Physico-Chemical and Resistance Characteristics of Rosehip Seeds

Abstract

1. Introduction

2. Materials and Methods

2.1. Initial Characteristics of Rosehip Fruits and Seeds

2.2. Compression Test of Rosehip Seeds

3. Results

4. Discussion

5. Conclusions

- (a)

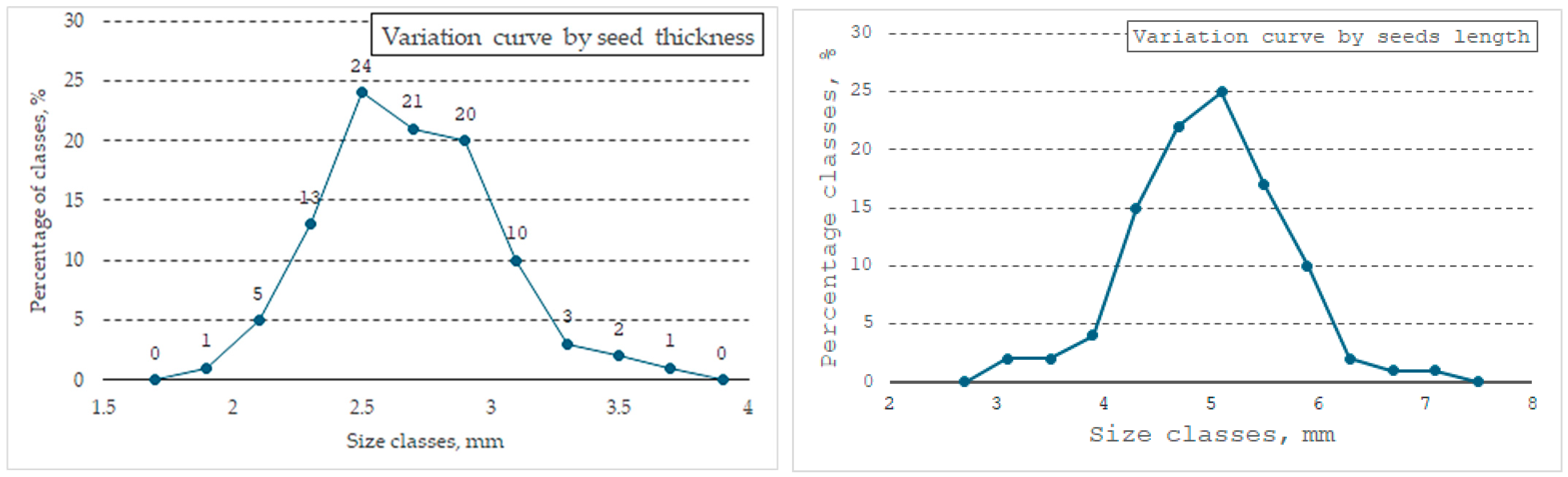

- A relatively wide range of seed thickness values was found (1.54–3.72 mm).

- (b)

