Investigation of Collision Damage Mechanisms and Reduction Methods for Pod Pepper

Abstract

1. Introduction

2. Materials and Methods

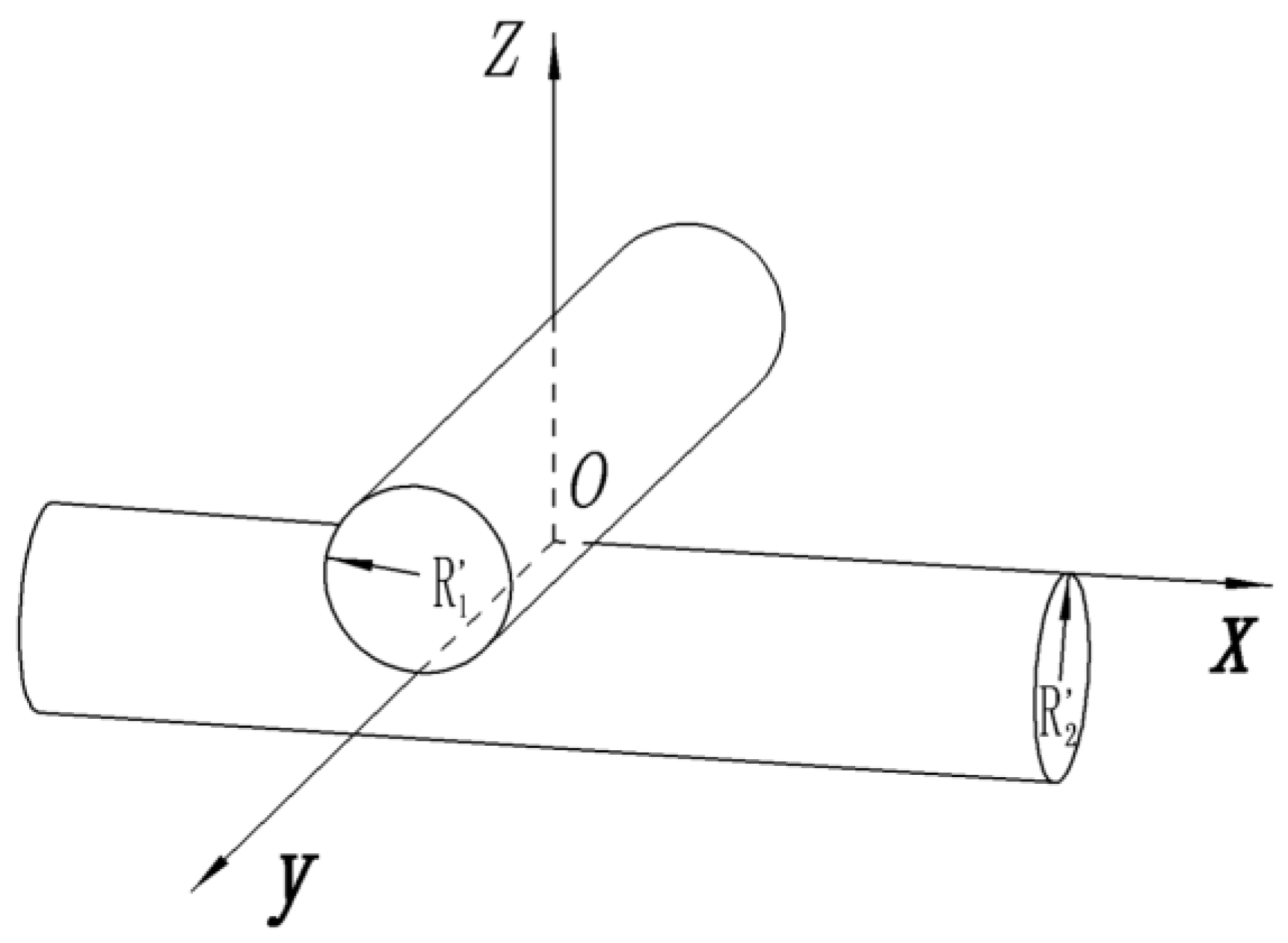

2.1. Mechanical Analysis of Contact between Pod Pepper and Comb Fingers

- a: long axis of elliptical contact area (mm);

- b: short axis of elliptical contact area (mm);

- δ: compression amount;

- p0: maximum stress (N);

- ∑ρ: sum of principal curvatures; .

- E*: equivalent elastic modulus;

- : elastic modulus and Poisson’s ratio of pod pepper and comb fingers;

- Define .

