1. Introduction

The challenges posed by global population growth and food security concerns have necessitated ongoing innovation in agricultural technology [

1,

2,

3,

4,

5]. Modern agricultural machinery increasingly integrates advanced technologies such as navigation, sensing, and communication to boost productivity, optimize resource use, and accelerate the shift toward smart agriculture [

6,

7,

8,

9,

10]. With the rapid evolution of information technology and precision agriculture, emerging production models demand greater intelligence, automation, and digitalization in equipment—making autonomy and precision inevitable trends. Among these advancements, autonomous navigation has become a cornerstone of smart agriculture [

11,

12,

13]. It has been widely applied to field operations such as tillage, seeding, fertilization, crop protection, and harvesting—delivering significant gains in operational efficiency, reducing labor dependency, and improving farmland management precision [

14,

15,

16,

17,

18,

19].

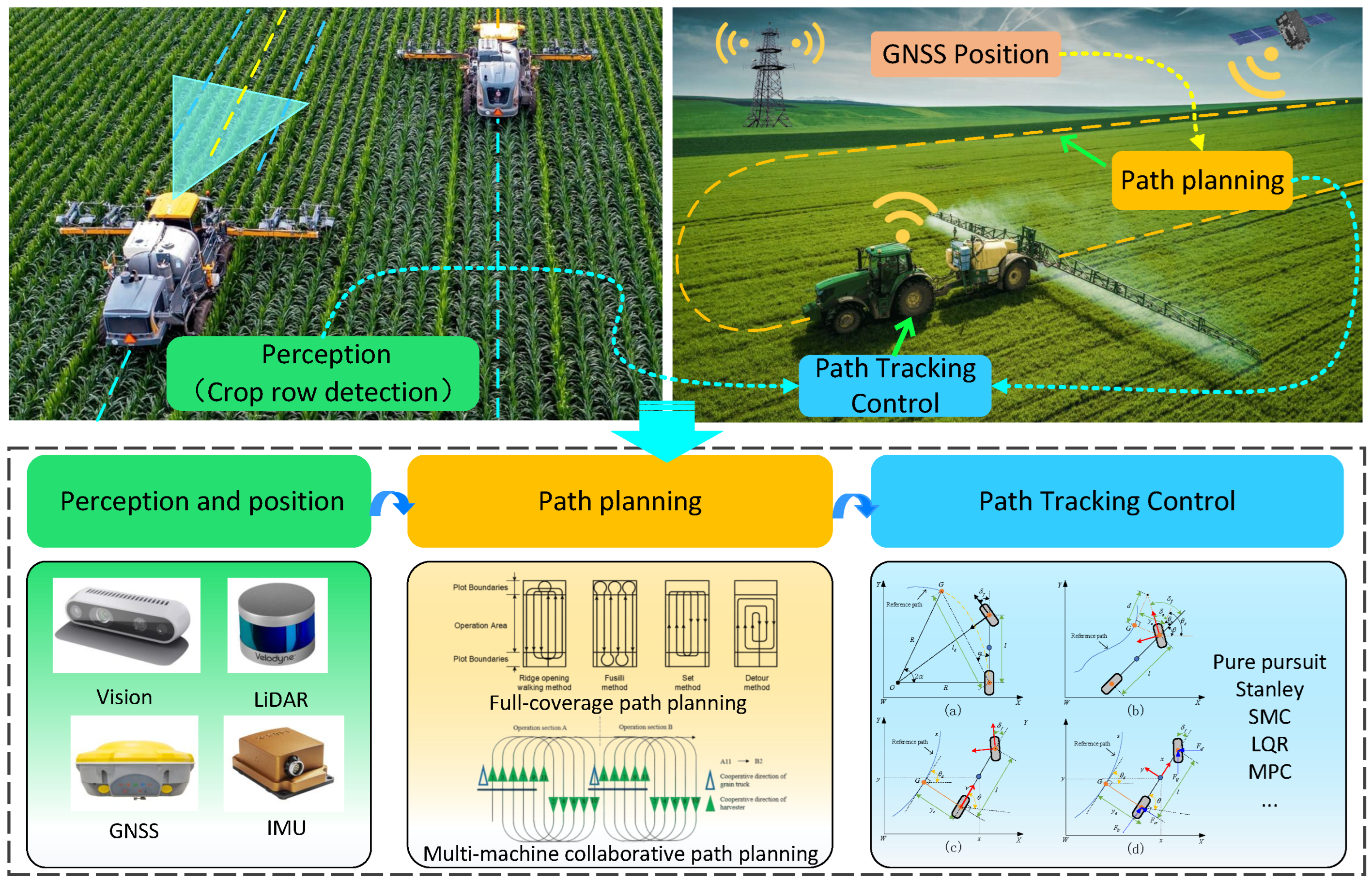

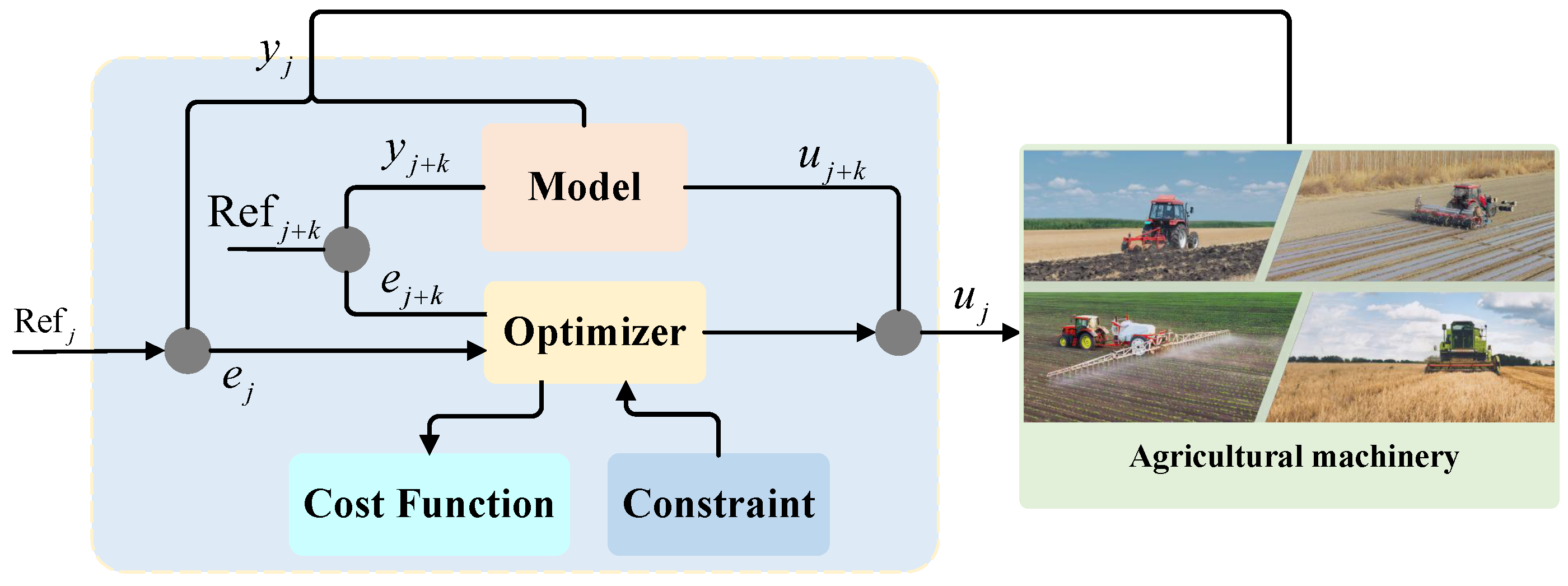

The core technological framework of autonomous navigation in field agricultural machinery primarily consists of three key components: environmental perception [

20,

21,

22,

23,

24], path planning [

25,

26], and path-tracking control [

27,

28] (

Figure 1). Environmental perception involves high-precision positioning and crop row recognition, forming the foundation for situational awareness in complex field environments. Path planning encompasses full-coverage path generation and multi-machine collaborative optimization, aimed at improving operational efficiency and coordination. Path-tracking control ensures that agricultural machinery accurately follows the planned path while maintaining stability and reliability during operation. In practical field applications, guidance systems have been shown to reduce overlaps by up to 6%, minimize gaps by up to 16%, and increase overall operational efficiency by as much as 20%, thereby lowering input usage and promoting both economic and environmental sustainability–particularly for small-scale farms [

29]. However, the unstructured nature of farmland, varying terrain and topography, diverse operational requirements, and unpredictable weather conditions continue to pose significant challenges to the practical implementation of autonomous agricultural navigation systems [

30].

In recent years, extensive academic research has driven significant advancements in the core technologies underpinning autonomous navigation for field agricultural machinery. High-precision positioning has evolved beyond traditional Global Navigation Satellite Systems (GNSS) to incorporate robust multi-sensor fusion strategies, enhancing stability in unstructured and dynamic field environments. Environmental perception has progressed through the integration of machine vision and LiDAR, enabling accurate crop row recognition, obstacle detection, and terrain mapping. Path planning methods have become more adaptive and computationally efficient by integrating operation-specific constraints and intelligent optimization algorithms, supporting both full-coverage planning and multi-machine coordination. Simultaneously, path-tracking control technologies–based on geometric, kinematic, and dynamic models–have achieved greater tracking accuracy and robustness under varying terrain and external disturbances. These technological advances provide a strong foundation for the development of intelligent and sustainable agricultural production systems.

This paper presents a structured and in-depth review of recent research advances in high-precision positioning, environmental perception, path planning, and path-tracking control for autonomous navigation in agricultural settings. In addition to synthesizing methodologies and application cases, this review critically examines prevailing technical challenges and outlines promising research directions aimed at promoting practical deployment in smart farming systems. The unique contribution of this review lies in its comprehensive and up-to-date synthesis of research over the past five years, specifically focused on field-based agricultural machinery. Unlike generic surveys, it dissects the core navigation modules–environmental perception, path planning, and path-tracking control–in an application-driven manner. It further compares the strengths, limitations, and suitable application conditions of different techniques. This integrative perspective offers both academic insights and practical guidance for advancing autonomous systems in real-world agricultural operations.

As the deployment of autonomous agricultural machinery progresses from research to commercial applications, adherence to international standards and safety regulations becomes increasingly critical. Guidelines such as ISO 18497 [

31] for the safety of highly automated agricultural machines, the EU Machinery Regulation (EU) 2023/1230 [

32], and region-specific policies in the U.S. and China play an essential role in ensuring the safe, transparent, and reliable operation of these systems. Although this review primarily focuses on core navigation technologies, the integration of technical innovation with regulatory compliance is indispensable for the real-world adoption and policy-driven deployment of autonomous tractors.

2. Positioning and Environmental Sensing

The positioning and perception technologies of agricultural machinery are critical enablers of autonomous navigation. Currently, the primary sensors employed for environmental perception include visual sensors [

33] and LiDAR [

34], while positioning systems are mainly based on GNSS and Inertial Navigation Systems (INS). The integration of GNSS and INS enables high-precision localization and navigation, thereby improving the stability and robustness of unmanned agricultural machinery [

35]. Furthermore, visual sensors and LiDAR are widely used for data acquisition related to crop row or navigation line recognition, particularly in between-row agricultural operations such as spraying and harvesting. Each type of sensor offers distinct advantages and limitations; thus, a comprehensive understanding and appropriate fusion of these sensing modalities can substantially enhance the perception capability and autonomy of agricultural machines.

