Study on the Relationship between Crack Initiation and Crack Bifurcation in Walnut Shells Based on Energy

Abstract

:1. Introduction

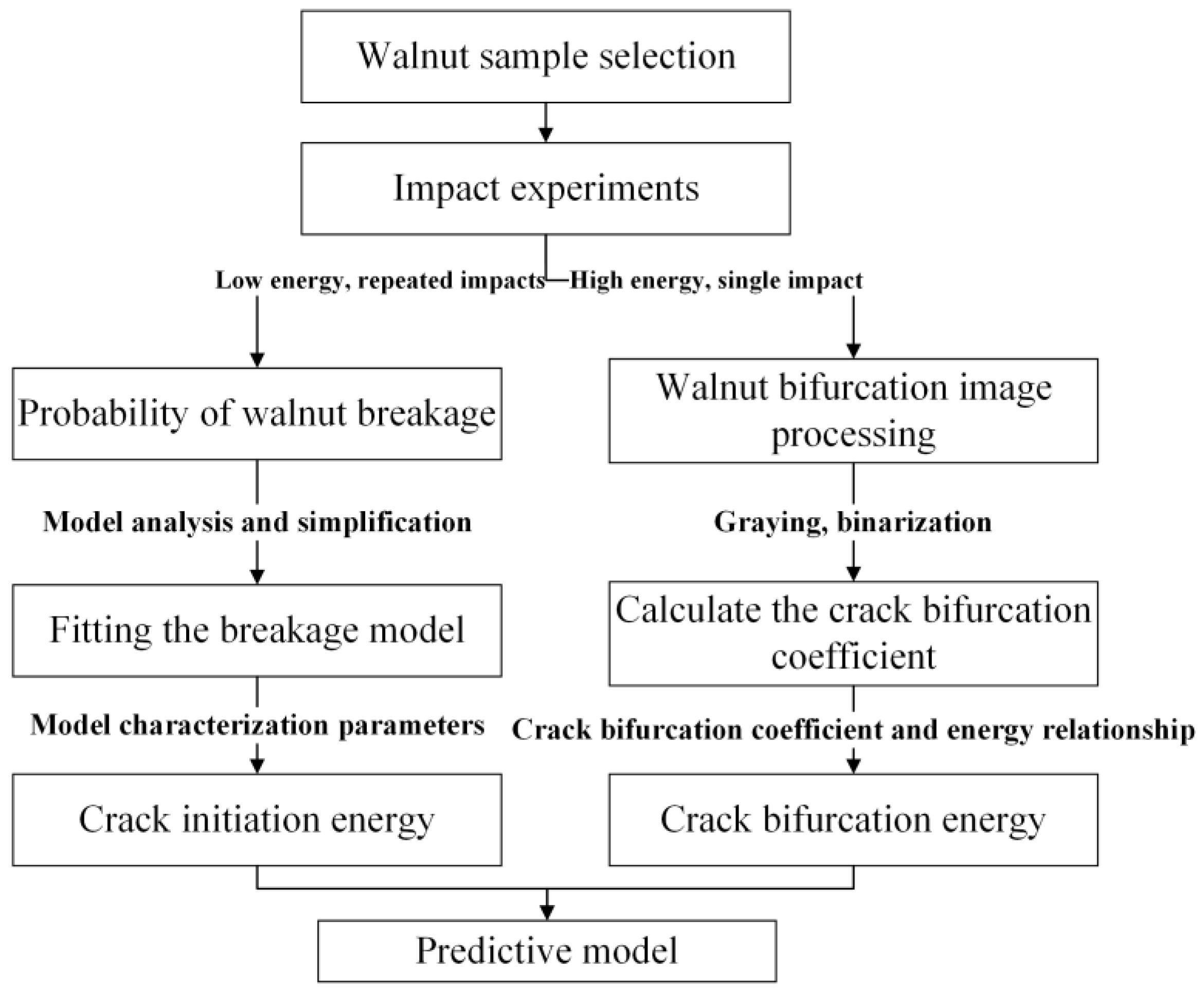

2. Materials and Methods

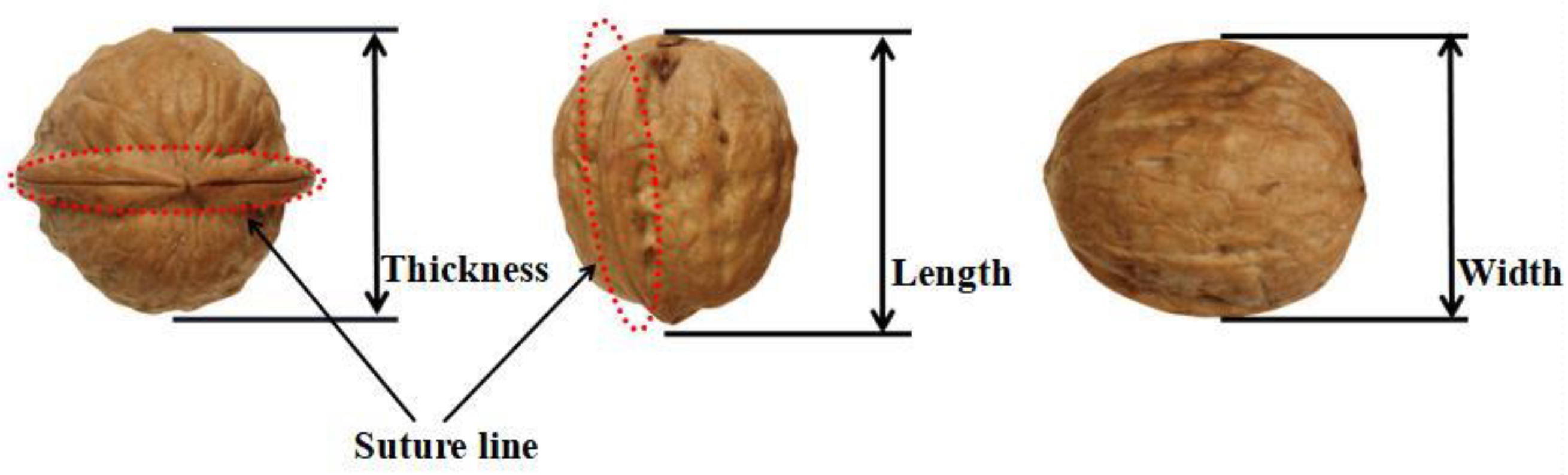

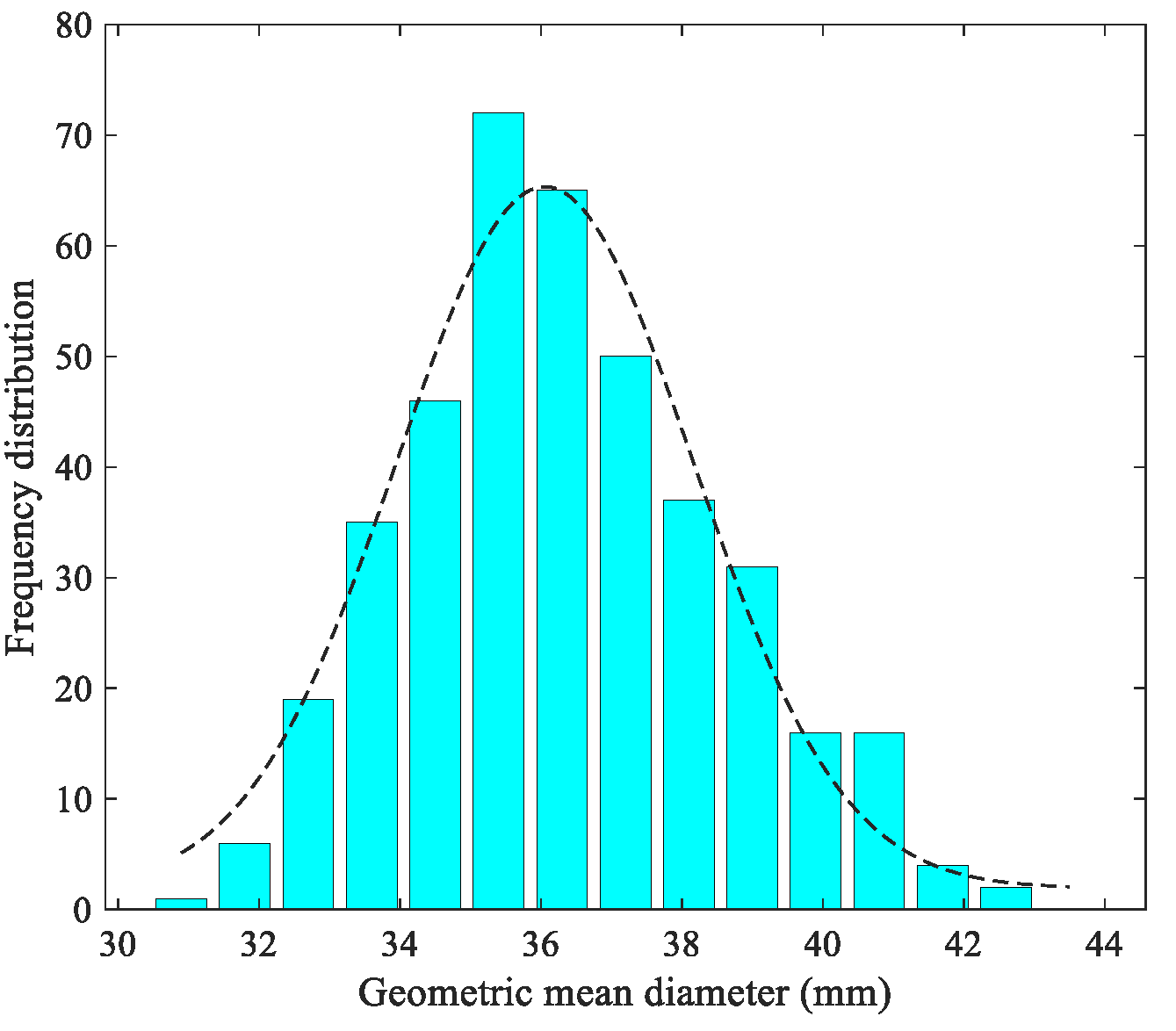

2.1. Preparation of the Walnut Samples

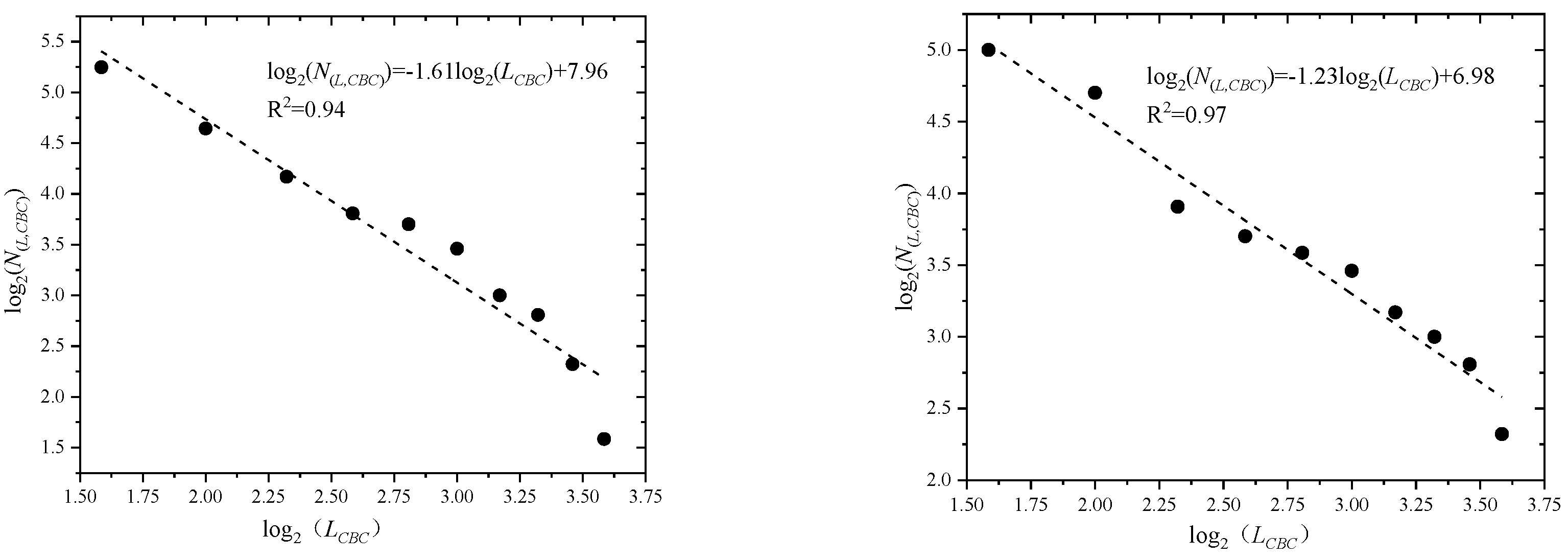

2.2. Calculation of Fractal Dimension

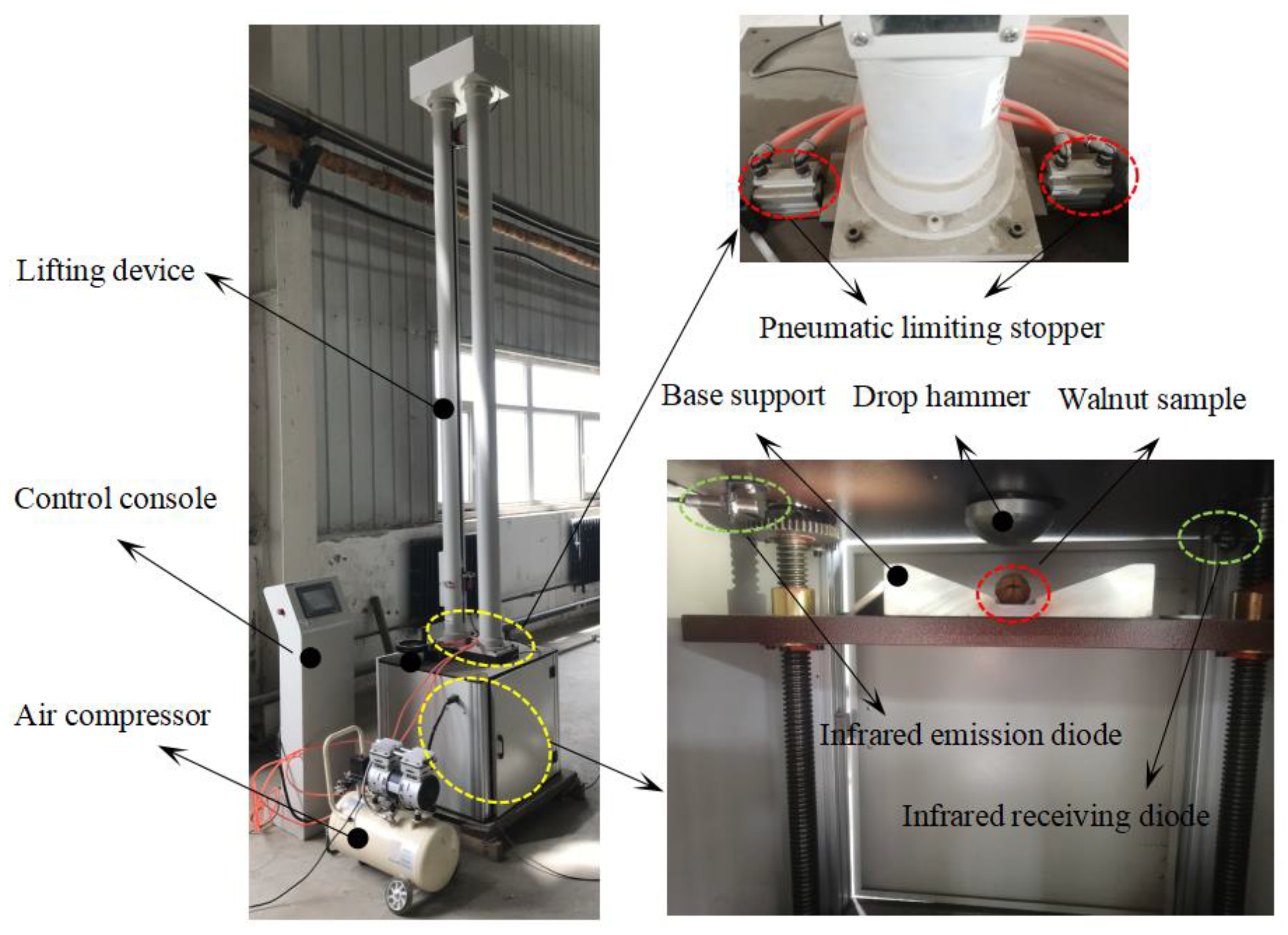

