Study on Agricultural Machinery-Load-Testing Technology and Equipment Based on Six-Dimensional Force Sensor

Abstract

:1. Introduction

2. Materials and Methods

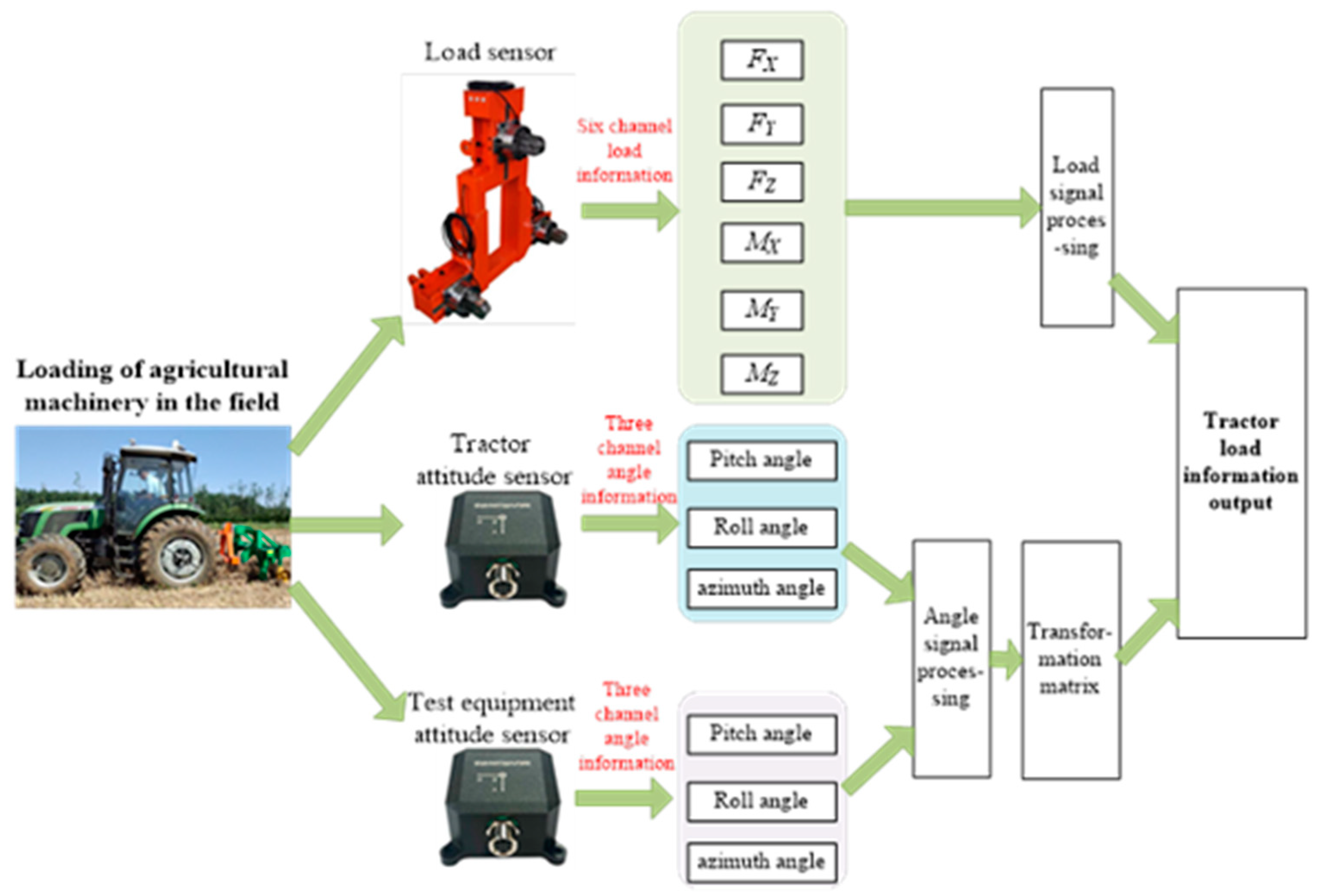

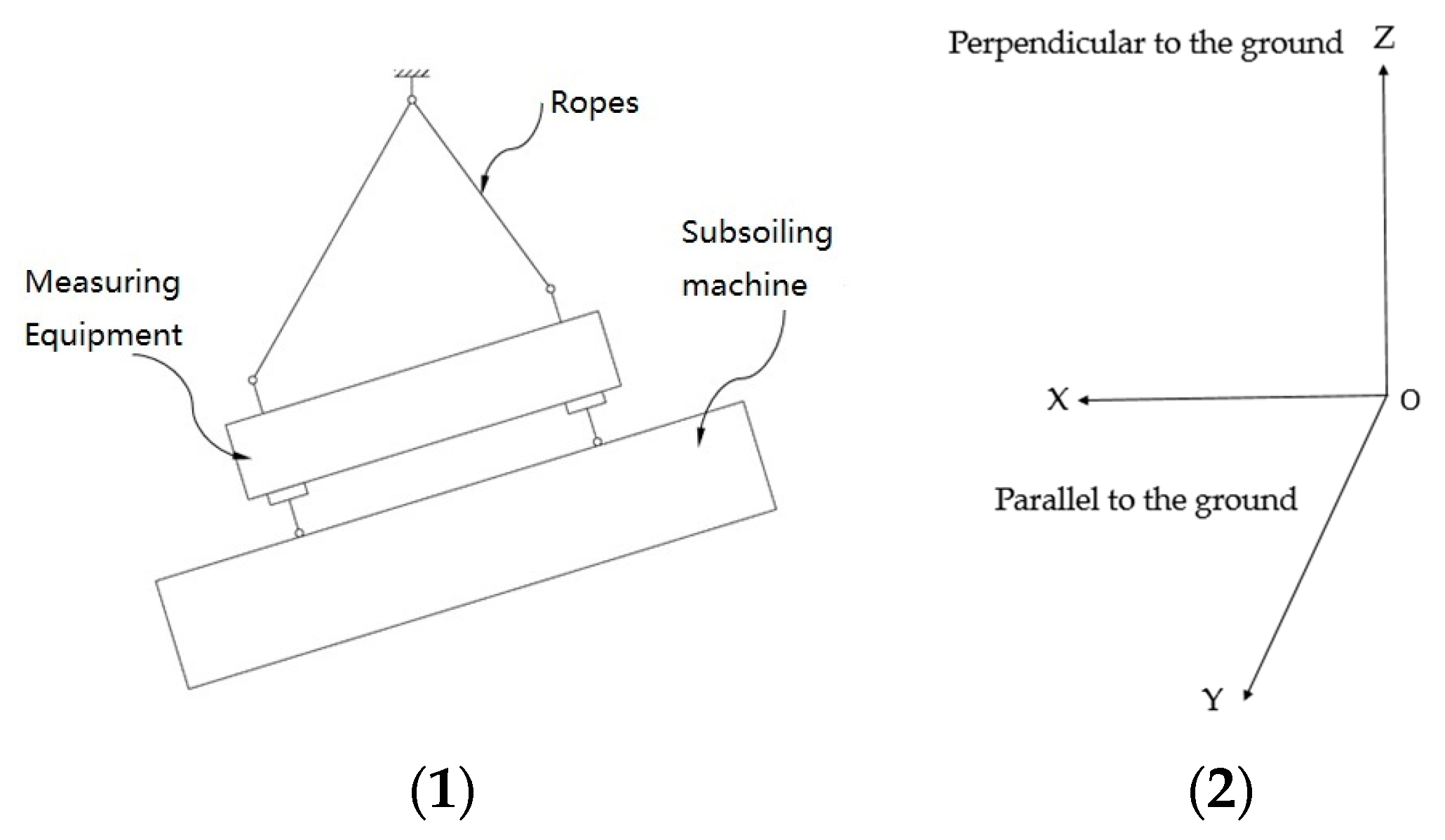

2.1. Design of Load Test Scheme for Whole Machine Operation

