1. Introduction

Peanut (also known as groundnut) is a crucial cash crop recognized for its high nutritional value and diverse applications, with cultivation occurring in over 100 countries worldwide. According to data from the FAO and the National Bureau of Statistics of China, the area under peanut cultivation in China was approximately 4.68 million hectares in 2022, accounting for 15.32% of the global total. China also ranked first in peanut production, yielding around 18.33 million tons, which constituted approximately 33.79% of the total global output [

1,

2,

3]. The economic value of peanuts is primarily derived from their substantial oil and protein content, which range from 16% to 36% for protein, and around 50% for fat, along with being rich in many nutrients, such as unsaturated fatty acids [

4].

The moisture content of freshly harvested peanut pods is high (about 45% wet base moisture content), making it susceptible to some harmful microorganisms and deterioration [

5]. Thus, drying peanut pods after harvest is essential; the effectiveness of this drying process significantly influences the quality, safety, and convenience of subsequent peanut processing and storage [

6]. While traditional drying methods, such as natural drying and hot-air drying, are extensively used in many regions, they remain plagued by numerous challenges. These challenges, such as prolonged drying time, inefficient drying, uneven moisture distribution, and high energy consumption, severely compromise both the drying efficiency and economic benefits of peanuts [

7,

8]. As a result, the advancement of more efficient drying technologies has emerged as a key area for contemporary research.

In recent years, microwave drying technology has gained widespread attention due to its ability to significantly enhance drying efficiency and reduce drying time. Microwave drying works by directly applying microwave radiation to the material, causing rapid evaporation of moisture, thereby improving the drying process [

9,

10]. Compared with traditional drying methods, microwave drying allows the material to be heated more deeply and thoroughly and minimizes the thermal gradient [

11,

12]. However, relying solely on microwave drying can result in the surface overheating as well as uneven heating overall. By alternating between hot air and microwave drying, more uniform drying can be achieved in a shorter time, reducing uneven moisture distribution, and effectively lowering excessive energy consumption. Additionally, intermittent drying helps to stabilize temperature fluctuations during the drying process, thus preventing over-drying or quality degradation on the surface of the peanut pods. This ultimately improves the drying quality and enhances the economic benefits of the final product. In summary, the technique of intermittently introducing microwave energy during the hot-air-drying process combines the rapid heating capabilities of microwaves with the uniform drying characteristics of hot air, resulting in thorough material drying and a stabilized drying environment that reduces surface overheating and promotes uniform drying [

13]. In previous studies, Ling et al. [

14] identified the optimal process parameters for the intermittent microwave–hot-air drying of peanuts through a response surface optimization analysis. The optimal conditions were established as T = 45 °C, MW = 1.25 W/g, and an intermittent ratio of 1.10 [

5]. Their findings demonstrated that this intermittent drying technique is highly efficient, ensuring both effective drying and the preservation of peanut quality, and indicate that this drying technology can effectively reduce costs while ensuring high quality in peanut production. Additionally, studies involving other materials, such as apple [

15], taro [

16], potato [

17], oleifera seeds [

18], papaya [

19], jujube [

20], and rice [

21], have demonstrated that intermittent microwave–hot-air drying yields significant improvements in drying efficiency and can substantially shorten the drying time.

Although this drying technology offers significant theoretical advantages compared with traditional drying methods, such as the potential to improve energy efficiency, reduce drying time, and better preserve product quality, currently, this method has not been widely studied. Moreover, research specifically focusing on the drying kinetics of peanut pods is still scarce. Most existing studies have concentrated on only microwave or hot-air drying, with the performance of peanut pods under this combined drying process not having been fully validated. Furthermore, as an important agricultural product, peanut pods have unique drying characteristics. By contrast, this study not only analyzes the microwave–hot-air-drying process but investigates key factors in drying kinetics, such as the moisture diffusion coefficient, and conducts an energy analysis, including specific energy consumption and thermal efficiency. These analyses contribute to a deeper understanding of the drying process and provide theoretical support for optimizing drying conditions for peanut pods.