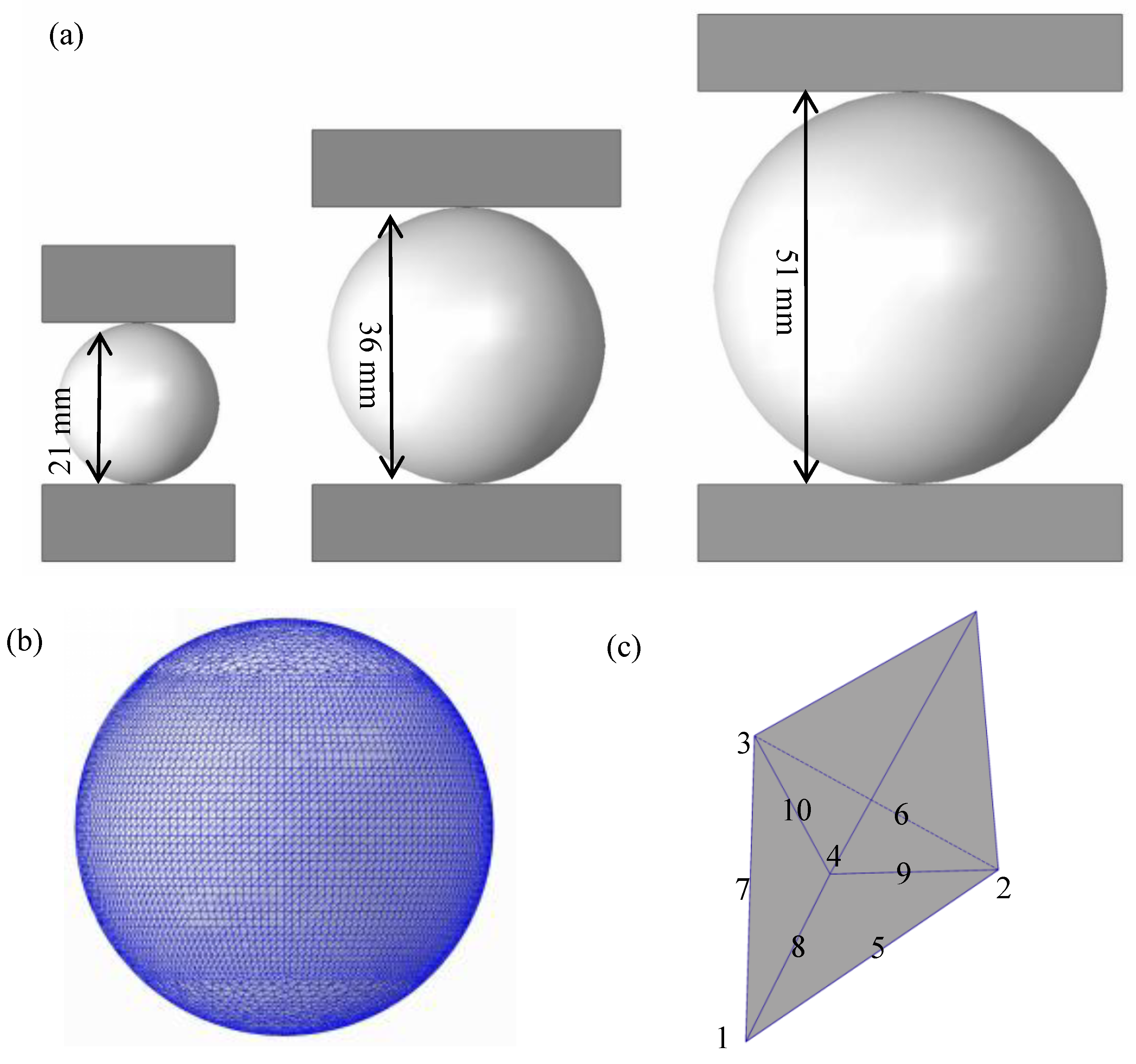

2.3. Drop Hammer Impact Experiment

3. Results and Discussion

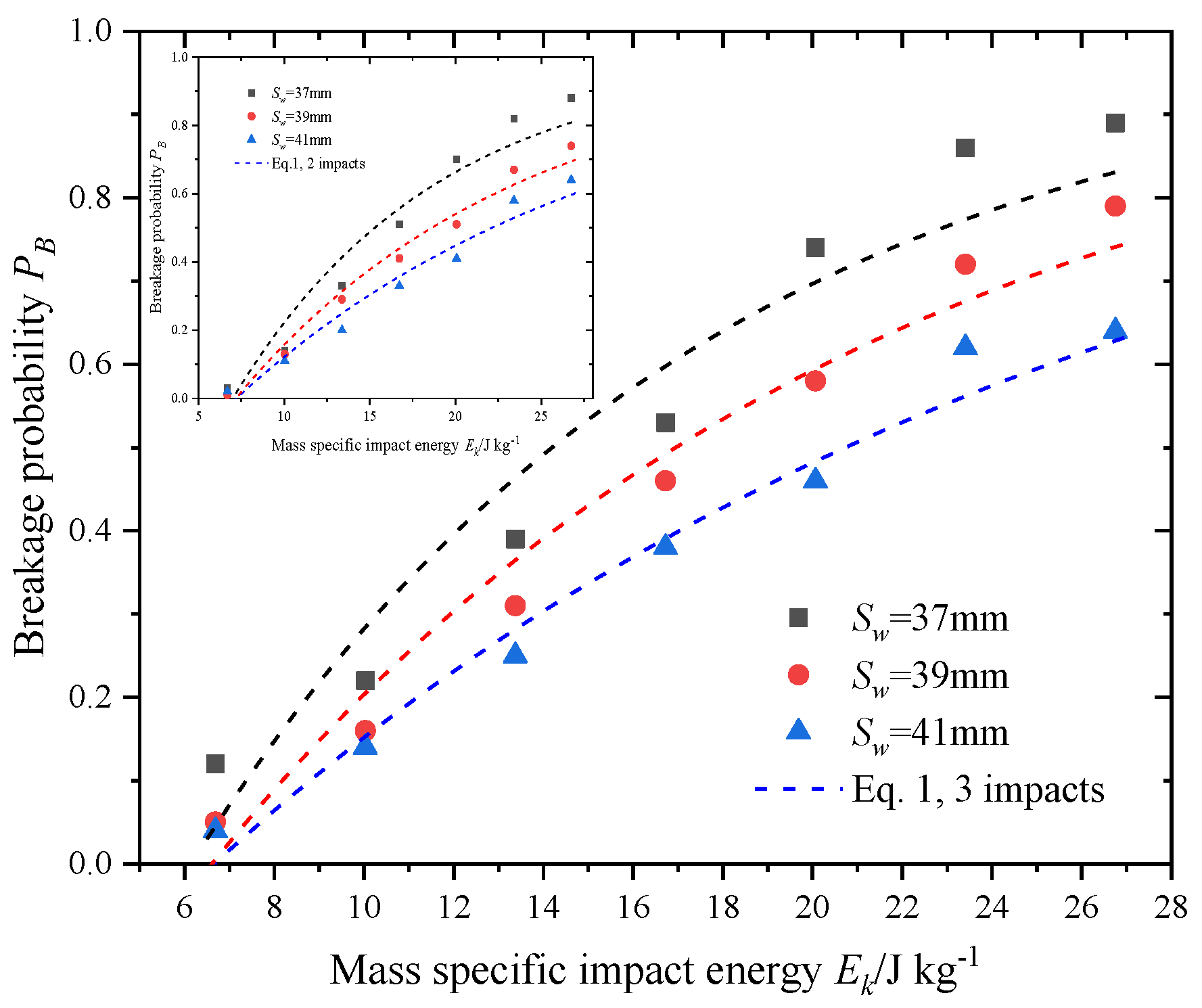

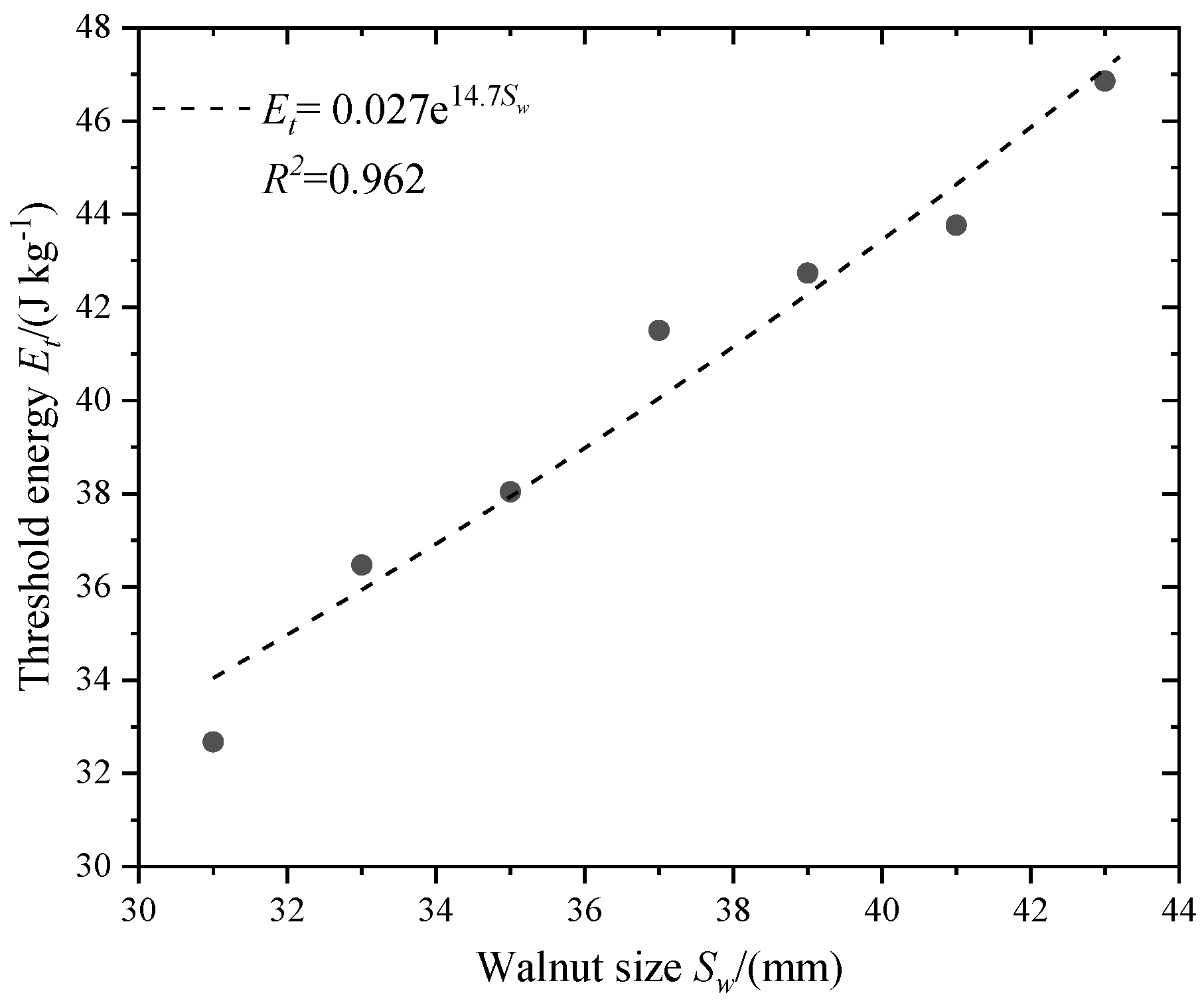

3.1. Crack Initiation Energy

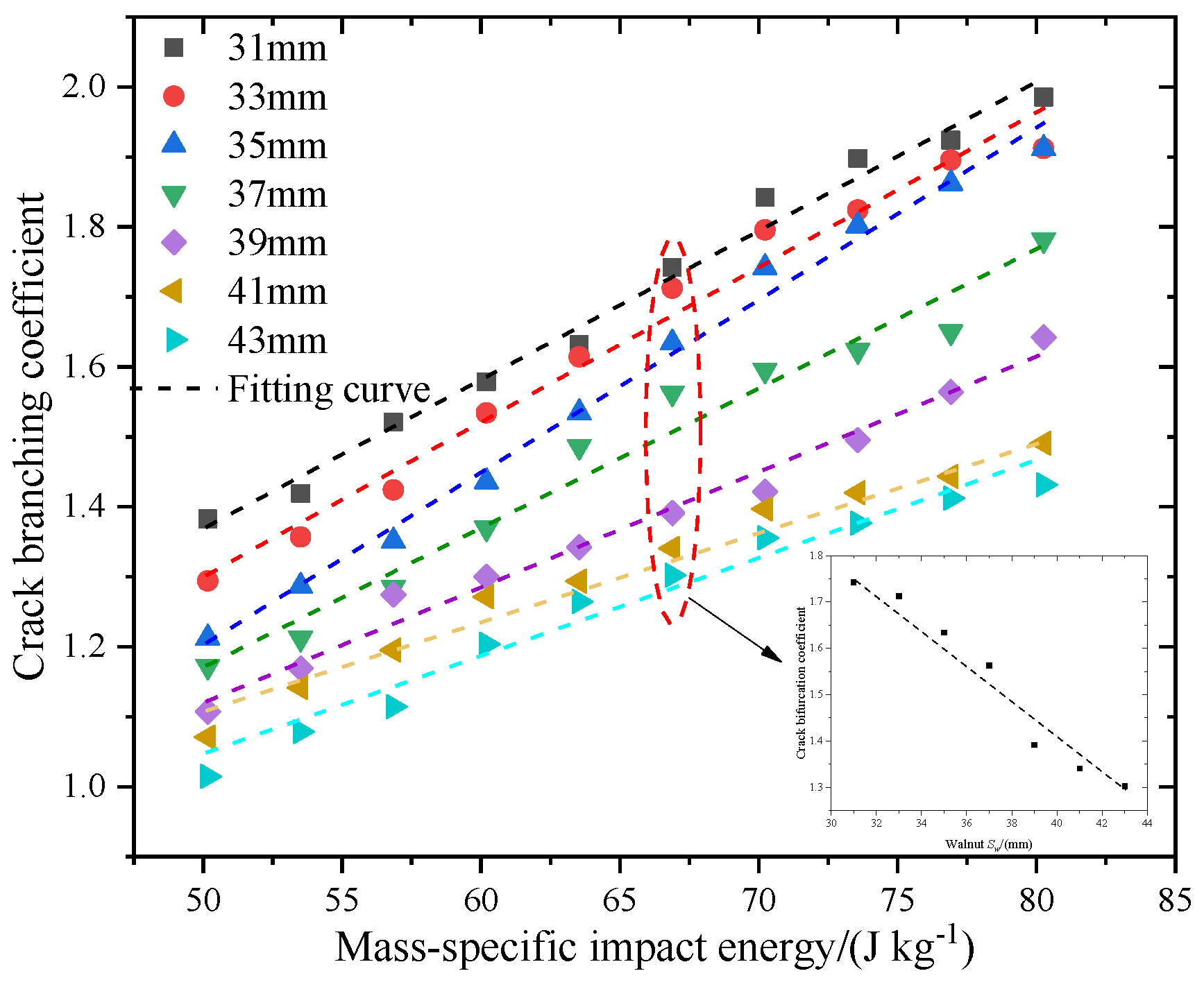

3.2. Crack Bifurcation Coefficient

3.3. Correlation and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Udayarajana, C.T.; Mohana, K.; Nisha, P. Tree nuts: Treasure mine