Innovative Designs for Cotton Bionic Topping Manipulator

Abstract

1. Introduction

2. Materials and Methods

2.1. Physical Characteristics of Cotton Plants

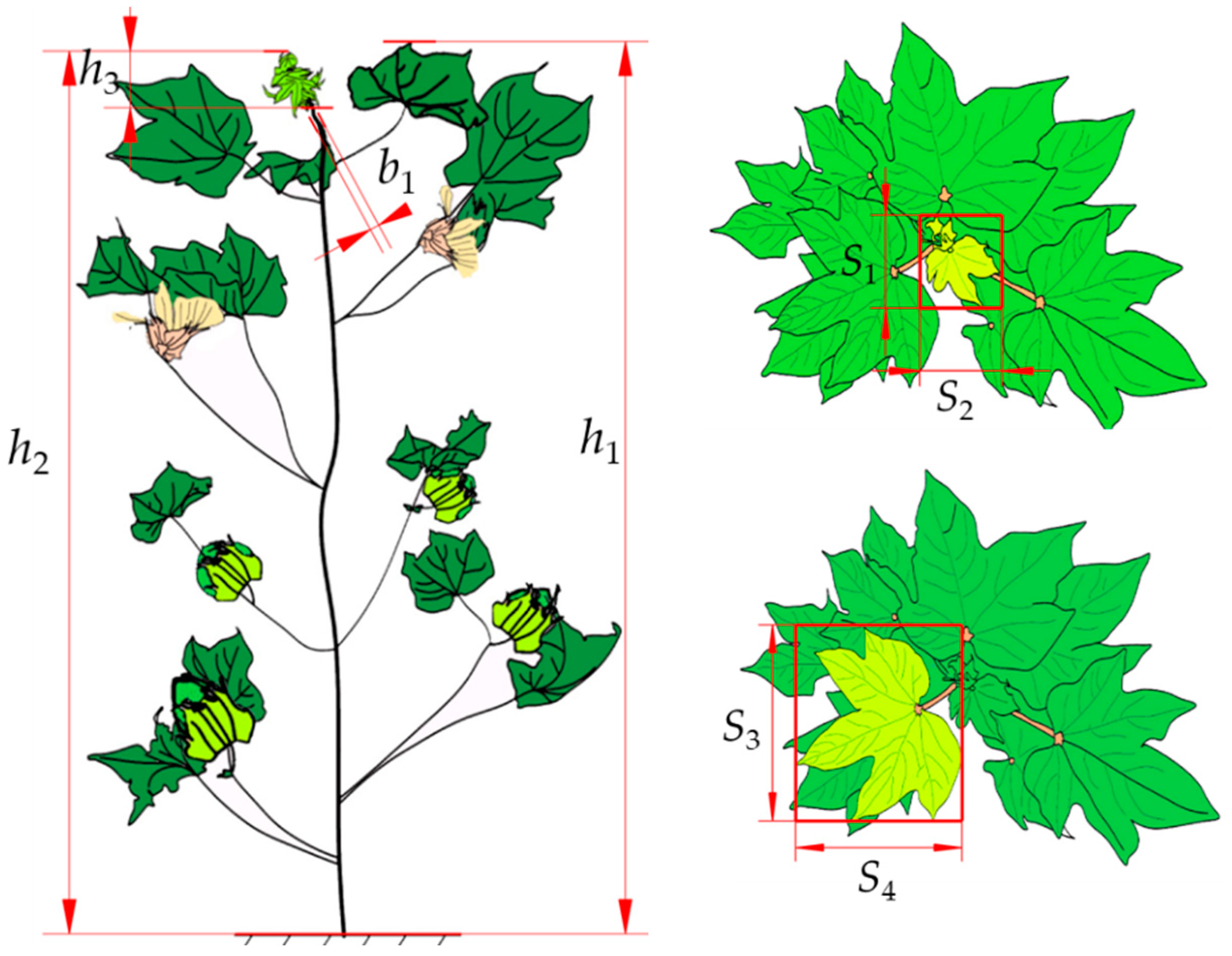

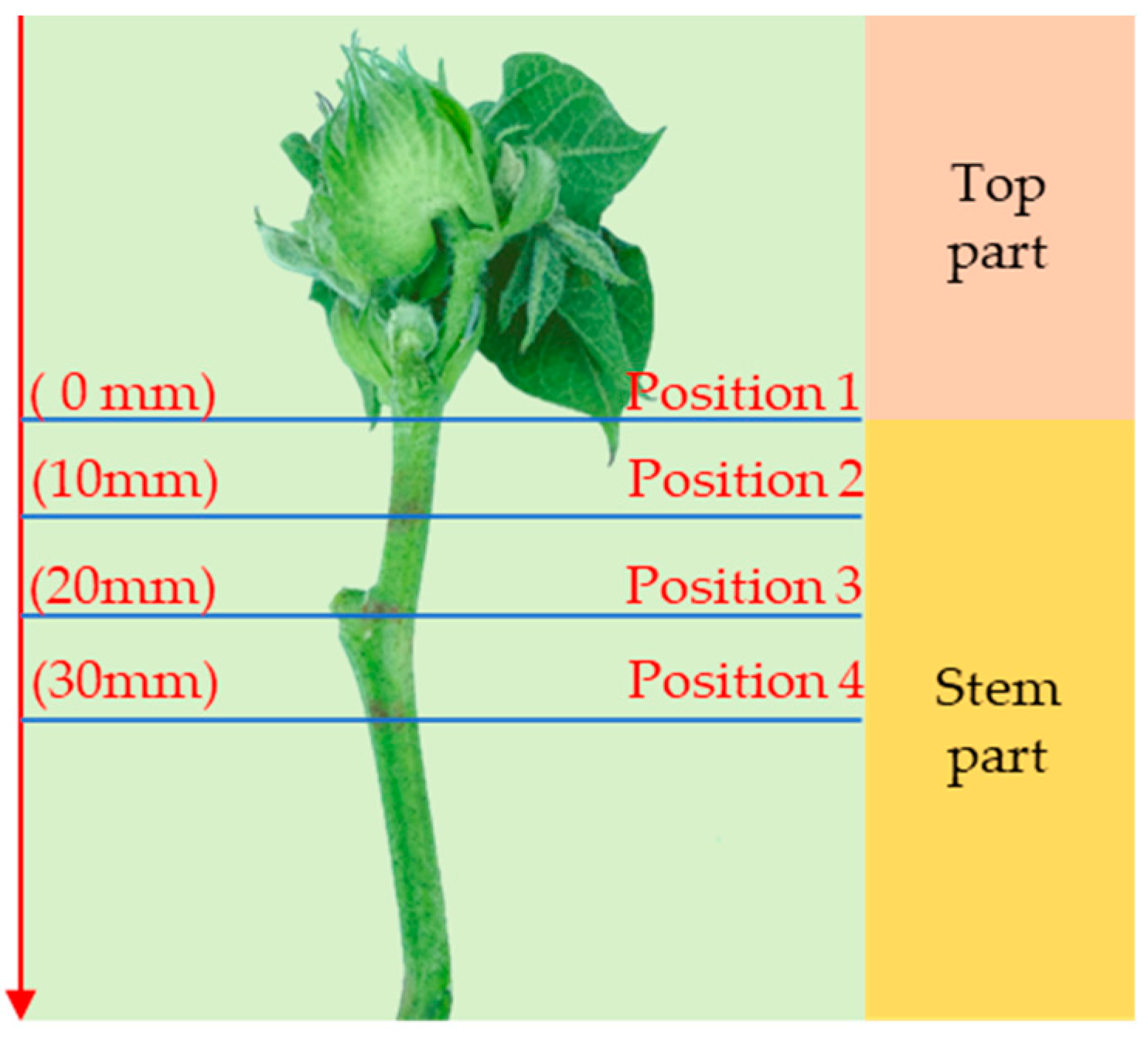