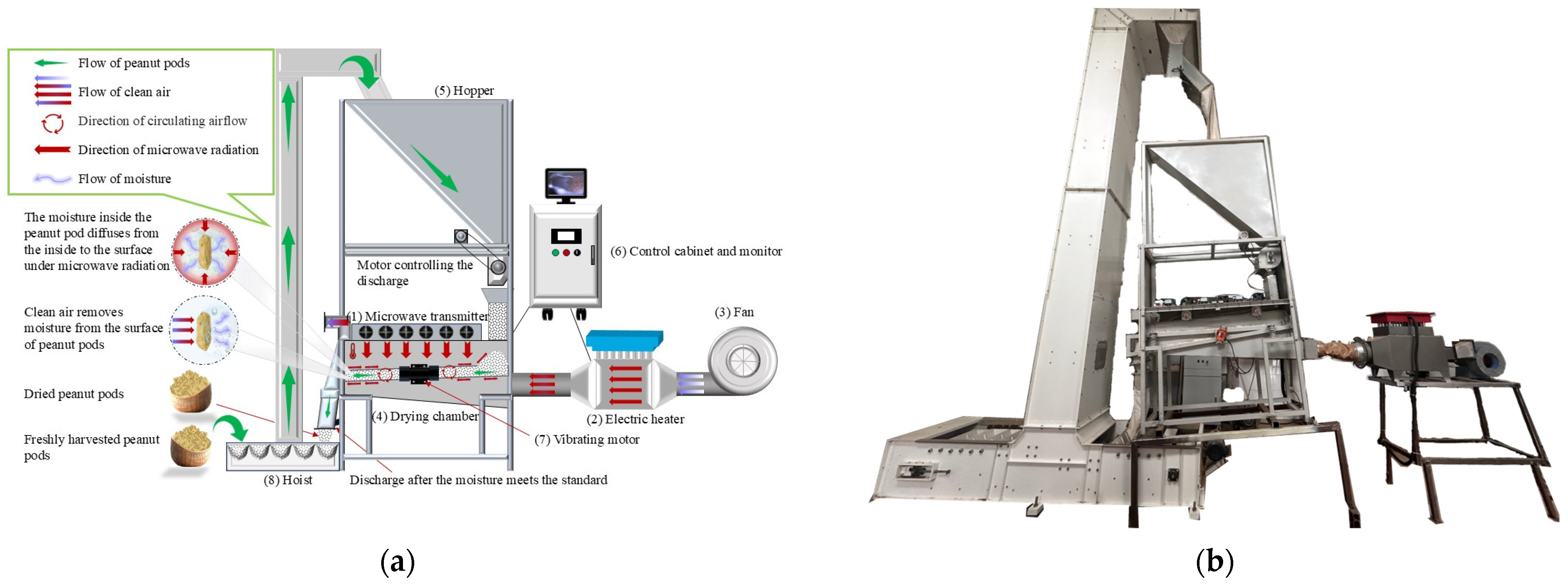

In this study, an intermittent microwave drying method was used to examine its effects on the drying kinetics of peanut pods, and single-factor tests were employed to compare the influences of microwave power and temperature on energy consumption and thermal efficiency. The goal of this research was to reveal the dynamic mechanisms of combined intermittent microwave and hot-air drying, to assess their potential, to optimize the technological parameters involved in the drying process, and to explore technologies appropriate for peanut pod drying. Furthermore, this work aspires to contribute to the advancement of drying technologies for agricultural products, to facilitate the modernization of agricultural post-harvest processing, to enhance the economic value of these products, and to minimize energy consumption, thereby offering valuable references for related domains.