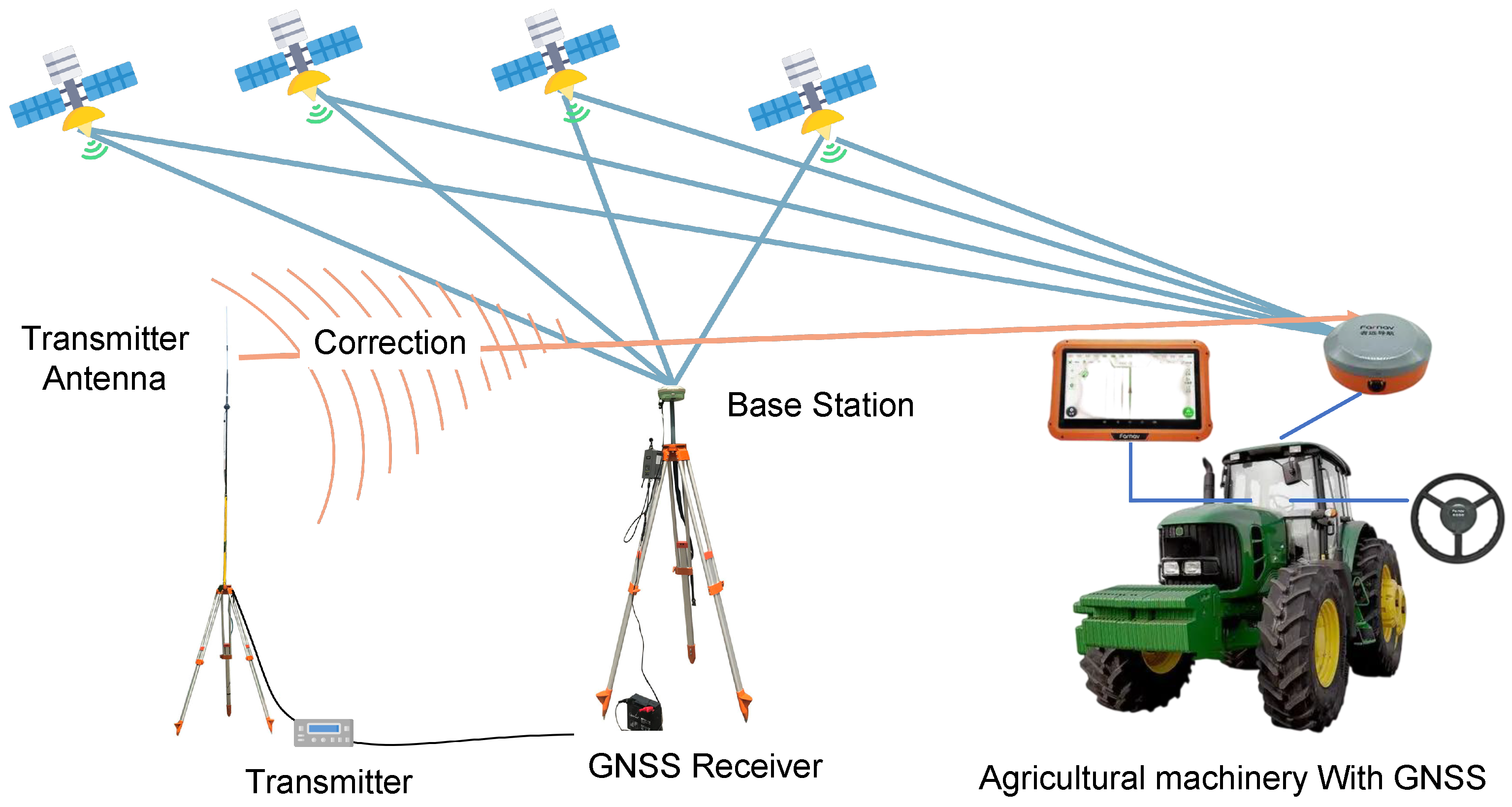

2.1. Positioning Technology

GNSS is a space-based positioning system composed of one or more satellite constellations. It provides users with all-weather, three-dimensional location, velocity, and time information anywhere on the Earth’s surface or in near-Earth space [

36,

37]. Currently, GNSS systems mainly include the United States’ Global Positioning System (GPS), Russia’s GLONASS, the European Union’s Galileo, and China’s BeiDou Satellite Navigation System (BDS). In agricultural machinery navigation, Real-Time Kinematic (RTK) technology (

Figure 2) is commonly used, which enables real-time centimeter-level positioning accuracy in open field environments [

38,

39]. However, satellite navigation positioning also has some limitations, such as susceptibility to adverse weather conditions and signal interruptions [

40]. The INS demonstrates high independence and reliability, achieving good accuracy in the short term. Due to the inherent limitations of individual navigation systems, integrated navigation has attracted significant research attention [

41]. Huang et al. [

42] proposed an RTK-GNSS and INS integrated navigation system to address the challenges of achieving high-precision positioning and strong anti-interference capability for autonomous navigation agricultural machinery. The system employs a self-developed navigation control board and low-cost RTK technology through differential reference stations. Experimental results demonstrate that the system achieves a positioning error within 3 cm, an azimuth error within 0.6 degree, and an inclination error within 1 degree, showing strong adaptability and anti-interference performance. Jing et al. [

43] developed a GNSS and INS-based autonomous land levelling system aimed at improving the efficiency and accuracy of land preparation operations. The system integrates an adaptive square root cubature Kalman filter for enhanced positioning and incorporates an automatic steering and lifting control strategy. Experimental results demonstrated that the system significantly improved positioning accuracy and met the precision requirements for unmanned land levelling tasks. Li et al. [

44] proposed a fuzzy adaptive finite impulse response Kalman filter algorithm to enhance the positioning accuracy and stability of GNSS and INS integrated agricultural machinery navigation systems. Simulation and field tests demonstrated that the algorithm effectively reduces noise interference, achieving centimeter-level tracking accuracy and reducing average error and RMSE by up to

and

under non-differential GNSS conditions. The method significantly improves the robustness and precision of autonomous navigation for agricultural machinery.

2.2. Crop Row Detection Technology

Crop row detection is a fundamental prerequisite for enabling autonomous navigation between crop rows by unmanned agricultural machinery [

45,

46]. Accurate detection of crop rows allows the machinery to follow reference paths aligned with row structures, thereby minimizing crop damage from wheel intrusion during operation and enhancing both production efficiency and economic returns. However, crop row detection presents several challenges. During the early growth stages, seedlings are often too small and sparse to be reliably identified. Conversely, in later growth stages, dense and overlapping foliage can obscure the row structure, making detection difficult [

47]. In recent years, extensive research has been conducted by both domestic and international scholars on crop row detection for field crops.

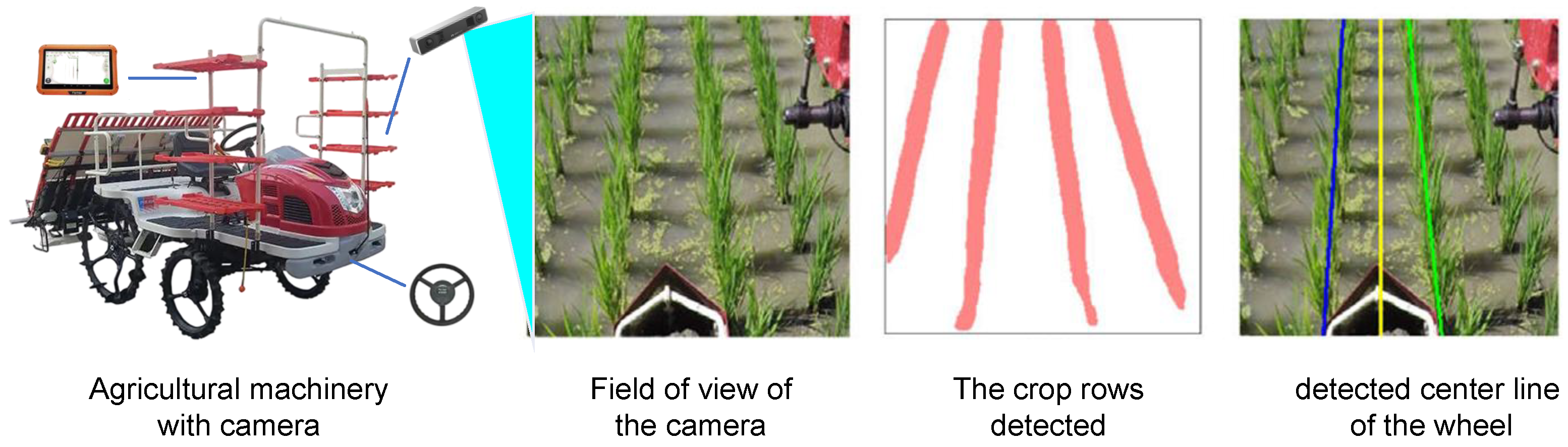

2.2.1. Machine Vision-Based Crop Row Detection

As show in

Figure 3, The visual navigation line detection mainly include image preprocessing, feature extraction, and navigation line recognition [

33]. In the image preprocessing stage, to address the challenges posed by complex field environments and variable lighting conditions, techniques such as image denoising, illumination compensation, and image enhancement are widely applied to improve image quality and reduce background interference [

48]. For feature extraction, traditional edge detection algorithms like Canny [

49] and Sobel operators [

50], as well as Hough transform-based line detection methods [

51], have been extensively used. However, these conventional approaches are susceptible to interference in scenarios with dense weeds or blurred field ridges.

In recent years, the methods for recognizing navigation lines in agricultural machine vision navigation have primarily focused on the challenges posed by complex field environments [

52]. To address the issue of row spacing recognition for different crops, researchers have proposed various techniques based on deep learning and traditional image processing. Shi et al. [

53] utilized an improved YOLOv8 model, combining deformable convolution with a Global Attention Mechanism (GAM), to enhance the robustness of multi-crop recognition. They achieved precise crop row extraction through threshold-DBSCAN clustering and B-spline curves. Li et al. [

54] focused on the irregularity of the growth morphology of rice seedlings, proposing a morphology anchor point detection method based on the stem of the rice plant, which employs a Transformer semantic segmentation model for identifying the rice stem, thus achieving high precision in crop row detection. Additionally, Ma et al. [

55] combined line clustering with supervised learning to propose a robust algorithm for detecting the root rows of rice, effectively addressing natural lighting and weed interference. Ruan et al. [

56] proposed a crop row detection method based on YOLO-R and DBSCAN, which shows improvements in both computational efficiency and accuracy compared to traditional methods. Gai et al. [

57] paid attention to navigation beneath the canopy, using Time-of-Flight (ToF) depth cameras to detect crop rows and constructing a field environment model through occupancy grid mapping, thereby enhancing the autonomous navigation capability of agricultural robots in areas with unstable GPS signals. Furthermore, Liu et al. [

58] proposed a maize seedling row detection method based on MS-ERFNet, increasing the model’s adaptability to lighting and weed interference through multi-scale feature extraction. Yang et al. [

59] employed the YOLO network for the autonomous extraction of Regions of Interest (ROI), improving detection real-time performance. Cao et al. [

60] introduced an improved ENet semantic segmentation network, significantly enhancing the precision of crop row boundaries and optimizing navigation line extraction through a random sampling consistency algorithm. Silva et al. [

61] proposed a deep learning-based crop row detection method that established a dataset targeting various field environment variables to enhance detection robustness. Rabab et al. [

62] developed a template-free crop row detection algorithm capable of achieving robust row detection under different viewpoints and lighting conditions. These studies indicate that the combination of deep learning and traditional methods can effectively enhance agricultural robots’ adaptability and navigation accuracy in complex field environments. Additionally, semantic segmentation networks like U-Net [

63,

64,

65,

66] and SegNet [

67,

68,

69] demonstrate excellent performance in extracting continuous and complex-shaped navigation lines, balancing real-time performance and accuracy.

As summarized in

Table 1, the crop row detection methods based on machine vision sensors are categorized and analyzed.

