Research Review of Agricultural Machinery Power Chassis in Hilly and Mountainous Areas

Abstract

1. Introduction

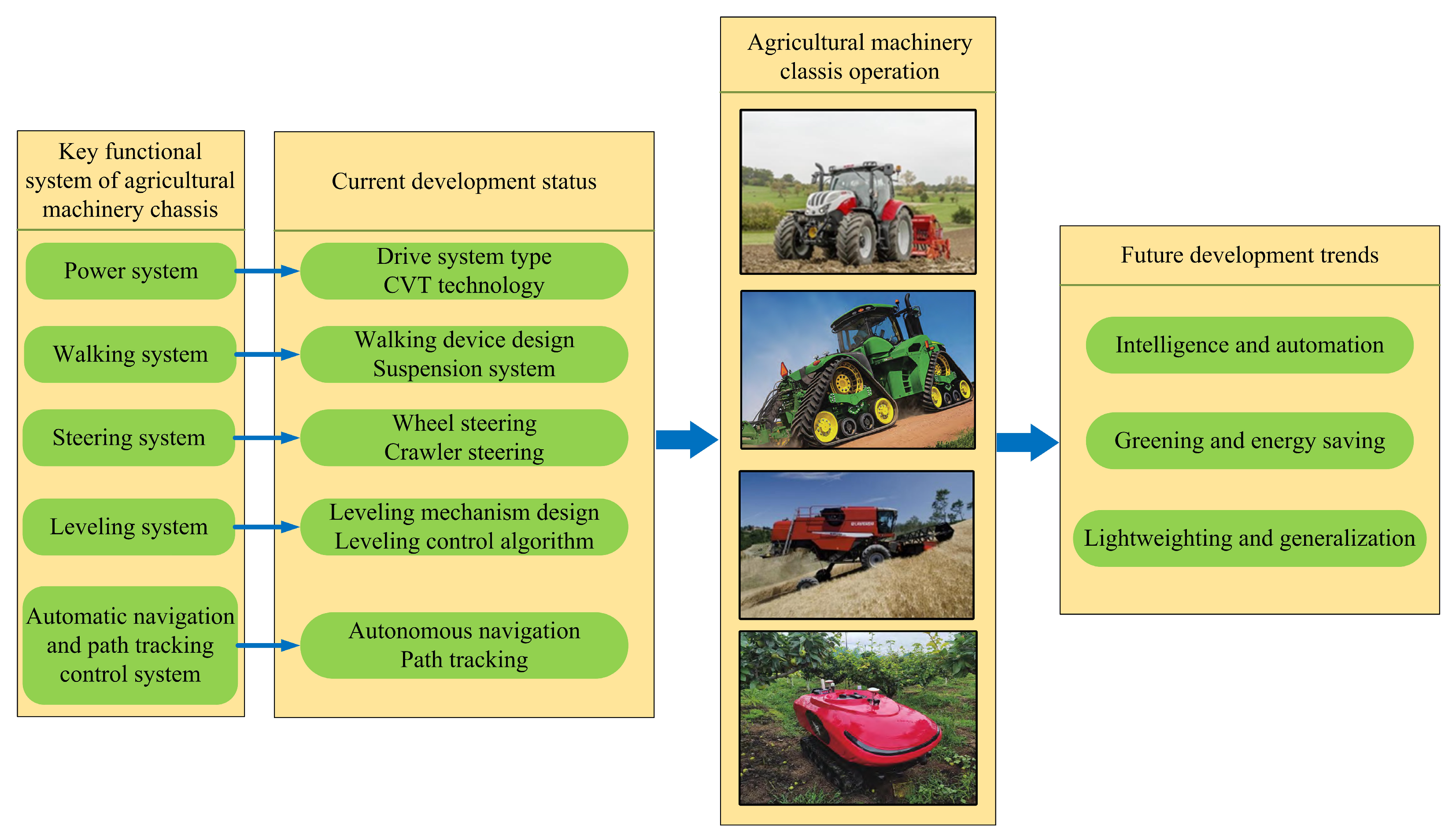

2. Power Systems of Agricultural Machinery Power Chassis

2.1. Chassis Drive System Type

2.2. Agricultural Machinery CVT Technology

3. Walking Systems of Agricultural Machinery Power Chassis

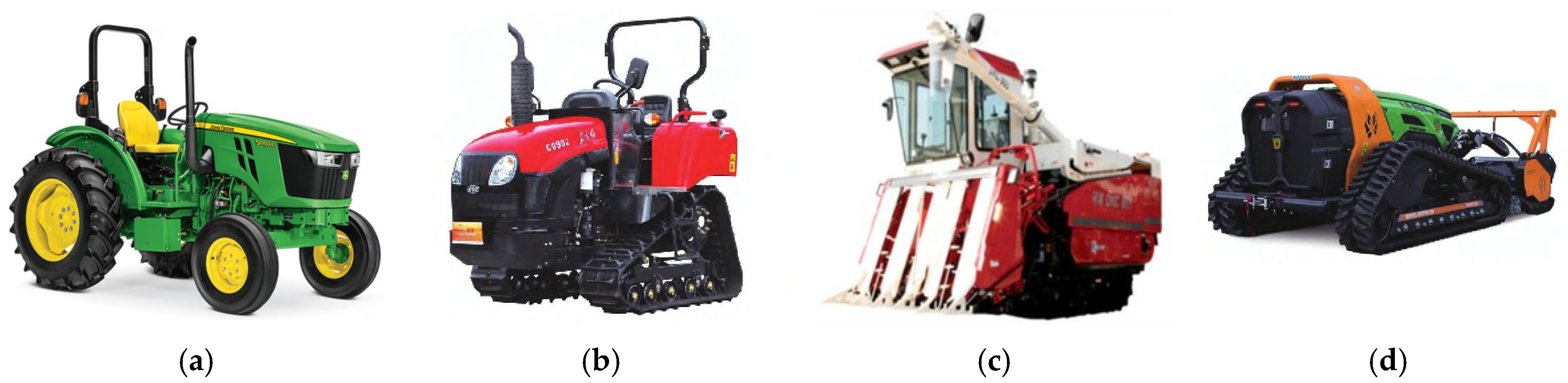

3.1. Walking Device Design

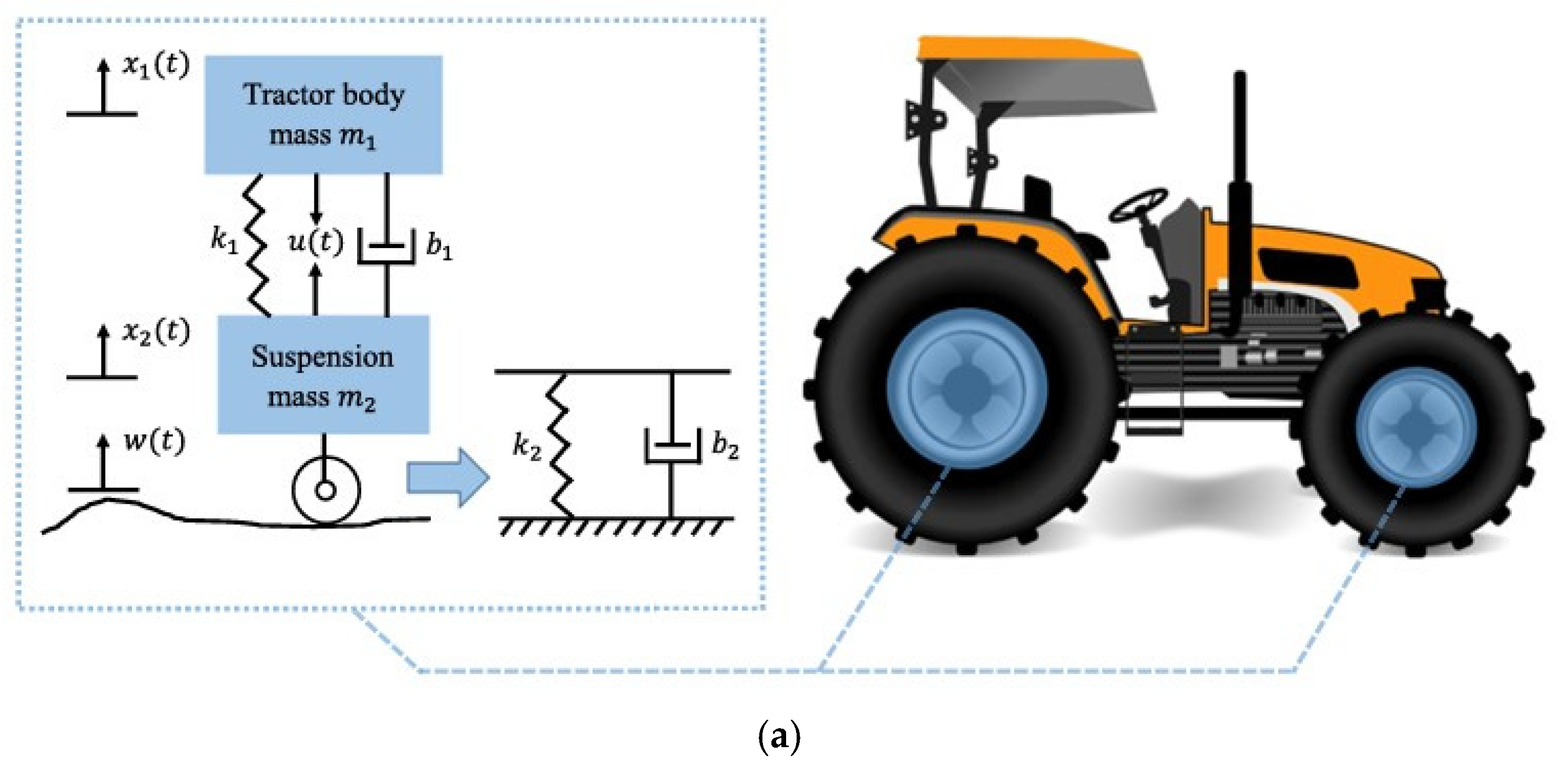

