Agricultural Machinery Adequacy for Handling the Mombaça Grass Biomass in Agroforestry Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Experiment General Characterization, Implementation and Conduction

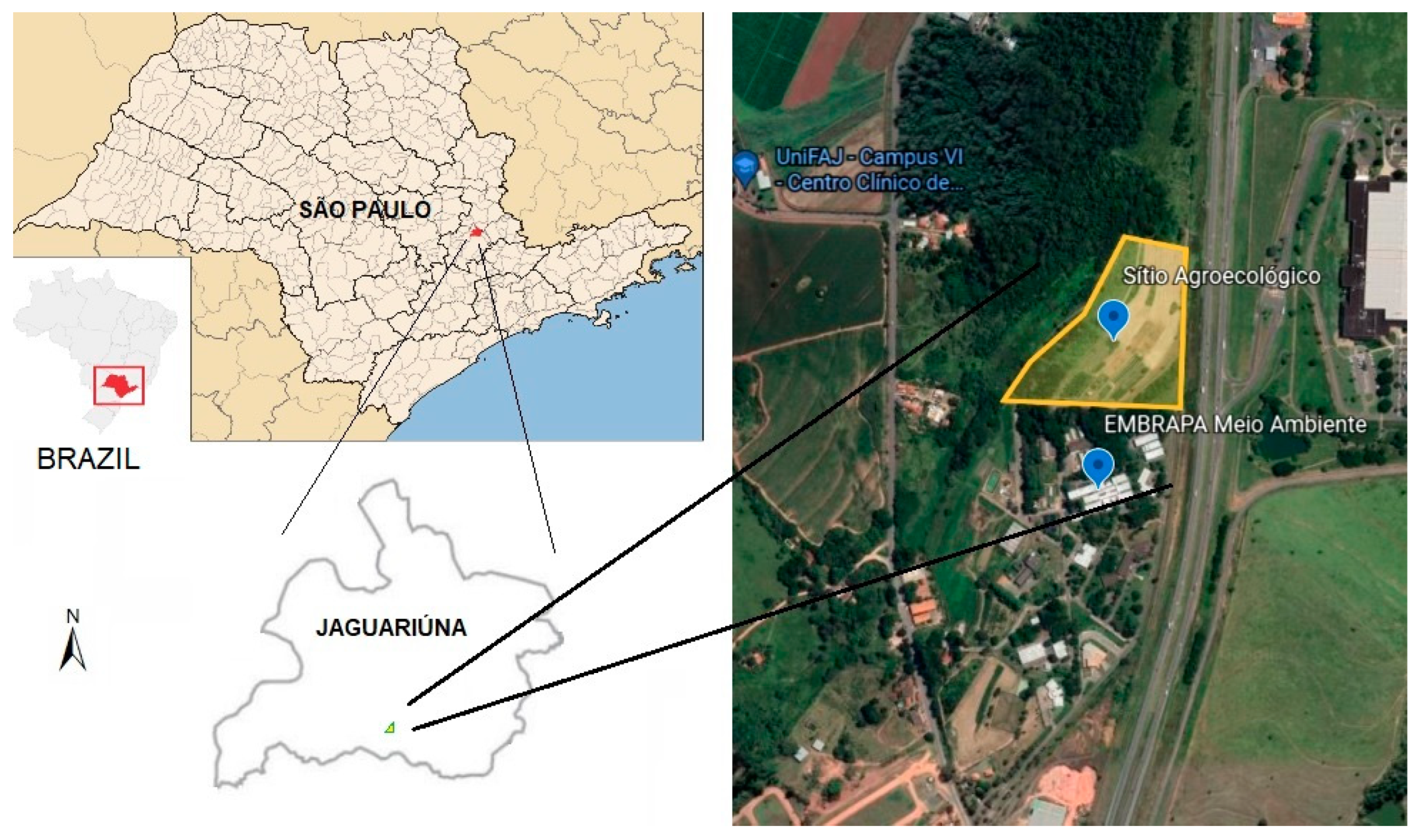

2.2. Study Area

2.3. Agroforestry System Studied

2.4. Material

2.4.1. Cultivated Species

2.4.2. Tested Machines

- Costal brushcutter. A portable machine (Figure 4a) with rotating blades (Figure 4b) driven by power that is generated by a power take-off (PTO). It incorporates a compact engine connected to a cutting disc, and it is secured to the operator’s torso through a belt. The machine has a weight of approximately 14 kg, and it features a three-pointed cutting blade. The specific model tested in this study was the Husqvarna 143 R-II, which runs on gasoline, has a cylinder volume of 41.5 cm3, a power output of 1.5 kW (2.01 hp), a maximum speed of 7500 rpm, and a fuel tank capacity of 0.95 L.

