The Effect of Agricultural Mechanization Services on the Technical Efficiency of Cotton Production

Abstract

1. Introduction

1.1. Literature Review

1.2. Research Hypothesis

2. Materials and Methods

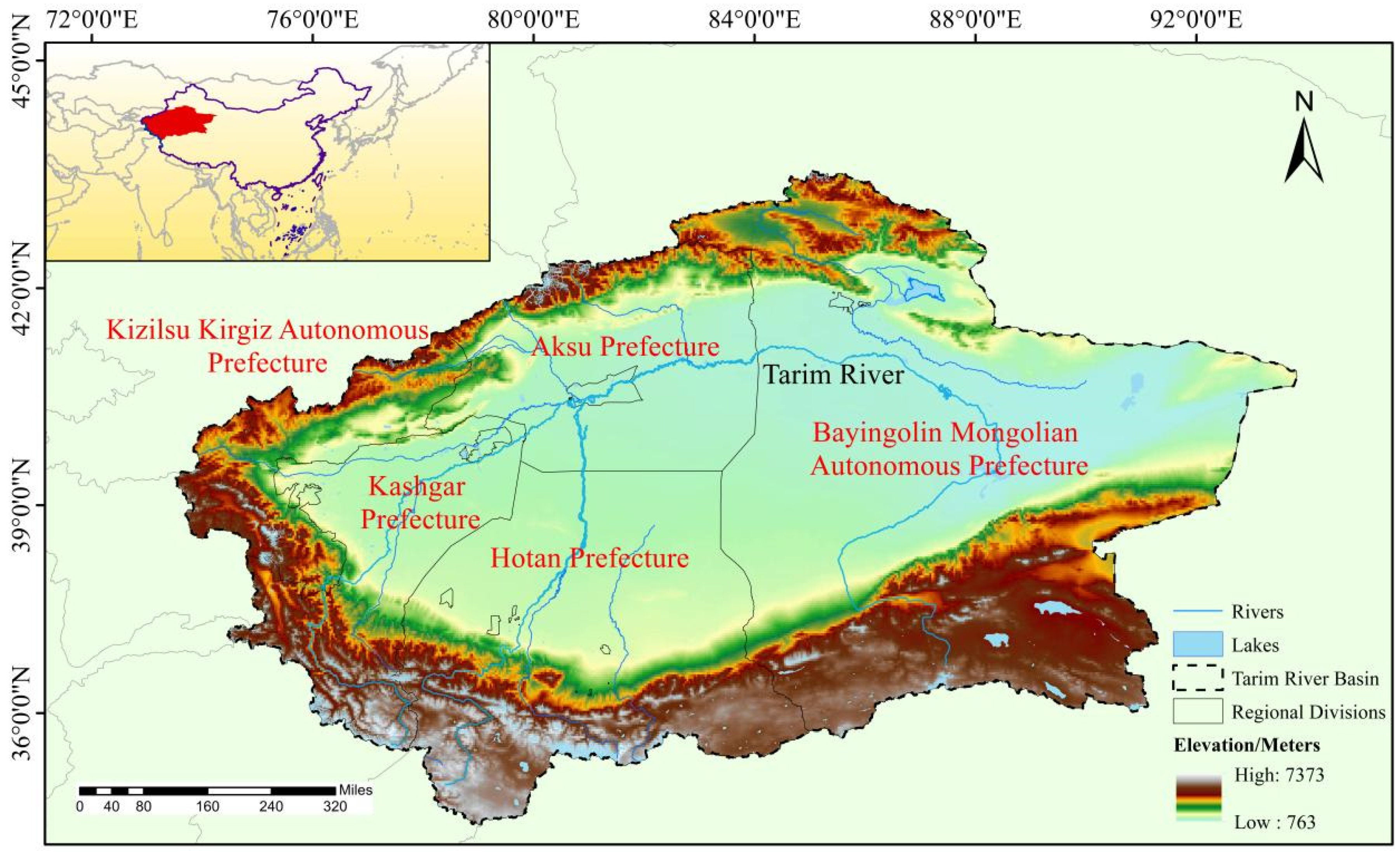

2.1. Description of the Study Area

2.2. Data Sources

2.3. Research Methods

2.3.1. Stochastic Frontier Analysis

2.3.2. Propensity Score Matching Method

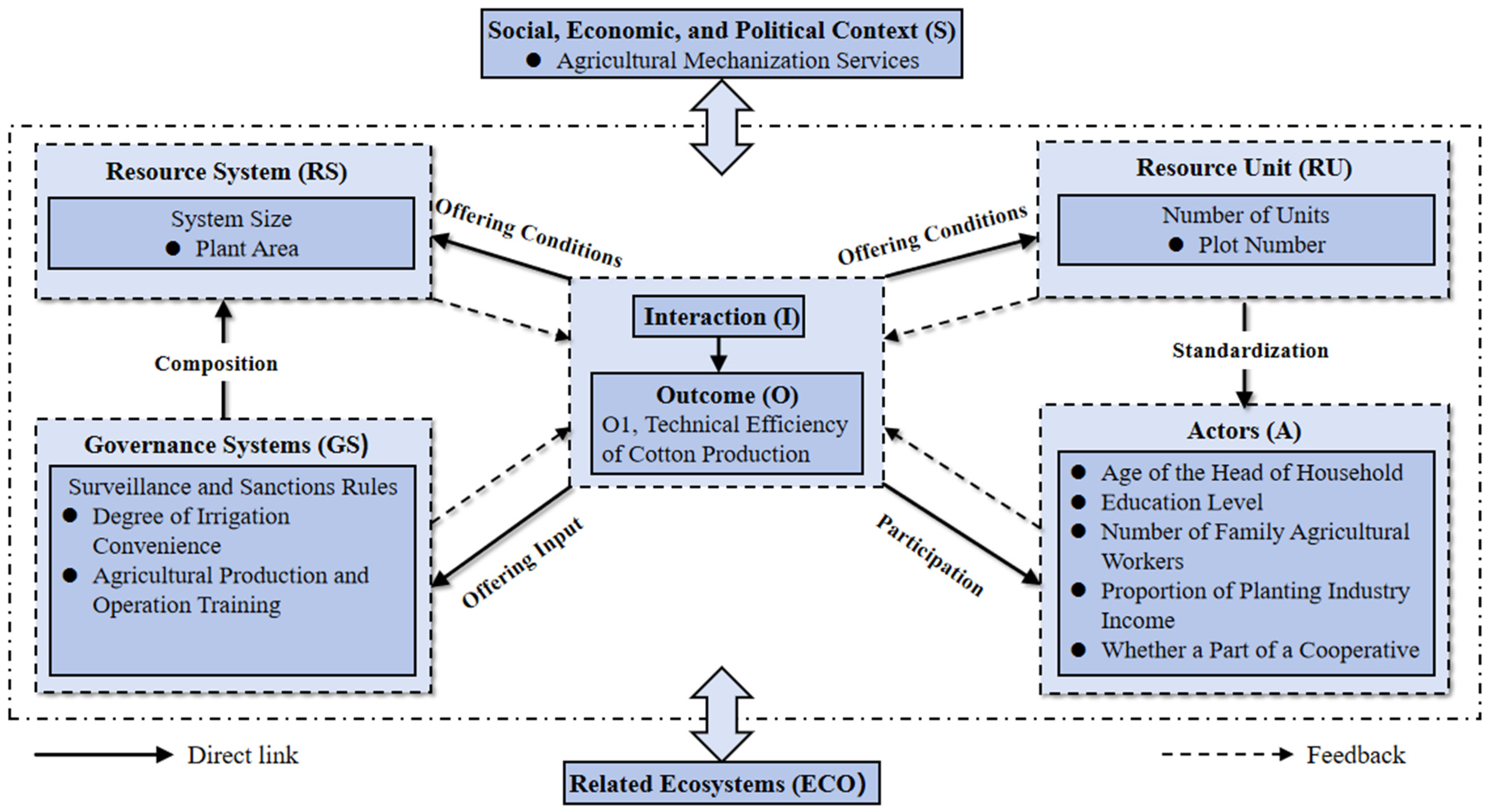

2.4. Research Framework and Variable Selection

3. Results

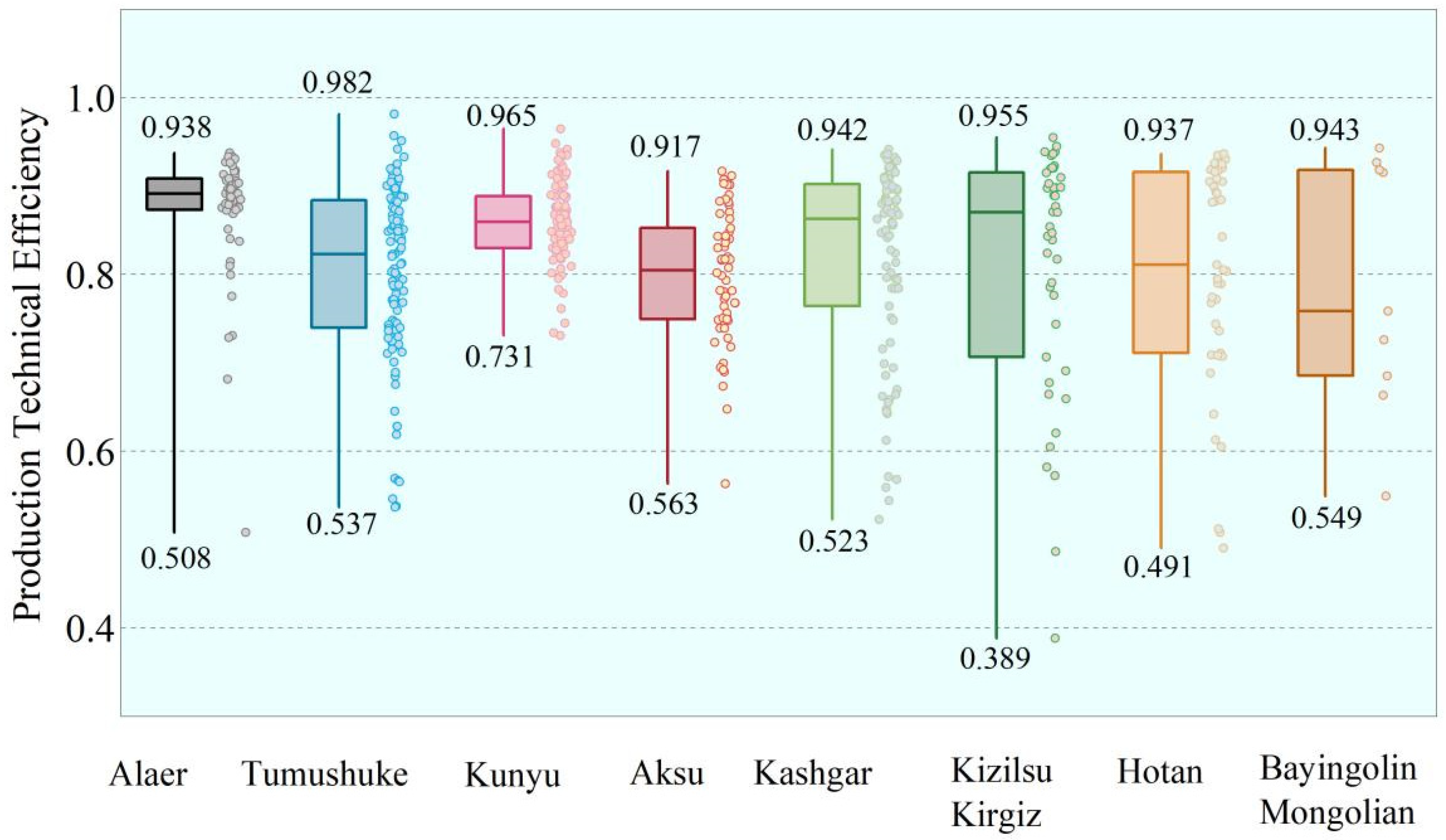

3.1. Estimation Results of Cotton Production’s Technical Efficiency