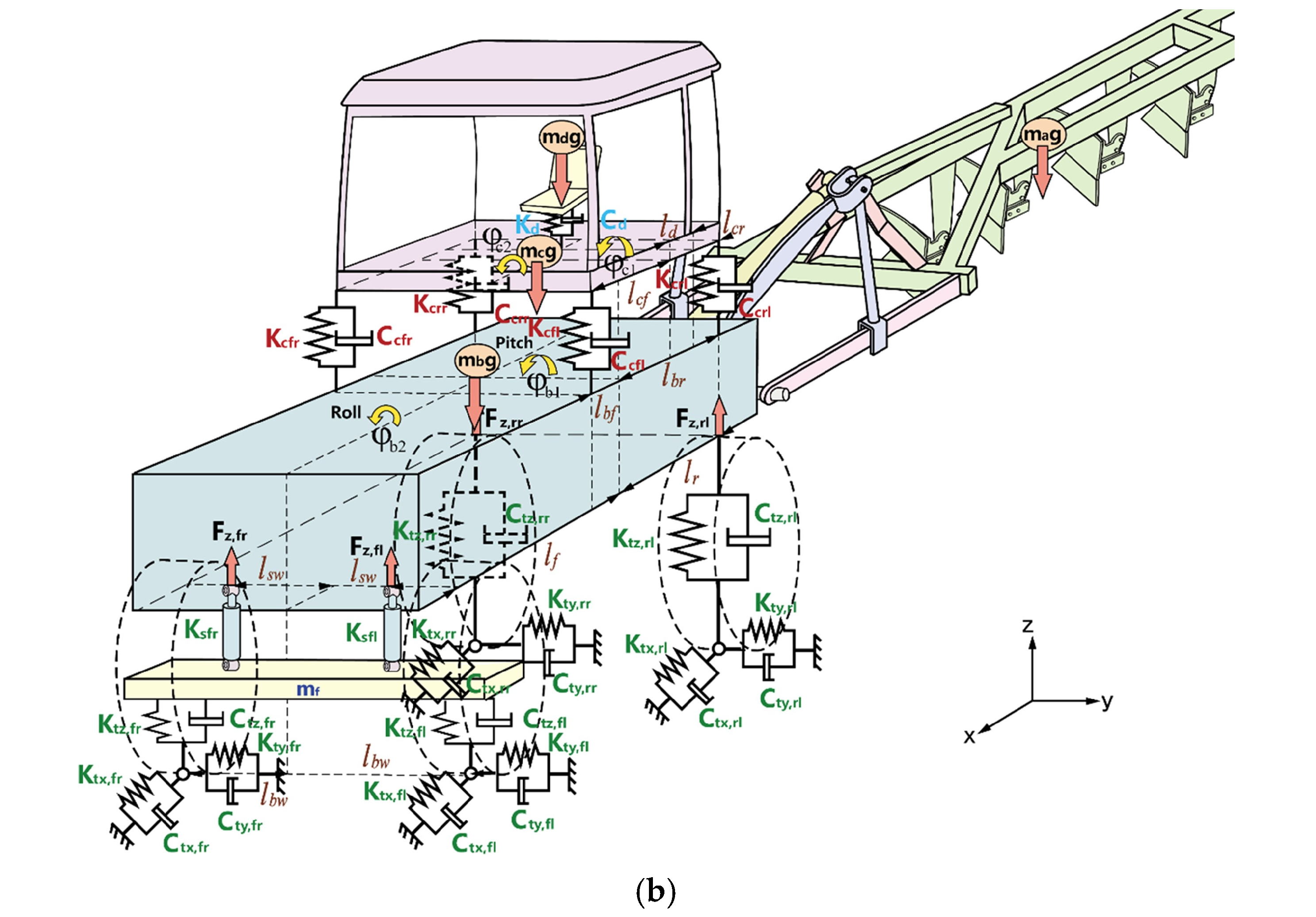

3.2. Suspension Systems

4. Steering Systems of Agricultural Machinery Power Chassis

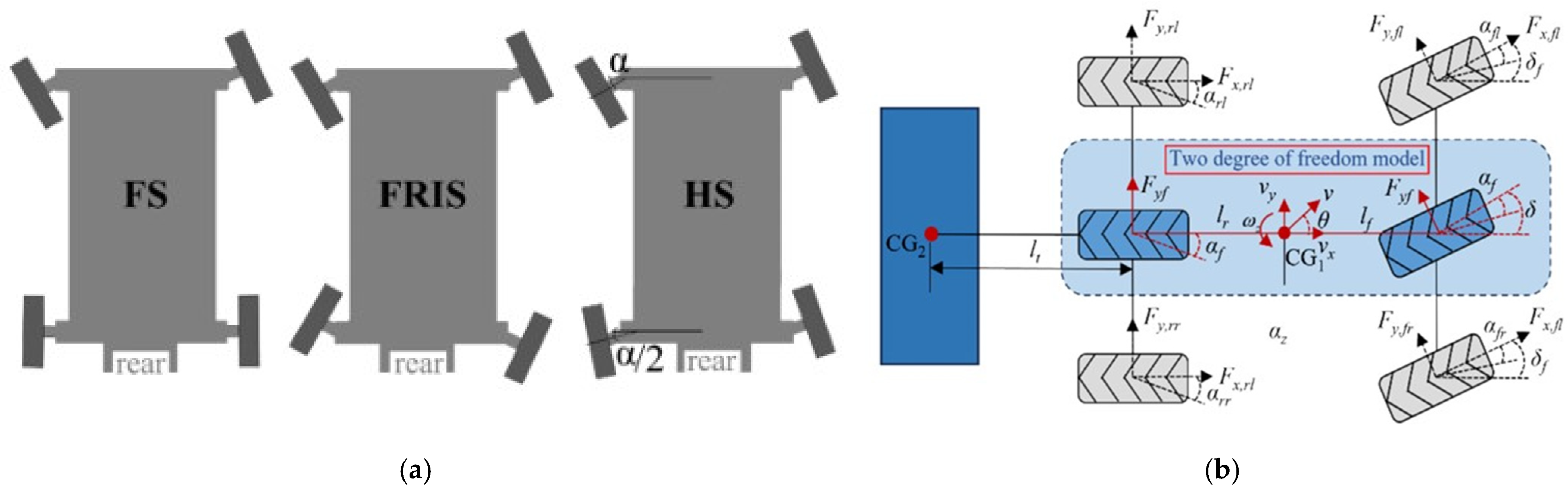

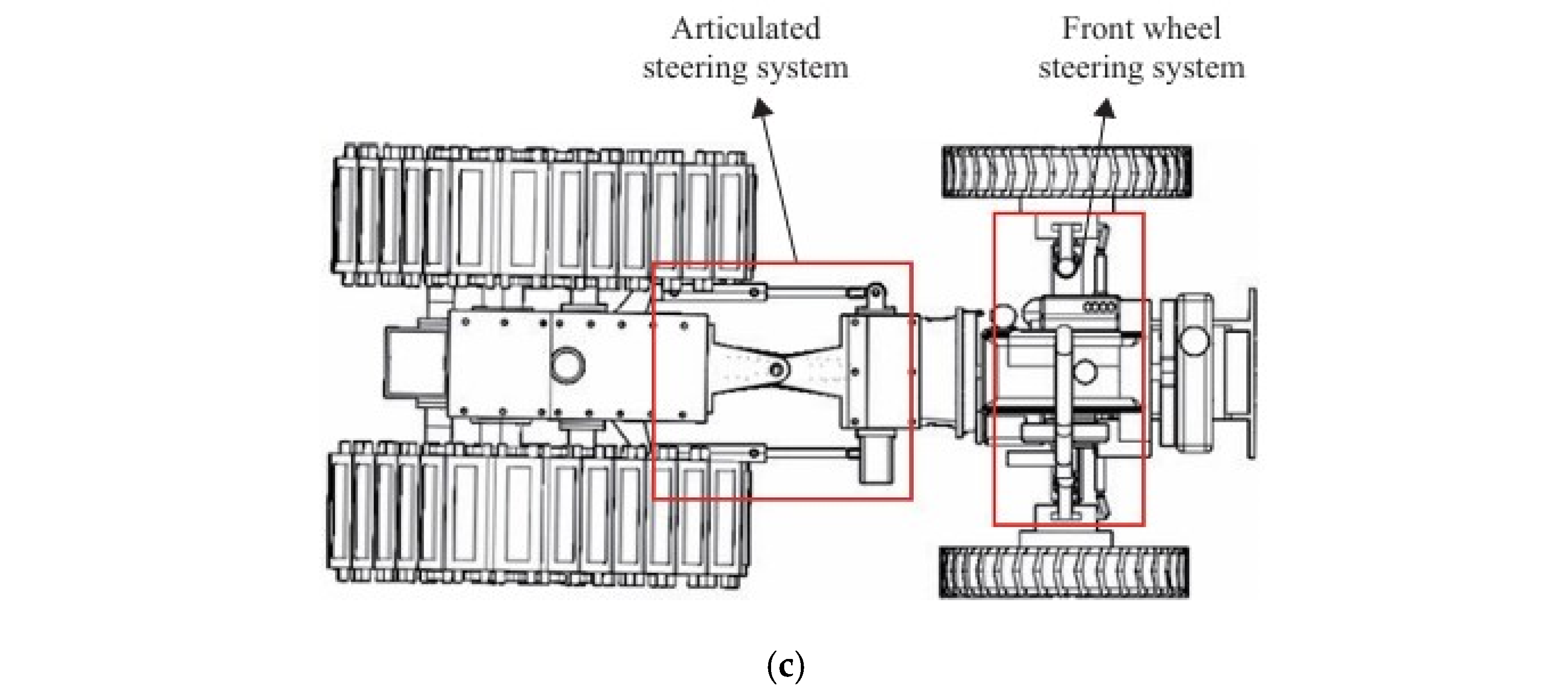

4.1. Steering Systems of Wheeled Agricultural Machinery Chassis

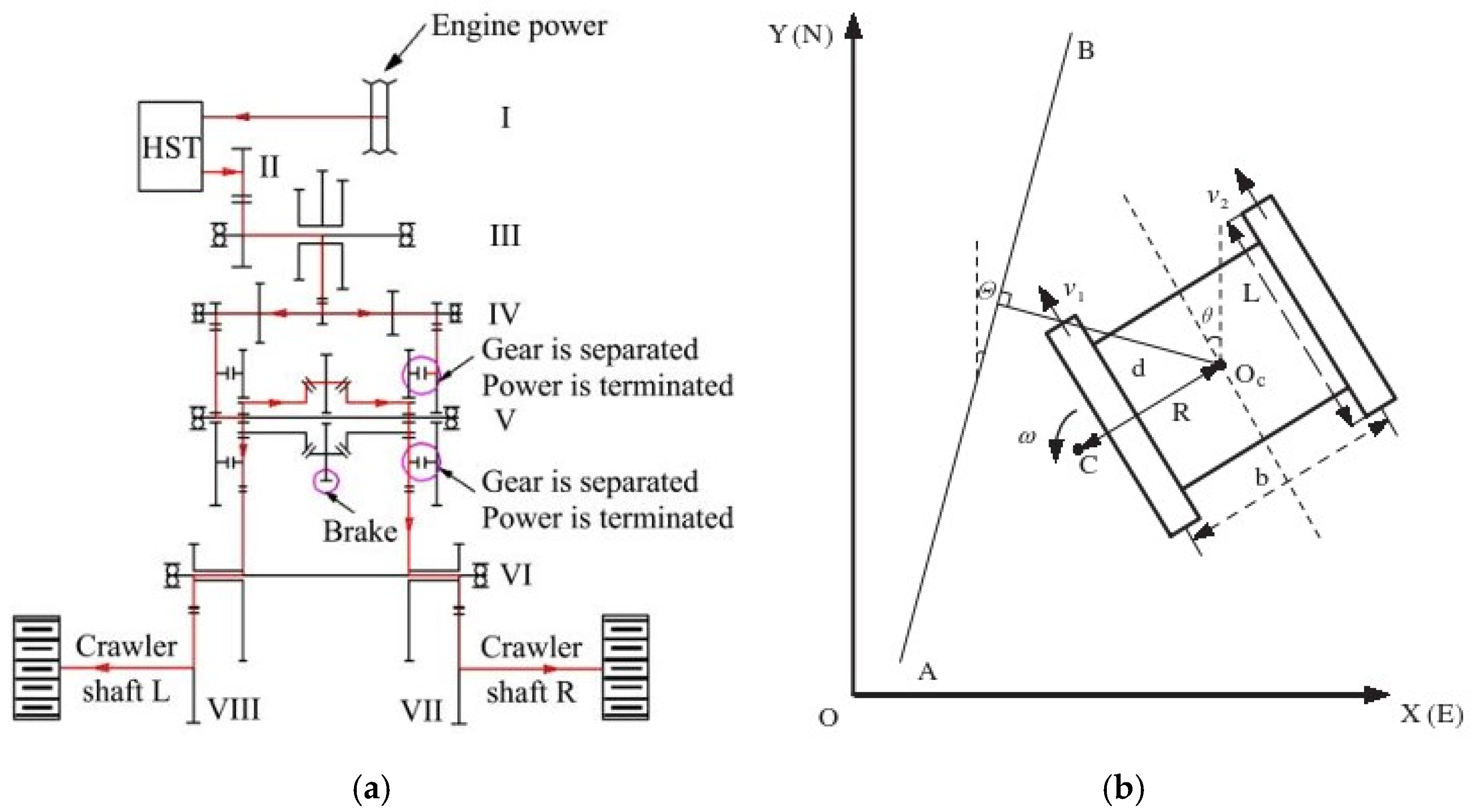

4.2. Steering Systems of Crawler Agricultural Machinery Chassis

5. Leveling Systems of Agricultural Machinery Power Chassis

