Application of Seed Miss Prevention System for a Spoon-Wheel Type Precision Seed Metering Device: Effectiveness and Limitations

Abstract

1. Introduction

2. Materials and Methods

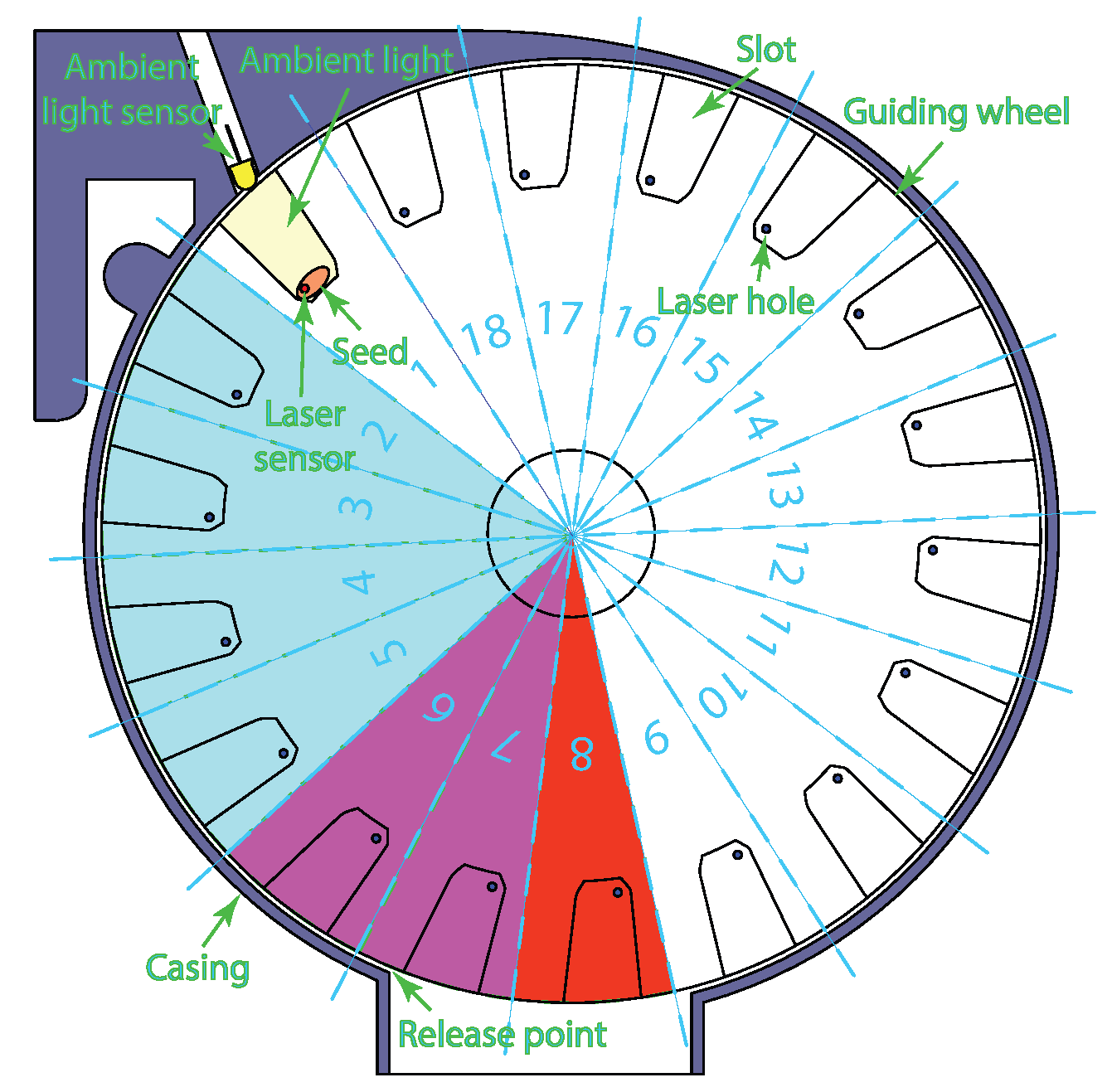

2.1. CAD Model of the Spoon-Wheel Type Precision Seed Metering Device

2.2. Working Principle of the System

2.3. DEM Simulation

2.3.1. Bulk Material Properties

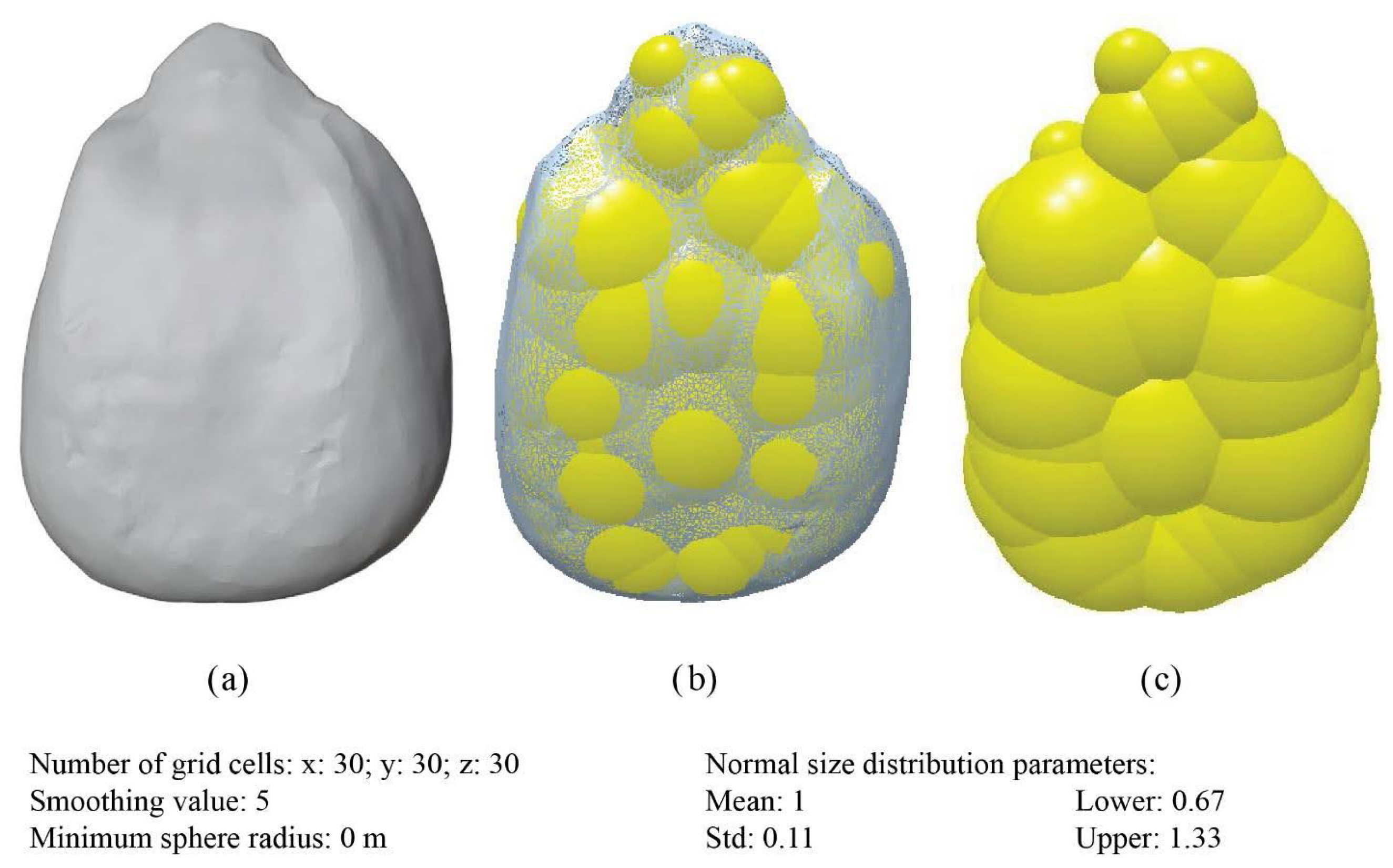

- Particle shape: The particle shapes were created by scanning 10 randomly selected corn seeds (Figure 3a) using a 3D scanner, similar to Li et al. [40]. Scanned seed meshes were then imported into EDEM software (Figure 3b) as seed templates. To create final particle shapes (Figure 3c), EDEM Particle Shape Editor was used. These particle shapes were then used to create a granular material model of corn seeds similar to Chen et al. [9] but more detailed, varying from 40 up to 70 spheres per particle.