2.1.1. Test Procedure Introduction

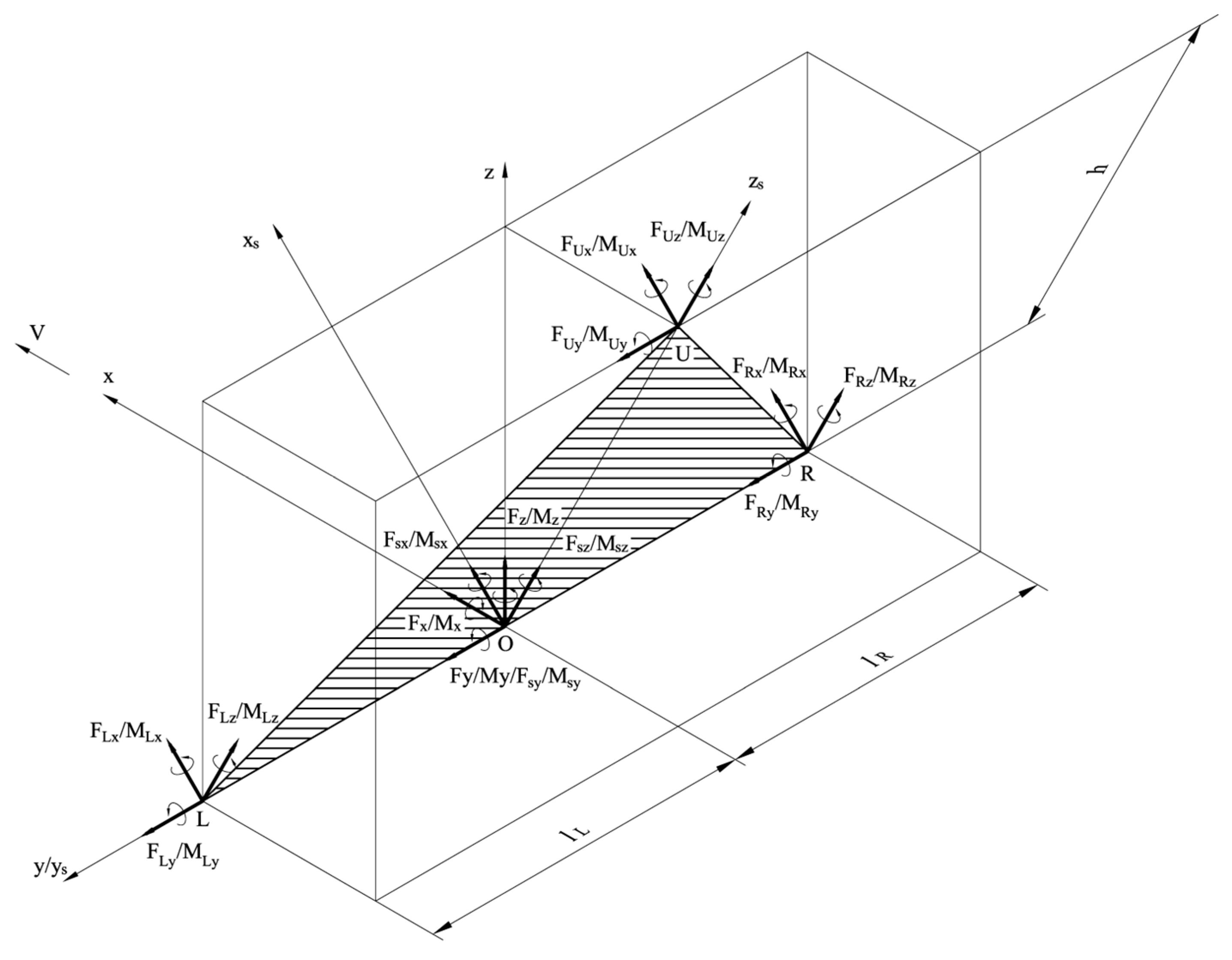

2.1.2. Test Device Connection and Spatial Matrix Derivation

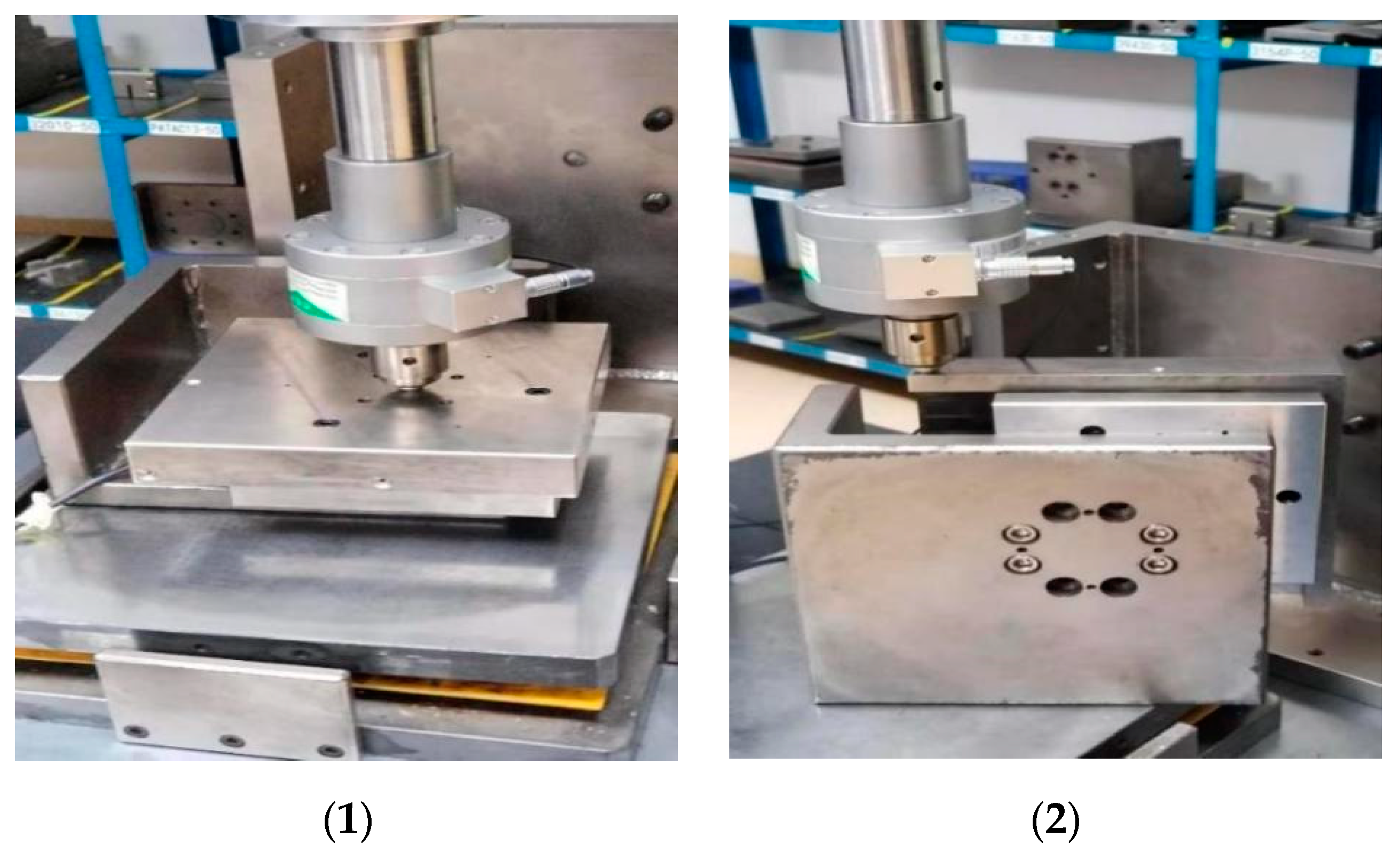

2.2. Static Data Acquisition of the Six-Component Force Sensor

2.3. Static Data of the Six-Component Force Sensor Acquisition

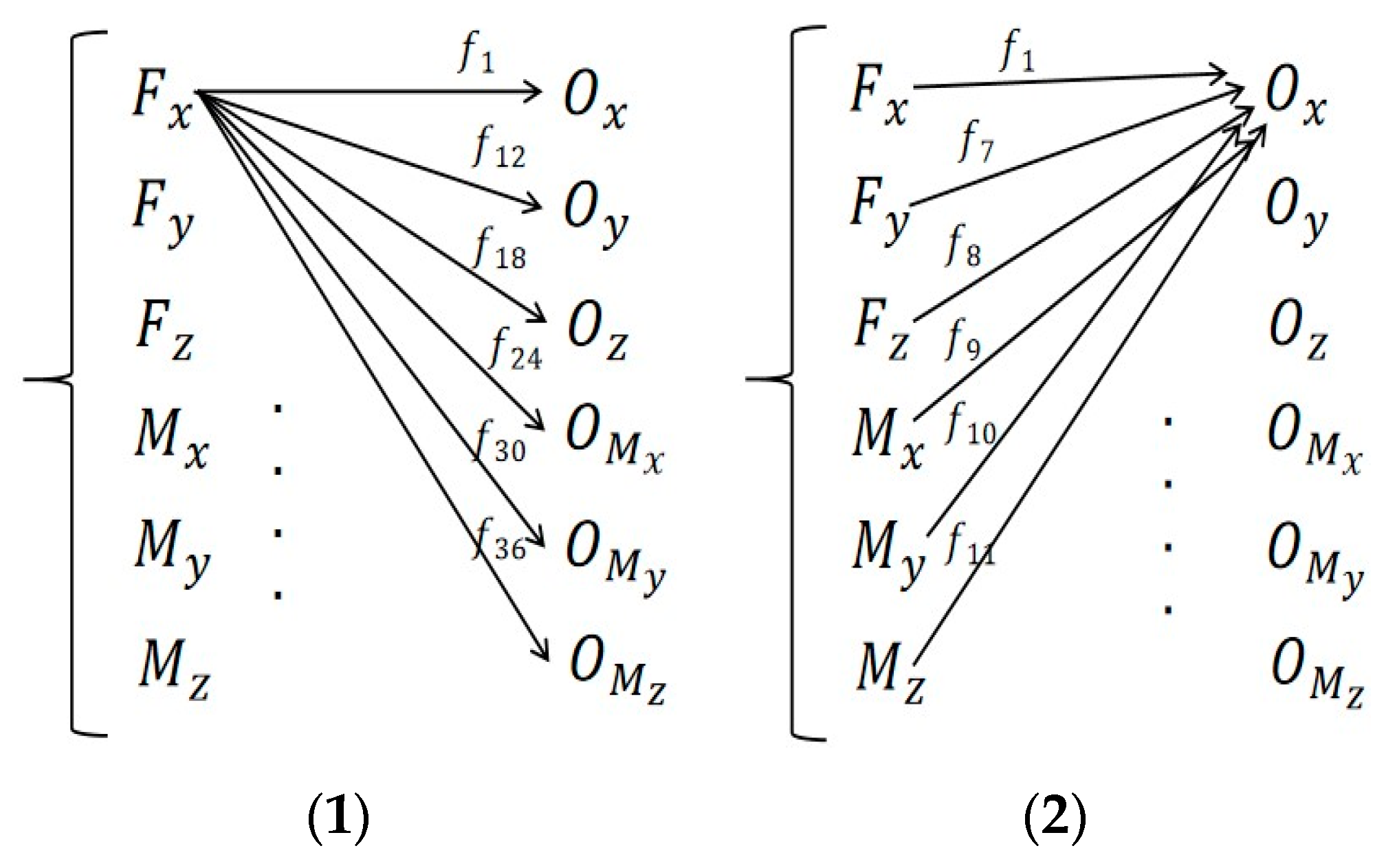