5.1. Leveling Mechanism Design

5.2. Leveling Control Algorithm

6. Automatic Navigation and Path Tracking Control Systems of Agricultural Machinery Power Chassis

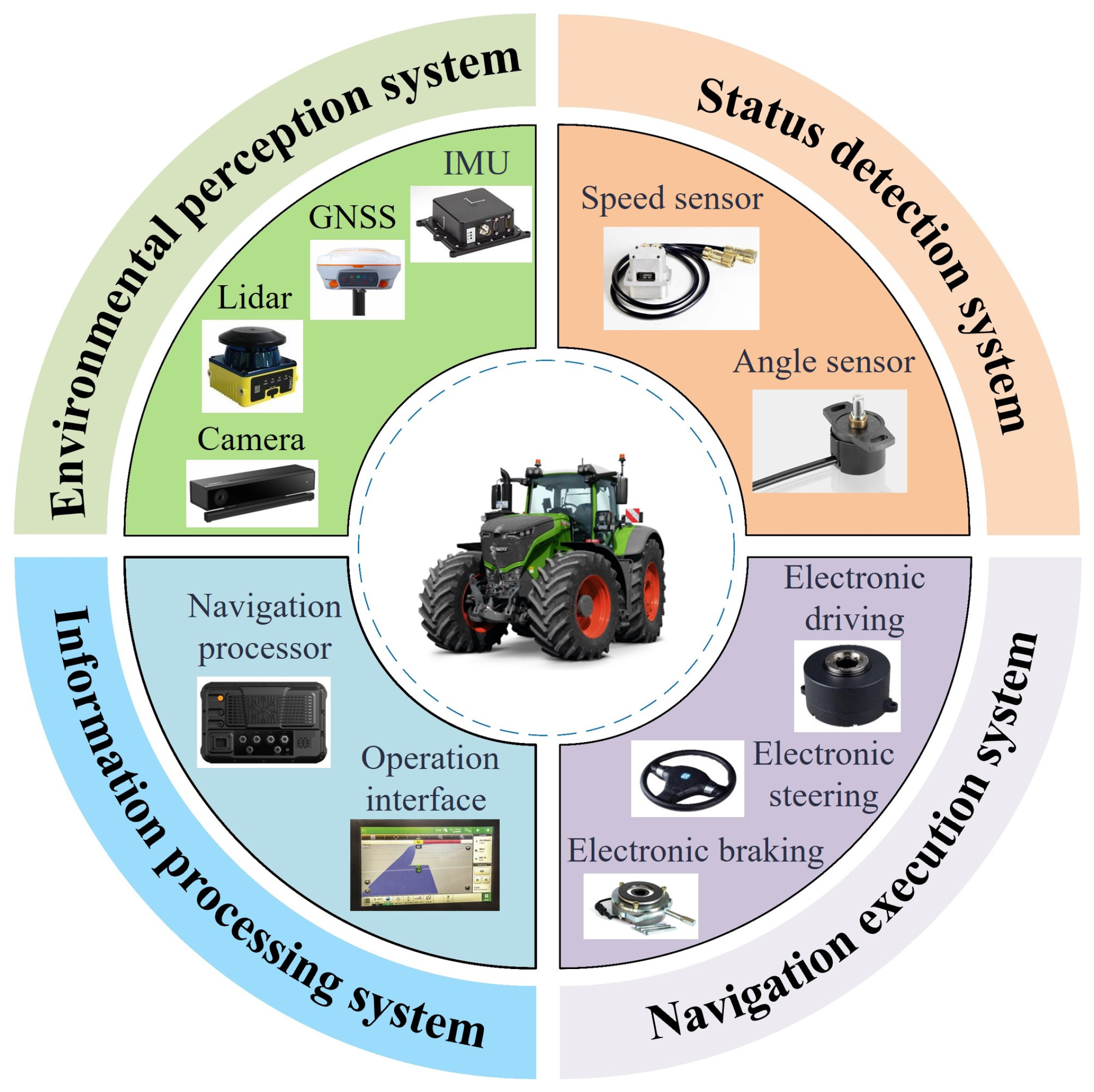

6.1. Automatic Navigation Systems of Agricultural Machinery Chassis

6.2. Path Tracking Control System of Agricultural Machinery Chassis

7. Conclusions and Prospects

- (1)

- Intelligence and automation.

- (2)

- Greening and energy saving.

