Abstract

A high-speed camera was applied to observe the shaking detachment tests with ‘Guiwei’ litchi clusters using 7 Hz, 9.5 Hz, and 12 Hz and the amplitudes of 40 mm, 60 mm, and 80 mm. The fruit’s detachment time and the number of fruit–fruit impacts were affected by the vibrational parameters and the fruit position (inside or outside of the cluster). A high and stable detachment speed and a low number of impacts could be achieved with the parameter combination of 9.5 Hz/80 mm. The cluster index, considering both the shaking position and the total fruit mass, was found to have a stronger correlation with the detachment time than the average fruit-to-shaker distance (distance from the shaker to the fruit). Thus, the detachment time can be estimated based on the cluster indexes. The fruit-to-shaker distance also affected the fruit-to-shaker impact. A fruit-to-shaker distance of 50~60 mm was recommended to avoid almost all the impacts, depending on the shaking parameters. The horizontal throw distance of the fruit was calculated based on the detachment velocity and angle, which can be used as the design basis for the catching devices. With a high enough drop height, a disc-shaped catching surface with a radius of 475 mm, 489 mm, 591 mm, 741 mm, 844 mm, and 832 mm, respectively, could collect 90% of all the fruit at six different vibrational parameter combinations. A closer catching surface to the fruit could effectively reduce the horizontal throw distance.

1. Introduction

Litchi (Litchi chinensis Sonn.) is a subtropical fruit widely grown in India, Vietnam, Australia, South Africa, South China, and other places. China has the largest planting area and the highest global litchi yield. In 2020, the total output in China reached 2,553,500 t [1]. The picking period of litchi is as short as one week to avoid overripening. However, almost all the litchi in China is picked manually [2], so great demand for labor is required during the picking season. There is an urgent need for high efficiency harvesting machinery to replace the human workforce. The key issue in the research is the development of harvesters to improve the harvesting efficiency and reduce fruit damage. Vibration harvesting is one of the main methods of mechanical fruit harvesting. A litchi vibration harvester was developed in previous research, and the separation patterns and mechanisms in the vibration detachment were explored [3,4], which indicated that this method was feasible for litchi harvesting. However, limited systematic research on fruit detachment and the impact characteristics was conducted on fruit growing in clusters.

Litchi is vulnerable fruit and can be easily damaged, and studies have shown that 7.6% of the fruit was lost due to mechanical damage during the manual picking process [5]. Bryant [6] found that the impact would lead to browning or cracking the litchi peel. Recent research showed that the number of impacts and the speed of the impact affected the damage degree of litchi fruit [7,8]. On the other hand, studies on litchi and other fruits showed that a low vibration frequency and amplitude may lead to a low removal percentage [9,10,11]. Xu et al. [12] found that mechanical vibration had a great effect on the quality of blueberries, which increased the decay rate of the blueberries and decreased the activity of enzymes. Lu et al. [13] found that vibration significantly increased the ethylene release and respiration rate of apple fruit, resulting in faster apple damage and shorter storage time. Leili et al. [14] chose appropriate vibration techniques, including the shaker type, amplitude, frequency, and clamp position according to the tree characteristics and fruit properties to improve the nut harvest efficiency. Sergio et al. [15] achieved a high harvest quality, and a harvesting efficiency near 85% by choosing an appropriate frequency range for harvesting Pinus pinea L. Zhao et al. [16] optimized the harvesting machine of Lycium barbarum L. using the finite element method and the response surface method. The optimum range for the rotating speed and amplitude was obtained, the harvesting efficiency was improved, and its damage was reduced. Therefore, it is very important to select the appropriate vibration parameters to improve the fruit removal percentage and reduce the damage degree.