- V: linear speed of comb fingers (m s−1);

- Vp: instantaneous velocity during contact between pod pepper and comb fingers (m s−1).

- Ft: instantaneous squeezing force during contact process;

- m: due to , ;

- m1: quality of comb fingers (g);

- mp: quality of pod pepper (g).

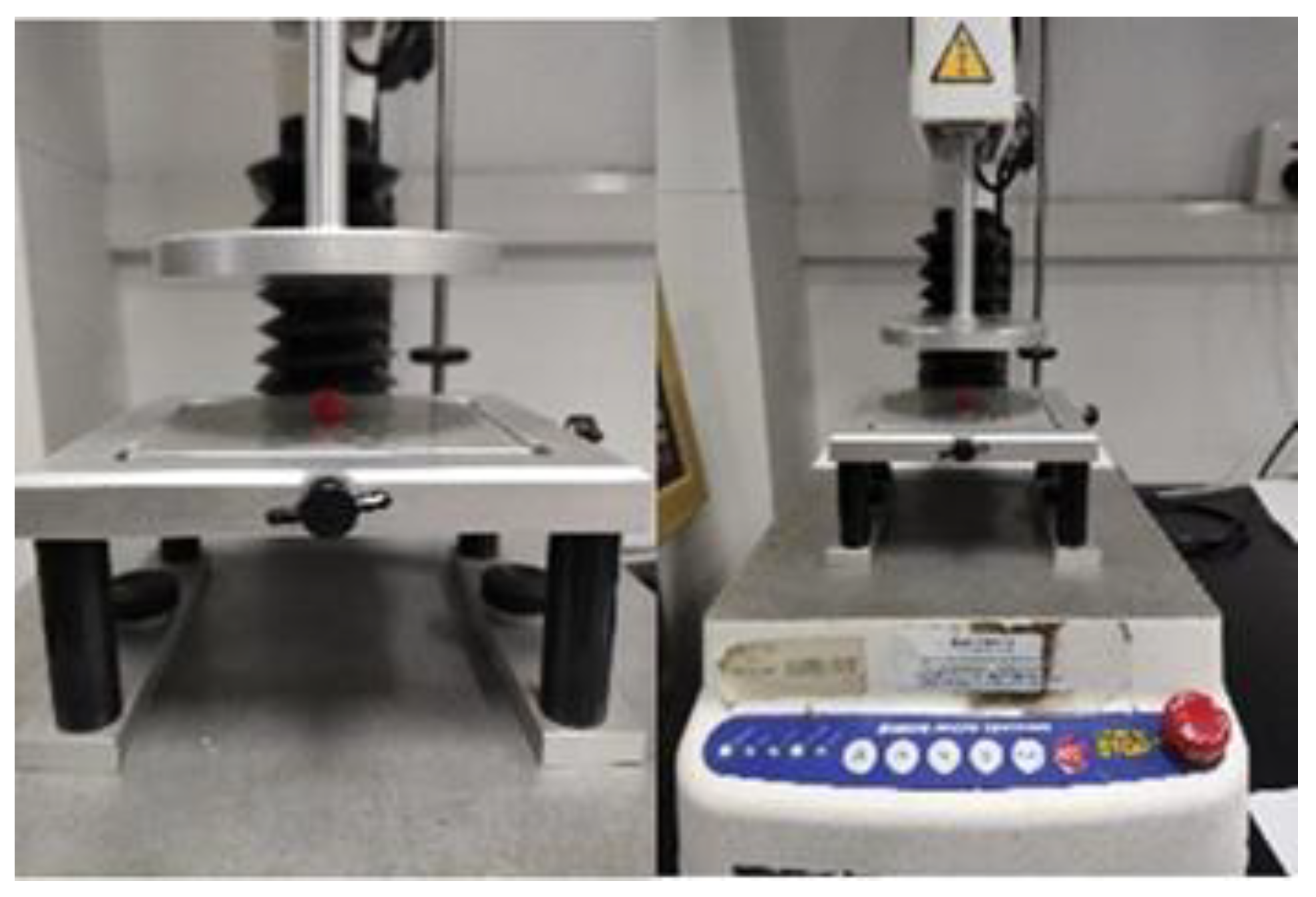