2.1.1. Measurement of Cotton Plant Growth Parameters

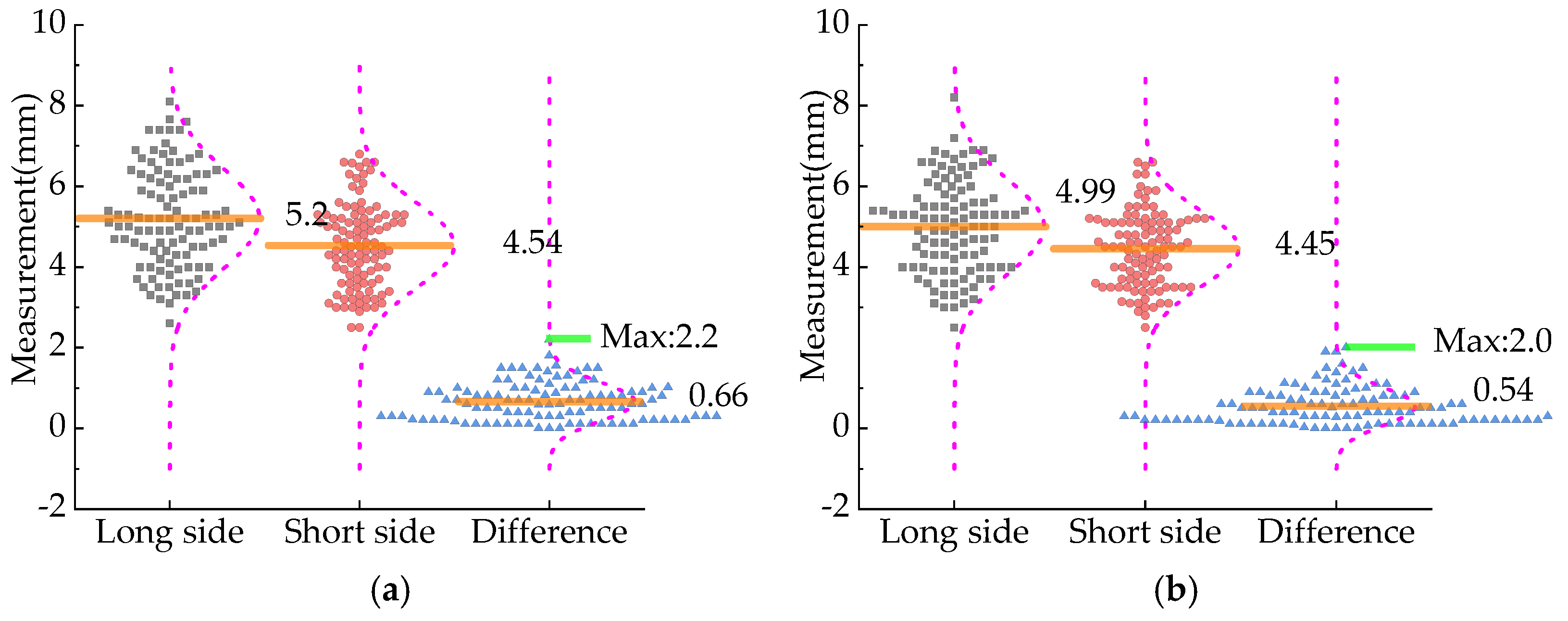

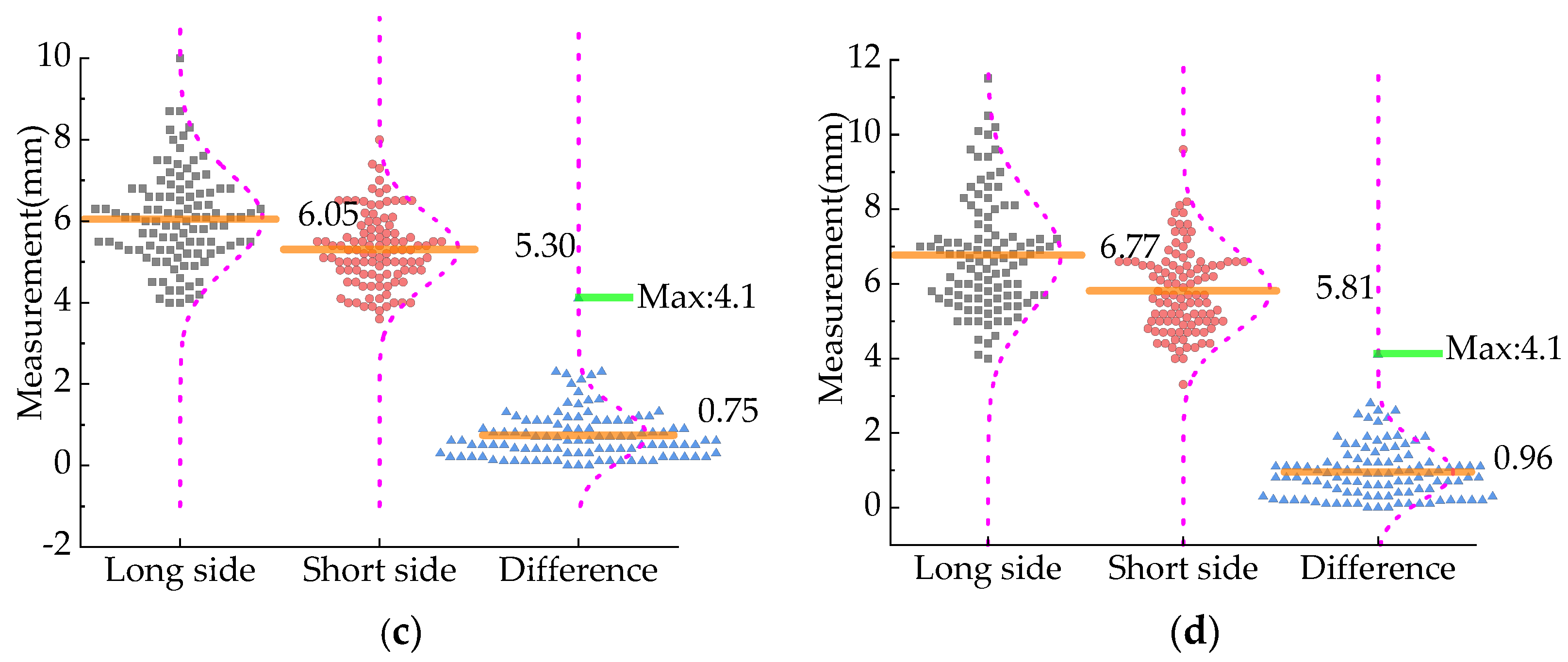

2.1.2. Determination of Mechanical Properties of Cotton Stalk Shearing at the Top of Cotton