Shaking harvesting is widely used in sweet cherry, citrus, olive, and other fruits, and many studies focused on the influence of vibrational parameters on the vibration efficiency. A canopy shaker system can achieve more than a 90% fruit removal percentage under appropriate vibration parameters [17]. Using the proper shaking frequency and shaking duration could improve sweet cherries’ removal percentage and efficiency [18]. Shaking citrus trees with the proper parameters and duration could also make the fruit detachment more effective [19,20]. The harvesting efficiency of olive shakers could be improved using the proper vibrational frequency and amplitude for the different maturity stages [21]. Blanco et al. [22] studied the effects of the duration and repetitions of trunk shakers on the olive harvesting efficiency. The shaking harvesting experiments of Roka et al. [23] on citrus and Sola-Guirado et al. [24] on olives showed that when the vibrational parameters were properly selected, the fruit harvesting efficiency could be increased without damaging the fruit trees. Coral et al. [25] reduced the frequency and increased the amplitude to achieve the best mechanical harvest for citrus. Carlos et al. [26] determined the optimal frequency range to detach high ripe coffee fruit in their experiments. The shaking position also had an important influence on the fruit detachment. Zhou et al. [27] applied a hand-held shaker to the branches of sweet cherry trees. The results showed that the distance between the excitation position and the fruiting zone affected the fruit detachment efficiency. He et al. [28] introduced the fruit location index that contained both the geometric dimensions of the fruiting twigs and the exciting branches. The results showed strong correlations between the indexes and the acceleration of the fruit. The detachment time of the fruit during the shaking was very important, and it was one of the main limitations for improving the traveling speed of the shaking machines [29]. Therefore, determining an efficient shaking position for the litchi cluster is a problem to be solved.

The surface impact is a major reason for inducing fruit damage. For fruits grown in clusters, such as litchis and sweet cherries, the impact between the fruit is inevitable during shaking harvesting [7,30]. Zhou et al. [31] found that the impact might also occur between the fruit and the branches, and the number of these impacts was less than that of the fruit-to-fruit impacts. Since the fruiting branches of the litchi clusters were long and thin, the shaking position must be close to the fruit to obtain enough energy for detachment [3]. Thus, the impacts between the fruit and the shaker may also happen, which has not been studied yet.

Therefore, the previous research mainly focused on the vibrational parameters (e.g., the frequency, amplitude, ) on the harvesting efficiency, removal percentage, and fruit damage. A few studies also observed the influence of the morphological characteristics (e.g., thickness and length of the branches, distance from the shaking position to the fruit) on the harvesting effect. However, for fruit growing in clusters, the group effect (e.g., number of fruit, the position of fruit) on the fruit detachment remains unclear. In the present paper, a linear reciprocating vibration mechanism was used to harvest litchi clusters to study the following subjects. (1) The effect of the fruit position (inside or outside) on the detachment time and the fruit-to-fruit impact under different vibrational frequencies and amplitudes. (2) A litchi cluster index considering both the information of the total fruit mass and the shaking position was introduced to study its effect on the detachment time. The effect of the shaking position on the fruit-to-shaker impact was also observed. (3) The detached litchi fruit horizontal throw distance was calculated. In this paper, machine vision and target vibrational harvesting were combined to harvest the litchi fruit. Machine vision technologies can analyze the morphological characteristics of litchi clusters to guide the shaker to excite them at the appropriate positions with the appropriate vibrational parameters. Meanwhile, the harvesting route planning and the prediction of the harvesting time can be carried out, and each cluster’s detachment process can be tracked. As a result, this study provides a basis for applying machine vision in litchi harvesting and developing litchi cluster shakers.

2. Materials and Methods

2.1. Sample Preparation

‘Guiwei’ litchi was used for the vibrational detachment tests. In June 2021, the litchi samples were picked manually in orchards located in Guangzhou City every day and then carried to the laboratory at the university within 2 h. Regarding the high perishability of litchi fruit, these samples were consumed on the same day for the tests. Before the tests, the operators checked all the fruit, and those with obvious damage or disease were eliminated. A total of 567 litchis in 81 clusters were used for nine groups of tests. Each test was repeated nine times.