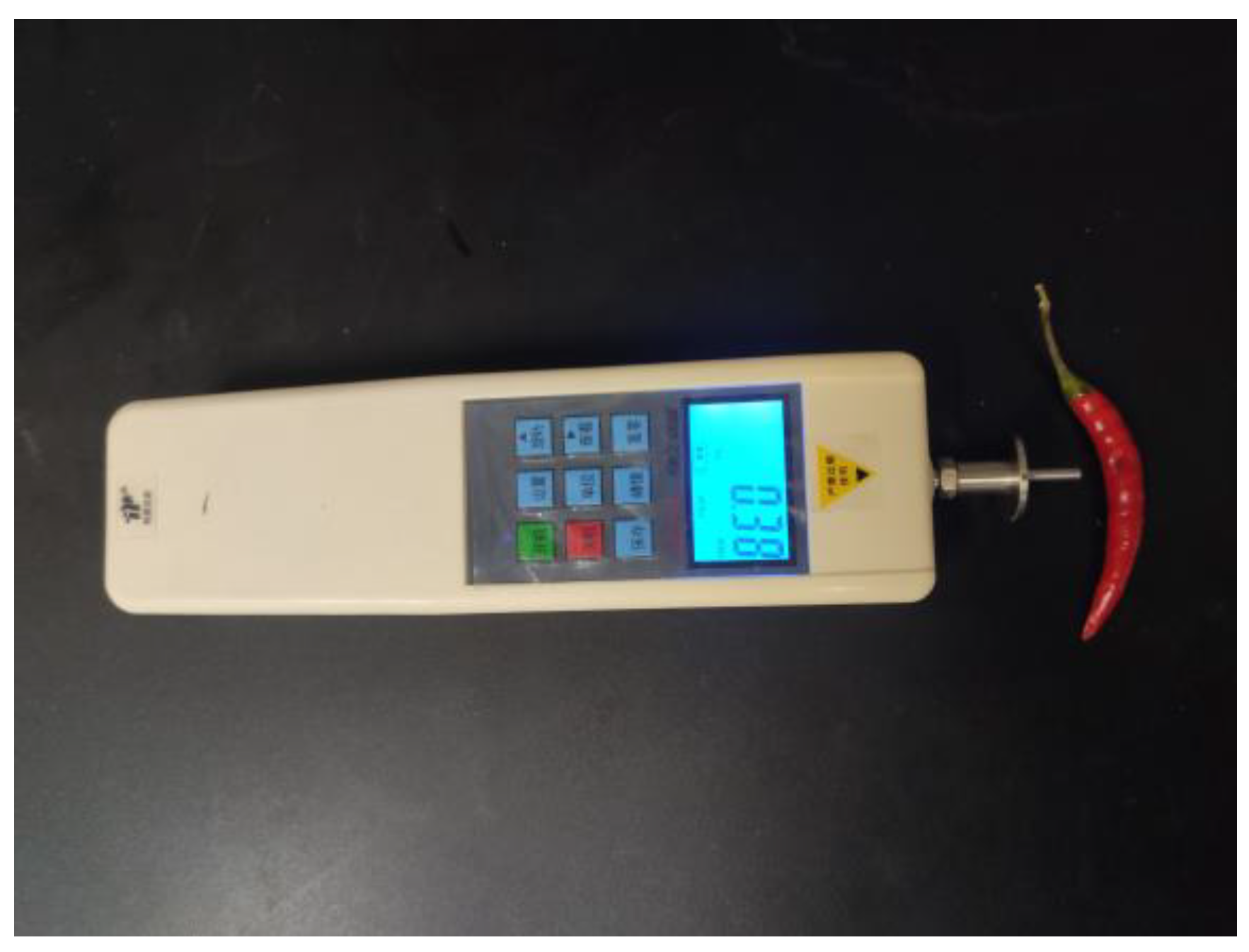

2.2. Tests on the Intrinsic Parameters of Pod Pepper

- E: elastic modulus of pod pepper (MPa);

- σ: axial compressive stress of pod pepper;

- ε: axial strain of pod pepper.

- W: moisture content of pod pepper (%);

- m1: quality of pod pepper before testing (g);

- m2: quality of pod pepper after testing (g).

