Design and Experiment of Dual Flexible Air Duct Spraying Device for Orchards

Abstract

1. Introduction

2. Materials and Methods

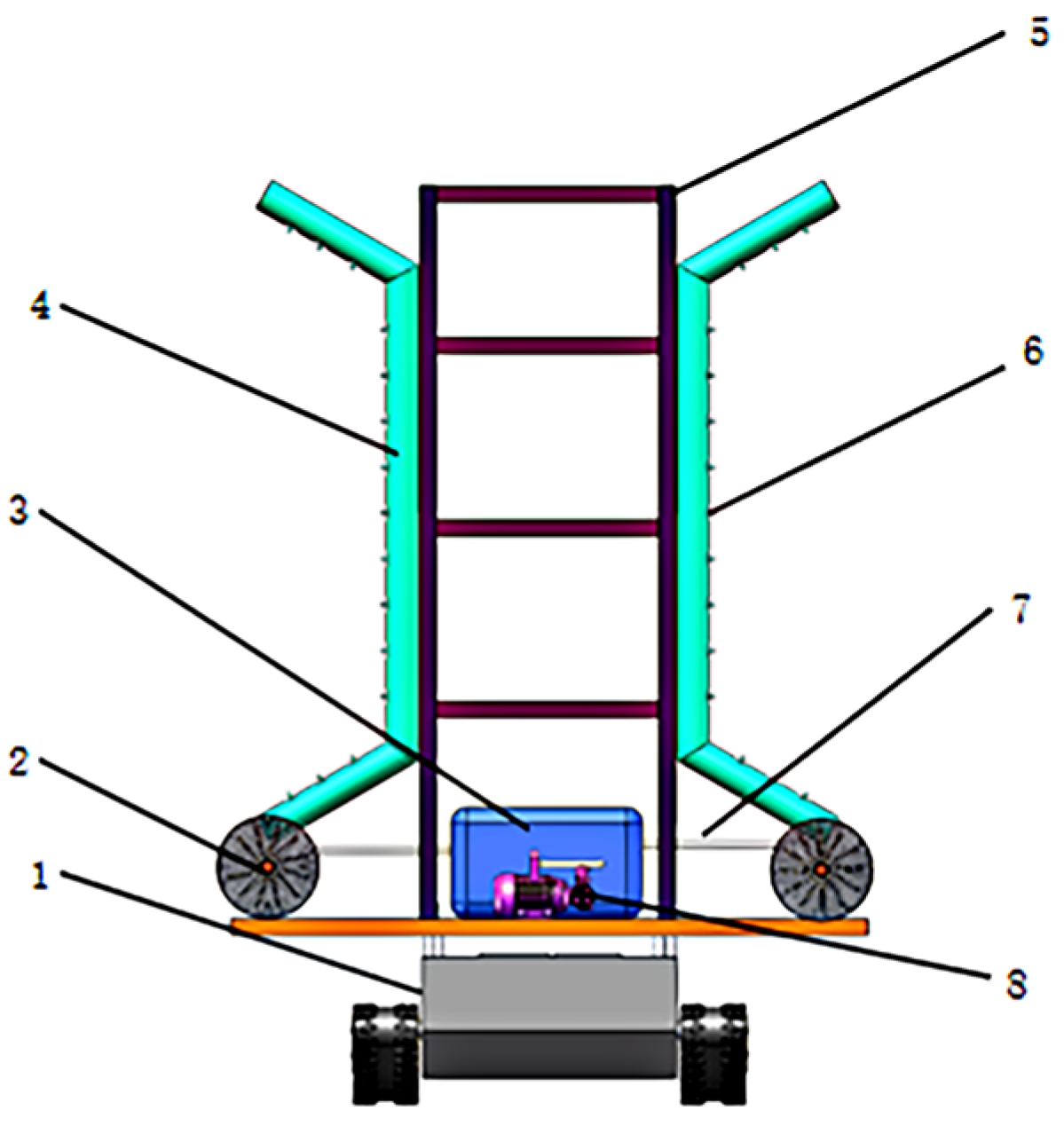

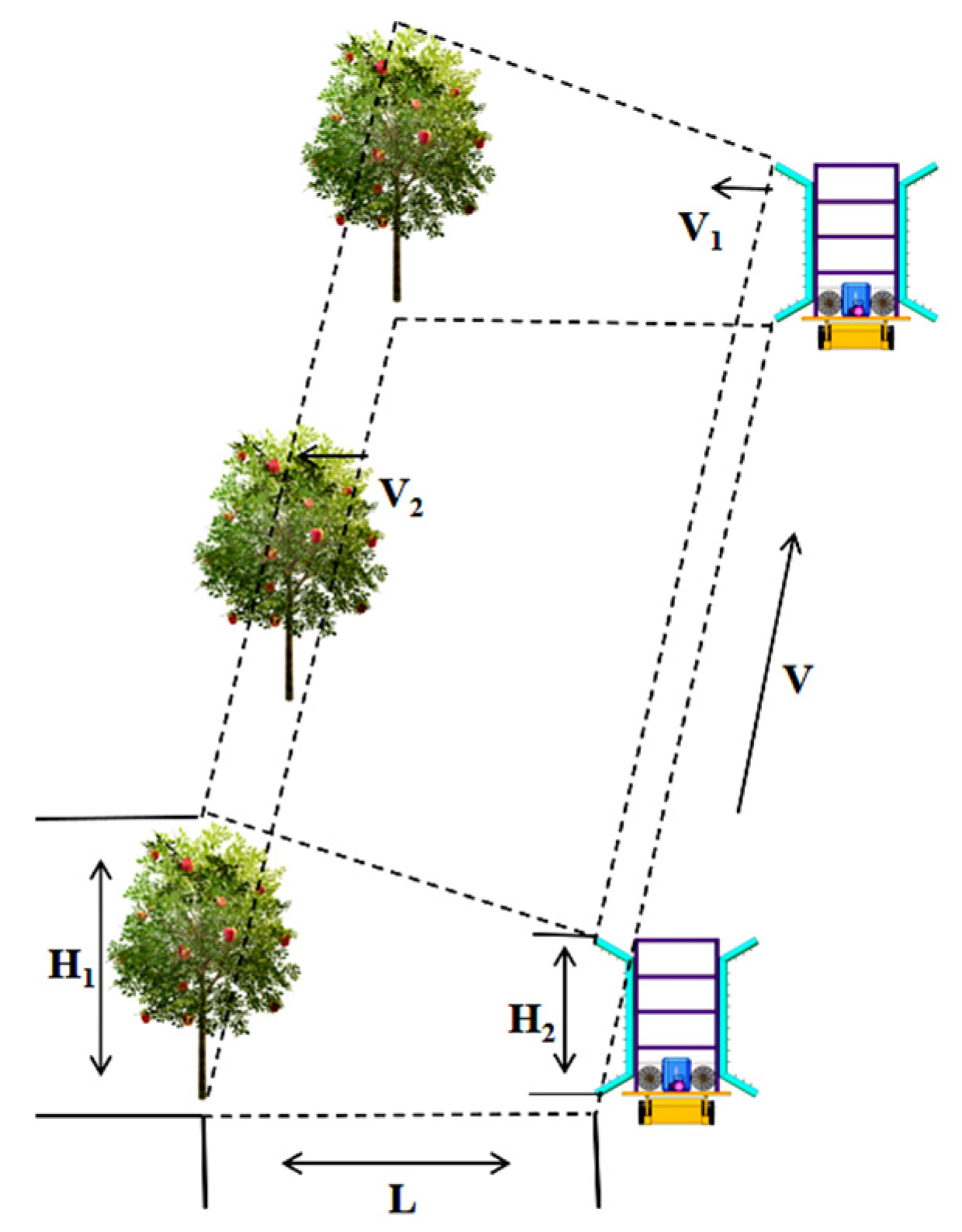

2.1. Double Flexible Duct Spraying Device Working Principle

2.2. Dual Flexible Ductwork Design

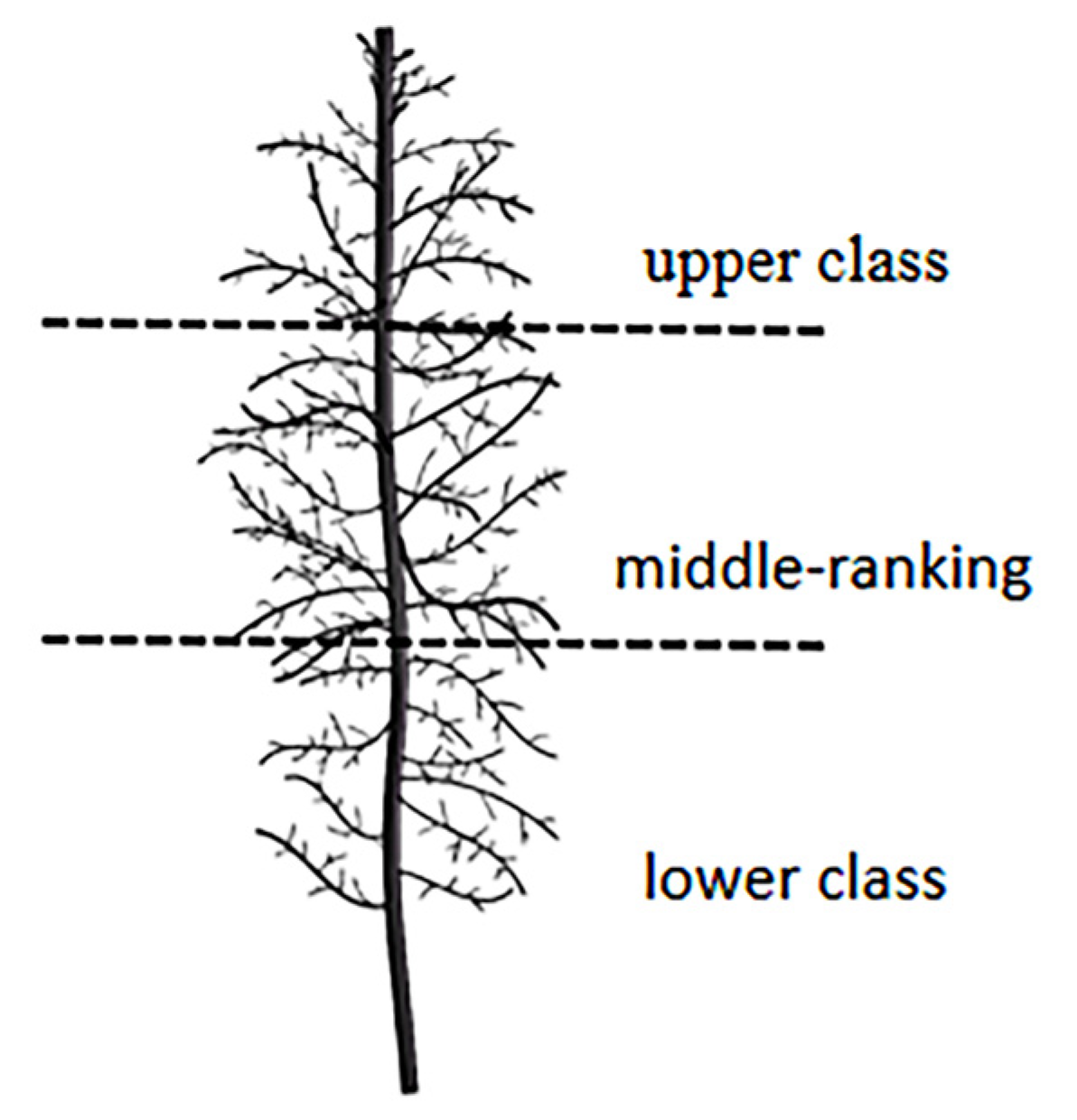