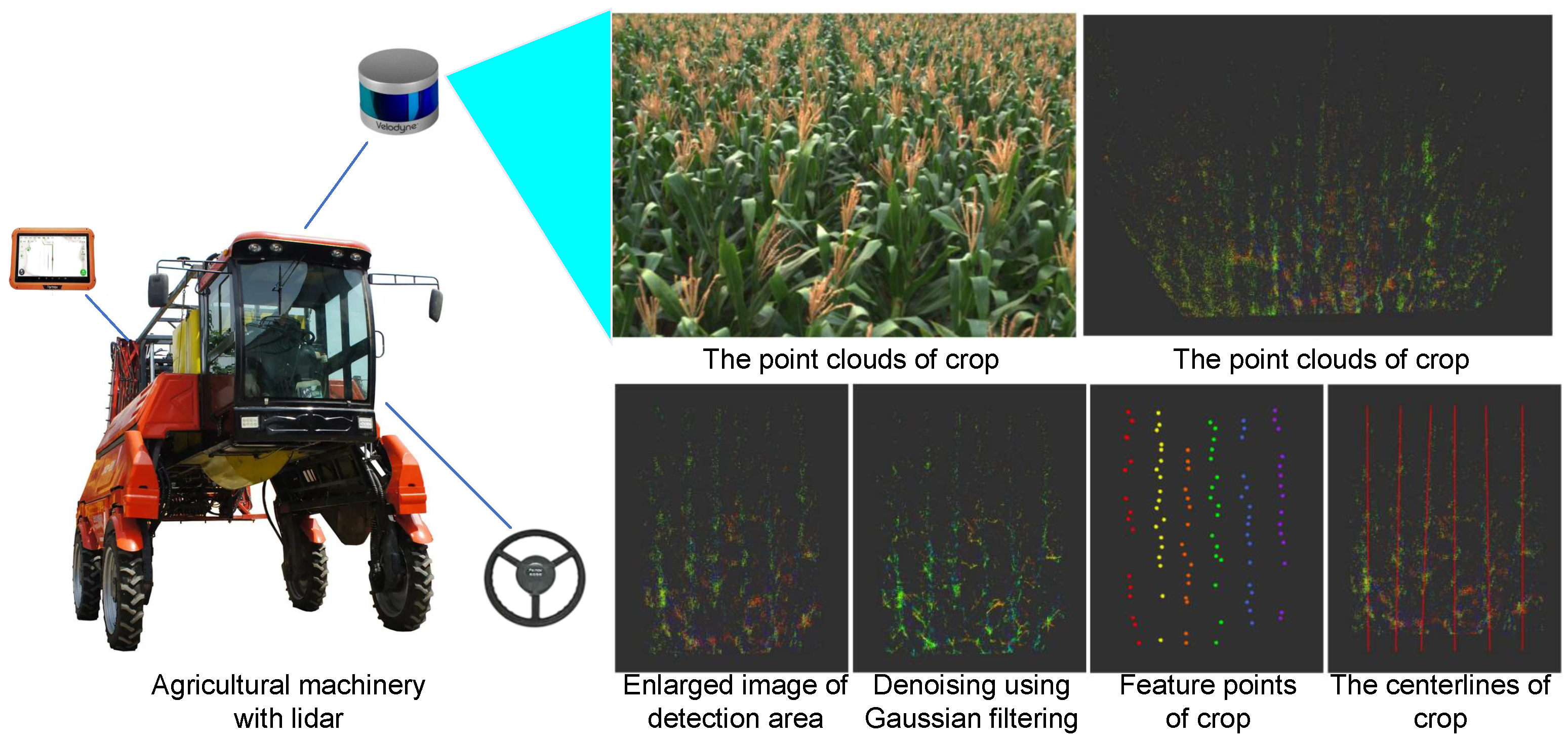

2.2.2. LiDAR Point Cloud-Based Crop Row Detection

Machine vision-based methods excel at capturing rich semantic information, making them highly effective in structured environments with clearly defined crop rows. However, they are susceptible to environmental disturbances such as lighting variations, shadows, and occlusions [

70,

71,

72]. In contrast, LiDAR demonstrate stability under adverse weather and low-visibility conditions, providing reliable distance measurements and supporting high-precision point cloud data processing. Consequently, point cloud-based navigation line recognition has garnered increasing attention in the field of autonomous navigation for agricultural machinery [

73,

74,

75,

76]. The general process of navigation line recognition based on point cloud is shown in

Figure 4.

Existing studies have shown that three-dimensional LiDAR point clouds enable more precise navigation line extraction and apply to various agricultural scenarios. Biglia et al. [

77] employed a density clustering method to detect vineyard rows. By extracting key points and fitting interpolation curves, they achieved precise localization of vine rows in complex agricultural environments, enhancing the path planning capability of autonomous agricultural machinery. Additionally, Goetz et al. [

78] proposed a furrow recognition method for plowing navigation. By detecting furrow edges using 3D LiDAR and fitting navigation reference lines with the RANSAC algorithm, their approach achieved an accuracy of over

. For crop row detection, Yang et al. [

79] developed a 3D LiDAR-based crop row detection algorithm that utilizes a dual-threshold method to distinguish point cloud density variations between near and far regions. Combined with least-squares fitting, this algorithm extracts the crop canopy centerline, enabling adaptability to different crop growth stages and meeting the real-time navigation demands of agricultural machinery. Furthermore, Liu et al. [

80] proposed a GPS-independent cross-crop-row navigation method, which relies on LiDAR point cloud detection of crop rows. Their method enables autonomous navigation even in scenarios where the canopy fully covers the inter-row space, ensuring high-precision operations across the entire farmland. Luna et al. [

81] adopted a template matching and noise removal strategy to detect crop furrows in high-density vegetation environments, guiding tracked robots along the furrow path and preventing crop damage. However, the high cost of LiDAR, coupled with the complexity of data processing and stringent hardware requirements, poses challenges for its widespread adoption in low-cost, low-power agricultural machinery.

As presented in

Table 2, crop row detection methods based on LiDAR sensors are classified and summarized.

2.3. Summary

This section reviews the key technologies enabling positioning and environmental sensing in autonomous agricultural machinery. GNSS and INS-based integrated navigation systems provide high-precision localization, while visual and LiDAR sensors offer complementary strengths in crop row detection under different field conditions. A comparative analysis of machine vision and LiDAR-based methods highlights their respective suitability, challenges, and advancements, laying the foundation for robust autonomous navigation in diverse agricultural environments.

3. Path Planning Techniques

Path planning is a key aspect of autonomous navigation in agricultural machinery, directly affecting operational efficiency, field coverage quality, and energy consumption [

82,

83,

84,

85,

86]. In large-scale field operations, path planning primarily focuses on full-coverage planning and headland turning coordination. Full-coverage planning aims to ensure complete coverage of the target area while minimizing overlap and gaps [

87]. Headland turning coordination addresses the challenge of smoothly connecting adjacent coverage paths, while minimizing time loss and soil compaction during turns [

88,

89]. Effectively integrating full-coverage planning with headland turning coordination is crucial for improving field operation efficiency and reducing operational costs.

3.1. Full-Coverage Path Planning

As shown in

Figure 5, the autonomous navigation path planning of large-scale agricultural machinery consists of full-coverage path planning and field turning planning. Traditional full-coverage path planning methods typically adopt systematic patterns, such as the ridge opening walking method, fusilli method, set method, and detour method. The ridge opening walking method starts from a central lane and sequentially covers the area on both sides, whereas the fusilli and detour methods adopt spiral and perimeter-inward paths to reduce redundant turning. The set method divides the operation area into rectangular segments for structured traversal, improving coverage in large, regular plots. Common headland turning strategies include the U-turn, smooth turn,

-turn, hook turn, and fishtail turn. U-turns and smooth turns are simple and applicable in wide headland areas, while

-turns, hook turns, and fishtail turns are designed for narrow or irregular boundaries, enabling compact maneuvering and fast alignment. Although these methods are easy to implement, with the continuous development of precision agriculture, it has become essential to minimize path overlap, gaps, and operational costs in path planning to enhance field efficiency and reduce resource waste.

As a result, Arab et al. [

90] proposed the row-skip pattern to reduce redundant coverage while increasing working area and efficiency. Liu et al. [

91] developed a multi-strategy dung beetle optimization algorithm to address the path planning problem for orchard mowers, thereby reducing fuel consumption and operation time. Han et al. [

92] proposed an improved Markov genetic algorithm to enhance the convergence speed of path planning and reduce path length and redundancy. Ren et al. [

93] improved work coverage and overall path quantity through multi-objective optimization. Xie et al. [

94] designed a genetic-ant colony hybrid optimization algorithm that, combined with 3D point cloud maps, optimized the paths of horticultural pruning robots, reducing turning times and enhancing coverage efficiency. Wang et al. [

95] further explored multi-objective constraint issues in harvesting machinery path planning, developing an adaptive path planning algorithm that combines machine characteristics with field shapes to achieve high coverage and efficient operation. Additionally, Hameed [

96] employed the Dubins curve optimization method, effectively reducing the number of headland turns while ensuring path continuity and smoothness. Yang et al. [

97] focused on the path for hillside terraced rice sowing robots and used Bézier curve fitting to smooth boundary paths, improving adaptability in complex terrain. Jeon et al. [

98] proposed an autonomous farming path planning method suitable for polygonal rice fields, optimizing both internal and external work paths to enhance tracking performance and reduce missed areas. Shen et al. [

99] studied the path planning problem in hilly terrains, combining energy consumption optimization with genetic algorithms to improve operational efficiency in complex terrains. Plessen et al. [

100] introduced an optimization path planning algorithm for non-convex farmland environments, suitable for multiple obstacles and irregular terrains, thus enhancing the applicability of path planning. Tan et al. [

101] proposed a biologically inspired Q-learning algorithm to ensure 100% coverage while reducing path redundancy, thereby improving adaptability in dynamic environments. Furthermore, Evans et al. [

102] optimized the traveling path for row crop harvesters using genetic algorithms, significantly reducing non-operational driving time and fuel consumption, and proposed a dynamic headland turning path planning method for unmanned agricultural machines, which reduces trajectory length and lateral deviation compared to traditional turn-back path planning methods.

Table 3 provides a comparative summary of representative path planning methods for agricultural robots, highlighting their application scenarios and specific optimization objectives.

3.2. Multi-Machine Collaborative Path Planning

Multi-machine collaborative path planning is an important direction for the intelligent development of agricultural machinery in the future [

103,

104]. Efficient and reasonable multi-machine collaborative path planning can enhance the working efficiency of agricultural machinery, optimize farmland coverage, and reduce redundant travel and energy consumption. By properly planning the collaborative work paths of multiple agricultural machines, path conflicts can be avoided, work safety can be improved, and the system’s robustness can be enhanced to ensure continuity and stability of operations. Soitinaho et al. [

105] proposed a collaborative path planning method for multiple agricultural robots, enabling collision avoidance and real-time task scheduling for autonomous tractors with varying working widths and steering characteristics. Wang et al. [

106] studied collaborative path planning and task allocation, improving scheduling efficiency by optimizing path costs. Cao et al. [

107] proposed a multi-tractor formation path planning method based on probabilistic landmarking, utilizing multiple lightweight tractors to reduce soil compaction and labor costs, achieving time-optimal coverage. Utamima et al. [

108] developed a Fast Hybrid Algorithm (FHA) for multi-vehicle collaborative path optimization, significantly reducing travel distance and operating time compared to genetic algorithms and ant colony algorithms.

3.3. Summary

This section reviews path planning strategies for autonomous agricultural machinery, focusing on full-coverage and multi-machine collaborative planning. Recent advances integrate optimization algorithms and terrain adaptability to reduce path redundancy, fuel consumption, and turning time. The combination of geometric patterns, evolutionary algorithms, and multi-robot coordination enables efficient, scalable, and terrain-aware field operations. These developments form the basis for seamless integration with path-tracking control strategies in the next stage of autonomous navigation.

4. Path-Tracking Control Techniques

Path-tracking control is the core of the autonomous navigation system for unmanned agricultural vehicles and directly affects the overall performance of the navigation system [

109,

110,

111]. However, the application of path-tracking control in complex environments faces numerous challenges. First, agricultural vehicles are non-linear coupled systems with complex non-integrable constraints, making them susceptible to adverse impacts from factors such as modeling errors, parameter disturbances, and other system uncertainties, as well as external disturbances. Second, the motion control of unmanned agricultural vehicles is constrained by the driving road environment and restricted by the saturation of the actuators [

112,

113,

114]. Therefore, path-tracking control algorithms for agricultural vehicles need to possess a certain degree of adaptability and robustness. As shown in

Figure 6, commonly used path-tracking control methods for unmanned agricultural vehicles mainly include geometric model-based, kinematic model-based, dynamic model-based, and intelligent model-free control approaches.