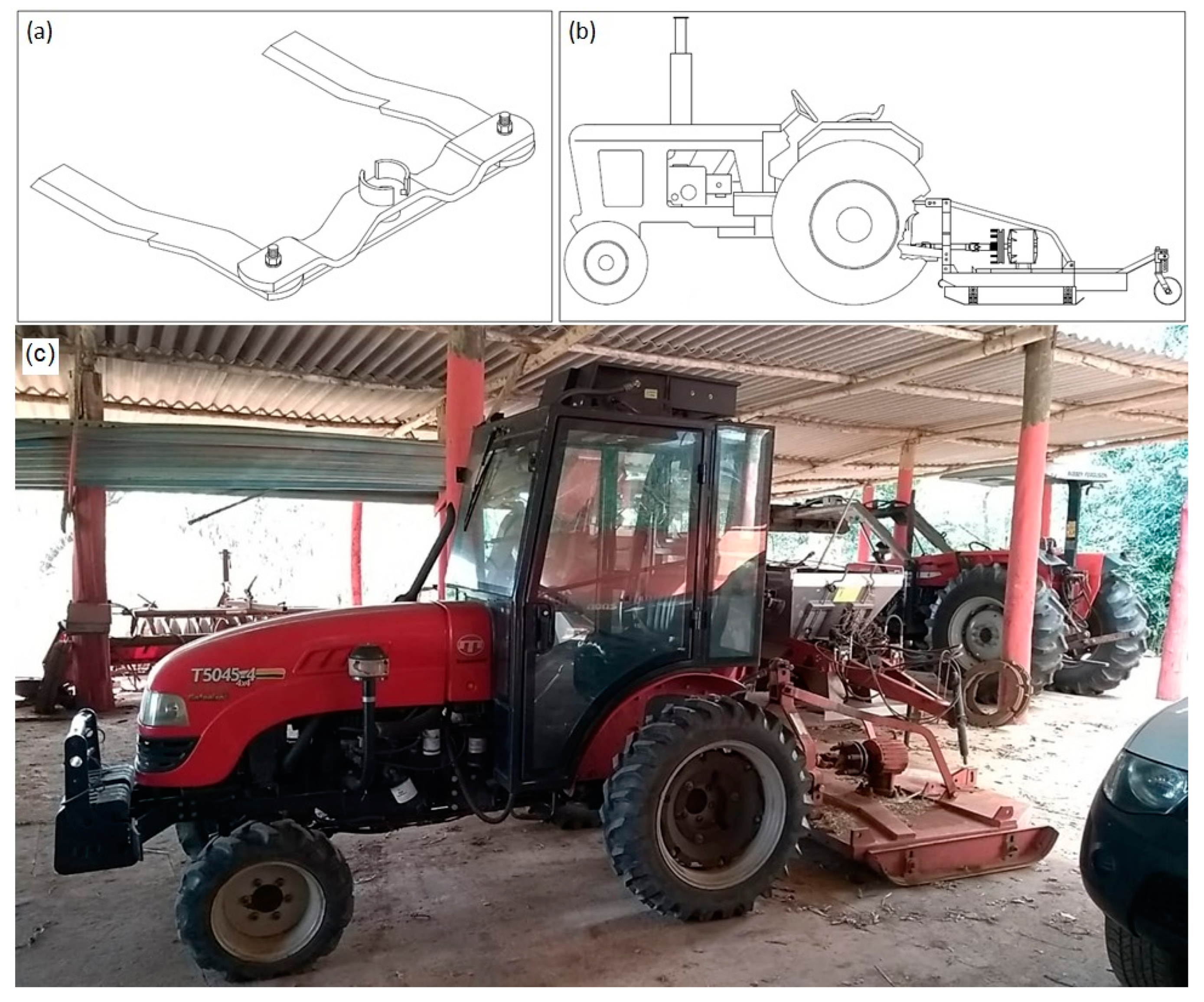

- Tractor mounted rotary brushcutter. The specific model utilized in the experiment was the Jumil JM-RUTD-A 1.4, manufactured in 2010 with a cutting width of 1.3 m and a cutting height that can be adjusted between 2 and 10 cm. It is equipped with two rotating blades (Figure 5a) that operate at a speed between 800 and 1.100 rpm, and it weighs 342 kg, with dimensions of 1.5 m in width, 1.95 m in length, and 1.13 m in height. An attachment can be connected to the three-point system of a tractor using a drawbar and hitch (Figure 5b). The machine is driven by the tractor’s PTO, and it is specifically designed for cutting forage and controlling weeds and unwanted plants. The tractor employed to operate the brushcutter was a Tramontini T5045-4, which is a 4 × 4 model from the Brasil Cafeeiro series (Figure 5c). It has a width of 1.170 m, hydrostatic steering, hydraulic auxiliary control, a dual-stage clutch, PTO that can be set to 540 to 1000 rpm, 50 CV of power, and a 4-cylinder engine.

- Mini grain reaper machine. The machine was chosen for its superior cutting system, which minimizes damage to the grass tussocks and ensures their health for subsequent growth cycles. This is expected to result in enhanced regrowth vigor and increased biomass production during successive cuttings. The machine, used as a prototype in this study, is small in size and designed as a reaper-type harvester originally intended for grains like rice and wheat [41]. GRM was imported from China, and it has dimensions similar to those of a power tiller. It is manually operated, with the operator walking behind the machine.

2.5. Methods

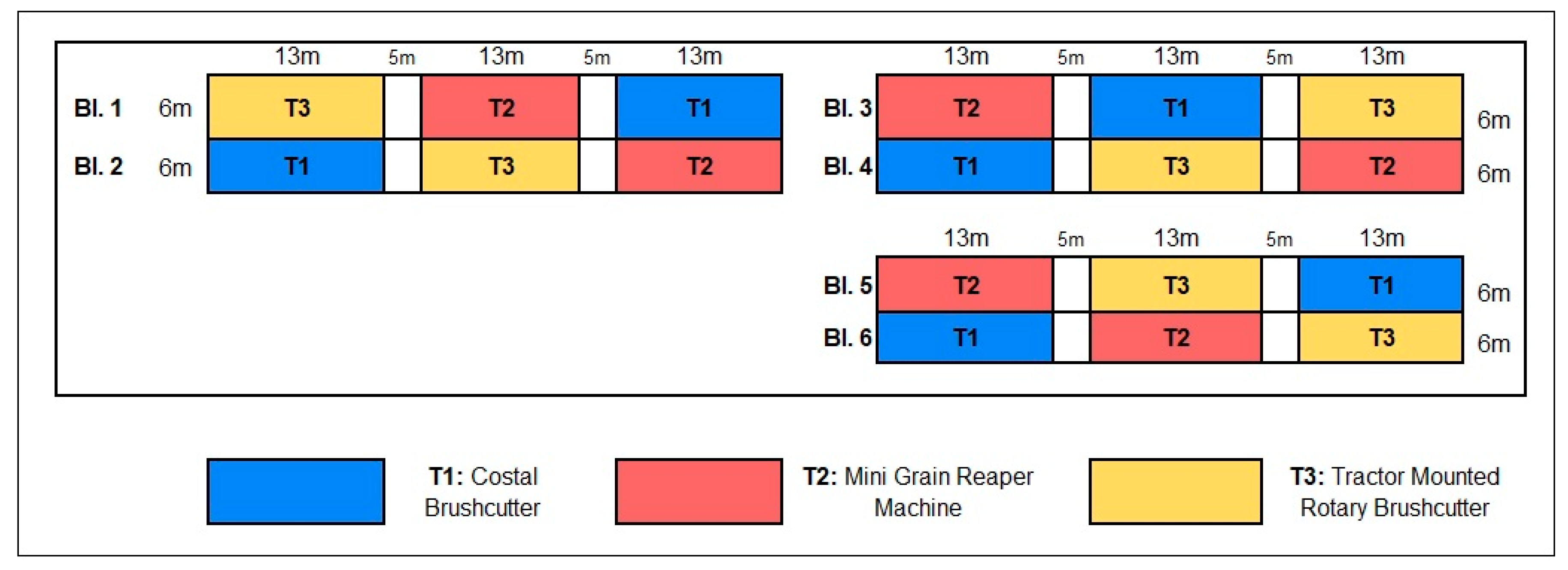

2.5.1. Experimental Design

2.5.2. Data Collection

- Count of basal tiller and regrowth. This was conducted to assess grass regrowth speed (RS). This assessment involved tallying the total number of tillers and regrowth within the sample units [42], 21 days after each grass cutting cycle. This specific timeframe was chosen as it enabled the accurate identification of the tillers and regrowths in the tussocks.

- Regrowth speed (RS). This was assessed by measuring the length of leaves in selected regrowths within the sampling units following each treatment cycle. The length was measured twice, at 7 and 42 days after cutting, resulting in a total of 12 measurements per plot and 4 per sampling unit. Both tillers and regrowths were included in the measurements, with 2 measurements for each. To calculate the RS in centimeters per day, the difference between the final and initial length values was divided by the number of days involved, according to Equation (2), as suggested by [43]:where RS = grass regrowth speed (cm/day); FL = grass final length (cm); IL = grass initial length (cm); and ND = number of days involved (days).RS = (FL − IL)/ND

- Cutting height (CH). This was determined by positioning a ruler vertically adjacent to the tussocks and measuring the distance from the ground to the point of the cut made by the machines [44,45]. In order to obtain the plot value, nine measurements were randomly taken within the sample units, and the simple average was computed.

- Handling time (HT). This refers to the duration taken by the machines to cut the grass within each plot, which was meticulously recorded. The grass in each plot was systematically divided into strips, and the cutting time for each individual strip was cumulatively summed to derive the total HT for each treatment. It is important to note that the time allocated for maneuvering the machines was not taken into account when calculating the HT.

- Fuel consumption value (FC). This was calculated to compare the fuel consumption efficiency of machines with different characteristics, including size, weight, engine, and fuel type. The correlation analysis considered three key factors: (a) fuel price, (b) handling time per treatment (HT), and (c) fuel consumption of each machine. The methodology used to determine these values is elucidated below:

- (a)

- Fuel price: The fuel price values in “reais” (R$) per liter were obtained using publicly available data from the National Petroleum, Natural Gas, and Biofuels Agency [46], which is linked to the Ministry of Mines and Energy (MME) of the Federal Government of Brazil. The data were obtained through the agency’s Price Survey System (SLP), and they were filtered based on the types of fuel used (gasoline and diesel), the location of the fuel purchase (Campinas, São Paulo), and the specific one-week period corresponding to the days on which the grass was cut.

- (b)

- Handling time (HT): The HT values were determined as described earlier in the methodology section.

- (c)

- Fuel consumption: This was determined based on the size and handling capacity of the machines, using two distinct methods.

- For the CBC and GRM, both of which are small and utilize gasoline as fuel, the fuel tank was emptied and a precisely measured amount of gasoline was added. The machines were then operated under working conditions, cutting Mombaça grass, until the entire quantity of gasoline was fully consumed. The FC values were calculated, as suggested by [45], by dividing the volume of gasoline consumed (in liters) by the total working time (in hours).