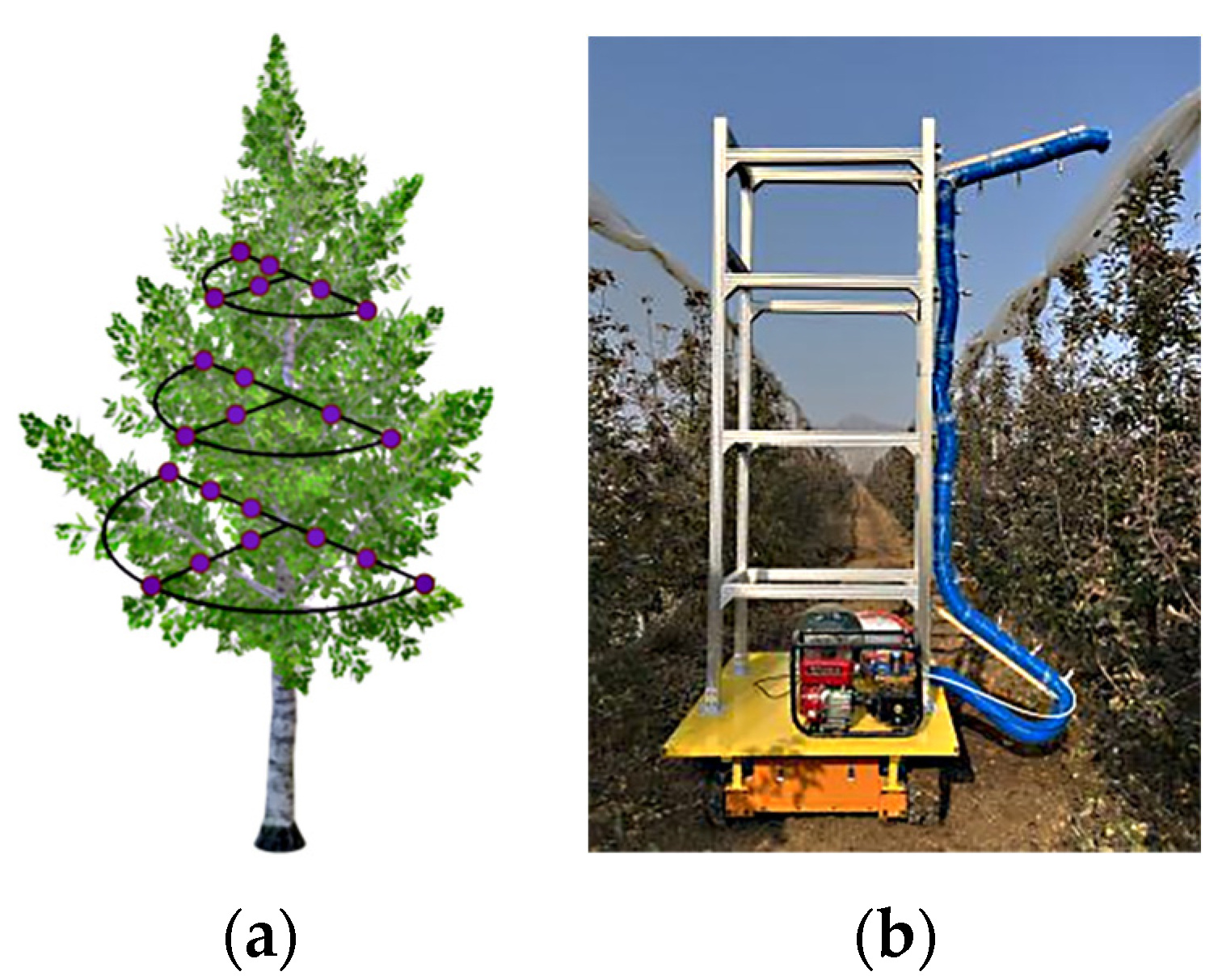

2.2.1. Analysis of Fruit Tree Shape and Canopy Structure

2.2.2. Structural Design of Flexible Ducts

2.3. Analysis of Wind Volume and Wind Resistance

2.3.1. Calculation of Airflow

2.3.2. Calculation of Wind Resistance

2.4. Analysis of Drug Flow Resistance

2.4.1. Calculation of Along-Stream Pressure Loss

2.4.2. Calculation of Local Pressure Loss