4. Discussion

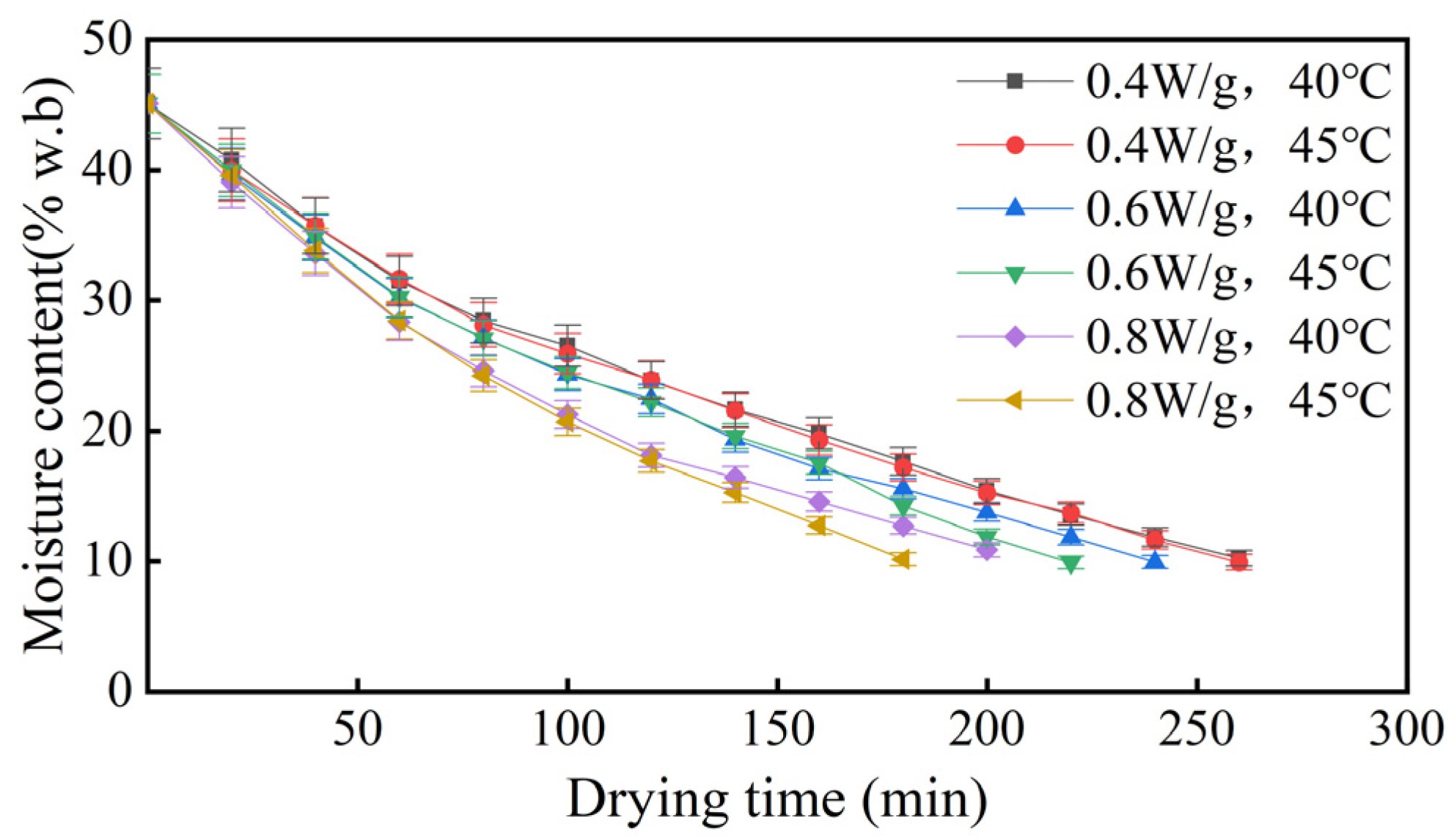

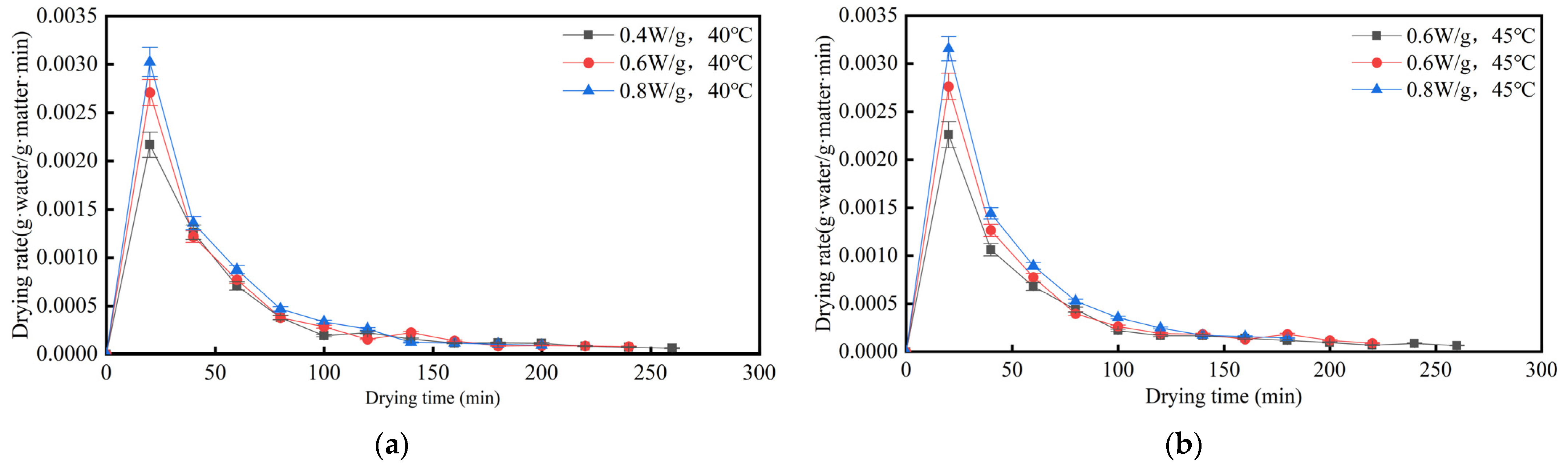

This study involved a comprehensive investigation into the dynamic characteristics of peanut drying using intermittent microwave–hot-air drying. By analyzing the key parameters that influence moisture content, drying rate, moisture diffusion coefficient, and energy consumption in peanut pods, we found that both the microwave power density and temperature significantly affect the drying behavior of peanut pods. These findings offer valuable theoretical insights for optimizing the drying process.

Firstly, the increase in microwave power density and temperature enhances the migration and evaporation of moisture within peanut pods by elevating the internal temperature and pressure [

41,

42]. This acceleration promotes the evaporation of surface moisture, increases the moisture gradient, and may alter the microstructure of the peanut pod, thereby reducing its moisture content [

43,

44]. Similar findings have been reported by other researchers [

14,

45]. During the early stages of drying, peanut pods hold a considerable amount of moisture. With increasing microwave power and temperature, the thermal movement of the internal moisture accelerates, which raises the evaporation rate and accelerates the drying rate [

46]. Nonetheless, over time, the amount of free moisture diminishes, leading to a decrease in the rate of moisture diffusion. At this point, evaporation demands additional energy to disrupt the bound moisture and the moisture adsorbed within the material [

5]. This shift results in the moisture content reaching equilibrium quicker, ultimately slowing both the drying rate and the moisture ratio [

47]. The effective moisture diffusivity ranges from 0.987 × 10

−9 to 1.227 × 10

−9 m

2/s, which aligns with previous studies and confirms the efficacy of the intermittent microwave–hot-air-drying method [

5,

47,

48,

49]. The Verma model demonstrated the best fit in this study, indicating its effectiveness in describing moisture migration in peanut pods, consistent with evaluations of this model in the drying processes of peanuts and other foods found in the literature.