2.3.1. Method of Linearity Analysis

2.3.2. Method of Hysteresis Analysis

2.3.3. Method of Sensitivity and Zero-Drift Analysis

2.3.4. Method of Static Decoupling Analysis

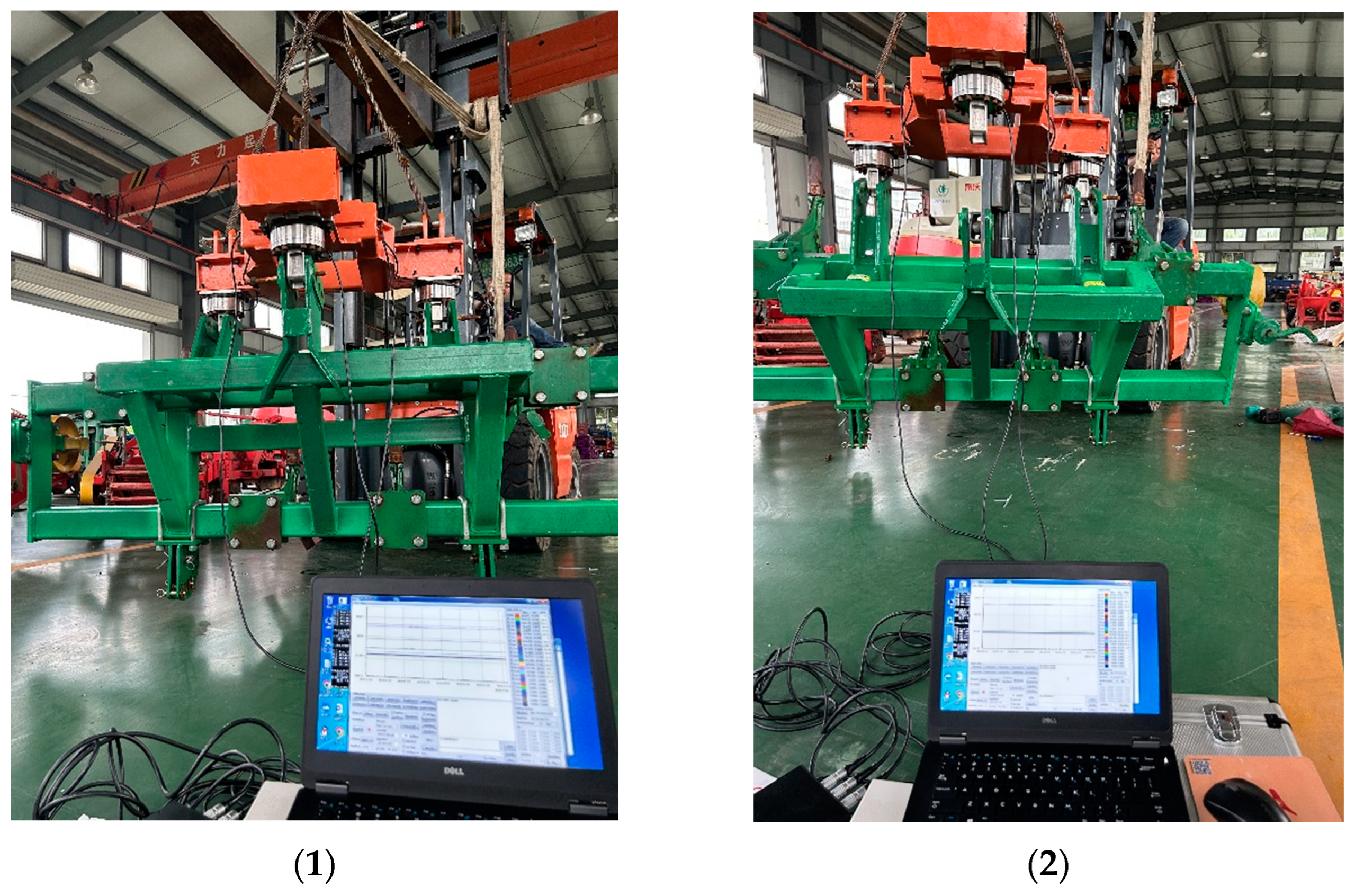

2.4. Integrated Test Research of Array Test Equipment

- (1)

- Use electronic hanging scale to weigh out the mass of the sub-soiling machine;

- (2)

- Set the direction of gravity acceleration of the angle sensor as reset in the software;

- (3)

- Connect the measuring equipment to the sub-soiling machine and complete the connection work of signal acquisition system;

- (4)

- Lift equipment and signal acquisition.