2.4.3. Pump and Nozzle Flow Analysis

3. Results

3.1. One-Way Test for Analysis of Duct Parameters

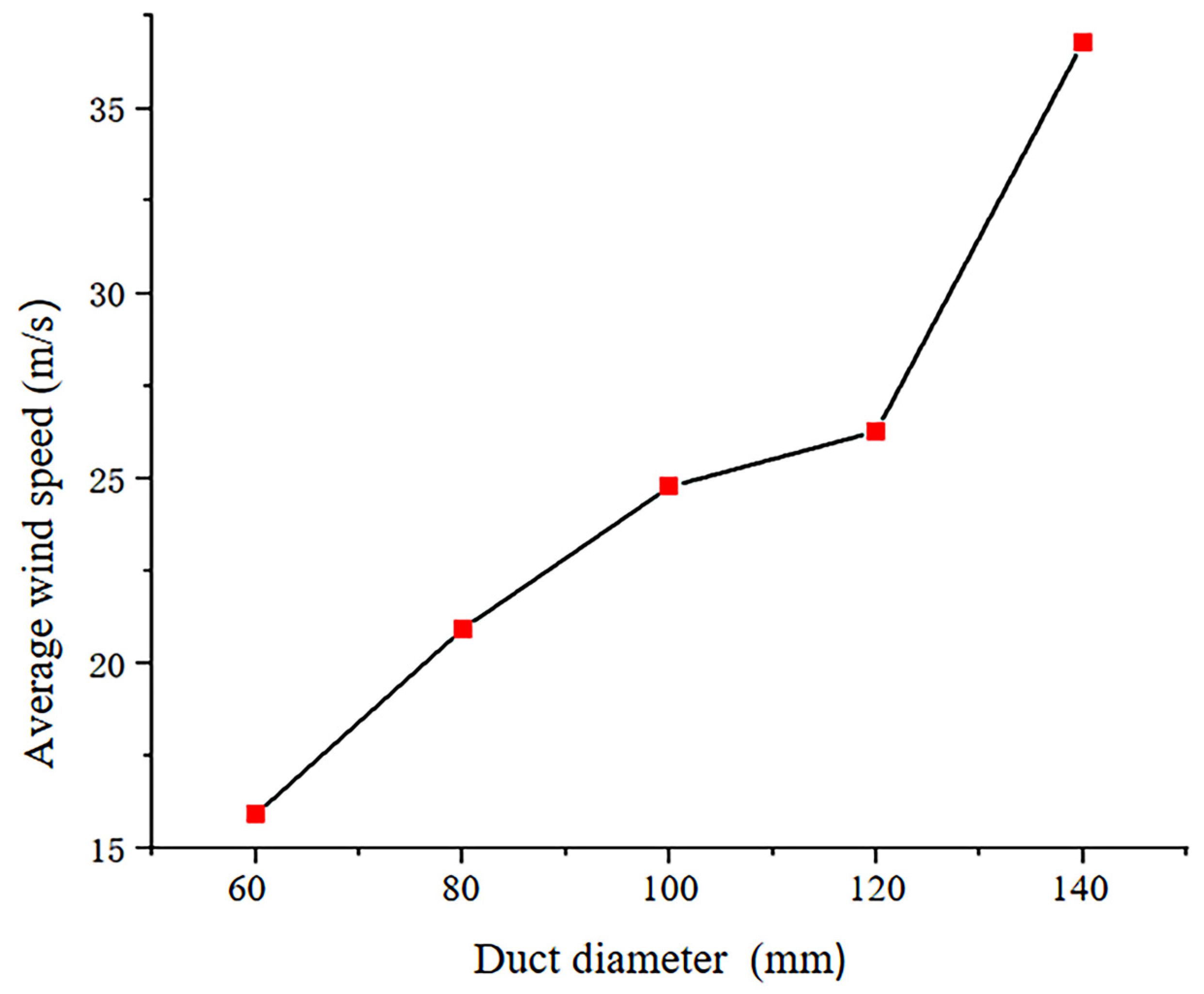

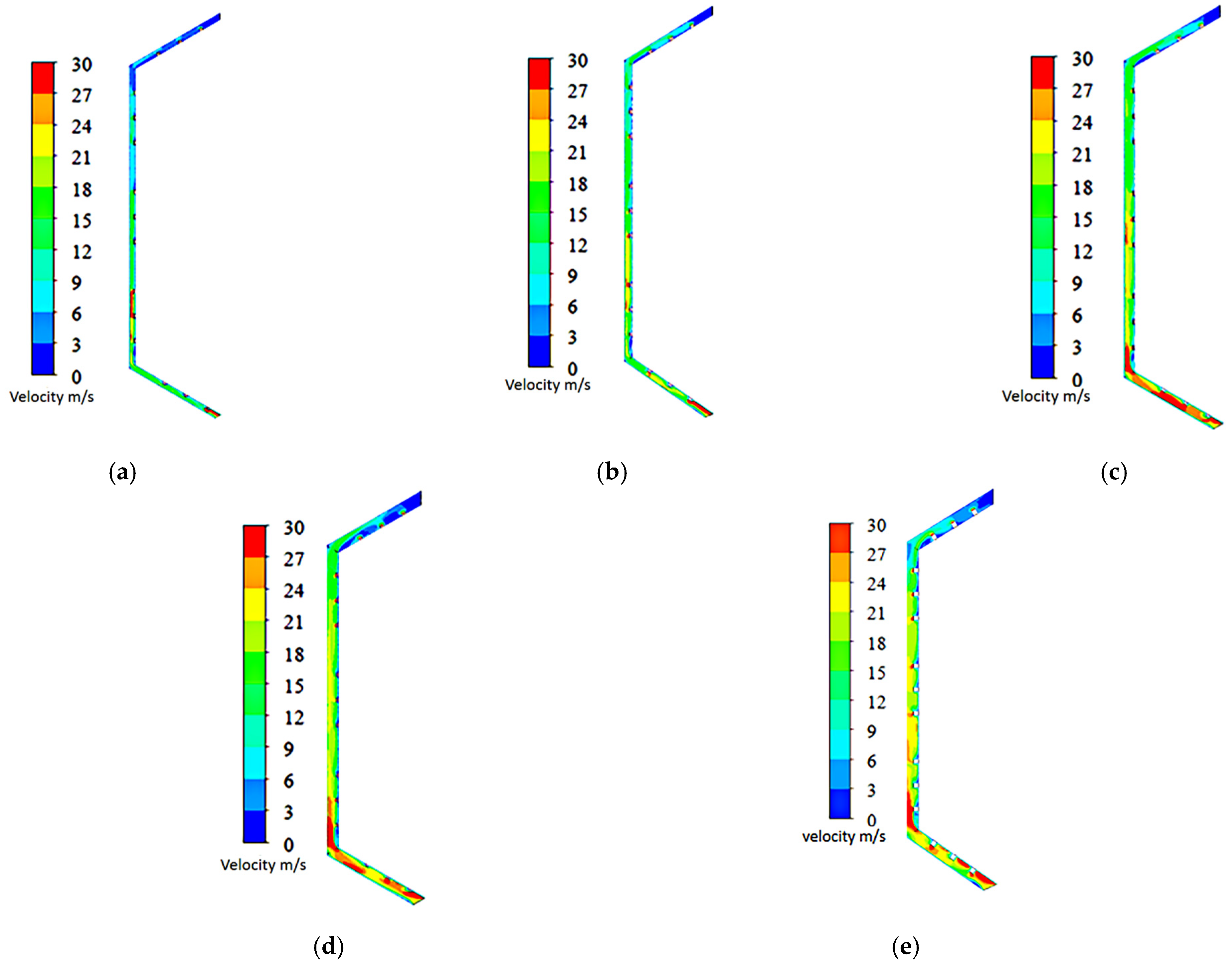

3.1.1. Effect of Duct Diameter on Air Velocity

3.1.2. Effect of Outlet Diameter on Air Velocity

3.2. Multi-Factor Test for Analysis of Duct Structure

3.2.1. Test Program and Results