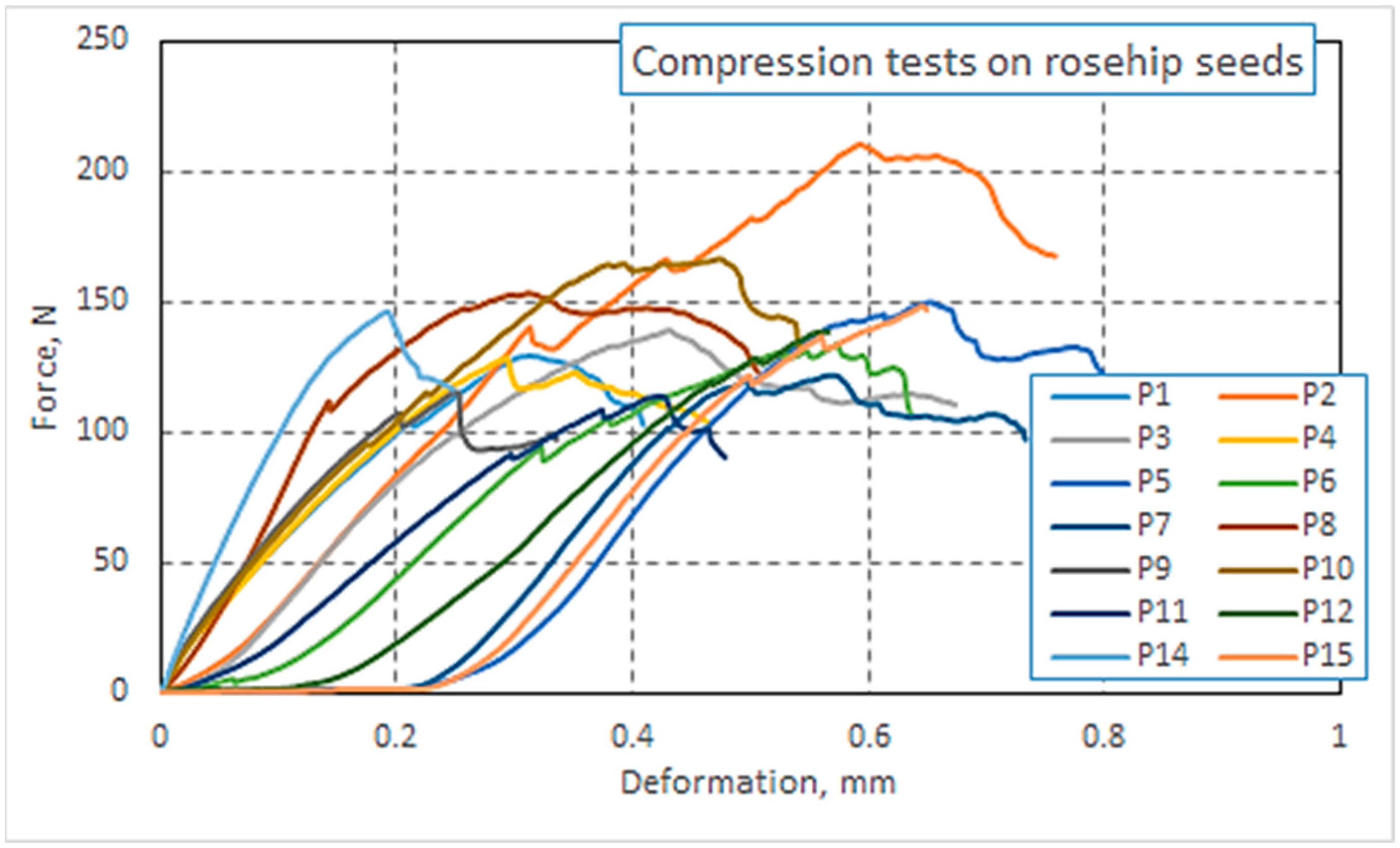

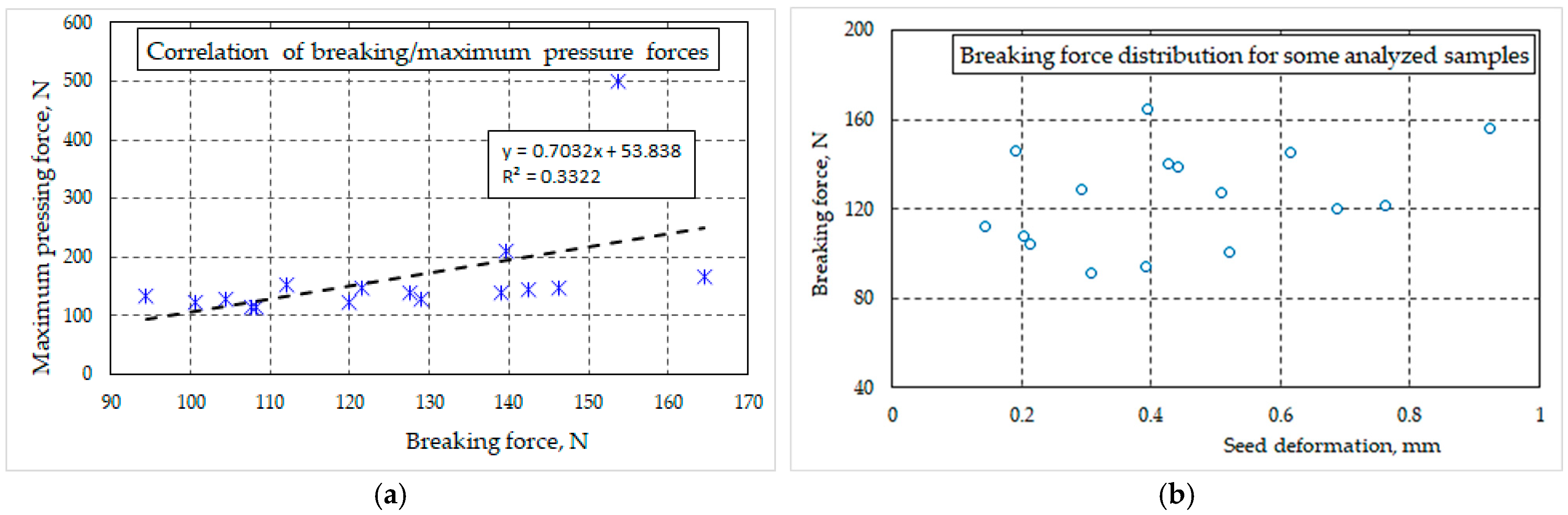

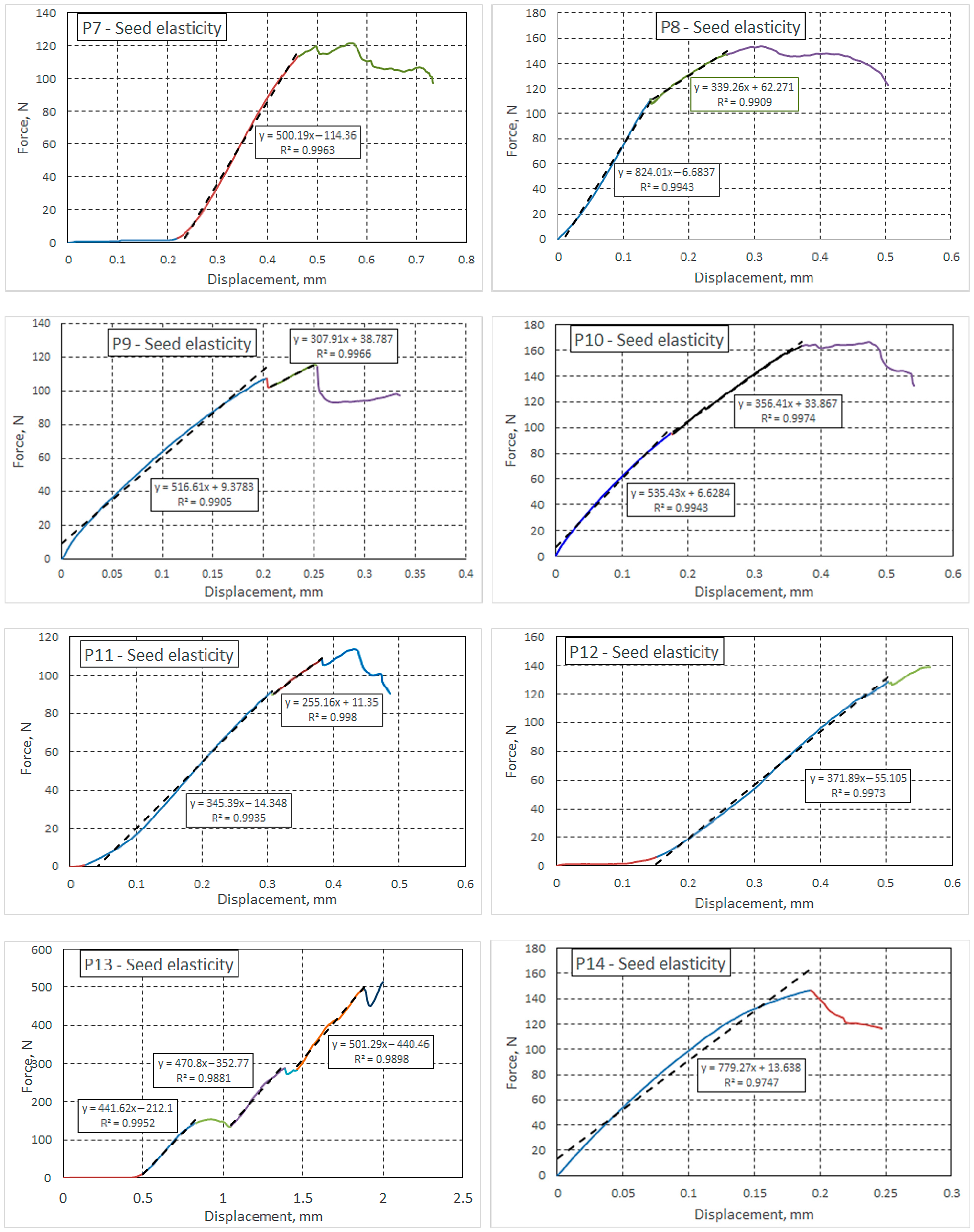

- The deformations of the rosehip seeds ranged between 0.142 and 0.916 mm until the first cracks appeared, and the forces at the same moment were within the limits of 94.4–156.0 N. On the other hand, the deformations had values between 0.248 and 1.878 mm at the moment of final breakage, where the maximum forces were 114.0–495.0 N.