3. Results and Discussion

3.1. Results of Input–Output Linear Relationship

3.2. Results of Hysteresis

3.3. Results of Sensitivity and Zero Drift

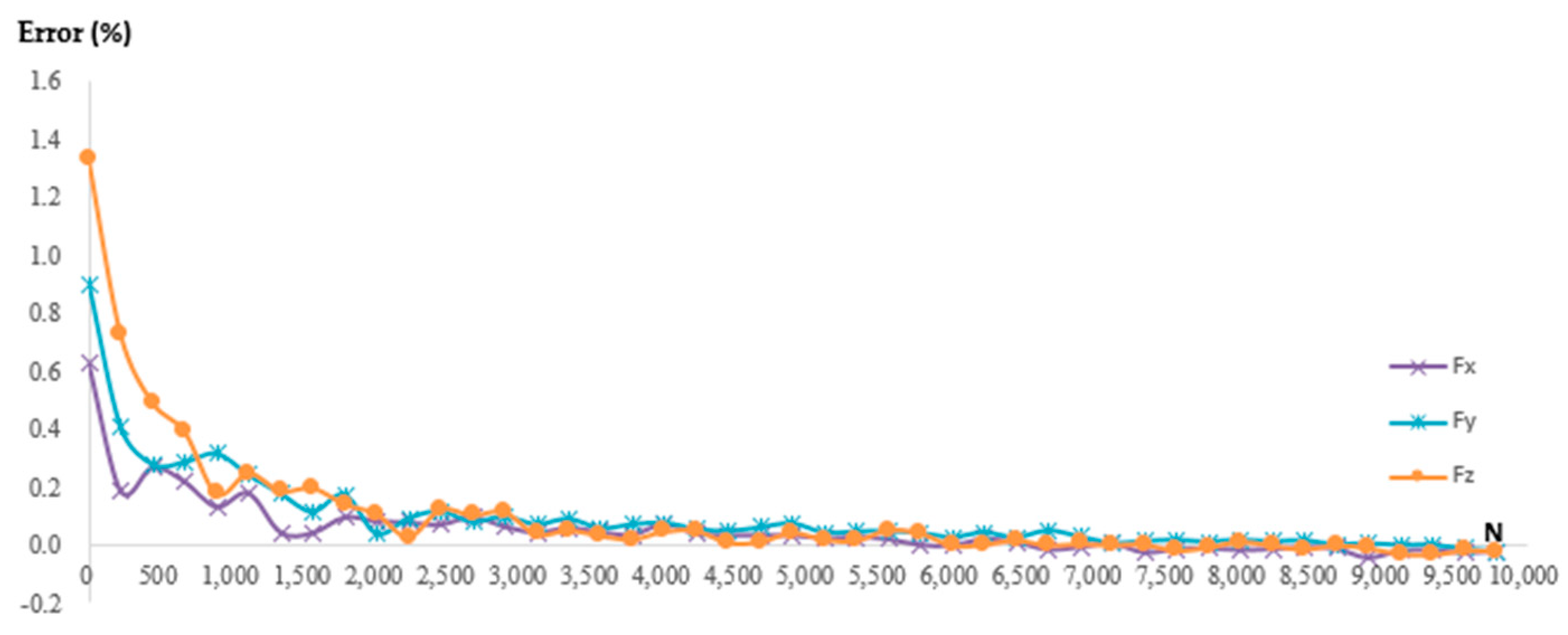

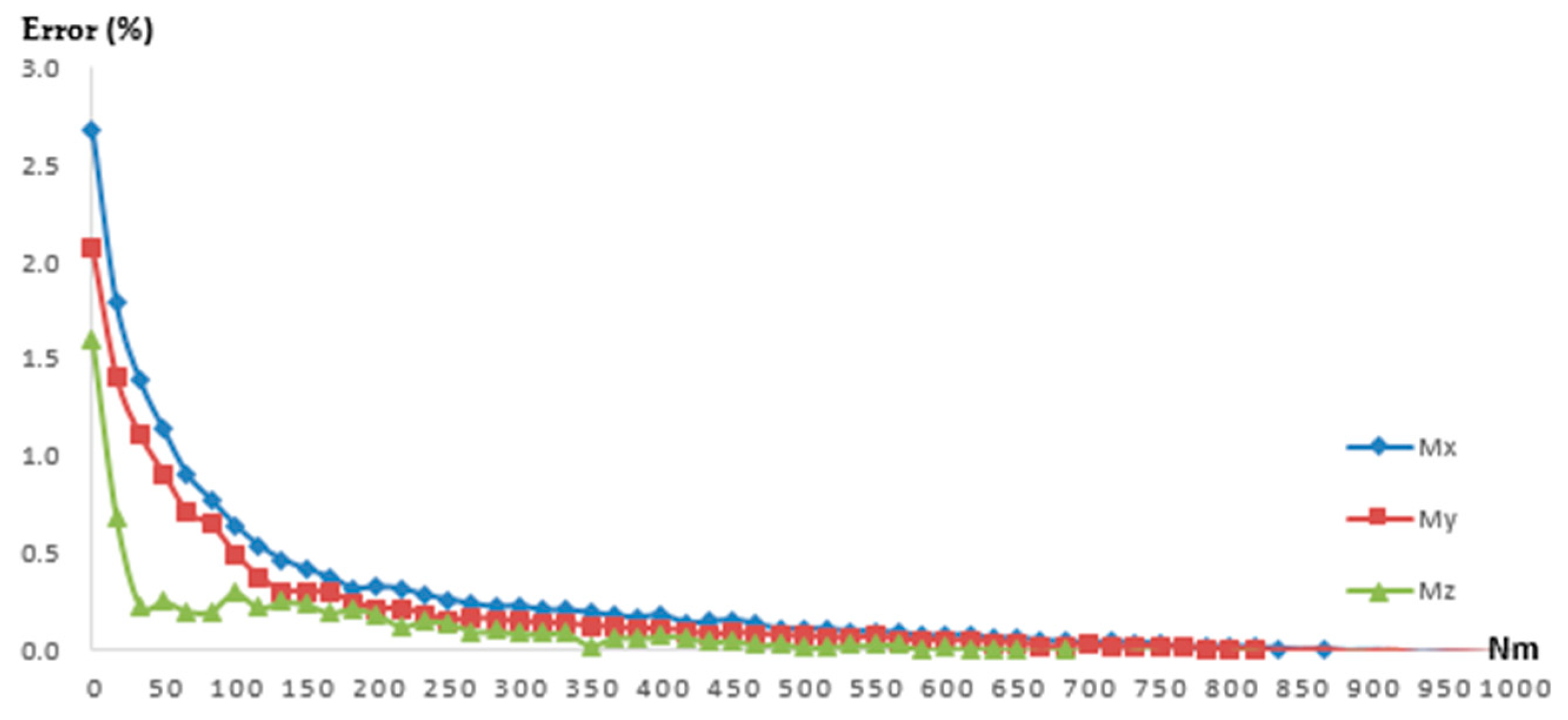

3.4. Result of Static Decoupling

3.5. Result of Integrated Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Beigi, M.; Ghazavi, M.A.; Ahmadi, I. Design and Construction of Load Cell of a Three Point Hitch Dynamometer for Tractor John Deere 3140. J. Mod. Process. Manuf. Prod. 2014, 3, 2. [Google Scholar]

- Mishra, T.; Rooij, D.M.; Shisode, M.; Hazrati, J.; Schipper, D.J. Analytical, numerical and experimental studies on ploughing behaviour in soft metallic coatings. Wear 2020, 448–449, 203219. [Google Scholar] [CrossRef]

- Shafaei, S.M.; Loghavi, M.; Kamgar, S. On the Reliability of Intelligent Fuzzy System for Multivariate Pattern Scrutinization of Power Consumption Efficiency of Mechanical Front Wheel Drive Tractor. J. Biosyst. Eng. 2021, 46, 1–15. [Google Scholar] [CrossRef]