- In order to determine the FC value of the tractor that was coupled to the RBC, a different methodology was employed. As the tractor is a large machine powered by diesel fuel, it was not practical to measure the fuel consumption directly. Therefore, the specific method in [47] was utilized as a reference to calculate the machine fuel consumption (Equation (4)):where mfc = machine fuel consumption (L/h); SFC = specific fuel consumption (L/kW.h); and Y = current power delivery (KW).mfc = SFC × Y

- Using the obtained values of “a”, “b”, and “c”, a correlation was established among them (Equation (5)) in order to calculate the FC in basic dimensions:where FC = fuel consumption value (R$/ha); HT = handling time in each plot (h/ha); mfc = machine fuel consumption (L/h); and FP = fuel price (R$/L).FC = HT × mfc × FP

- Labor cost (LC). The machines employed for grass cutting in each plot have varying operation times and the operators of these machines also have different wages. To facilitate the comparison of LC across treatments, it was necessary to establish a correlation between (a) labor cost and (b) handling time (HT) in order to ensure the compatibility of the values. The specific methodology employed to calculate these factors is elaborated in the following sections:

- (a)

- Labor value: Two roles were taken into account for machine operation: tractor operator for the tractor and monthly employee for CBC and GRM. The hourly wages for these roles were sourced from publicly available data provided by the Institute of Agricultural Economics [48], an organization associated with the State of São Paulo Government’s Secretary of Agriculture and Supply. The data was filtered based on the roles, the region (state of São Paulo), and the grass-cutting dates to determine the respective hourly wage rates (in R$/month) for each role.

- (b)

- Handling time (HT): HT values were utilized in accordance with the aforementioned description.

- Once the values “a” and “b” were obtained, a correlation was established between them (Equation (6)) in order to calculate the LC in basic dimensions:where LC = labor cost (R$/ha); HT = handling time (hour/ha); and LV = labor value (R$/hour).LC = HT × LV

- Dry matter weight (DM). This was assessed through manual biomass collections carried out prior to each grass cutting using pruning shears. The collections were randomly conducted within a 1 m2 template, keeping a distance of 10 cm from the ground. The collected materials were carefully placed in sealed plastic bags, were weighed immediately to obtain the fresh weight, and were then transferred to paper bags for drying in an oven that was set at 50 °C until a stabilized weight was achieved [44,49]. The weight of the dried mass was recorded. The DM value was calculated by multiplying the weight of the green mass of the corresponding sample by the percentage of dry mass of each subsample.

- Raking time of cut grass (RT). This was determined by measuring the duration of the process involved in gathering and arranging the cut grass into windrows. This step aimed to simulate the handling of the grass within the AFS rows. The collected biomass was divided into two equal parts, with one half raked and piled up on one edge of the plot and the other half piled up on the opposite edge. The time taken to complete this task carefully was recorded.

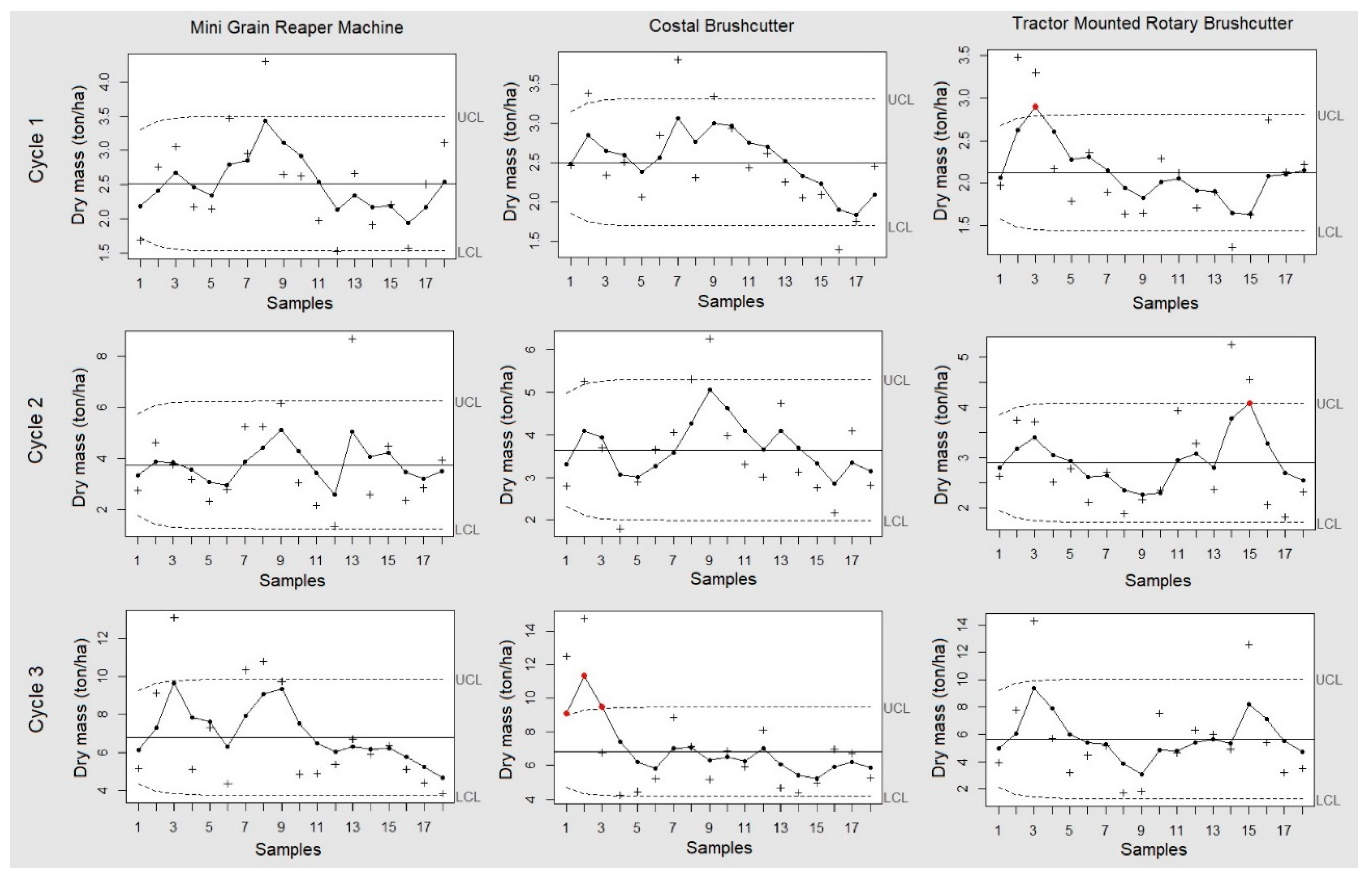

2.5.3. Statistical Analysis

2.5.4. Calculation of Minimum Number of Samples

3. Results

3.1. Statistical Analyses

3.2. Characterization of the Treatments’ Cutting Types in Mombaça Grass

3.3. Machines Adequacy for Mombaça Grass Biomass Handling in AFS

- GRM: dry matter (DM), fuel consumption (FC) and raking time (RT);

- CBC: regrowth speed (RS);

- RBC: handling time (HT) and labor cost (LC).

4. Discussion

4.1. Practical Application

4.2. Managerial Application

4.3. Impact on Sustainable Development

4.4. Future Scope

5. Conclusions

- The mini grain reaper machine is optimal for ensuring higher dry matter production at lower costs and providing quick raking time.

- The costal brushcutter is suitable for tasks in small areas.