2.2. Design of Bionic Topping Manipulator for Cotton

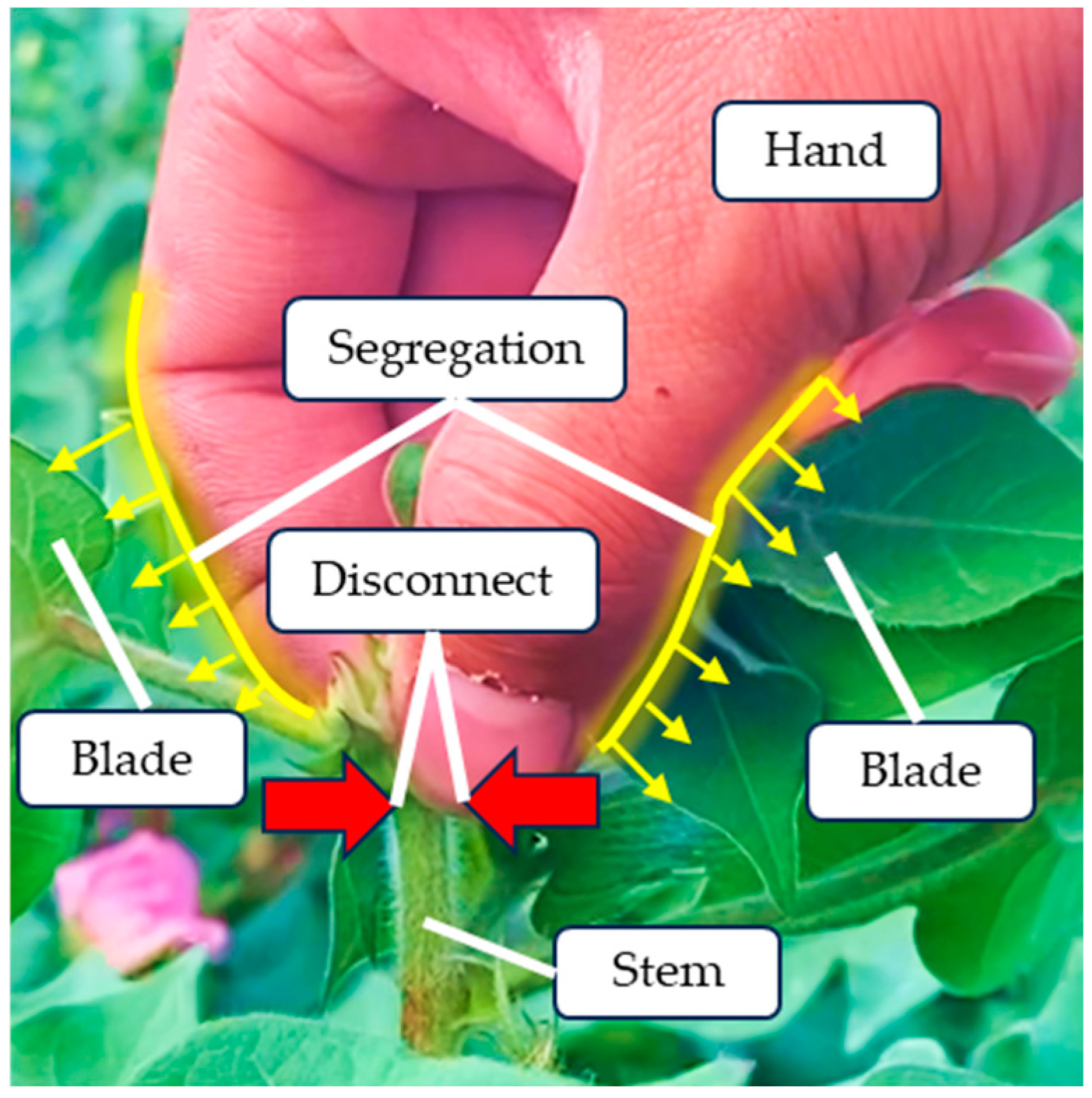

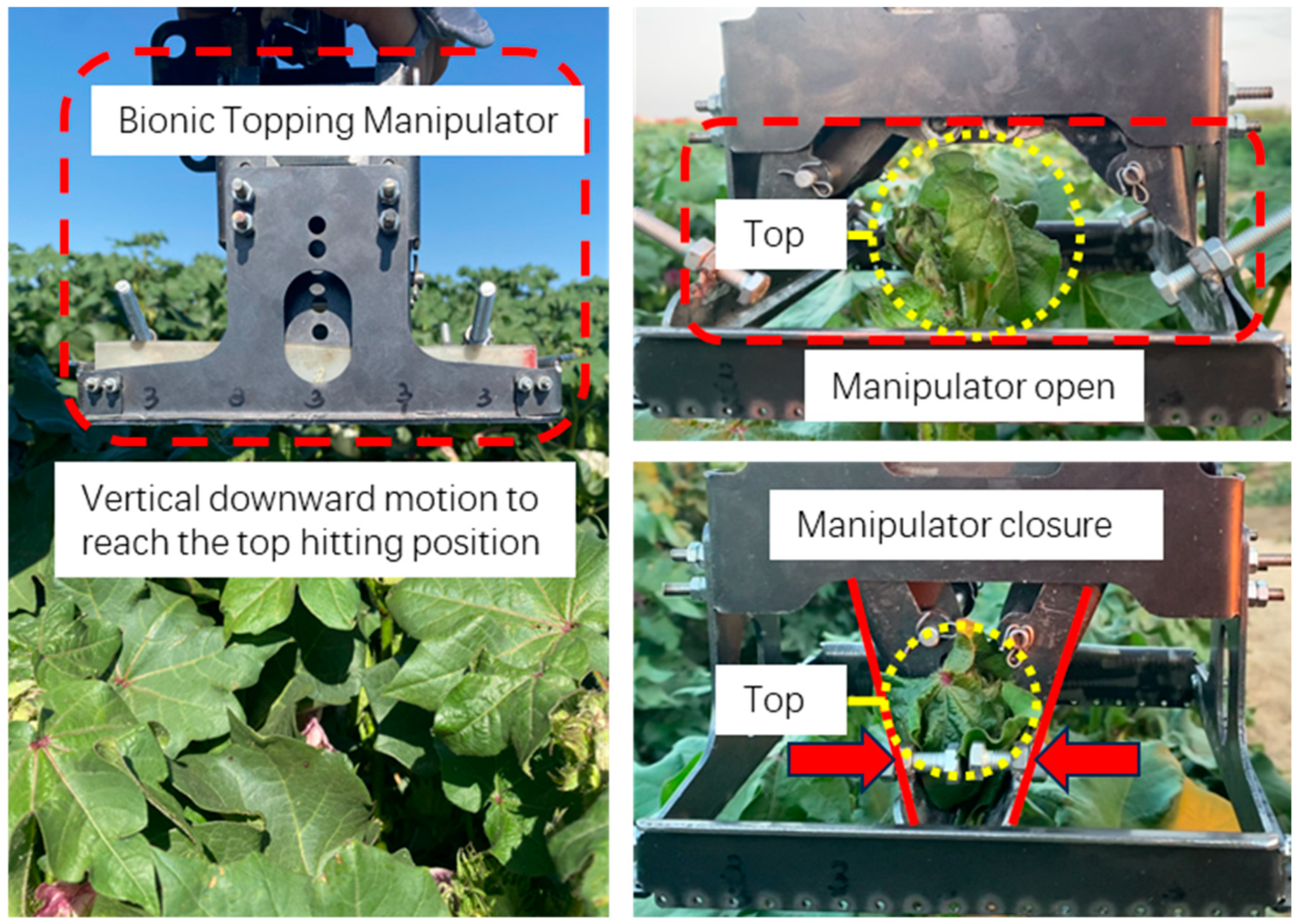

2.2.1. Artificial Topping Method

2.2.2. Working Principle of Bionic Topping Manipulator

2.2.3. Design of Key Components

- (1)