4.1. Control Method Based on Geometric Model

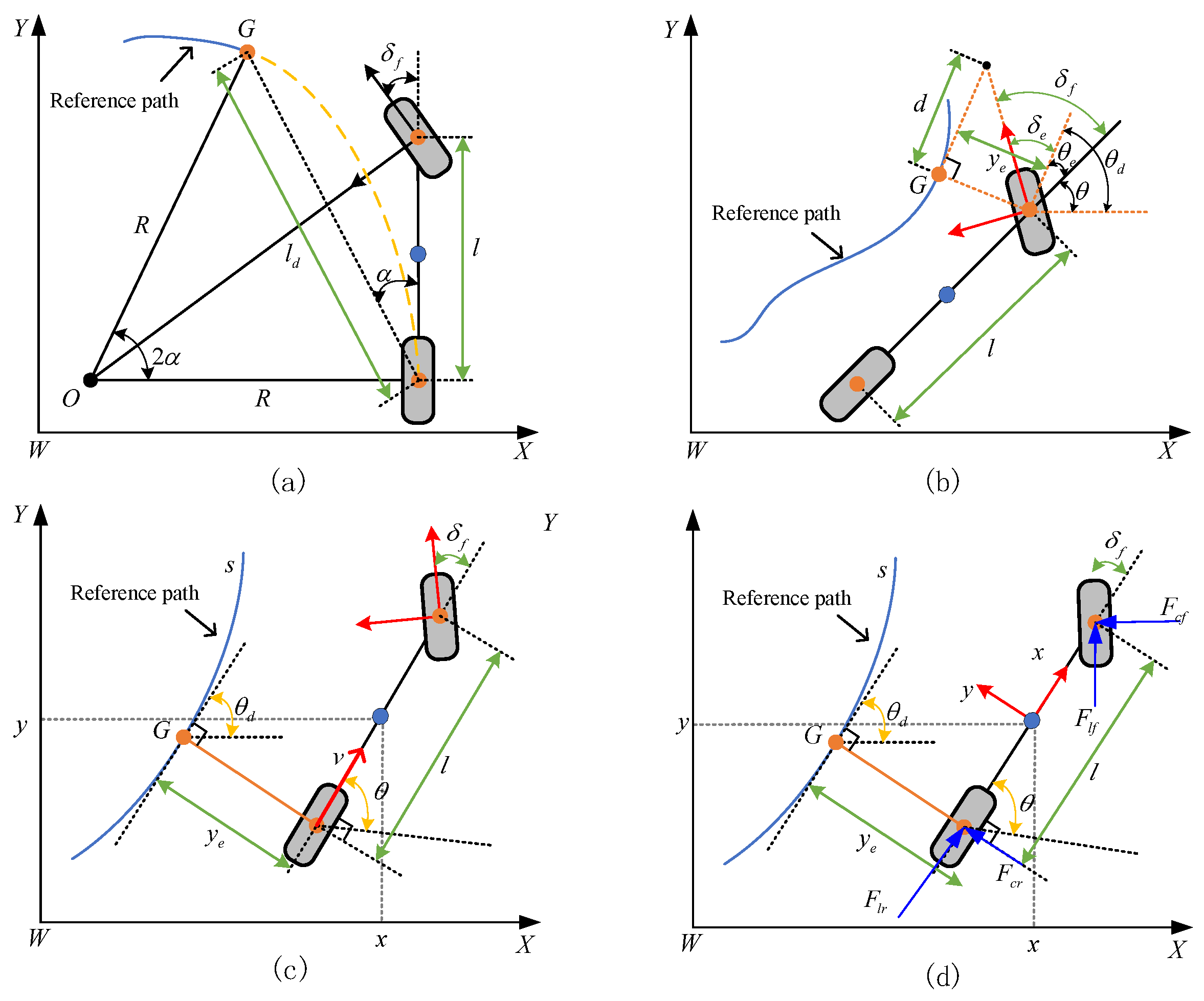

4.1.1. Pure Pursuit Control

Pure pursuit control is characterized by high stability, simple implementation, ease of parameter tuning, and low computational requirements. It is widely employed in autonomous navigation systems for agricultural machinery operating at relatively low speeds (0.5–3 m/s), such as spraying and sowing tasks [

115]. As illustrated in

Figure 6a, the pure pursuit algorithm is based on geometric principles. It transforms the lateral error between the vehicle’s current position and the target position at a preview distance into a lateral control variable. A proportional controller is subsequently designed to adjust the wheel steering angle, thereby ensuring effective path tracking. There is a one-to-one relationship between the vehicle’s turning radius and the steering wheel angle. To enable the vehicle’s rear wheel to follow the circular arc and reach the target point

G on the reference path at the preview distance, the following geometric relationship must be satisfied:

where

is the look-ahead distance,

is the heading angle error between the robot and the target point, and

R is the turning radius.

By simplifying the above equation, we obtain

To satisfy the turning radius

R, the control law for the front wheel steering angle

can be derived based on the Ackermann steering model as follows:

Based on the above derivation, it can be observed that the preview distance

L determines the selection of the target point. A preview distance that is too small may cause oscillations in the operating path of agricultural machinery, while a preview distance that is too large will reduce the speed at which the vehicle approaches the target line, making it difficult to meet the demands of high-precision navigation tasks. Therefore, researchers have proposed various improvement methods to enhance the tracking performance of the pure pursuit algorithm. Wang et al. [

116] introduced the heading error rate and combined it with an improved ant colony optimization strategy to achieve adaptive adjustment of control parameters, thereby reducing convergence time and increasing tracking accuracy. Kim et al. [

117] utilized Model Predictive Control (MPC) to optimize the preview distance, reducing it when the vehicle is about to deviate from the path and extending it in other situations to improve steering accuracy and smoothness in path tracking. In addition, Qiang et al. [

118] studied an automatic adjustment method for the preview distance, which allows agricultural tractors to achieve higher precision when following predetermined trajectories. Xu et al. [

119] adopted a fuzzy control strategy to dynamically adjust the preview distance based on lateral and heading deviations, enhancing the path-tracking performance of four-wheel independent steering–independent drive (4WIS-4WID) agricultural robots under different initial deviation conditions. Yang et al. [

120] proposed an improved PP algorithm based on optimal target points, searching for the optimal target point within the preview area by simulating the forward-looking behavior of a driver, resulting in a reduction of tracking errors by over

. Zhang et al. [

121] combined fuzzy control to adjust the preview distance and validated its good tracking accuracy and convergence through experiments on variable speed straight-line tracking and turning path tracking. Fue et al. [

122] addressed the issue of autonomous navigation in cotton fields by improving the pure pursuit algorithm based on low-cost RTK-GNSS and IMU, achieving stable tracking control. Experiments demonstrated that the mean absolute error ranged from 0.04 m to 0.09 m, indicating a high practical application value. These studies show that by optimizing preview distance, adaptively adjusting control parameters, and integrating intelligent control methods, the application of the pure pursuit algorithm in path tracking for agricultural robots has been significantly enhanced.

Numerous factors influence the optimal preview distance, including vehicle speed, tracking accuracy, control frequency, vehicle stability, and path curvature. Despite some progress, several challenges remain unresolved. The complex relationship between the preview distance and these factors makes determining the optimal value quite difficult. Moreover, the pure pursuit algorithm is fundamentally based on a simplified geometric model that does not account for the dynamic characteristics of the vehicle and the steering actuator. Rapid changes in steering curvature during high-speed travel can lead to vehicle skidding, and significant discrepancies between the system model and the actual vehicle characteristics may reduce tracking performance. Therefore, the pure pursuit algorithm is generally suitable for low-speed agricultural machinery with low lateral acceleration.

4.1.2. Stanley Control

The Stanley control method [

123] was initially proposed by researchers at Stanford University and applied in racing competitions. Similar to the pure pursuit algorithm, the Stanley method is grounded in geometric principles. It designs a front wheel steering angle feedback control law based on the lateral displacement error between the front axle’s control point and the nearest target point on the reference path, the heading angle error, and the front wheel steering angle error [

124]. This control strategy ensures the exponential convergence of the lateral displacement error to zero.

From the geometric relationships shown in

Figure 6b, the following equation can be obtained:

where

is the front wheel steering angle,

is the lateral control term, and

is the heading error.

It is evident that it satisfies

where

is the lateral error,

v is the vehicle speed,

k is a positive control gain, and

d is a virtual look-ahead distance.

Additionally, based on the geometric relationship,

where

is the desired heading angle and

is the current vehicle heading.

Combining the above equations, the control law for the front wheel steering angle is finally expressed as

Equation (

8) indicates that the Stanley control method does not require the determination of a preview distance. However, its control performance is significantly influenced by the adjustable parameter

k. The Stanley algorithm is more suitable for higher-speed operating conditions compared to the pure pursuit control method [

125]. However, it requires a relatively smooth reference path, and inadequate path smoothness may lead to excessive overshoot in vehicle response.

To achieve efficient and fully autonomous field operations for agricultural machinery, AbdElmoniem et al. [

126] proposed a Predictive Stanley controller based on model predictive control, utilizing a discrete predictive model to estimate future states. This approach enables the controller to better handle sudden changes in trajectory heading angles, thereby improving lateral error control capability and yaw stability. Subari et al. [

127] investigated a Stanley control-based path-tracking method for tracked vehicles and integrated the Ackermann steering model to achieve effective path-tracking control. Their method maintained an error of less than

across different speeds. Sun et al. [

128] employed particle swarm optimization to enhance a fuzzy Stanley controller, allowing the control gains to adaptively adjust based on error, speed, and actuator saturation state, thus improving the path-tracking capability of agricultural machinery in all operational scenarios. Wang et al. [

129] addressed the path-tracking problem of agricultural tractors by proposing an improved Stanley controller optimized using a multi-population genetic algorithm. Their approach optimized control parameters, enhancing steering accuracy and tracking stability, with particularly outstanding performance in U-shaped and S-shaped turning trajectories commonly encountered in agricultural operations.

4.2. Control Method Based on Kinematic Model and Dynamic Model

The kinematic model of agricultural machinery can effectively describe its position and orientation information. Consequently, path-tracking control methods designed based on kinematic models not only achieve higher accuracy but also allow for performance optimization. However, the control accuracy of kinematic model-based methods heavily depends on the precision and complexity of the established mathematical model [

130]. The bicycle model, known for its high accuracy and simplicity in parameterization, is currently the most widely used kinematic model. Based on this model, the path-tracking deviation model of agricultural machinery is obtained, as shown in

Figure 6c. Path-tracking control methods can then be designed accordingly. In contrast to kinematic models, which primarily describe position and orientation, dynamic models (

Figure 6d) incorporate the effects of forces and moments acting on agricultural machinery, enabling a more comprehensive representation of its motion characteristics [

131]. Path-tracking control methods based on dynamic models leverage this additional information to enhance stability and robustness, particularly in scenarios involving high-speed operations, varying terrain conditions, and external disturbances. By considering parameters such as mass distribution, tire forces, and actuator dynamics, these methods refine the control accuracy beyond the limitations of kinematic models. The development of path-tracking controllers based on dynamic models typically involves the derivation of motion equations, which account for system inertia, damping, and external forces.