- The tractor mounted rotary brushcutter is most suitable for large-scale handling, as it is the fastest machine and requires minimal physical effort and labor cost.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tubb, C.; Seba, T. Rethinking Food and Agriculture 2020-2030: The Second Domestication of Plants and Animals, the Disruption of the Cow, and the Collapse of Industrial Livestock Farming. Ind. Biotechnol. 2021, 17, 57–72. [Google Scholar] [CrossRef]

- Altman, A.; Mesoudi, A. Understanding Agriculture within the Frameworks of Cumulative Cultural Evolution, Gene-Culture Co-Evolution, and Cultural Niche Construction. Hum. Ecol. 2019, 47, 483–497. [Google Scholar] [CrossRef]

- John, D.A.; Babu, G.R. Lessons from the Aftermaths of Green Revolution on Food System and Health. Front. Sustain. Food Syst. 2021, 5, 644559. [Google Scholar] [CrossRef] [PubMed]

- Bebudovna, B.; Ganjiyevich, J.; Tairova, M. Ways Of Financing Innovative Activities in Agrobusiness. Int. J. Acad. Manag. Sci. Res. IJAMSR 2021, 5, 138–143. [Google Scholar]

- Mehrabi, S.; Perez-Mesa, J.C.; Giagnocavo, C. The Role of Consumer-Citizens and Connectedness to Nature in the Sustainable Transition to Agroecological Food Systems: The Mediation of Innovative Business Models and a Multi-Level Perspective. Agriculture 2022, 12, 203. [Google Scholar] [CrossRef]

- Borsatto, R.S.; Souza-Esquerdo, V.F. MST’s Experience in Leveraging Agroecology in Rural Settlements: Lessons, Achievements, and Challenges. Agroecol. Sustain. Food Syst. 2019, 43, 915–935. [Google Scholar] [CrossRef]

- Bonnet, C.; Gaudio, N.; Alletto, L.; Raffaillac, D.; Bergez, J.-E.; Debaeke, P.; Gavaland, A.; Willaume, M.; Bedoussac, L.; Justes, E. Design and Multicriteria Assessment of Low-Input Cropping Systems Based on Plant Diversification in Southwestern France. Agron. Sustain. Dev. 2021, 41, 65. [Google Scholar] [CrossRef]

- Rebello, J.F.; Sakamoto, D.G. Agricultura Sintrópica Segundo Ernst Götsch; Editora Reviver: São Paulo, Brazil, 2021. [Google Scholar]

- Nair, P.K.R.; Kumar, B.M.; Nair, V.D. Definition and Concepts of Agroforestry. In An Introduction to Agroforestry: Four Decades of Scientific Developments; Springer: Cham, Switzerland, 2021; pp. 21–28. [Google Scholar] [CrossRef]

- Minc, C. Brasil Instrução Normativa MMA n.4, de 8 de Setembro de 2009; Brasil Ministério do Meio Ambiente: Rio de Janeiro, Brazil, 2009. [Google Scholar]

- Marsden, C.; Martin-Chave, A.; Cortet, J.; Hedde, M.; Capowiez, Y. How Agroforestry Systems Influence Soil Fauna and Their Functions—A Review. Plant Soil 2020, 453, 29–44. [Google Scholar] [CrossRef]

- da Silva, B.A.; Berteloni, D.G.; de Morais, G.F.; Fernandes, J.d.S.; Sais, A.C.; Cardoso-Leite, E.; Oliveira, R.E. de Árvores para geração de serviços ecossistêmicos e bem-estar em paisagens rurais e urbanas. Cad. Comun. 2022, 1, 57–72. [Google Scholar] [CrossRef]

- Castle, S.E.; Miller, D.C.; Merten, N.; Ordonez, P.J.; Baylis, K. Evidence for the Impacts of Agroforestry on Ecosystem Services and Human Well-Being in High-Income Countries: A Systematic Map. Environ. Evid. 2022, 11, 10. [Google Scholar] [CrossRef]

- Duguma, L.A.; Minang, P.A.; Watson, C.; Nath, A.J.; Muthee, K.W.; van Noordwijk, M.; Mutune, J.M.; Sileshi, G.W. Agroforestry as a Key Intervention to Achieve Nationally Determined Contribution (NDC) Targets. In Agroforestry for Sustainable Intensification of Agriculture in Asia and Africa. Sustainability Sciences in Asia and Africa; Springer: Singapore, 2023; pp. 641–664. [Google Scholar] [CrossRef]

- Rosenstock, T.S.; Wilkes, A.; Jallo, C.; Namoi, N.; Bulusu, M.; Suber, M.; Mboi, D.; Mulia, R.; Simelton, E.; Richards, M.; et al. Making Trees Count: Measurement and Reporting of Agroforestry in UNFCCC National Communications of Non-Annex I Countries. Agric. Ecosyst. Environ. 2019, 284, 106569. [Google Scholar] [CrossRef]

- Dhyani, S.; Murthy, I.K.; Kadaverugu, R.; Dasgupta, R.; Kumar, M.; Adesh Gadpayle, K. Agroforestry to Achieve Global Climate Adaptation and Mitigation Targets: Are South Asian Countries Sufficiently Prepared? Forests 2021, 12, 303. [Google Scholar] [CrossRef]

- Weidner, H.; Sousa, G.F.; Guimaraes, R.d.R. Ergonomia e tempo de trabalho para análise sócio-econômica de sistemas agroflorestais na Amazônia Ocidental. In Congresso Brasileiro em Sistemas Agroflorestais, 2., 1998, Belém, PA. Sistemas agroflorestais no contexto da qualidade ambiental e competitividade: Resumos expandidos. Belém, PA: Embrapa-CPATU; Embrapa Amazônia Ocidental: Manaus, Brazil, 1998; pp. 182–184. [Google Scholar]

- Rezende, G.C.D.; Tafner, P. Política Agrária: Modernização sem exclusão. Cad. Adenauer 2006, 7, 85–104. [Google Scholar]

- Gliessman, S.R.; Méndez, V.E.; Izzo, V.M.; Engles, E.W. Agroecology: Leading the Transformation to a Just and Sustainable Food System; CRC Press: Boca Raton, FL, USA, 2022; p. 470. [Google Scholar] [CrossRef]

- Hu, Y.; Feng, J.; Qiao, Y.; Yu, C.; Luo, W.; Zhang, K.; Liu, R.; Han, R. Research and Validation of Vibratory Harvesting Device for Red Jujube Based on ADAMS and ANSYS. Agriculture 2023, 13, 1334. [Google Scholar] [CrossRef]

- Centeno, A.S.; Kaercher, D. Custo Operacional Das Máquinas Agrícolas. Agrianual 2010, 15, 113–116. [Google Scholar]

- Oliveira, F.d.C.; de Sousa, V.F.; de Oliveira Júnior, J.O.L.; Oliveira, F.d.C. Estratégias de Desenvolvimento Rural e Alternativas Tecnológicas Para a Agricultura Familiar na Região Meio-Norte; Embrapa Meio-Norte: Teresina, Brazil, 2008. [Google Scholar]

- Felício, M.J. A conflitualidade dos paradigmas da questão agrária e do capitalismo agrário a partir dos conceitos de agricultor familiar e de camponês. Rev. Campo-Territ. 2006, 1, 14–30. [Google Scholar] [CrossRef]

- Weerabahu, S.K.; Samaranayake, P.; Dasanayaka, S.W.S.; Wickramasinghe, C.N. Challenges of Agri-Food Supply in City Region Food Systems: An Emerging Economy Perspective. J. Agribus. Dev. Emerg. Econ. 2021, 12, 161–182. [Google Scholar] [CrossRef]

- Pacheco, E.P. Seleção e Custo Operacional de Máquinas Agrícolas; Doc. No 58; Embrapa Acre: Rio Branco, Brazil, 2000; p. 21. [Google Scholar]

- Daum, T.; Adegbola, Y.P.; Kamau, G.; Kergna, A.O.; Daudu, C.; Zossou, R.C.; Crinot, G.F.; Houssou, P.; Mose, L.; Ndirpaya, Y.; et al. Perceived Effects of Farm Tractors in Four African Countries, Highlighted by Participatory Impact Diagrams. Agron. Sustain. Dev. 2020, 40, 47. [Google Scholar] [CrossRef]

- Kaur, M.; Malik, D.P.; Malhi, G.S.; Sardana, V.; Bolan, N.S.; Lal, R.; Siddique, K.H.M. Rice Residue Management in the Indo-Gangetic Plains for Climate and Food Security. A Review. Agron. Sustain. Dev. 2022, 42, 92. [Google Scholar] [CrossRef]

- Fan, S.-K.S.; Chang, Y.-J. Multiple-Input Multiple-Output Double Exponentially Weighted Moving Average Controller Using Partial Least Squares. J. Process Control 2010, 20, 734–742. [Google Scholar] [CrossRef]

- Albiero, D.; Maciel, A.J.d.S.; Milan, M.; Monteiro, L.d.A.; Mion, R.L. Avaliação da distribuição de sementes por uma semeadora de anel interno rotativo utilizando média móvel exponencial. Rev. Ciênc. Agron. 2012, 43, 86–95. [Google Scholar] [CrossRef]