- (c)

- The energy consumed for the deformation of the seeds until the first crack was between 0.012 and 0.041 J and that until final breakage was between 0.017 and 0.322 J.

- (d)

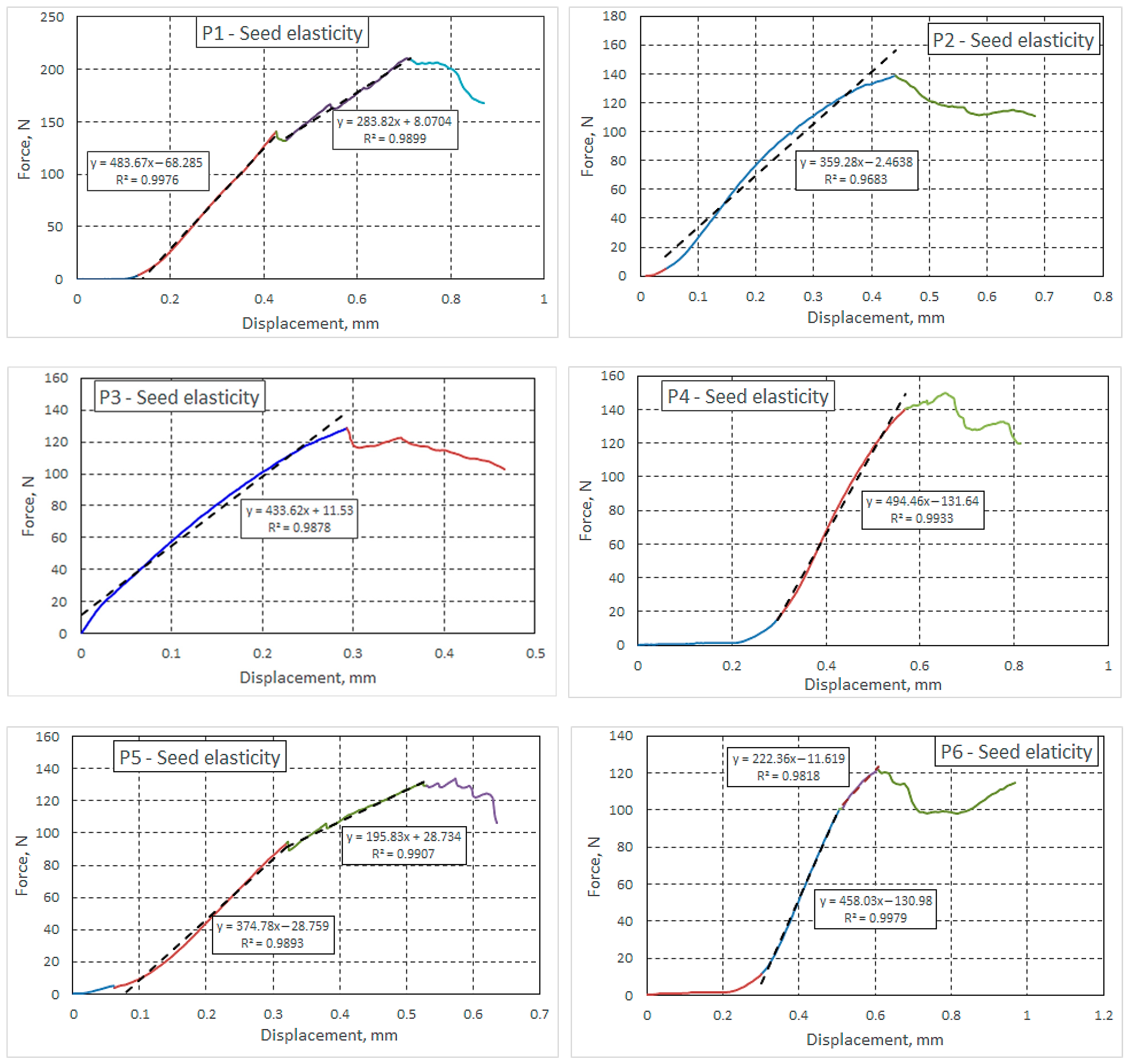

- The elasticity of the seeds was in the range of 159.9–789.1 N/mm, and the time elapsed from the beginning of the compression of the seeds to the appearance of the first crack was between 8.52 and 36.66 s for a deformation rate of 1 mm/min. The mean elastic modulus, as estimated from the experimental results, was 130.67 MPa.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nađpal, J.; Lesjak, M.; Mrkonjic, Z.; Majkic, T.; Cetojevic-Simin, D.; Mimica-Dukic, N.; Beara, I. Phytochemical composition and in vitro functional properties of three wild rose hips and their traditional preserves. Food Chem. 2018, 241, 290–300. [Google Scholar] [CrossRef] [PubMed]