- (3)

- Lightweighting and generalization.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, B.; Zhu, J.; Chai, X.; Liu, B.; Zhang, G.; Yao, W. Research status and development trend of key technology of agricultural machinery chassis in hilly and mountainous areas. Comput. Electron. Agric. 2024, 226, 109447. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, G.; Lu, Z.; Xiao, Y.; Nie, J.; Yang, L.; Zhou, Z.; Chen, L.; Wang, H. A new framework for delineating farmland consolidation priority areas for promoting agricultural mechanization in hilly and mountainous areas. Comput. Electron. Agric. 2024, 218, 108681. [Google Scholar] [CrossRef]

- Li, H.; Chen, L.; Zhang, Z. A Study on the Utilization Rate and Influencing Factors of Small Agricultural Machinery: Evidence from 10 Hilly and Mountainous Provinces in China. Agriculture 2023, 13, 51. [Google Scholar] [CrossRef]

- Sun, J.; Liu, Z.; Yang, F.; Sun, Q.; Liu, Q.; Luo, P. Research review of agriculture equipment and slope operation key technologies in hilly and mountains region. Trans. Chin. Soc. Agric. Mach. 2023, 54, 1–18. [Google Scholar]

- Han, J.; Yan, X.; Tang, H. Method of controlling tillage depth for agricultural tractors considering engine load characteristics. Biosyst. Eng. 2023, 227, 95–106. [Google Scholar] [CrossRef]

- Zhou, M.; Shan, Y.; Xue, X.; Yin, D. Theoretical analysis and development of a mechanism with punching device for transplanting potted vegetable seedlings. Int. J. Agric. Biol. Eng. 2020, 13, 85–92. [Google Scholar] [CrossRef]

- Liu, J.; Xia, C.; Jiang, D.; Sun, Y. Development and testing of the power transmission system of a crawler electric tractor for greenhouses. Appl. Eng. Agric. 2020, 36, 797–805. [Google Scholar] [CrossRef]

- Hou, G.; Chen, H.; Niu, R.; Li, T.; Ma, Y.; Zhang, Y. Research on multi-layer model attitude recognition and picking strategy of small tomato picking robot. Comput. Electron. Agric. 2025, 232, 110125. [Google Scholar] [CrossRef]

- Wei, C.; Xu, L.; Wang, J.; Li, Y. Inertial force balance and ADAMS simulation of the oscillating sieve and return pan of a rice combine harvester. Int. J. Agric. Biol. Eng. 2018, 11, 129–137. [Google Scholar] [CrossRef]

- Zhu, Z.; Chai, X.; Xu, L.; Quan, L.; Yuan, C.; Tian, S. Design and performance of a distributed electric drive system for a series hybrid electric combine harvester. Biosyst. Eng. 2023, 236, 160–174. [Google Scholar] [CrossRef]

- Tang, Z.; Li, Y.; Cheng, C. Development of multi-functional combine harvester with grain harvesting and straw baling. Span. J. Agric. Res. 2017, 15, e0202. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, Z.; Jiang, Y.; Leng, Y.; Tang, J.; Wang, R.; Lv, X. Simulation and Experiment of the Smoothness Performance of an Electric Four-Wheeled Chassis in Hilly and Mountainous Areas. Sustainability 2023, 15, 16868. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.; Gao, Z.; Lu, E.; Li, Y. Effect of vibration on rapeseed header loss and optimization of header frame. Trans. ASABE 2021, 64, 1247–1258. [Google Scholar] [CrossRef]

- Chai, X.; Hu, J.; Ma, T.; Liu, P.; Shi, M.; Zhu, L.; Zhang, M.; Xu, L. Construction and Characteristic Analysis of Dynamic Stress Coupling Simulation Models for the Attitude Adjustable Chassis of a Combine Harvester. Agronomy 2024, 14, 1874. [Google Scholar] [CrossRef]

- Lohan, S.K.; Prakash, C.; Lohan, N.; Kansal, S.; Karkee, M. State-of-the-art in real-time virtual interfaces for tractors and farm machines: A systematic review. Comput. Electron. Agric. 2025, 231, 109947. [Google Scholar] [CrossRef]

- Chen, C.; Cao, G.; Zhang, J.; Hu, J. Dynamic monitoring of harvester working progress based on traveling trajectory and header status. Eng. Agríc. 2023, 43, e20220196. [Google Scholar]

- Tang, Z.; Wang, H.; Jing, T.; Liu, S.; Shen, C. Centroid swinging property of a machine body undergoing longitudinal excitation in a straw compression baler. Eng. Agríc. 2024, 44, e20230109. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, H.; Liu, S.; Lu, D.; Tang, Y. Development of structure and control system of self-propelled small green vegetables combine harvester. J. Agric. Sci. Technol. 2023, 25, 1045–1058. [Google Scholar]

- Lu, E.; Ma, Z.; Li, Y.; Xu, L.; Tang, Z. Adaptive backstepping control of tracked robot running trajectory based on real-time slip parameter estimation. Int. J. Agric. Biol. Eng. 2020, 13, 178–187. [Google Scholar] [CrossRef]

- Ahmad, F.; Adeel, M.; Qiu, B.; Ma, J.; Shoaib, M.; Aamir, S.; Chandio, F.A. Sowing uniformity of bed-type pneumatic maize planter at various seedbed preparation levels and machine travel speeds. Int. J. Agric. Biol. Eng. 2021, 14, 165–171. [Google Scholar] [CrossRef]

- Wang, B.; Du, X.; Wang, Y.; Mao, H. Multi-machine collaboration realization conditions and precise and efficient production mode of intelligent agricultural machinery. Int. J. Agric. Biol. Eng. 2024, 17, 27–36. [Google Scholar]

- Zhu, S.; Wang, B.; Pan, S.; Ye, Y.; Wang, E.; Mao, H. Task Allocation of Multi-Machine Collaborative Operation for Agricultural Machinery Based on the Improved Fireworks Algorithm. Agronomy 2024, 14, 710. [Google Scholar] [CrossRef]

- Fu, S.; Lan, T.; Du, Y.; Mao, E. Rapid design system for agricultural machinery using knowledge-based engineering: Case study of a wheeled combine chassis. Trans. ASABE 2020, 63, 955–966. [Google Scholar] [CrossRef]

- Ding, C.; Wang, L.; Chen, X.; Yang, H.; Huang, L.; Song, X. A blockchain-based wide-area agricultural machinery resource scheduling system. Appl. Eng. Agric. 2023, 39, 1–12. [Google Scholar] [CrossRef]

- Reddy, G.C.; Sultana, W.R.; Sunitha, V. Towards sustainable farming: A state of art review on electrification of a farm tractor. Results Eng. 2025, 25, 104403. [Google Scholar]

- Wen, C.; Ren, W.; Zhu, Q.; Zhao, C.; Luo, Z.; Zhang, S.; Xie, B.; Meng, Z. Reducing Operation Emissions and Improving Work Efficiency Using a Pure Electric Wheel Drive Tractor. Engineering 2024, 37, 230–245. [Google Scholar] [CrossRef]

- Yang, F.; Liu, Q.; Ji, Y.; Chu, H.; Duan, L.; Lin, Z.; Shou, Y.; Liu, Z. Development and validation of sloped ground pressure prediction model for a tracked tractor in hilly and mountainous environments. Soil Tillage Res. 2024, 241, 106135. [Google Scholar] [CrossRef]

- Chen, J.; Ning, X.; Li, Y.; Yang, G.; Wu, P.; Chen, S. A Fuzzy control strategy for the forward speed of a combine harvester based on KDD. Appl. Eng. Agric. 2017, 33, 15–22. [Google Scholar]

- Zhu, Z.; Yang, Y.; Wang, D.; Cai, Y.; Lai, L. Energy Saving Performance of Agricultural Tractor Equipped with Mechanic-Electronic-Hydraulic Powertrain System. Agriculture 2022, 12, 436. [Google Scholar] [CrossRef]

- Damanauskas, V.; Janulevičius, A. Differences in tractor performance parameters between single-wheel 4WD and dual-wheel 2WD driving systems. J. Terramech. 2015, 60, 63–73. [Google Scholar] [CrossRef]

- Xie, X.; Han, X.; Zhang, Z.; Qin, Y.; Li, Y.; Yan, Z. Structural design and test of arch waist dynamic chassis for hilly and mountainous areas. Int. J. Adv. Manuf. Technol. 2022, 127, 1921–1933. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, Q. Comparison of straight line driving synchronous control methods and validation of 4WD sprayer chassis with hydraulic power. Trans. Chin. Soc. Agric. Eng. 2016, 32, 43–50. [Google Scholar]

- Zhu, Z.; Zeng, L.; Chen, L.; Zou, R.; Cai, Y. Fuzzy Adaptive Energy Management Strategy for a Hybrid Agricultural Tractor Equipped with HMCVT. Agriculture 2022, 12, 1986. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, G.; Chu, G.; Niu, H.; Zhang, Y.; Yang, F. Design Matching and Dynamic Performance Test for an HST-Based Drive System of a Hillside Crawler Tractor. Agriculture 2021, 11, 466. [Google Scholar] [CrossRef]

- Yang, S.; Zhai, C.; Gao, Y.; Dou, H.; Zhao, X.; He, Y.; Wang, X. Planting uniformity performance of motor-driven maize precision seeding systems. Int. J. Agric. Biol. Eng. 2022, 15, 101–108. [Google Scholar] [CrossRef]

- Huang, X.; Wang, X.; Wang, Y.; Shi, Y.; Lv, H.; Zheng, J.; Chen, Y. Multi-objective optimization and experimental analysis of rotary tillage parameters for horticultural electric tractors. Comput. Electron. Agric. 2025, 231, 109962. [Google Scholar] [CrossRef]

- Liu, J.; Xia, C.; Jiang, D.; Shang, G.; Han, J.; Sun, Y. Determination and application of maximum efficiency curve of crawler electric tractor motors. Math. Probl. Eng. 2021, 2021, 1310926. [Google Scholar] [CrossRef]

- Yuko, U.; Jun, Y.; Kazunobu, S.; Yoshinori, D. Study on the development of the electric tractor: Specifications and traveling and tilling performance of a prototype electric tractor. Eng. Agric. Environ. Food 2013, 6, 160–164. [Google Scholar]

- Han, J.; Wang, F. Design and testing of a small orchard tractor driven by a power battery. Eng. Agríc. 2023, 43, e20220195. [Google Scholar]

- Troncon, D.; Alberti, L. Case of Study of the Electrification of a Tractor: Electric Motor Performance Requirements and Design. Energies 2020, 13, 2197. [Google Scholar] [CrossRef]

