Propagation Laws of Ultrasonic Continuous Signals at the Transmitting Transducer–Soil Interface

Abstract

1. Introduction

2. Materials and Methods

2.1. The Ultrasound–Soil Interaction Model

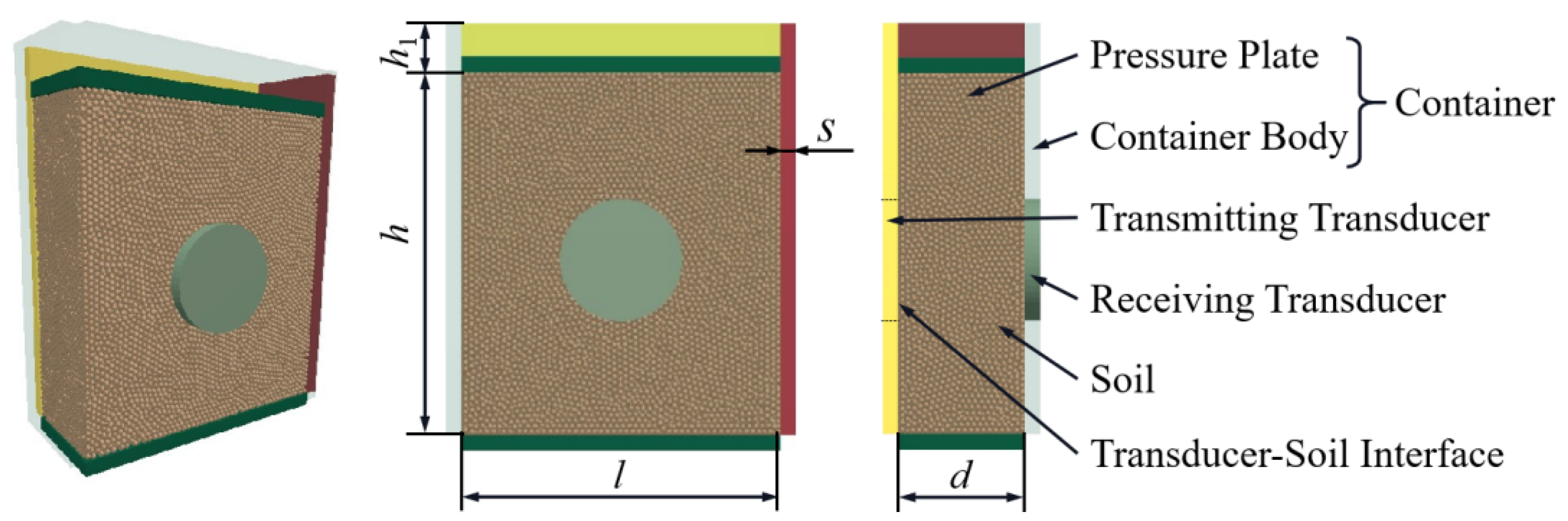

2.1.1. The Geometric Model

2.1.2. The Soil Particle Model and Parameters

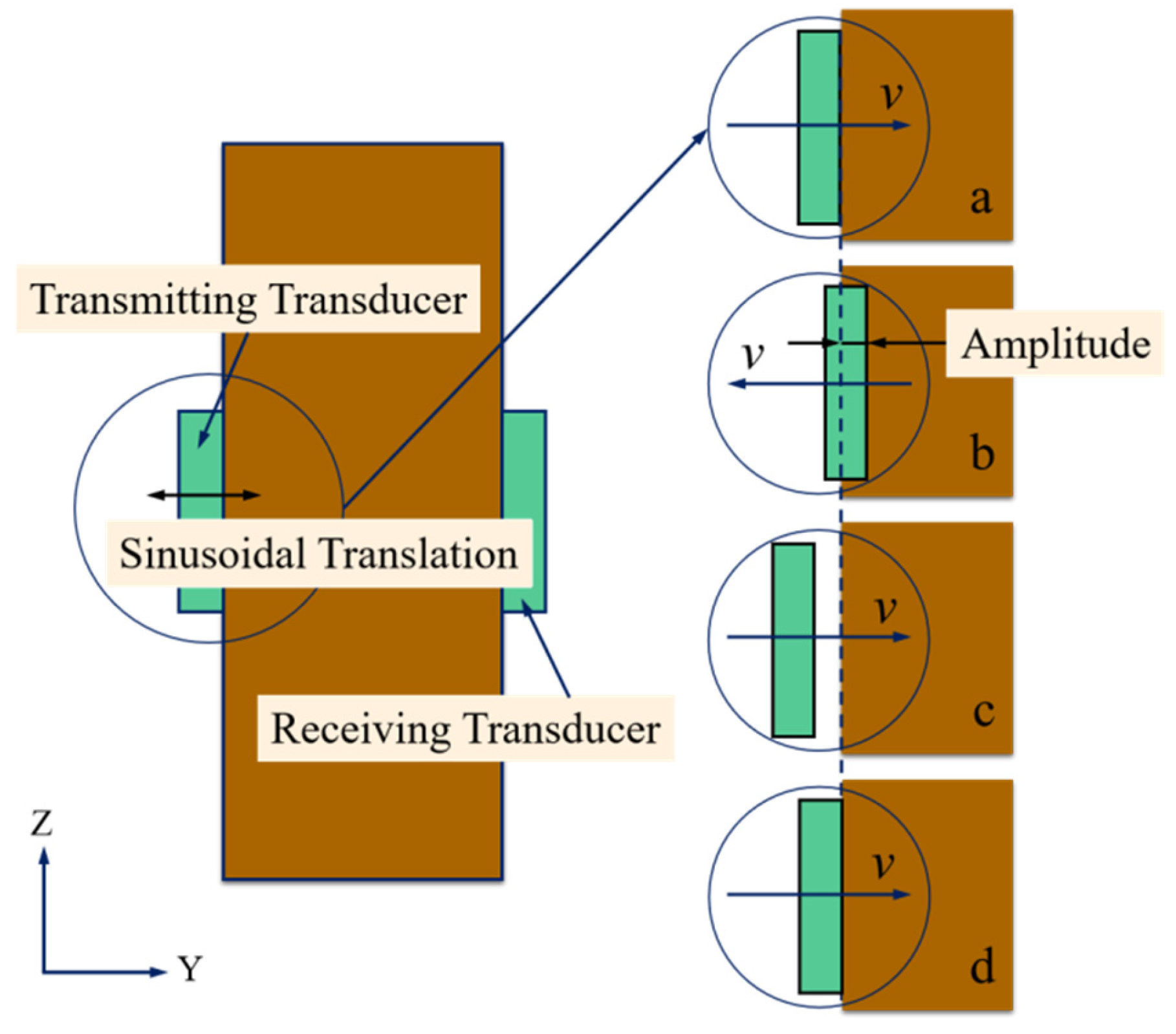

2.1.3. Generation of Ultrasonic Continuous Signals

2.2. Characterization of Ultrasonic Signals

2.2.1. Characterization Method before Entering Interface

2.2.2. Characterization after Passing through the Interface

2.3. Experiment Factors and Levels

2.4. Data Acquisition

2.4.1. The Peak Value of the First Wave |H0|

