Experimental Study on the Characteristics of Camellia oleifera Fruit Shell Explosion by Hot Air Drying

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

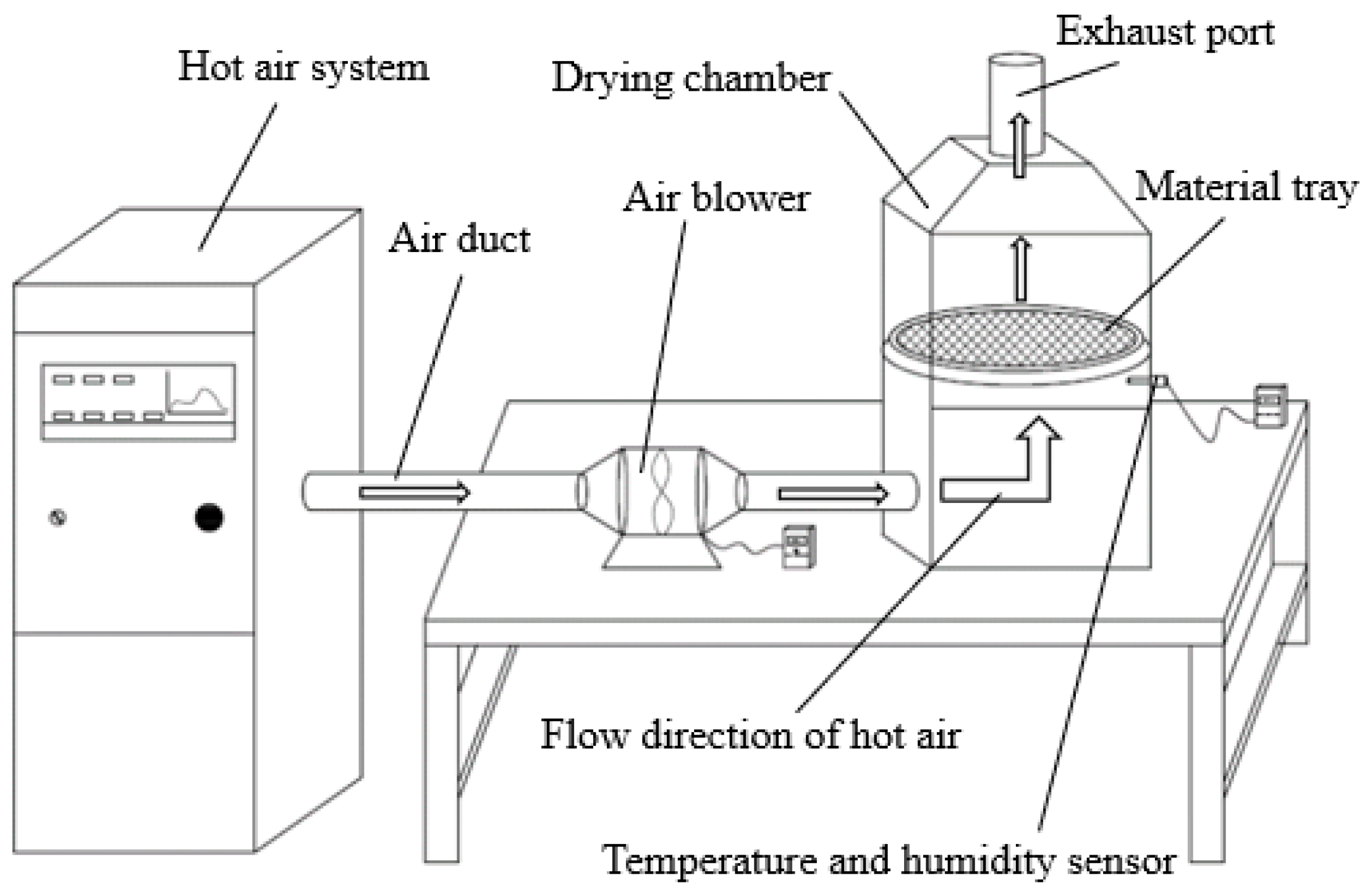

2.2. Hot Air Drying System and COF Drying Process

2.3. Physical Properties of COF

2.4. Parameters of Shell Explosion by Hot Air Drying

2.4.1. Setting of Shell Explosion Rate Standard

2.4.2. Setting of Shell Explosion Rate Standard

2.4.3. Calculation of Drying Rate

2.4.4. Calculation of Moisture Ratio

2.4.5. Calculation of Moisture Effective Diffusivity

2.5. Experiment Method

2.6. Statistical Analysis

3. Results and Discussion

3.1. Analysis of Physical Characteristics of COF

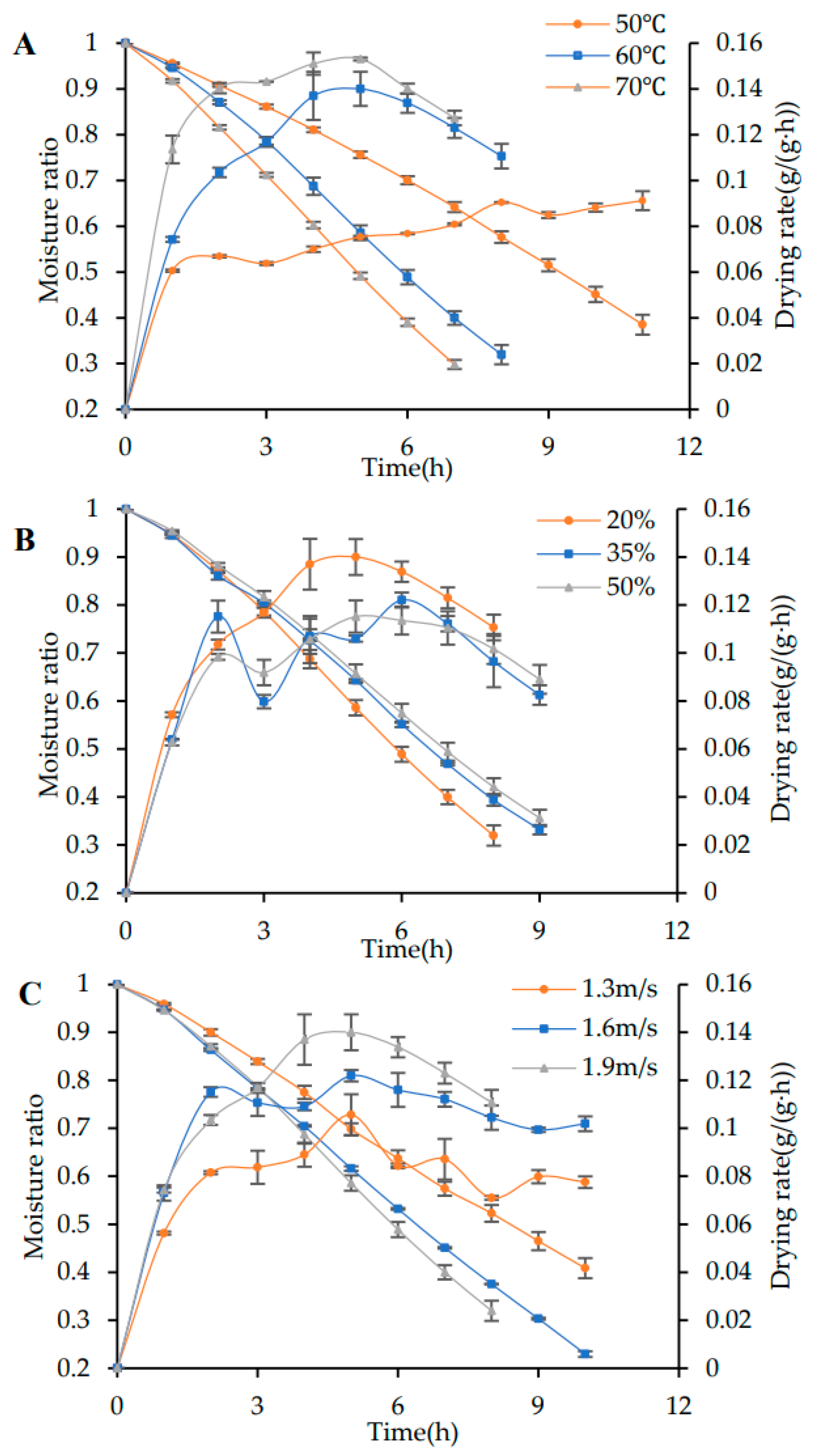