- Liu, H.; Shen, C.; Hu, L.; Chang, C.; Cao, G. Research progress and development trend of electric agricultural equipments. Trans. Chin. Soc. Agric. Eng. 2024, 40, 39–51. [Google Scholar]

- Li, Y.; Liu, Y.; Ji, K.; Zhu, R. A Fault Diagnosis Method for a Differential Inverse Gearbox of a Crawler Combine Harvester Based on Order Analysis. Agriculture 2022, 12, 1300. [Google Scholar] [CrossRef]

- Wang, G.; Song, Y.; Wang, J.; Xiao, M.; Cao, Y.; Chen, W.; Wang, J. Shift quality of tractors fitted with hydrostatic power split CVT during starting. Biosyst. Eng. 2020, 196, 183–201. [Google Scholar] [CrossRef]

- Xue, L.; Jiang, H.; Zhao, Y.; Wang, J.; Wang, G.; Xiao, M. Fault diagnosis of wet clutch control system of tractor hydrostatic power split continuously variable transmission. Comput. Electron. Agric. 2022, 194, 106778. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, Z. System response modeling of HMCVT for tractors and the comparative research on system identification methods. Comput. Electron. Agric. 2022, 202, 107386. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, Z.; Qian, J. A new non-geometric transmission parameter optimization design method for HMCVT based on improved GA and maximum transmission efficiency. Comput. Electron. Agric. 2019, 167, 105034. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, Z. Research on Load Disturbance Based Variable Speed PID Control and a Novel Denoising Method Based Effect Evaluation of HST for Agricultural Machinery. Agriculture 2021, 11, 960. [Google Scholar] [CrossRef]

- Zhao, Z.; Huang, H.; Yin, J.; Yang, S.X. Dynamic analysis and reliability design of round baler feeding device for rice straw harvest. Biosyst. Eng. 2018, 174, 10–19. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, S.; Li, N.; Faheem, M.; Zhou, T.; Cai, W.; Zhao, M.; Zhu, X.; Li, P. Development and field test of an autonomous strawberry plug seeding transplanter for use in elevated cultivation. Appl. Eng. Agric. 2019, 35, 1067–1078. [Google Scholar] [CrossRef]

- Sun, J.; Chen, Z.; Song, R.; Fan, S.; Han, X.; Zhang, C.; Wang, J.; Zhang, H. An intelligent self-propelled double-row orchard trenching and fertilizing machine: Modeling, evaluation, and application. Comput. Electron. Agric. 2025, 229, 109818. [Google Scholar] [CrossRef]

- Liu, S.; Tang, Z.; Zhang, B.; Liang, Y. Ergonomic design of cab structure for wheeled combine harvesrer. Eng. Agríc. 2022, 42, e20220023. [Google Scholar] [CrossRef]

- Han, L.; Mao, H.; Hu, J.; Kumi, F. Development of a riding-type fully automatic transplanter for vegetable plug seedlings. Span. J. Agric. Res. 2019, 17, e0205. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, X.; Wang, W.; Song, Y.; Cui, Y. Joint control method based on speed and slip rate switching in plowing operation of wheeled electric tractor equipped with sliding battery pack. Comput. Electron. Agric. 2023, 215, 108426. [Google Scholar] [CrossRef]

- Liu, S.; Tang, Z.; Shen, C.; Wang, T.; Liang, Y. Effect of rice stubble on soil compaction properties of a crawler undergoing combine harvester harvesting. Eng. Agríc. 2023, 43, e20230057. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, J.; Wang, J.; Cai, L.; Jin, Y.; Zhao, S.; Xie, B. Realtime Picking Point Decision Algorithm of Trellis Grape for High-Speed Robotic Cut-and-Catch Harvesting. Agronomy 2023, 13, 1618. [Google Scholar] [CrossRef]

- Yuan, L.; Tang, Z.; Liu, S.; Wang, T.; Ding, Z. Design for Copying Grouser and Bionic Convex Hull Patterns on Track Surfaces of Crawler Combine Harvesters. Agriculture 2024, 14, 1079. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, G.; Tang, Z.; Cao, Y.; Zhao, Y. Structural form and field operation effect of crawler type broccoli harvester. Eng. Agríc. 2023, 43, e20230132. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Yang, K.; Liu, X.; Liu, C.; Wang, Z. Motion-Control Strategy for a Heavy-Duty Transport Hexapod Robot on Rugged Agricultural Terrains. Agriculture 2023, 13, 2131. [Google Scholar] [CrossRef]

- Zhang, F.; Teng, S.; Wang, Y.; Guo, Z.; Wang, J.; Xu, R. Design of bionic goat quadruped robot mechanism and walking gait planning. Int. J. Agric. Biol. Eng. 2020, 13, 32–39. [Google Scholar] [CrossRef]

- Grazioso, A.; di Maria, E.; Giannoccaro, N.I.; Ishii, K. Multibody Modeling of a New Wheel/Track Reconfigurable Locomotion System for a Small Farming Vehicle. Machines 2022, 10, 1117. [Google Scholar] [CrossRef]

- Bruzzone, L.; Baggetta, M.; Nodehi, S.E.; Bilancia, P.; Fanghella, P. Functional Design of a Hybrid Leg-Wheel-Track Ground Mobile Robot. Machines 2021, 9, 10. [Google Scholar] [CrossRef]

- Pang, J.; Li, Y.; Ji, J.; Xu, L. Vibration excitation identification and control of the cutter of a combine harvester using triaxial accelerometers and partial coherence sorting. Biosyst. Eng. 2019, 185, 25–34. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, Y.; Tang, Z.; Lu, S. Modal vibration response of rice combine harvester frame under multi-source excitation. Biosyst. Eng. 2020, 194, 177–195. [Google Scholar] [CrossRef]

- Ji, K.; Li, Y.; Liu, Y.; Yu, Z.; Cheng, J. Vibration signal extraction and analysis of combine harvester based on low-pass filter-eemd combination. Eng. Agríc. 2024, 44, e20240006. [Google Scholar] [CrossRef]

- Xu, L.; Chai, X.; Gao, Z.; Li, Y.; Wang, Y. Experimental study on driver seat vibration characteristics of crawler-type combine harvester. Int. J. Agric. Biol. Eng. 2019, 12, 90–97. [Google Scholar] [CrossRef]

- Mohammadikia, R.; Aliasghary, M. Design of an interval type-2 fractional order fuzzy controller for a tractor active suspension system. Comput. Electron. Agric. 2019, 167, 105049. [Google Scholar] [CrossRef]

- Gao, Y.; Hu, Y.; Yang, Y.; Feng, K.; Han, X.; Li, P.; Zhu, Y.; Song, Q. Optimization of Operating Parameters for Straw Returning Machine Based on Vibration Characteristic Analysis. Agronomy 2024, 14, 2388. [Google Scholar] [CrossRef]

- Sain, D.; Mohan, B.M.; Yang, M.J. Development of a 2-DoF nonlinear fuzzy PI–PD controller for a tractor active suspension system. Comput. Electron. Agric. 2025, 232, 110076. [Google Scholar] [CrossRef]

- Fernandes, R.H.; Garcia, P.A. Design and control of an active suspension system for unmanned agricultural vehicles for field operations. Biosyst. Eng. 2018, 174, 107–114. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Wang, R.; Xu, X.; Shen, Y.; Liu, Y. Modeling and test on height adjustment system of electrically-controlled air suspension for agricultural vehicles. Int. J. Agric. Biol. Eng. 2016, 9, 40–47. [Google Scholar]

- Chen, Y.; Zhang, S.; Mao, E.; Du, Y.; Chen, J.; Yang, S. Height stability control of a large sprayer body based on air suspension using the sliding mode approach. Inf. Process. Agric. 2020, 7, 20–29. [Google Scholar] [CrossRef]

- Zheng, E.; Zhong, X.; Zhu, R.; Xue, J.; Cui, S.; Gao, H.; Lin, X. Investigation into the vibration characteristics of agricultural wheeled tractor-implement system with hydro-pneumatic suspension on the front axle. Biosyst. Eng. 2019, 186, 14–33. [Google Scholar] [CrossRef]

- Sim, K.; Lee, H.; Yoon, W.J. Effectiveness evaluation of hydro-pneumatic and semi-active cab suspension for the improvement of ride comfort of agricultural tractors. J. Terramech. 2017, 69, 23–32. [Google Scholar] [CrossRef]

- Cui, L.; Mao, H.; Xue, X.; Ding, S.; Qiao, B. Optimized design and test for a pendulum suspension of the crop spray boom in dynamic conditions based on a six DOF motion simulator. Int. J. Agric. Biol. Eng. 2018, 11, 76–85. [Google Scholar]

- Tang, Z.; Zhang, B.; Wang, M.; Zhang, H. Damping behaviour of a prestressed composite beam designed for the thresher of a combine harvester. Biosyst. Eng. 2021, 204, 130–146. [Google Scholar] [CrossRef]

- Watanabe, M.; Sakai, K. Numerical analysis of steering instability in an agricultural tractor induced by bouncing and sliding. Biosyst. Eng. 2020, 192, 108–116. [Google Scholar] [CrossRef]

- Qin, J.; Wu, A.; Song, Z.; He, Z.; Suh, C.S.; Zhu, Z.; Li, Z. Recovering tractor stability from an intensive rollover with a momentum flywheel and active steering: System formulation and scale-model verification. Comput. Electron. Agric. 2021, 190, 106458. [Google Scholar] [CrossRef]

- Qin, J.; Zhu, Z.; Ji, H.; Zhu, Z.; Li, Z.; Du, Y.; Song, Z.; Mao, E. Simulation of active steering control for the prevention of tractor dynamic rollover on random road surfaces. Biosyst. Eng. 2019, 185, 135–149. [Google Scholar] [CrossRef]