2.4.2. The Peak Value of Other Waves |H|

2.4.3. The Trough Value |L|

2.4.4. The Difference J between |H| and |L|

3. Results and Analysis

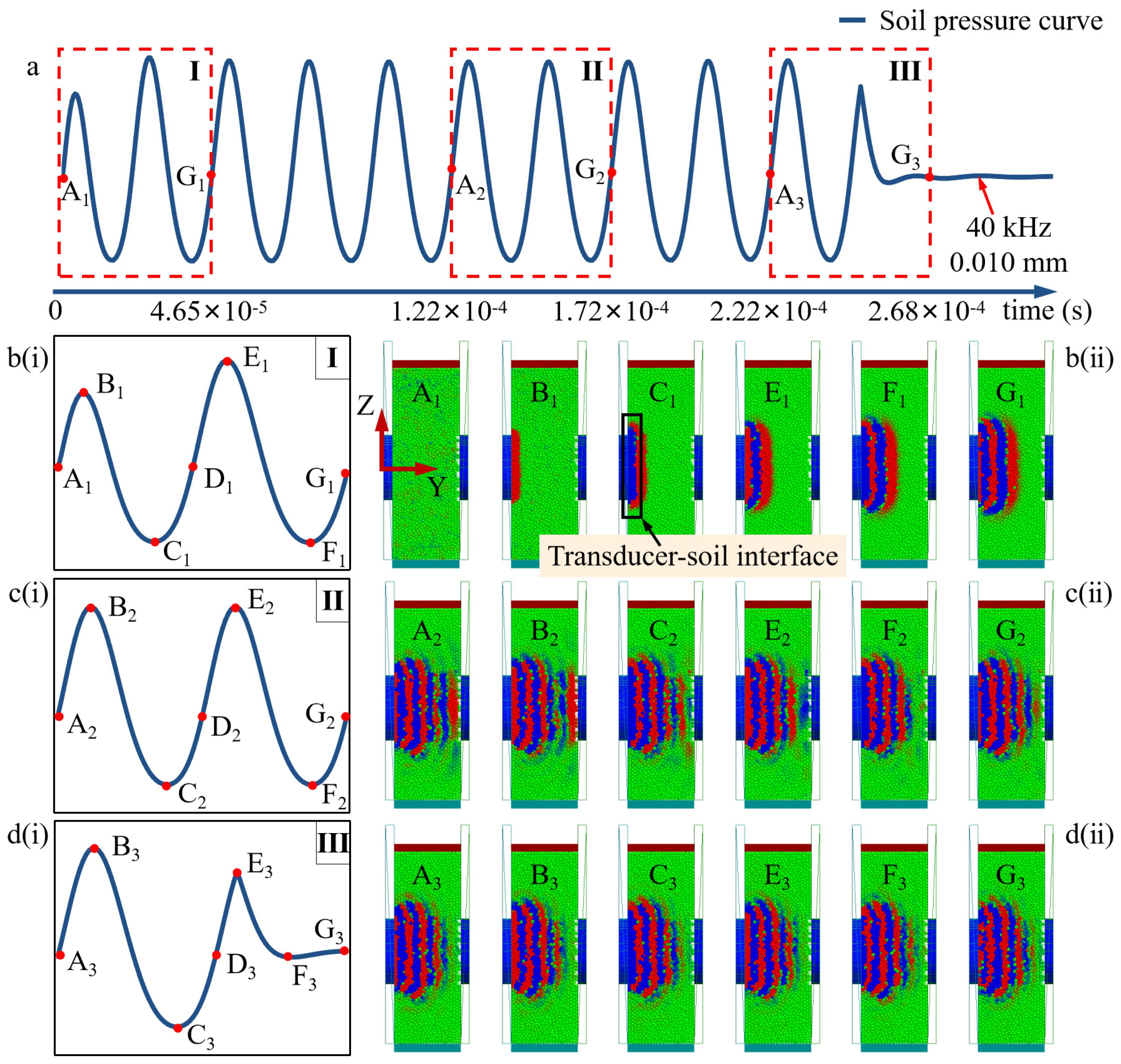

3.1. Analysis of Continuous Ultrasonic Signal Transmitting Process

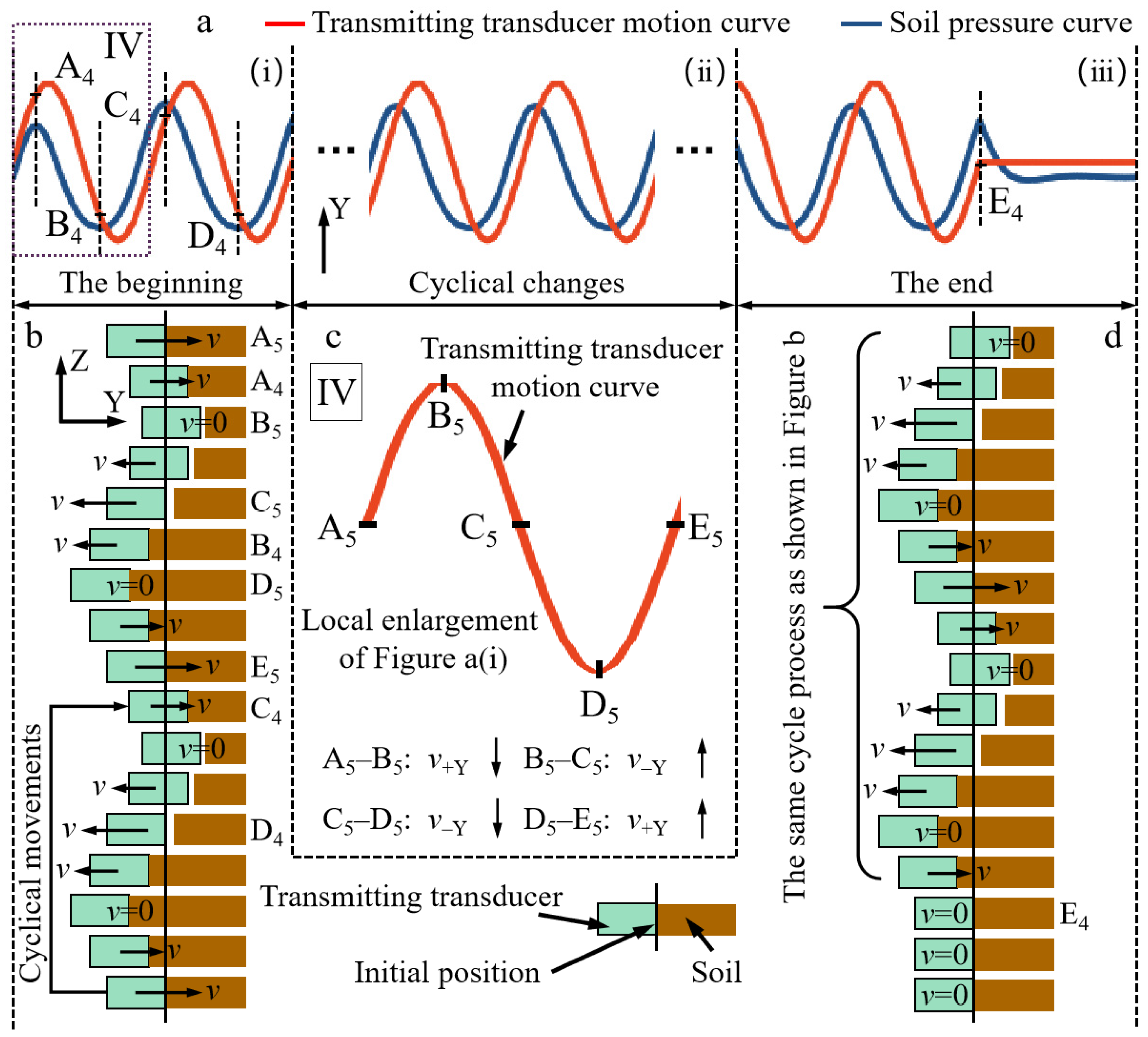

3.1.1. The Initial Stage of Signal Transmission

3.1.2. The Stage of Signal Transmission Process

3.1.3. The End Stage of Signal Transmission

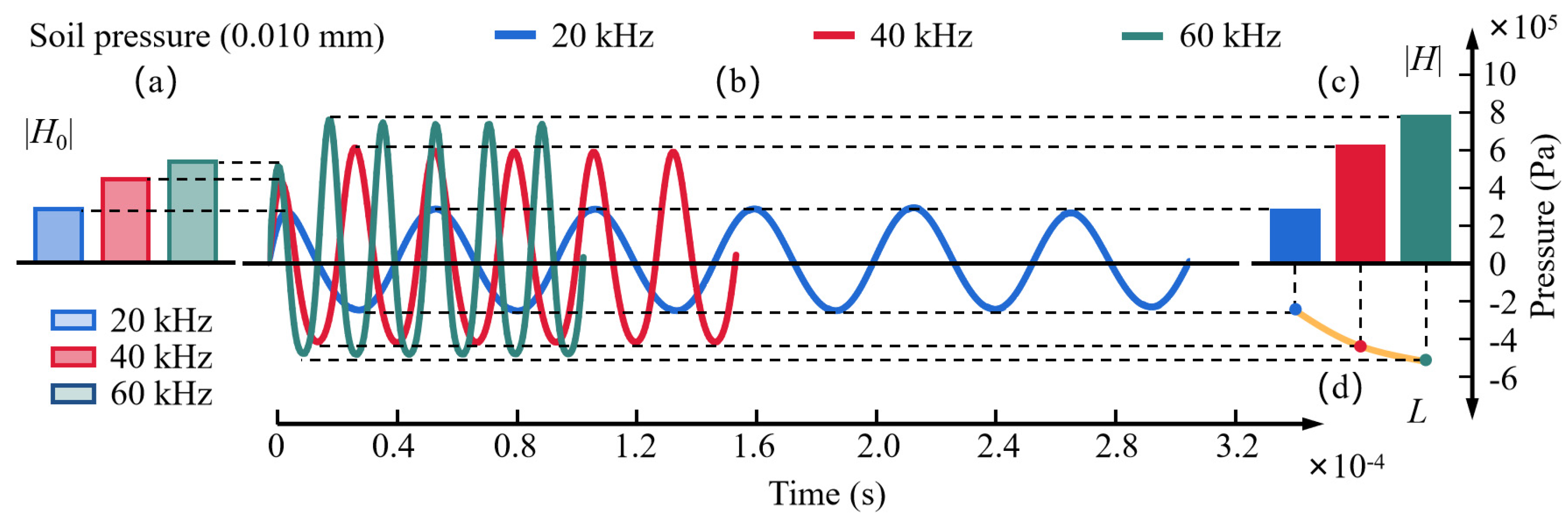

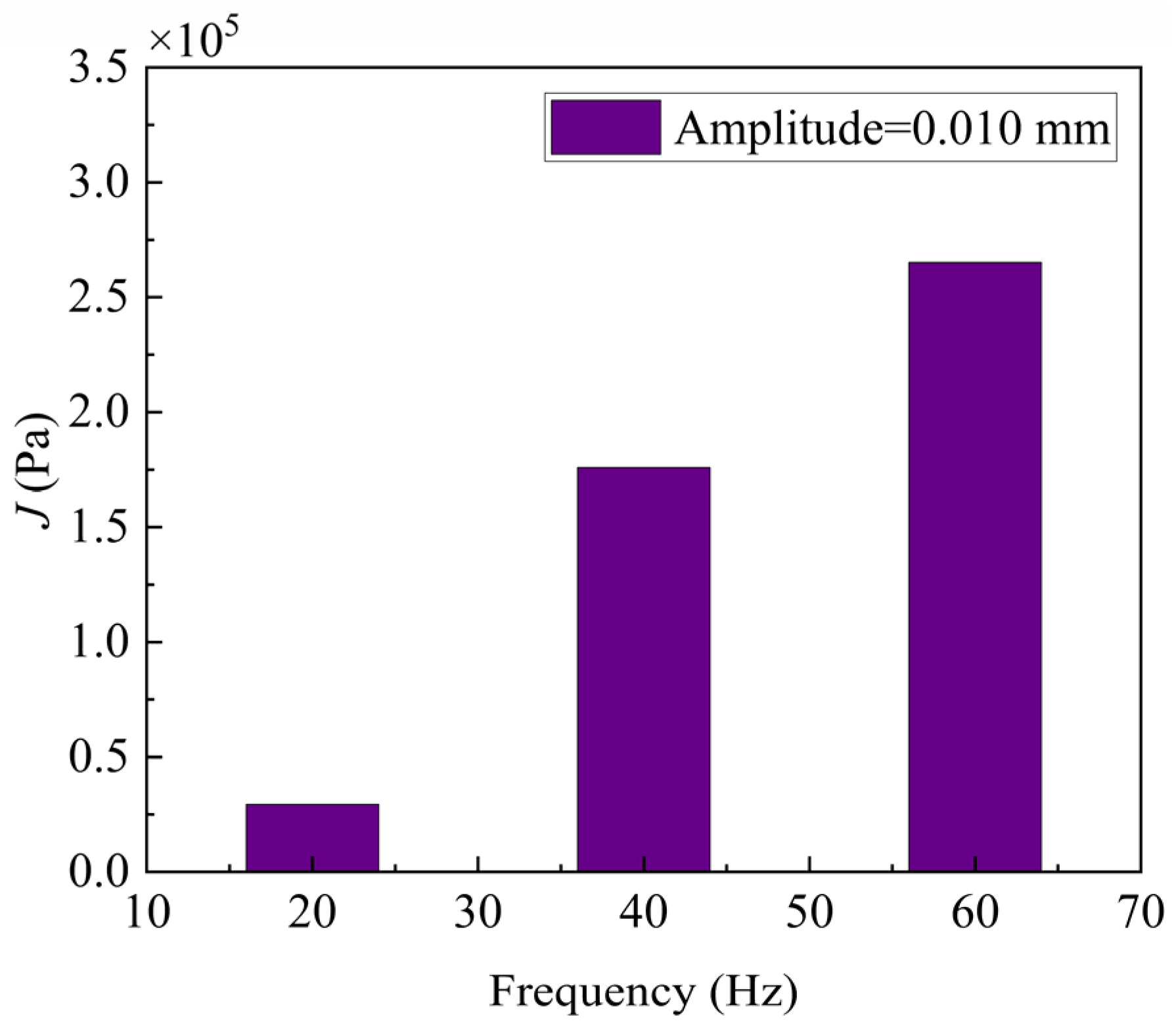

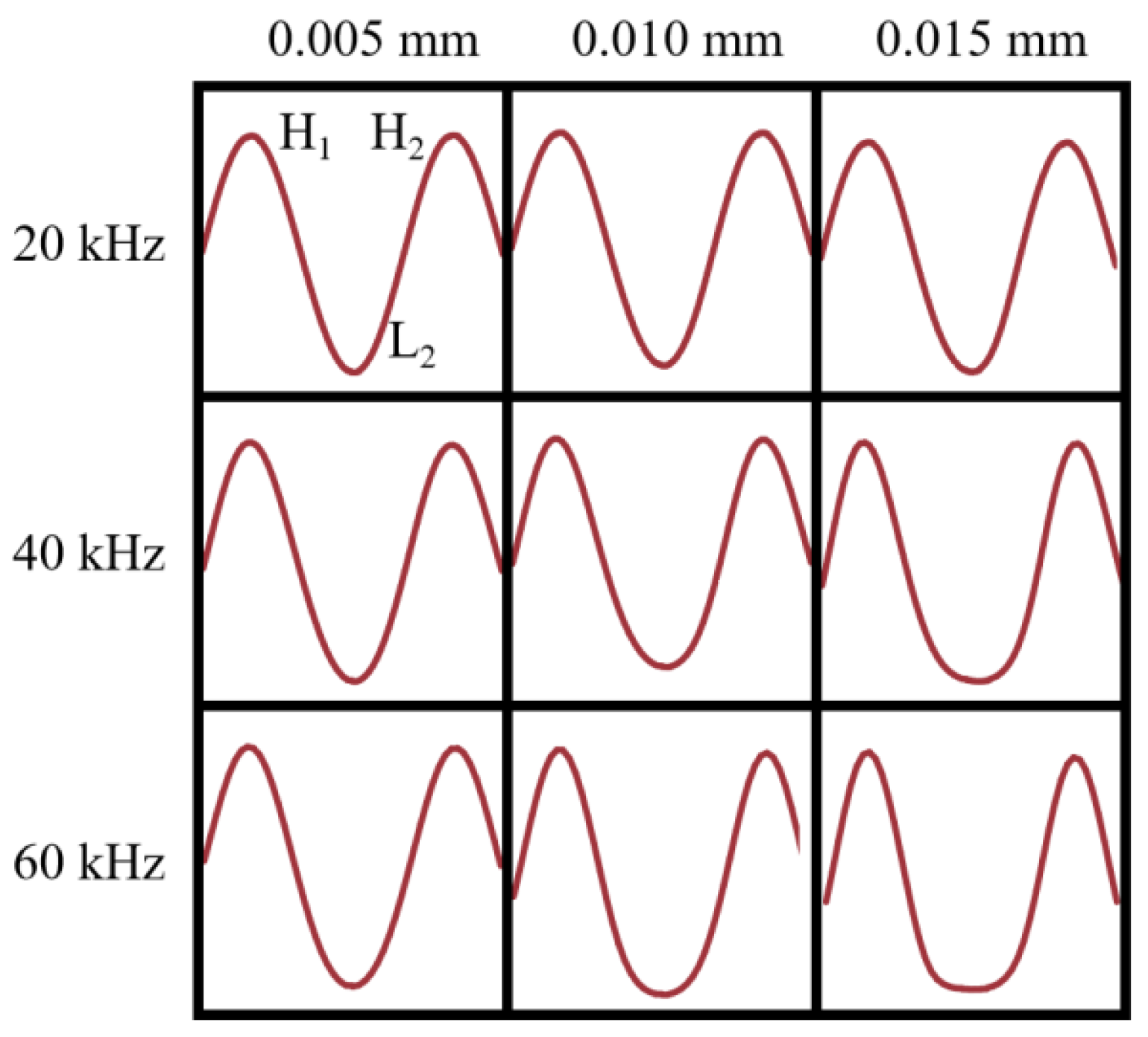

3.2. The Effect of the Excitation Frequency on the Waveform

3.2.1. The Peak Value of the First Wave |H0| and the Peak Value of Other Waves |H|