for prebiotic and probiotic dairy free vegan products. Trends Food Sci. Technol. 2022, 124, 208–218. [Google Scholar] [CrossRef]

- Gama, T.; Wallace, H.M.; Trueman, S.J.; Hosseini-Bai, S. Quality and shelf life of tree nuts: A review. Sci. Hortic. 2019, 242, 116–126. [Google Scholar] [CrossRef]

- Chen, C.; Pan, Z.L. Postharvest processing of tree nuts: Current status and future prospects-a comprehensive review. Compr. Rev. Food Sci. F 2022, 21, 1702–1731. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Liu, H.L.; Zeng, Y.; Tang, Y.R.; Zhang, Z.G.; Che, J. Design and Performance Evaluation of a Multi-Point Extrusion Walnut Cracking Device. Agriculture 2022, 12, 1494. [Google Scholar] [CrossRef]

- Sharifian, F.; Derafshi, M.H. Mechanical Behavior of Walnut under Cracking Conditions. J. Appl. Sci. 2008, 8, 886–890. [Google Scholar] [CrossRef]

- Koyuncu, M.A.; Ekinci, K.; Savran, E. Cracking Characteristics of Walnut. Biosyst. Eng. 2004, 87, 305–311. [Google Scholar] [CrossRef]

- Man, X.L.; Li, L.; Zeng, Y.; Tang, Y.R.; Yang, J.L.; Fan, X.W.; Zhang, Y.C.; Zhang, H.; Su, G.G.; Wang, J.P. Mechanical impact characteristics of hollow shell granule based on continuous damage theory. Powder Technol. 2023, 429, 118946. [Google Scholar] [CrossRef]

- Rumpf, H. Physical aspects of comminution and new formulation of a law of comminution. Powder Technol. 1973, 7, 145–159. [Google Scholar] [CrossRef]

- Vogel, L.; Peukert, W. From single particle impact behaviour to modelling of impact mills. Chem. Eng. Sci. 2005, 60, 5164–5176. [Google Scholar] [CrossRef]

- Lecoq, O.; Guigon, P.; Pons, M. A grindability test to study the influence of the material processing on the impact behaviour. Powder Technol. 1999, 105, 21–29. [Google Scholar] [CrossRef]