3.2. The Impact of AMSs on Production Technology Efficiency

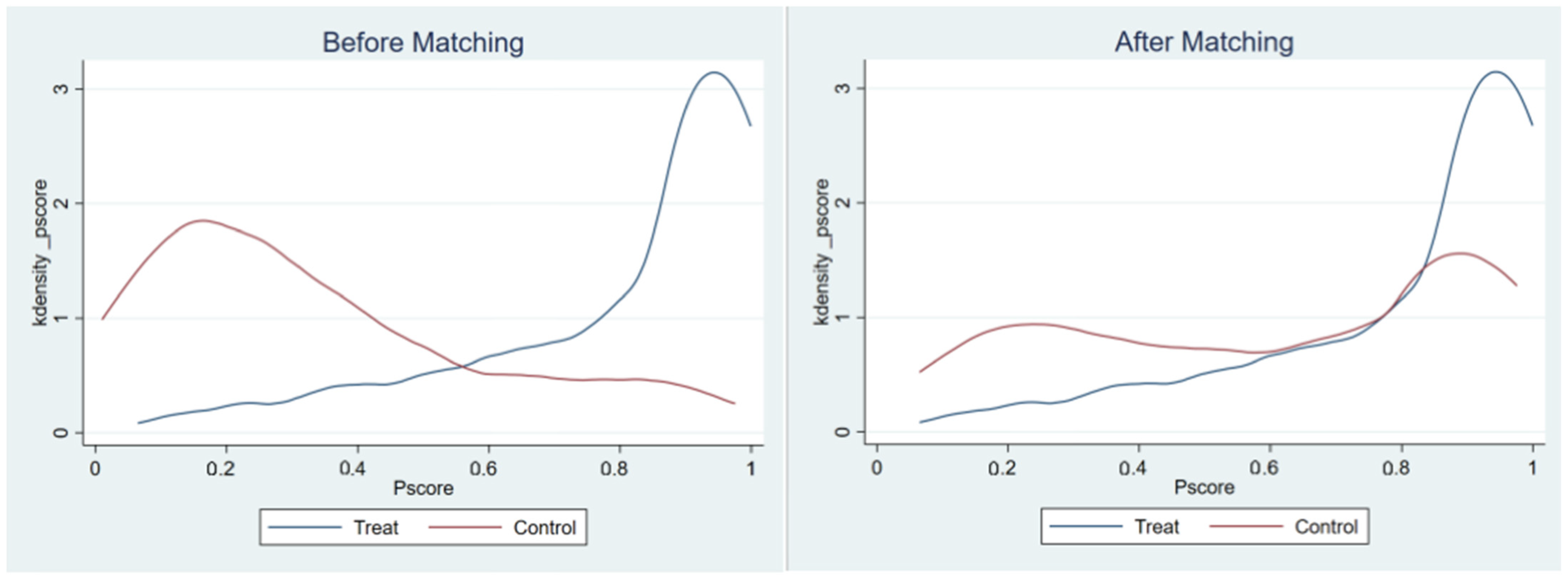

3.3. Robustness Test

4. Discussion

5. Conclusions and Recommendations

- (1)

- Strengthening the construction and decentralization of the AMS. At the resource system level, the extension of the agricultural machinery service network to grassroots levels essentially optimizes the allocation of material capital, forming a complementarity through government-led institutional design (governance system) and participation from social organizations (actors). Financial subsidies and tax incentives can be seen as positive incentives for social capital, promoting the establishment of trust between agricultural machinery service organizations and cotton farmers by reducing the transaction costs of service provision. Especially during critical farming periods, such as sowing and harvesting, ensuring efficient and timely agricultural machinery operation services is crucial for safeguarding agricultural production. These policy measures not only help enhance the enthusiasm of agricultural machinery service organizations but also effectively reduce the production costs for cotton farmers, improving the overall efficiency of agricultural production.