- Huang, X.; Wang, W.; Li, Z.; Wang, Q.; Zhu, C.; Chen, L. Design method and experiment of machinery for combined application of seed, fertilizer and herbicide. Int. J. Agric. Biol. Eng. 2019, 12, 63–71. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Li, M.; Shang, Z. Dynamic Measurement Method for Steering Wheel Angle of Autonomous Agricultural Vehicles. Agriculture 2024, 14, 1602. [Google Scholar] [CrossRef]

- Liu, H.; Long, Y.; He, S.; Cui, Y.; Yue, S. Design and experiment of the auxiliary steering ststem for a four-wheel independent electrically driven high clearance sprayer. Trans. Chin. Soc. Agric. Eng. 2021, 37, 30–37. [Google Scholar]

- Wang, W.; Chen, L.; Yang, Y.; Liu, L. Development and prospect of agricultural machinery chassis technology. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–15. [Google Scholar]

- Tejero, B.S.; Sarri, D.; Guirado, S.R.R. Design and field validation of a Dual-Axle steering system for autonomous tractors. Comput. Electron. Agric. 2025, 231, 110000. [Google Scholar] [CrossRef]

- Liu, H.; Yan, S.; Shen, Y.; Li, C.; Zhang, Y.; Hussain, F. Model predictive control system based on direct yaw moment control for 4WID self-steering agriculture vehicle. Int. J. Agric. Biol. Eng. 2021, 14, 175–181. [Google Scholar] [CrossRef]

- Chen, F.; Ding, J.; Luo, Z.; Zheng, E.; Lu, Y.; Shi, Y.; Zhang, Y.; Wang, X. A novel robust model predictive controller for improving the steering stability of electric drive mobile platform considering the effect of both yaw motion and rototiller lifting. Comput. Electron. Agric. 2025, 230, 109846. [Google Scholar] [CrossRef]

- Satyam, R.; Jens, F.; Thomas, H. Navigation and control development for a four-wheel-steered mobile orchard robot using model-based design. Comput. Electron. Agric. 2022, 202, 107410. [Google Scholar]

- He, Z.; Song, Z.; Wang, L.; Zhou, X.; Gao, J.; Wang, K.; Yang, M.; Li, Z. Fasting the stabilization response for prevention of tractor rollover using active steering: Controller parameter optimization and real-vehicle dynamic tests. Comput. Electron. Agric. 2023, 204, 107525. [Google Scholar] [CrossRef]

- Xu, G.; Chen, M.; He, X.; Pang, H.; Miao, H.; Cui, P.; Wang, W.; Diao, P. Path following control of tractor with an electro-hydraulic coupling steering system: Layered multi-loop robust control architecture. Biosyst. Eng. 2021, 209, 282–299. [Google Scholar] [CrossRef]

- An, G.; Zhong, Z.; Yang, S.; Yang, L.; Jin, C.; Du, J.; Yin, X. EASS: An automatic steering system for agricultural wheeled vehicles using fuzzy control. Comput. Electron. Agric. 2024, 217, 108544. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, G.; Chen, Z.; Wen, X.; Cheng, S.; Ma, Q.; Qi, J.; Zhou, Y.; Chen, L. An independent steering driving system to realize headland turning of unmanned tractors. Comput. Electron. Agric. 2022, 201, 107278. [Google Scholar] [CrossRef]

- Luo, Y.; Wei, L.; Xu, L.; Zhang, Q.; Liu, J.; Cai, Q.; Zhang, W. Stereo-vision-based multi-crop harvesting edge detection for precise automatic steering of combine harvester. Biosyst. Eng. 2022, 215, 115–128. [Google Scholar] [CrossRef]

- Qi, Z.; Zhou, J.; Ye, Z.; Zhou, X.; Yang, H. Local path planing method in automatic walking of single-side brake steering track chassis. Trans. Chin. Soc. Agric. Mach. 2024, 55, 52–59. [Google Scholar]

- Lv, X.; Lv, X.; Shi, X.; Wang, T. Experimental verification of the steering performance of all-hydraulic crawler chassis. Eng. Trans. 2018, 66, 427–442. [Google Scholar]

- Tang, Z.; Zhang, H.; Li, H.; Li, Y.; Ding, Z.; Chen, J. Development of crawler steering gearbox for combine harvester straight forward and teering in situ. Int. J. Agric. Biol. Eng. 2020, 13, 120–126. [Google Scholar]

- Wang, Y.; Jin, C.; Yang, T.; Wang, T.; Ni, Y. Analysis and Experimental Investigation of Steering Kinematics of Driven Steering Crawler Harvester Chassis. Agriculture 2024, 14, 65. [Google Scholar] [CrossRef]

- Chen, T.; Xu, L.; Ahn, H.S.; Lu, E.; Liu, Y.; Xu, R. Evaluation of headland turning types of adjacent parallel paths for combine harvesters. Biosyst. Eng. 2023, 233, 93–113. [Google Scholar] [CrossRef]

- Wang, M.; Zhao, B.; Wang, C.; Li, H.; Liu, Y.; Fang, X. Method for controlling turning radius of crawler-type tractors based on GMM. Trans. Chin. Soc. Agric. Mach. 2020, 51, 557–563. [Google Scholar]

- Qin, W.; Zhang, G.; Hu, S.; Zhou, Y.; Wen, C.; Fu, W.; Meng, Z. Differential steering control system for single HST tracked tractors. Trans. Chin. Soc. Agric. Mach. 2024, 55, 405–411+426. [Google Scholar]

- Zhou, B.; Chen, S.; Hu, J.; You, Y.; Wang, D.; Zhang, Q. Multi-body dynamics modeling and test of an articulated steering half-track tractor. Int. J. Agric. Biol. Eng. 2023, 16, 124–133. [Google Scholar] [CrossRef]

- Hu, C.; Ru, Y.; Li, X.; Fang, S.; Zhou, H.; Yan, X.; Liu, M.; Xie, R. Path tracking control for brake-steering tracked vehicles based on an improved pure pursuit algorithm. Biosyst. Eng. 2024, 242, 1–15. [Google Scholar] [CrossRef]

- Guan, Z.; Mu, S.; Wu, C.; Chen, K.; Liao, Y.; Ding, Y.; Liao, Q. Steering kinematic analysis and experiment of tracked combine harvester working in paddy field. Trans. Chin. Soc. Agric. Eng. 2020, 36, 29–38. [Google Scholar]

- Zhang, Z.; Huang, H.; Luo, X.; Zhang, G.; Zhang, W.; Peng, M.; Liu, W. Steering control system for a tractor using electric steering wheel. Trans. Chin. Soc. Agric. Eng. 2024, 40, 48–57. [Google Scholar]

- Wang, Z.; Xia, Y. Model establishment of body attitude adjustment system based on Backstepping control algorithm and automatic leveling technology. Clust. Comput. 2019, 22, 14327–14337. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, J.; Liu, P.; Long, X.; Li, H.; Wei, W. Development of an agricultural vehicle levelling system based on rapid active levelling. Biosyst. Eng. 2019, 186, 337–348. [Google Scholar] [CrossRef]

- Zhu, H.; Jin, H.; Hou, Y.; Wang, S.; Chen, Y.; Zhang, S.; Shen, J. An omnidirectional dynamic levelling system with less tuning parameters for mountainous tea plantations. Biosyst. Eng. 2025, 251, 117–127. [Google Scholar] [CrossRef]

- Guo, H.; Lu, H.; Gao, G.; Wu, T.; Chen, H.; Qiu, Z. Design and Test of a Levelling System for a Mobile Safflower Picking Platform. Appl. Sci. 2023, 13, 4465. [Google Scholar] [CrossRef]

- Yin, C.; Gao, J.; Xu, G.; Song, J.; Xie, F.; Wu, X.; Wang, K. Key technologies on the rollover protection and anti-rollover control for agricultural tractors. Trans. Chin. Soc. Agric. Eng. 2024, 40, 1–11. [Google Scholar]

- Chen, R.; Ou, Y.; Fang, W.; Shi, Y.; Liu, L. Simulation analysis of a self-balancing hydraulic platform for agricultural machinery in mountainous regions. J. Eur. Syst. Autom. 2020, 53, 203–211. [Google Scholar] [CrossRef]

- Sun, J.; Meng, C.; Zhang, Y.; Chu, G.; Zhang, Y.; Yang, F.; Liu, Z. Design and physical model experiment of an attitude adjustment device for a crawler tractor in hilly and mountainous regions. Inf. Process. Agric. 2020, 7, 466–478. [Google Scholar] [CrossRef]

- Shang, H.; Li, X.; Zhang, C.; Xu, C.; Hou, Y.; Jia, M. Optimization design and experiment of automatic leveling system for orchard operaing platform in hilly and mountainous areas. INMATEH Agric. Eng. 2024, 73, 364–374. [Google Scholar] [CrossRef]

- Jiang, Y.; Sun, Z.; Wang, R.; Ding, R.; Ye, Q. Design and control of a new omnidirectional levelling system for hilly crawler work machines. Comput. Electron. Agric. 2024, 218, 108661. [Google Scholar] [CrossRef]

- Jiang, Y.; Sun, Z.; Wang, R.; Xia, C.; Ye, Q.; Guo, Y. Design and performance test of omnidirectional leveling system for hilly crawler work machine. Trans. Chin. Soc. Agric. Eng. 2023, 39, 64–73. [Google Scholar]

- Cui, L.; Xue, X.; Le, F.; Mao, H.; Ding, S. Design and experiment of electro hydraulic active suspension for controlling the rolling motion of spray boom. Int. J. Agric. Biol. Eng. 2019, 12, 72–81. [Google Scholar] [CrossRef]

- Lv, X.; Liu, Z.; Lv, X.; Wang, X. Design and study on the leveling mechanism of the tractor body in hilly and mountainous areas. J. Eng. Des. Technol. 2024, 22, 679–689. [Google Scholar]