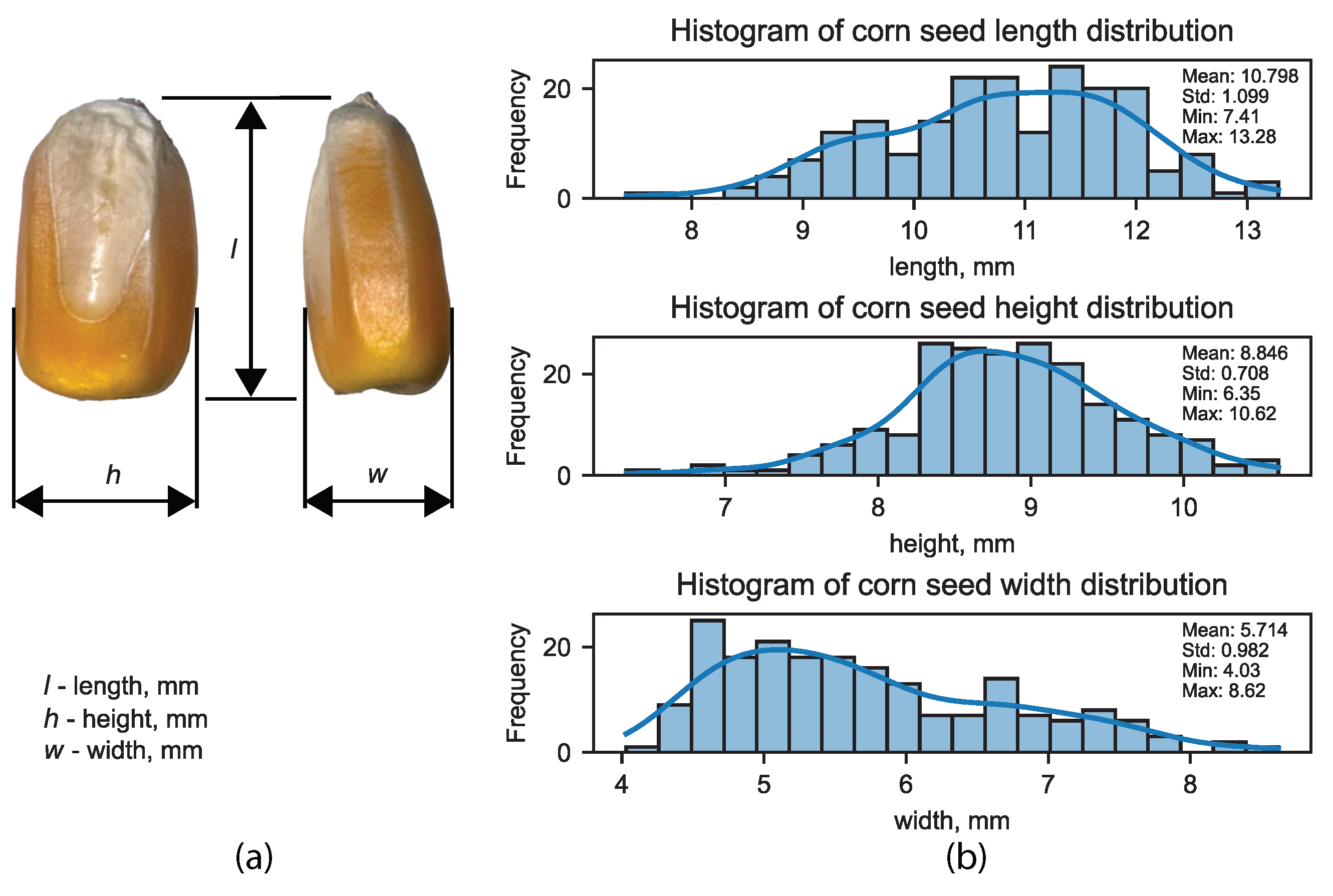

- Particle size distribution: The size distribution of the particles in the bulk material should be defined. This can be carried out using experimental data or by generating, though less precise, an approximate size distribution. To analyze the seed distribution, 200 randomly chosen corn seeds were measured with the 3-dimensional parameters as shown in Figure 4a. The resulting standard deviation value was formed by taking an average from all 3 dimensions (Figure 4b) in order to obtain the single scale factor for DEM. In order to obtain this value, the average standard deviation value was scaled by the average dimensions, Equation (1). The resulting scale factor was then used, and then, the particle was generated using normal distribution.whereS—scale factor for EDEM simulation;—standard deviation of the seed height, mm;—standard deviation of the seed length, mm;—standard deviation of the seed width, mm;—average height of the seed, mm;—average length of the seed, mm;—average width of the seed, mm.For each particle, upper and lower bounds were defining by adding and subtracting 3× of the scaler factor value, Equations (2) and (3).where—minimum scale factor of randomly generated seeds;—maximum scale factor of randomly generated seeds.

- Material properties: The material properties of the particles, such as density, elasticity, coefficient of friction, and coefficient of restitution, should be defined. The material properties of the simulation materials including corn grains, galvanized steel, and acrylic plastic (polymethyl methacrylate PMMA) in EDEM have been well-defined in Chen et al. [41]; Simões et al. [42]; Wang et al. [43] Horabik and Molenda [44]; Stigh and Biel [45]; and Pawar [46]. The parameters used in the modeling are presented in Table 1.

- Particle–wall interaction properties: The properties that govern the interaction between particles and walls, such as the wall roughness and the coefficient of friction, were defined. Based on the material composition of the metering device, corn–acrylic, corn–galvanized, steel and corn–corn interactions must be defined; the properties of these interactions are obtained from previous research Chen et al. [41]; Chen et al. [49]; Hastie [50]; and Adilet et al. [31].

- Loading conditions: The loading conditions such as the velocity and mass flow rate of the particles are normally defined at the start of the simulation. However, for ease of simulation, particles were pregenerated to fill the inlet of the seed metering device model, and simulation time was reset to 0. Therefore, these parameters were not further required for the simulation.

- Geometry of the simulation domain: The geometry of the simulation domain, including the size and shape of the container, is obtained by simplifying the SolidWorks model of the seed metering device (Figure 1).

- Simulation parameters: The time integration method was set to Euler, with a fixed time step of s. The total simulation time was 30 s. The simulation utilized a GPU solver with NVIDIA RTX3060 GPU. The smallest particle radius was set to 0.00033953 m, and the grid cell size was approximately 1 m.