- (2)

- Optimizing resource allocation and enhancing the efficiency balance within regions. The differences in agricultural production efficiency reflect the spatial heterogeneity of resource systems and resource units. Inefficient areas often experience low resource utilization efficiency due to land fragmentation, outdated technology, or insufficient infrastructure. The government can adjust resource distribution through differentiated policies, such as specialized technical guidance and financial support, to improve the resource conditions in inefficient areas. At the same time, promoting land transfer and moderate-scale operations can optimize the organizational methods of resource units, create economies of scale, reduce production costs, and enhance the overall productivity of the system. This process also involves adjustments in the behavior of actors, such as farmers’ willingness to participate in land transfers, which needs to be guided through reasonable institutional designs.

- (3)

- Enhancing the intrinsic motivation of farmers to adopt agricultural machinery services. Farmers’ decision-making behaviors are influenced by social norms, cognitive levels, and external incentives [62]. Publicity and education, along with the sharing of successful cases, can change farmers’ perceptions of agricultural machinery services, while incentive mechanisms (such as subsidies and insurance linkages) can reduce adoption risks through the rules within the governance system. Additionally, rural education and human resource development can improve farmers’ technical acceptance capacity, thereby enhancing their adaptability to agricultural machinery services. This process reflects the interaction between social subsystems and governance subsystems, with the ultimate goal of optimizing the interaction between farmers and resource systems to achieve sustainability in agricultural production.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AMSs | agricultural mechanization services |

| SES | social–ecological system |

| SFA | stochastic frontier analysis |

| PSM | Propensity Score Matching |

Appendix A

| Social, economic, and political contexts (S) S1, Economic development; S2, Demographic trends; S3, Policy stability; S4, Government policy; S5, Marketization; S6, Expert Team; S7, Techniques | |||

| Resource system (RS) | Governance system (GS) | Resource unit (RU) | User (U) |

| RS1, Resource sector | GS1, Government organizations | U1, Number of users | |

| RS2, Whether the system boundaries are clear | GS2, Non-governmental organizations | RU1, Liquidity of resource unit | U2, Socio-economic attributes of users |

| RS3, System size | GS3, Network structure | RU2, Increase, decrease, and turnover rate | U3, Use history and experience |

| RS4, Man-made facilities | GS4, Property rights system | RU3, Interactivity of resource units | U4, Geographical location |

| RS5, System productivity | GS5, Operational rules | RU4, Economic value of resource units | U5, Leadership |

| RS6, Ability to maintain self balance | GS6, Rules of collective choice | RU5, Number of units | U6, Social norms/social capital |

| RS7, Predictability of facility provision | GS7, Constitutional rules | RU6, Distinguishable features | U7, Perception of socio-ecological systems |

| RS8, Resource storage feature | GS8, Surveillance and sanctions rules | RU7, Spatiotemporal allocation of resources | U8, Dependence on resources |

| RS9, Locations | U9, Techniques used | ||

| Interaction (I) → Outcomes (O) | |||

| I1, Level of resources obtained I2, Information sharing between users I3, Negotiation I4, Conflicts between users I5, Investment in equipment maintenance I6, Lobbying behavior I7, Self-organizing actions I8, Networked action I9, Supervision activities I10, Evaluation activities | |||

| O1, Social performance measurement | |||

| O2, Ecological performance measurement | |||

| O3, Externalities (impact on other systems) | |||

| Associated ecosystem (ECO) ECO1, Climatic conditions; ECO2, Pollution patterns; ECO3, Focused inflow and outflow of SES | |||

References

- Xu, Z.X.; Liu, Z.F.; Fu, G.B.; Chen, Y.N. Trends of major hydroclimatic variables in the Tarim River basin during the past 50 years. J. Arid Environ. 2010, 74, 256–267. [Google Scholar] [CrossRef]

- Feng, M.Q.; Chen, Y.N.; Duan, W.L.; Fang, G.H.; Li, Z.; Jiao, L.; Sun, F.; Li, Y.P.; Hou, Y.F. Comprehensive evaluation of the water-energy-food nexus in the agricultural management of the Tarim River Basin, Northwest China. Agric. Water Manag. 2022, 271, 107811. [Google Scholar] [CrossRef]

- Qian, L.; Lu, H.; Gao, Q.; Lu, H.L. Household-owned farm machinery vs. outsourced machinery services: The impact of agricultural mechanization on the land leasing behavior of relatively large-scale farmers in China. Land Use Policy 2022, 115, 106008. [Google Scholar] [CrossRef]

- Zhou, X.; Ma, W. Agricultural mechanization and land productivity in China. Int. J. Sustain. Dev. World Ecol. 2022, 29, 530–542. [Google Scholar] [CrossRef]

- Belton, B.; Fang, P.X.; Thomas, R. Combine Harvester Outsourcing Services and Seasonal Rural Non-Farm Employment in Myanmar. Appl. Econ. Perspect. Policy 2025, 47, 97–124. [Google Scholar] [CrossRef]

- Qiu, H.L.; Feng, M.R.; Tang, W.Y.; Luo, M.Z.; Wang, J.W.; Ye, F. Analysis of the impact of farm machinery outsourcing services on farmers’ cropping structure and grain production: An empirical evidence from Henan Province, China. Front. Sustain. Food Syst. 2024, 8, 1365576. [Google Scholar] [CrossRef]

- Lu, Q.; Du, X.; Qiu, H. Adoption patterns and productivity impacts of agricultural mechanization services. Agric. Econ. 2022, 53, 826–845. [Google Scholar] [CrossRef]