3.2.2. Mathematical Modeling and Analysis of Variance

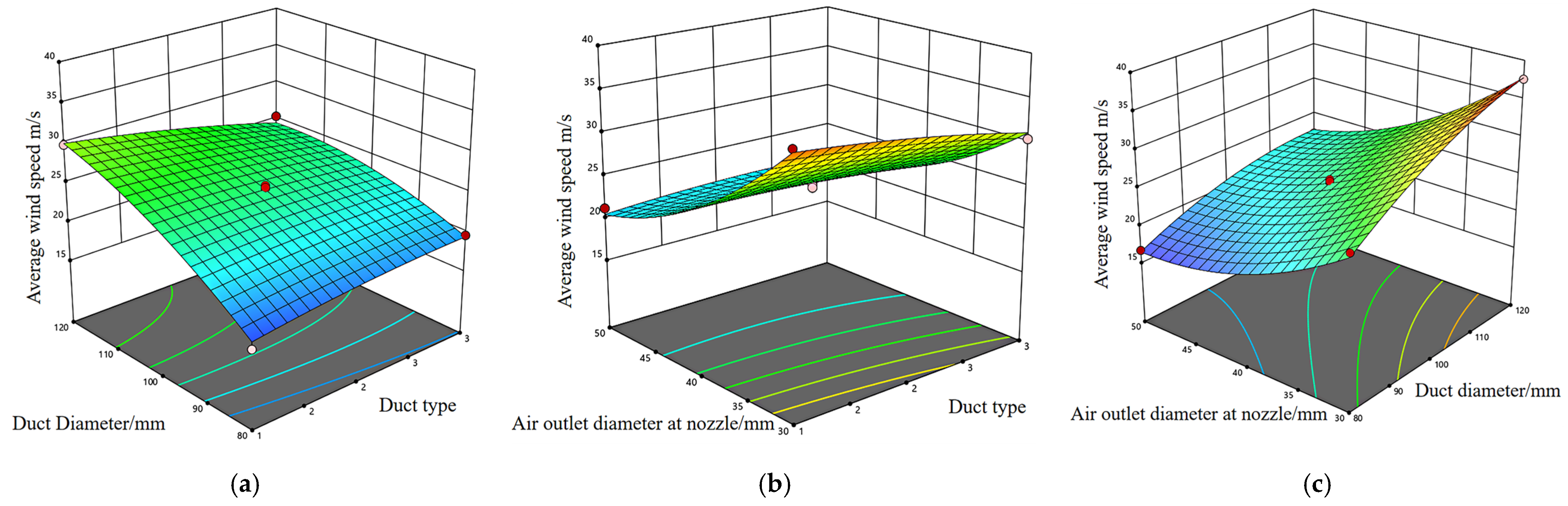

3.2.3. Interactions

4. Experimental Validation and Results Analysis

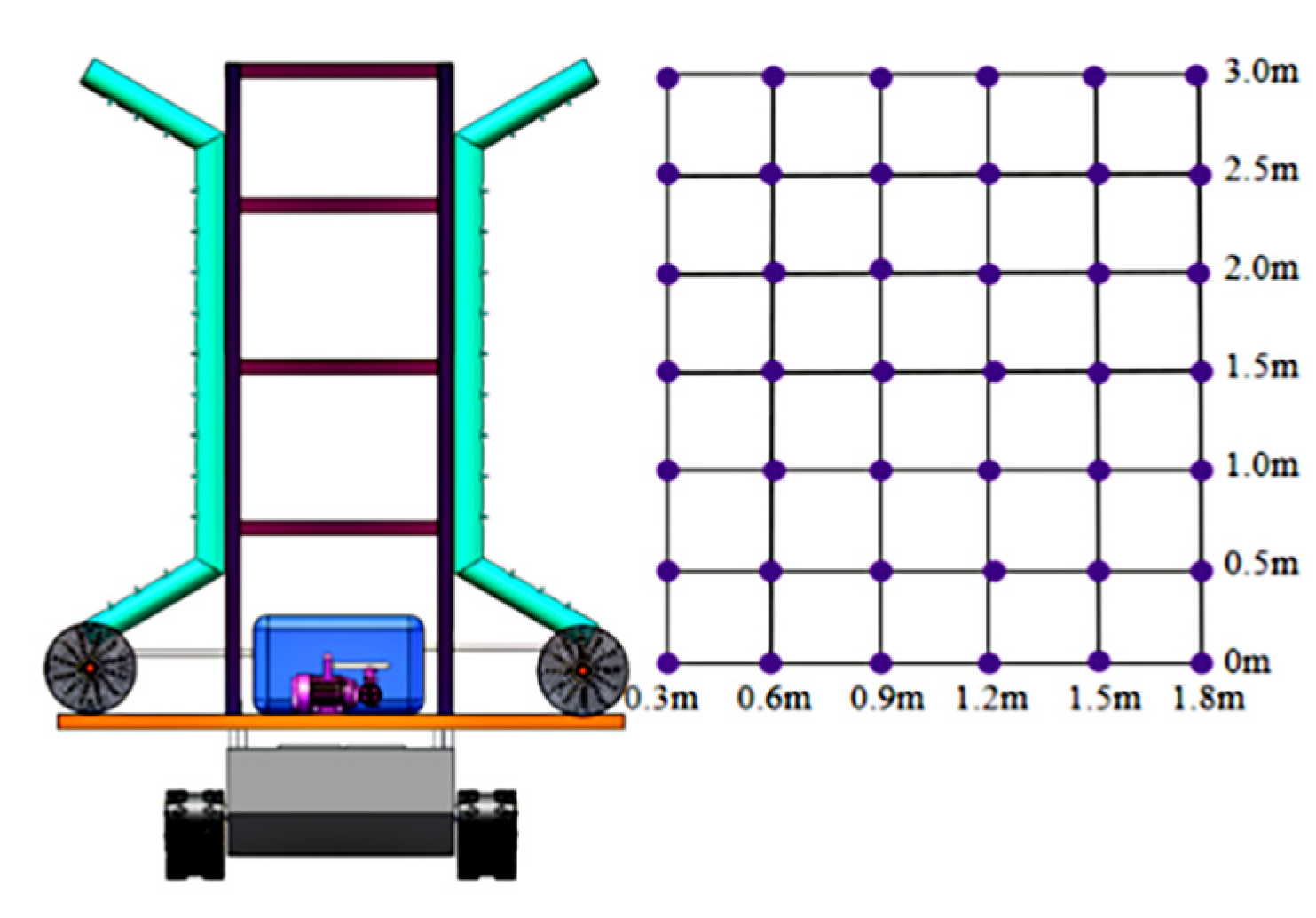

4.1. Test Materials and Equipment

4.2. Spray Device Wind Field Uniformity Test and Analysis

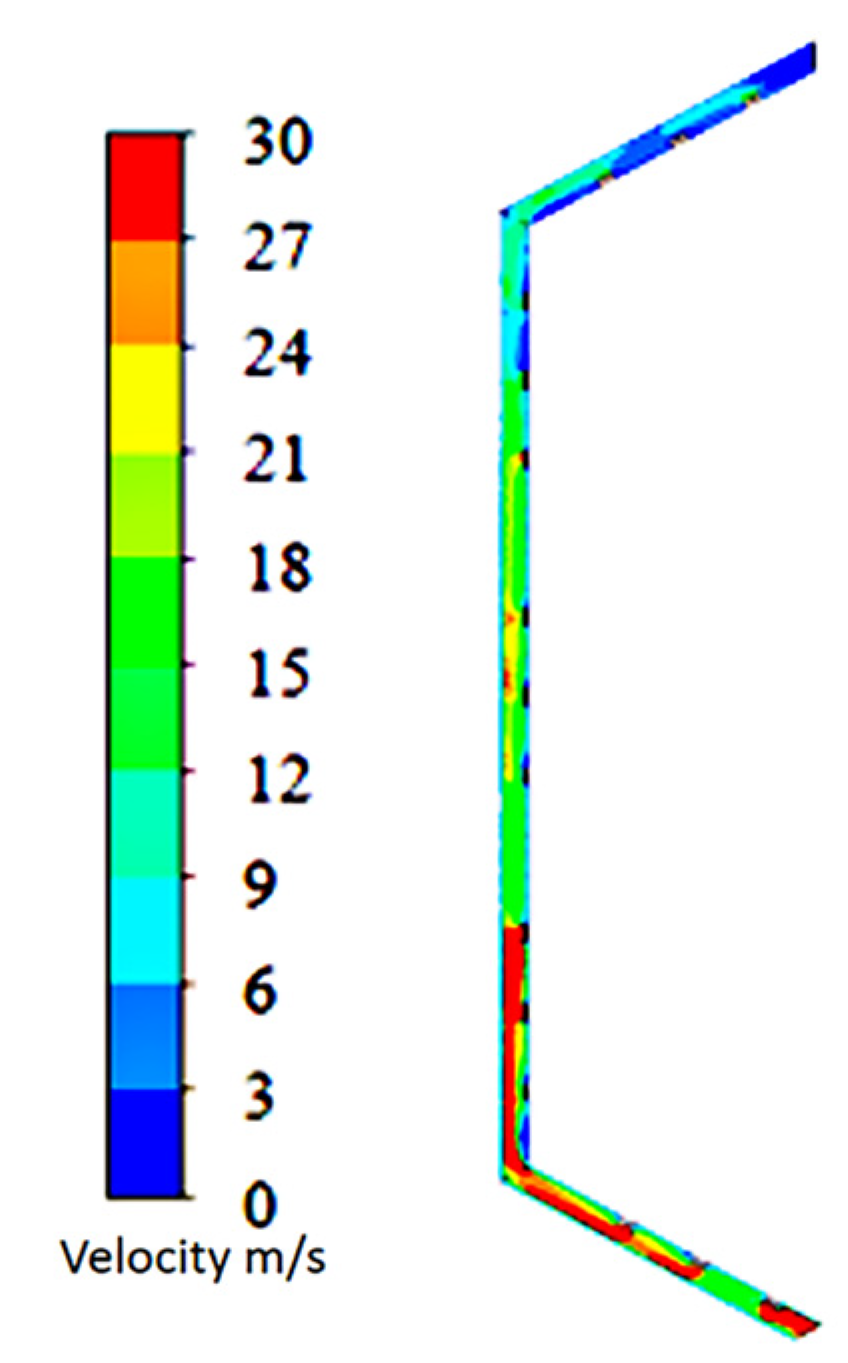