3.2. Analysis of Drying Rate of COF

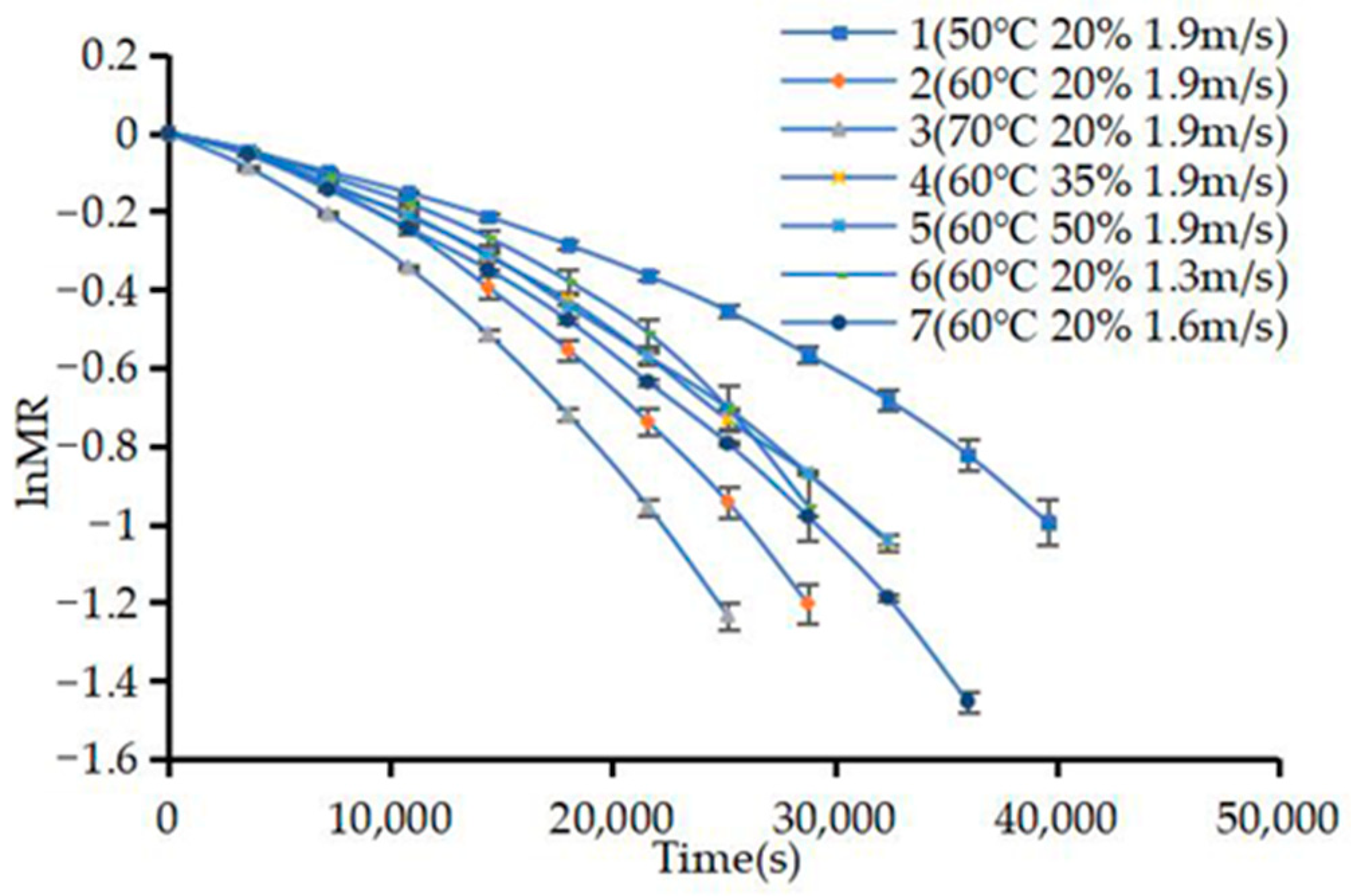

3.3. Analysis of Effective Moisture Diffusion Characteristics of COF

3.4. Response Surface Experiment Design and Results

3.5. Establishment of Model for COF Shell Explosion Rate by Hot Air Drying

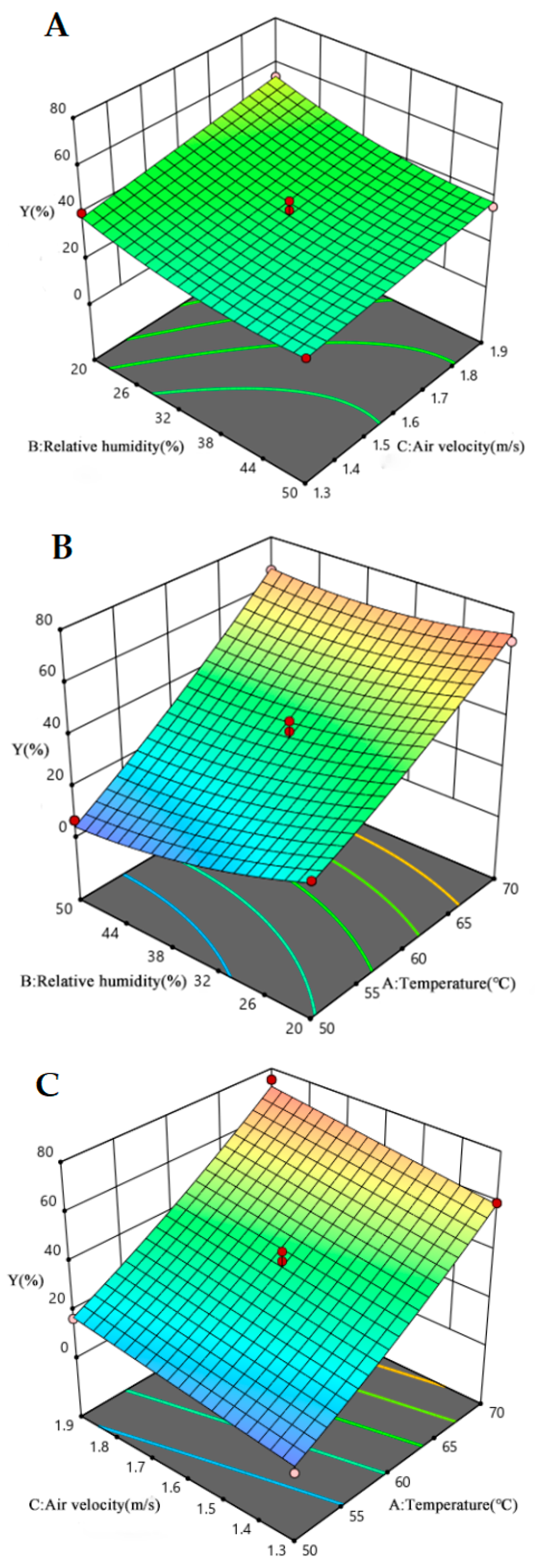

3.6. Analysis of the Influence of Experimental Factors on Response Values

3.7. Analysis of the Influence of Experimental Factors on Response Values

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, T.; Cui, K.; Chen, J.; Wang, R.; Wang, X.; Chen, L.; Zhang, Z.; He, Z.; Liu, C.; Tang, W.; et al. Biodiversity of Culturable Endophytic Actinobacteria Isolated from High Yield Camellia oleifera and Their Plant Growth Promotion Potential. Agriculture 2021, 11, 1150. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, T.; Ying, Y.; Yao, X. Effects of different additives on the chemical composition and microbial diversity during composting of Camellia oleifera shell. Bioresour. Technol. 2021, 330, 124990. [Google Scholar] [CrossRef] [PubMed]

- Fei, L.; Zeng, J.; Yang, Y.; He, X.; Wang, B.; Gao, Y.; Zeng, N. Recent advance in Camellia oleifera Abel: A review of nutritional constituents, biofunctional properties, and potential industrial applications. J. Funct. Foods 2020, 75, 104242. [Google Scholar] [CrossRef]

- Wu, D.; Zhao, E.; Fang, D.; Jiang, S.; Wu, C.; Wang, W.; Wang, R. Determination of Vibration Picking Parameters of Camellia oleifera Fruit Based on Acceleration and Strain Response of Branches. Agriculture 2022, 12, 1222. [Google Scholar] [CrossRef]

- Xiao, X.; He, L.; Chen, Y.; Wu, L.; Wang, L.; Liu, Z. Anti-inflammatory and antioxidative effects of Camellia oleifera Abel components. Future Med. Chem. 2017, 9, 2069–2079. [Google Scholar] [CrossRef]

- Ma, J.; Ye, H.; Rui, Y.; Chen, G.; Zhang, N. Fatty acid composition of Camellia oleifera oil. J. Consum. Prot. Food Saf. 2011, 6, 9–12. [Google Scholar] [CrossRef]

- Liu, R.; Xiao, Z.; Hashem, A.; Abd_Allah, E.F.; Wu, Q. Mycorrhizal Fungal Diversity and Its Relationship with Soil Properties in Camellia oleifera. Agriculture 2021, 11, 470. [Google Scholar] [CrossRef]