- Ning, Y.; Li, T.; Du, W.; Yao, C.; Zhang, Y.; Shao, J. Inverse kinematics and planning/control co-design method of redundant manipulator for precision operation: Design and experiments. Robot. Comput.-Integr. Manuf. 2023, 80, 102457. [Google Scholar] [CrossRef]

- Griffel, L.M.; Griffel, D.; Edwards, J. Using Support Vector Machines classification to differentiate spectral signatures of potato plants infected with Potato Virus Y. Comput. Electron. Agric. 2018, 153, 318–324. [Google Scholar] [CrossRef]

- Titus, S.S.K.; Jain, S.K. Establishment and development of torque metrology in CSIR-NPL for providing the traceability in torque measurements to user industries. MAPAN-J. Metrol. Soc. India 2013, 28, 11–16. [Google Scholar] [CrossRef]

- Marine, L.; Gawain, J.; Romain, F. Unsupervised classification algorifhm for early weed detection in row-crops by combining spatial and spectral information. Remote Sens. 2018, 10, 761. [Google Scholar]

- Rajabi, V.; Abbaspour, F.; Rohani, A. Development of a prediction model for estimating tractor engine torque based on soft computing and low cost sensors. Measurement 2018, 121, 83–95. [Google Scholar] [CrossRef]