- Tamrat, G.; Mengistu, K.; Arega, S.; Getachew, L.F. Impact of farm mechanization on crop productivity and economic efficiency in central and southern Oromia, Ethiopia. Front. Sustain. Food Syst. 2024, 8, 1414912. [Google Scholar] [CrossRef]

- Xu, J.Y.; Lu, J. The Industrialization of Agricultural Machinery Services and the Transformation of Agricultural Production Methods in China. Agric. Technol. Econ. 2000, 2, 60–64. [Google Scholar] [CrossRef]

- Zou, B.L.; Ashok, K.M. Modernizing Smallholder Agriculture and Achieving Food Security: An Exploration in Machinery Services and Labor Reallocation in China. Appl. Econ. Perspect. Policy 2024, 46, 1662–1691. [Google Scholar] [CrossRef]

- Belton, B.; Win, M.T.; Zhang, X.; Filipski, M. The rapid rise of agricultural mechanization in Myanmar. Food Policy 2021, 101, 102095. [Google Scholar] [CrossRef]

- Luo, X.W.; Liao, J.; Zang, Y.; Qu, Y.G.; Wang, P. The Development Direction of Agricultural Production in Our Country: From Mechanization to Intelligence. China Eng. Sci. 2022, 24, 46–54. [Google Scholar] [CrossRef]

- Yangchen, D.C.; Hong, M.; Yang, Q. The Effect of Farmland Transfer on the Technical Efficiency of Farm Households in China: An Empirical Result of External Environmental Factors. Land 2023, 12, 64. [Google Scholar] [CrossRef]

- Muhamad, M.Z.; Kamarulzaman, N.H.; Nawi, N.M.; Shamsudin, M.N.; Laham, J. Assessing Technical Efficiency in Malaysian Pineapple Farms: A Stochastic Frontier Analysis Approach. Emir. J. Food Agric. 2023, 35, 1–9. [Google Scholar] [CrossRef]

- Zhong, Z.; Jiang, W.Y.; Yang, S.S. Does agricultural outsourcing improve technical efficiency? Evidence from farms of various scales in China. J. Rural Stud. 2025, 117, 103650. [Google Scholar] [CrossRef]

- Fuksová, Z.; Mareš, D.; Křápek, M. The impact of efficiency on the profitability of large farms in the Visegrad Four. Agric. Econ.-Czech. 2024, 70, 457–464. [Google Scholar] [CrossRef]

- Boakye, K.; Lee, Y.F.; Annor, F.F.; Dadzie, S.K.N.; Salifu, I. Data Envelopment Analysis (DEA) to Estimate Technical and Scale Efficiencies of Smallholder Pineapple Farmers in Ghana. Agriculture 2024, 14, 1032. [Google Scholar] [CrossRef]

- Aslam, M.; Li, Z.; Golubinova, I.; Alamer, K.; Ahmad, S. Determinants of Agricultural Productivity in Rice-Wheat Crop Rotation and Its Impact on Agricultural Cohesion: Lessons Learned from Pakistan. C. R. Acad. Bulg. Sci. 2024, 77, 936–943. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, W.; Jetté-Nantel, S.; Tian, Z.H. The influence of labor price change on agricultural machinery usage in Chinese agriculture. Can. J. Agric. Econ. 2014, 62, 219–243. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, J.; Thomas, R. Mechanization outsourcing clusters and division of labor in Chinese agriculture. China Econ. Rev. 2017, 43, 184–195. [Google Scholar] [CrossRef]

- Long, Y.J.; Liang, Y.; Liang, J.; Zhang, Y.J. Research on the Impact of Agricultural Machinery Socialized Services on Corn Production Efficiency—Based on Survey Data from Corn Growers in Jilin Province. Maize Sci. 2024, 32, 119–126. [Google Scholar] [CrossRef]

- Yang, S.; Li, W. The Impact of Socialized Agricultural Machinery Services on Land Productivity: Evidence from China. Agriculture 2022, 12, 2072. [Google Scholar] [CrossRef]

- Wu, A.; Elahi, E.; Cao, F.; Yusuf, M.; Abro, M.I. Sustainable grain production growth of farmland–A role of agricultural socialized services. Heliyon 2024, 73, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Qing, Y.; Chen, M.; Sheng, Y.; Huang, J. Mechanization services, farm productivity and institutional innovation in China. China Agric. Econ. Rev. 2019, 11, 536–554. [Google Scholar] [CrossRef]

- Liu, X.; Li, X. The Influence of Agricultural Production Mechanization on Grain Production Capacity and Efficiency. Processes 2023, 11, 487. [Google Scholar] [CrossRef]

- Nguyen, H.Q.; Warr, P. Land consolidation as technical change: Economic impacts in rural. World Dev. 2020, 127, 104750. [Google Scholar] [CrossRef]

- Takeshima, H. Mechanize or exit farming? Multiple-treatment-effects model and external validity of adoption impacts of mechanization among Nepalese smallholders. Rev. Dev. Econ. 2018, 22, 1620–1641. [Google Scholar] [CrossRef]

- Kotu, B.H.; Manda, J.; Mutungi, C.; Fischer, G.; Gaspar, A. Farmers’ willingness to invest in mechanized maize shelling and potential financial benefits: Evidence from Tanzania. Agribusiness 2023, 39, 854–874. [Google Scholar] [CrossRef]

- Hamilton, S.F.; Richards, T.J.; Shafran, A.P.; Vasilaky, K.N. Farm labor productivity and the impact of mechanization. Am. J. Agric. Econ. 2022, 104, 1435–1459. [Google Scholar] [CrossRef]