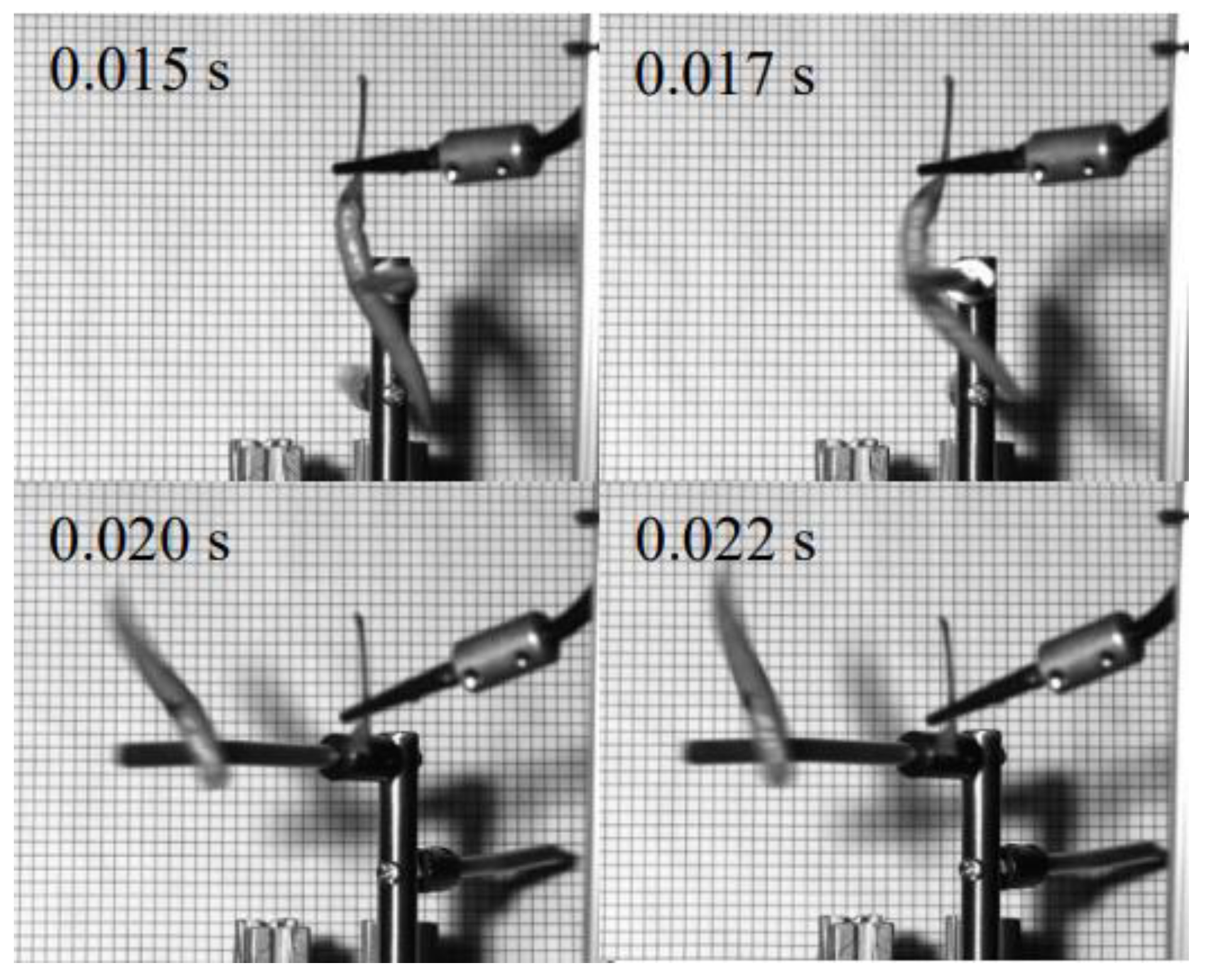

2.3. Picking Speed Measurement

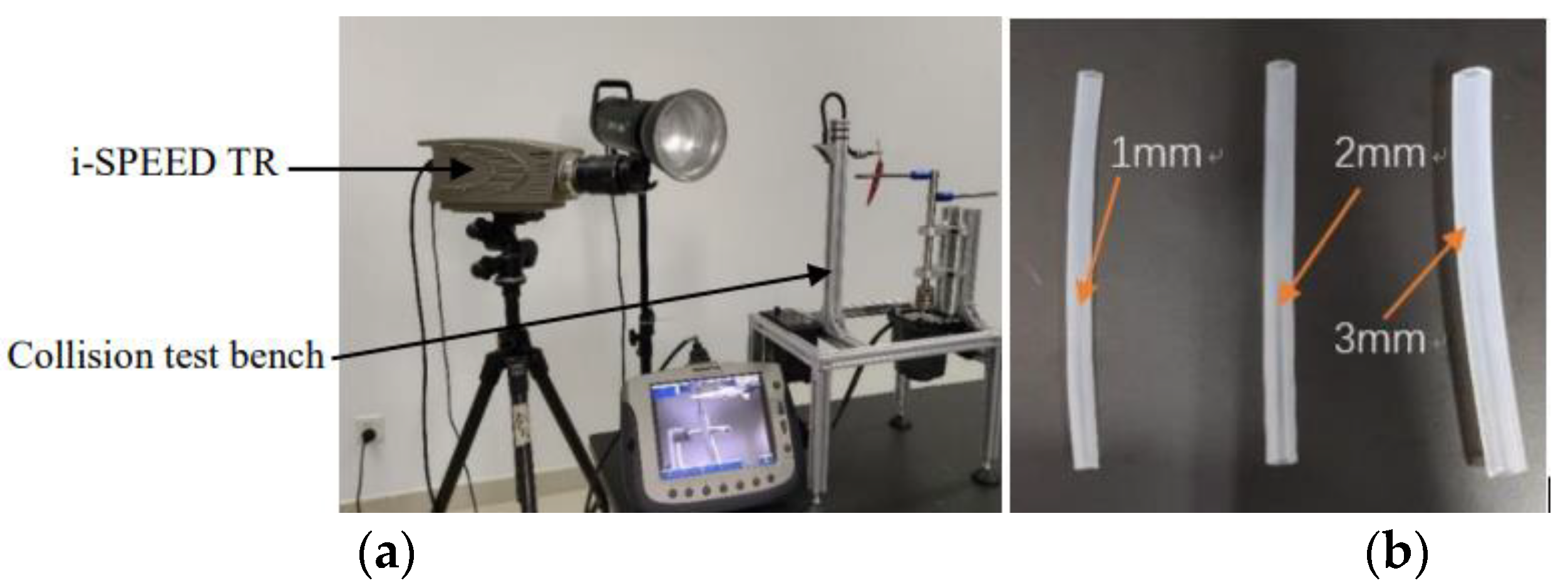

2.4. Crash Test of Pod Pepper

2.4.1. Theoretical Results Verification Test

- ηp: damage rate of the pod pepper (%);

- ηp: shedding rate at the fruit stalk (%);

- m: total mass of pod pepper specimen (g);

- m1: quality of broken and torn pilchards (g);

- m2: quality of pod pepper bruises (g);

- m3: quality of peeling at the stem of pod pepper fruit (g).

2.4.2. Material Rigidity–Flexibility Coupling Test

3. Results and Discussion

3.1. Theoretical Results Analysis

3.2. Analysis of Results for Intrinsic Parameters

3.3. Analysis of Crash Velocity Results for Pod Pepper

3.4. Analysis of Crash Test Results of Pod Pepper

3.4.1. Analysis of Theoretical Validation Test Results

3.4.2. Analysis of the Results of the Material Rigidity–Flexibility Coupling Test

4. Conclusions

- (1)

- Substituting each parameter of the test sample of pod pepper into the critical velocity function, V0 = 11.487 m s−1 was obtained.

- (2)

- The average moisture content of pod pepper was 75.22%, 70.868%, and 65.943%, while the average values of its elastic modulus at the corresponding moisture content were 2.682 MPa, 2.115 MPa, and 1.712 MPa. It can be seen that the elastic modulus of pod pepper increased with the increase in moisture content.

- (3)