4.2.1. Duct Model Validation Tests and Analysis

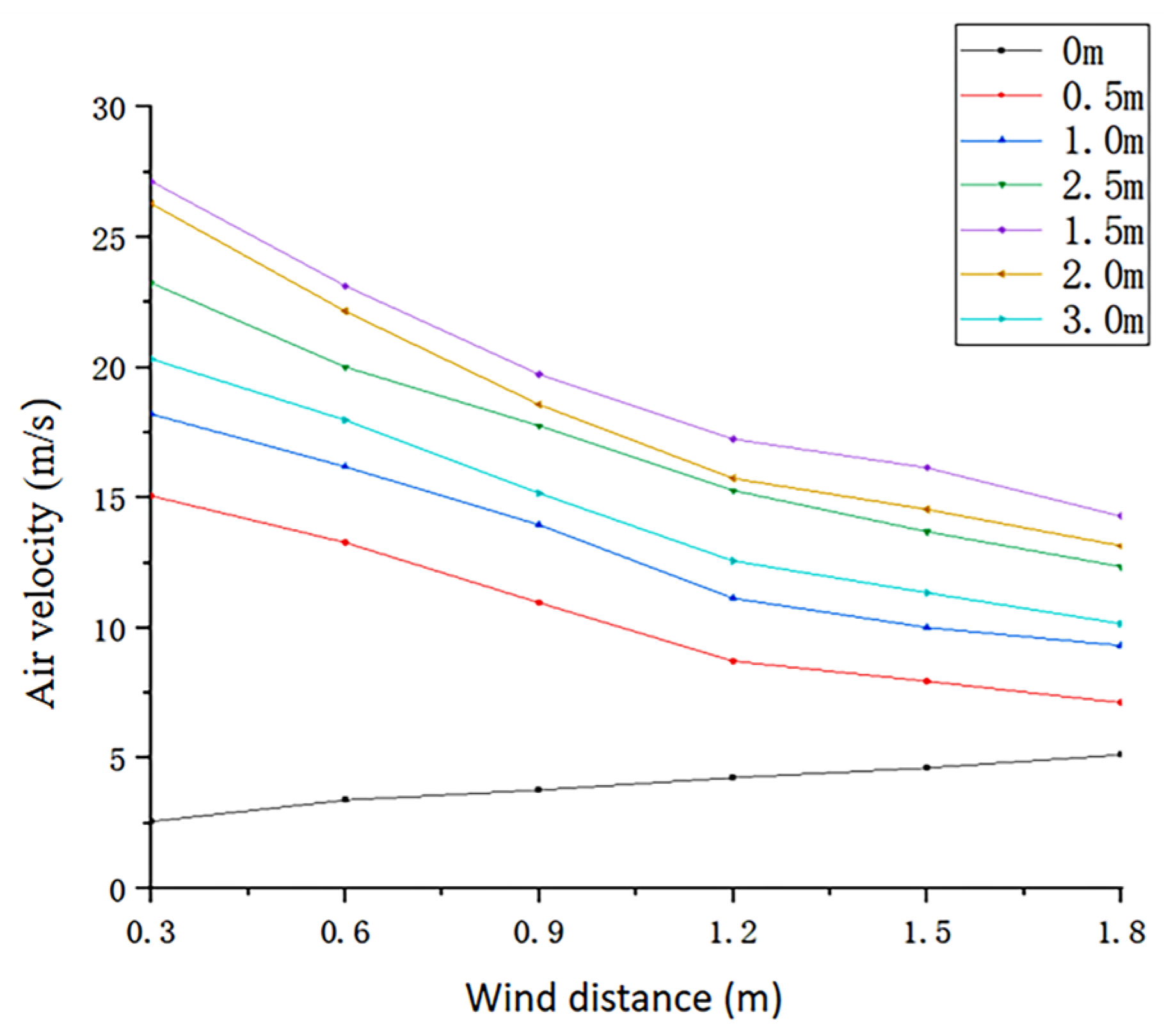

4.2.2. Test and Analysis of the External Flow Field of Air Ducts

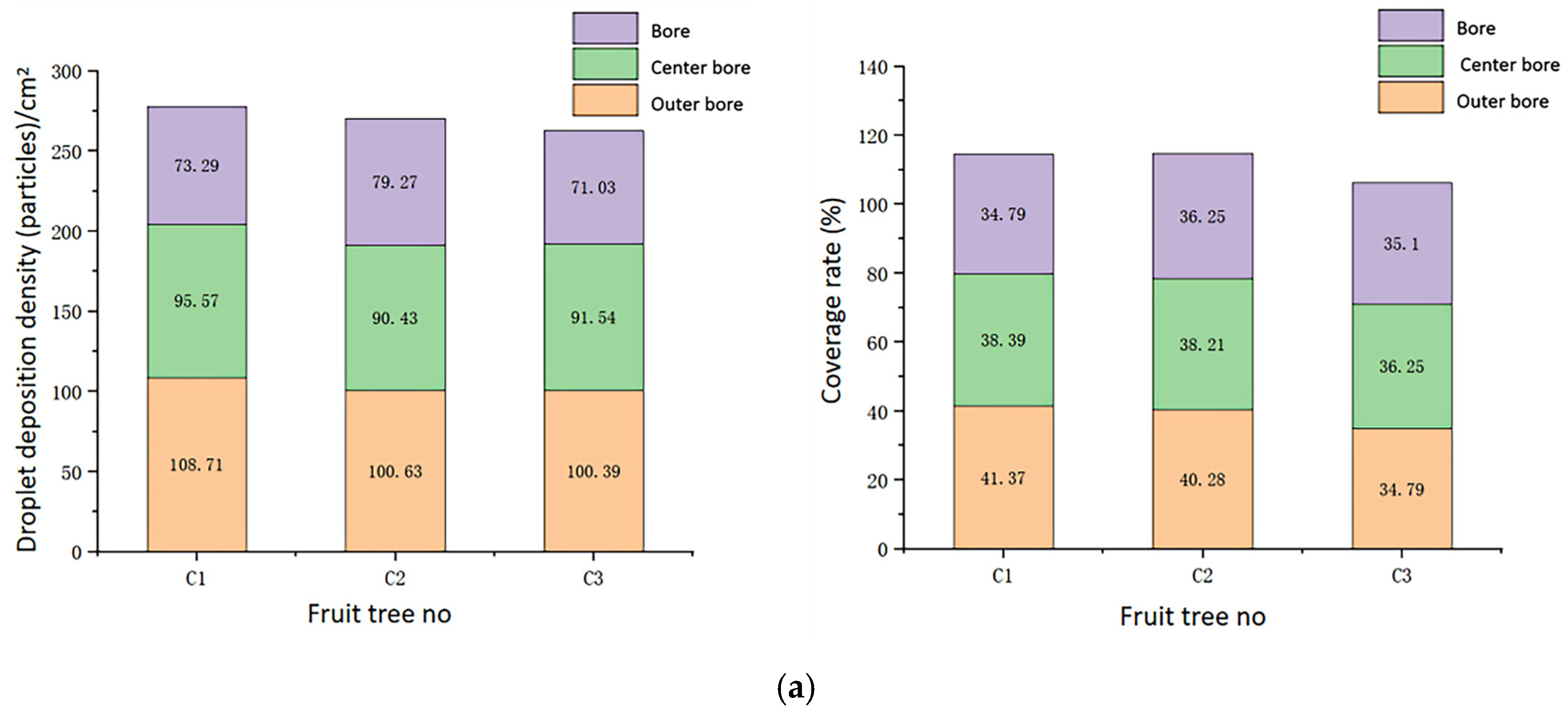

4.3. Test and Analysis of Droplet Deposition Uniformity

4.3.1. Droplet Penetration Analysis

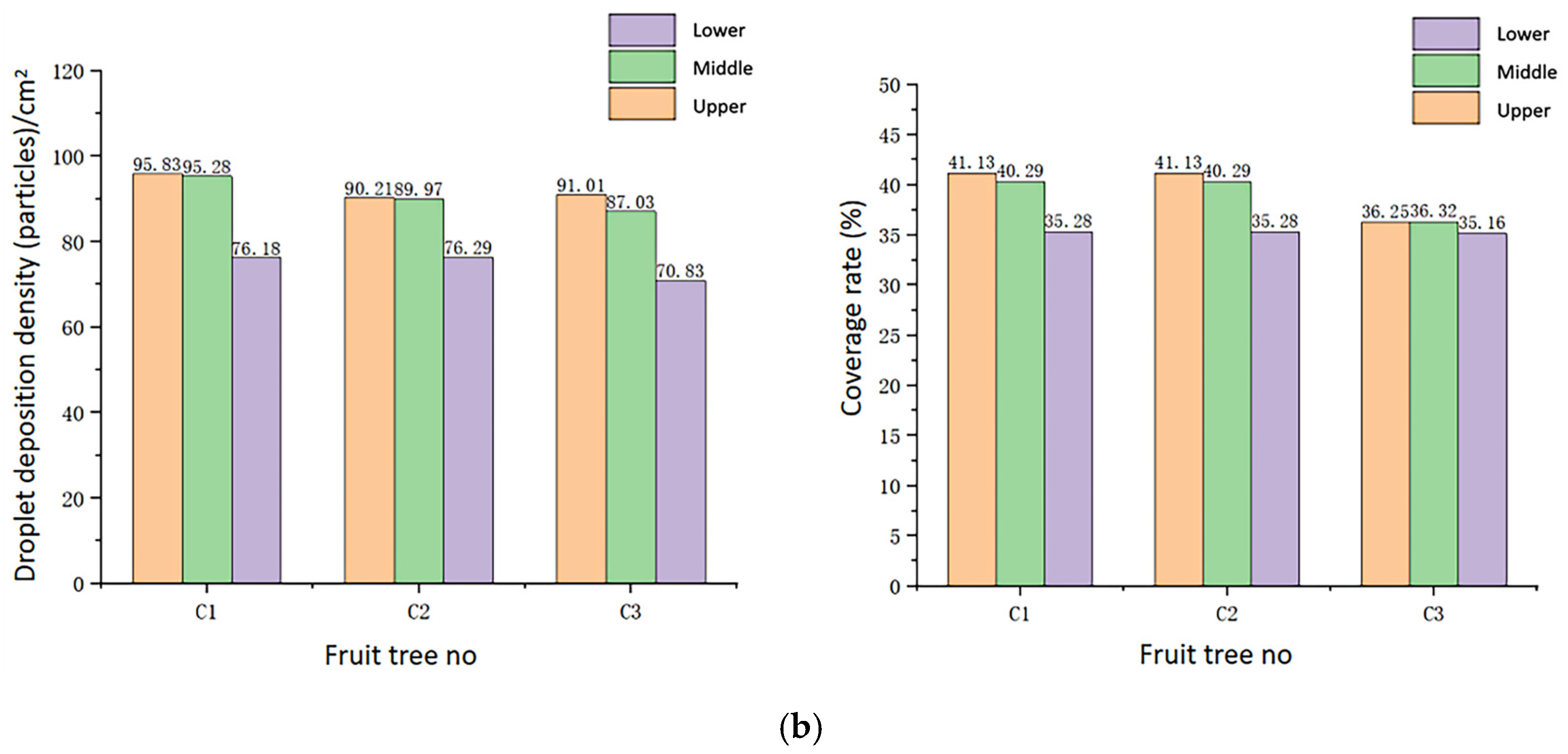

4.3.2. Vertical Distribution Uniformity Analysis of Spray Droplets

5. Discussion

6. Conclusions

- (1)

- A dual flexible duct sprayer designed for apple orchards with wide rows and dense planting was developed. The key components were selected and structurally optimized, with us identifying the nozzle outlet diameter, duct diameter, and duct type as the core factors influencing the performance of the air delivery system.