3.2.2. The Trough Value |L|

3.2.3. The Difference J between |H| and |L|

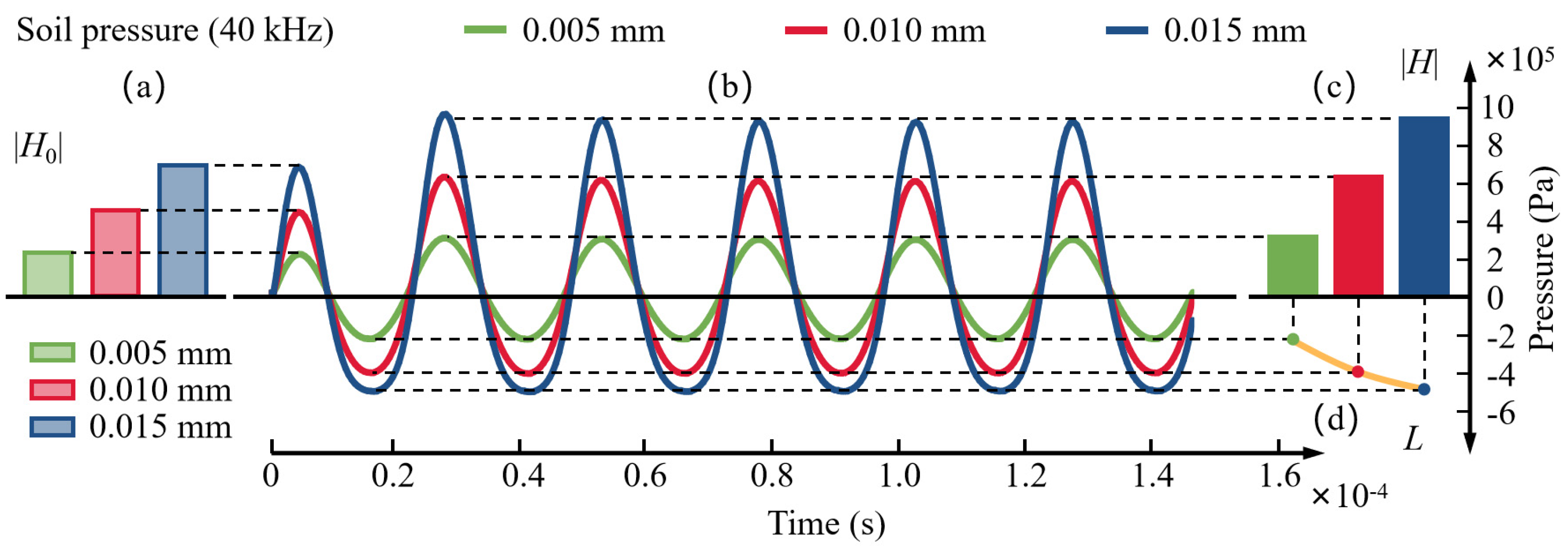

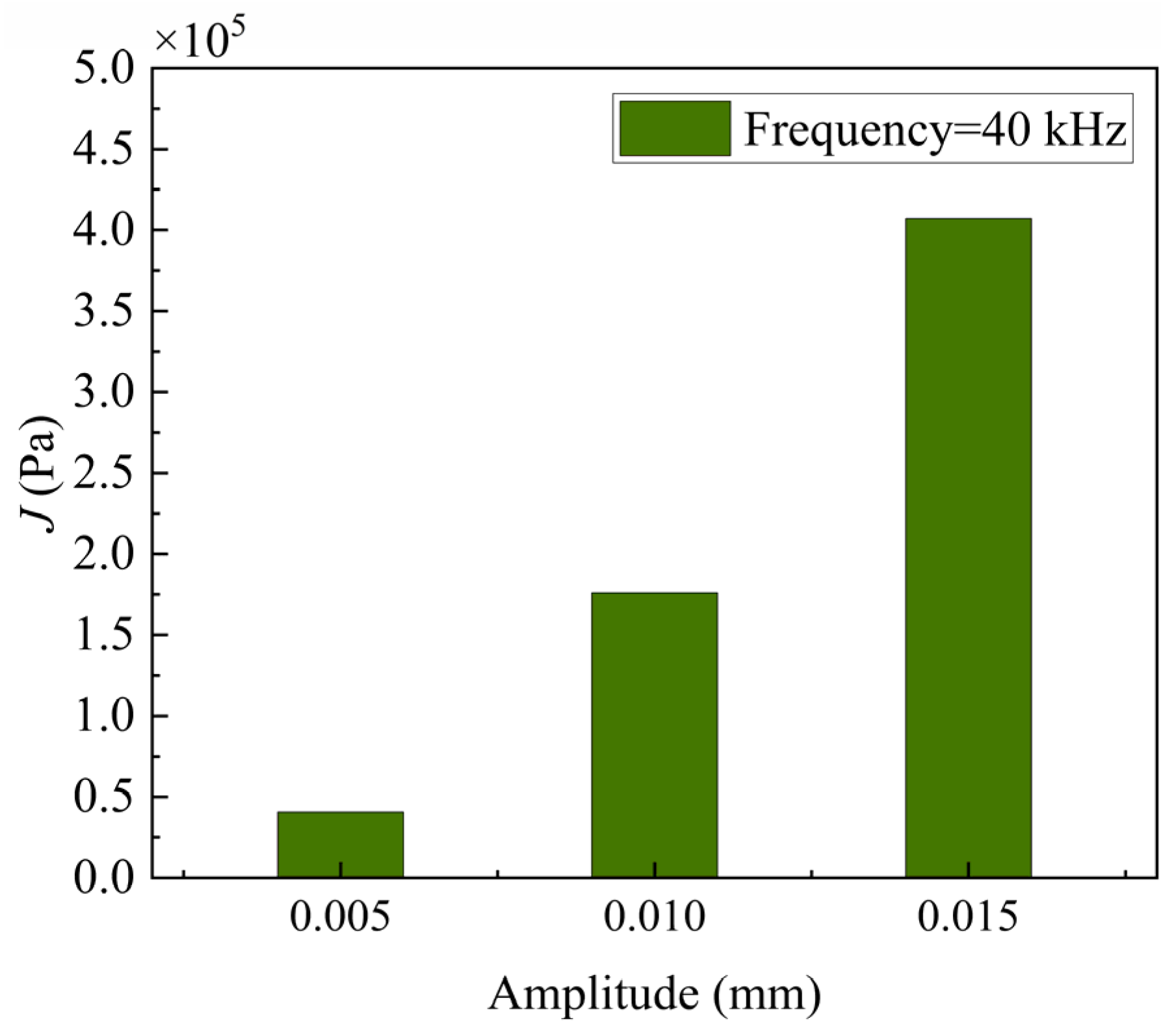

3.3. The Effect of the Excitation Amplitude on the Waveform

3.3.1. The Peak Value of the First Wave |H0| and the Peak Value of Other Waves |H|

3.3.2. The Trough Value |L|

3.3.3. The Difference J between |H| and |L|

4. Discussion

4.1. Validation of the Reliability of the EDEM Simulation Model

4.2. The Potential of This Study in Practical Agricultural Applications

4.2.1. Advantages of |H|

4.2.2. Role of Excitation Frequency and Amplitude