- Sun, Y.; Xu, L.; Jing, B.; Chai, X.; Li, Y. Development of a four-point adjustable lifting crawler chassis and experiments in a combine harvester. Comput. Electron. Agric. 2020, 173, 105416. [Google Scholar] [CrossRef]

- Hu, J.; Pan, J.; Dai, B.; Chai, X.; Sun, Y.; Xu, L. Development of an Attitude Adjustment Crawler Chassis for Combine Harvester and Experiment of Adaptive Leveling System. Agronomy 2022, 12, 717. [Google Scholar] [CrossRef]

- Peng, H.; Ma, W.; Zhao, E.; Lu, X.; Feng, X. Design and physical model experiment of body leveling system for roller tractor in hilly and mountainous region. Trans. Chin. Soc. Agric. Eng. 2018, 34, 36–44. [Google Scholar]

- Yang, F.; Niu, H.; Sun, J.; Liu, Z.; Li, Y.; Chu, H. Design and experiment of attitude cooperative control system of mountain crawler tractor and farm tools. Trans. Chin. Soc. Agric. Mach. 2022, 53, 414–422. [Google Scholar]

- Sun, J.; Zeng, L.; Ying, J.; Zheng, H.; Sun, Q.; Meng, X. Research status and prospect of key technologies of agricultural track chassis. Trans. Chin. Soc. Agric. Mach. 2024, 55, 202–220. [Google Scholar]

- Lv, H.; Hu, Z.; Yu, Y.; Kang, F.; Zheng, Y. Feedforward PID control method for the automatic leveling of an orchard high-position operation platform. Trans. Chin. Soc. Agric. Eng. 2021, 37, 20–28. [Google Scholar]

- Qi, W.; Li, Y.; Zhang, J.; Qin, C.; Liu, C.; Yin, Y. Double closed loop fuzzy PID control method of tractor body leveling on hilly and mountainous areas. Trans. Chin. Soc. Agric. Mach. 2019, 50, 17–23+34. [Google Scholar]

- Zhang, J.; Li, Y.; Qi, W.; Liu, C.; Yang, F.; Li, Z. Synchronous control system of tractor attitude in hills and mountains based on neural network PID. Trans. Chin. Soc. Agric. Mach. 2020, 51, 356–366. [Google Scholar]

- Sun, Z.; Xia, C.; Jiang, Y.; Guo, Y.; Wang, R. Omnidirectional leveling control of crawler machine based on QBP-PID. Trans. Chin. Soc. Agric. Mach. 2023, 54, 397–406. [Google Scholar]

- Wang, R.; Zhang, K.; Ding, R.; Jiang, Y.; Jiang, Y. A Novel Hydraulic Interconnection Design and Sliding Mode Synchronizatio Control of Leveling System for Crawler Work Machine. Agriculture 2025, 15, 137. [Google Scholar] [CrossRef]

- Peng, H.; Ma, W.; Wang, Z.; Yuan, Z. Leveling Control of Hillside Tractor Body Based on Fuzzy Sliding Mode Variable Structure. Appl. Sci. 2023, 13, 6066. [Google Scholar] [CrossRef]

- Federico, D.; Matteo, C.; Daniele, D.; Andrea, A.; Francesco, T.; Sergio, M. Modeling, control design and experimental automatic calibration of a leveling system for combine harvesters. Control Eng. Pract. 2023, 132, 105411. [Google Scholar]

- Chen, X.; Lv, X.; Wang, X.; Tu, X.; Lv, X. Design and study on the adaotive leveling control system of the crawler tractor in hilly and mountainous areas. INMATEH Agric. Eng. 2022, 66, 301–310. [Google Scholar] [CrossRef]

- Yao, Z.; Zhao, C.; Zhang, T. Agricultural machinery automatic navigation technology. iScience 2024, 27, 108714. [Google Scholar] [CrossRef]

- Zhang, J.; Li, D. Research on path tracking algorithm of green agricultural machinery for sustainable development. Sustain. Energy Technol. Assess. 2023, 55, 102917. [Google Scholar] [CrossRef]

- Zhang, S.; Xue, X.; Chen, C.; Sun, Z.; Sun, T. Development of a low-cost quadrotor UAV based on ADRC for agricultural remote sensing. Int. J. Agric. Biol. Eng. 2019, 12, 82–87. [Google Scholar] [CrossRef]

- Jia, W.; Tai, K.; Wang, X.; Dong, X.; Ou, M. Design and Simulation of Intra-Row Obstacle Avoidance Shovel-Type Weeding Machine in Orchard. Agriculture 2024, 14, 1124. [Google Scholar] [CrossRef]

- Ahmed, S.; Qiu, B.; Kong, C.W.; Xin, H.; Ahmad, F.; Lin, J. A Data-Driven Dynamic Obstacle Avoidance Method for Liquid-Carrying Plant Protection UAVs. Agronomy 2022, 12, 873. [Google Scholar] [CrossRef]

- Xie, B.; Jin, Y.; Muhammad, F.; Gao, W.; Liu, J.; Jiang, H.; Cai, L.; Li, Y. Research progress of autonomous navigation technology for multi-agricultural scenes. Comput. Electron. Agric. 2023, 211, 107963. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, W.; Xu, B.; Yu, X. Optimizing Contact Force on an Apple Picking Robot End-Effector. Agriculture 2024, 14, 996. [Google Scholar] [CrossRef]

- Li, S.; Zhang, M.; Ji, Y.; Zhang, Z.; Gao, R.; Chen, B.; Li, H.; Yin, Y. Agricultural machinery GNSS/IMU-integrated navigation based on fuzzy adaptive finite impulse response Kalman filtering algorithm. Comput. Electron. Agric. 2021, 191, 106524. [Google Scholar] [CrossRef]

- Cui, B.; Cui, X.; Wei, X.; Zhu, Y.; Ma, Z.; Zhao, Y.; Liu, Y. Design and Testing of a Tractor Automatic Navigation System Based on Dynamic Path Search and a Fuzzy Stanley Model. Agriculture 2024, 14, 2136. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, F.; Guan, Z.; Zhu, Y.; Shi, H.; Cheng, K. Development of a combined harvester navigation control system based on visual simultaneous localization and mapping-inertial guidance fusion. J. Agric. Eng. 2024, 55. [Google Scholar] [CrossRef]

- Li, C.; Wu, J.; Pan, X.; Dou, H.; Zhao, X.; Gao, Y.; Yang, S.; Zhai, C. Design and Experiment of a Breakpoint Continuous Spraying System for Automatic-Guidance Boom Sprayers. Agriculture 2023, 13, 2203. [Google Scholar] [CrossRef]

- Nakaguchi, V.M.; Abeyrathna, D.R.R.; Liu, Z.; Noguchi, R.; Ahamed, T. Development of a Machine stereo vision-based autonomous navigation system for orchard speed sprayers. Comput. Electron. Agric. 2024, 227, 109669. [Google Scholar] [CrossRef]

- Thanpattranon, P.; Ahamed, T.; Takigawa, T. Navigation of autonomous tractor for orchards and plantations using a laser range finder: Automatic control of trailer position with tractor. Biosyst. Eng. 2016, 147, 90–103. [Google Scholar] [CrossRef]

- Wang, D.; Yuan, H. Data-driven tube model predictive control of autonomous agricultural tractors for cross-slope navigation. Smart Agric. Technol. 2025, 10, 100844. [Google Scholar] [CrossRef]

- Liu, W.; Hu, J.; Liu, J.; Yue, R.; Zhang, T.; Yao, M.; Li, J. Method for the navigation line recognition of the ridge without crops via machine vision. Int. J. Agric. Biol. Eng. 2024, 17, 230–239. [Google Scholar]

- Shi, Y.; Cheng, X.; Xi, X.; Shan, X.; Jin, Y.; Zhang, R. Research progress on the path tracking control methods for agriculture machinery navigation. Trans. Chin. Soc. Agric. Eng. 2023, 39, 1–14. [Google Scholar]

- Lu, E.; Xu, L.; Li, Y.; Tang, Z.; Ma, Z. Modeling of working environment and coverage path planning method of combine harvesters. Int. J. Agric. Biol. Eng. 2020, 13, 132–137. [Google Scholar] [CrossRef]

- Cheng, J.; Zhang, B.; Zhang, C.; Zhang, Y.; Shen, G. A model-free adaptive predictive path-tracking controller with PID terms for tractors. Biosyst. Eng. 2024, 242, 38–49. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Z.; Ding, S.; Xia, J.; Xing, G. Adaptive disturbance observer-based fixed time nonsingular terminal sliding mode control for path-tracking of unmanned agricultural tractors. Biosyst. Eng. 2024, 246, 96–109. [Google Scholar] [CrossRef]

- Ge, Z.; Man, Z.; Wang, Z.; Bai, X.; Wang, X.; Xiong, F.; Li, D. Robust adaptive sliding mode control for path tracking of unmanned agricultural vehicles. Comput. Electr. Eng. 2023, 108, 108693. [Google Scholar] [CrossRef]

- Li, J.; Shang, Z.; Li, R.; Cui, B. Adaptive Sliding Mode Path Tracking Control of Unmanned Rice Transplanter. Agriculture 2022, 12, 1225. [Google Scholar] [CrossRef]

- Zhang, S.; Wei, X.; Liu, C.; Ge, J.; Cui, X.; Wang, F.; Wang, A.; Chen, W. Adaptive path tracking and control system for unmanned crawler harvesters in paddy fields. Comput. Electron. Agric. 2025, 230, 109878. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, R.; Zhang, D.; Yi, T.; Ding, C.; Chen, L. Path curvature incorporated reinforcement learning method for accurate path tracking of agricultural vehicles. Comput. Electron. Agric. 2025, 234, 110243. [Google Scholar] [CrossRef]