- Research on hoses of different thicknesses found that the speed of pod pepper collisions gradually decreased with the increase in the thickness of the flexible hose. According to the experimental results, the average values of the collision speed corresponding to different thicknesses of hose are as follows: no hose (7.656 m s−1), 1 mm flexible hose (6.226 m s−1), 2 mm hose (5.626 m s−1), 3 mm hose (4.66 m s−1).

- (4)

- The reliability of the theoretical results was verified by the crash test bench. In the research results, the impact of three factors on the damage rate to the pod peppers is listed in descending order: rotational speed, hose thickness, and moisture content. The impact of three factors on the rate of stem shedding in pod chili peppers, from highest to lowest, is as follows: rotational speed, thickness of the hose, and moisture content in pod chili peppers. This study determined the optimal experimental parameters for the harvesting process of the pod pepper, with a rotational speed of 705.04 rpm, a hose thickness of 3 mm, and a moisture content of 71.27%. The research results are of great significance for improving the structural parameters and motion parameters of the pod pepper harvester and increasing the income of farmers in planting pod peppers. These results are also of great significance for in-depth research on the pod pepper-harvesting device in the future.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, Q.; Xin, Z.; Kong, L.; Wang, X.; Yang, X.; He, W. Current situation of pepper industry development and breeding countermeasures in China. J. China Agric. Univ. 2023, 28, 82–95. [Google Scholar]