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, B.B.; Wang, C.; Wang, P.F.; Zheng, S.L.; Sun, W.M. Research on Fatigue Damage in High-Strength Steel (FV520B) Using Nonlinear Ultrasonic Testing. Shock Vib. 2020, 2020, 15. [Google Scholar] [CrossRef]

- Beamish, S.; Reddyhoff, T.; Hunter, A.; Dwyer-Joyce, R.S. A method to determine acoustic properties of solids and its application to measuring oil film thickness in bearing shells of unknown composition. Measurement 2022, 195, 111176. [Google Scholar] [CrossRef]

- Hussin, M.; Chan, T.H.T.; Fawzia, S.; Ghasemi, N. Identifying the Prestress Force in Prestressed Concrete Bridges Using Ultrasonic Technology. Int. J. Struct. Stab. Dyn. 2020, 20, 25. [Google Scholar] [CrossRef]

- Secanellas, S.A.; Gallego, J.C.L.; Catalán, G.A.; Navarro, R.M.; Heras, J.O.; Izquierdo, M.A.G.; Hernández, M.G.; Velayos, J.J.A. An Ultrasonic Tomography System for the Inspection of Columns in Architectural Heritage. Sensors 2022, 22, 6646. [Google Scholar] [CrossRef] [PubMed]

- Zielinska, M.; Rucka, M. Assessment of Wooden Beams from Historical Buildings Using Ultrasonic Transmission Tomography. Int. J. Archit. Herit. 2023, 17, 249–261. [Google Scholar] [CrossRef]

- Di Battista, A.; Price, A.; Malkin, R.; Drinkwater, B.W.; Kuberka, P.; Jarrold, C. The effects of high-intensity 40 kHz ultrasound on cognitive function. Appl. Acoust. 2022, 200, 109051. [Google Scholar] [CrossRef]

- Yan, X.L.; Dong, S.Y.; Xu, B.S.; Cao, Y. Progress and Challenges of Ultrasonic Testing for Stress in Remanufacturing Laser Cladding Coating. Materials 2018, 11, 293. [Google Scholar] [CrossRef]

- Li, W.; Ma, H.L.; He, R.H.; Ren, X.F.; Zhou, C.N. Prospects and application of ultrasound and magnetic fields in the fermentation of rare edible fungi. Ultrason. Sonochem. 2021, 76, 105613. [Google Scholar] [CrossRef]

- Danielak, M.; Przybyl, K.; Koszela, K. The Need for Machines for the Nondestructive Quality Assessment of Potatoes with the Use of Artificial Intelligence Methods and Imaging Techniques. Sensors 2023, 23, 1787. [Google Scholar] [CrossRef]