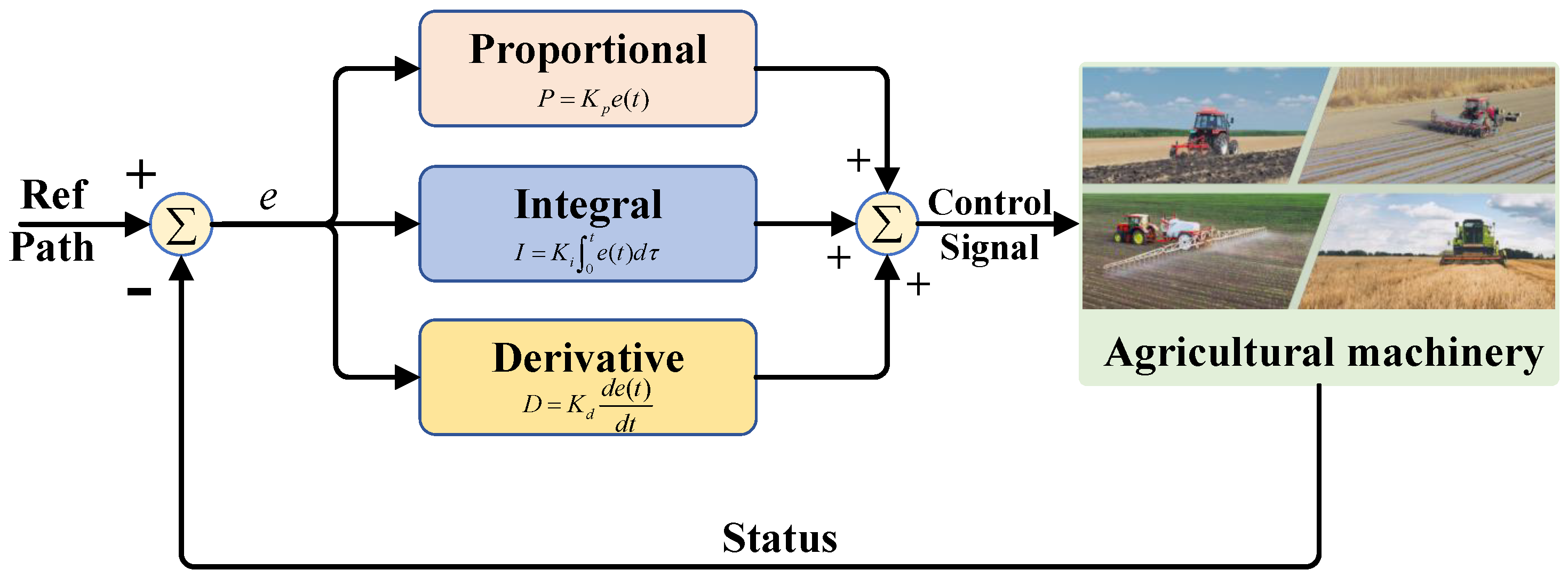

4.2.1. PID Control

As illustrated in

Figure 7, the PID control system generates the steering signal based on the error between the reference path and the actual vehicle state [

132]. The control input is composed of three components, namely a proportional term

that reacts to the present error, an integral term

that accounts for accumulated past errors, and a derivative term

that predicts future error trends. These components are summed to produce a unified control signal, which is then transmitted to the actuator of agricultural machinery. The feedback loop ensures that the system continuously adjusts based on current status, allowing for correction and stability during path tracking. This structure reflects the classical architecture of PID control, widely adopted for its simplicity and real-time responsiveness in field navigation scenarios.

where

is the control input,

is the tracking error,

is the proportional gain,

is the integral gain, and

is the derivative gain.

The path-tracking deviation formula derived from the kinematic model is:

where

is the lateral position error,

is the heading error, and

,

are non-negative weighting coefficients.

Since the PID algorithm does not require an accurate system model and is relatively easy to implement, it has been widely applied in path-tracking control systems [

133,

134]. However, PID control faces challenges in parameter tuning. Therefore, numerous studies have focused on improving its control accuracy and robustness through methods such as fuzzy control, adaptive optimization, and feedforward compensation. Liu et al. [

135] investigated a fuzzy adaptive PID-based path-tracking control for intelligent weeding machines in agricultural fields. This method dynamically adjusts PID parameters based on the front wheel steering angle deviation and its rate of change, significantly enhancing the system’s disturbance rejection capability and path-tracking accuracy. Yin et al. [

136] proposed a composite fuzzy PID control algorithm and applied it to the automatic steering control of rice transplanters. Experimental results demonstrated that this approach effectively reduced path deviation and improved automation accuracy in both straight-line tracking and headland turning. Qun et al. [

137], considering the complexity of the agricultural greenhouse environment, proposed a fuzzy PID-based path-tracking control method that dynamically adjusts PID parameters to enhance the navigation accuracy of agricultural robots in confined spaces. Experiments validated the superiority of this algorithm in fixed-point parking and linear position control. Cheng et al. [

138] studied a model-free adaptive predictive control combined with PID for path tracking. By augmenting the proportional and derivative terms, the system’s adaptability was improved. Simulations and hardware-in-the-loop tests indicated that this method exhibited strong disturbance rejection and insensitivity to variations in the controlled object. Amertet et al. [

139] explored path-tracking control for drones in intelligent agricultural systems and proposed a hybrid fuzzy PID controller. Compared to conventional PID, this method improved roll, flight altitude, and airspeed control accuracy by 41.5%, 11%, and 44%, respectively, enhancing the feasibility of drones in agricultural applications. Zhang et al. [

140] addressed the path-tracking problem of large rear wheel steering combine harvesters by integrating feed-forward PID with a preview Ackermann algorithm, achieving an average lateral deviation of less than 5 cm.

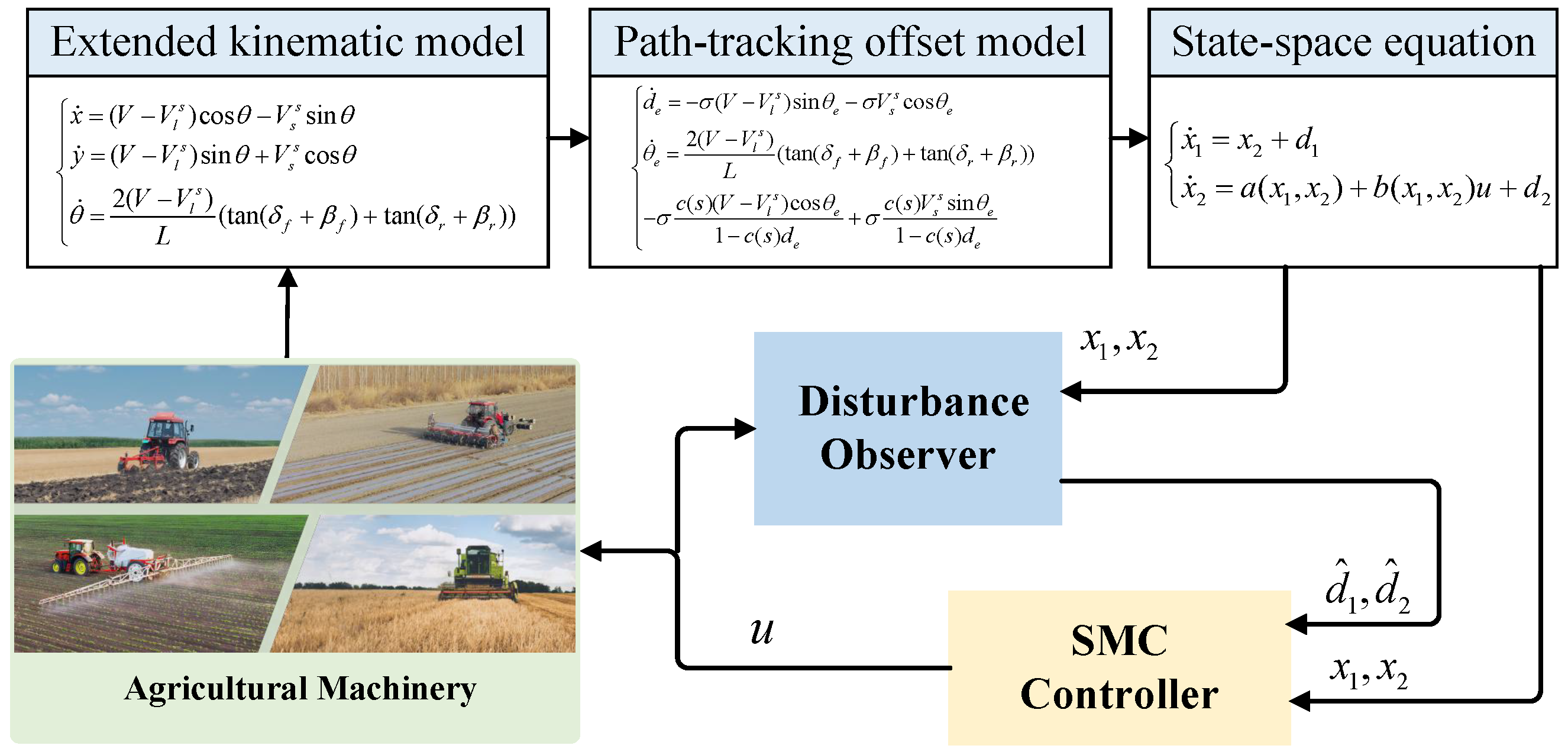

4.2.2. SMC Control

Sliding Mode Control (SMC) is essentially a special class of non-linear control that offers advantages such as fast response, insensitivity to parameter variations and disturbances, no need for online system identification, and simple physical implementation [

141,

142,

143].

Due to its discontinuous switching characteristics, SMC tends to produce chattering, which is a major challenge in practical applications. Reducing chattering is a current research focus [

144]. Yin et al. [

145] proposed a sliding mode control scheme based on lateral deviation and adaptive adjustment parameters. By introducing tunable parameters related to the sliding surface and system error and employing a modified Smith predictor to construct a two-degree-of-freedom control structure, they achieved precise front-wheel angle tracking while suppressing chattering. Additionally, they integrated fuzzy logic with a three-degree-of-freedom model to design a trajectory tracking control system, resulting in improved dynamic performance in steering control [

146]. To further enhance the controller’s robustness against external disturbances, Ding et al. [

147] normalized the path-tracking error dynamic model through coordinate transformation and reconstructed unknown states using a second-order robust exact differentiator. They then designed an output feedback sliding mode controller and proved that the tracking error converges within a finite time. Subsequently, they incorporated a disturbance observer and adaptive barrier function technique to refine the sliding surface design, ensuring finite-time stability under both known and unknown disturbances while mitigating chattering [

148].

Moreover, considering the uncertain disturbances in the field that can reduce the accuracy of the kinematic model of agricultural machinery, leading to prolonged convergence times and suboptimal tracking performance, many researchers have combined non-linear Disturbance Observers (DOB) with SMC methods. As shown in

Figure 8, the SMC+DOB control framework integrates the SMC with a DOB to enhance robustness in unstructured agricultural environments. The control strategy is based on an extended kinematic model and a path-tracking offset model, which are then transformed into a state-space representation. The disturbance observer estimates unknown external disturbances

, which are fed back to the SMC controller for real-time compensation. The control input

u is then applied to the agricultural machinery. This framework significantly improves resistance to environmental uncertainties such as soil unevenness, wheel slip, and dynamic model inaccuracies, making it suitable for harsh field conditions. These combinations enhance the robustness of the control system while reducing chattering. Ji et al. [

149] designed a composite terminal sliding mode controller based on a finite-time disturbance observer, effectively reducing chattering through sliding mode filtering and an adaptive mechanism. They further developed an adaptive second-order sliding mode control method by constructing a lateral deviation model based on a preview kinematics model, demonstrating superior tracking performance compared to traditional approaches in simulation environments [

150]. Regarding system convergence within a fixed time, Sun et al. [

151] proposed a fixed-time nonsingular terminal sliding mode control scheme based on an adaptive disturbance observer, proving that both lateral and heading deviations can stably converge within a fixed time. Li et al. [

152] employed a radial basis function neural network for online parameter tuning and significantly reduced deviations caused by environmental uncertainties such as sideslip through adaptive sliding mode variable structure control. For rough terrains and complex disturbances in agricultural operations, Yang et al. [

153] combined an anti-peak extended state observer with fast super-twisting sliding mode control to effectively mitigate disturbance effects, verifying the advantages of this approach in path-tracking control through simulations and experiments. Additionally, Zhang et al. [

154] proposed a composite sliding mode control scheme based on an extended disturbance observer specifically for the path-tracking control of a 4WID agricultural robot. By online estimation and compensation of disturbances caused by wheel slip, this method significantly improved control accuracy and robustness in uneven and paddy field terrains.