- Melo, R.P.; Albiero, D.; Monteiro, L.A.; Souza, F.H.; Silva, J.G. Qualidade na distribuição de sementes de milho em semeadoras em um solo cearense. Rev. Ciênc. Agron. 2013, 44, 94–101. [Google Scholar] [CrossRef]

- Melo, R.P.; Fernandes, F.R.B.; Nascimento, H.C.F.D.; Maia, C.L.; Albiero, D. Análise do Controlede Qualidade da Densidade de Distribução de Arroz por uma Semeadora de Fluxxo Contínuo. Rev. Bras. Eng. Biossistemas 2014, 8, 343–350. [Google Scholar] [CrossRef]

- de Morais, G.F. Aplicação de análise dimensional no estudo de máquinas agrícolas para manejo de biomassa de sistemas agroflorestais. Master’s Thesis, Universidade Estadual de Campinas, Faculdade de Engenharia Agrícola, Campinas, Brazil, 2022. [Google Scholar]

- Montgomery, D.C. Introdução Ao Controle Estatístico da Qualidade, 4th ed.; LTC: Rio de Janeiro, Brazil, 2004. [Google Scholar]

- Costa, J.R. Técnicas Experimentais Aplicadas Às Ciências Agrárias; Embrapa Agrobiologia: Seropédica, Brazil, 2003; p. 102. [Google Scholar]

- Kichel, A.N.; Kichel, A.G. Requisitos Básicos Para Boa Formação e Persistência de Pastagens; Embrapa Gado de Corte: Campo Grande, Brazil, 2001. [Google Scholar]

- Neves, M.C.; Moriconi, W.; Canuto, J.C.; Corrales, F.M.; Malagodi-Braga, K.S.; de Camargo, R.C.R.; de Queiroga, J.L.; Ramos Filho, L.O.; Urchei, M.A.; Ramos, M.S.T.a.S. O sítio agroecológico da Embrapa Meio Ambiente. In Trajetória das Ações em agroecologia na Embrapa Meio Ambiente; Embrapa: Brasília, Brazil, 2017; pp. 95–115. [Google Scholar]

- Santos, D.; Calderano Filho, B. Levantamento Detalhado dos Solos do Campo Experimental da Embrapa Meio Ambiente Jaguariúna, SP; Embrapa Solos: Rio de Janeiro, Brazil, 2000; p. 37. [Google Scholar]

- de Análise de Dados, F.S.E. Avaliações de Impacto de Programas Públicos No Estado de São Paulo. Produto 6—Vol. 4. 2017. Available online: https://retps.org.br/wp-content/uploads/2020/01/C.1.1-Relat%C3%B3rio-Final-Sa%C3%BAde-Satisfa%C3%A7%C3%A3o-dos-Usu%C3%A1rios.pdf (accessed on 6 June 2023).

- Xavier, M.G.B. Práticas e Percepções de Agricultoras e Agricultores Sobre o Manejo do Capim-Mombaça (Megathyrsus Maximus) em Sistemas Agroflorestais. Master’s Thesis, Universidade Federal de São Carlos, Araras, Brazil, 2022. [Google Scholar]

- Miccolis, A.; Peneireiro, F.M.; Marques, H.R.; Vieira, D.L.M.; Arco-Verde, M.F.; Hoffmann, M.R.; Rehder, T.; Pereira, A.V.B. Restauração Ecológica com Sistemas Agroflorestais: Como Conciliar Conservação com Produção: Opções Para Cerrado e Caatinga; Centro Internacional de Pesquisa Agroflorestal: Brasília, Brazil, 2016. [Google Scholar]

- Schalch, W.; Colton, J. Analysis of Manufacturing Methods and Die Design for Rice Transplanter Claws and Combine Harvester Blades in Bangladesh. Machines 2023, 11, 219. [Google Scholar] [CrossRef]

- Bernache, L.; Tedesco-Oliveira, D.; de Oliveira, L.P.; Corrêa, L.N.; Silva, R.P.d. Can basal cutting blade wear affect sugarcane regrowth? Eng. Agríc. 2020, 40, 53–60. [Google Scholar] [CrossRef]

- de Oliveira, M.A.; Pereira, O.G.; Huaman, C.A.M.Y.; Garcia, R.; Gomide, J.A.; Cecon, P.R.; da Silveira, P.R. Características Morfogênicas e Estruturais do Capim-Bermuda ‘Tifton 85′ (Cynodon spp.) em Diferentes Idades de Rebrota. Rev. Bras. Zootec. 2000, 29, 1939–1948. [Google Scholar]

- Thaiana Rueda da Silva, C.; Bonfim-Silva, E.M.; de Araújo da Silva, T.J.; Alves Rodrigues Pinheiro, E.; Vieira José, J.; Pereira Freire Ferraz, A. Yield Component Responses of the Brachiaria Brizantha Forage Grass to Soil Water Availability in the Brazilian Cerrado. Agriculture 2020, 10, 13. [Google Scholar] [CrossRef]

- Dixit, J. Adaption of Modified Brush Cutter for Rice Harvesting. Agric. Eng. Int. CIGR J. 2022, 24, 90–101. [Google Scholar]

- ANP—Agência Nacional do Petróleo. Gás Natural e Biocombustíveis Sistema de Levantamento de Preços; ANP: Rio de Janeiro, Brazil, 2022. [Google Scholar]

- ASAE D497.6: 2009; Agricultural Machinery Management. ASAE: Washington, DC, USA, 2009.

- IEA. Salários Rurais; IEA: Paris, France, 2022. [Google Scholar]

- Dubis, B.; Jankowski, K.J.; Załuski, D.; Bórawski, P.; Szempliński, W. Biomass Production and Energy Balance of Miscanthus over a Period of 11 Years: A Case Study in a Large-Scale Farm in Poland. GCB Bioenergy 2019, 11, 1187–1201. [Google Scholar] [CrossRef]

- Oliveira, J.U.C. Estatistica Uma Nova Abordagem, 1st ed.; Ciência Moderna: Rio de Janeiro, Brazil, 2010. [Google Scholar]

- Roberts, S.W. Control Chart Tests Based on Geometric Moving Averages. Technometrics 1959, 1, 239–250. [Google Scholar] [CrossRef]

- Frigo, J.P.; Boas, M.A.V.; Frigo, J.P.; Frigo, E.P. Comparação entre Gráficos de Controle de Shewhart, Cusum e MMEP no Processo de Irrigação por Aspersão Convencional. IRRIGA 2018, 1, 56. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Wang, F.; Zhang, W.; Di, M.; Wu, X.; Song, Z.; Xie, B.; Yang, G.; Ma, S. Sugarcane Cutting Quality Using Contra-Rotating Basecutters. Trans. ASABE 2019, 62, 737–747. [Google Scholar] [CrossRef]

- Campos, C.M.; Milan, M.; Siqueira, L.F.F. Identificação e avaliação de variáveis críticas no processo de produção da cana-de-açúcar. Eng. Agríc. 2008, 28, 554–564. [Google Scholar] [CrossRef]

- Barros, F.F.; Milan, M. Qualidade operacional do plantio de cana-de-açúcar. Bragantia 2010, 69, 221–229. [Google Scholar] [CrossRef]

- Grace, C.; Boland, T.M.; Sheridan, H.; Brennan, E.; Fritch, R.; Lynch, M.B. The Effect of Grazing versus Cutting on Dry Matter Production of Multispecies and Perennial Ryegrass-Only Swards. Grass Forage Sci. 2019, 74, 437–449. [Google Scholar] [CrossRef]

- Hassan, M.A.; Afify, M.K.; El-Shal, H.M.; Abd El-Atty, A.A.A. Study on the Mechanization of Bean (Phaseolus Vulgaris) Crop under Egyptian Conditions. Misr J. Agric. Eng. 2015, 32, 503–520. [Google Scholar] [CrossRef]

- Cardoso, R.R.; Sousa, L.F.; Holanda, A.C.F.; Bentes, G.N. Performance Supplementation and Ingestive Behavior of Sheep Finished in Continuous Pasture in the Period of Water Restriction. Acta Sci. Anim. Sci. 2022, 44, e53855. [Google Scholar] [CrossRef]