- Schmitz, A.; Badgujar, C.; Mansur, H.; Flippo, D.; McCornack, B.; Sharda, A. Design of a Reconfigurable Crop Scouting Vehicle for Row Crop Navigation: A Proof-of-Concept Study. Sensors 2022, 22, 6203. [Google Scholar] [CrossRef]

- Shimizu, H.; Sato, T. Development of strawberry pollination system using ultrasonic radiation pressure. In Proceedings of the 6th International-Federation-of-Automatic-Control (IFAC) Conference on Bio-Robotics (BIOROBOTICS), Beijing, China, 13–15 July 2018; Elsevier: Beijing, China, 2018; pp. 57–60. [Google Scholar] [CrossRef]

- Mizrach, A. Determination of avocado and mango fruit properties by ultrasonic technique. Ultrasonics 2000, 38, 717–722. [Google Scholar] [CrossRef]

- Ag, M.R.; Mawandha, H.G.; Huda, M.W.N.; Ngadisih, N. The utilization of Sentinel-1 soil moisture satellite imagery for runoff coefficient analysis. IOP Conf. Ser. Earth Environ. Sci. 2022, 1116, 012017. [Google Scholar] [CrossRef]

- Bryk, M.; Kolodziej, B. Pedotransfer Functions for Estimating Soil Bulk Density Using Image Analysis of Soil Structure. Sensors 2023, 23, 1852. [Google Scholar] [CrossRef]

- Li, J.Z.; Sun, S.L.; Sun, C.R.; Liu, C.; Tang, W.G.; Wang, H.B. Analysis of Effect of Grouser Height on Tractive Performance of Tracked Vehicle under Different Moisture Contents in Paddy Soil. Agriculture 2022, 12, 1581. [Google Scholar] [CrossRef]

- Starovoitova, O.A.; Starovoitov, V.I.; Manokhina, A.A.; Voronov, N.V. Methodological Approaches to Constructing 3D Models of Soil in Potato Farming. In Proceedings of the International Conference on World Technological Trends in Agribusiness (WTTA), Omsk, Russia, 4–5 July 2020; IOP Publishing Ltd.: Omsk, Russia, 2020. [Google Scholar] [CrossRef]

- Stolt, M.H.; O’Geen, A.T.; Beaudette, D.E.; Drohan, P.J.; Galbraith, J.M.; Lindbo, D.L.; Monger, H.C.; Needelman, B.A.; Ransom, M.D.; Rabenhorst, M.C.; et al. Changing the hierarchical placement of soil moisture regimes in Soil Taxonomy. Soil Sci. Soc. Am. J. 2021, 85, 488–500. [Google Scholar] [CrossRef]

- Baskota, A.; Kuo, J.; Lal, A. Gigahertz Ultrasonic Multi-Imaging of Soil Temperature, Morphology, Moisture, and Nematodes. In Proceedings of the 35th IEEE International Conference on Micro Electro Mechanical Systems Conference (IEEE MEMS), Tokyo, Japan, 9–13 January 2022; IEEE: Tokyo, Japan, 2022; pp. 519–522. [Google Scholar] [CrossRef]

- Zhang, J.W.; Murton, J.; Liu, S.J.; Sui, L.L.; Zhang, S. Detection of the freezing state and frozen section thickness of fine sand by ultrasonic testing. Permafr. Periglac. Process. 2021, 32, 76–91. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Yang, G.; Chen, W.W.; Sun, L.Z. Relation between Microstructures and Macroscopic Mechanical Properties of Earthen-Site Soils. Materials 2022, 15, 23. [Google Scholar] [CrossRef]

- Zhao, Z.; Ma, K.; Luo, Y. Application of Ultrasonic Pulse Velocity Test in the Detection of Hard Foreign Object in Farmland Soil. In Proceedings of the 2019 IEEE 4th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chengdu, China, 20–22 December 2019; pp. 1311–1315. [Google Scholar] [CrossRef]

- Asteris, P.G.; Mokos, V.G. Concrete compressive strength using artificial neural networks. Neural Comput. Appl. 2020, 32, 11807–11826. [Google Scholar] [CrossRef]

- Zeng, Y.Q.; Liu, Q.H. Acoustic detection of buried objects in 3-D fluid saturated porous media: Numerical modeling. IEEE Trans. Geosci. Remote Sens. 2001, 39, 1165–1173. [Google Scholar] [CrossRef]

- Bakhtiari-Nejad, M.; Hajj, M.R.; Shahab, S. Dynamics of acoustic impedance matching layers in contactless ultrasonic power transfer systems. Smart Mater. Struct. 2020, 29, 035037. [Google Scholar] [CrossRef]

- Wu, J.F.; Zhao, S.X.; Zhang, J.W.; Wang, R.H. A continuous phase-frequency modulation technique and adaptive pump noise cancellation method of continuous-wave signal over mud telemetry channel. Digit. Signal Prog. 2021, 117, 103147. [Google Scholar] [CrossRef]

- Cho, S.; Jeon, K.; Kim, C.W. Vibration analysis of electric motors considering rotating rotor structure using flexible multibody dynamics-electromagnetic-structural vibration coupled analysis. J. Comput. Des. Eng. 2023, 10, 578–588. [Google Scholar] [CrossRef]

- Shen, H.M.; Li, X.Y.; Li, Q.; Wang, H.B. A method to model the effect of pre-existing cracks on P-wave velocity in rocks. J. Rock Mech. Geotech. Eng. 2020, 12, 493–506. [Google Scholar] [CrossRef]

- Yan, D.X.; Yu, J.Q.; Wang, Y.; Zhou, L.; Sun, K.; Tian, Y. A Review of the Application of Discrete Element Method in Agricultural Engineering: A Case Study of Soybean. Processes 2022, 10, 1305. [Google Scholar] [CrossRef]

- Zhao, H.B.; Huang, Y.X.; Liu, Z.D.; Liu, W.Z.; Zheng, Z.Q. Applications of Discrete Element Method in the Research of Agricultural Machinery: A Review. Agriculture 2021, 11, 425. [Google Scholar] [CrossRef]