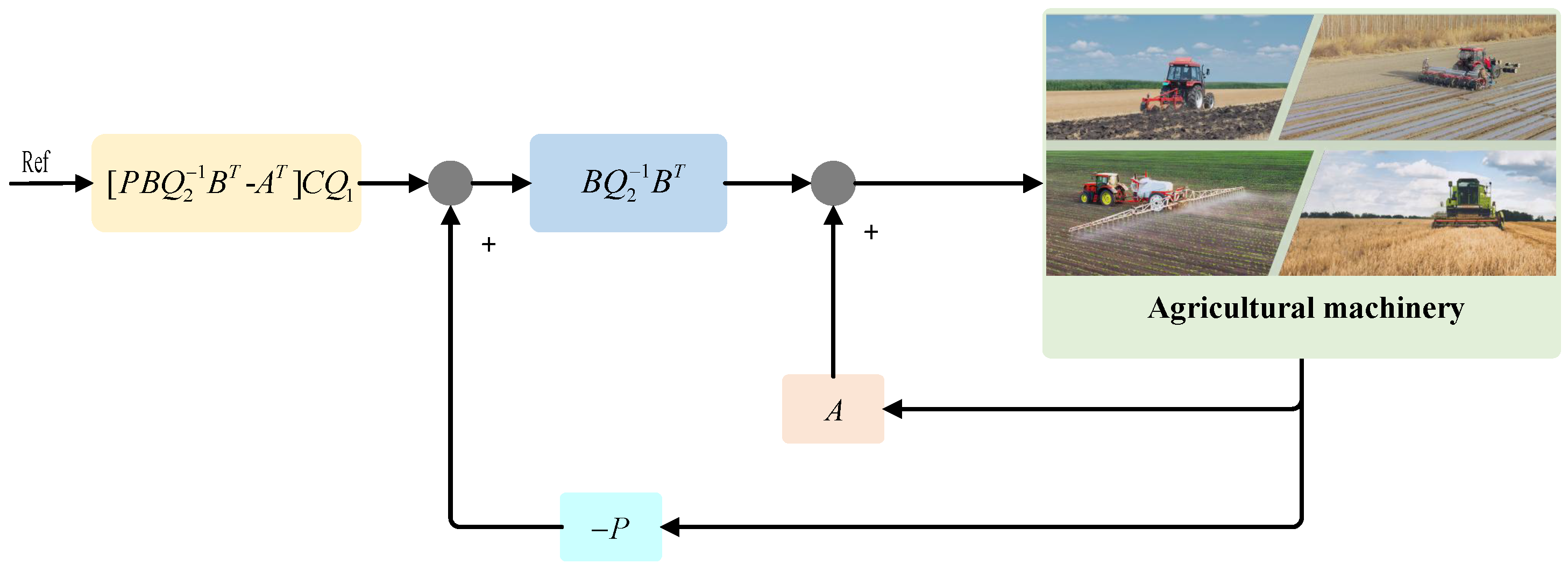

4.2.3. LQR Control

Linear Quadratic Regulator (LQR) control is a full state feedback control strategy that aims to minimize a quadratic cost function composed of the state deviations and control inputs over a specified time horizon [

155]. By constructing a quadratic cost function (

) that balances the trade-off between system state deviations and control effort, the optimal gain matrix is obtained, resulting in the desired control sequence.

Figure 9 illustrates the block diagram of LQR control, where the control law is derived by minimizing a quadratic cost function that balances tracking accuracy and control effort. The regulator computes the optimal gain matrix using system matrices

and the weighting matrices

. The feedback control action

u ensures optimal trajectory tracking of the agricultural machinery. This approach guarantees closed-loop stability for linearized models and is effective for systems where a dynamic response needs to be regulated precisely under limited input effort.

LQR control has been widely applied in agricultural machinery path-tracking control due to its well-defined mathematical formulation and optimization performance. However, in practical applications, LQR control still faces challenges such as parameter tuning difficulties and sensitivity to system non-linearity and uncertainty. To address these challenges, researchers have proposed various improvements to enhance the applicability and control accuracy of LQR in agricultural vehicle path tracking. Fan et al. [

156] employed an improved quantum genetic algorithm (IQGA) to optimize the LQR weight matrix, overcoming the empirical nature and limitations of traditional LQR weight selection. Simulation results demonstrated that this method significantly improved the trajectory tracking accuracy of autonomous wheeled tractors, reduced tracking errors, and enhanced global search capability. Ni et al. [

157] introduced a fast rolling optimization algorithm based on path-tracking errors within the LQR control framework, optimizing the Q and R weight matrices to improve the adaptability and control accuracy of tracked mobile robots in trajectory tracking. Zhao et al. [

158], addressing the path-tracking requirements of agricultural machinery in different operating environments, combined LQR with feedforward control to establish a two-degree-of-freedom dynamic model for agricultural machinery, eliminating lateral steady-state errors in the path-tracking process. Simulation results showed that this method effectively enhanced the autonomous navigation capability of agricultural machinery. Li et al. [

159] focused on the straight-line trajectory tracking problem of agricultural vehicles and proposed an LQ control method based on optimal control theory. They analyzed the stability of the controller under different speeds using Lyapunov stability theory, with experimental validation confirming its effectiveness in large-scale field operations. Additionally, considering the impact of soil conditions on path-tracking control in agricultural operations, Lee et al. [

160] studied the dynamic characteristics of tractor path tracking under different soil conditions. They proposed a kinematic control method based on Lyapunov stability theory, integrating LQR state feedback control to optimize lateral dynamic response. Simulation results indicated that this method maintained excellent tracking performance even in uncertain soil environments, enhancing system robustness.

4.2.4. MPC Control

MPC is a real-time closed-loop optimal control method that solves an optimization problem (

) within a finite prediction horizon to obtain the optimal solution [

161,

162,

163]. As depicted in

Figure 10, the MPC scheme predicts the future behavior of the system using a dynamic model and solves an optimization problem over a finite time horizon. At each time step, the optimizer minimizes a cost function subject to system constraints, generating an optimal control sequence. Only the first control action

is applied, while the process is repeated in a receding horizon manner. The prediction includes future reference values and estimated system outputs

, allowing the controller to anticipate changes in terrain and motion. This predictive capability is particularly valuable for handling constraints and non-linearities in autonomous agricultural navigation.

Some researchers have concentrated on information fusion and model optimization. Manikandan et al. [

164] proposed a curvature-aware MPC that extracts trajectory curvature information, effectively reducing lateral and longitudinal errors on indoor, road, and agricultural terrains. He et al. [

165] combined agricultural machinery posture correction with MPC to improve trajectory deviations caused by side-slip in paddy field environments. Another line of research combines MPC with other control strategies to handle complex operating conditions. Li et al. [

166] proposed a control algorithm integrating MPC and PID, achieving coordinated control of steering and speed for agricultural vehicles. Ou et al. [

167] focused on real-time compensation for friction and gravity effects on sloped road surfaces by combining a steering compensation strategy with MPC. To address the challenges of parameter tuning, Wang et al. [

168] implemented adaptive MPC parameter adjustment using fuzzy control and particle swarm optimization, while Zhou et al. [

169] optimized MPC’s time-domain parameters through a genetic algorithm to improve the tracking accuracy of articulated tractors. In terms of slip prevention and motion stability. Liu et al. [

170] effectively balanced tracking accuracy and lateral stability in mountainous and wheeled agricultural machinery using adaptive variable-parameter MPC and adaptive sliding mode predictive control.

4.3. Summary

Table 4 compares representative path-tracking control methods used in agricultural robotics, highlighting their respective strengths, limitations, and typical application references.

This section presents a comprehensive overview of path-tracking control techniques for autonomous agricultural vehicles, including geometric, kinematic, dynamic, and intelligent model-free approaches. Each method–such as pure pursuit, Stanley, PID, SMC, LQR, and MPC–was analyzed in terms of its control principles, application scenarios, advantages, and limitations. Recent enhancements have focused on improving adaptability, robustness, and precision in complex field conditions. These developments provide a solid foundation for addressing the real-world challenges discussed in the subsequent section.

5. Challenges and Future Perspectives

Despite recent advancements, several challenges persist in the practical deployment of autonomous navigation systems in agricultural machinery. In particular, ensuring the robustness of navigation algorithms under unstructured and dynamically changing farmland conditions remains a critical bottleneck. Based on the reviewed literature, this paper outlines the following key future research directions:

(1) Multi-sensor fusion is expected to become a foundational technology across intelligent agriculture, autonomous driving, and robotic navigation. By integrating heterogeneous data sources—such as machine vision, LiDAR, millimeter-wave radar, and IMUs—and leveraging AI-driven perception algorithms, future systems can achieve more accurate environmental perception, stronger adaptability to complex field conditions, and higher levels of autonomous decision-making. This trend is poised to accelerate the development of agricultural robots, intelligent machinery, and autonomous systems, thereby enabling more intelligent and efficient agricultural operations.

(2) Most existing path-tracking controllers for agricultural machinery rely on simplified two-degree-of-freedom kinematic models. While computationally efficient, these models fail to capture the true dynamics of the agricultural machinery chassis, leading to modeling inaccuracies and susceptibility to disturbances. Furthermore, the highly variable and often extreme conditions encountered in real-world field operations demand control strategies that go beyond idealized scenarios. Future research should focus on dynamic modeling and online system identification methods to capture non-linearities and coupling effects among longitudinal, lateral, and vertical motion. This will facilitate the development of high-fidelity chassis models that improve control accuracy while ensuring real-time applicability.

(3) Improving controller performance alone is insufficient to guarantee the overall effectiveness of an autonomous navigation system. If path planning fails to consider the actuation limits and dynamic constraints of agricultural machinery, the planned trajectories may be infeasible or suboptimal, leading to degraded tracking performance and trade-offs between competing objectives such as stability, accuracy, and obstacle avoidance. Therefore, motion control algorithms should be tightly integrated with perception and planning modules. MPC, known for its ability to handle multivariable constraints, offers a promising framework for the joint optimization of local path planning and control. Future research should explore integrated planning–control approaches that incorporate real-time perception and predictive information to effectively manage environmental uncertainties, thereby enhancing safety and operational efficiency.

(4) Agronomy provides the theoretical basis for agricultural operations and should be systematically integrated into control system design. Future control strategies must consider agronomic constraints, environmental complexity, and task-specific requirements to ensure that machinery operations align with crop needs and cultivation practices. Advanced control algorithms can be employed to improve the precision of implement operations, ensuring compliance with agronomic standards. Moreover, control systems should be adaptable to evolving agronomic practices, fostering the coordinated development of intelligent agricultural machinery and modern agronomy.

(5) As digital agriculture advances, the security and integrity of data acquired from sensors and autonomous systems become increasingly critical. Although not the primary focus of this review, it is important to acknowledge that cybersecurity threats–such as unauthorized access to autonomous tractors or tampering with navigation data–pose risks to operational safety and user trust. Future research should consider incorporating secure communication protocols, encryption strategies, and intrusion detection mechanisms to protect navigation systems and ensure the reliability of autonomous agricultural operations.

To further understand the barriers to real-world adoption,

Table 5 summarizes key challenges and possible countermeasures across technical, economic, and infrastructural dimensions.

6. Conclusions

Autonomous navigation technology plays a vital role in advancing smart agriculture by enabling precise, efficient, and intelligent execution of key field operations such as tillage, seeding, fertilization, crop protection, and harvesting. The integration of high-precision positioning, environmental perception, path planning, and path-tracking control has significantly improved the operational performance of agricultural machinery under complex and dynamic field conditions. This paper aims to provide a comprehensive summary of recent progress in the core technologies of autonomous navigation systems, including multi-sensor fusion, machine vision and LiDAR-based perception, as well as optimization-based planning and control strategies. These advancements have laid a solid foundation for the practical application and further development of intelligent agricultural machinery.

By consolidating current research findings, this paper offers valuable insights for researchers and practitioners in the field, and serves as a reference for the continued evolution and refinement of autonomous navigation systems in agricultural production. Moreover, the technical discussions and evaluations presented in this review can provide meaningful guidance to manufacturers of navigation systems, tractors, and harvesters. Specifically, understanding the advantages and limitations of different sensor integration methods, planning strategies, and control algorithms may support the design and deployment of more robust, efficient, and adaptive agricultural machinery products. As the agricultural industry moves toward greater automation, collaboration between academic research and industrial development will be essential to bridge the gap between innovation and market-ready solutions.

Author Contributions

Conceptualization, H.W. and X.W.; methodology, H.W.; software, Y.Z. (Yafei Zhang); validation, H.W. and X.W.; formal analysis, H.W.; investigation, H.W.; resources, H.W.; data curation, H.W.; writing—original draft preparation, Y.Z. (Yaowen Zhang); writing—review and editing, X.W.; visualization, X.W.; supervision, X.W.; project administration, X.C.; funding acquisition, X.W. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by Key Technologies Research and Development Program (No. 2022YFD2002403), the Ministry of Industry and Information Technology’s Residual Film Recycling Machine Project (No. zk20230359) and the Priority Academic Program Development of Jiangsu Higher Education Institutions (No. PAPD-2023-87).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in the article.