- Malavazi, F.; Guyonneau, R.; Fasquel, B. LiDAR-only based navigation algorithm for an autonomous agricultural robot. Comput. Electron. Agric. 2018, 154, 71–79. [Google Scholar] [CrossRef]

- Upadhyay, G.; Raheman, H. Specific draft estimation model for offset disc harrows. Soil Tillage Res. 2019, 191, 75–84. [Google Scholar] [CrossRef]

- Wang, S.; Wang, C.; Lin, Q.; Zhang, Y.; Zhang, Y.; Liu, Z.; Luo, Y.; Xu, X.; Han, F.; Jiang, Z. Flexible three-dimensional force sensor of high sensing stability with bonding and supporting composite structure for smart devices. Smart Mater. Struct. 2021, 30, 10. [Google Scholar] [CrossRef]

- Li, X.; Lin, J.; Pang, Y.; Yang, D.; Zhong, L.; Li, Z. Three-Dimensional Force Sensor Based on Fiber Bragg Grating for Medical Puncture Robot. Photonics 2022, 9, 630. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, S.; Baek, S.; Baek, S. Development of DEM-MBD coupling model for draft force prediction of agricultural tractor with plowing depth. Comput. Electron. Agric. 2022, 202, 107405. [Google Scholar] [CrossRef]

- Sadek, A.; Ying, C.; Zhiwei, Z. Draft force prediction for a high-speed disc implement using discrete element modelling. Biosyst. Eng. 2021, 202, 133–141. [Google Scholar] [CrossRef]

- Barzegar, M.; Hashemi, S.; Nazokdast, H.; Karimi, R. Evaluating the draft force and soil-tool adhesion of a UHMW-PE coated furrower. Soil Tillage Res. 2016, 163, 160–167. [Google Scholar] [CrossRef]

- Ziqing, L.; Shenglei, P.; Guiliang, F. The Model Design of Medical Data Life Cycle Based on Big Data Platform. J. Phys. Conf. Ser. 2021, 1865, 4. [Google Scholar]

- Zhou, S.; Sun, J.; Chen, W.; Li, W.; Gao, F. Method of designing a six-axis force sensor for stiffness decoupling based on Stewart platform. Measurement 2019, 148, 106966. [Google Scholar] [CrossRef]

- You, Z.; Yulong, Z. Research of a Cross-Interference Suppression Method for Piezoresistive Three-Dimensional Force Sensor. Sensors 2023, 23, 4573. [Google Scholar]

- Kim, E.K.; Moon, S.G.; Oh, C.M.; Han, J.W. Working Load Measurement using 6-Component Load Cell and Fatigue Damage Analysis of Composite Working Implement. J. Agric. Life Environ. Sci. 2017, 29, 225–236. [Google Scholar]

- Ucgul, M.; Saunders, C.; Fielke, J.M. Discrete element modelling of tillage forces and soil movement of a one-third scale mouldboard plough. Biosyst. Eng. 2017, 155, 44–45. [Google Scholar] [CrossRef]

- Čupera, J.; Bauer, F.; Severa, L.; Tatíček, M. Analysis of force effects measured in the tractor three-point linkage. Res. Agric. Eng. 2011, 57, 79–87. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, L.; Jiang, B.; Pei, Y.; Lu, H. Surface Quality Improvement for Ultrasonic-Assisted Inner Diameter Sawing with Six-Axis Force Sensors. Sensors 2023, 23, 6444. [Google Scholar] [CrossRef] [PubMed]

- Pijuan, J.; Berga, J.; Comellas, M.; Potau, X.; Roca, J. A three-point hitch dynamometer for load measurements between tillage implements and agricultural tractors during operation. Res. Gate 2015. [Google Scholar]

- Mahlein, A.K. Plant disease detection by imaging sensors–parallels and specific demands for precision agriculture and plant phenotyping. Plant Dis. 2016, 100, 241–251. [Google Scholar] [CrossRef]

- Askari, M.; Komarizade, M.H.; Nikbakht, A.M.; Nobakht, N.; Teimourlou, R.F. A novel three-point hitch dynamometer to measure the draft requirement of mounted implements. Res. Agric. Eng. 2011, 57, 128–136. [Google Scholar] [CrossRef]

- Kim, Y.S.; Kim, T.J.; Kim, Y.J.; Lee, S.D.; Park, S.U.; Kim, W.S. Development of a Real-Time Tillage Depth Measurement System for Agricultural Tractors: Application to the Effect Analysis of Tillage Depth on Draft Force during Plow Tillage. Sensors 2020, 20, 912. [Google Scholar] [CrossRef]

- Sahu, R.K.; Raheman, H. An approach for draft prediction of combination tillage implements in sandy clay loam soil. Soil Tillage Res. 2005, 90, 145–155. [Google Scholar] [CrossRef]

- Jonathan, C.; Michael, L.; Youmin, Z. Three-Point Hitch Dynamometer Design and Calibration. Appl. Eng. Agric. 1987, 3, 10–13. [Google Scholar] [CrossRef]

- Tewari, V.K.; Ravi, N.; Jha, K.R.; Ashok, A. Design and Development of a Three-Point-Linkage Dynamometer for Tillage Research. Agric. Eng. Today 2012, 36, 33–38. [Google Scholar]

- Niu, Z.; Zhao, Y.; Zhang, H.; Zhou, J.; Du, R. Performance analysis of over-constrained orthogonal parallel six-axis force sensor. Measurement 2022, 202, 111863. [Google Scholar] [CrossRef]