- Azlan, A.; Sultana, S.; Huei, C.S.; Razman, M.R. Antioxidant, Anti-Obesity, Nutritional and Other Beneficial Effects of Different Chili Pepper: A Review. Molecules 2022, 27, 898. [Google Scholar] [CrossRef] [PubMed]

- Duan, Y.; Kong, L.; Cheng, Y. Tine drum pepper picking device picking hot pepper mechanical damage characteristic and mechanism. Trans. Chin. Soc. Agric. Mach. 2014, 35, 79–82. [Google Scholar] [CrossRef]

- Nam, J.N.; Byun, J.; Kim, T.; Kim, M.; Kim, D. Measurement of Mechanical and Physical Properties of Pepper for Particle Behavior Analysis. J. Biosyst. Eng. 2018, 43, 173–184. [Google Scholar]

- Kim, T.H.; Kim, D.C.; Cho, Y. Performance Comparison and Evaluation of Two Small Chilli Pepper Harvester Prototypes That Attach to Walking Cultivators. Appl. Sci. 2020, 10, 2570. [Google Scholar] [CrossRef]

- Funk, P.A.; Walker, S.J. Evaluation of Five Green Chile Cultivars Utilizing Five Different Harvest Mechanisms. Appl. Eng. Agric. 2010, 26, 955–964. [Google Scholar] [CrossRef]

- Palau, E.; Torregrosa, A. Mechanical harvesting of Paprika peppers in Spain. J. Agric. Eng. Res. 1997, 66, 195–201. [Google Scholar] [CrossRef]

- Cheng, Y.; Hu, S.; Yuan, Y. Research of comb-type picking device for chilli peppers. In Proceedings of the 2012 International Academic Annual Conference of China Agricultural Machinery Society, Hangzhou, China, 20 October 2012; pp. 942–948. [Google Scholar]

- Qin, X.; Lei, J.; Chen, Y. Design and research on key components of a novel self-propelled chili pepper harvester. Adv. Mater. Res. 2012, 468–471, 794–797. [Google Scholar] [CrossRef]

- Du, C.; Han, D.; Song, Z.; Chen, Y.; Wang, X. Calibration of contact parameters for complex shaped fruits based on discrete element method: The case of pod pepper (Capsicum annuum). Biosyst. Eng. 2023, 226, 43–54. [Google Scholar] [CrossRef]

- Xu, L.; Li, Y. Critical speed of impact damage on a rice kernel. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2009, 40, 54–57. [Google Scholar]

- Cao, M.; Gao, X.; Wang, J.; You, Z.; Wu, H.; Wang, G. Research on mechanical properties and threshing-impact damage of Astragalus sinicus seeds. J. Chin. Agric. Mech. 2022, 43, 77. [Google Scholar] [CrossRef]

- Liang, Z.; Huang, Y.; Li, D.; Wada, M.E. Parameter determination of a viscoelastic–plastic contact model for potatoes during transient collisions. Biosyst. Eng. 2023, 234, 156–171. [Google Scholar] [CrossRef]

- Yuan, X.; Yang, S.; Jin, R.; Zhao, L.; Dao, E.; Zheng, N.; Fu, W. Design and experiment of double helix pair roller pepper harvesting device. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1. [Google Scholar] [CrossRef]

- Wall, M.M.; Walker, S.; Wall, A.D.; Hughs, E.; Phillips, R. Yield and quality of machine harvested red chile peppers. HortTechnology 2003, 13, 296–302. [Google Scholar] [CrossRef]

- Kang, K.-S.; Park, H.-S.; Park, S.-J.; Kang, Y.-S.; Kim, D.-C. Study on Optimal Working Conditions for Picking Head of Self-Propelled Pepper Harvester by Factorial Test. J. Biosyst. Eng. 2016, 41, 12–20. [Google Scholar] [CrossRef]

- Stanly, N.M.; Jayan, P.R.; Malkani, P.; Wankhade, R.D. Designe and Development and Evaluation of Pepper Harvester. J. AgriSearch 2020, 6, 82–85. [Google Scholar] [CrossRef]