- Saini, A.; Kaur, R.; Kumar, S.; Kumar-Saini, R.; Kashyap, B.; Kumar, V. New horizon of rosehip seed oil: Extraction, characterization for its potential applications as a functional ingredient. Food Chem. 2024, 437, 137568. [Google Scholar] [CrossRef] [PubMed]

- Rosehip Tea, the Liqueur with Dozens of Benefits for Your Health (in Romanian). Available online: https://livadacuceai.ro/simple_blog/article/view/ceaiul-de-macese-licoarea-cu-zeci-de-beneficii/ (accessed on 15 November 2024).

- Ghendov-Mosanu, A.; Cristea, E.; Patras, A.; Sturza, R.; Niculaua, M. Rose Hips, a valuable source of antioxidants to improve gingerbread characteristics. Molecules 2020, 25, 5659. [Google Scholar] [CrossRef] [PubMed]

- Rosehip Tea: Health Benefits and Properties (in Romanian). Available online: https://www.medicover.ro/despre-sanatate/ceai-de-macese-beneficii-si-proprietati-pentru-sanatate,1662,n,1948 (accessed on 15 October 2024).

- Marmol, I.; Sánchez-de-Diego, C.; Jiménez-Moreno, N.; Ancín-Azpilicueta, C.; Rodríguez-Yoldi, M.J. Therapeutic applications of rose hips from different rosa species. Int. J. Mol. Sci. 2017, 18, 1137. [Google Scholar] [CrossRef] [PubMed]

- Peña, F.; Valencia, S.; Tereucán, G.; Nahuelcura, J.; Jiménez-Aspee, F.; Cornejo, P.; Ruiz, A. Bioactive Compounds and Antioxidant Activity in the Fruit of Rosehip (Rosa canina L. and Rosa rubiginosa L.). Molecules 2023, 28, 3541. [Google Scholar] [CrossRef] [PubMed]

- Phetcharat, L.; Wongsuphasawat, K.; Winther, K. The effectiveness of a standardized rose hip powder, containing seeds and shells of Rosa canina, on cell longevity, skin wrinkles, moisture, and elasticity. Clin. Interv. Aging 2015, 10, 1849–1856. [Google Scholar] [CrossRef] [PubMed]

- Mertoğlu, K.; Durul, M.S.; Korkmaz, N.; Polat, M.; Ibrahim Bulduk, I.; Esatbeyoglu, T. Screening and classification of rosehip (Rosa canina L.) genotypes based on horticultural characteristics. BMC Plant Biol. 2024, 24, 345. [Google Scholar] [CrossRef] [PubMed]

- Kulaitiene, J.; Medveckienė, B.; Levickienė, D.; Vaitkevičienė, N.; Makarevičienė, V.; Jarienė, E. Changes in fatty acids content in organic rosehip (Rosa spp.) seeds during ripening. Plants 2020, 9, 1793. [Google Scholar] [CrossRef] [PubMed]

- Stryjecka, M.; Kiełtyka-Dadasiewicz, A.; Michalak, M. Physico-chemical characteristics of Rosa canina L. seeds and determining their potential use. Appl. Sci. 2025, 15, 168. [Google Scholar] [CrossRef]

- Corapci, B. The effect of rosehip seed oil nanoemulsion on some physical, chemical, and microbiological properties of sea bass fillets stored at 4 ± 1 C. J. Aquat. Food Prod. Technol. 2022, 31, 672–685. [Google Scholar] [CrossRef]

- Abujazar, M.S.; Karaagac, S.U.; Abu Amr, S.S.; Fatihah, S.; Bashir, M.J.K.; Alazaiza, M.Y.D.; Ibrahim, E. The effectiveness of rosehip seeds powder as a plant-based natural coagulant for sustainable treatment of steel industries wastewater. Desalination Water Treat. 2022, 270, 44–51. [Google Scholar] [CrossRef]