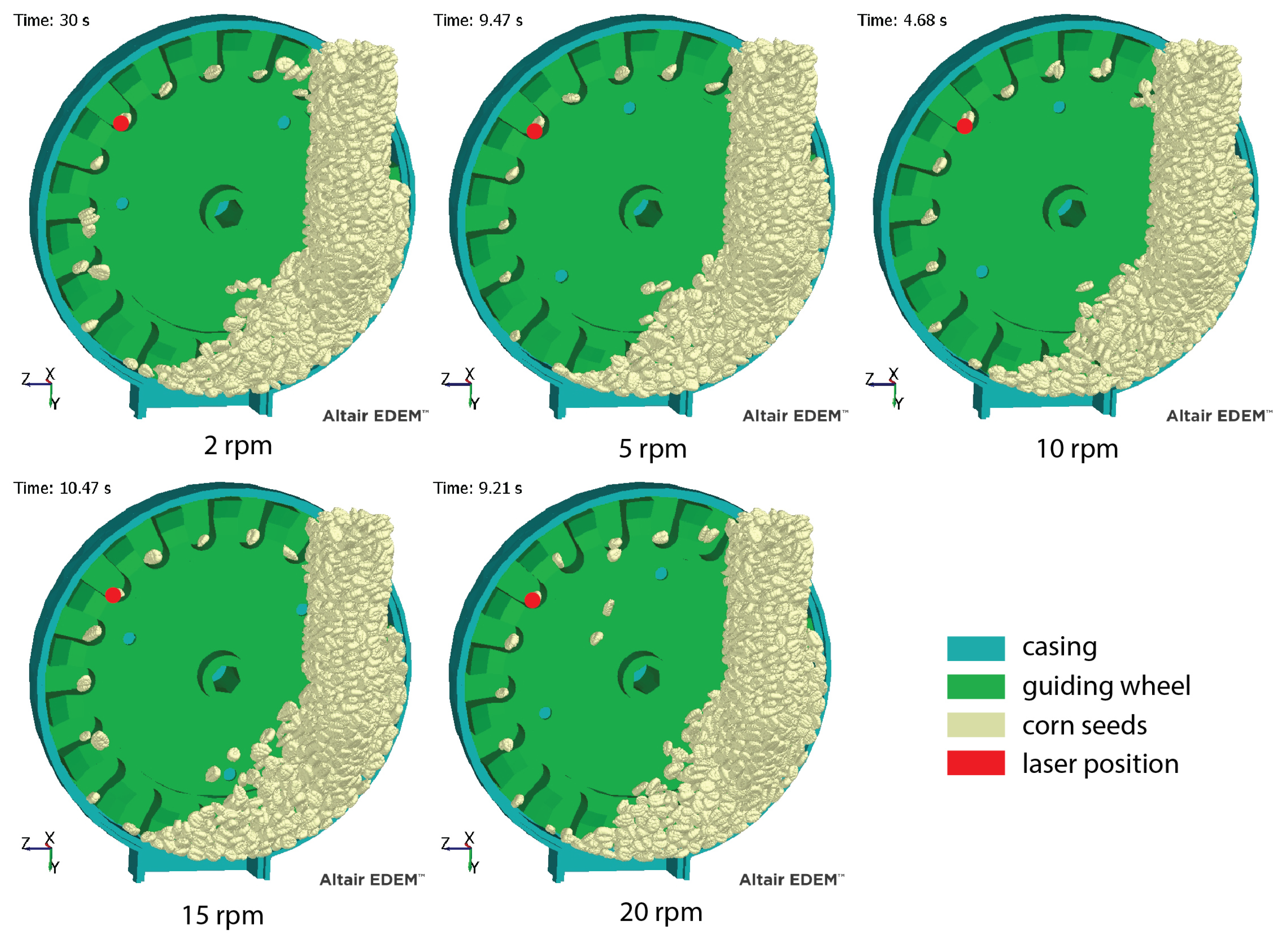

2.3.2. EDEM Simulation Scenarios

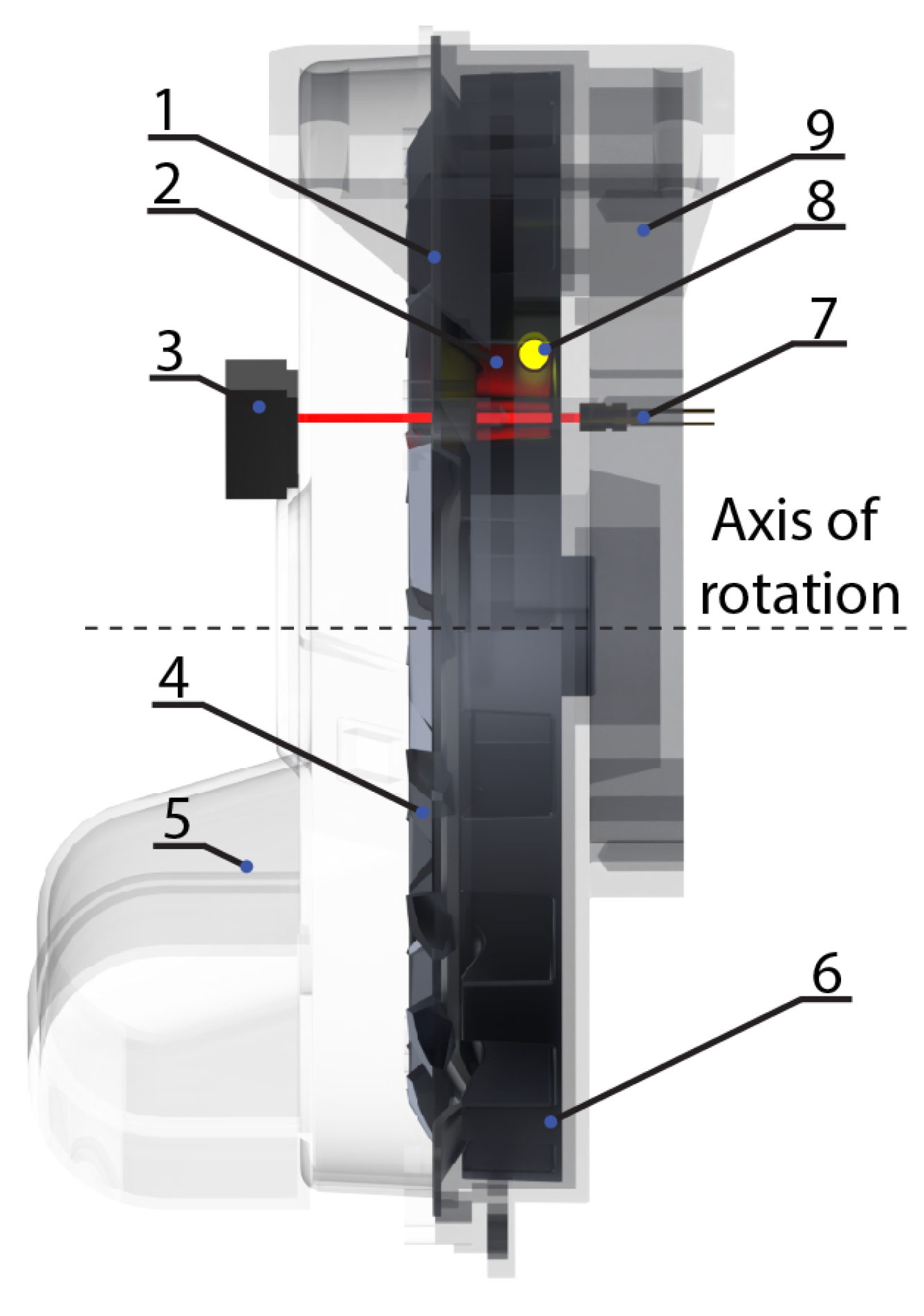

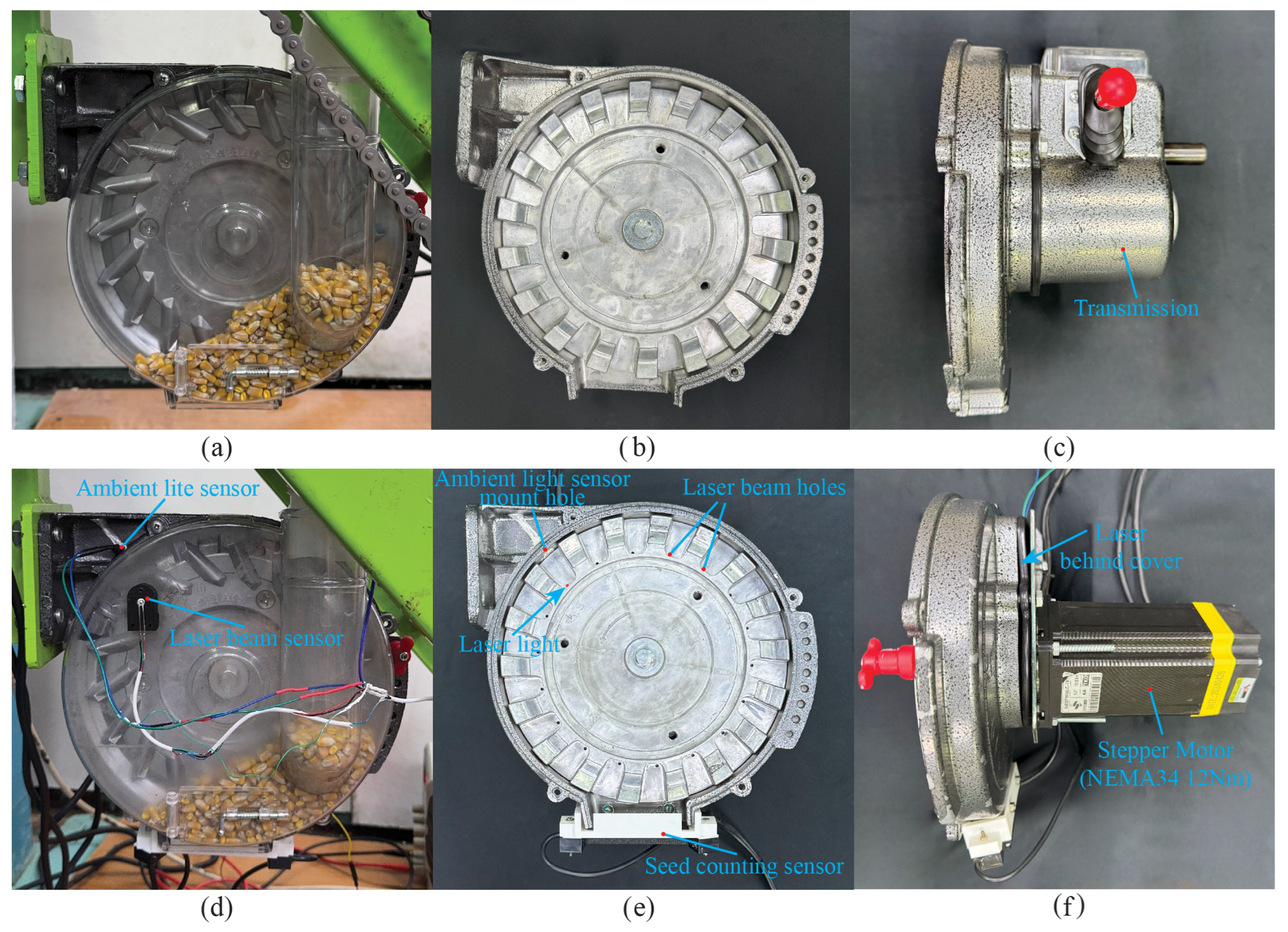

2.4. Retrofitting the Spoon-Wheel Precision Seed Metering Device with a Seed Miss Prevention System

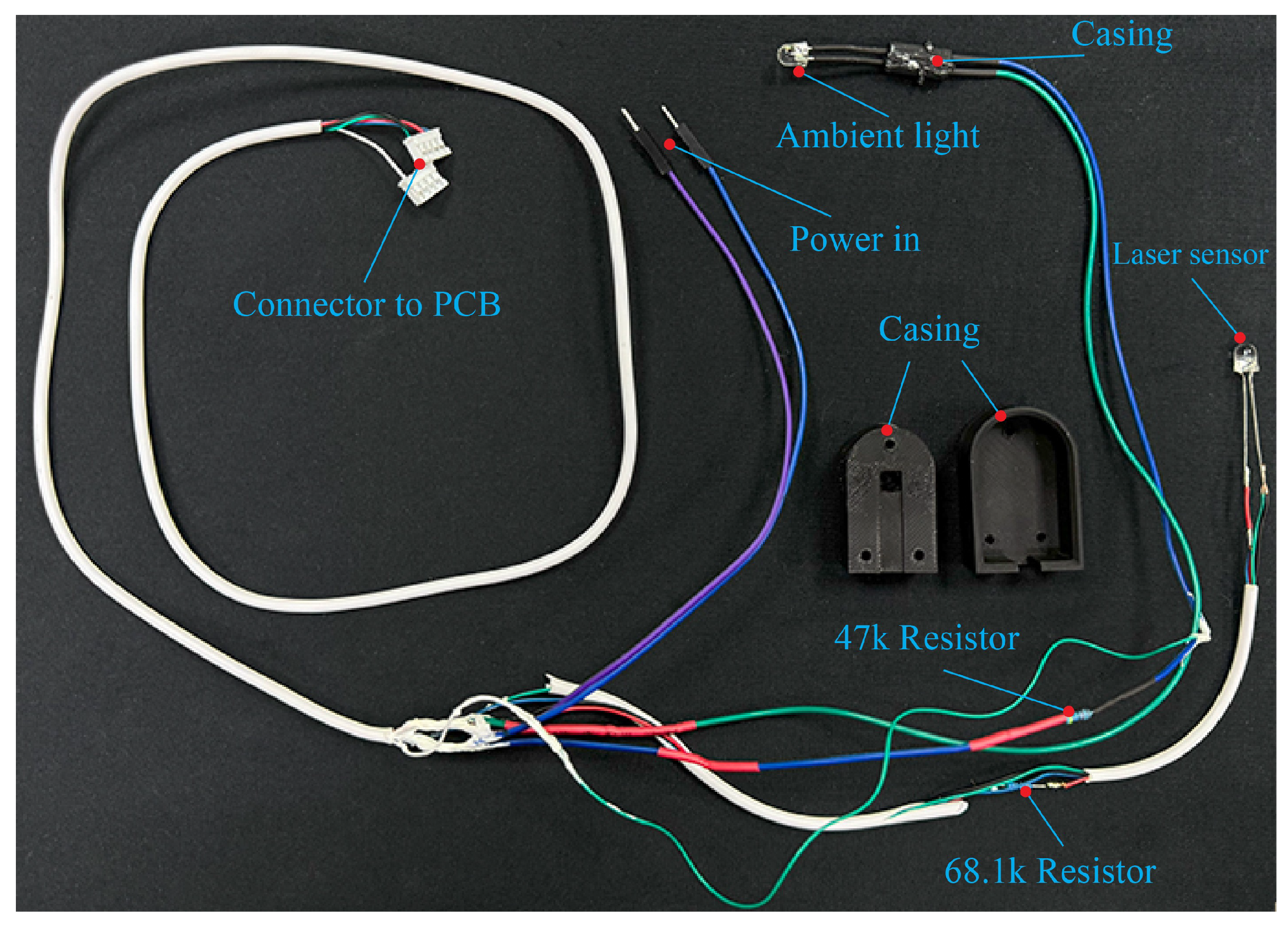

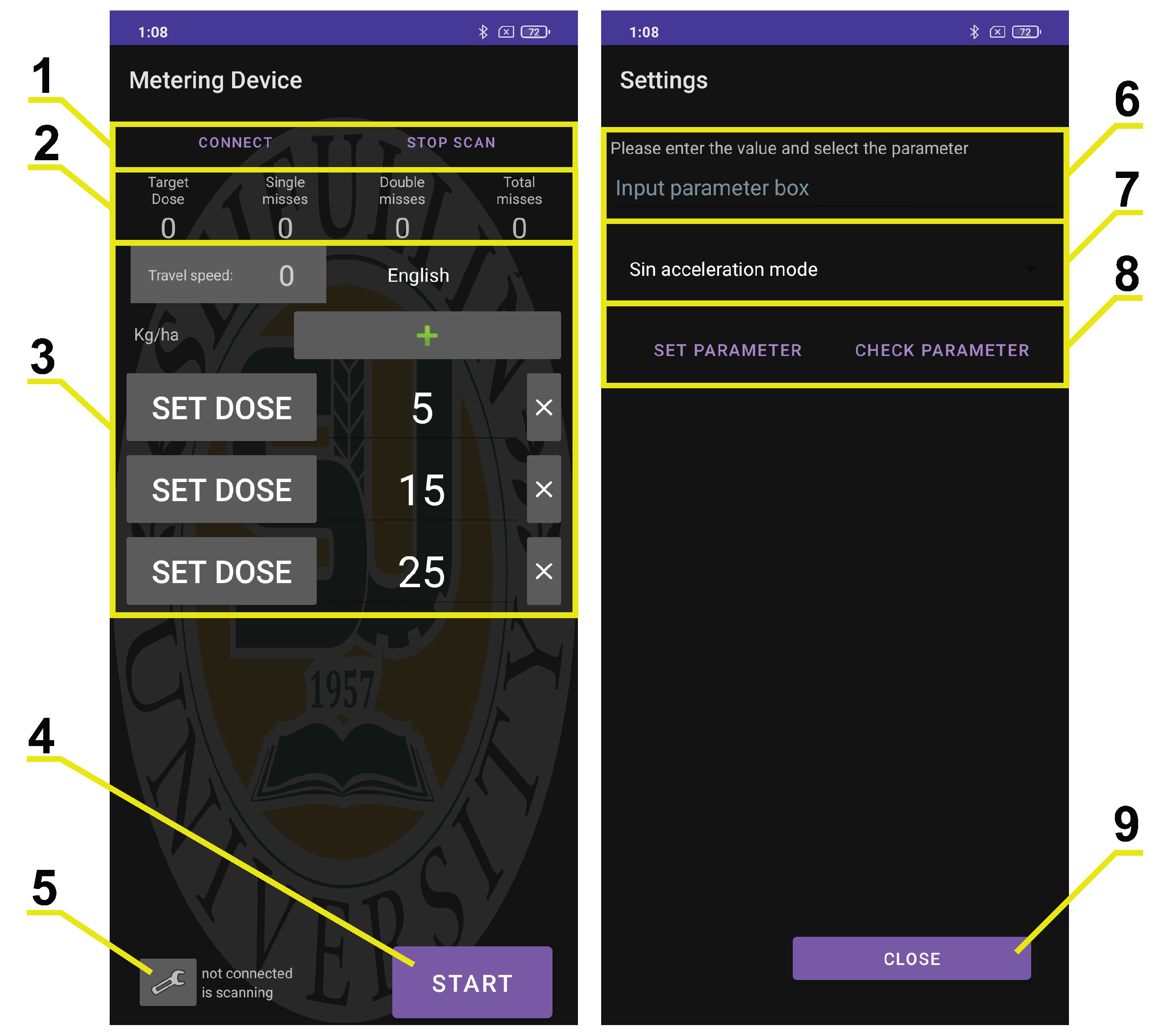

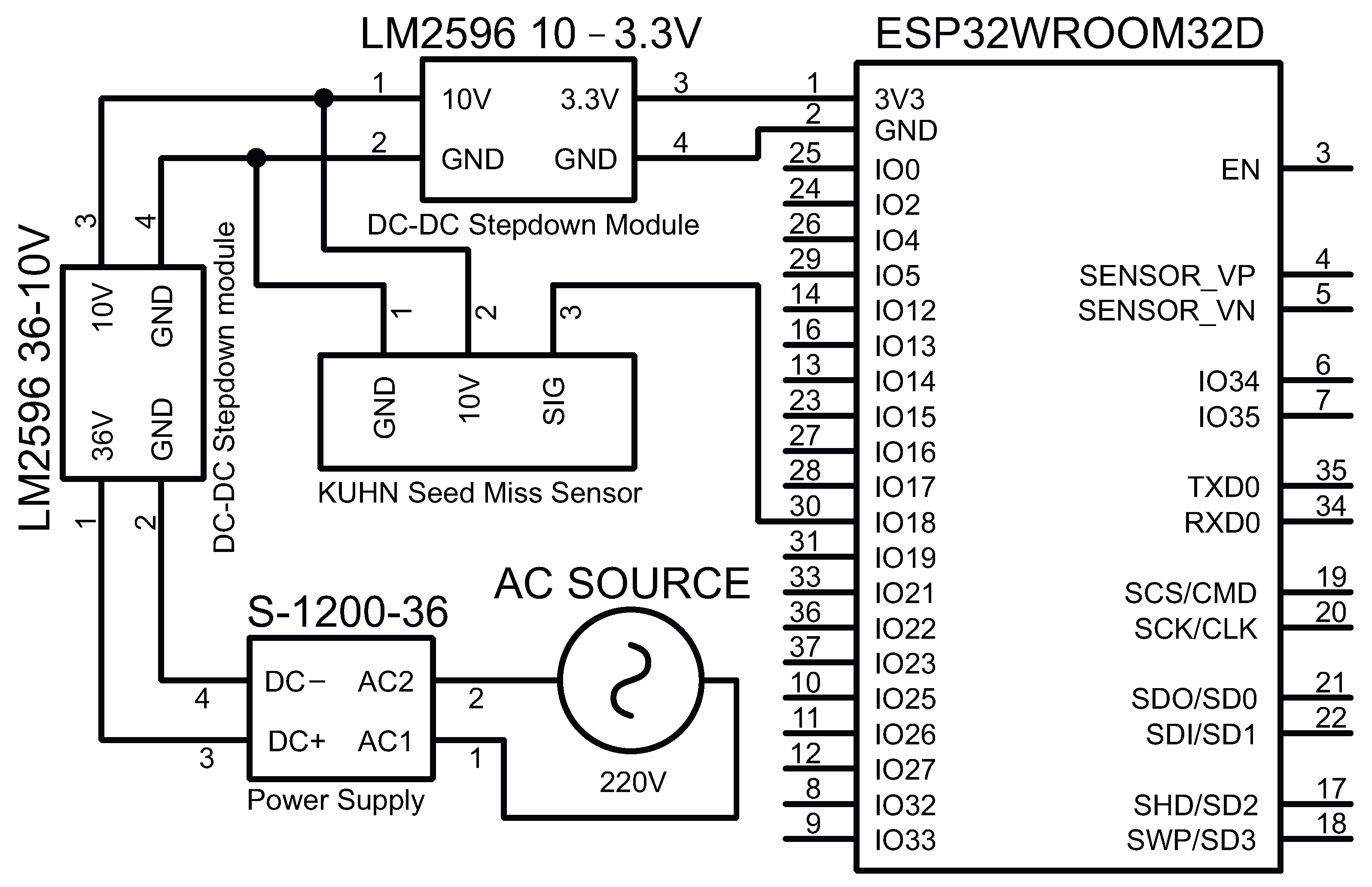

2.4.1. Adapting Seed Miss Prevention System Electronics for Spoon-Wheel Type Precision Seed Metering Device

2.4.2. Mechanical Modification of the Seed Metering Device

2.4.3. Software Implementation and Control System

2.5. Laboratory Experimentation

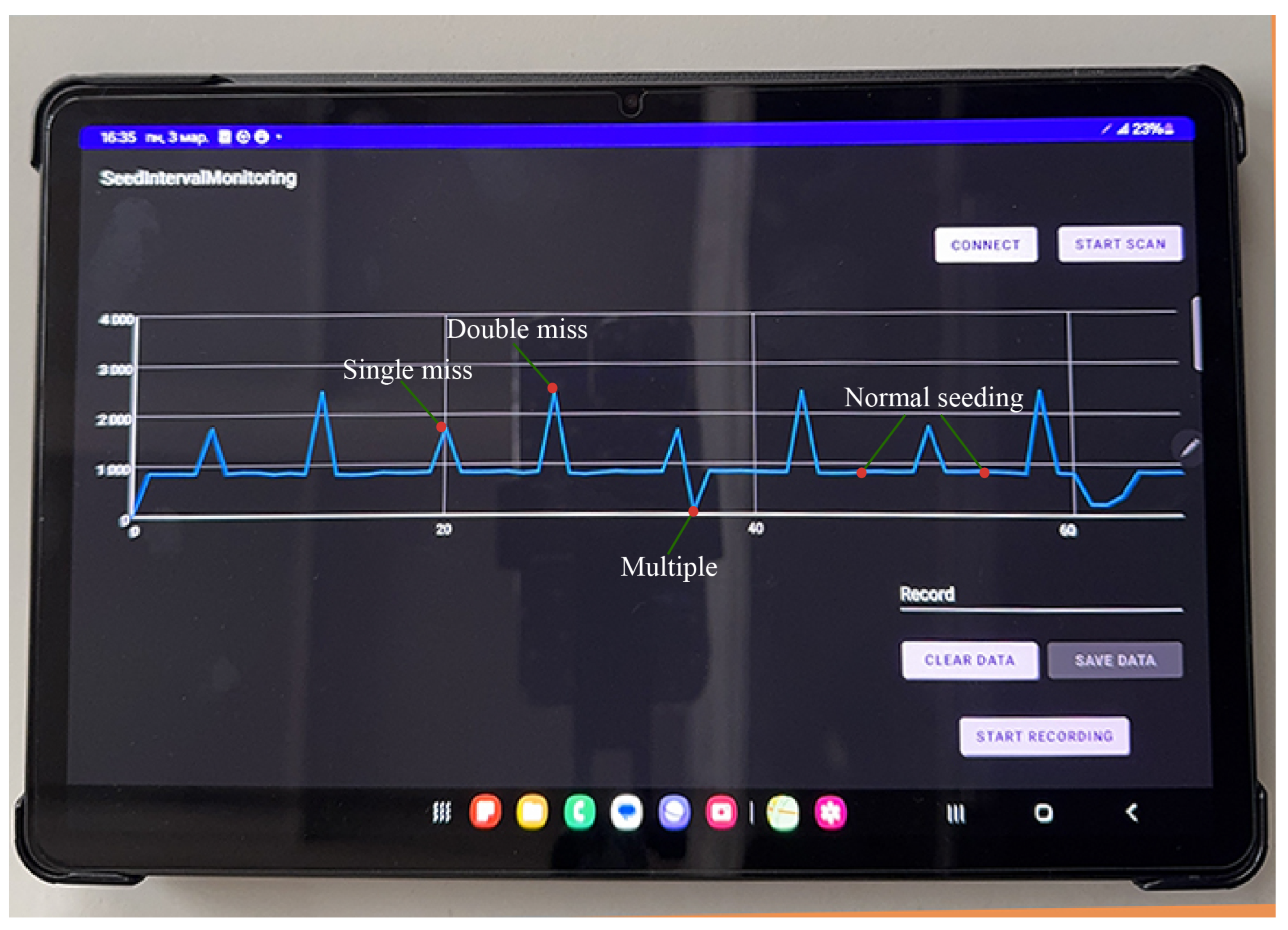

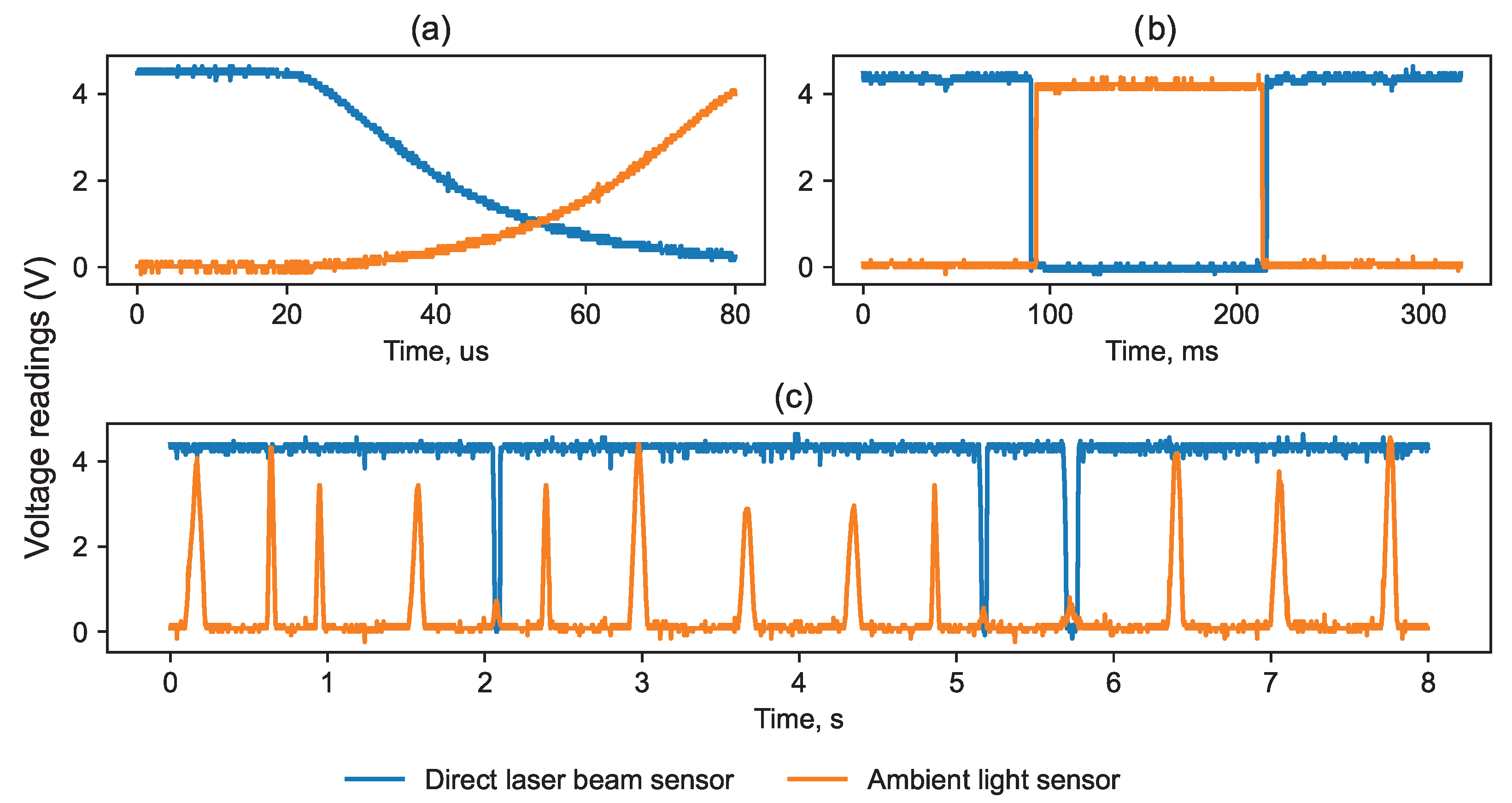

2.5.1. Design of Data Acquisition Instrumentation

2.5.2. Design Experiment

3. Results and Discussion

3.1. Results of DEM Simulation

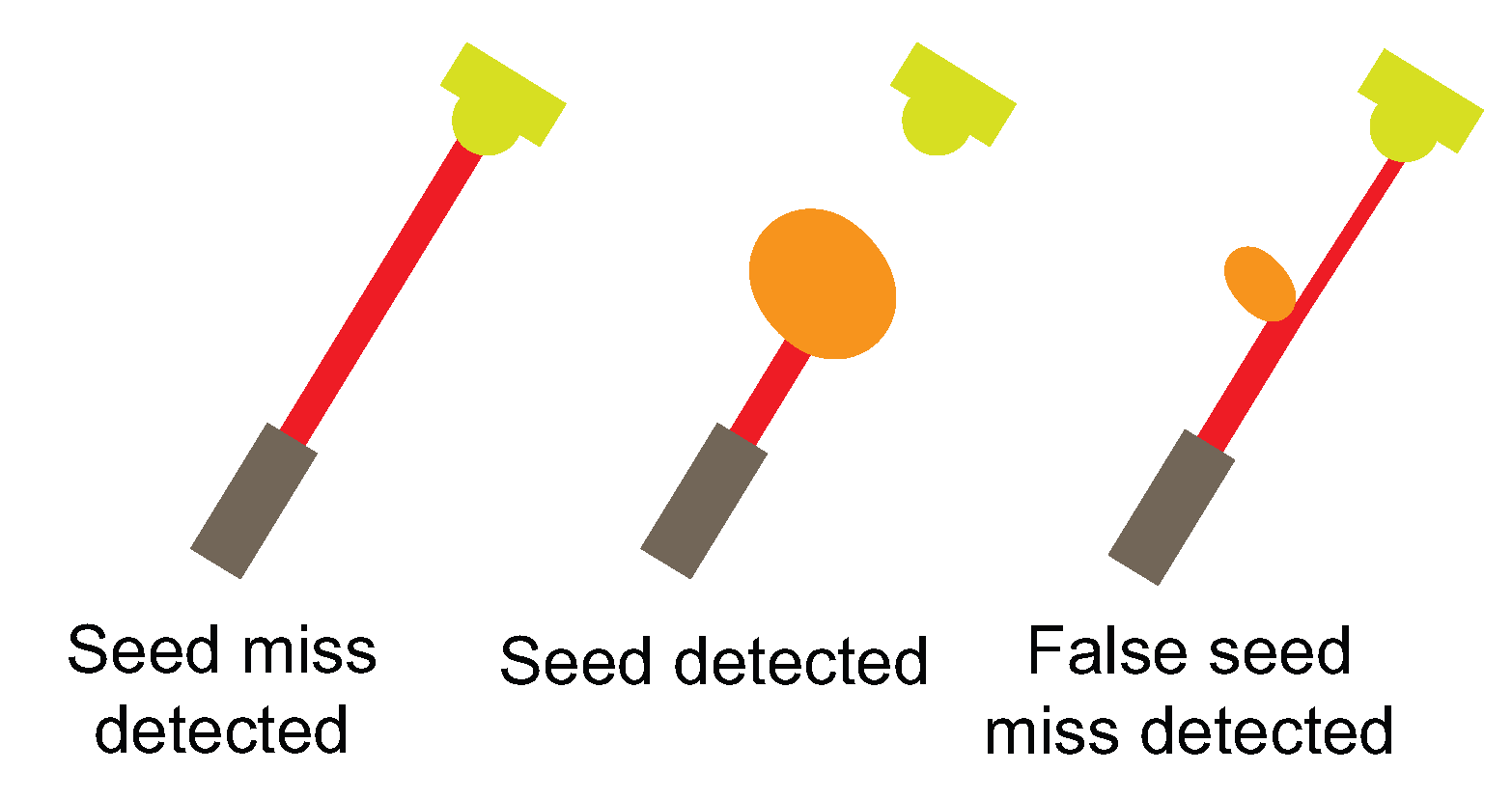

3.2. Results of Retrofitting and Signal Analysis

3.3. Experimental Results

3.3.1. One Sensor Setup

3.3.2. Two-Sensor Setup

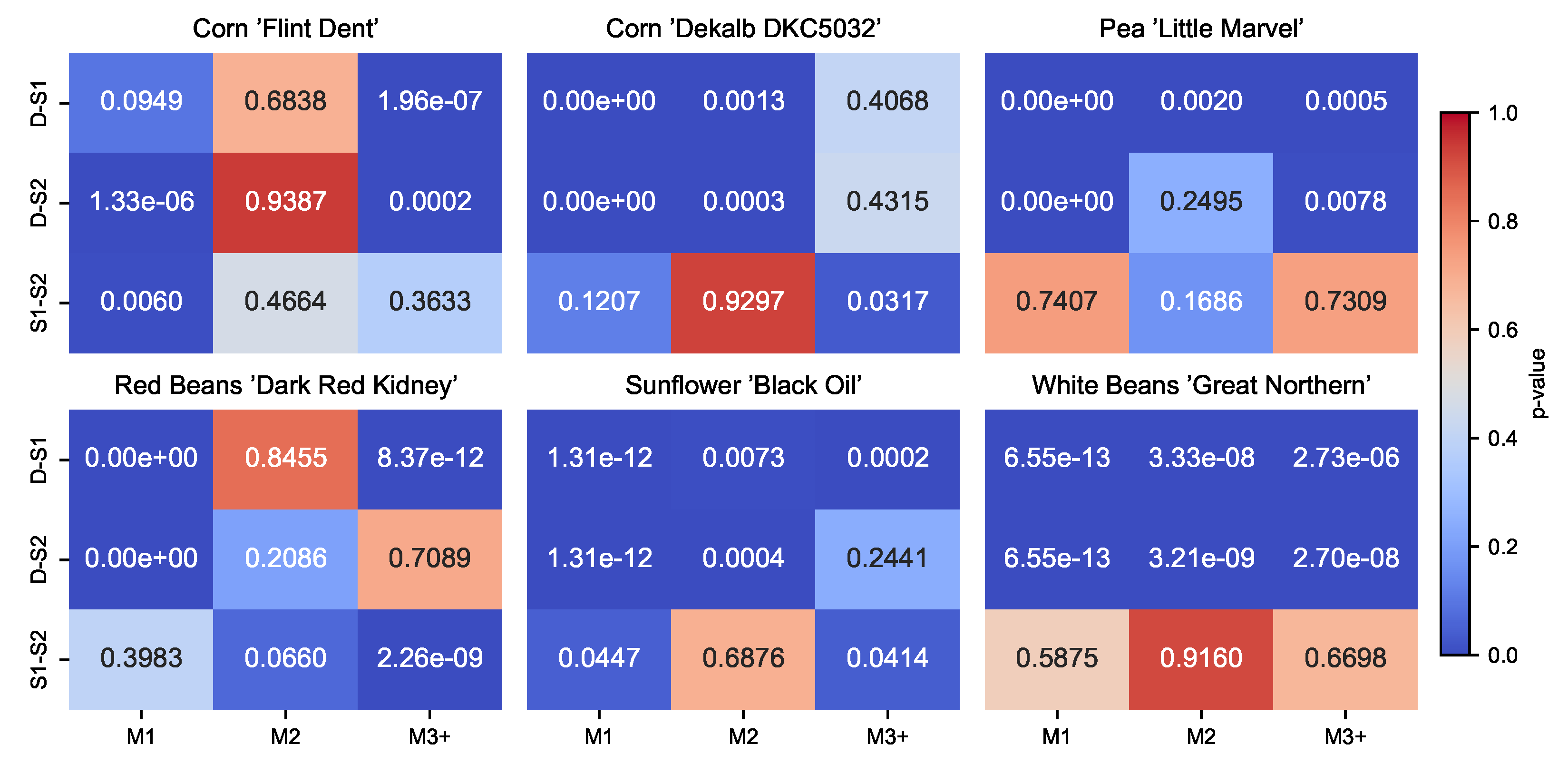

3.3.3. Tukey Test Results

3.3.4. Real-World Applicability and Discussion

- -

- Miss detection accuracy. Although the system, especially with two sensors, clearly demonstrated significant seed miss prevention capability, the target zero or near-zero miss prevention was not achieved, as we could not bring the seed Miss Index to zero by using the system. Even though using an additional ambient light sensor seemed to solve the problem of false positive seed miss detection, it is not clear if this completely eliminated false positives, or whether some may still occur and hide among naturally occurring multiples.