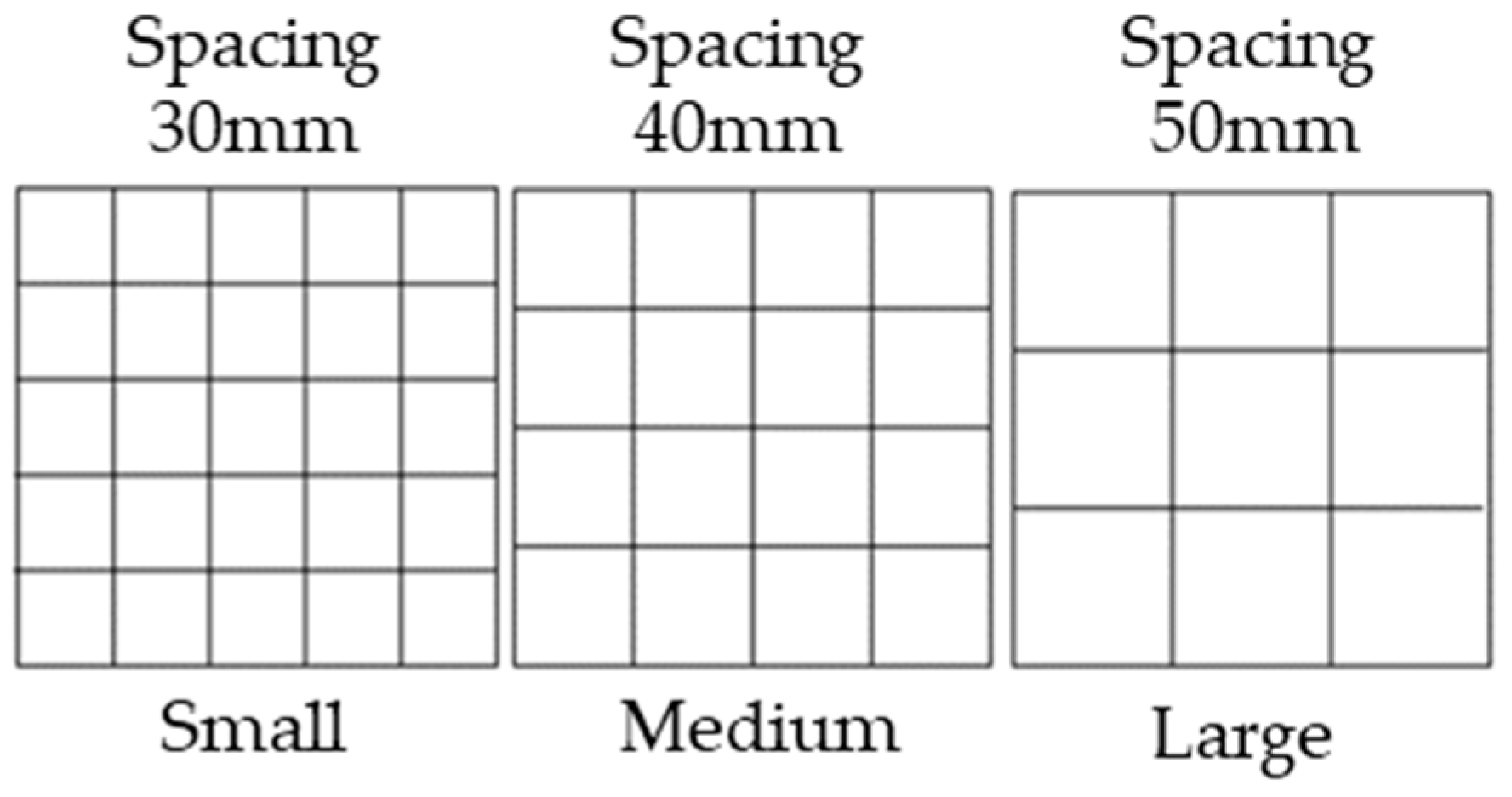

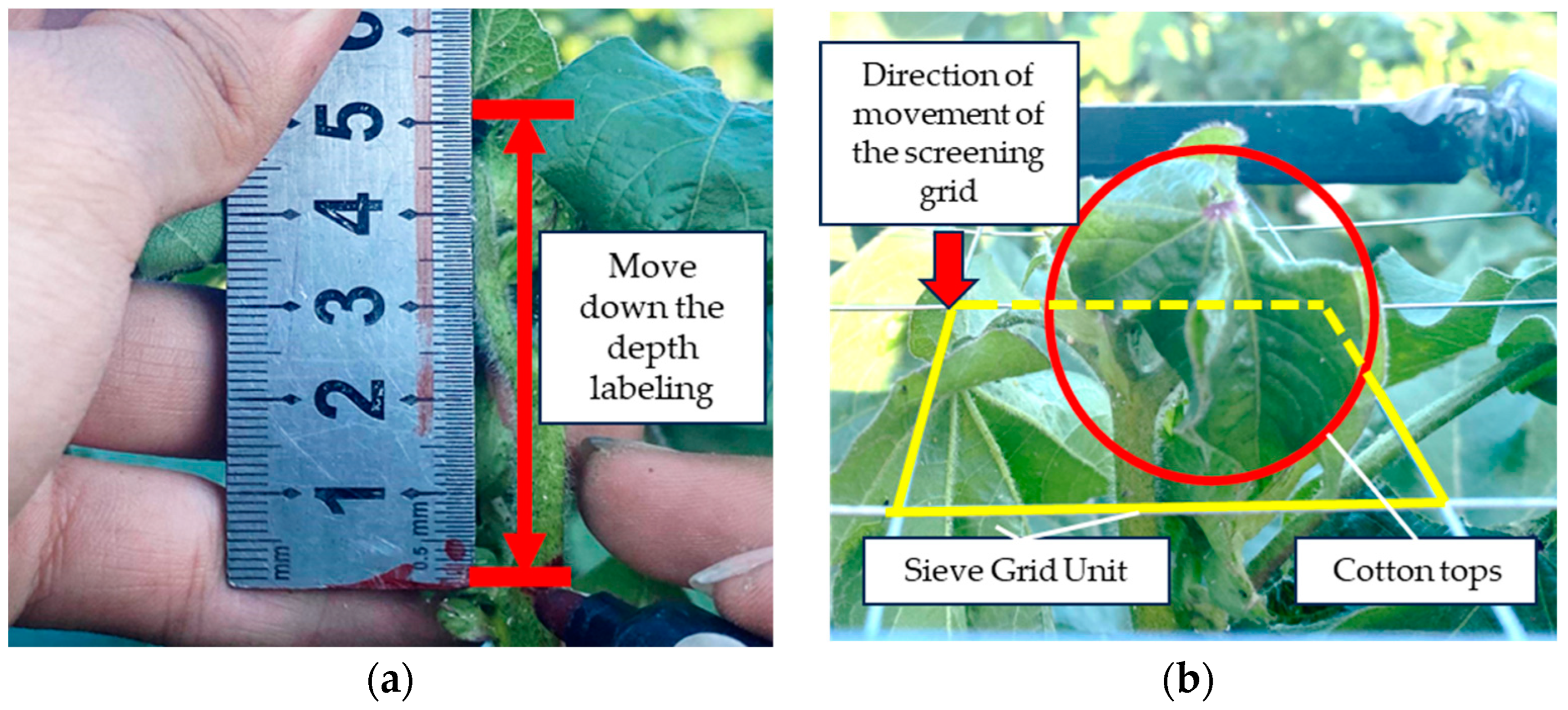

- Design of sieving grid:

- (2)

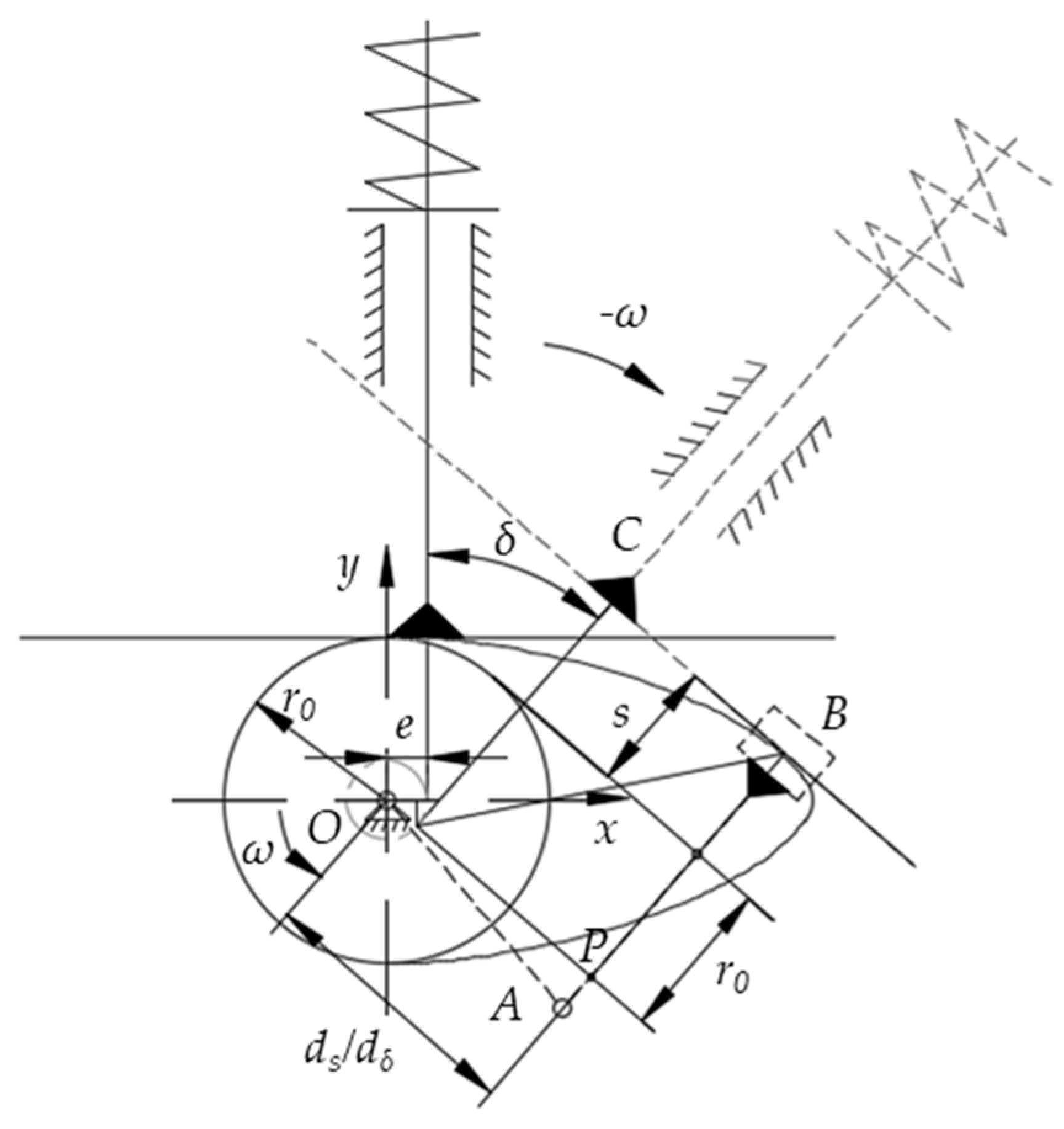

- Design of cam mechanism

- (3)