- Tingley, D.; Pascoe, S.; Coglan, L. Factors affecting technical efficiency in fisheries: Stochastic production frontier versus data envelopment analysis approaches. Fish. Res. 2005, 73, 363–376. [Google Scholar] [CrossRef]

- Yang, H.L.; Li, Y.; Han, X.D.; Zheng, F.T. Does land fragmentation increase the agricultural production costs of “large-scale farmers”?—Based on a micro survey of 776 family farms and 1166 specialized large households nationwide. China Land Sci. 2019, 33, 76–83. [Google Scholar] [CrossRef]

- McGinnis, M.D.; Ostrom, E. Social-ecological system framework: Initial changes and continuing challenges. Ecol. Soc. 2014, 19, 30. [Google Scholar] [CrossRef]

- Poteete, A.R.; Ostrom, E. In pursuit of comparable concepts and data about collective action. Agric. Syst. 2004, 82, 215–232. [Google Scholar] [CrossRef]

- Huan, M.; Dong, F.; Chi, L. Mechanization services, factor allocation, and farm efficiency: Evidence from China. Rev. Dev. Econ. 2022, 26, 1618–1639. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. China Statistical Yearbook 2024. 2024. Available online: http://www.stats.gov.cn/ (accessed on 10 October 2024).

- Liu, X.H.; Xu, H.L.; Ling, H.B.; Bai, Y.; Fu, J.Y.; Dai, Y. Research on the Ecological Water Demand of the Main Stream of the Tarim River. Arid Zone Res. 2012, 29, 984–991. [Google Scholar] [CrossRef]

- Chen, Y.N.; Hao, X.M.; Chen, Y.P.; Zhu, C.G. Research on the Connectivity of Water Systems and Ecological Protection Strategies in the Tarim River Basin, Xinjiang. Bull. Chin. Acad. Sci. 2019, 34, 1156–1164. [Google Scholar] [CrossRef]

- Wu, H.; Xu, M.; Peng, Z.Y.; Chen, X.P. Quantifying the potential impacts of meltwater on cotton yields in the Tarim River Basin, Central Asia. Agric. Water Manag. 2022, 269, 107639. [Google Scholar] [CrossRef]

- Lu, Q.; Yang, Y.; Li, B.; Li, Y.; Wang, D. Coupling Relationship and Influencing Factors of the Water–Energy–Cotton System in Tarim River Basin. Agronomy 2022, 12, 2333. [Google Scholar] [CrossRef]

- Xinjiang Uygur Autonomous Region Department of Agriculture and Rural Affairs. Xinjiang Cotton Industry Development Report; Xinjiang Uygur Autonomous Region Department of Agriculture and Rural Affairs: Urumqi, China, 2022. [Google Scholar]

- Kopp, R.J. The Measurement of Productive Efficiency; Oxford University Press: Oxford, UK, 1981. [Google Scholar]

- Farrell, M.J. The Measurement of Productive Efficiency. J. R. Stat. Soc. 1957, 120, 253–290. [Google Scholar] [CrossRef]

- Battese, G.E.; Coelli, T.J. Frontier production functions, technical efficiency and panel data: With application to paddy farmers in India. J. Product. Anal. 1992, 3, 153–169. [Google Scholar] [CrossRef]

- Taylor, T.G.; Shonkwiler, S.J. Alternative stochastic specifications of the frontier production function in the analysis of agricultural credit programs and technical efficiency. J. Dev. Econ. 1986, 21, 149–160. [Google Scholar] [CrossRef]

- Kopp, R.J.; Smith, V.K. Frontier production function estimates for steam electric generation: A comparative analysis. Econom. J. 1980, 47, 1049–1059. [Google Scholar] [CrossRef]

- Abadie, A.; Imbens, G.W. Matching on the Estimated Propensity Score. Econometrica 2016, 84, 781–807. [Google Scholar] [CrossRef]

- Ostrom, E. A diagnostic approach for going beyond panaceas. Proc. Natl. Acad. Sci. USA 2007, 104, 15181–15187. [Google Scholar] [CrossRef]

- Ostrom, E. A general framework for analyzing sustainability of social-ecological systems. Science 2009, 325, 419–422. [Google Scholar] [CrossRef]

- Kumbhakar, S.C. Stochastic Frontier Analysis; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar] [CrossRef]

- Chiristensen, L.; Jorgenson, D.W.; Lau, L.J. Transcendental logarithmic production function. Rev. Econ. Stat. 1973, 55, 28–45. [Google Scholar] [CrossRef]

- Nguyen, T.; Nguyen, T.T.; Grote, U. Credit, shocks and production efficiency of rice farmers in Vietnam. Econ. Anal. Policy 2023, 77, 780–791. [Google Scholar] [CrossRef]

- Mano, Y.; Takahashi, K.; Otsuka, K. Mechanization in land preparation and agricultural intensification: The case of rice farming in the Cote d’Ivoire. Agric. Econ. 2020, 51, 899–908. [Google Scholar] [CrossRef]

- Kansanga, M.M.; Mkandawire, P.; Kuuire, V.; Luginaah, I. Agricultural mechanization, environmental degradation, and gendered livelihood implications in northern Ghana. Land Degrad. Dev. 2020, 31, 1422–1440. [Google Scholar] [CrossRef]

- Kirui, O.K.; Kornher, L.; Bekchanov, M. Productivity growth and the role of mechanisation in African agriculture. Agrekon 2023, 62, 80–97. [Google Scholar] [CrossRef]