- -

- Operational speed constraints. Although data at high rpms suggest a degradation in performance, practical operation likely remains within the threshold due to the relatively poor seeding speed characteristic of the metering device itself. Future studies might focus on refining the system on better-performing seed metering devices that are less affected by centrifugal and inertial forces.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Seed Miss Prevention System Hardware

Appendix B. Data Acquisition Hardware

Appendix C. Recommended Operational Parameters

| Crop & Variety | Recommended Operational Parameters 1 | Baseline Performance (No SMPS at 10 rpm) | Miss Index in Recomemded Range | Performance Metrics at 10 rpm 2 | Key Finding and Limitation |

|---|---|---|---|---|---|

| Corn ‘Dekalb DKC5032’ | Optimal Speed: 3–10 rpm. Est. Tractor Speed: 0.8–2.7 km/h. (at seed spacing 25 cm) | 4.8% Miss Index | 0.001–0.007 | Baseline (No SMPS): 4.8% With SMPS (S2): 0.7% Effectiveness: 85.4% Improvement | The system performs best with uniform seeds, effectively maintaining precision. |

| Corn ‘Flint Dent’ | Optimal Speed: 3–10 rpm. Est. Tractor Speed: 1.6–5.4 km/h. (at seed spacing 25 cm) | 2.9% Miss Index | 0.007–0.022 | Baseline (No SMPS): 2.2% With SMPS (S2): 1.2% Effectiveness: 45.5% Improvement | More challenging than uniform hybrids due to variable seed size. The SMPS provides a notable, but not total, reduction in misses. |