- Abujazar, M.S.S.; Karaagaç, S.U.; Abu Amr, S.S.; Alazaiza, M.Y.D.; Albahnasavi, A.; Nassani, D.E. The synergistic power of rosehip seed powder and aluminum chloride in steel industry wastewater treatment. Water 2024, 16, 2770. [Google Scholar] [CrossRef]

- Gavaric, A.; Pastor, K.; Nastic, N.; Vidovic, S.; Živanovic, N.; Simin, N.; Duarte, A.R.C.; Vladic, J. Recovery of polyphenols from rosehip seed waste using natural deep eutectic solvents and ultrasonic waves simultaneously. Foods 2023, 12, 3655. [Google Scholar] [CrossRef] [PubMed]

- Ilyasoglu, H. Characterization of rosehip (Rosa canina L.) seed and seed oil. Int. J. Food Prop. 2014, 17, 1591–1598. [Google Scholar] [CrossRef]

- Popovic-Djordjevic, J.; Špirović-Trifunović, B.; Pećinar, I.; Cappa de Oliveira, L.F.; Krstic, D.; Mihajlovic, D.; Fotiric Aksic, M.; Simal-Gandara, J. Fatty acids in seed oil of wild and cultivated rosehip (Rosa canina L.) from different locations in Serbia. Ind. Crops Prod. 2023, 191, 115797. [Google Scholar] [CrossRef]

- Negrean, O.-R.; Farcas, A.C.; Nemes, S.A.; Cic, D.-E.; Socaci, S.A. Recent advances and insights into the bioactive properties and applications of Rosa canina L. and its by-products. Heliyon 2024, 10, e30816. [Google Scholar] [CrossRef] [PubMed]

- Grajzer, M.; Prescha, A.; Korzonek, K.; Wojakowska, A.; Dziadas, M.; Kulma, A.; Grajeta, H. Characteristics of rose hip (Rosa canina L.) cold-pressed oil and its oxidative stability studied by the differential scanning calorimetry method. Food Chem. 2015, 188, 459–466. [Google Scholar] [CrossRef] [PubMed]

- Ilyasoglu, H. Antioxidant effect of rosehip seed powder in raw and cooked meatballs during refrigerated storage. Turk. J. Vete-Anim. Sci. 2014, 38, 73–76. [Google Scholar] [CrossRef]

- Demir, B.; Sayıncı, B.; Yaman, M.; Sümbül, A.; Yıldız, E.; Karakaya, O.; Alkaya, G.B.; Ercişli, S. Biochemical composition and shape-dimensional traits of rosehip genotypes. Folia Hortic. 2021, 33, 293–308. [Google Scholar] [CrossRef]

- Kayahan, S.; Ozdemir, Y.; Gülbağ, F. Functional Compounds and Antioxidant Activity of Rosa Species Grown in Turkey. Erwerbs-Obstbau 2023, 65, 1079–1086. [Google Scholar] [CrossRef] [PubMed]

- Raxmanova, T.T.; Mambetsheripova, A.; Safarov, J.S.; Abduvakhitovna, S.S. Mathematical modelling of the process of drying rosehips. In Proceedings of the IOP Conference Series Earth and Environmental Science, Krasnoyarsk, Russia, 29–31 March 2023; Volume 1231, p. 012037. [Google Scholar]

- Vasić, D.; Paunovic, D.; Spirovic-Trifunovic, B.; Miladinović, J.; Vujošević, L.; Popovic-Djordjevic, J.B. Fatty acid composition of rosehip seed oil. Acta Agric. Serbica 2020, 25, 45–49. [Google Scholar] [CrossRef]

- Çınar, O.; Dayısoylu, K.S. Rose hip seeds are not waste. Acta Hortic. 2005, 690, 293–298. [Google Scholar] [CrossRef]

- Szentmihályi, K.; Vinkler, P.; Lakatos, B.; Illés, V.; Then, M. Rose hip (Rosa canina L.) oil obtained from waste hip seeds by different extraction methods. Bioresour. Technol. 2002, 82, 195–201. [Google Scholar] [CrossRef] [PubMed]

- Jahongir, H.; Miansong, Z.; Amankeldi, I.; Yu, Z.; Changheng, L. The influence of particle size on supercritical extraction of dog rose (Rosa canina) seed oil. J. King Saud Univ.-Eng. Sci. 2019, 31, 140–143. [Google Scholar] [CrossRef]