- Wicki, L.; Dudek, H.; Parzonko, A.; Kusz, D.; Naglis-Liepa, K. Factors Influencing the Productivity of Direct Energy Inputs in EU Agriculture. Sustainability 2025, 17, 1217. [Google Scholar] [CrossRef]

- Dinis, I. Exploring the Drivers of Microregional Agricultural Labor Productivity: Empirical Insights from Portugal. Agriculture 2023, 13, 2150. [Google Scholar] [CrossRef]

- Singh, K.M.; Ahmad, N.; Sinha, D.K.; Kumar, A.; Singh, R.K.P. Cost efficiency of principal crops in Bihar (India)—A stochastic frontier approach. Indian J. Agric. Sci. 2020, 90, 1445–1452. [Google Scholar] [CrossRef]

- Hinkel, J.; Cox, M.E.; Schlüter, M.; Binder, C.R.; Falk, T. A diagnostic procedure for applying the social-ecological systems framework in diverse cases. Ecol. Soc. 2015, 20, 32. [Google Scholar] [CrossRef]

- Patil, V.; Veettil, P.C. Farmers’ risk attitude, agricultural technology adoption and impacts in Eastern India. Agric Food Secur. 2024, 13, 50. [Google Scholar] [CrossRef]

- Wu, F.; Guo, X.; Guo, X. Cooperative membership and new technology adoption of family farms: Evidence from China. Ann. Public Coop. Econ. 2023, 94, 719–739. [Google Scholar] [CrossRef]

- Coventry, D.R.; Poswal, R.S.; Yadav, A.; Zhou, Y.; Riar, A.; Kumar, A.; Cummins, J.A. A novel framework for identifying the interactions between biophysical and social components of an agricultural system: A guide for improving wheat production in Haryana, NW India. J. Agric. Educ. Ext. 2018, 24, 263–284. [Google Scholar] [CrossRef]

- Savari, M.; Damaneh, H.E.; Damaneh, H.E.; Cotton, M. Integrating the norm activation model and theory of planned behaviour to investigate farmer pro-environmental behavioural intention. Sci. Rep. 2023, 13, 5584. [Google Scholar] [CrossRef]

| SES Attributes | Variable Types | Variable | Definition | Mean | Std. Dev | Min | Max |

|---|---|---|---|---|---|---|---|

| Contextual variables (I→O) | Dependent variable | Technical efficiency of cotton production | Stochastic frontier measurement | 0.824 | 0.100 | 0.389 | 0.982 |

| Social, economic, and political contexts (S) | Core explanatory variables | AMSs | Adoption of any agricultural mechanization service (tillage, sowing, plant protection, irrigation and drainage, and harvesting) = 1, not adopted = 0 | 0.631 | 0.483 | 0 | 1 |

| Resource system (RS) | Control variables | Planting area | Continuous variable | 30.863 | 41.490 | 0.45 | 600 |

| Resource unit (RU) | Plots Number | Continuous variable | 2.611 | 1.696 | 1 | 9 | |

| Governance system (GS) | Degree of irrigation convenience | 1, Very inconvenient; 2, inconvenient; 3, Mostly convenient; 4, Convenient; 5, Very convenient | 4.310 | 0.812 | 1 | 5 | |

| Whether received agricultural production and operation training | 0, No 1, Yes | 0.679 | 0.467 | 0 | 1 | ||

| Actors (A) | Age of the household head | Continuous variable | 46.921 | 11.045 | 21 | 90 | |

| Education level | 1, Low level; 2, Lower middle level; 3, Medium level; 4, Upper middle level; 5, High level | 1.849 | 0.873 | 1 | 5 | ||

| Number of family agricultural works | Continuous variable | 2.199 | 0.721 | 1 | 6 | ||

| Proportion of planting industry income (%) | Continuous variable | 46.875 | 33.161 | 0.088 | 100 | ||

| Whether a part of a cooperative | 0, No 1, Yes | 0.415 | 0.493 | 0 | 1 |

| Variable | Unit | Mean | Std. Dev | Min | Max |

|---|---|---|---|---|---|

| Cotton Yield | kg/hm2 | 339.412 | 73.718 | 30.000 | 524.000 |

| Seed Input | CNY/hm2 | 68.649 | 42.899 | 2.000 | 300.000 |

| Chemical Input | CNY/hm2 | 168.278 | 137.441 | 2.114 | 960.000 |

| Machinery Input | CNY/hm2 | 159.862 | 188.324 | 2.105 | 1590.909 |

| Irrigation Water Input | CNY/hm2 | 145.282 | 98.408 | 5.313 | 500.000 |

| Labor Input | person·d/hm2 | 15.196 | 18.235 | 0.225 | 150.000 |

| Project | Coefficient Estimate | Standard Error | Z Value |

|---|---|---|---|

| Constant | 5.7010 *** | 0.0670 | 87.40 |

| In S | 0.0543 *** | 0.0161 | 1.87 |

| In C | −0.0074 | 0.0102 | −0.68 |

| In M | −0.0208 ** | 0.0079 | −1.49 |

| In W | 0.0302 *** | 0.0103 | 2.37 |

| In L | 0.0460 *** | 0.0066 | 5.78 |

| lnsig2v | −4.3050 *** | 0.2240 | −23.99 |

| lnsig2u | −2.6760 *** | 0.1660 | −11.25 |

| Production Technology Efficiency Range | All Samples | Subsample (Adopted Group) | Subsample (Non-Adopted Group) | |||