| Sunflower ‘Black Oil’ | Optimal Speed: 3–15 rpm. Est. Tractor Speed: 4.5–9.0 km/h. (at seed spacing 35 cm) | 3.6% Miss Index | 0.001–0.029 | Baseline (No SMPS): 6.4% With SMPS (S2): 1.3% Effectiveness: 79.7% Improvement | Shows excellent performance and stability even at higher operational speeds compared to irregular seeds. |

| Pea ‘Little Marvel’ | Optimal Speed: 3–10 rpm. Est. Tractor Speed: 0.9–2.4 km/h. (at seed spacing 8 cm) | 2.7% Miss Index | 0.001–0.025 | Baseline (No SMPS): 5.0% With SMPS (S2): 0.5% Effectiveness: 90.0% Improvement | At speeds above 10 rpm, miss indices exceed practical thresholds for precision agriculture. |

| Beans, Red ‘Dark Red Kidney’ | Optimal Speed: 3–10 rpm. Est. Tractor Speed: 1.8–6.0 km/h. (at seed spacing 15 cm) | 5.0% Miss Index | 0.002–0.017 | Baseline (No SMPS): 4.6% With SMPS (S2): 0.4% Effectiveness: 91.3% Improvement | Higher miss rates at increased speeds due to the mechanical limitations of the metering device handling irregular forms. |

| Beans, White ‘Great Northern’ | Optimal Speed: 3–10 rpm. Est. Tractor Speed: 1.8–3.0 km/h. (at seed spacing 15 cm) | 6.1% Miss Index | 0.003–0.015 | Baseline (No SMPS): 8.1% With SMPS (S2): 2.9% Effectiveness: 64.2% Improvement | At higher speeds (≥15 rpm), miss rates increase significantly, particularly for irregularly shaped seeds like white beans. |

References

- Balafoutis, A.; Beck, B.; Fountas, S.; Vangeyte, J.; Wal, T.V.D.; Soto, I.; Gómez-Barbero, M.; Barnes, A.; Eory, V. Precision Agriculture Technologies positively contributing to GHG emissions mitigation, farm productivity and economics. Sustainability 2017, 9, 1339. [Google Scholar] [CrossRef]