- (2)

- Through FLUENT fluid simulation analysis, it was determined that the parameters of the air ducts impact the uniformity of air velocity in the air supply system in the following descending order: the diameter of the nozzle outlet, the diameter of the air duct, and the type of air duct. It was found that the optimal configuration for the double flexible air duct spray device is air duct Type C, with an air duct diameter of 100 mm and a nozzle outlet diameter of 50 mm.

- (3)

- Based on the field experimental data of spray droplet deposition, when the optimized orchard dual flexible duct spraying device is in operation, the average inner canopy spray droplet coverage is 35.88%, indicating that the sprayer has excellent penetrability. The average inner canopy spray droplet deposition density is 74.53 droplets/cm2, demonstrating an efficient deposition of spray droplets within the tree’s inner canopy. The vertical distribution of spray droplet deposition follows the trend of lower > middle > upper, which aligns with the pesticide adhesion requirements for high fusiform fruit trees. This lower-layer > middle-layer > upper-layer vertical deposition pattern meets the liquid adhesion needs of high fusiform canopies, ensuring a uniform pesticide coverage across all parts of the fruit trees.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, Y.; Chen, B.; Lyu, H.; Kang, F.; Jiang, S. Research progress of orchard plant protection mechanization technology and equipment in China. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 110–124. [Google Scholar]

- Lü, X.; Fu, X.; Wu, P.; Ding, S.; Zhou, L.; Yan, H. Influence of Spray Operating Parameters on Droplet Deposition. Trans. Chin. Soc. Agric. Mach. 2011, 42, 70–75. [Google Scholar]

- Wang, Z.; Niu, H.; Tang, Y. Research status of orchard spray machinery and technology. J. Tarim Univ. 2019, 31, 83–91. [Google Scholar]

- Wang, J.; Tao, Z.; Ru, Y. Research status and Prospect of fan application in Agriculture and forestry plant protection machinery. Chin. J. Agric. Mech. 2016, 37, 67–74. [Google Scholar]

- Ade, G.; Molari, G.; Rondelli, V. Recycling tunnel sprayer for poesticide dose adjustment to the crop environment. Trans. ASABE 2007, 50, 409–413. [Google Scholar] [CrossRef]

- Salcedo, R.; Alleta, A.; Granell, R. Eulerian–Lagrangian model of the behaviour of droplets produced by an air–assisted sprayer in a citrus orchard. Biosyst. Eng. 2017, 154, 76–91. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, H.; Liu, J. Research and Development Tendency of Counter–roating Axial. Equip. Manuf. Technol. 2012, 1, 120–121. [Google Scholar]

- Chang, Z.; Luo, H.; Guo, L. Application of CFD Software in the Design of Fan. Fan Technol. 2009, 2, 60–64+72. [Google Scholar]

- Sidahmed, M.; Brownr, B. Simulation of spray dispersal and deposition from a forestry airblast sprayer—Part I: Air jet mode. Trans. ASAE 2001, 44, 5–10. [Google Scholar] [CrossRef]

- Zhou, L.; Xue, X.; Jia, W. Application of CFD technology in air–assisted spraying in orchard and analysis of its prospects. J. Drain. Irrig. Mach. Eng. 2014, 32, 776–782. [Google Scholar]

- Lv, X.; Zhang, M.; Chang, Y. Influence of deflector angles for orchard air–assisted sprayer on 3D airflow distribution. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 81–87. [Google Scholar]

- Ru, Y.; Chen, X.; Liu, B.; Wang, S.; Lin, M. Optimized Design and Performance Test of Axial Flow Orchard Sprayer Air Delivery System. Trans. Chin. Soc. Agric. Mach. 2022, 53, 147–157. [Google Scholar]

- Endalew, A.; Derbaer, M.; Rutten, N. A new integrated CFD modelling approach towards air–assisted orchard spraying—Part II: Validation for different sprayer types. Comput. Electron. Agric. 2010, 71, 137–147. [Google Scholar] [CrossRef]

- Endalew, A.; Derbaer, C.; Rutten, N. Modelling pesticide flow and deposition from air–assisted orchard spraying in orchards: A new integrated CFD approach. Agric. For. Meteorol. 2010, 150, 1383–1392. [Google Scholar] [CrossRef]

- Wang, P.; Xu, S.; Yang, X.; Li, S. Optimization Design and Test of Air Delivery System for Tower Sprayer. Trans. Chin. Soc. Agric. Mach. 2024, 55, 342–351, 390. [Google Scholar]

- Yang, X.; Liu, Y.; Wang, Y. Flow field simulation and test of air delivery system for orchard multi–duct sprayer. J. Jilin Univ. (Eng. Ed.) 2024, 54, 2723–2732. [Google Scholar]

- Jiang, H.; Niu, C.; Liu, L.; Wang, D.; Wang, J.; Mao, W. Design and Experiment of Air Volume Control System of Orchard Multi–pipe Air Spraye. Trans. Chin. Soc. Agric. Mach. 2020, 51, 298–307. [Google Scholar]

- Li, L.; He, X.; Song, J.; Wang, X.; Jia, X.; Liu, C. Design and experiment of automatic profiling orchard sprayer based on variable air volume and flow rate. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 70–76. [Google Scholar]

- Duga, A.T.; Delele, M.A.; Rysen, K.; Dekeyser, D.; Nuyttens, D.; Bylemans, D.; Nicolai, B.M.; Verboven, P. Development and a; idation of a 3D CFD model of drift and its application to air–assisted orchard sprayers. Biosyst. Eng. 2016, 154, 62–75. [Google Scholar] [CrossRef]

- Ding, T. Research on Airflow field Characteristics of Double–fan double–channel orchard sprayer. Chin. Acad. Agric. Sci. 2016. [Google Scholar]

- Qiu, W.; Ding, W.; Wang, X.; Gong, Y.; Zhang, X.; Lü, X. 3WZ–700 Self–propelled Air–blowing Orchard Sprayer. Trans. Chin. Soc. Agric. Mach. 2012, 43, 26–30, 44. [Google Scholar]

- Wang, J.; Ru, Y.; Zhou, H. Optimal design and airflow field test of seedling sprayer air–assisted system. J. For. Eng. 2020, 5, 129–138. [Google Scholar]

- Zhou, L.; Xue, X.; Zhou, L.; Zhang, L.; Ding, S.; Chang, C.; Zhang, X.; Chen, C. Research situation and progress analysis on orchard variable rate spraying technology. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 80–92. [Google Scholar]

- Ma, C.; Li, G.; Li, X.; Huang, X.; Song, J.; Yang, S. Development of multi–orientation automatic spraying device for citrus orchards in hilly and mountainous areas. Trans. CSAE Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 31–41. [Google Scholar]

- Xu, S.; Zhai, C.; Zhu, R. Design of an orchard air–assisted sprayer with adjustable spray height. J. Northwest AF Univ. (Nat. Sci. Ed.) 2013, 41, 229–234. [Google Scholar]

- Ryszard, H.; Grzegorz, D.; Waldemar, S. Variable air assistance system for orchard sprayers, concept, design and preliminary testing. Biosyst. Eng. 2017, 163, 134–149. [Google Scholar]

- Mirand–Fuentes, A.; Rodrguez–Lizana, A.; Gil, E. Influence of liquid–volume and airflow rates on spray application quality and homogeneity in super–intensive olive tree canopies. Sci. Total Environ. 2015, 537, 250–259. [Google Scholar] [CrossRef]