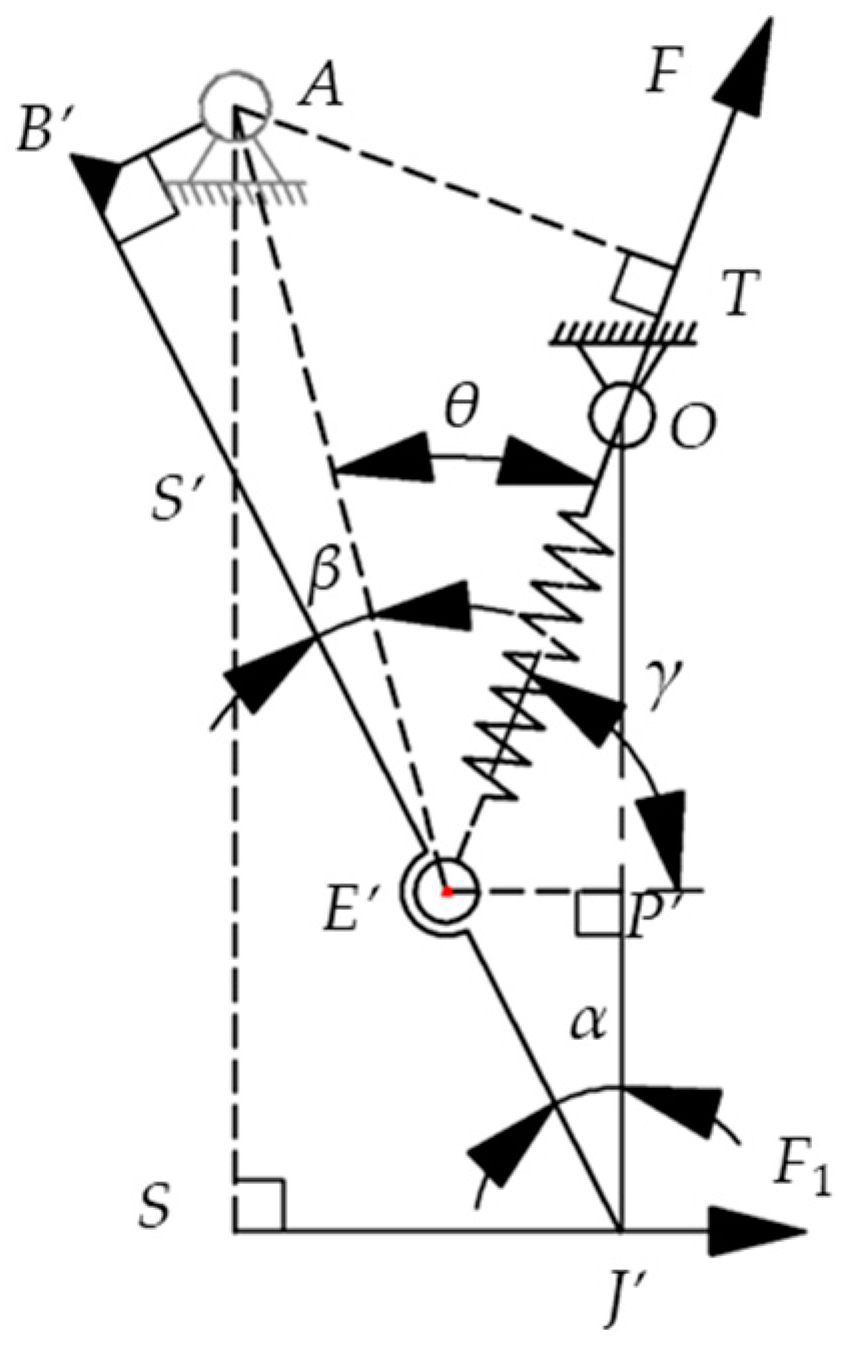

- Design of the tension spring

2.3. Field Trial Design

2.3.1. Screening Performance Test of Different Screening Grid Specifications

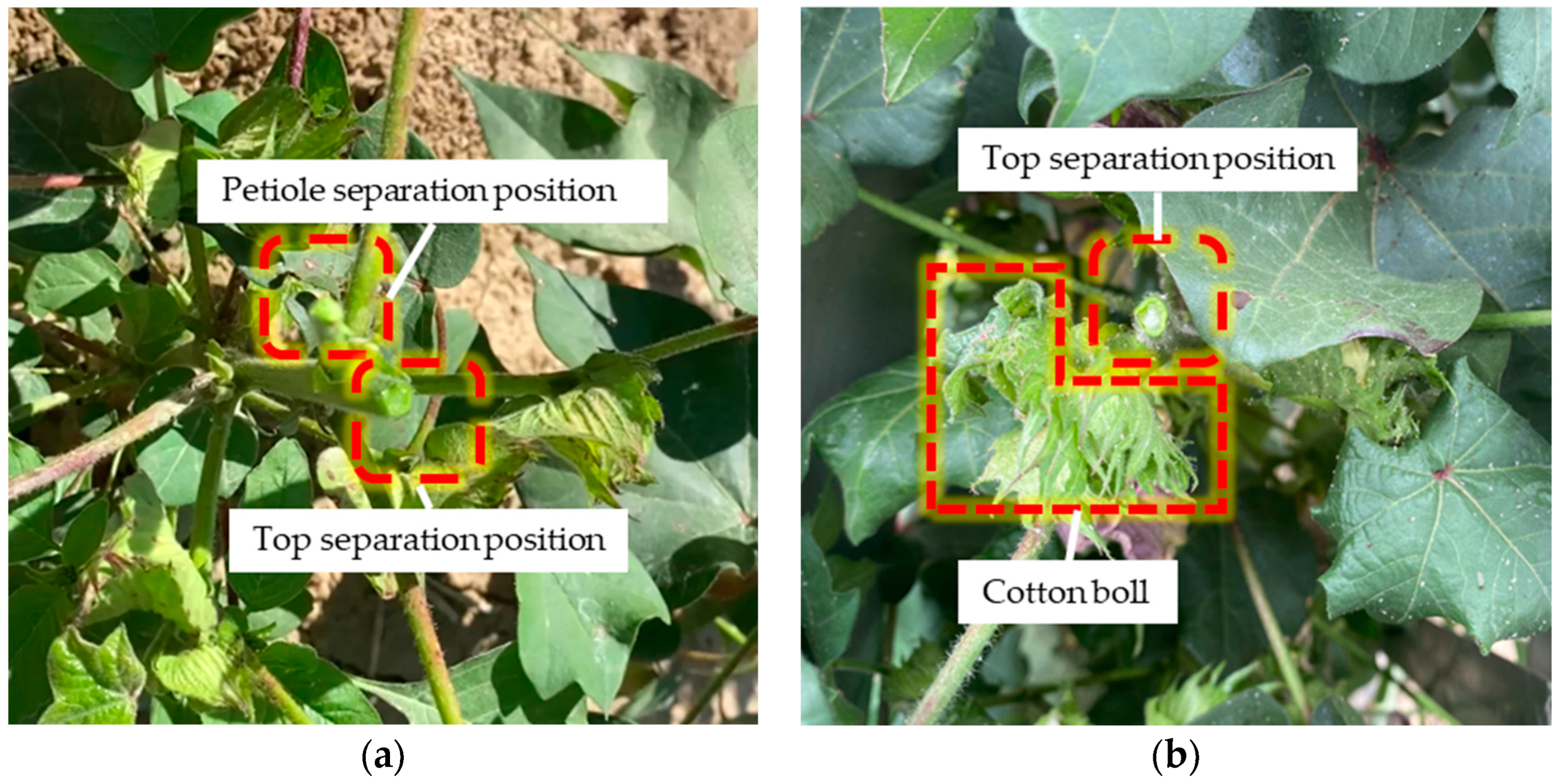

2.3.2. Verification Test of Top-Shearing Performance

2.3.3. Bionic Topping Manipulator Topping Performance Verification Test

3. Results and Discussion

3.1. Test Results and Analysis of Screening Performance of Different Screen Specifications

3.2. Verification Test Results and Analysis of Top Shear Performance

3.3. Bionic Topping Manipulator Topping Performance Verification Test Results and Analysis

4. Conclusions

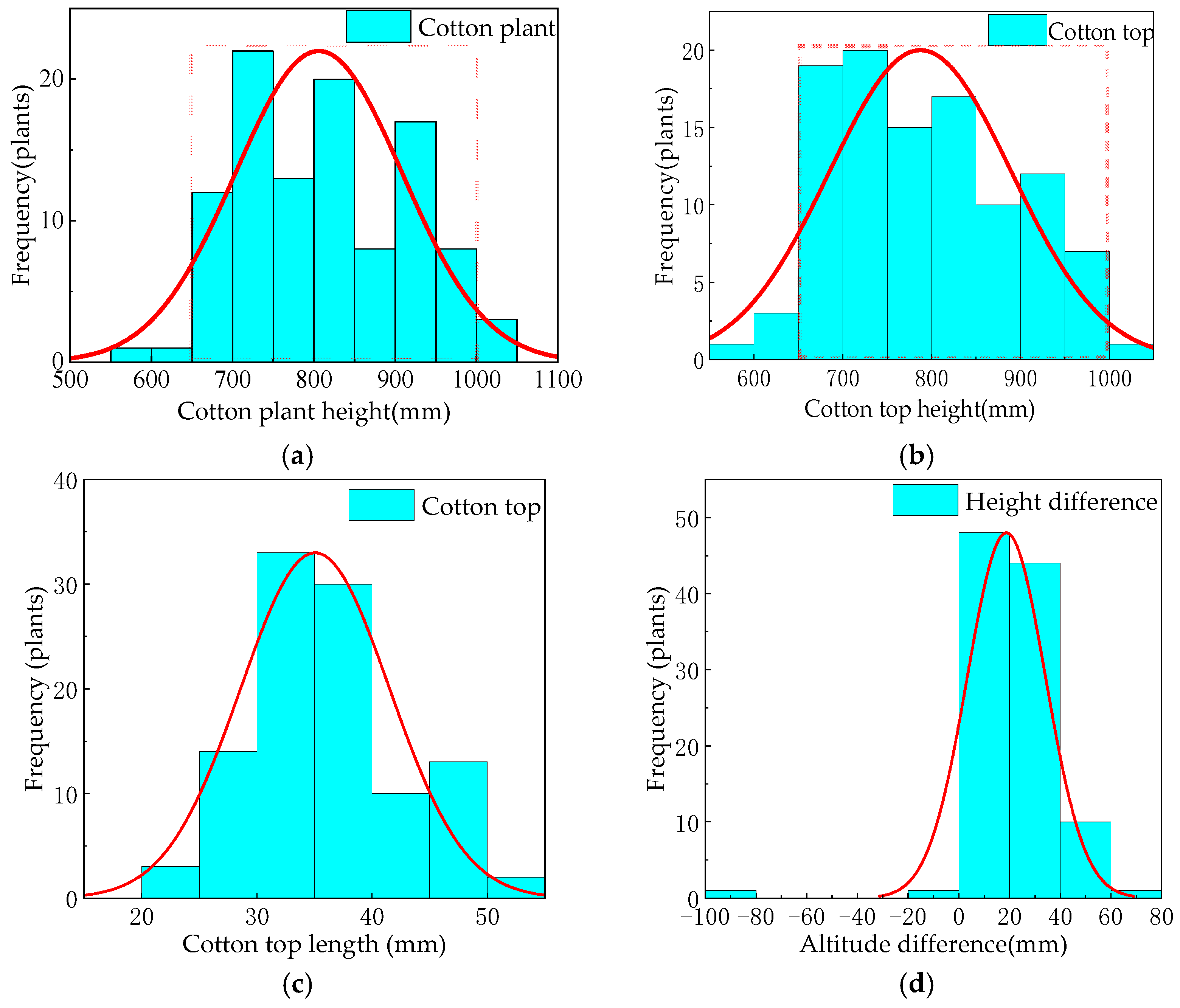

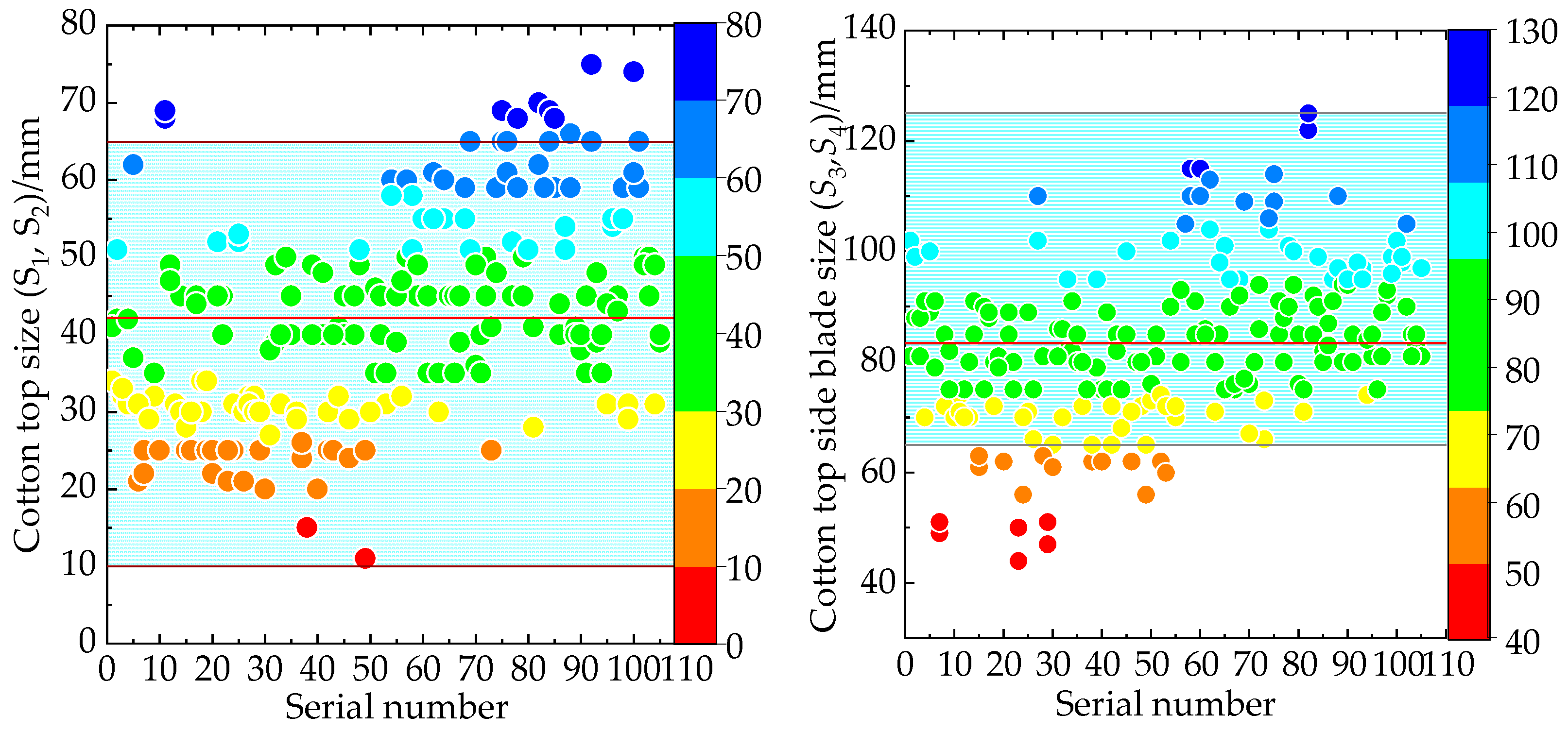

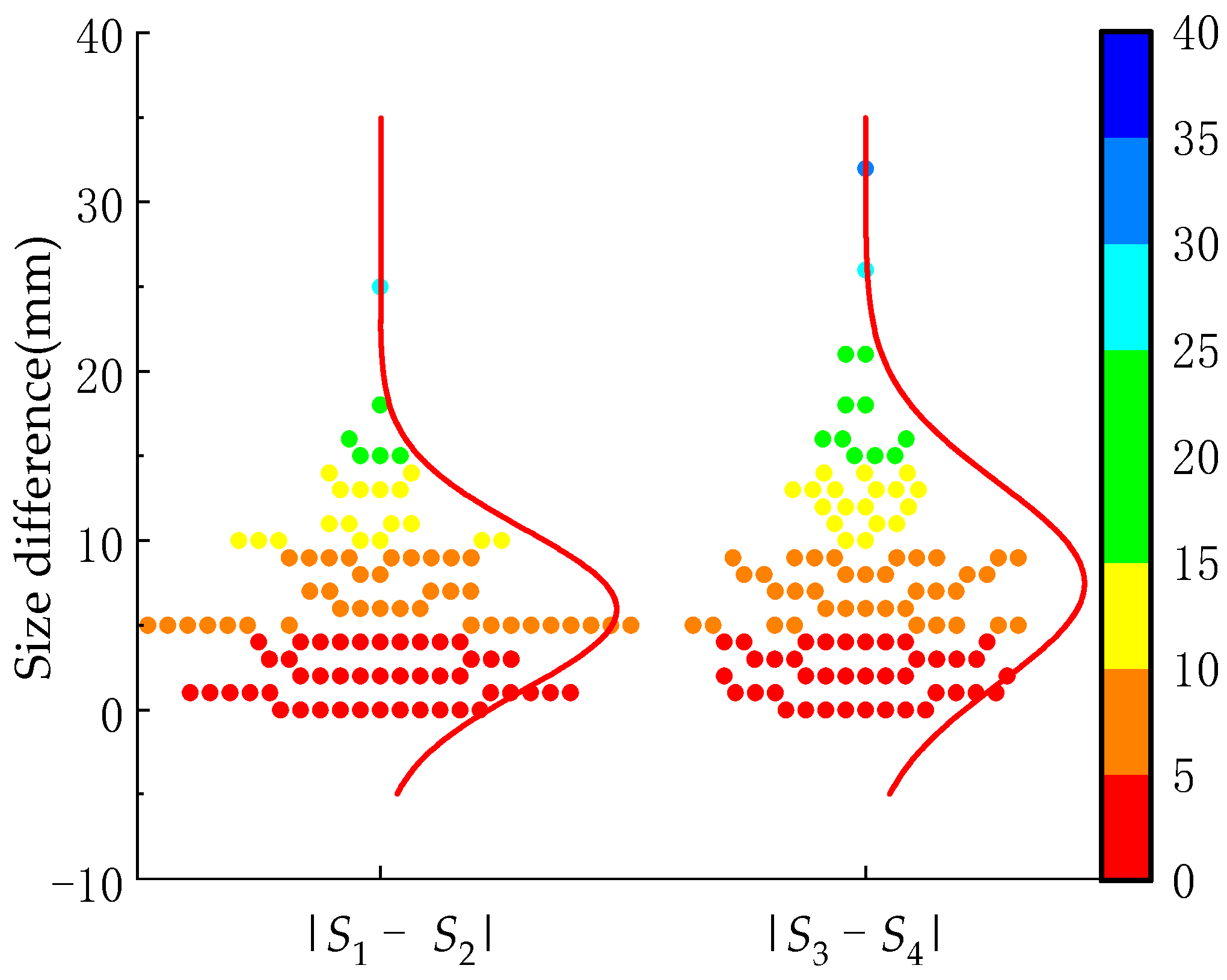

- Studying the physical characteristics of cotton plants, it was evident that the height of cotton plants exceeded the height of the cotton tops in approximately 98.10% of the selected samples. The average height difference between the cotton plant and the top of the cotton was less than 20 mm. Additionally, 98.10% of the cotton plants had a height difference of less than 50 mm from the top of the cotton. This implies that the blades adjacent to the cotton top were positioned closely, making them susceptible to damage during mechanical topping, which can lead to over-topping. Statistically analyzing the size of the outer contour of the cotton top and the adjacent blades, the selected samples showed that the outer contour shape of the top and the surrounding blades was approximately square. The mean size of the cotton tops (S1, and S2) was approximately 42.2 mm, with 95.24% of the sample having tops measuring not greater than 65 mm. The mean size of the parietal blades (S3, and S4) was approximately 83.4 mm, with 90.95% of the sample having blade tops measuring not less than 65 mm. The shear test of the stem top reveals the following measurements in the specimen: (1) an average long side dimension of 3.49 mm, with a maximum of 4.78 mm, and (2) an average shear force of 15.94 N, peaking at 30.56 N. This implies that the farther a cotton plant is from the top, the greater the shearing force on its main stalks. The study of the physical characteristics of the cotton plants reveals several important points. During topping, the height difference between the top of the cotton and the height of the plant is minimal. This means that the leaves and the cotton top