- Quan, W.; Wang, A.; Gao, C.; Li, C. Applications of Chinese Camellia oleifera and its by-products: A review. Front. Chem. 2022, 10, 602. [Google Scholar] [CrossRef]

- Zhu, G.; Ren, J.; Wang, Z.; Xiang, H.; Mou, R.; Li, S. Design of shelling machine for Camellia oleifera fruit and operating parameter optimization. Trans. Chin. Soc. Agric. Eng. 2016, 32, 19–27. [Google Scholar] [CrossRef]

- Yuan, C.; Huang, X.; Wang, H.; Zhang, W.; Yuan, S.; Ge, Y.; Zhang, J. Research Status and Development Trend of Camellia oleifera Harvesting and Preliminary Processing Machinery and Equipment. For. Mach. Woodwork. Equip. 2022, 50, 4–8+13. [Google Scholar] [CrossRef]

- Tian, X.; Fang, X.; Liu, S.; Du, M. Effects of Shelling Treatment on Nutritional Qualities and Antioxidant Properties of Oil-Tea Camellia Seed Oil. J. Chin. Cereals Oils 2020, 35, 98–103. [Google Scholar] [CrossRef]

- Liu, Z.; Xiang, H.; Hu, S.; Mou, R.; Ren, J.; Zhang, S. Drying technology and equipment of oil-tea camellia seeds. China Oils Fats 2014, 39, 74–77. [Google Scholar]

- Wang, F.; Liu, Z.; Ding, Y.; Yang, D. Study on the splitting by hot-air drying of Camellia oleifera fruit. Int. J. Food Eng. 2021, 18, 143–151. [Google Scholar] [CrossRef]

- Zhao, H.; Teng, Z.; Yang, H.; Chen, K.; Zhang, X. Drying Characteristics of Camellia oleifera Fruit and Shelling Technologies. Agric. Eng. 2021, 11, 61–67. [Google Scholar]

- Luo, F.; Fei, X.; Guo, S.; Chen, J.; Li, K. Effects of harvest time and drying methods on quality of oil-tea camellia seed oil. China Oils Fats 2015, 40, 69–73. [Google Scholar] [CrossRef]

- Liao, J.; Zhong, M.; Wu, Z.; Wu, M. Low-Temperature Airflow-Drying Cracking Coupling with Flexible Mechanical Deshelling for Camellia oleifera Fruit: Process and Mechanism. Dry. Technol. 2024, 42, 871–879. [Google Scholar] [CrossRef]

- Wang, F.; Shao, W.; Yang, D. Effect of different drying methods on drying characteristics and quality of Camellia oleifera seeds. J. Food Process. Preserv. 2021, 47, e15976. [Google Scholar] [CrossRef]

- Shi, H.; Zhang, M.; Mujumdar, A.; Xu, J.; Wang, W. Influence of drying methods on the drying kinetics, bioactive compounds and flavor of solid-state fermented okara. Dry. Technol. 2021, 39, 644–654. [Google Scholar] [CrossRef]

- Wen, Y.; Chen, L.; Li, B.; Ruan, Z.; Pan, Q. Effect of infrared radiation-hot air (IR-HA) drying on kinetics and quality changes of star anise (Illicium verum). Dry. Technol. 2020, 39, 90–103. [Google Scholar] [CrossRef]

- Dumitru Velescu, I.; Nicoleta Ratu, R.; Arsenoaia, V.-N.; Rosca, R.; Marian Cârlescu, P.; Tenu, I. Research on the Process of Convective Drying of Apples and Apricots Using an Original Drying Installation. Agriculture 2023, 13, 820. [Google Scholar] [CrossRef]

- Tawfik, M.A.; Oweda, K.M.; Abd El-Wahab, M.K.; Abd Allah, W.E. A New Mode of a Natural Convection Solar Greenhouse Dryer for Domestic Usage: Performance Assessment for Grape Drying. Agriculture 2023, 13, 1046. [Google Scholar] [CrossRef]

- Niu, Y.; Yao, X.; Xiao, H.; Wang, D.; Zheng, X.; Wang, Q.; Zhu, R.; Zang, Y.; Liu, H. Effects of radio frequency assisted hot air drying on the texture and microstructure of jujube slices. Trans. Chin. Soc. Agric. Eng. 2022, 38, 296–306. [Google Scholar] [CrossRef]