- Xu, L.F.; Feng, T.T.; Song, Y.P.; Li, F.D.; Song, Z.H. Research on Drag Reduction Mechanism of Bionic Rib Subsoiling Shovel Based on Discrete Element Method. In Proceedings of the 3rd International Workshop on Renewable Energy and Development (IWRED), Guangzhou, China, 8–10 March 2019; IOP Publishing Ltd.: Guangzhou, China, 2019. [Google Scholar] [CrossRef]

- Yang, L.W.; Chen, L.S.; Zhang, J.Y.; Liu, H.J.; Sun, Z.C.; Sun, H.; Zheng, L.H. Fertilizer sowing simulation of a variable-rate fertilizer applicator based on EDEM. In Proceedings of the 6th International-Federation-of-Automatic-Control (IFAC) Conference on Bio-Robotics (BIOROBOTICS), Beijing, China, 13–15 July 2018; Elsevier: Beijing, China, 2018; pp. 418–423. [Google Scholar] [CrossRef]

- Zhou, W.Q.; Ni, X.; Song, K.; Wen, N.; Wang, J.W.; Fu, Q.; Na, M.J.; Tang, H.; Wang, Q. Bionic Optimization Design and Discrete Element Experimental Design of Carrot Combine Harvester Ripping Shovel. Processes 2023, 11, 1526. [Google Scholar] [CrossRef]

- Huang, S.H.; Lu, C.Y.; Li, H.W.; He, J.; Wang, Q.J.; Yuan, P.P.; Gao, Z.; Wang, Y.B. Transmission rules of ultrasonic at the contact interface between soil medium in farmland and ultrasonic excitation transducer. Comput. Electron. Agric. 2021, 190, 106477. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C.; Fielke, J.M. Discrete element modelling of tillage forces and soil movement of a one-third scale mouldboard plough. Biosyst. Eng. 2017, 155, 44–54. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielke, J.M.; Saunders, C. 3D DEM tillage simulation: Validation of a hysteretic spring (plastic) contact model for a sweep tool operating in a cohesionless soil. Soil Tillage Res. 2014, 144, 220–227. [Google Scholar] [CrossRef]

- Sarro, W.S.; Assis, G.M.; Ferreira, G.C.S. Experimental investigation of the UPV wavelength in compacted soil. Constr. Build. Mater. 2021, 272, 121834. [Google Scholar] [CrossRef]

- Ferreira, C.; Rios, S.; Cristelo, N.; Viana da Fonseca, A. Evolution of the optimum ultrasonic testing frequency of alkali-activated soil–ash. Géotech. Lett. 2021, 11, 158–163. [Google Scholar] [CrossRef]

- Tanaka, K.; Suda, T.; Hirai, K.; Sako, K.; Fukagawa, R. Monitoring of Soil Moisture and Groundwater Level Using Ultrasonic Waves to Predict Slope Failures. Jpn. J. Appl. Phys. 2009, 48, 09KD12. [Google Scholar] [CrossRef]

- Yang, Z.B.; Wang, X.F.; Zhang, L.; Wang, J.Y. Research on influencing factors of rock breaking efficiency under ultrasonic vibration excitation. AIP Adv. 2023, 13, 13. [Google Scholar] [CrossRef]

- Gheibi, A.; Hedayat, A. Ultrasonic investigation of granular materials subjected to compression and crushing. Ultrasonics 2018, 87, 112–125. [Google Scholar] [CrossRef]

- Han, J.P.; Zhao, D.J.; Zhang, S.L.; Zhou, Y. Damage Evolution of Granite under Ultrasonic Vibration with Different Amplitudes. Shock Vib. 2022, 2022, 14. [Google Scholar] [CrossRef]

| Object | Soil | Steel | Pzt |

|---|---|---|---|

| Poisson’s Ratio | 0.30 | 0.25 | 0.32 |

| Density (kg/m3) | 2650 | 7860 | 7900 |

| Shear Modulus (Pa) | 1.2 × 109 | 7.9 × 1010 | 7.5 × 1010 |

| Object | Soil-Soil | Soil-Steel | Soil-Pzt |

|---|---|---|---|

| Coefficient of Restitution | 0.6 | 0.5 | 0.5 |

| Coefficient of Static Friction | 0.5 | 0.5 | 0.4 |

| Coefficient of Rolling Friction | 0.16 | 0.05 | 0.04 |

| Factor | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Frequency (kHz) | 20 | 40 | 60 |

| Amplitude (mm) | 0.005 | 0.010 | 0.015 |

| Object | Dominant Frequency | ||||

|---|---|---|---|---|---|

| Simulation result (kHz) | Fourier analysis result | ||||

| 20 | |||||

| Experiment result (kHz) | 1st Meas. | 2nd Meas. | 3rd Meas. | 4th Meas. | Average |

| 20.16 | 19.84 | 20.16 | 10.00 | 20.04 | |

| Error (%) | 0.2 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Lu, C.; Li, H.; Wang, C.; Wang, L.; Yang, H. Propagation Laws of Ultrasonic Continuous Signals at the Transmitting Transducer–Soil Interface. Agriculture 2024, 14, 1470. https://doi.org/10.3390/agriculture14091470

Wang Z, Lu C, Li H, Wang C, Wang L, Yang H. Propagation Laws of Ultrasonic Continuous Signals at the Transmitting Transducer–Soil Interface. Agriculture. 2024; 14(9):1470. https://doi.org/10.3390/agriculture14091470

Chicago/Turabian StyleWang, Zhinan, Caiyun Lu, Hongwen Li, Chao Wang, Longbao Wang, and Hanyu Yang. 2024. "Propagation Laws of Ultrasonic Continuous Signals at the Transmitting Transducer–Soil Interface" Agriculture 14, no. 9: 1470. https://doi.org/10.3390/agriculture14091470

APA StyleWang, Z., Lu, C., Li, H., Wang, C., Wang, L., & Yang, H. (2024). Propagation Laws of Ultrasonic Continuous Signals at the Transmitting Transducer–Soil Interface. Agriculture, 14(9), 1470. https://doi.org/10.3390/agriculture14091470