Acknowledgments

The authors would like to thank the editor and reviewers for their valuable suggestions for improving this paper.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Darko, R.O.; Yuan, S.; Hong, L.; Liu, J.; Yan, H. Irrigation, a productive tool for food security—A review. Acta Agric. Scand. Sect. B—Soil Plant Sci. 2016, 66, 191–206. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Tunio, M.H.; Ahmad, F.; Solangi, K.A. Overview of the aeroponic agriculture—An emerging technology for global food security. Int. J. Agric. Biol. Eng. 2020, 13, 1–10. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Wang, R.; Xu, X.; Shen, Y.; Liu, Y. Modeling and test on height adjustment system of electrically-controlled air suspension for agricultural vehicles. Int. J. Agric. Biol. Eng. 2016, 9, 40–47. [Google Scholar]

- Awais, M.; Li, W.; Hussain, S.; Cheema, M.J.M.; Li, W.; Song, R.; Liu, C. Comparative evaluation of land surface temperature images from unmanned aerial vehicle and satellite observation for agricultural areas using in situ data. Agriculture 2022, 12, 184. [Google Scholar] [CrossRef]

- Xu, J.; Gu, B.; Tian, G. Review of agricultural IoT technology. Artif. Intell. Agric. 2022, 6, 10–22. [Google Scholar] [CrossRef]

- Wang, H.; Gu, J.; Wang, M. A review on the application of computer vision and machine learning in the tea industry. Front. Sustain. Food Syst. 2023, 7, 1172543. [Google Scholar] [CrossRef]

- Li, C.; Wu, J.; Pan, X.; Dou, H.; Zhao, X.; Gao, Y.; Yang, S.; Zhai, C. Design and Experiment of a Breakpoint Continuous Spraying System for Automatic-Guidance Boom Sprayers. Agriculture 2023, 13, 2203. [Google Scholar] [CrossRef]

- Zhang, S.; Xue, X.; Chen, C.; Sun, Z.; Sun, T. Development of a low-cost quadrotor UAV based on ADRC for agricultural remote sensing. Int. J. Agric. Biol. Eng. 2019, 12, 82–87. [Google Scholar] [CrossRef]

- Qing, Y.; Li, Y.; Yang, Y.; Xu, L.; Ma, Z. Development and experiments on reel with improved tine trajectory for harvesting oilseed rape. Biosyst. Eng. 2021, 206, 19–31. [Google Scholar] [CrossRef]

- Chen, J.; Lian, Y.; Zou, R.; Zhang, S.; Ning, X.; Han, M. Real-time grain breakage sensing for rice combine harvesters using machine vision technology. Int. J. Agric. Biol. Eng. 2020, 13, 194–199. [Google Scholar] [CrossRef]

- Zhu, C.; Hao, S.; Liu, C.; Wang, Y.; Jia, X.; Xu, J.; Guo, S.; Huo, J.; Wang, W. An Efficient Computer Vision-Based Dual-Face Target Precision Variable Spraying Robotic System for Foliar Fertilisers. Agronomy 2024, 14, 2770. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, S.; Li, N.; Faheem, M.; Zhou, T.; Cai, W.; Zhao, M.; Zhu, X.; Li, P. Development and field test of an autonomous strawberry plug seeding transplanter for use in elevated cultivation. Appl. Eng. Agric. 2019, 35, 1067–1078. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Li, M.; Shang, Z. Dynamic Measurement Method for Steering Wheel Angle of Autonomous Agricultural Vehicles. Agriculture 2024, 14, 1602. [Google Scholar] [CrossRef]

- Ahmed, S.; Qiu, B.; Ahmad, F.; Kong, C.W.; Xin, H. A state-of-the-art analysis of obstacle avoidance methods from the perspective of an agricultural sprayer UAV’s operation scenario. Agronomy 2021, 11, 1069. [Google Scholar] [CrossRef]

- Hu, J.; Zhao, X.; Liu, W.; Yao, M.; Zhao, J. Development of a seeding control method based on seed height in the hopper of a precision wheat drill. Appl. Eng. Agric. 2021, 37, 1131–1138. [Google Scholar] [CrossRef]

- Liu, W.; Zhou, J.; Zhang, T.; Zhang, P.; Yao, M.; Li, J.; Sun, Z.; Ma, G.; Chen, X.; Hu, J. Key Technologies in Intelligent Seeding Machinery for Cereals: Recent Advances and Future Perspectives. Agriculture 2024, 15, 8. [Google Scholar] [CrossRef]

- Ji, W.; Zhang, T.; Xu, B.; He, G. Apple recognition and picking sequence planning for harvesting robot in a complex environment. J. Agric. Eng. 2024, 55, 1549. [Google Scholar] [CrossRef]

- Liu, J.; Liang, J.; Zhao, S.; Jiang, Y.; Wang, J.; Jin, Y. Design of a virtual multi-interaction operation system for hand–eye coordination of grape harvesting robots. Agronomy 2023, 13, 829. [Google Scholar] [CrossRef]

- Pei, H.; Sun, Y.; Huang, H.; Zhang, W.; Sheng, J.; Zhang, Z. Weed detection in maize fields by UAV images based on crop row preprocessing and improved YOLOv4. Agriculture 2022, 12, 975. [Google Scholar] [CrossRef]

- Hu, T.; Wang, W.; Gu, J.; Xia, Z.; Zhang, J.; Wang, B. Research on apple object detection and localization method based on improved YOLOX and RGB-D images. Agronomy 2023, 13, 1816. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Z.; Zhang, Y.; Zhou, J.; Wu, J.; Li, P. Real-time detection and location of potted flowers based on a ZED camera and a YOLO V4-tiny deep learning algorithm. Horticulturae 2021, 8, 21. [Google Scholar] [CrossRef]

- Wu, Q.; Gu, J. Design and research of robot visual servo system based on artificial intelligence. Agro Food Ind. Hi-Tech 2017, 28, 125–128. [Google Scholar]

- Jia, W.; Zheng, Y.; Zhao, D.; Yin, X.; Liu, X.; Du, R. Preprocessing method of night vision image application in apple harvesting robot. Int. J. Agric. Biol. 2018, 11, 158–163. [Google Scholar] [CrossRef]

- Gasparetto, A.; Boscariol, P.; Lanzutti, A.; Vidoni, R. Path planning and trajectory planning algorithms: A general overview. In Motion and Operation Planning of Robotic Systems: Background and Practical Approaches; Springer: Berlin/Heidelberg, Germany, 2015; pp. 3–27. [Google Scholar]

- Aggarwal, S.; Kumar, N. Path planning techniques for unmanned aerial vehicles: A review, solutions, and challenges. Comput. Commun. 2020, 149, 270–299. [Google Scholar] [CrossRef]

- Amer, N.H.; Zamzuri, H.; Hudha, K.; Kadir, Z.A. Modelling and control strategies in path tracking control for autonomous ground vehicles: A review of state of the art and challenges. J. Intell. Robot. Syst. 2017, 86, 225–254. [Google Scholar] [CrossRef]

- Lu, E.; Xue, J.; Chen, T.; Jiang, S. Robust trajectory tracking control of an autonomous tractor-trailer considering model parameter uncertainties and disturbances. Agriculture 2023, 13, 869. [Google Scholar] [CrossRef]

- Kharel, T.P.; Ashworth, A.J.; Shew, A.; Popp, M.P.; Owens, P.R. Tractor guidance improves production efficiency by reducing overlaps and gaps. Agric. Environ. Lett. 2020, 5, e20012. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, B.; Shen, C.; Liu, H.; Huang, J.; Tian, K.; Tang, Z. Review of the field environmental sensing methods based on multi-sensor information fusion technology. Int. J. Agric. Biol. Eng. 2024, 17, 1–13. [Google Scholar]

- Aby, G.R.; Issa, S.F.; Chowdhary, G. Safety risk assessment of an autonomous agricultural machine. J. Agric. Saf. Health 2024, 30, 1–15. [Google Scholar] [CrossRef]

- de Koning, M.; Machado, T.; Ahonen, A.; Strokina, N.; Dianatfar, M.; De Rosa, F.; Minav, T.; Ghabcheloo, R. A comprehensive approach to safety for highly automated off-road machinery under Regulation 2023/1230. Saf. Sci. 2024, 175, 106517. [Google Scholar] [CrossRef]

- Liu, W.; Hu, J.; Liu, J.; Yue, R.; Zhang, T.; Yao, M.; Li, J. Method for the navigation line recognition of the ridge without crops via machine vision. Int. J. Agric. Biol. Eng. 2024, 17, 230–239. [Google Scholar]

- Ma, Z.; Yang, S.; Li, J.; Qi, J. Research on slam localization algorithm for orchard dynamic vision based on YOLOD-SLAM2. Agriculture 2024, 14, 1622. [Google Scholar] [CrossRef]

- Zhu, F.; Chen, J.; Guan, Z.; Zhu, Y.; Shi, H.; Cheng, K. Development of a combined harvester navigation control system based on visual simultaneous localization and mapping-inertial guidance fusion. J. Agric. Eng. 2024, 55, 1583. [Google Scholar] [CrossRef]

- Radočaj, D.; Plaščak, I.; Jurišić, M. Global navigation satellite systems as state-of-the-art solutions in precision agriculture: A review of studies indexed in the web of science. Agriculture 2023, 13, 1417. [Google Scholar] [CrossRef]

- Hernández-Pajares, M.; Olivares-Pulido, G.; Graffigna, V.; García-Rigo, A.; Lyu, H.; Roma-Dollase, D.; de Lacy, M.C.; Fernández-Prades, C.; Arribas, J.; Majoral, M.; et al. Wide-area GNSS corrections for precise positioning and navigation in agriculture. Remote Sens. 2022, 14, 3845. [Google Scholar] [CrossRef]

- Cui, B.; Zhang, J.; Wei, X.; Cui, X.; Sun, Z.; Zhao, Y.; Liu, Y. Improved information fusion for agricultural machinery navigation based on context-constrained Kalman filter and dual-antenna RTK. Actuators 2024, 13, 160. [Google Scholar] [CrossRef]

- Catania, P.; Comparetti, A.; Febo, P.; Morello, G.; Orlando, S.; Roma, E.; Vallone, M. Positioning accuracy comparison of GNSS receivers used for mapping and guidance of agricultural machines. Agronomy 2020, 10, 924. [Google Scholar] [CrossRef]

- Valente, D.S.M.; Momin, A.; Grift, T.; Hansen, A. Accuracy and precision evaluation of two low-cost RTK global navigation satellite systems. Comput. Electron. Agric. 2020, 168, 105142. [Google Scholar] [CrossRef]

- Qu, J.; Zhang, Z.; Qin, Z.; Guo, K.; Li, D. Applications of autonomous navigation technologies for unmanned agricultural tractors: A review. Machines 2024, 12, 218. [Google Scholar] [CrossRef]

- Huang, Y.; Fu, J.; Xu, S.; Han, T.; Liu, Y. Research on integrated navigation system of agricultural machinery based on RTK-BDS/INS. Agriculture 2022, 12, 1169. [Google Scholar] [CrossRef]

- Jing, Y.; Li, Q.; Ye, W.; Liu, G. Development of a GNSS/INS-based automatic navigation land levelling system. Comput. Electron. Agric. 2023, 213, 108187. [Google Scholar] [CrossRef]

- Li, S.; Zhang, M.; Ji, Y.; Zhang, Z.; Cao, R.; Chen, B.; Li, H.; Yin, Y. Agricultural machinery GNSS/IMU-integrated navigation based on fuzzy adaptive finite impulse response Kalman filtering algorithm. Comput. Electron. Agric. 2021, 191, 106524. [Google Scholar] [CrossRef]

- Zheng, K.; Zhao, X.; Han, C.; He, Y.; Zhai, C.; Zhao, C. Design and experiment of an automatic row-oriented spraying system based on machine vision for early-stage maize corps. Agriculture 2023, 13, 691. [Google Scholar] [CrossRef]

- Chen, J.; Song, J.; Guan, Z.; Lian, Y. Measurement of the distance from grain divider to harvesting boundary based on dynamic regions of interest. Int. J. Agric. Biol. Eng. 2021, 14, 226–232. [Google Scholar] [CrossRef]

- Luo, Y.; Wei, L.; Xu, L.; Zhang, Q.; Liu, J.; Cai, Q.; Zhang, W. Stereo-vision-based multi-crop harvesting edge detection for precise automatic steering of combine harvester. Biosyst. Eng. 2022, 215, 115–128. [Google Scholar] [CrossRef]

- Shi, J.; Bai, Y.; Diao, Z.; Zhou, J.; Yao, X.; Zhang, B. Row detection BASED navigation and guidance for agricultural robots and autonomous vehicles in row-crop fields: Methods and applications. Agronomy 2023, 13, 1780. [Google Scholar] [CrossRef]