are almost at the same height, making it challenging to avoid shaking the top and potentially damaging the leaves when using mechanical topping methods. However, there is a significant size difference between the cotton top and the surrounding leaves. This size disparity creates an opportunity for effectively separating the top of the cotton from the adjacent leaves during topping operations. Additionally, the shear force required decreases as the distance from the top to the stem diminishes. This characteristic facilitates the optimization of shear force settings, allowing for more precise and efficient topping with minimal plant damage.

- Based on the statistical analysis of the physical characteristics of the cotton plants, a bionic topping manipulator was designed using bionics principles. The design process involved analyzing manual topping methods, studying topping actions, and developing key components. To minimize the over-topping rate of the bionic topping manipulator, a screening grid based on the statistical analysis of the biological parameters of cotton tops was designed. Testing with tops and blades showed that a chosen grid spacing of 40 mm provided a comparatively good screening effectiveness. To achieve the automatic opening and closing of the bionic top-beating manipulator, a direct-acting flat-bottomed follower disc cam mechanism was designed using analytical methods. The base circle radius of the cam was determined to be 6 mm, with the flat-bottomed follower measuring 43 mm. From the mechanical tests of stem-shearing at the top and considering the dimensional parameters of the bionic topping manipulator, it was observed that the tension force of the tension spring should exceed 81.5 N. Based on the structural parameters of the top-beating manipulator, the specifications of the tension spring were calculated as follows: (1) the spring material diameter (d) was 1.6 mm, and (2) an effective number of turns (n) was set at 46. The tension spring exhibited a free length of 88.8 mm and a working length of 113.8 mm, yielding a working tension of 85.03 N.