- Ju, H.; Zhang, W.; Zhang, P.; Zhang, Q.; Gao, Z.; Xiao, H. Hot drying characteristics of fruits and vegetables during heat and mass transfer using Biot numbers. Trans. Chin. Soc. Agric. Eng. 2022, 38, 317–324. [Google Scholar] [CrossRef]

- Lou, Z.; Liu, Q.; Shi, J.; Zhao, Y.; Gao, Z. Air Impingement Drying Shrinkage Characteristic of Chinese Jujube. Trans. Chin. Soc. Agric. Mach. 2014, 45, 241–246. [Google Scholar] [CrossRef]

- Zhou, Z. Physical Properties of Bio-Materials; China Agriculture Press: Beijing, China, 1994. [Google Scholar]

- Ju, H.; Vidyarthi, S.; Karim, M.; Yu, X.; Zhang, W.; Xiao, H. Drying quality and energy consumption efficient improvements in hot air drying of papaya slices by step-down relative humidity based on heat and mass transfer characteristics and 3D simulation. Dry. Technol. 2023, 41, 460–476. [Google Scholar] [CrossRef]

- Abdellatief, M.; Elemam, W.E.; Alanazi, H.; Tahwia, A.M. Production and optimization of sustainable cement brick incorporating clay brick wastes using response surface method. Ceram. Int. 2023, 49, 9395–9411. [Google Scholar] [CrossRef]

- Li, B.; Yue, R.; Shen, L.; Chen, C.; Li, R.; Xu, Y.; Zhang, M.; Hong, H.; Lin, H. A novel method integrating response surface method with artificial neural network to optimize membrane fabrication for wastewater treatment. J. Clean. Prod. 2022, 376, 134236. [Google Scholar] [CrossRef]

- Sun, J.; Tu, Z.; Wang, H.; Hu, Y. Process Optimization and Quality Analysis of Mango Cake Prepared with Fish Protein Gelatin. Sci. Technol. Food Ind. 2022, 43, 189–195. [Google Scholar] [CrossRef]

- Phitakwinai, S.; Thepa, S.; Nilnont, W. Thin-layer drying of parchment Arabica coffee by controlling temperature and relative humidity. Food Sci. Nutr. 2019, 7, 2921–2931. [Google Scholar] [CrossRef]

- Ju, H.; Zhao, S.; Mujumdar, A.; Zhao, H.; Duan, X.; Zheng, Z.; Gao, Z.; Xiao, H. Step-down relative humidity convective air drying strategy to enhance drying kinetics, efficiency, and quality of American ginseng root (Panax quinquefolium). Dry. Technol. 2019, 7, 1–14. [Google Scholar] [CrossRef]

- Maftoonazad, N.; Dehghani, M.; Ramaswamy, H. Hybrid microwave-hot air tunnel drying of onion slices: Drying kinetics, energy efficiency, product rehydration, color, and flavor characteristics. Dry. Technol. 2020, 40, 966–986. [Google Scholar] [CrossRef]

- Guan, Z.; Wang, X.; Li, M.; Jiang, X.; Xie, J. Mathematical Modeling of Hot Air Drying of Thin Layer Litchi Flesh. Trans. Chin. Soc. Agric. Mach. 2012, 43, 151–158+191. [Google Scholar] [CrossRef]

- Bialobrzewski, I.; Markowski, M.; Zielińska, M.; Mujumdar, A.S. Heat and mass transfer during drying of a bed of shrinking particles-simulation for carrot cubes dried in a spout-fluid-bed drier. Int. J. Heat Mass Transf. 2008, 51, 4704–4716. [Google Scholar] [CrossRef]

- Ju, H.; Xiao, H.; Zheng, X.; Guo, X.; Liu, Y.; Zhang, W.; Yuan, J.; Gao, Z. Effect of hot air relative humidity on drying characteristics of carrot slabs. Trans. Chin. Soc. Agric. Eng. 2015, 31, 296–304. [Google Scholar] [CrossRef]

- Shi, J.; Wu, H.; Lou, Z.; Wu, Z.; Liu, Q. Drying characterstics and model of cowpea in tunnel hot air dryer. Trans. Chin. Soc. Agric. Eng. 2013, 29, 232–240. [Google Scholar]

- Lu, Y.; Wang, W.; Zhong, B.; Jin, Q.; Wang, B. Design and Experiment of Belt Screen Sorter for Camellia oleifera Fused with Photoelectric Color Sorting Technology. Trans. Chin. Soc. Agric. Mach. 2020, 51, 429–439. [Google Scholar] [CrossRef]

