 2021, 35, 2605–2614. [Google Scholar] [CrossRef]

- Rahul, K.; Raheman, H.; Paradkar, V. Design and development of a 5R 2DOF parallel robot arm for handling paper pot seedlings in a vegetable transplanter. Comput. Electron. Agric. 2019, 166, 105014. [Google Scholar] [CrossRef]

- Khadatkar, A.; Magar, A.P.; Sawant, C.P.; Modi, R.U. Development and testing of automatic seedling extractor in robotic transplanter using mechatronics for nursery seedlings. Discov. Appl. Sci. 2024, 6, 51. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, J.; Wu, J.; Ying, W. Kinematic Modeling and Analysis of Deformed Elliptic Geared Seven-bar Linkage Plant setting Mechanism. China Mech. Eng. 2013, 24, 1001–1007. [Google Scholar]

- Yu, G.; Wang, X.; Liu, J.; Ye, B.; Li, X.; Zhao, X. Design and Experiment of Multi Row Seedling Taking Mechanism for Dense Planting and Transplanting of Vegetable Pot Seedlings. Trans. Chin. Soc. Agric. 2023, 54, 94–103. [Google Scholar]

- Yin, D.; Wang, J.; Zhou, M.; Yang, Y.; Wang, J. Optimal Design and Experiment of Vegetable Potted Seedlings Pick-up Mechanism for Exploring and Picking-Pushing Plugs. Trans. Chin. Soc. Agric. 2019, 50, 64–71. [Google Scholar]

- Yuan, T.; Wang, D.; Wen, Y.S.; Zhu, S.S.; Chen, Y.; Tan, Y. Design and Experiment of Seedlings Unloading Mechanism Based on Methods of Air-blowing and Vibration for Vegetable Transplanter. Trans. Chin. Soc. Agric. 2019, 50, 80–87. [Google Scholar]

- Shi, J.; Hu, J.; Li, J.; Liu, W.; Yue, R.; Zhang, T.; Yao, M. Design and Experiment of Planting Mechanism of Automatic Transplanter for Densely Planted Vegetables. Agriculture 2024, 14, 1357. [Google Scholar] [CrossRef]

| Input Parameter | Parameter Value/mm | Input Parameter | Parameter Value/° |

|---|---|---|---|

| r0 | 40 | θ1 | 30 |

| r1 | 60 | θ2 | 60 |

| r2 | 120 | θ3 | 90 |

| r3 | 40 | θ4 | 120 |

| r4 | 40 | θ5 | 150 |

| r5 | 40 | θ6 | 180 |

| r6 | 100 | θ7 | 210 |

| r7 | 120 | θ8 | 240 |

| r8 | 60 | θ9 | 270 |

| r9 | 80 | θ10 | 300 |

| r10 | 60 | θ11 | 330 |

| S | 180 | Det | −60 |

| H1 | 80 | φH0 | 284 |

| YX | 434 | Yy | 97 |

| Ya | 57 | ɑ1 | −50 |

| H | 120 | ɑ2 | 60 |

| The Clips Begin to Close | The Clips Are Completely Closed | The Clips Begin to Open | The Clips Are Completely Open |

|---|---|---|---|

| 337.41° | 336.26° | 286.26° | 285.12° |

| Optimization Software | High-Speed Camera Test | Bench Seedling-Picking Test | |

|---|---|---|---|

| The clips start to close | 337.26° | 337.41° | 337.67° |

| The clips are completely closed | 336.14° | 336.26° | 336.59° |

| The clips start to open | 285.72° | 286.26° | 285.83° |

| The clips are completely open | 284.24° | 285.12° | 284.58° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Z.; Li, X.; Sun, H.; Zhou, M.; Yin, J.; He, J.; Yin, D. Design and Experimental Validation of Stem-Clamping-and-Pull-Out-Type Pepper Plug Seedling-Picking Mechanism. Agriculture 2025, 15, 1563. https://doi.org/10.3390/agriculture15141563

Lin Z, Li X, Sun H, Zhou M, Yin J, He J, Yin D. Design and Experimental Validation of Stem-Clamping-and-Pull-Out-Type Pepper Plug Seedling-Picking Mechanism. Agriculture. 2025; 15(14):1563. https://doi.org/10.3390/agriculture15141563

Chicago/Turabian StyleLin, Zhenhua, Xiao Li, Hao Sun, Maile Zhou, Jianjun Yin, Jijia He, and Daqing Yin. 2025. "Design and Experimental Validation of Stem-Clamping-and-Pull-Out-Type Pepper Plug Seedling-Picking Mechanism" Agriculture 15, no. 14: 1563. https://doi.org/10.3390/agriculture15141563

APA StyleLin, Z., Li, X., Sun, H., Zhou, M., Yin, J., He, J., & Yin, D. (2025). Design and Experimental Validation of Stem-Clamping-and-Pull-Out-Type Pepper Plug Seedling-Picking Mechanism. Agriculture, 15(14), 1563. https://doi.org/10.3390/agriculture15141563