- Zatserkovny, V.; Vorokh, V. Differential technologies of precision agriculture. Tech. Sci. Technol. 2024, 2024, 1–5. [Google Scholar] [CrossRef]

- Ahmed, K.; Saleh, A.; Musa, A.; Kalu, G. Determination of selected parameters that influence planting space uniformity on maize seed. Fudma J. Sci. 2023, 7, 30–33. [Google Scholar] [CrossRef]

- Xu, C.; Li, R.; Song, W.; Wu, T.; Sun, S.; Han, T.; Wu, C. High Density and Uniform Plant Distribution Improve Soybean Yield by Regulating Population Uniformity and Canopy Light Interception. Agronomy 2021, 11, 1880. [Google Scholar] [CrossRef]

- Badua, S.; Sharda, A.; Flippo, D. Sensing system for real-time measurement of seed spacing, depth, and geo-location of corn: A proof-of-concept study. Trans. ASABE 2019, 62, 1779–1788. [Google Scholar] [CrossRef]

- Ahmad, S.F.; Dar, A.H. Precision farming for resource use efficiency. In Resources Use Efficiency in Agriculture; Springer: Singapore, 2020; pp. 109–135. [Google Scholar]

- Xiyin, W. Improve design and experiment on spoon of spoon precision seed metering device. J. Northeast Agric. Univ. 2015, 46, 79–85. [Google Scholar]

- Wang, G.; Sun, W.; Zhang, H.; Liu, X.; Li, H.; Yang, X.; Zhu, L. Research on a kind of seeding-monitoring and compensating control system for potato planter without additional seed-metering channel. Comput. Electron. Agric. 2020, 177, 105681. [Google Scholar] [CrossRef]

- Chen, Z.; Xue, D.; Guan, W.; Guo, J.; Liu, Z. Performance Optimization of a Spoon Precision Seed Metering Device Based on a Maize Seed Assembly Model and Discrete Element Method. Processes 2023, 11, 3076. [Google Scholar] [CrossRef]