- Li, L.; Mao, B.Q.; Zeng, Y.; Tang, Y.T.; Man, X.L.; Fan, X.W.; Zhang, Y.C.; Zhang, H. Experimental study on crack irregularity of hollow shell particle under impact loading. Powder Technol. 2023, 427, 118704. [Google Scholar] [CrossRef]

- Han, B.W.; Su, G.G.; Zeng, Y.; Yang, J.; Fan, X.W.; Zhang, Y.C.; Zhang, H.; Wang, J.F. FDEM investigation on the crack propagation characteristics of walnut shell under multi-contact loadings. Front. Mater. 2023, 10, 1293683. [Google Scholar] [CrossRef]

- Shen, Q.; Rao, Q.; Zhang, Q.; Li, Z.; Yi, W. A New Method for Predicting Double-Crack Propagation Trajectories of Brittle Rock. Int. J. Appl. Mech. 2021, 13, 2150026. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Xu, S. A practical testing approach to determine mode II fracture energy GIIF for concrete. Int. J. Fract. 2000, 105, 107–125. [Google Scholar] [CrossRef]

- Momber, A.W. Deformation and fracture of rocks loaded with spherical indenters. Int. J. Fract. 2004, 125, 263–279. [Google Scholar] [CrossRef]

- Bouzeboudja, H.; Melbouci, B.; Bouzeboudja, A. Experimental Study of Crushed Granular Materials by the Notion of Fractal Dimension in 2D and 3D. Geotech. Geol. Eng. 2022, 40, 2009–2031. [Google Scholar] [CrossRef]

- Delellis, D.P.; Mecholsky, N.A.; Mecholsky, J.J., Jr.; Quinn, G.D. A fractal analysis of crack branching in borosilicate glass. J. Am. Ceram. Soc. 2020, 103, 5283–5290. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, W.; Venkitasamy, C.; Khir, R.; McHugh, T.; Pan, Z. Walnut structure and its influence on the hydration and drying characteristics. Drying Technol. 2019, 38, 975–986. [Google Scholar] [CrossRef]

- Altuntas, E.; Özkan, Y. Physical and Mechanical Properties of Some Walnut (Juglans regia L.) Cultivars. Int. J. Food Eng. 2008, 4, 1–13. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, S.; Weng, L.; Li, Z.; Xu, L. Fractal analysis of cracking in a clayey soil under freeze-thaw cycles. Eng. Geol. 2016, 208, 93–99. [Google Scholar] [CrossRef]

- Rosa, A.F.; Arago, F.; Motta, L. Effects of particle size distribution and lithology on the resistance to breakage of ballast materials, Constr. Build. Mater. 2020, 267, 121015. [Google Scholar] [CrossRef]

- Zeng, Y.; Jia, F.G.; Meng, X.Y.; Han, Y.L.; Xiao, Y.W. The effects of friction characteristic of particle on milling process in a horizontal rice mill. Adv. Powder Technol. 2018, 29, 1280–1291. [Google Scholar] [CrossRef]

- Zeng, Y.; Mao, B.Q.; Li, A.Q.; Han, Y.L.; Jia, F.G. DEM investigation of particle flow in a vertical rice mill: Influence of particle shape and rotation speed. Powder Technol. 2022, 399, 117115. [Google Scholar] [CrossRef]

- Zeng, Y.; Jia, F.G.; Chen, P.Y.; Qiu, H.L.; Han, Y.L.; Meng, X.Y.; Xiao, Y.W. Effects of convex rib height on spherical particle milling in a lab-scale horizontal rice mill. Powder Technol. 2019, 342, 1–10. [Google Scholar] [CrossRef]

- Cherepanov, G.P.; Balankin, A.S.; Ivanova, V.S. Fractal fracture mechanics-a review. Eng. Fract. Mech. 1995, 51, 997–1033. [Google Scholar] [CrossRef]

- Zheng, G.M.; Zhao, J.; Li, L.; Cheng, X.; Wang, M. A fractal analysis of the crack extension paths in a Si3N4 ceramic tool composite. Int. J. Refract. Met. Hard Mater. 2015, 51, 160–168. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Mousavi, S.M.; Hamedi, M. Mechanical behaviour of Persian Walnut and its kernel under compression loading: An experimental and computational study. J. Food Process. Preserv. 2012, 36, 423–430. [Google Scholar] [CrossRef]

- Han, Y.L.; Li, G.R.; Jia, F.G.; Meng, X.Y.; Chu, Y.H.; Chen, P.Y.; Bai, S.G.; Zhao, H.W. Analysis of breakage behavior of rice under impact. Powder Technol. 2021, 394, 533–546. [Google Scholar] [CrossRef]

- Rajpoot, D.; Tandaiya, P.; Narayan, R.L.; Ramamurty, U. Size effects and failure regimes in notched micro-cantilever beam fracture. Acta Mater. 2022, 234, 118041. [Google Scholar] [CrossRef]

- Yu, H.; Zhou, B.; Zhu, L.; Yan, J.; Li, J.; Zhang, J. Mathematical law of size effect on the flexural property of ceramics. Ceram. Int. 2022, 48, 769–775. [Google Scholar] [CrossRef]

- Rozenblat, Y.; Grant, E.; Levy, A.; Kalman, H.; Tomas, J. Selection and breakage functions of particles under impact loads. Chem. Eng. Sci. 2012, 71, 56–66. [Google Scholar] [CrossRef]

- Capece, M.; Bilgili, E.; Davé, R.N. Formulation of a Physically Motivated Specific Breakage Rate Parameter for Ball Milling via the Discrete Element Method. AIChE J. 2014, 60, 2404–2415. [Google Scholar] [CrossRef]

- Liu, D.; Zhu, H.T.; Liu, F.; Cao, J.Q.; Ding, Z.J.; Zhang, Y. Buckling failure analysis of PMMA spherical pressure hull. Ocean Eng. 2022, 245, 110465. [Google Scholar] [CrossRef]