- Ercişli, S.; Esitken, A. Fruit characteristics of native rose hip (Rosa spp.) selections from the Erzurum province of Turkey. New Zealand J. Crop Hortic. Sci. 2004, 32, 51–53. [Google Scholar] [CrossRef]

- Ubaydullayev, F.; Gaffarov, S. Selection of prosperous varieties of rosehips (Rosa L.) and their seed productivity in Tashkent oasis, Uzbekistan. E3S Web Conf. 2021, 258, 04027. [Google Scholar] [CrossRef]

- Oarga, D.P.; Cornea-Cipcigan, M.; Cordea, M.I. Unveiling the mechanisms for the development of rosehip-based dermatological products: An updated review. Front. Pharmacol. 2024, 11, 1390419. [Google Scholar]

- Bakhtiar, Z.; Eghlima, G.; Hatami, M.; Mirjalili, M.H. Quantification of fatty acids in seed oil and important bioactive compounds in Iranian Rosa canina L. ecotypes for potential cosmetic and medicinal uses. Sci. Rep. 2023, 13, 22721. [Google Scholar] [CrossRef] [PubMed]

- Eren, T.; Ok, S.; Yılmaz, E. Comprehensive characterization of physicochemical, thermal, compositional, and sensory properties of cold-pressed rosehip seed oil. Grasas Y Aceites 2024, 74, 11. [Google Scholar] [CrossRef]

- del Valle, J.M.; Uquiche, E. Particle size effects on supercritical CO2 extraction of oil-containing seeds. J. Am. Oil Chem. Soc. 2002, 79, 1261–1266. [Google Scholar] [CrossRef]

- Marudova, M.; Zsivanovits, G.; Viraneva, A.; Gechev, B.; Rusinova-Videva, S. Rosehip Seed Oil-Incorporated Chitosan Films for Potential Fruit Packaging Applications. Appl. Sci. 2024, 14, 7669. [Google Scholar] [CrossRef]

- Abbaspour-Fard, M.H.; Khodabakhshian, R.; Emadi, B.; Sadrnia, H. Evaluation the effects of some relevant parameters on elastic modulus of pumpkin seed and its kernel. Int. J. Biomater. 2012, 2012, 271650. [Google Scholar] [CrossRef] [PubMed]

- Khodabakhshian, R.; Emadi, B.; Abbaspour-Fard, M.H.; Saiedirad, M.H. Modeling the fracture resistance of sunflower seed and its kernel as a function of moisture content, variety, size and loading orientation. Int. J. Food Eng. 2011, 7, 17. [Google Scholar] [CrossRef]

- Koya, O.A.; Ogunsina, B.S.; Opeyemi, O.O. Deformation and Dehulling of Sponge Gourd (Luffa aegyptiaca) Seeds. Int. J. Food Prop. 2011, 14, 432–440. [Google Scholar] [CrossRef]

- Emadi, B.; Khodabakhshian, R.; Abbaspour Fard, M.H.; Sadrnia, H. Experimental comparison of applying different theories in elasticity for determination of the elasticity modulus of agricultural produce, Pumpkin seed as a case study. J. Agric. Technol. 2011, 7, 1495–1508. [Google Scholar][Green Version]

- Kabutey, A.; Herák, D.; Chotěborský, R.; Navrátilová, M. Model for energy and deformation determination of selected oilseeds under compression loading—Short communication. Res. Agric. Eng. 2012, 58, 155–158. [Google Scholar] [CrossRef]

- Divisova, M.; Herak, D.; Kabutey, A.; Sleger, V.; Sigalingging, R.; Svatonova, T. Deformation curve characteristics of rapeseeds and sunflower seeds under compression loading. Sci. Agric. Bohem. 2014, 45, 80–186. [Google Scholar] [CrossRef]

- Eze, P.C.; Eze, C.N.; Ide, P.E. Effect of Moisture Content on the Mechanical Properties of Watermelon Seed Varieties. Turk. J. Agric. Eng. Res. 2021, 2, 308–320. [Google Scholar] [CrossRef]

- Cejudo Bastante, M.J.; Rodríguez-Pulido, F.J.; Heredia, F.J.; González-Miret, M.L. Assessment of sensory and texture profiles of grape seeds at real maturity stages using image analysis. Foods 2021, 10, 1098. [Google Scholar] [CrossRef] [PubMed]