- Wang, Q.; Han, D.D.; Xu, Y.Z.; Huang, Y.; Tang, C.; Li, W. Experimental study on the seeding performance of the spoon-wheel maize seed-metering device under vibration conditions. INMATEH Agric. Eng. 2024, 72, 324–338. [Google Scholar] [CrossRef]

- Chakraborty, D.; Ladha, J.K.; Rana, D.S.; Jat, M.L.; Gathala, M.K.; Yadav, S.; Rao, A.N.; Ramesha, M.S.; Raman, A. A global analysis of alternative tillage and crop establishment practices for economically and environmentally efficient rice production. Sci. Rep. 2017, 7, 9342. [Google Scholar] [CrossRef]

- Barr, J.B.; Desbiolles, J.M.; Fielke, J.M.; Ucgul, M. Development and field evaluation of a high-speed no–till seeding system. Soil Tillage Res. 2019, 194, 104337. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, J.; Zhang, X.; Shi, Z.; Wang, M.; Wu, H.; Fu, H. Design and experiment of pressure-holding precision seed-metering device for maize. INMATEH Agric. Eng. 2023, 69, 13–25. [Google Scholar] [CrossRef]

- Kai-xing, Z.; Yuanyuan, S.; Lei, L.; Xianxi, L.; Xiuyan, Z. Design and test of variable diameter pneumatic drum type bean seed metering device. INMATEH-Agric. Eng. 2020, 60, 9–18. [Google Scholar] [CrossRef]

- Tian, L.; Ding, Z.; Su, Z.; Li, L.; Wang, Z. Design and experiment of rotary precision hill direct seed-metering device for rice. INMATEH Agric. Eng. 2022, 66, 311. [Google Scholar] [CrossRef]

- Zhang, J.; Hou, Y.; Ji, W.; Zheng, P.; Yan, S.; Hou, S.; Cai, C. Evaluation of a Real-Time Monitoring and Management System of Soybean Precision Seed Metering Devices. Agronomy 2023, 13, 541. [Google Scholar] [CrossRef]

- Liu, Z.; Xia, J.; Hu, M.; Du, J.; Luo, C.; Zheng, K. Design and analysis of a performance monitoring system for a seed metering device based on pulse width recognition. PLoS ONE 2021, 16, e0261593. [Google Scholar] [CrossRef]

- Borja, A.A.; Amongo, R.M.C.; Suministrado, D.C.; Pabico, J.P. A machine vision assisted mechatronic seed meter for precision planting of corn. In Proceedings of the 2018 3rd International Conference on Control and Robotics Engineering (ICCRE), Nagoya, Japan, 20–23 April 2018; pp. 183–187. [Google Scholar]

- Nikolay, Z.; Nikolay, K.; Gao, X.; Li, Q.W.; Mi, G.P.; Huang, Y.X. Design and testing of novel seed miss prevention system for single seed precision metering devices. Comput. Electron. Agric. 2022, 198, 107048. [Google Scholar] [CrossRef]

- Goyal, D.; Vanraj; Pabla, B.; Dhami, S. Non-contact sensor placement strategy for condition monitoring of rotating machine-elements. Eng. Sci. Technol. Int. J. 2019, 22, 489–501. [Google Scholar] [CrossRef]

- Colyer, S.L.; Evans, M.; Cosker, D.P.; Salo, A.I. A review of the evolution of vision-based motion analysis and the integration of advanced computer vision methods towards developing a markerless system. Sport. Med.-Open 2018, 4, 24. [Google Scholar] [CrossRef]

- Li, Y.; Zang, L.; Shi, T.; Lv, T.; Lin, F. Design and dynamic simulation analysis of a wheel–track composite chassis based on RecurDyn. World Electr. Veh. J. 2021, 13, 12. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, Y.; Chen, J.; Zheng, Z.; Hu, C.; Cao, J. Design and experiment of the buckwheat hill-drop planter hole forming device. Agriculture 2021, 11, 1085. [Google Scholar] [CrossRef]

- Ishida, T. Application of distinct element analysis to three simple block models aimed at practical application to toppling failure of fissured rock slopes. Comput. Geotech. 1990, 9, 341–353. [Google Scholar] [CrossRef]

- Jensen, R.P.; Bosscher, P.J.; Plesha, M.E.; Edil, T.B. DEM simulation of granular media—structure interface: Effects of surface roughness and particle shape. Int. J. Numer. Anal. Methods Geomech. 1999, 23, 531–547. [Google Scholar] [CrossRef]

- Tan, Y.; Yang, D.; Sheng, Y. Discrete element method (DEM) modeling of fracture and damage in the machining process of polycrystalline SiC. J. Eur. Ceram. Soc. 2009, 29, 1029–1037. [Google Scholar] [CrossRef]

- Chen, L.; Mou, X.; Peng, Z. Application of discrete element method in agricultural engineering. Adv. Mod. Agric. 2022, 2, 2084. [Google Scholar] [CrossRef]

- Tijskens, E.; Ramon, H.; De Baerdemaeker, J. Discrete element modelling for process simulation in agriculture. J. Sound Vib. 2003, 266, 493–514. [Google Scholar] [CrossRef]

- Guzman, L.J.; Chen, Y.; Landry, H. Discrete element modeling of seed metering as affected by roller speed and damping coefficient. Trans. ASABE 2020, 63, 189–198. [Google Scholar] [CrossRef]

- Jun, G.; Yue, Y.; Memon, M.S.; Chuang, T.; Linyu, W.; Pei, T. Design and simulation for seeding performance of high-speed inclined corn metering device based on discrete element method (DEM). Sci. Rep. 2022, 12, 19415. [Google Scholar] [CrossRef]

- Adilet, S.; Zhao, J.; Sayakhat, N.; Chen, J.; Nikolay, Z.; Bu, L.; Sugirbayeva, Z.; Hu, G.; Marat, M.; Wang, Z. Calibration strategy to determine the interaction properties of fertilizer particles using two laboratory tests and DEM. Agriculture 2021, 11, 592. [Google Scholar] [CrossRef]

- Tekeste, M.Z.; Mousaviraad, M.; Rosentrater, K.A. Discrete element model calibration using multi-responses and simulation of corn flow in a commercial grain auger. Trans. ASABE 2018, 61, 1743–1755. [Google Scholar] [CrossRef]

- Mousaviraad, M.; Tekeste, M.Z.; Rosentrater, K.A. Calibration and validation of a discrete element model of corn using grain flow simulation in a commercial screw grain auger. Trans. ASABE 2017, 60, 1403. [Google Scholar] [CrossRef]

- Yu, Y.; Fu, H.; Yu, J. DEM-based simulation of the corn threshing process. Adv. Powder Technol. 2015, 26, 1400–1409. [Google Scholar] [CrossRef]

- Han, D.; Zhang, D.; Jing, H.; Yang, L.; Cui, T.; Ding, Y.; Wang, Z.; Wang, Y.; Zhang, T. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Gao, X.; Cui, T.; Zhou, Z.; Yu, Y.; Xu, Y.; Zhang, D.; Song, W. DEM study of particle motion in novel high-speed seed metering device. Adv. Powder Technol. 2021, 32, 1438–1449. [Google Scholar] [CrossRef]

- Wei, H.; Zan, L.; Li, Y.; Wang, Z.; Saxén, H.; Yu, Y. Numerical and experimental studies of corn particle properties on the forming of pile. Powder Technol. 2017, 321, 533–543. [Google Scholar] [CrossRef]

- González-Montellano, C.; Fuentes, J.; Ayuga-Téllez, E.; Ayuga, F. Determination of the mechanical properties of maize grains and olives required for use in DEM simulations. J. Food Eng. 2012, 111, 553–562. [Google Scholar] [CrossRef]

- Boac, J.; Casada, M.; Pordesimo, L.; Petingco, M.; Maghirang, R.; Harner III, J. Evaluation of particle models of corn kernels for discrete element method simulation of shelled corn mass flow. Smart Agric. Technol. 2023, 4, 100197. [Google Scholar] [CrossRef]

- Li, H.; Zeng, R.; Niu, Z.; Zhang, J. A calibration method for contact parameters of maize kernels based on the discrete element method. Agriculture 2022, 12, 664. [Google Scholar] [CrossRef]

- Chen, Z.; Wassgren, C.; Veikle, E.; Ambrose, K. Determination of material and interaction properties of maize and wheat kernels for DEM simulation. Biosyst. Eng. 2020, 195, 208–226. [Google Scholar] [CrossRef]

- Simões, B.D.; Marques, E.A.; Carbas, R.J.; Maul, S.; Stihler, P.; Weißgraeber, P.; da Silva, L.F. Rheological and Mechanical Properties of an Acrylic PSA. Polymers 2023, 15, 3843. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, Z.; Yu, Y.; Liu, T.; Zhang, Z. Determination of the energetic coefficient of restitution of maize grain based on laboratory experiments and DEM simulations. Powder Technol. 2020, 362, 645–658. [Google Scholar] [CrossRef]

- Horabik, J.; Molenda, M. Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosyst. Eng. 2016, 147, 206–225. [Google Scholar] [CrossRef]

- Stigh, U.; Biel, A. Effects of strain rate on the cohesive properties and fracture process of a pressure sensitive adhesive. Eng. Fract. Mech. 2018, 203, 266–275. [Google Scholar] [CrossRef]

- Pawar, E. A review article on acrylic PMMA. IOSR J. Mech. Civ. Eng 2016, 13, 1–4. [Google Scholar]

- Wang, L.; Wu, B.; Wu, Z.; Li, R.; Feng, X. Experimental determination of the coefficient of restitution of particle-particle collision for frozen maize grains. Powder Technol. 2018, 338, 263–273. [Google Scholar] [CrossRef]

- Batista, J.; Santos, D.; Béttega, R. Determination of the physical and interaction properties of sorghum grains: Application to computational fluid dynamics–discrete element method simulations of the fluid dynamics of a conical spouted bed. Particuology 2021, 54, 91–101. [Google Scholar] [CrossRef]