- Friso, D.; Baldoin, C.; Pezzle, F. Mathematical modeling of the dynamics of air jet crossing the canopy of tree crops during pesticide application. Appl. Math. Sci. 2015, 9, 1281–1296. [Google Scholar] [CrossRef]

- Salcedo, R.; Garcera, C.; Granell, R. Description of the airflow produced by an air–assisted sprayer during pesticide applications to citrus. Span. J. Agric. Res. 2015, 13, e0208. [Google Scholar] [CrossRef]

- Dai, F. Selection and calculation of air flow rate of wind sprayer. Plant Prot. 2008, 6, 124–127. [Google Scholar]

- Li, C.; Zhang, X.; Jiang, J.; Hu, Y. Development and experiment of riser air–blowing sprayer in vineyard. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2013, 29, 71–78. [Google Scholar]

- Li, B.; Yang, Q.; Xu, Z. Windbreak performance of tree on wind load on low–rise building. J. Build. Struct. 2016, 37, 33–38. [Google Scholar]

- Maruyama, T. Large eddy simulation of turbulent flow around a windbreak. J. Wind Eng. Ind. Aerodyn. 2008, 96, 1998–2006. [Google Scholar] [CrossRef]

- Zhang, Y. CFD Modeling of Spraying Space Wind Field and Wind Tree Interaction in Orchard; Northwest A&F University: Shaanxi, China, 2021. [Google Scholar]

- Li, J.; Bian, Y.; Yang, X. Operational parameter optimization and testing of an air–assisted multi–fan orchard sprayer. J. Jilin Univ. (Eng. Technol. Ed.) 2022, 52, 2474–2485. [Google Scholar]

- National Agricultural Machinery Standardization Technical Committee. Operation Quality of Air–Driven Orchard Sprayer: NY/T 992–2006; Ministry of Agriculture, People’s Republic of China: Beijing, China, 2006.

- Cao, J.; Qi, L.; Yang, Z. Experimental study of droplet distribution based on image processing. J. China Agric. Univ. 2019, 24, 130–137. [Google Scholar]

- Chen, Y. Study on the relationship between properties of spray liquid and utilization rate of pesticide deposition. Chin. Acad. Agric. Sci. 2021. [Google Scholar] [CrossRef]

| Technical Parameters | Numerical Value |

|---|---|

| Motorized chassis traveling speed | 0.5~1 m/s |

| Motorized chassis platform dimensions (Length × Width) | 2000 × 1600 mm |

| Axial fan air volume | 18,700 m3/h |

| Bracket dimensions (Length × Width × Height) | 1600 × 1200 × 3000 mm |

| Pesticide tank capacity | 150 L |

| Flexible duct length | 4.3 m |

| Pesticide tube length | 5.3 m |

| Ge qiang 65 series nozzle flow range | 0.14~0.35 L/min |

| Ge qiang 65 series nozzle pressure | 1 MPa |

| Plunger pump flow range | 20.21~23.78 L/min |

| Plunger pump pressure | 1~4.5 MPa |

| Plunger pump rotational speed | 800~1400 r/min |

| Encoding | Factor | ||

|---|---|---|---|

| Duct Type | Duct Diameter/mm | Air Outlet Diameter at Nozzle/mm | |

| −1 | A | 80 | 30 |

| 0 | B | 100 | 40 |

| 1 | C | 120 | 50 |

| Number | Level of Factors | Average Wind Speed (m/s) | ||

|---|---|---|---|---|

| 1 | 1 | 80 | 40 | 16.50 |

| 2 | 3 | 80 | 40 | 19.59 |

| 3 | 1 | 120 | 40 | 29.86 |

| 4 | 3 | 120 | 40 | 25.39 |

| 5 | 1 | 100 | 30 | 35.60 |

| 6 | 3 | 100 | 30 | 30.41 |

| 7 | 1 | 100 | 50 | 21.21 |

| 8 | 3 | 100 | 50 | 20.64 |

| 9 | 2 | 80 | 30 | 36.85 |

| 10 | 2 | 120 | 30 | 37.60 |

| 11 | 2 | 80 | 50 | 16.69 |

| 12 | 2 | 120 | 50 | 22.22 |

| 13 | 2 | 100 | 40 | 24.92 |

| 14 | 2 | 100 | 40 | 24.71 |

| 15 | 2 | 100 | 40 | 25.35 |

| 16 | 2 | 100 | 40 | 24.26 |

| 17 | 2 | 100 | 40 | 25.09 |

| Source | Square Sum | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|

| Model | 535.57 | 9 | 59.51 | 93.69 | <0.0001 ** |

| X1 | 6.37 | 1 | 6.37 | 10.03 | 0.0158 * |

| X2 | 157.00 | 1 | 157.00 | 247.17 | <0.0001 ** |

| X3 | 308.76 | 1 | 308.76 | 486.10 | <0.0001 ** |

| X1X2 | 14.29 | 1 | 14.29 | 22.50 | 0.0021 ** |

| X1X3 | 5.34 | 1 | 5.34 | 8.40 | 0.0230 * |

| X2X3 | 6.81 | 1 | 6.81 | 10.72 | 0.0136 * |

| X12 | 0.7894 | 1 | 0.7894 | 1.24 | 0.3017 |

| X22 | 10.22 | 1 | 10.22 | 16.09 | 0.0051 ** |

| X32 | 27.85 | 1 | 27.85 | 43.85 | 0.0003 ** |

| residual | 4.45 | 7 | 0.6352 | ||

| vector term | 3.67 | 3 | 1.22 | 6.33 | 0.0533 |

| pure error | 0.7733 | 4 | 0.1933 | ||

| Sum | 540.02 | 16 |

| Air Outlet | Analog Value (m/s) | Experimental Value (m/s) | Relative Error % |

|---|---|---|---|

| 1 | 29.27 | 29.92 | 2.22 |

| 2 | 17.25 | 18.53 | 7.42 |

| 3 | 28.41 | 29.27 | 3.02 |

| 4 | 25.91 | 27.83 | 7.41 |

| 5 | 15.10 | 15.81 | 4.70 |

| 6 | 15.25 | 16.12 | 5.70 |

| 7 | 20.79 | 21.53 | 3.56 |

| 8 | 26.81 | 28.69 | 7.01 |

| 9 | 16.51 | 17.38 | 5.27 |

| 10 | 16.44 | 17.21 | 4.68 |

| 11 | 20.40 | 21.27 | 4.26 |

| 12 | 15.11 | 16.57 | 9.66 |

| 13 | 18.23 | 19.18 | 5.21 |

| 14 | 21.34 | 22.35 | 4.73 |

| 15 | 22.72 | 23.14 | 1.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Wang, D.; Li, J.; Wang, P.; Guo, Y.; Tian, S. Design and Experiment of Dual Flexible Air Duct Spraying Device for Orchards. Agriculture 2025, 15, 1031. https://doi.org/10.3390/agriculture15101031

Zhang Z, Wang D, Li J, Wang P, Guo Y, Tian S. Design and Experiment of Dual Flexible Air Duct Spraying Device for Orchards. Agriculture. 2025; 15(10):1031. https://doi.org/10.3390/agriculture15101031

Chicago/Turabian StyleZhang, Zhu, Dongxuan Wang, Jianping Li, Peng Wang, Yuankai Guo, and Sibo Tian. 2025. "Design and Experiment of Dual Flexible Air Duct Spraying Device for Orchards" Agriculture 15, no. 10: 1031. https://doi.org/10.3390/agriculture15101031

APA StyleZhang, Z., Wang, D., Li, J., Wang, P., Guo, Y., & Tian, S. (2025). Design and Experiment of Dual Flexible Air Duct Spraying Device for Orchards. Agriculture, 15(10), 1031. https://doi.org/10.3390/agriculture15101031