- Mecholsky, J.J., Jr.; Linhart, R.; Kwitkin, B.D. On the fractal nature of crack branching in MgF2. J. Mater. Res. 1998, 13, 3153–3159. [Google Scholar] [CrossRef]

- Jacquet, N.; Tardif, N.; Elguedj, T.; Garnier, C. Buckling of thick elasto-visco-plastic egg shells under external pressure: Experiments and bifurcation analysis. Int. J. Solids Struct. 2022, 257, 111591. [Google Scholar] [CrossRef]

- Hirata, R.; Ooi, A.; Tada, E.; Nishikata, A. Influence of the degree of saturation on carbon steel corrosion in soil. Corros. Sci. 2021, 189, 109568. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, Z.M.; Zhou, L.; Gao, W.T.; Dong, Y.Q.; Niu, C.Y.; Ai, T. Study the effect of circular hole on dynamic fracture properties of cracked PMMA specimen under impact loads. Int. J. Impact Eng. 2021, 156, 103948. [Google Scholar] [CrossRef]

- Kazarinov, N.A.; Bratov, V.A.; Morozov, N.F.; Petrov, Y.V.; Balandin, V.V.; Iqbald, M.A.; Gupta, N.K. Experimental and numerical analysis of PMMA impact fracture. Int. J. Impact Eng. 2020, 143, 103597. [Google Scholar] [CrossRef]

- Koya, O.A.; Faborode, M.O. Mathematical modelling of palm nut cracking based on Hertz’s theory. Biosyst. Eng. 2005, 91, 471–478. [Google Scholar] [CrossRef]

- Bobaru, F.; Zhang, G. Why do cracks branch? A peridynamic investigation of dynamic brittle fracture. Int. J. Fract. 2015, 196, 59–98. [Google Scholar] [CrossRef]

- Gao, J.; Bai, Y.; Fan, H.; Song, G.; Zou, X.; Zheng, Y.; He, X. Phase-field simulation of microscale crack propagation/deflection in SiCf/SiC composites with weak interphase. J. Am. Ceram. Soc. 2023, 106, 4877–4890. [Google Scholar] [CrossRef]

| Walnut Size/(mm) | Length /(mm) | Width /(mm) | Thickness /(mm) | Sphericity | Average Mass of Walnut Shell/(g) |

|---|---|---|---|---|---|

| 31 | 35.76 ± 1.16 | 29.65 ± 0.96 | 30.22 ± 1.13 | 0.91 ± 0.08 | 3.57 |

| 33 | 36.73 ± 1.08 | 30.8 ± 0.98 | 32.06 ± 1.25 | 0.93 ± 0.1 | 3.95 |

| 35 | 39.94 ± 1.08 | 33.12 ± 0.87 | 34.28 ± 1.13 | 0.92 ± 0.11 | 4.19 |

| 37 | 40.16 ± 1.16 | 34.76 ± 1.03 | 35.68 ± 1.2 | 0.94 ± 0.17 | 4.46 |

| 39 | 41.92 ± 1.01 | 36 ± 0.75 | 37.78 ± 1.18 | 0.93 ± 0.17 | 4.99 |

| 41 | 43.57 ± 1.21 | 39.74 ± 1.11 | 39.78 ± 1.21 | 0.94 ± 0.09 | 5.35 |

| 43 | 43.57 ± 1.21 | 43.27 ± 1.07 | 43.27 ± 1.07 | 0.95 ± 0.09 | 5.81 |

| Bifurcation experiment (J kg−1) | 50.162 | 53.506 | 56.85 | 60.195 | 63.539 | 66.883 | 70.227 | 73.571 | 76.915 | 80.26 |

| Cracking experiment (J kg−1) | 6.688 | 10.032 | 13.376 | 16.72 | 20.065 | 23.409 | 26.753 | |||

| Plexiglas Properties | Values | |

|---|---|---|

| Density | 1.2 × 103 (kg m3) | |

| Elasticity modulus | 3100 (MPa) | |

| Poisson ratio | 0.37 | |

| Brittle cracking | Direct stress after cracking | Direct cracking strain |

| 36.8 | 0 | |

| 34.1 | 3.33 × 10−6 | |

| 21.1 | 6.67 × 10−6 | |

| Direct cracking failure strain | 1 × 10−6 | |

| Brittle shear | Shear retention factor | Crack opening strain |

| 1 | 0 | |

| 0.5 | 0.001 | |

| 0.25 | 0.002 | |

| 0.125 | 0.003 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Man, X.; Li, L.; Zhang, H.; Lan, H.; Fan, X.; Tang, Y.; Zhang, Y. Study on the Relationship between Crack Initiation and Crack Bifurcation in Walnut Shells Based on Energy. Agriculture 2024, 14, 69. https://doi.org/10.3390/agriculture14010069

Man X, Li L, Zhang H, Lan H, Fan X, Tang Y, Zhang Y. Study on the Relationship between Crack Initiation and Crack Bifurcation in Walnut Shells Based on Energy. Agriculture. 2024; 14(1):69. https://doi.org/10.3390/agriculture14010069

Chicago/Turabian StyleMan, Xiaolan, Long Li, Hong Zhang, Haipeng Lan, Xiuwen Fan, Yurong Tang, and Yongcheng Zhang. 2024. "Study on the Relationship between Crack Initiation and Crack Bifurcation in Walnut Shells Based on Energy" Agriculture 14, no. 1: 69. https://doi.org/10.3390/agriculture14010069

APA StyleMan, X., Li, L., Zhang, H., Lan, H., Fan, X., Tang, Y., & Zhang, Y. (2024). Study on the Relationship between Crack Initiation and Crack Bifurcation in Walnut Shells Based on Energy. Agriculture, 14(1), 69. https://doi.org/10.3390/agriculture14010069