- Li, X.; Lloyd, R.; Ward, S.; Cox, J.; Coutts, S.; Fox, C. Robotic crop row tracking around weeds using cereal-specific features. Comput. Electron. Agric. 2022, 197, 106941. [Google Scholar] [CrossRef]

- Burgos-Artizzu, X.P.; Ribeiro, A.; Tellaeche, A.; Pajares, G.; Fernández-Quintanilla, C. Analysis of natural images processing for the extraction of agricultural elements. Image Vis. Comput. 2010, 28, 138–149. [Google Scholar] [CrossRef]

- Correa, C.; Valero, C.; Barreiro, P. Row crop’s identification through hough transform using images segmented by robust fuzzy possibilistic c-means. In Proceedings of the Spanish Association for Artificial Intelligence, La Laguna, Spain, 7–11 November 2011. [Google Scholar]

- Zhang, T.; Zhou, J.; Liu, W.; Yue, R.; Shi, J.; Zhou, C.; Hu, J. SN-CNN: A Lightweight and Accurate Line Extraction Algorithm for Seedling Navigation in Ridge-Planted Vegetables. Agriculture 2024, 14, 1446. [Google Scholar] [CrossRef]

- Shi, J.; Bai, Y.; Zhou, J.; Zhang, B. Multi-crop navigation line extraction based on improved YOLO-v8 and threshold-DBSCAN under complex agricultural environments. Agriculture 2023, 14, 45. [Google Scholar] [CrossRef]

- Li, D.; Li, B.; Long, S.; Feng, H.; Xi, T.; Kang, S.; Wang, J. Rice seedling row detection based on morphological anchor points of rice stems. Biosyst. Eng. 2023, 226, 71–85. [Google Scholar] [CrossRef]

- Ma, Z.; Tao, Z.; Du, X.; Yu, Y.; Wu, C. Automatic detection of crop root rows in paddy fields based on straight-line clustering algorithm and supervised learning method. Biosyst. Eng. 2021, 211, 63–76. [Google Scholar] [CrossRef]

- Ruan, Z.; Chang, P.; Cui, S.; Luo, J.; Gao, R.; Su, Z. A precise crop row detection algorithm in complex farmland for unmanned agricultural machines. Biosyst. Eng. 2023, 232, 1–12. [Google Scholar] [CrossRef]

- Gai, J.; Xiang, L.; Tang, L. Using a depth camera for crop row detection and mapping for under-canopy navigation of agricultural robotic vehicle. Comput. Electron. Agric. 2021, 188, 106301. [Google Scholar] [CrossRef]

- Liu, X.; Qi, J.; Zhang, W.; Bao, Z.; Wang, K.; Li, N. Recognition method of maize crop rows at the seedling stage based on MS-ERFNet model. Comput. Electron. Agric. 2023, 211, 107964. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Y.; Yue, X.; Zhang, G.; Wen, X.; Ma, B.; Xu, L.; Chen, L. Real-time detection of crop rows in maize fields based on autonomous extraction of ROI. Expert Syst. Appl. 2023, 213, 118826. [Google Scholar] [CrossRef]

- Cao, M.; Tang, F.; Ji, P.; Ma, F. Improved real-time semantic segmentation network model for crop vision navigation line detection. Front. Plant Sci. 2022, 13, 898131. [Google Scholar] [CrossRef]

- De Silva, R.; Cielniak, G.; Wang, G.; Gao, J. Deep learning-based crop row detection for infield navigation of agri-robots. J. Field Robot. 2024, 41, 2299–2321. [Google Scholar] [CrossRef]

- Rabab, S.; Badenhorst, P.; Chen, Y.P.P.; Daetwyler, H.D. A template-free machine vision-based crop row detection algorithm. Precis. Agric. 2021, 22, 124–153. [Google Scholar] [CrossRef]

- Diao, Z.; Guo, P.; Zhang, B.; Zhang, D.; Yan, J.; He, Z.; Zhao, S.; Zhao, C. Maize crop row recognition algorithm based on improved UNet network. Comput. Electron. Agric. 2023, 210, 107940. [Google Scholar] [CrossRef]

- Guo, Z.; Geng, Y.; Wang, C.; Xue, Y.; Sun, D.; Lou, Z.; Chen, T.; Geng, T.; Quan, L. InstaCropNet: An efficient Unet-based architecture for precise crop row detection in agricultural applications. Artif. Intell. Agric. 2024, 12, 85–96. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Q.; Wang, X.; Li, H.; He, J.; Lu, C.; Yang, Y.; Jiang, S. Automated detection of Crop-Row lines and measurement of maize width for boom spraying. Comput. Electron. Agric. 2023, 215, 108406. [Google Scholar] [CrossRef]

- Zhong, W.; Yang, W.; Zhu, J.; Jia, W.; Dong, X.; Ou, M. An Improved UNet-Based Path Recognition Method in Low-Light Environments. Agriculture 2024, 14, 1987. [Google Scholar] [CrossRef]

- Wang, Q.; Qin, W.; Liu, M.; Zhao, J.; Zhu, Q.; Yin, Y. Semantic Segmentation Model-Based Boundary Line Recognition Method for Wheat Harvesting. Agriculture 2024, 14, 1846. [Google Scholar] [CrossRef]

- Zheng, D.; Yan, J.; Xue, T.; Liu, Y. An instance segmentation framework based on parallelogram mask for crop row detection in various farmlands. Multimed. Tools Appl. 2024, 83, 48701–48717. [Google Scholar] [CrossRef]

- Li, G.; Le, F.; Si, S.; Cui, L.; Xue, X. Image Segmentation-Based Oilseed Rape Row Detection for Infield Navigation of Agri-Robot. Agronomy 2024, 14, 1886. [Google Scholar] [CrossRef]

- Hongyang, T.; Daming, H.; Xingyi, H.; Aheto, J.H.; Yi, R.; Yu, W.; Ji, L.; Shuai, N.; Mengqi, X. Detection of browning of fresh-cut potato chips based on machine vision and electronic nose. J. Food Process Eng. 2021, 44, e13631. [Google Scholar] [CrossRef]

- Huang, X.; Yu, S.; Xu, H.; Aheto, J.H.; Bonah, E.; Ma, M.; Wu, M.; Zhang, X. Rapid and nondestructive detection of freshness quality of postharvest spinaches based on machine vision and electronic nose. J. Food Saf. 2019, 39, e12708. [Google Scholar] [CrossRef]

- Zhu, J.; Cai, J.; Sun, B.; Xu, Y.; Lu, F.; Ma, H. Inspection and classification of wheat quality using image processing. Qual. Assur. Saf. Crop. Foods 2023, 15, 43–54. [Google Scholar] [CrossRef]

- Rivera, G.; Porras, R.; Florencia, R.; Sánchez-Solís, J.P. LiDAR applications in precision agriculture for cultivating crops: A review of recent advances. Comput. Electron. Agric. 2023, 207, 107737. [Google Scholar] [CrossRef]

- Fei, B.; Yang, W.; Chen, W.M.; Li, Z.; Li, Y.; Ma, T.; Hu, X.; Ma, L. Comprehensive review of deep learning-based 3d point cloud completion processing and analysis. IEEE Trans. Intell. Transp. Syst. 2022, 23, 22862–22883. [Google Scholar] [CrossRef]

- Sun, Y.; Luo, Y.; Zhang, Q.; Xu, L.; Wang, L.; Zhang, P. Estimation of crop height distribution for mature rice based on a moving surface and 3D point cloud elevation. Agronomy 2022, 12, 836. [Google Scholar] [CrossRef]

- Gu, W.; Wen, W.; Wu, S.; Zheng, C.; Lu, X.; Chang, W.; Xiao, P.; Guo, X. 3D reconstruction of wheat plants by integrating point cloud data and virtual design optimization. Agriculture 2024, 14, 391. [Google Scholar] [CrossRef]

- Biglia, A.; Zaman, S.; Gay, P.; Aimonino, D.R.; Comba, L. 3D point cloud density-based segmentation for vine rows detection and localisation. Comput. Electron. Agric. 2022, 199, 107166. [Google Scholar] [CrossRef]

- Goetz, K.T.; Soitinaho, R.; Oksanen, T. Ploughing furrow recognition for onland ploughing using a 3D-LiDAR sensor. Comput. Electron. Agric. 2023, 210, 107941. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, X.; An, D.; Han, H.; Tang, W.; Wang, Y.; Yang, Y.; Ma, Q.; Chen, L. Crop Row Detection Algorithm Based on 3D LiDAR: Suitable for Crop Row Detection in Different Periods. IEEE Trans. Instrum. Meas. 2024, 73, 8503413. [Google Scholar]

- Liu, R.; Yandun, F.; Kantor, G. Towards Over-Canopy Autonomous Navigation: Crop-Agnostic LiDAR-Based Crop-Row Detection in Arable Fields. arXiv 2024, arXiv:2403.17774. [Google Scholar]

- Luna-Santamaria, J.; Martínez de Dios, J.R.; Ollero Baturone, A. LIDAR-based detection of furrows for agricultural robot autonomous navigation. In Proceedings of the XLIII Jornadas de Automática, La Rioja, Spain, 7–9 September 2022; Universidade da Coruña: A Coruña, Spain, 2022; pp. 728–734. [Google Scholar]

- Chakraborty, S.; Elangovan, D.; Govindarajan, P.L.; ELnaggar, M.F.; Alrashed, M.M.; Kamel, S. A comprehensive review of path planning for agricultural ground robots. Sustainability 2022, 14, 9156. [Google Scholar] [CrossRef]

- Lu, E.; Xu, L.; Li, Y.; Tang, Z.; Ma, Z. Modeling of working environment and coverage path planning method of combine harvesters. Int. J. Agric. Biol. Eng. 2020, 13, 132–137. [Google Scholar] [CrossRef]

- Xie, F.; Guo, Z.; Li, T.; Feng, Q.; Zhao, C. Dynamic Task Planning for Multi-Arm Harvesting Robots Under Multiple Constraints Using Deep Reinforcement Learning. Horticulturae 2025, 11, 88. [Google Scholar] [CrossRef]

- Shi, R.; Han, X.; Guo, W. Uncertain multi-objective programming approach for planning supplementary irrigation areas in rainfed agricultural regions. Irrig. Drain. 2024, 73, 1–11. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, W.; Wei, X. Improved Field Obstacle Detection Algorithm Based on YOLOv8. Agriculture 2024, 14, 2263. [Google Scholar] [CrossRef]

- Santos, L.C.; Santos, F.N.; Pires, E.S.; Valente, A.; Costa, P.; Magalhaes, S. Path planning for ground robots in agriculture: A short review. In Proceedings of the 2020 IEEE International Conference on Autonomous Robot Systems and Competitions (ICARSC), Ponta Delgada, Portugal, 15–17 April 2020; pp. 61–66. [Google Scholar]

- Chen, T.; Xu, L.; Ahn, H.S.; Lu, E.; Liu, Y.; Xu, R. Evaluation of headland turning types of adjacent parallel paths for combine harvesters. Biosyst. Eng. 2023, 233, 93–113. [Google Scholar] [CrossRef]

- Höffmann, M.; Patel, S.; Büskens, C. Optimal coverage path planning for agricultural vehicles with curvature constraints. Agriculture 2023, 13, 2112. [Google Scholar] [CrossRef]

- Arab, D.P.; Spisser, M.; Essert, C. Introduction of A Row-Skip Pattern in Complete Coverage Path Planning for Agricultural Fields. In Proceedings of the 2023 9th International Conference on Automation, Robotics and Applications (ICARA), Abu Dhabi, United Arab Emirates, 10–12 February 2023; pp. 107–111. [Google Scholar]

- Liu, L.; Wang, X.; Liu, H.; Li, J.; Wang, P.; Yang, X. A full-coverage path planning method for an orchard mower based on the dung beetle optimization algorithm. Agriculture 2024, 14, 865. [Google Scholar] [CrossRef]

- Han, J.; Li, W.; Xia, W.; Wang, F. Research on Complete Coverage Path Planning of Agricultural Robots Based on Markov Chain Improved Genetic Algorithm. Appl. Sci. 2024, 14, 9868. [Google Scholar] [CrossRef]