- The verification test for topping performance confirmed the bionic topping manipulator’s effectiveness in separating the top within the specified length range (a topping position not greater than 50 mm). Insufficient shearing force outside the top length range (a topping position more than 50 mm) reduced the damage to the cotton plant, although the shearing rate was lower. The bionic topping manipulator underwent functional verification tests with a screening grid installed, achieving a topping rate of 100% and an over-topping rate of 6.67%. This design effectively reduced the over-topping rate and enhanced the reliability of the topping process. Traditional topping methods, such as manual topping and chemical sealing, cannot be fully replaced in the short term. However, based on the current tests, the bionic topping manipulator developed by our team is only a core component of a bionic topping system. It performs the essential topping action with manual assistance and meets the agronomic requirements. From the perspective of reducing labor intensity and environmental impact, this is a promising start. With ongoing advancements in detection, identification, and automation technologies, the bionic topping manipulator is expected to become a more practical solution.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Bureau of Statistics. China Statistical Yearbook; China Statistical Press: Beijing, China, 2023. [Google Scholar]

- Yang, Y.; Ouyang, Z.; Yang, Y.; Liu, X. Simulation of the effect of pruning and topping on cotton growth using cotton2k model. Field Crops Res. 2008, 106, 126–137. [Google Scholar] [CrossRef]

- Kittock, D.L.; Fry, K.E. Effects of topping pima cotton on lint yield and boll retention. Agron. J. 1977, 69, 65–67. [Google Scholar] [CrossRef]

- Bennett, O.L.; Ashley, D.A.; Doss, B.D.; Scarsbrook, C.E. Influence of topping and side pruning on cotton yield and other characteristics. Agron. J. 1965, 57, 25–27. [Google Scholar] [CrossRef]

- Gu, S.; Evers, J.; Zhang, L.; Mao, L.; Zhang, S.; Zhao, X.; Liu, S.; Van der werf, W.; Li, Z. Modelling the structural response of cotton plants to mepiquat chloride and population density. Ann. Bot. 2014, 114, 877–887. [Google Scholar] [CrossRef] [PubMed]

- Llandres, A.L.; Raki, A.; Thierry, B.; Alain, R.; Idrissa, T.; Janine, J.; Goebel, F. Plant training for induced defense against insect pests: A promising tool for integrated pest management in cotton. Pest Manag. Sci. 2018, 74, 2004–2012. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Du, M.; Xu, D.; Lu, H.; Tian, X.; Li, Z. Interactions of single mepiquat chloride application at different growth stages with climate, cultivar, and plant population for cotton yield. Crop Sci. 2017, 57, 1713–1724. [Google Scholar] [CrossRef]