- Yao, L.; Gao, Q.; Zhang, D.; Zhang, W.; Chen, Y. An Integrated Compensation Method for the Force Disturbance of a Six-Axis Force Sensor in Complex Manufacturing Scenarios. Sensors 2021, 21, 4706. [Google Scholar] [CrossRef] [PubMed]

- Bentaher, H.; Hamza, E.; Kantchev, G.; Maalej, A.; Arnold, W. Three-point hitch-mechanism instrumentation for tillage power optimization. Biosyst. Eng. 2008, 100, 24–30. [Google Scholar] [CrossRef]

| Specifications | |

|---|---|

| Excitation (V) | 5 |

| Sampling frequency (HZ) | 4000 |

| Crosstalk (%FS) | 2 |

| Linearity (%FS) | 0.5 |

| Hysteresis (%FS) | 0.5 |

| Operating temp (°C) | −40–100 |

| Mass (kg) | 5.8 |

| Capacity (N/N∙m) | 10,000 | 10,000 | 10,000 | 1000 | 1000 | 1000 |

| Linearity (FS%) | Loading Separately | |||||

|---|---|---|---|---|---|---|

| 0.28 | 3.34 | 2.43 | 1.40 | 0.79 | 13.43 | |

| 0.02 | 0.31 | 25.94 | 0.05 | 0.81 | 2.91 | |

| 2.24 | 9.20 | 0.38 | 14.98 | 15.08 | 2.05 | |

| 66.56 | 11.56 | 0.03 | 0.25 | 3.99 | 1.77 | |

| 8.54 | 7.35 | 1.02 | 3.88 | 0.35 | 3.16 | |

| 4.70 | 11.94 | 8.15 | 6.05 | 0.29 | 0.11 | |

| Hysteresis (%FS) | −0.10 | 0.10 | 0.12 | −0.13 | −0.14 | −0.12 |

| Sensitivity (10−3) | Loaded Separately | |||||

|---|---|---|---|---|---|---|

| −0.08 | 0.0004 | 0.0001 | 0.006 | 0.006 | 0.009 | |

| −0.0001 | 0.08 | −0.00003 | −0.005 | 0.006 | −0.004 | |

| −0.0005 | −0.0001 | 0.06 | −0.009 | 0.002 | −0.006 | |

| 0.0006 | 0.0003 | 0.0006 | −2.2 | 0.01 | 0.02 | |

| −0.001 | −0.0002 | −0.0003 | −0.01 | −2.2 | −0.02 | |

| 0.00006 | −0.0003 | 0.00005 | 0.003 | 0.003 | −0.9 | |

| Signal Value (mV/V) | Loaded Separately | |||||

|---|---|---|---|---|---|---|

| The minimum load signal | −0.0178 | 0.0181 | 0.0146 | −0.0382 | −0.0388 | −0.0153 |

| The zero offset | −0.0002 | 0.0002 | 0.0002 | −0.0007 | −0.0004 | −0.0002 |

| The zero offset/minimum load signal | 1.1% | 1.1% | 1.4% | 1.8% | 1% | 1.3% |

| Error (%) | ||||||

|---|---|---|---|---|---|---|

| Maximum | 0.62 | 0.9 | 1.32 | 2.6 | 2.08 | 1.55 |

| Minimum | −0.0001 | −0.00001 | 0.81 | 0.1 | 0.001 | 0.0002 |

| Stable value | 0.02 | 0.02 | 0.8 | 0.36 | 0.018 | 0.06 |

| Angle of Deflection (°) | Condition 1 | Condition 2 |

|---|---|---|

| X | 0 | 0.2 |

| Y | 0.55 | 5.05 |

| Z | 89.75 | 5.2 |

| Measured mass (kN) | 6.2942 | 6.1422 |

| Actual mass (kN) | 6.2171 | |

| Error (%) | 1.24 | −1.2 |

| Performance Index | ||||||

|---|---|---|---|---|---|---|

| Linearity (%FS) | 0.28 | 0.31 | 0.38 | 0.25 | 0.35 | 0.11 |

| Sensitivity (10−3) | −0.08 | 0.08 | 0.06 | −2.2 | −2.2 | −0.9 |

| Hysteresis (%FS) | −0.1 | −0.1 | 0.12 | −0.13 | −0.14 | −0.12 |

| Zero drift (10−3) | −0.2 | 0.2 | 0.2 | −0.7 | −0.4 | −0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Cao, G.; Yuan, D.; Ding, Y.; Zhu, J.; Chen, X. Study on Agricultural Machinery-Load-Testing Technology and Equipment Based on Six-Dimensional Force Sensor. Agriculture 2023, 13, 1649. https://doi.org/10.3390/agriculture13091649

Chen W, Cao G, Yuan D, Ding Y, Zhu J, Chen X. Study on Agricultural Machinery-Load-Testing Technology and Equipment Based on Six-Dimensional Force Sensor. Agriculture. 2023; 13(9):1649. https://doi.org/10.3390/agriculture13091649

Chicago/Turabian StyleChen, Wei, Guangqiao Cao, Dong Yuan, Yan Ding, Jiping Zhu, and Xiaobing Chen. 2023. "Study on Agricultural Machinery-Load-Testing Technology and Equipment Based on Six-Dimensional Force Sensor" Agriculture 13, no. 9: 1649. https://doi.org/10.3390/agriculture13091649

APA StyleChen, W., Cao, G., Yuan, D., Ding, Y., Zhu, J., & Chen, X. (2023). Study on Agricultural Machinery-Load-Testing Technology and Equipment Based on Six-Dimensional Force Sensor. Agriculture, 13(9), 1649. https://doi.org/10.3390/agriculture13091649