- Duarte, J.A.V.; Junior, M.A.P.O.; Junior, N.P.d.A.; Junior, F.M.d.V.; Montagner, D.B.; Burin, P.C.; Britez, G.D.V.; Aguero, M.A.F.; Duarte, N.D.L.; Giménez, W.M. Chemical Composition of Urochloa Brizantha Depending on the Seasons and Cutting Frequencies. AJAR 2019, 14, 1411–1414. [Google Scholar] [CrossRef]

- Bukhtoyarov, L.; Kunickaya, O.; Urazova, A.; Perfiliev, P.; Druzyanova, V.; Egipko, S.; Burgonutdinov, A.; Tikhonov, E. Substantiating Optimum Parameters and Efficiency of Rotary Brush Cutters. J. Appl. Eng. Sci. 2022, 20, 788–797. [Google Scholar] [CrossRef]

- Schimidt, L.; de Morais, G.F.; de Castro, F.T.; Maia, A.d.H.N.; Ramos Filho, L.O. Influência de Tipo de Corte Sobre o Perfilhamento, Rebrotação e Produção de Massa Seca de Capim Mombaça. In Proceedings of the 16th Congresso Interinstitucional de Iniciação Científica—CIIC 2022, online, 30–31 August 2022. [Google Scholar]

- Magenau, E.; Kiesel, A.; Clifton-Brown, J.; Lewandowski, I. Influence of Cutting Height on Biomass Yield and Quality of Miscanthus Genotypes. GCB Bioenergy 2021, 13, 1675–1689. [Google Scholar] [CrossRef]

- Furmanov, D.V.; Tyuremnov, I.S.; Chizhov, V.S. Energy Efficiency of Rotary Brush Cutters. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 052086. [Google Scholar] [CrossRef]

- Puyt, R.W.; Lie, F.B.; Wilderom, C.P.M. The Origins of SWOT Analysis. Long Range Plan. 2023, 56, 102304. [Google Scholar] [CrossRef]

- Falana, O.B.; Aluko, O.B.; Adetan, D.A.; Osunbitan, J.A. Adaptation of a Brush Cutter for Kenaf (Hibiscus Cannabinus) Harvesting. Agric. Eng. Int. CIGR J. 2020, 22, 59–67. [Google Scholar]

- Albiero, D.; Xavier, R.S.; Garcia, A.P.; Marques, A.R.; Rodrigues, R.L. The Technological Level of Agricultural Mechanization in the State of Ceará, Brazil. Eng. Agríc. 2019, 39, 133–138. [Google Scholar] [CrossRef]

- Palma, M.A.Z.; Volpato, C.E.S.; da Silva, F.C.; de Souza, P.; Silva, J.A. Resistência do solo à penetração em cafezais cultivados com sistema mecanizado e manual. Coffee Sci. 2013, 8, 364–370. [Google Scholar]

- Liao, W.; Zeng, F.; Chanieabate, M. Mechanization of Small-Scale Agriculture in China: Lessons for Enhancing Smallholder Access to Agricultural Machinery. Sustainability 2022, 14, 7964. [Google Scholar] [CrossRef]

- Mialhe, L.G. Manual de Mecanização Agrícola; (Ceres, 11); Agronômica Ceres: São Paulo, Brazil, 1974. [Google Scholar]

- Parthiban, K.T.; Fernandaz, C.C.; Sudhagar, R.J.; Sekar, I.; Kanna, S.U.; Rajendran, P.; Devanand, P.S.; Vennila, S.; Kumar, N.K. Industrial Agroforestry: A Sustainable Value Chain Innovation through a Consortium Approach. Sustainability 2021, 13, 7126. [Google Scholar] [CrossRef]

- Aryal, J.P.; Rahut, D.B.; Thapa, G.; Simtowe, F. Mechanisation of Small-Scale Farms in South Asia: Empirical Evidence Derived from Farm Households Survey. Technol. Soc. 2021, 65, 101591. [Google Scholar] [CrossRef]

- Daum, T.; Birner, R. Agricultural Mechanization in Africa: Myths, Realities and an Emerging Research Agenda. Glob. Food Secur. 2020, 26, 100393. [Google Scholar] [CrossRef]

- Amare, D.; Endalew, W. Agricultural Mechanization: Assessment of Mechanization Impact Experiences on the Rural Population and the Implications for Ethiopian Smallholders. Eng. Appl. Sci. 2016, 1, 39–48. [Google Scholar] [CrossRef]

- Wu, Y.; Yan, Y.; Wang, S.; Liu, F.; Xu, C.; Zhang, T. Study on Location Decision Framework of Agroforestry Biomass Cogeneration Project: A Case of China. Biomass Bioenergy 2019, 127, 105289. [Google Scholar] [CrossRef]

- Belton, B.; Win, M.T.; Zhang, X.; Filipski, M. The Rapid Rise of Agricultural Mechanization in Myanmar. Food Policy 2021, 101, 102095. [Google Scholar] [CrossRef]

- Meshram, V.; Patil, K.; Meshram, V.; Hanchate, D.; Ramkteke, S.D. Machine Learning in Agriculture Domain: A State-of-Art Survey. Artif. Intell. Life Sci. 2021, 1, 100010. [Google Scholar] [CrossRef]

- Azadi, H.; Movahhed Moghaddam, S.; Burkart, S.; Mahmoudi, H.; Van Passel, S.; Kurban, A.; Lopez-Carr, D. Rethinking Resilient Agriculture: From Climate-Smart Agriculture to Vulnerable-Smart Agriculture. J. Clean. Prod. 2021, 319, 128602. [Google Scholar] [CrossRef]

- Fahad, S.; Chavan, S.B.; Chichaghare, A.R.; Uthappa, A.R.; Kumar, M.; Kakade, V.; Pradhan, A.; Jinger, D.; Rawale, G.; Yadav, D.K.; et al. Agroforestry Systems for Soil Health Improvement and Maintenance. Sustainability 2022, 14, 14877. [Google Scholar] [CrossRef]

- Santos, J.d.S.G.; Ferreira, V.d.S.; de Moraes, G.d.A.C.; Magalhães, J.V.d.F.; Garcia, A.P.; Umezu, C.K.; Neto, A.F.D.; Albiero, D. Technological Advancements in Mechanized Sugarcane Cultivation Applicable to Familiar Farming: Influences on Sdg. A Review. Contrib. Cienc. Soc. 2023, 16, 269–289. [Google Scholar] [CrossRef]

- Golovkov, A.; Boiko, A.; Chaava, M. Justification of the Choice of the Type of Forage Harvester for Farms. E3S Web Conf. 2019, 126, 00053. [Google Scholar] [CrossRef]

- Kawatkar, S.A.; Baviskar, B.S.; Chavan, P.R.; Dhule, R.R.; Lakade, D.S. Design and Fabrication of Solar Brush Cutter. TIJER-Int. Res. J. 2023, 10, 167–172. [Google Scholar]

- Manikanta, R.; Kumar, N.P.; Lakshman, N.; Rajesh, S.; Vijay, M. Design and Fabrication of Solar Grass Cutter Using Arduino. Ind. Eng. J. 2023, 52, 412–418. [Google Scholar]

- Troncon, D.; Alberti, L.; Bolognani, S.; Bettella, F.; Gatto, A. Electrification of Agricultural Machinery: A Feasibility Evaluation. In Proceedings of the 2019 Fourteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, France, 8–10 May 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Lowenberg-DeBoer, J.; Huang, I.Y.; Grigoriadis, V.; Blackmore, S. Economics of Robots and Automation in Field Crop Production. Precis. Agric. 2020, 21, 278–299. [Google Scholar] [CrossRef]

- Ranjitha, B.; Nikhitha, M.N.; Aruna, K.; Afreen; Murthy, B.T.V. Solar Powered Autonomous Multipurpose Agricultural Robot Using Bluetooth/Android App. In Proceedings of the 2019 3rd International conference on Electronics, Communication and Aerospace Technology (ICECA), Coimbatore, India, 12–14 June 2019; pp. 872–877. [Google Scholar] [CrossRef]