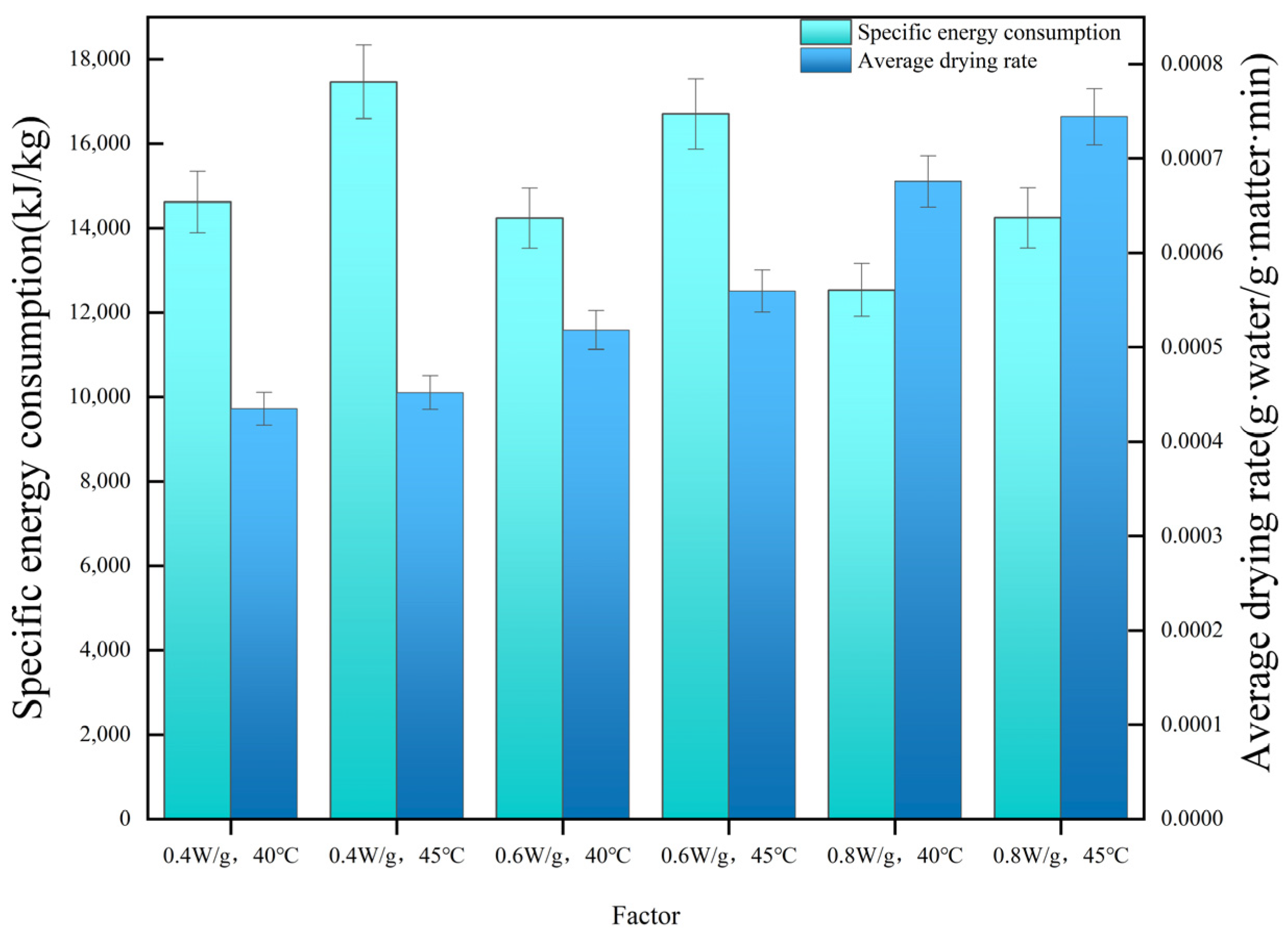

Secondly, in the thermodynamic assessment, the lowest specific energy consumption (12,535 kJ/kg) and the highest thermal efficiency (18.1%) were recorded at a microwave power density of 0.8 W/g and a temperature of 40 °C. This finding demonstrates that careful control of drying parameters can significantly improve energy utilization efficiency. Nonetheless, the lower thermal efficiency observed in this study, compared with the thermal efficiency in other studies, may indicate that the experimental conditions were not optimal, underscoring the importance of fine-tuning drying parameters in future investigations.

In summary, this study identifies several limitations in the investigation of peanut-drying kinetics using a combination of intermittent microwave and hot-air drying. The selected test parameters did not encompass all potential drying conditions, which limits a comprehensive understanding of the underlying drying mechanisms. Additionally, factors such as peanut variety, size, and initial moisture content were not considered, yet these can significantly influence drying efficacy in practical applications. Future research should aim to broaden the range of parameters studied and account for the diversity of peanut varieties. Moreover, the thermal efficiency observed in this study is lower compared with that in other studies, suggesting that the amount of energy consumed during drying needs to be improved. Future investigations should explore advanced drying technologies and methods, including intelligent control systems and multi-stage drying strategies, to further reduce energy consumption and enhance drying quality. Research into thermal energy recovery and reuse during the peanut-drying process could also contribute to improved energy efficiency and reduced production costs, ultimately leading to a more efficient and sustainable drying process.

5. Conclusions

In this study, a specifically designed batch microwave–hot-air-drying system was utilized to explore the drying kinetics of peanuts. We conducted a comprehensive analysis of key parameters, including moisture content, drying rate, moisture effective diffusion coefficient, thermal efficiency, and specific energy consumption. The experimental results demonstrated that the effective moisture diffusion coefficient ranged from 0.987 × 10−9 to 1.227 × 10−9 m2/s. We found that the Verma model yielded the best fitting results, with an R2 of 0.9997, signifying its effectiveness in accurately modeling the drying process of peanuts. With regard to energy consumption, setting the microwave power at 0.8 W/g and maintaining a temperature of 40 °C resulted in a minimal unit energy consumption of 12,535 kJ/kg, while achieving a thermal efficiency of 18.1%. Nonetheless, the relatively low thermal efficiency is attributed to suboptimal experimental parameter configurations. Therefore, future research should focus on further optimizing drying parameters to enhance thermal efficiency and minimize energy consumption, thereby increasing the feasibility and economic advantages of this drying technology.