- Gupta, C.; Tewari, V.K.; Machavaram, R. Evaluation of a Laboratory-based Prototype of a Comb-type Picking Mechanism for Chili Pepper Harvester. J. Biosyst. Eng. 2022, 47, 69–78. [Google Scholar] [CrossRef]

- Popov, V.L. Contact mechanics and friction: Physical principles and applications, second edition. In Contact Mechanics and Friction: Physical Principles and Applications, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Shull, K.R. Elastomer Surfaces, Contact Mechanics Testing of Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Eds.; Elsevier: Oxford, UK, 2001; pp. 2449–2451. [Google Scholar]

- Sitkei, G. Mechanics of Agricultural Materials; Elsevier Science Publishers: Amsterdam, The Netherlands, 1986. [Google Scholar]

- Deng, S.; Jia, Q.; Xue, J. Principles of Rolling Bearing Design, 2nd ed.; China Standard Press: Beijing, China, 2014; Chapter 5. [Google Scholar]

- Physical properties of plant and animal materials. J. Agric. Eng. Res. 1968, 13, 379. [CrossRef]

- Li, Y.; Wang, X.; Xu, L.; Chen, J. Study on compression properties of rice grains. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2007, 38, 56–59. [Google Scholar]

- Bazaria, B.; Kumar, P. Optimization of spray drying parameters for beetroot juice powder using response surface methodology (RSM). J. Saudi Soc. Agric. Sci. 2018, 17, 408–415. [Google Scholar] [CrossRef]

| Item | Proportion (%) | Average Ratio (%) | Variance | Modulus of Elasticity (MPa) | Average Ratio (MPa) | Variance |