- Habib, M.d.R.; Ahmed, K.; Khan, N.; Kiran, M.R.; Habib, M.d.A.; Hasan, M.d.T.; Farrok, O. PID Controller Based Automatic Solar PowerDriven Grass Cutting Machine. In Proceedings of the 2019 International Conference on Computer, Communication, Chemical, Materials and Electronic Engineering (IC4ME2), Rajshahi, Bangladesh, 11–12 July 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Zatta, A.; Zegada-Lizarazu, W.; Pritoni, G.; Vecchi, S.; Monti, A. Reduction of Biomass Losses in Mechanized Harvest of Perennial Grasses: A Shortcut to Increase the Competitiveness of Energy Crops. In Proceedings of the 19th European Biomass Conference and Exhibition, Berlin, Germany, 6–10 June 2011; pp. 52–54. [Google Scholar]

- Wilson, M.H.; Lovell, S.T. Agroforestry—The Next Step in Sustainable and Resilient Agriculture. Sustainability 2016, 8, 574. [Google Scholar] [CrossRef]

- Çakmakçı, R.; Salık, M.A.; Çakmakçı, S. Assessment and Principles of Environmentally Sustainable Food and Agriculture Systems. Agriculture 2023, 13, 1073. [Google Scholar] [CrossRef]

- Mehta, C.R.; Chandel, N.S.; Rajwade, Y.A. Smart Farm Mechanization for Sustainable Indian Agriculture. Agric. Mech. Asia Afr. Lat. Am. 2020, 51, 99–105. [Google Scholar]

| CH | RS | DM | HT | FC | LC | RT | ||

|---|---|---|---|---|---|---|---|---|

| (cm) | (mm/Day) | (ton/ha) | (h/ha) | (R$/ha) | (R$/ha) | (h/ha) | ||

| Mini Grain Reaper Machine | Samples | 18 | 18 | 18 | 6 | 6 | 6 | 6 |

| Average | 8.89 | 6.07 | 2.52 | 5.82 | 41.59 | 36.75 | 27.78 | |

| Variance | 4.22 | 2.02 | 0.51 | 5.40 | 276.01 | 215.47 | 40.12 | |

| Standard Deviation | 2.05 | 1.42 | 0.71 | 2.32 | 16.61 | 14.68 | 6.33 | |

| Coefficient of Variation | 23.12 | 23.40 | 28.24 | 39.94 | 39.94 | 39.94 | 22.81 | |

| Range | 6.00 | 6.90 | 2.77 | 5.38 | 38.46 | 33.98 | 13.89 | |

| Kurtosis | 1.74 | 6.32 | 3.34 | 1.55 | 1.55 | 1.55 | 1.30 | |

| Skewness | 0.20 | −1.26 | 0.70 | 0.62 | 0.62 | 0.62 | −0.22 | |

| Costal Brushcutter | Samples | 18 | 18 | 18 | 6 | 6 | 6 | 6 |

| Average | 12.22 | 5.82 | 2.50 | 34.22 | 208.38 | 216.18 | 37.50 | |

| Variance | 5.95 | 2.59 | 0.35 | 1.28 | 47.70 | 51.28 | 30.10 | |

| Standard Deviation | 2.44 | 1.61 | 0.59 | 1.13 | 6.91 | 7.16 | 5.49 | |

| Coefficient of Variation | 19.95 | 27.61 | 23.63 | 3.31 | 3.31 | 3.31 | 14.63 | |

| Range | 10.00 | 6.55 | 2.40 | 3.20 | 19.52 | 20.24 | 13.89 | |

| Kurtosis | 3.33 | 3.03 | 2.99 | 3.13 | 3.13 | 3.14 | 2.61 | |

| Skewness | 0.24 | 0.51 | 0.45 | 1.08 | 1.08 | 1.09 | 0.94 | |

| Tractor Mounted Rotary Brushcutter | Samples | 18 | 18 | 18 | 6 | 6 | 6 | 6 |

| Average | 8.61 | 5.08 | 2.13 | 5.50 | 160.29 | 46.72 | 36.11 | |

| Variance | 2.84 | 3.88 | 0.33 | 0.05 | 41.66 | 3.54 | 92.55 | |

| Standard Deviation | 1.69 | 1.97 | 0.57 | 0.22 | 6.45 | 1.88 | 9.62 | |

| Coefficient of Variation | 19.57 | 38.83 | 26.94 | 4.07 | 4.03 | 4.03 | 26.64 | |

| Range | 6.00 | 7.24 | 2.23 | 0.61 | 17.65 | 5.15 | 19.44 | |

| Kurtosis | 2.84 | 2.46 | 3.61 | 2.41 | 2.43 | 2.43 | 1.26 | |

| Skewness | 0.79 | 0.35 | 1.04 | 0.83 | 0.83 | 0.83 | −0.25 |

| CH | RS | DM | HT | FC | LC | RT | ||

|---|---|---|---|---|---|---|---|---|

| (cm) | (mm/Day) | (ton/ha) | (h/ha) | (R$/ha) | (R$/ha) | (h/ha) | ||

| Mini Grain Reaper Machine | Samples | 18 | 18 | 18 | 6 | 6 | 6 | 6 |

| Average | 7.65 | 12.18 | 3.76 | 5.59 | 48.32 | 36.84 | 30.56 | |

| Variance | 6.27 | 16.98 | 3.13 | 0.52 | 38.91 | 22.60 | 46.30 | |

| Standard Deviation | 2.50 | 4.12 | 1.77 | 0.72 | 6.24 | 4.75 | 6.80 | |

| Coefficient of Variation | 32.73 | 33.84 | 47.05 | 12.89 | 12.91 | 12.90 | 22.27 | |

| Range | 9.50 | 15.32 | 7.33 | 1.93 | 16.69 | 12.72 | 16.67 | |

| Kurtosis | 2.95 | 2.74 | 4.38 | 1.78 | 1.78 | 1.78 | 2.04 | |

| Skewness | 0.54 | 0.53 | 1.24 | −0.15 | −0.15 | −0.15 | 0.63 | |

| Costal Brushcutter | Samples | 18 | 18 | 18 | 6 | 6 | 6 | 6 |

| Average | 11.18 | 14.14 | 3.65 | 10.83 | 79.65 | 71.31 | 33.33 | |

| Variance | 8.76 | 25.17 | 1.35 | 2.55 | 138.05 | 110.68 | 27.79 | |

| Standard Deviation | 2.96 | 5.02 | 1.16 | 1.60 | 11.75 | 10.52 | 5.27 | |

| Coefficient of Variation | 26.47 | 35.49 | 31.85 | 14.75 | 14.75 | 14.75 | 15.82 | |

| Range | 11.50 | 20.66 | 4.45 | 4.52 | 33.27 | 29.79 | 16.67 | |

| Kurtosis | 3.23 | 3.33 | 2.74 | 3.72 | 3.71 | 3.71 | 3.00 | |

| Skewness | 0.82 | 0.51 | 0.59 | 1.47 | 1.47 | 1.47 | 0.00 | |

| Tractor Mounted Rotary Brushcutter | Samples | 18 | 18 | 18 | 6 | 6 | 6 | 6 |

| Average | 7.81 | 10.37 | 2.90 | 4.62 | 172.77 | 40.57 | 43.06 | |

| Variance | 3.83 | 13.70 | 0.95 | 0.03 | 40.54 | 2.24 | 113.44 | |

| Standard Deviation | 1.96 | 3.70 | 0.98 | 0.17 | 6.37 | 1.50 | 10.65 | |

| Coefficient of Variation | 25.09 | 35.68 | 33.59 | 3.68 | 3.69 | 3.69 | 24.74 | |

| Range | 8.00 | 12.17 | 3.44 | 0.44 | 16.45 | 3.87 | 30.56 | |

| Kurtosis | 3.40 | 1.96 | 3.05 | 1.70 | 1.70 | 1.70 | 3.69 | |

| Skewness | −0.35 | 0.18 | 1.01 | 0.15 | 0.14 | 0.14 | 1.45 |

| CH | RS | DM | HT | FC | LC | RT | ||

|---|---|---|---|---|---|---|---|---|

| (cm) | (mm/Day) | (ton/ha) | (h/ha) | (R$/ha) | (R$/ha) | (h/ha) | ||

| Mini Grain Reaper Machine | Samples | 18 | 18 | 18 | 6 | 6 | 6 | 6 |

| Average | 7.81 | 12.57 | 6.80 | 10.51 | 89.72 | 73.55 | 34.72 | |

| Variance | 5.26 | 20.89 | 7.26 | 2.69 | 196.14 | 131.77 | 113.45 | |

| Standard Deviation | 2.29 | 4.57 | 2.69 | 1.64 | 14.01 | 11.48 | 10.65 | |

| Coefficient of Variation | 29.39 | 36.36 | 39.62 | 15.61 | 15.61 | 15.61 | 30.67 | |