- Lu, E.; Xue, J.; Chen, T.; Jiang, S. Robust Trajectory Tracking Control of an Autonomous Tractor-Trailer Considering Model Parameter Uncertainties and Disturbances. Agriculture 2023, 13, 869. [Google Scholar] [CrossRef]

- He, J.; Hu, L.; Wang, P.; Liu, Y.; Man, Z.; Tu, T.; Yang, L.; Li, Y.; Yi, Y.; Li, W. Path tracking control method and performance test based on agricultural machinery pose correction. Comput. Electron. Agric. 2022, 200, 107185. [Google Scholar] [CrossRef]

| Drive System Type | Fundamental Principle | Technical Characteristics | Applicable Models | Example Diagram | Prototype Performance |

|---|---|---|---|---|---|

| Mechanical | Mechanical transmission devices transfer power directly | Simple structure; high efficiency; low cost; limited speed regulation range | Transmission tractors; small agricultural machinery |  BETTER 180 mountain tractor | Electronic 6-speed shifting BETCAM system that could downshift automatically: power: 129 kW/176 HP; maximum engine speed: 2375 rpm |

| Hydraulic | Hydraulic system transmits power | Wide speed regulation range; simple and convenient operation; stable transmission; low efficiency | Large agricultural machinery; agricultural machinery for operation in complex terrains |  Rogator 600 series self-propelled sprayer | HydroStar CVT gearbox in combination with engine wheel hubs: 40/50 km/h at reduced engine speed; maximum operating width of 39 m. |

| Electric | Motor converts electrical energy into mechanical energy | Environmental protection; good speed regulation performance; simple structure; dependent on external power supply | Small-sized electric agricultural machinery; precision agricultural machinery |  ET1004-W electric tractor | Power: 100 HP; distributed control technology, four-wheel drive and four-wheel steering combined for control; driverless wheel-side drive |

| Type | Fundamental Principle | Technical Characteristics | Example Diagram | Applicable Models |

|---|---|---|---|---|

| Mechanical CVT | Stepless speed change is achieved through a chain belt and pulley system, enabling the continuous adjustment of the transmission ratio. | Continuous gear shifting capability; simple structure; limited torque capacity |  | Fendt 1100 Vario series tractors |

| HMCVT | Stepless speed variation is achieved through the coordinated operation of hydraulic and gear systems. | High transmission efficiency; stable power output; complex structure |  | Massey Ferguson MF8700 series tractors |

| HST | Power is transmitted through the hydraulic pump and the hydraulic motor to achieve stepless speed variation. | Precise speed and torque control; relatively low transmission efficiency |  | John Deere 4000 series large self-propelled harvester; Case A8000 sugarcane harvester |

| Type | Advantages | Disadvantages | Application Scenarios | Example Diagram |

|---|---|---|---|---|

| Wheeled | Fast speed; suitable for long-distance movement and transportation; convenient steering and handling | Susceptibility to skidding or becoming immobilized on soft or uneven terrain; significant rollover possibility when walking on slopes or slippery surfaces | Flat land; gently undulating slopes |  Transplanter [52] |

| Crawler | Superior traversability on soft, muddy, and uneven terrain; high stability; suitable for working on slopes | Slow speed; unsuitable for long-distance movement; damages hard pavement easily | Muddy ground; sloping land |  Grass cutter |

| Legged | Strong adaptability; capable of walking on complex terrain; high flexibility | Slow speed; unsuitable for long-distance movement; unsuitable for heavy-load operations | Mountainous areas; forest land |  Transport robot [59] |

| Composite | Suitable for various types of working terrains | Complex structure; heavy weight | Hills; wetlands |  Wheel–track tractor |

| Type | Example Diagram | Advantages | Disadvantages | Application Scenarios |

|---|---|---|---|---|

| Wheeled steering |  | Small turning radius; steering flexibly; prompt steering response; small steering resistance | prone to skidding when turning on soft and slippery ground; turning easily aggravates soil compaction; prone to tipping over when turning on sloping ground | Field margins; narrow plots; flat and hard road surfaces |

| Crawler steering |  [95] | Turns on complex terrain stably; uniform traction force distribution during turning; low center of gravity means it is not easy to roll over when turning | Complex steering operation; slow steering speed; easy to scratch ground when steering on hard pavement | Muddy land; sloping land; rugged mountainous land |

| Control Algorithm | Advantages | Disadvantages | Reference |

|---|---|---|---|

| Feedforward PID Control | The compensation amount can be directly generated based on the interference signal to offset the disturbance influence in advance; the leveling response speed is fast; and the dependence on the feedback loop is low. | The method relies on the precise mathematical model of the leveling system; the unmeasurable disturbances cannot be eliminated. | Lv et al. [121] |

| Fuzzy PID Control | There is no need for an accurate mathematical model; nonlinear, time-varying or complex coupled leveling systems can be handled through empirical rules; and it has strong robustness. | The design complexity of the fuzzy rules is high, and the controls’ real-time performance is limited. | Qi et al. [122] |

| Neural Network PID Control | The method is applicable to strongly nonlinear or time-varying leveling systems, and the PID parameters are dynamically adjusted through the backpropagation algorithm to adapt to environmental disturbances. | The computational complexity is high, and the control response may be delayed; the network may overfit the training data, and the performance when generalized to new working conditions is unstable. | Zhang et al. [123] Sun et al. [124] |

| Synovial Control | The method has strong robustness against parameter changes in the leveling system and external disturbances; it converges to a sliding surface within a finite time and has a relatively fast response speed. | The method may cause high-frequency buffeting, and the high-frequency switching control signal will increase the energy consumption of the system. | Wang et al. [125] Peng et al. [126] |

| Model Predictive Control | The method’s multi-variable control ability is strong; it is suitable for solving coupling problems; and through rolling optimization, the control strategy can be adjusted in real time. | The method’s computational complexity is high and the parameter debugging is complex; it relies on the precise mathematical model of the leveling system. | Federico et al. [127] |

| Linear Proportional Control | The structure is simple and easy to implement, and the leveling control response speed is fast. | The steady-state error cannot be completely eliminated, the method is sensitive to changes in control parameters, and its anti-interference ability is weak. | Chen et al. [128] |

| Reference | Automatic Navigation Technology | Reference | Path Tracking Control Method |

|---|---|---|---|

| Li et al. [136] | A system based on the integration of Global Navigation Satellite System (GNSS) positioning equipment and an inertial measurement unit, integrating accelerometers and gyroscopes. | Cheng et al. [146] | A tracking system based on the heading deviation angle and a MFAPC-PID path tracking controller. |

| Cui et al. [137] | An unmanned tractor automatic navigation system based on dynamic path search and the Fuzzy Stanley Model (FSM). | Sun et al. [147] | A fixed-time terminal sliding mode controller for unmanned agricultural tractors based on the fixed-time nonsingular terminal sliding mode and adaptive disturbance observer technology. |

| Chen et al. [138] | A navigation control system for combine harvesters based on the fusion of visual simultaneous localization and mapping (SLAM) and inertial guidance. | Ge et al. [148] | An adaptive sliding mode control (ASMC) method for path tracking in unmanned agricultural vehicles. |

| Li et al. [139] | An operation breakpoint identification algorithm combining the real-time dynamic Global Navigation Satellite System (RTK-GNSS) and a wheel odometer based on the spray lag compensation algorithm. | Li et al. [149] | An autonomous rice transplanter path tracking method based on adaptive sliding mode variable structure control. |

| Nakaguchi et al. [140] | A deep learning machine stereo vision guidance system. | Zhang et al. [150] | A multi-parameter optimization feedback algorithm to improve the accuracy of fully autonomous operation and path tracking of crawler harvesters. |

| Thanpattranon et al. [141] | A single-sensor navigation control algorithm and a control scheme for stopping a tractor–trailer using a laser rangefinder (LRF) in various field tasks. | Zhang et al. [151] | A path tracking control algorithm based on deep reinforcement learning combined with path curvature. |

| Wang et al. [142] | A navigation control method that combines a Long Short-Term Memory (LSTM) network with Robust Tube Model Predictive Control (TMPC). | Lu et al. [152] | The model predictive control (MPC) method was adopted in the attitude control layer, the sliding mode control (SMC) method was adopted in the power layer, and a nonlinear disturbance observer (NDO) was designed. |

| Liu et al. [143] | A machine vision navigation method based on the color of field ridges. | He et al. [153] | An MPC path tracking control method based on the attitude of agricultural machinery. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Wang, R.; Ding, R.; Sun, Z.; Jiang, Y.; Liu, W. Research Review of Agricultural Machinery Power Chassis in Hilly and Mountainous Areas. Agriculture 2025, 15, 1158. https://doi.org/10.3390/agriculture15111158

Jiang Y, Wang R, Ding R, Sun Z, Jiang Y, Liu W. Research Review of Agricultural Machinery Power Chassis in Hilly and Mountainous Areas. Agriculture. 2025; 15(11):1158. https://doi.org/10.3390/agriculture15111158

Chicago/Turabian StyleJiang, Yiyong, Ruochen Wang, Renkai Ding, Zeyu Sun, Yu Jiang, and Wei Liu. 2025. "Research Review of Agricultural Machinery Power Chassis in Hilly and Mountainous Areas" Agriculture 15, no. 11: 1158. https://doi.org/10.3390/agriculture15111158

APA StyleJiang, Y., Wang, R., Ding, R., Sun, Z., Jiang, Y., & Liu, W. (2025). Research Review of Agricultural Machinery Power Chassis in Hilly and Mountainous Areas. Agriculture, 15(11), 1158. https://doi.org/10.3390/agriculture15111158