|---|---|---|---|---|---|---|

| Sample Size | Proportion (%) | Sample Size | Proportion (%) | Sample Size | Proportion (%) | |

| Below 0.6 | 21 | 4.23 | 0 | 0 | 21 | 11.48 |

| [0.6, 0.7) | 38 | 7.66 | 0 | 0 | 38 | 20.77 |

| [0.7, 0.8) | 99 | 19.96 | 53 | 16.93 | 46 | 25.14 |

| [0.8, 0.9) | 225 | 45.36 | 166 | 53.04 | 59 | 32.24 |

| [0.9, 1.0) | 113 | 22.78 | 94 | 30.03 | 19 | 10.38 |

| Variable | Coefficient Estimate | Standard Error | Z Value |

|---|---|---|---|

| Age of the household head | 0.037 * | 0.014 | 2.56 |

| Education level | 0.488 ** | 0.183 | 2.67 |

| Number of family agricultural works | 0.850 *** | 0.190 | 4.46 |

| Planting area | 0.001 | 0.003 | 0.31 |

| Proportion of planting industry income | 0.053 *** | 0.006 | 8.90 |

| Number of Plots | −0.288 *** | 0.077 | −3.72 |

| Whether they received agricultural production and operation training | 0.680 * | 0.265 | 2.57 |

| Whether they joined a cooperative | 0.106 | 0.258 | 0.41 |

| Degree of irrigation convenience | 0.794 *** | 0.170 | 4.66 |

| Constant | −9.139 *** | 1.470 | −6.22 |

| LR statistic | 260.86 | ||

| Pseudo R2 | 0.399 | ||

| Sample size | 496 | ||

| Matching Methods | Pseudo R2 | LR chi2 | p > chi2 | Mean Bias | Med Bias |

|---|---|---|---|---|---|

| Before matching | 0.399 | 260.32 | 0.000 | 46.6 | 30.6 |

| Nearest neighbor matching | 0.017 | 11.54 | 0.241 | 8.8 | 7.2 |

| Caliper nearest neighbor matching | 0.017 | 11.54 | 0.241 | 8.8 | 7.2 |

| Caliper matching | 0.021 | 14.69 | 0.100 | 10.9 | 7.1 |

| Kernel matching | 0.028 | 19.77 | 0.019 | 10.2 | 9.6 |

| Matching Methods | Treatment Group Mean | Control Group Mean | ATT | ATU | t Value | Standard Error |

|---|---|---|---|---|---|---|

| Nearest neighbor matching | 0.854 | 0.763 | 0.8577 | 0.761 | 0.136 *** | 0.020 |

| Caliper nearest neighbor matching | 0.854 | 0.763 | 0.8577 | 0.761 | 0.136 *** | 0. 019 |

| Caliper matching | 0.862 | 0.756 | 0.8578 | 0.762 | 0.126 *** | 0.021 |

| Kernel matching | 0.858 | 0.761 | 0.8577 | 0.761 | 0.137 *** | 0.019 |

| Project | Coefficient Estimate | Standard Error | Project | Coefficient Estimate | Standard Error |

|---|---|---|---|---|---|

| In S | 0.170 *** | 0.1697 | In S × In C | −0.031 | 0.0307 |

| In C | −0.016 | 0.0159 | In S × In M | −0.031 * | 0.0309 |

| In M | −0.145 *** | 0.1452 | In S × In W | 0.011 ** | 0.0114 |

| In W | 0.283 *** | 0.2830 | In S × In L | 0.020 *** | 0.0197 |

| In L | 0.054 *** | 0.0537 | In C × In M | 0.020 | 0.0203 |

| In S2 | 0.000 *** | 0.0004 | In C × In W | 0.001 | 0.0006 |

| In C2 | 0.003 | 0.0034 | In C × In L | −0.005 | 0.0053 |

| In M2 | −0.002 * | 0.0017 | In M × In W | −0.022 * | 0.0224 |

| In W2 | 0.283 | 0.0226 | In M × In L | −0.000 ** | 0.0010 |

| In L2 | −0.007 ** | 0.0074 | In W × In L | −0.007 *** | 0.0070 |

| lnsig2v | −4.870 *** | 0.3965 | lnsig2u | −1.602 *** | 0.0640 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Wang, G.; Du, H.; Liu, J.; Yang, Q. The Effect of Agricultural Mechanization Services on the Technical Efficiency of Cotton Production. Agriculture 2025, 15, 1233. https://doi.org/10.3390/agriculture15111233

Zhu Y, Wang G, Du H, Liu J, Yang Q. The Effect of Agricultural Mechanization Services on the Technical Efficiency of Cotton Production. Agriculture. 2025; 15(11):1233. https://doi.org/10.3390/agriculture15111233

Chicago/Turabian StyleZhu, Yaxue, Guangyao Wang, Huijuan Du, Jiajia Liu, and Qingshan Yang. 2025. "The Effect of Agricultural Mechanization Services on the Technical Efficiency of Cotton Production" Agriculture 15, no. 11: 1233. https://doi.org/10.3390/agriculture15111233

APA StyleZhu, Y., Wang, G., Du, H., Liu, J., & Yang, Q. (2025). The Effect of Agricultural Mechanization Services on the Technical Efficiency of Cotton Production. Agriculture, 15(11), 1233. https://doi.org/10.3390/agriculture15111233