- Xu, Q.; Shan, C.; Chen, H.; Zhu, J.; Zeng, Y.; Li, S.; Pan, H.; Zhang, W. Numerical simulation and optimization of air distribution in kiwifruit controlled atmosphere pallet bags. Trans. Chin. Soc. Agric. Eng. 2024, 40, 307–316. [Google Scholar] [CrossRef]

- MacGregor, W. Effects of air velocity, air temperature, and berry diameter on wild blueberry drying. Dry. Technol. 2005, 23, 387–396. [Google Scholar] [CrossRef]

- Li, C. Analytical theory study on latent heat coefficient of grain water vaporization. Dry. Technol. 2021, 39, 803–819. [Google Scholar] [CrossRef]

- Li, C. Theoretical analysis of exergy transfer and conversion in grain drying process. Trans. Chin. Soc. Agric. Eng. 2018, 34, 1–8. [Google Scholar] [CrossRef]

- Li, T.; Li, C.; Li, C.; Xu, F.; Fang, Z. Porosity of flowing rice layer: Experiments and numerical simulation. Biosyst. Eng. 2019, 179, 1–12. [Google Scholar] [CrossRef]

- Li, Y.; Yang, X.; Liu, J.; Wu, J.; Wang, Z.; Zhang, X. Ultrasonic-assisted alkaline extraction of Plukenetia volubilis protein isolate and its processing properties. Food Ferment. Ind. 2021, 47, 128–135. [Google Scholar] [CrossRef]

| Codes | Factors | ||

|---|---|---|---|

| Temperature (A)/°C | Relative Humidity (B)/% | Air Velocity (C)/m/s | |

| −1 | 50 | 20 | 1.3 |

| 0 | 60 | 35 | 1.6 |

| 1 | 70 | 50 | 1.9 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Moisture content (% d.b.) | 142.5 | 157.0 | 137.3 | 123.8 | 207.0 | 227.2 |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Moisture content (% d.b.) | 122.8 | 141.7 | 181.3 | 204.2 | 203.0 | 209.0 |

| No. | 13 | 14 | 15 | 16 | 17 | 18 |

| Moisture content (% d.b.) | 153.3 | 136.5 | 182.0 | 190.1 | 116.2 | 172.3 |

| No. | 19 | 20 | 21 | 22 | 23 | 24 |

| Moisture content (% d.b.) | 217.9 | 179.1 | 166.1 | 181.8 | 178.3 | 173.5 |

| No. | 25 | 26 | 27 | 28 | 29 | 30 |

| Moisture content (% d.b.) | 162.5 | 190.4 | 167.2 | 204.3 | 152.0 | 193.1 |

| No. | Equation of Linear Regression | R2 | Deff/10−9 m2/s |

|---|---|---|---|

| 1 | ln MR = 0.0883 − 2.418 × 10−5 t | 0.9601 | ± 0.033 e |

| 2 | ln MR = 0.1229 − 4.154 × 10−5 t | 0.9620 | b |

| 3 | ln MR = 0.1035 − 4.851 × 10−5 t | 0.9693 | a |

| 4 | ln MR = 0.0923 − 3.260 × 10−5 t | 0.9450 | d |

| 5 | ln MR = 0.9105 − 3.232 × 10−5 t | 0.9762 | d |

| 6 | ln MR = 0.1031 − 3.143 × 10−5 t | 0.9318 | d |

| 7 | ln MR = 0.1385 − 3.962 × 10−5 t | 0.9653 | c |

| No. | Factors | Index | ||

|---|---|---|---|---|

| Temperature/°C | Relative Humidity/% | Air Velocity/m/s | Shell Explosion Rate/% | |

| 1 | −1 | −1 | 0 | 11.11 |

| 2 | 1 | −1 | 0 | 69.31 |

| 3 | −1 | 1 | 0 | 6.67 |

| 4 | 1 | 1 | 0 | 66.67 |

| 5 | −1 | 0 | −1 | 2.08 |

| 6 | 1 | 0 | −1 | 59.72 |

| 7 | −1 | 0 | 1 | 16.67 |

| 8 | 1 | 0 | 1 | 75.28 |

| 9 | 0 | −1 | −1 | 40.58 |

| 10 | 0 | 1 | −1 | 28.59 |

| 11 | 0 | −1 | 1 | 54.09 |

| 12 | 0 | 1 | 1 | 36.37 |

| 13 | 0 | 0 | 0 | 33.33 |

| 14 | 0 | 0 | 0 | 31.11 |

| 15 | 0 | 0 | 0 | 38.41 |

| 16 | 0 | 0 | 0 | 42.38 |

| 17 | 0 | 0 | 0 | 34.47 |

| Project | Source of Variation | Sum of Squares | Sum of Squares. | Mean Square | F | p |