|---|---|---|---|---|---|---|

| 1 | 73.791 | 75.220 | 0.6727 | 2.652 | 2.682 | 0.0152 |

| 74.907 | 2.538 | |||||

| 75.500 | 2.582 | |||||

| 75.775 | 2.763 | |||||

| 76.135 | 2.876 | |||||

| 2 | 70.242 | 70.868 | 0.55752 | 1.936 | 2.115 | 0.0127 |

| 71.328 | 2.182 | |||||

| 70.828 | 2.103 | |||||

| 69.932 | 2.079 | |||||

| 72.011 | 2.275 | |||||

| 3 | 66.174 | 65.943 | 0.6615 | 1.746 | 1.712 | 0.0103 |

| 65.588 | 1.579 | |||||

| 67.058 | 1.791 | |||||

| 64.613 | 1.607 | |||||

| 66.284 | 1.835 |

| Item | 1 | 2 | 3 | 4 | 5 | Averages | Variance |

|---|---|---|---|---|---|---|---|

| Without hose | 7.92 | 7.36 | 6.47 | 8.21 | 8.32 | 7.656 | 0.462 |

| 1 mm hose | 6.03 | 5.72 | 7.00 | 6.48 | 5.90 | 6.226 | 0.213 |

| 2 mm hose | 5.16 | 6.49 | 5.82 | 5.91 | 4.75 | 5.626 | 0.370 |

| 3 mm hose | 4.80 | 5.24 | 3.85 | 4.53 | 4.88 | 4.660 | 0.215 |

| RPM | ηp (%) | Averages (%) | Variance | ηt (%) | Averages (%) | Variance |

|---|---|---|---|---|---|---|

| 550 | 1.386 | 1.405 | 0.0104 | 76.530 | 77.877 | 1.1565 |

| 1.290 | 79.162 | |||||

| 1.538 | 77.940 | |||||

| 600 | 1.681 | 1.611 | 0.0031 | 82.407 | 84.744 | 2.9121 |

| 1.544 | 85.391 | |||||

| 1.609 | 87.434 | |||||

| 650 | 1.936 | 1.952 | 0.0081 | 86.237 | 88.243 | 2.5472 |

| 1.852 | 88.350 | |||||

| 2.070 | 90.142 | |||||

| 700 | 3.268 | 3.224 | 0.0490 | 94.38 | 93.357 | 0.2573 |

| 2.934 | 93.258 | |||||

| 3.471 | 93.357 | |||||

| 750 | 6.493 | 6.015 | 0.1270 | 95.718 | 95.981 | 0.2650 |

| 5.916 | 95.524 | |||||

| 5.637 | 96.700 | |||||

| 800 | 7.934 | 8.317 | 0.0986 | 94.490 | 95.985 | 1.1464 |

| 8.316 | 96.524 | |||||

| 8.703 | 96.941 | |||||

| 850 | 10.317 | 10.128 | 0.0272 | 97.138 | 96.714 | 0.2980 |

| 10.152 | 97.060 | |||||

| 9.915 | 95.943 | |||||

| 900 | 11.749 | 12.379 | 0.2882 | 95.726 | 96.779 | 0.8505 |

| 12.327 | 96.640 | |||||

| 13.061 | 97.972 |

| Item | RPM | Hose Thickness (mm) | Water Content (%) | ηp (%) | ηt (%) |

|---|---|---|---|---|---|

| 1 | 700 | 1 | 70.868 | 2.34 | 90.93 |

| 2 | 750 | 2 | 70.868 | 2.63 | 95.14 |

| 3 | 800 | 2 | 75.22 | 5.81 | 95.94 |

| 4 | 700 | 3 | 70.868 | 1.23 | 88.31 |

| 5 | 700 | 2 | 75.22 | 1.98 | 88.75 |

| 6 | 700 | 2 | 65.943 | 1.78 | 89.96 |

| 7 | 750 | 3 | 75.22 | 2.35 | 94.08 |

| 8 | 800 | 3 | 70.868 | 3.43 | 96.23 |

| 9 | 750 | 2 | 70.868 | 2.47 | 95.33 |

| 10 | 800 | 2 | 65.943 | 4.08 | 97.83 |

| 11 | 750 | 2 | 70.868 | 2.74 | 94.08 |

| 12 | 750 | 2 | 70.868 | 2.18 | 95.29 |

| 13 | 750 | 1 | 75.22 | 3.94 | 94.91 |

| 14 | 750 | 1 | 65.943 | 3.26 | 96.82 |

| 15 | 750 | 2 | 70.868 | 2.57 | 95.63 |

| 16 | 800 | 1 | 70.868 | 6.17 | 96.52 |

| 17 | 750 | 3 | 65.943 | 2.05 | 95.38 |

| Source | Sum of Squares | DF | F-Value | p-Value |

|---|---|---|---|---|

| Model | 28.58 | 9 | 51.69 | <0.0001 |

| RPM | 16.27 | 1 | 264.82 | <0.0001 |

| Hose Thickness | 5.07 | 1 | 82.50 | <0.0001 |

| Water Content | 0.64 | 1 | 10.39 | 0.00146 |

| Residual | 0.4301 | 7 | ||

| Lack of Fit | 0.2490 | 3 | 1.83 | 0.2812 |

| Pure Error | 0.1811 | 4 | ||

| Cor Total | 29.01 | 16 |

| Model | Sum of Squares | DF | F-Value | p-Value |

|---|---|---|---|---|

| RPM | 131.20 | 9 | 58.17 | <0.0001 |

| Hose Thickness | 98.84 | 1 | 394.41 | <0.0001 |

| Water Content | 3.43 | 1 | 13.69 | 0.0077 |

| Residual | 4.91 | 1 | 19.58 | 0.0031 |

| Lack of Fit | 1.75 | 7 | ||

| Pure Error | 0.3425 | 3 | 0.3235 | 0.8096 |

| Cor Total | 1.41 | 4 | ||

| Model | 132.95 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; He, B.; Han, D.; Zhang, H.; Wang, X.; Chen, Y.; Chen, X.; Zhao, R.; Li, G. Investigation of Collision Damage Mechanisms and Reduction Methods for Pod Pepper. Agriculture 2024, 14, 117. https://doi.org/10.3390/agriculture14010117

Wang G, He B, Han D, Zhang H, Wang X, Chen Y, Chen X, Zhao R, Li G. Investigation of Collision Damage Mechanisms and Reduction Methods for Pod Pepper. Agriculture. 2024; 14(1):117. https://doi.org/10.3390/agriculture14010117

Chicago/Turabian StyleWang, Gaoliang, Binghua He, Dianlei Han, He Zhang, Xinzhong Wang, Yongcheng Chen, Xuegeng Chen, Rongqiang Zhao, and Guoyu Li. 2024. "Investigation of Collision Damage Mechanisms and Reduction Methods for Pod Pepper" Agriculture 14, no. 1: 117. https://doi.org/10.3390/agriculture14010117

APA StyleWang, G., He, B., Han, D., Zhang, H., Wang, X., Chen, Y., Chen, X., Zhao, R., & Li, G. (2024). Investigation of Collision Damage Mechanisms and Reduction Methods for Pod Pepper. Agriculture, 14(1), 117. https://doi.org/10.3390/agriculture14010117