| Range | 9.25 | 16.21 | 9.31 | 4.63 | 39.52 | 32.39 | 30.56 | |

| Kurtosis | 3.67 | 2.14 | 2.77 | 2.58 | 2.57 | 2.57 | 3.69 | |

| Skewness | 0.87 | 0.14 | 0.97 | −0.70 | −0.69 | −0.69 | 1.45 | |

| Costal Brushcutter | Samples | 18 | 18 | 18 | 6 | 6 | 6 | 6 |

| Average | 10.40 | 13.07 | 6.83 | 11.28 | 82.01 | 78.95 | 42.13 | |

| Variance | 17.82 | 21.31 | 7.96 | 2.27 | 119.95 | 111.11 | 492.04 | |

| Standard Deviation | 4.22 | 4.62 | 2.82 | 1.51 | 10.95 | 10.54 | 22.18 | |

| Coefficient of Variation | 40.58 | 35.32 | 41.33 | 13.35 | 13.35 | 13.35 | 52.65 | |

| Range | 14.25 | 17.02 | 10.53 | 4.27 | 31.07 | 29.90 | 61.11 | |

| Kurtosis | 3.06 | 3.69 | 5.03 | 2.90 | 2.90 | 2.90 | 3.81 | |

| Skewness | 1.01 | 1.27 | 1.64 | −1.04 | −1.05 | −1.05 | 1.57 | |

| Tractor Mounted Rotary Brushcutter | Samples | 18 | 18 | 18 | 6 | 6 | 6 | 6 |

| Average | 6.49 | 11.93 | 5.67 | 5.74 | 224.06 | 53.26 | 46.30 | |

| Variance | 6.70 | 28.54 | 10.89 | 0.20 | 312.78 | 17.67 | 26.74 | |

| Standard Deviation | 2.59 | 5.34 | 3.30 | 0.45 | 17.69 | 4.20 | 5.17 | |

| Coefficient of Variation | 39.91 | 44.80 | 58.23 | 7.88 | 7.89 | 7.89 | 11.17 | |

| Range | 12.00 | 23.05 | 12.62 | 1.12 | 43.67 | 10.38 | 11.11 | |

| Kurtosis | 7.73 | 5.51 | 4.45 | 1.58 | 1.58 | 1.58 | 1.18 | |

| Skewness | 1.93 | 1.44 | 1.38 | 0.03 | 0.02 | 0.02 | 0.12 |

| Treatments | Grass | Working Time | Costs | ||||

|---|---|---|---|---|---|---|---|

| CH | RS | DM | HT | RT | FC | LC | |

| (cm) | (mm/Day) | (ton/ha) | (h/ha) | (h/ha) | (R$/ha) | (R$/ha) | |

| Mini Grain Reaper Machine | 8.12 | 10.27 | 4.36 | 7.31 | 31.02 | 59.88 | 49.05 |

| Costal Brushcutter | 11.27 | 11.01 | 4.33 | 18.78 | 37.65 | 123.34 | 122.15 |

| T. Mounted Rotary Brushcutter | 7.63 | 9.13 | 3.57 | 5.28 | 41.82 | 185.71 | 46.85 |

| Strengths | Weaknesses | Opportunities | Threats | |

|---|---|---|---|---|

| Mini Grain Reaper Machine | Superior cutting quality with minimal damage to grass tussocks and apical buds | Clogging issues when used to harvest Mombaça grass | Technological improvements to address clogging issues and optimize performance | Competition from alternative machines with higher capacity and versatility |

| Provides greater biomass productivity compared to other machines | Increased handling time due to necessary stops for unclogging | Adaptation for grass species or crops with similar characteristics | Potential high costs associated with advanced technological features | |

| Results in whole cut leaves | Uneven grass cutting | Growing demand for high-quality cutting and biomass harvesting machines | Competition with machines commonly available on the market | |

| Deposits the cut grass leaves already piled up | Operational limitations in specific agricultural environments, terrains and grass species | Can be improved with technological advancements to reduce physical effort and increase efficiency | Market unavailability | |

| Provides fastest raking time | - | - | - | |

| Suitable for minimizing operational costs | - | - | - | |

| Costal Brushcutter | Affordable, cost-effective and easy handling option for small-scale farmers | Slow operation | Can be improved with technological advancements to reduce physical effort and increase efficiency | Competition from other machines with higher efficiency and lower physical effort requirements |

| Suitable for smaller areas and operations | Higher labor costs | Market demand for affordable and small-scale machinery in agroforestry systems | Potential challenges in adapting the machine for different grass species or agricultural contexts | |

| Provides the fastest regrowth speed | Requires significant labor and physical effort | Reduction in fuel costs by improving machine performance | - | |

| Results in whole-cut leaves | Unsuitable for larger scales | - | - | |

| Do not damage apical buds | - | - | - | |

| Good grass biomass production over time | - | - | - | |

| Homogeneous cutting | - | - | - | |

| Tractor Mounted Rotary Brushcutter | Suitable for larger-scale contexts and operations | Uneven grass cutting | Potential integration with precision agriculture technologies for enhanced efficiency | Competition from other machines with better stability and lower costs |

| Reduces working time, physical effort, and labor costs | Higher fuel consumption compared to other machines | Demand for larger-scale machinery in agroforestry systems and commercial agriculture | Potential limitations in maneuverability and accessibility in certain terrains or areas | |

| - | May not be cost-effective for small-scale farmers or limited areas | Potential for modifications to minimize damage to grass plants and improve regrowth vigor | Market saturation and price competition with alternative machines | |

| - | Damages apical buds and tussocks, resulting in productivity losses | Tractor purchase, usage and maintenance can be shared with many farmers | Less availability of skilled labor | |

| - | Grass leaves shredded and scattered after cutting, resulting in longer raking time | Adaptation of the brushcutter to the front of the tractor | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Morais, G.F.; Santos, J.d.S.G.; Han, D.; Ramos Filho, L.O.; Xavier, M.G.B.; Schimidt, L.; de Souza, H.T.; de Castro, F.T.; de Souza-Esquerdo, V.F.; Albiero, D. Agricultural Machinery Adequacy for Handling the Mombaça Grass Biomass in Agroforestry Systems. Agriculture 2023, 13, 1416. https://doi.org/10.3390/agriculture13071416

de Morais GF, Santos JdSG, Han D, Ramos Filho LO, Xavier MGB, Schimidt L, de Souza HT, de Castro FT, de Souza-Esquerdo VF, Albiero D. Agricultural Machinery Adequacy for Handling the Mombaça Grass Biomass in Agroforestry Systems. Agriculture. 2023; 13(7):1416. https://doi.org/10.3390/agriculture13071416

Chicago/Turabian Stylede Morais, Gelton Fernando, Jenyffer da Silva Gomes Santos, Daniela Han, Luiz Octávio Ramos Filho, Marcelo Gomes Barroca Xavier, Leonardo Schimidt, Hugo Thiago de Souza, Fernanda Ticianelli de Castro, Vanilde Ferreira de Souza-Esquerdo, and Daniel Albiero. 2023. "Agricultural Machinery Adequacy for Handling the Mombaça Grass Biomass in Agroforestry Systems" Agriculture 13, no. 7: 1416. https://doi.org/10.3390/agriculture13071416

APA Stylede Morais, G. F., Santos, J. d. S. G., Han, D., Ramos Filho, L. O., Xavier, M. G. B., Schimidt, L., de Souza, H. T., de Castro, F. T., de Souza-Esquerdo, V. F., & Albiero, D. (2023). Agricultural Machinery Adequacy for Handling the Mombaça Grass Biomass in Agroforestry Systems. Agriculture, 13(7), 1416. https://doi.org/10.3390/agriculture13071416