- Ionescu, M.; Voicu, G.; Biriş, S.S.; Stefan, E.M.; Ungureanu, N.; Dinca, M.N. Determination of some mechanical properties for oilseeds using uniaxial compression tests. INMATEH–Agric. Eng. 2016, 49, 71–76. [Google Scholar]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials, 2nd ed.; Gordon and Breach Science Publications: New York, NY, USA, 1986. [Google Scholar]

- Baltatu, C.; Biris, S.S.; Mateescu, M.; Marin, E.; Gheorghe, G. Determination of the main properties of grape seeds and improving the mechanical oil extraction. UPB Sci. Bull 2023, 85, 291–304. [Google Scholar]

- Ionescu, A.D.; Voicu, G.; Stefan, E.-M.; Constantin, G.A. Characterization and assessment of physical and mechanical properties of rosehip (Rosa canina L.) fruits and seeds. In Proceedings of the 24th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 21–23 May 2025; pp. 542–548. [Google Scholar]

| No. * | Breaking Moment | Maximum Force Moment | Slope of the Regression Line | Energy Consumption, N·m | |||

|---|---|---|---|---|---|---|---|

| Displacement, mm | Force, N | Displacement, mm | Force, N | at Breaking | at Maximum | ||

| P1 | 0.426 | 140.36 | 0.706 | 210.43 | 482.72 | 0.019 | 0.067 |

| P2 | 0.259 | 99.385 | 0.439 | 139.00 | 365.08 | 0.012 | 0.034 |

| P3 | 0.293 | 128.933 | 0.293 | 128.933 | 433.62 | 0.022 | 0.022 |

| P4 | 0.611 | 144.654 | 0.652 | 149.900 | 492.99 | 0.030 | 0.035 |

| P5 | 0.392 | 94.430 | 0.577 | 129.841 | 377.59 | 0.019 | 0.041 |

| P6 | 0.506 | 100.500 | 0.608 | 122.125 | 458.48 | 0.012 | 0.023 |

| P7 | 0.497 | 120.039 | 0.566 | 121.867 | 499.08 | 0.018 | 0.026 |

| P8 | 0.142 | 112.055 | 0.311 | 153.5 | 823.21 | 0.007 | 0.031 |

| P9 | 0.202 | 107.646 | 0.248 | 115.5 | 515.66 | 0.013 | 0.018 |

| P10 | 0.225 | 115.356 | 0.474 | 166.533 | 420.35 | 0.015 | 0.052 |

| P11 | 0.306 | 91.542 | 0.431 | 114.000 | 343.43 | 0.012 | 0.025 |

| P12 | 0.508 | 127.620 | 0.562 | 138.567 | 377.00 | 0.025 | 0.032 |

| P13 | 0.916 | 156.001 | 1.878 | 495.000 | 439.71 | 0.041 | 0.322 |

| P14 | 0.192 | 146.333 | 0.192 | 146.333 | 779.27 | 0.017 | 0.017 |

| P15 | 0.212 | 104.45 | 0.316 | 129.14 | 472.58 | 0.013 | 0.025 |

| P16 | 0.499 | 121.700 | 0.645 | 148.233 | 499.47 | 0.016 | 0.038 |

| Average | 0.387 | 119.44 | 0.556 | 163.06 | - | 0.018 | 0.051 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ionescu, A.-D.; Voicu, G.; Stefan, E.-M.; Constantin, G.-A.; Tudor, P.; Militaru, G. Physico-Chemical and Resistance Characteristics of Rosehip Seeds. Agriculture 2025, 15, 1539. https://doi.org/10.3390/agriculture15141539

Ionescu A-D, Voicu G, Stefan E-M, Constantin G-A, Tudor P, Militaru G. Physico-Chemical and Resistance Characteristics of Rosehip Seeds. Agriculture. 2025; 15(14):1539. https://doi.org/10.3390/agriculture15141539

Chicago/Turabian StyleIonescu, Alina-Daiana, Gheorghe Voicu, Elena-Madalina Stefan, Gabriel-Alexandru Constantin, Paula Tudor, and Gheorghe Militaru. 2025. "Physico-Chemical and Resistance Characteristics of Rosehip Seeds" Agriculture 15, no. 14: 1539. https://doi.org/10.3390/agriculture15141539

APA StyleIonescu, A.-D., Voicu, G., Stefan, E.-M., Constantin, G.-A., Tudor, P., & Militaru, G. (2025). Physico-Chemical and Resistance Characteristics of Rosehip Seeds. Agriculture, 15(14), 1539. https://doi.org/10.3390/agriculture15141539