- Chen, Z.; Wassgren, C.; Ambrose, K. Measurements of grain kernel friction coefficients using a reciprocating-pin tribometer. Trans. ASABE 2020, 63, 675–685. [Google Scholar] [CrossRef]

- Hastie, D. Experimental measurement of the coefficient of restitution of irregular shaped particles impacting on horizontal surfaces. Chem. Eng. Sci. 2013, 101, 828–836. [Google Scholar] [CrossRef]

- Zagainov, N.; Kostyuchenkov, N.; Huang, Y.X.; Sugirbay, A.; Xian, J. Line laser based sensor for real-time seed counting and seed miss detection for precision planter. Opt. Laser Technol. 2023, 167, 109742. [Google Scholar] [CrossRef]

- Singh, R.; Singh, G.; Saraswat, D. Optimisation of design and operational parameters of a pneumatic seed metering device for planting cottonseeds. Biosyst. Eng. 2005, 92, 429–438. [Google Scholar] [CrossRef]

- Xiong, D.; Wu, M.; Xie, W.; Liu, R.; Luo, H. Design and experimental study of the general mechanical pneumatic combined seed metering device. Appl. Sci. 2021, 11, 7223. [Google Scholar] [CrossRef]

- Wang, Q.; Han, D.; Chen, L.; Huang, Y.; Li, W.; Tang, C. Simulation and optimization of the spoon-wheel type maize precision seed-metering device based on vibration. INMATEH Agric. Eng. 2024, 73, 17–28. [Google Scholar] [CrossRef]

| Input Parameter | Value |

|---|---|

| Particle shape | Figure 3 |

| Particle mass | varies |

| Corn particles | |

| Young’s modulus (MPa) | 26 |

| Poisson’s ratio | 0.4 |

| Density (kg/m3) | 1450 |

| Acrylic plastic (PMMA) | |

| Young’s modulus (GPa) | 3.0 |

| Poisson’s ratio | 0.37 |

| Density (kg/m3) | 1180 |

| Galvanized steel | |

| Young’s modulus (GPa) | 208 |

| Poisson’s ratio | 0.3 |

| Density (kg/m3) | 7850 |

| Coefficients of static friction | |

| Corn–corn | 0.372 |

| Corn–acrylic plastic | 0.22 |

| Corn–galvanized steel | 0.45 |

| Coefficients of restitution | |

| Corn–corn | 0.3 |

| Corn–acrylic plastic | 0.62 |

| Corn–galvanized steel | 0.613 |

| Coefficients of rolling friction | |

| Corn–corn | |

| Corn–acrylic plastic | |

| Corn–galvanized steel | |

| Particle generation properties | |

| Standard deviation | 0.11 |

| Lower limit | 0.67 |

| Upper limit | 1.33 |

| Mode | Cultivar | SMPS Disabled | SMPS with 1 Sensor | SMPS with 2 Sensors | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| rpm | rpm | rpm | |||||||||||

| 3 | 5 | 10 | 15 | 3 | 5 | 10 | 15 | 3 | 5 | 10 | 15 | ||

| Count | Corn ‘Flint Dent’ | 1009 | 1033 | 1015 | 1000 | 1016 | 1239 | 1228 | 920 | 1001 | 1038 | 1014 | 1028 |

| Corn ‘Dekalb DKC5032’ | 1006 | 1000 | 1028 | 1013 | 1039 | 1027 | 963 | 921 | 1057 | 1050 | 1053 | 1017 | |

| Pea ‘Little Marvel’ | 1049 | 1014 | 1015 | 1018 | 996 | 1012 | 1129 | 985 | 1021 | 1021 | 1019 | 1031 | |

| Red beans ‘Dark Red Kidney’ | 1025 | 1028 | 1082 | 1026 | 1029 | 1003 | 1028 | 1007 | 1005 | 1003 | 1042 | 1057 | |

| Sunflower ‘Black Oil’ | 1000 | 1025 | 1015 | 1033 | 1014 | 1019 | 1014 | 1021 | 1016 | 1001 | 1029 | 1035 | |

| White balls (non-organic) | 1023 | 1016 | 1025 | 1046 | 1011 | 1009 | 1029 | 1046 | 1005 | 1012 | 1011 | 1010 | |

| White beans ‘Great Northern’ | 1002 | 1010 | 1001 | 1015 | 1023 | 1015 | 1015 | 1038 | 1014 | 1011 | 1009 | 1026 | |

| Single Misses | Corn ‘Flint Dent’ | 21 | 21 | 8 | 7 | 2 | 5 | 8 | 26 | 0 | 0 | 1 | 13 |

| Corn ‘Dekalb DKC5032’ | 22 | 26 | 12 | 16 | 1 | 1 | 2 | 13 | 0 | 1 | 1 | 0 | |

| Pea ‘Little Marvel’ | 39 | 54 | 47 | 41 | 9 | 7 | 14 | 42 | 0 | 4 | 18 | 39 | |

| Red beans ‘Dark Red Kidney’ | 55 | 39 | 48 | 27 | 4 | 2 | 6 | 19 | 1 | 1 | 3 | 11 | |

| Sunflower ‘Black Oil’ | 48 | 48 | 26 | 32 | 5 | 4 | 8 | 27 | 1 | 2 | 2 | 11 | |

| White balls (non-organic) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| White beans ‘Great Northern’ | 82 | 71 | 53 | 156 | 22 | 4 | 10 | 69 | 15 | 3 | 7 | 61 | |

| Double Misses | Corn ‘Flint Dent’ | 1 | 1 | 2 | 0 | 0 | 0 | 3 | 4 | 0 | 0 | 0 | 3 |

| Corn ‘Dekalb DKC5032’ | 2 | 1 | 8 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | |

| Pea ‘Little Marvel’ | 7 | 6 | 3 | 5 | 0 | 0 | 1 | 3 | 0 | 0 | 0 | 13 | |

| Red beans ‘Dark Red Kidney’ | 1 | 3 | 2 | 4 | 0 | 0 | 1 | 11 | 0 | 0 | 0 | 3 | |

| Sunflower ‘Black Oil’ | 3 | 3 | 6 | 3 | 0 | 0 | 0 | 4 | 0 | 0 | 0 | 1 | |

| White balls (non-organic) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| White beans ‘Great Northern’ | 7 | 9 | 6 | 33 | 0 | 0 | 0 | 14 | 0 | 0 | 0 | 11 | |

| More than two Misses | Corn ‘Flint Dent’ | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 32 | 0 | 0 | 0 | 25 |

| Corn ‘Dekalb DKC5032’ | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 6 | 0 | 0 | 0 | 0 | |

| Pea ‘Little Marvel’ | 0 | 1 | 0 | 5 | 0 | 1 | 3 | 26 | 0 | 0 | 0 | 25 | |

| Red beans ‘Dark Red Kidney’ | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 33 | 0 | 0 | 0 | 4 | |

| Sunflower ‘Black Oil’ | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 15 | 0 | 0 | 0 | 6 | |

| White balls (non-organic) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| White beans ‘Great Northern’ | 0 | 0 | 0 | 7 | 0 | 0 | 0 | 50 | 0 | 0 | 0 | 57 | |

| Miss Index | Corn ‘Flint Dent’ | 0.022 | 0.022 | 0.012 | 0.007 | 0.002 | 0.004 | 0.029 | 0.159 | 0.000 | 0.000 | 0.001 | 0.144 |

| Corn ‘Dekalb DKC5032’ | 0.025 | 0.027 | 0.027 | 0.025 | 0.001 | 0.001 | 0.002 | 0.046 | 0.000 | 0.001 | 0.001 | 0.000 | |

| Pea ‘Little Marvel’ | 0.048 | 0.064 | 0.050 | 0.063 | 0.009 | 0.010 | 0.024 | 0.131 | 0.000 | 0.004 | 0.017 | 0.128 | |

| Red beans ‘Dark Red Kidney’ | 0.053 | 0.042 | 0.046 | 0.033 | 0.004 | 0.002 | 0.013 | 0.186 | 0.001 | 0.001 | 0.003 | 0.029 | |

| Sunflower ‘Black Oil’ | 0.051 | 0.050 | 0.036 | 0.035 | 0.005 | 0.004 | 0.008 | 0.082 | 0.001 | 0.002 | 0.002 | 0.030 | |

| White balls (non-organic) | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | |

| White beans ‘Great Northern’ | 0.087 | 0.081 | 0.061 | 0.194 | 0.021 | 0.004 | 0.010 | 0.280 | 0.015 | 0.003 | 0.007 | 0.282 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bakirov, A.; Kostyuchenkov, N.; Kostyuchenkova, O.; Grishin, A.; Omarbekova, A.; Zagainov, N. Application of Seed Miss Prevention System for a Spoon-Wheel Type Precision Seed Metering Device: Effectiveness and Limitations. Agriculture 2025, 15, 1363. https://doi.org/10.3390/agriculture15131363

Bakirov A, Kostyuchenkov N, Kostyuchenkova O, Grishin A, Omarbekova A, Zagainov N. Application of Seed Miss Prevention System for a Spoon-Wheel Type Precision Seed Metering Device: Effectiveness and Limitations. Agriculture. 2025; 15(13):1363. https://doi.org/10.3390/agriculture15131363

Chicago/Turabian StyleBakirov, Aldiyar, Nikolay Kostyuchenkov, Oksana Kostyuchenkova, Alexsandr Grishin, Aruzhan Omarbekova, and Nikolay Zagainov. 2025. "Application of Seed Miss Prevention System for a Spoon-Wheel Type Precision Seed Metering Device: Effectiveness and Limitations" Agriculture 15, no. 13: 1363. https://doi.org/10.3390/agriculture15131363

APA StyleBakirov, A., Kostyuchenkov, N., Kostyuchenkova, O., Grishin, A., Omarbekova, A., & Zagainov, N. (2025). Application of Seed Miss Prevention System for a Spoon-Wheel Type Precision Seed Metering Device: Effectiveness and Limitations. Agriculture, 15(13), 1363. https://doi.org/10.3390/agriculture15131363