|---|---|---|---|---|---|---|

| shell explosion rate Y | model | 6841.93/6807.89 | 9/5 | 760.21/1361.58 | 44.68/97.81 | <0.0001 **/<0.0001 ** |

| A | 5989.10/5989.10 | 1/1 | 5989.10/5989.10 | 352.03/430.22 | <0.0001 **/<0.0001 ** | |

| B | 342.57/342.57 | 1/1 | 342.57/342.57 | 20.14/24.61 | 0.0028 **/0.0004 ** | |

| C | 330.76/330.76 | 1/1 | 330.76/330.76 | 19.44/23.76 | 0.0031 **/0.0005 ** | |

| AB | 75.34/75.34 | 1/1 | 75.34/75.34 | 4.43/5.41 | 0.0734/0.0401 * | |

| AC | 0.2352 | 1 | 0.2352 | 0.0138 | 0.9097 | |

| BC | 8.21 | 1 | 8.21 | 0.4825 | 0.5097 | |

| A2 | 25.48 | 1 | 25.48 | 1.50 | 0.2606 | |

| B2 | 65.03/70.11 | 1/1 | 65.03/70.11 | 3.82/5.04 | 0.0915/0.0464 * | |

| C2 | 0.0059 | 1 | 0.0059 | 0.0003 | 0.9856 | |

| residual. | 119.09/153.13 | 7/11 | 17.0/13.92 | |||

| Lack of fit | 39.21/73.26 | 3/7 | 13.07/10.47 | 0.6546/0.5241 | 0.6209/0.7860 | |

| sum | 6961.02/6961.02 | 16/16 | ||||

| R2 | 0.9829/0.9780 | |||||

| R2Adj | 0.9609/0.9680 |

| No. | Drying Condition. | Predictive Value of Shell Explosion Rate/% | Tested Value of Shell Explosion Rate% | R2 | RMSE | ||

|---|---|---|---|---|---|---|---|

| Temperature/°C | Relative Humidity/% | Air Velocity/m/s | |||||

| 1 | 50 | 20 | 1.9 | 26.22 | 27.56 | 0.9993 | 0.9743 |

| 2 | 50 | 20 | 1.3 | 10.49 | 10.33 | ||

| 3 | 50 | 50 | 1.9 | 10.27 | 9.67 | ||

| 4 | 60 | 20 | 1.6 | 45.32 | 46.79 | ||

| 5 | 60 | 35 | 1.9 | 45.60 | 47.10 | ||

| 6 | 70 | 35 | 1.6 | 66.14 | 65.33 | ||

| 7 | 70 | 20 | 1.9 | 80.94 | 81.17 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Z.; Tang, X.; Ai, Z.; Liu, M.; Deng, G.; Xu, H.; Tong, J.; Li, T. Experimental Study on the Characteristics of Camellia oleifera Fruit Shell Explosion by Hot Air Drying. Agriculture 2024, 14, 1242. https://doi.org/10.3390/agriculture14081242

Xiao Z, Tang X, Ai Z, Liu M, Deng G, Xu H, Tong J, Li T. Experimental Study on the Characteristics of Camellia oleifera Fruit Shell Explosion by Hot Air Drying. Agriculture. 2024; 14(8):1242. https://doi.org/10.3390/agriculture14081242

Chicago/Turabian StyleXiao, Zhifeng, Xin Tang, Ziping Ai, Muhua Liu, Gelong Deng, Huilong Xu, Jinjie Tong, and Tao Li. 2024. "Experimental Study on the Characteristics of Camellia oleifera Fruit Shell Explosion by Hot Air Drying" Agriculture 14, no. 8: 1242. https://doi.org/10.3390/agriculture14081242

APA StyleXiao, Z., Tang, X., Ai, Z., Liu, M., Deng, G., Xu, H., Tong, J., & Li, T. (2024). Experimental Study on the Characteristics of Camellia oleifera Fruit Shell Explosion by Hot Air Drying. Agriculture, 14(8), 1242. https://doi.org/10.3390/agriculture14081242