- Renou, A.; Idrissa, T.; Togola, M. Manual topping decreases bollworm infestations in cotton cultivation in mali. Crop Prot. 2011, 30, 1370–1375. [Google Scholar] [CrossRef]

- Dai, J.; Tian, L.; Zhang, Y.; Zhang, D.; Xu, S.; Cui, Z.; Li, Z.H.; Li, W.J.; Zhan, L.J.; Li, C.D. Plant topping effects on growth, yield, and earliness of field-grown cotton as mediated by plant density and ecological conditions. Field Crops Res. 2022, 275, 108337. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, C.; Zhao, J.; Zhang, R.; Zhao, X.; Li, F. Design and test of automatic row alignment device for cotton topping machine. J. Agric. Mach. 2021, 52, 93–101. [Google Scholar]

- Han, C.; Yan, C.; Qiu, S.; Xu, Y.; Hu, B.; Mao, H. Design and experiment of double disc cotton topping device based on machine vision. Trans. Chin. Soc. Agric. Mach. 2023, 54, 36–46. [Google Scholar]

- Xie, Q.; Kong, F.; Shi, L.; Chen, C.; Wu, T.; Sun, Y. Progress of key technologies for mechanical topping of cotton. Chin. J. Agric. Mech. Chem. 2023, 44, 28–34. [Google Scholar] [CrossRef]

- Griffith, T.K. Cotton Topper. U.S. Patent 0852715, 7 May 1907. [Google Scholar]

- Schwarz, O. Cotton Topper. U.S. Patent 0897935, 8 September 1908. [Google Scholar]

- Lowrey, L.A. Cotton Topper. U.S. Patent 1002412, 5 September 1911. [Google Scholar]

- Bell, J.W. Cotton Topper. U.S. Patent 2578963, 18 December 1951. [Google Scholar]

- Hu, B.; Wang, W.X.; Li, S.L.; Li, M.Z. Experimental study on 3MD-12 cotton topping machine. China Agric. Mech. 2004, 41–42. [Google Scholar]

- Peng, Q.; Kang, J.; Song, Y.; He, Q. Design of 3MDZ-4 self-propelled cotton topdressing and spraying combined operation machine. J. Agric. Eng. 2019, 35, 30–38. [Google Scholar]

- Deng, X.L.; Luo, Z.W.; Pang, J.Q.; Zhang, Y.M.; Yang, C.J.; Li, R.Q. Design and experiment of bionic nondestructive handheld suction apple picker. J. China Agric. Univ. 2019, 24, 106–114. [Google Scholar]

- Hayashi, S.; Shigematsu, K.; Yamamoto, S.; Kobayashi, K.; Kohno, Y.; Kamata, J.; Kurita, M. Evaluation of a strawberry-harvesting robot in a field test. Biosyst. Eng. 2010, 105, 160–171. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, F.; Zhang, J.; Guo, H.; Gao, J. Picking patterns evaluation for cherry tomato robotic harvesting end-effector design. Biosyst. Eng. 2024, 239, 1–12. [Google Scholar] [CrossRef]

- Li, M.; Liu, P. A bionic adaptive end-effector with rope-driven fingers for pear fruit harvesting. Comput. Electron. Agric. 2023, 211, 107952. [Google Scholar] [CrossRef]

- Pi, J.; Liu, J.; Zhou, K.; Qian, M. An octopus-inspired bionic flexible gripper for apple grasping. Agriculture 2021, 11, 1014. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Zhuang, J.; Liu, H.; Wang, Y.; Yu, Y. Coupled bionic design based on primnoa mouthpart to improve the performance of a straw returning machine. Agriculture 2021, 11, 775. [Google Scholar] [CrossRef]

- Aydın, İ.; Arslan, S. Mechanical properties of cotton shoots for topping. Ind. Crops Prod. 2018, 112, 396–401. [Google Scholar] [CrossRef]

- Hao, H.; Wu, S.; Li, Y.K.; Wen, W.; Fan, J.; Zhang, Y.; Zhuang, L.; Xu, L.; Li, H.; Guo, X.; et al. Automatic acquisition, analysis and wilting measurement of cotton 3d phenotype based on point cloud. Biosyst. Eng. 2024, 239, 173–189. [Google Scholar] [CrossRef]

- Esgici, R. The effect of knife type on cutting characteristics of cotton stalk. Fresenius Environ. Bull. 2020, 29, 2772–2777. [Google Scholar]

- Zhao, Y.; Tang, Z.; Chen, S. Loading model and mechanical properties of mature broccoli (Brassica oleracea L. var. italica plenck) stems at harvest. Agriculture 2022, 12, 1519. [Google Scholar] [CrossRef]

- Van Henten, E.J.; Van’t Slot, D.A.; Hol, C.W.J.; Van Willigenburg, L.G. Optimal manipulator design for a cucumber harvesting robot. Comput. Electron. Agric. 2009, 65, 247–257. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, X.; Zhang, H.; Shen, C.; Fu, W. Design and performance test of a jujube pruning manipulator. Agriculture 2022, 12, 552. [Google Scholar] [CrossRef]

- Islam, M.N.; Iqbal, M.Z.; Ali, M.; Chowdhury, M.; Kabir, M.S.N.; Park, T.; Kim, Y.J.; Chung, S.O. Kinematic analysis of a clamp-type picking device for an automatic pepper transplanter. Agriculture 2020, 10, 627. [Google Scholar] [CrossRef]

- Luo, B. Basic dimensioning of direct-acting flat-bottomed follower disk cam mechanisms. Appl. Sci. Technol. 2002, 29, 54. [Google Scholar]

- Liu, C.; Liu, Q.; Cai, C. Practical Design Manual of Automatic Mechanical Cam Mechanism; Science Press: Beijing, China, 2013; pp. 91–115. [Google Scholar]

- Cheng, D. Mechanical Design Manual (Single-Volume): Springs, 6th ed.; Chemical Industry Press: Beijing, China, 2017; pp. 15–42. [Google Scholar]

| Experiment Number | Screening Grid Specifications | Downward Depth/mm | Number of Trials/Plant | Number of Tops Passing through the Screening Grid/Plant | Number of Blades Passing through the Screening Grid/Plant | Top Passing Rate/% | Top Side Blade Passing Rate/% |

|---|---|---|---|---|---|---|---|

| 1 | Small | 50 mm | 30 | 19 | 2 | 63.33 | 6.67 |

| 2 | Medium | 50 mm | 30 | 29 | 4 | 96.67 | 13.33 |

| 3 | Large | 50 mm | 30 | 30 | 25 | 100 | 83.33 |

| Experiment Number | Topping Position (h)/mm | Number of Trials /Plant | Number of Cotton Tops Removed/Plant | Shear Rate/% |

|---|---|---|---|---|

| 1 | 40 | 30 | 30 | 100% |

| 2 | 50 | 30 | 30 | 100% |

| 3 | 60 | 30 | 17 | 56.67% |

| Experiment Number | Whether or Not a Screening Grid Is Installed | Number of Trials /Plant | Number of Blades Passing through the Screening Grid/Plant | Number of Blades Damaged/Plant | Topping Rate/% | Over-Topping Rate/% |

|---|---|---|---|---|---|---|

| 1 | Not | 30 | / | 21 | 100 | 70.00 |

| 2 | Yes | 30 | 6 | 2 | 100 | 6.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Han, C.; Zhang, J.; Hu, B.; Ma, X.; Mao, H. Innovative Designs for Cotton Bionic Topping Manipulator. Agriculture 2024, 14, 1469. https://doi.org/10.3390/agriculture14091469

Xu Y, Han C, Zhang J, Hu B, Ma X, Mao H. Innovative Designs for Cotton Bionic Topping Manipulator. Agriculture. 2024; 14(9):1469. https://doi.org/10.3390/agriculture14091469

Chicago/Turabian StyleXu, Yang, Changjie Han, Jing Zhang, Bin Hu, Xu Ma, and Hanping Mao. 2024. "Innovative Designs for Cotton Bionic Topping Manipulator" Agriculture 14, no. 9: 1469. https://doi.org/10.3390/agriculture14091469

APA StyleXu, Y., Han, C., Zhang, J., Hu, B., Ma, X., & Mao, H. (2024). Innovative Designs for Cotton Bionic Topping Manipulator. Agriculture, 14(9), 1469. https://doi.org/10.3390/agriculture14091469