2.2. Vibrational Detachment Tests

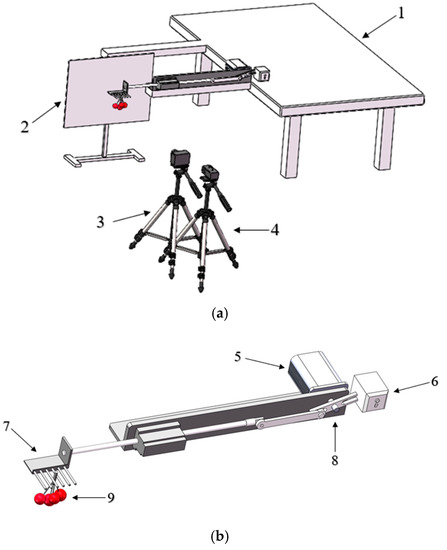

As shown in Figure 1, a fixed comb-shaped shaker driven by a direct current motor was used for the detachment tests. The length and diameter of the five teeth on the shaker were 100 mm and 5 mm, and the tooth space was 20 mm. A length-adjustable crank drove the shaker for the reciprocating movement. The vibration frequency and the amplification of the shaker could be continuously adjusted from 0 to 20 Hz and 40 to 100 mm, respectively. Amplitude = 2 × stroke. A high-speed camera (FASTCAM Mini UX50, Photron, Japan) mounted on a tripod was used to record the detachment processes of the litchi fruit at a rate of 1000 frames per second (FPS) and yielded 1280 × 1024 pixels videos. The longest recording time of the camera was 4.364 s. A white background was placed behind the experimental device, and a 120-W LED light source mounted on another tripod was applied to ensure sufficient brightness for the testing area. In the tests, the shaker shook the fruit at the amplitudes of 40, 60, and 80 mm, at the frequencies of 7, 9.5, and 12 Hz (the parameters were determined during the pretests). The specific parameters of the tests are shown in Table 1.

Figure 1.

Experimental setup of the shaking tests; (a) setup of the experimental system: 1—test table, 2—white background, 3—high-speed camera, 4—light source. (b) The sketch of the shaking mechanism: 5—motor, 6—control panel, 7—shaker, 8—crank, 9—litchi cluster.

Table 1.

Parameters of the vibrational detachment tests.

2.3. Determination of the Detachment Time

The detachment time of every litchi fruit was determined using the MATLAB program. First, the shaker’s starting and fruit detachment moment frame numbers were obtained. Then the detachment time t was given as the following.

where i1 is the frame number of the shaker’s starting moment (the moment the shaker begins to move), i2 is the frame number of the fruit detachment moment, and the figure ‘1000’ is the FPS of the high-speed camera.

2.4. The Fruit-to-Shaker Distance and the Cluster Index

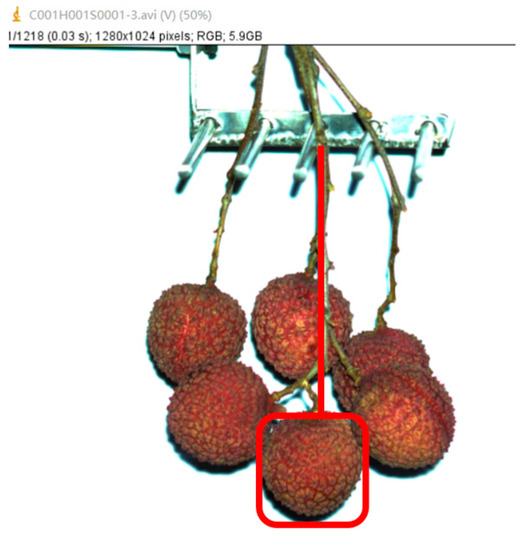

Since the fruit branches were flexible, the detachment time of the fruit could be affected by the shaking position on the branches. The shaking position can be presented by the length of the branches below the shaker. In the present study, the distance between the shaker and the fruit’s stem was measured using the software ImageJ (Figure 2), and this length was defined as the fruit-to-shaker distance.

Figure 2.

Measurement of the fruit-to-shaker distance. The length of the line represents the fruit-to-shaker distance of the fruit in the red box.

For a cluster of litchis, the total mass of all the fruit was another parameter that could affect the detachment time. Thus, a cluster index combined with these two parameters was introduced to describe the fruiting characteristics of a cluster.

where li and mi are, respectively, the fruit-to-shaker distance (the length between shaker and the stem) and the mass of each fruit (m), is the average mass of all the fruit (g), and n is the number of the fruit in the cluster.

Suppose that the mass of every fruit is equal to the average mass. Then, the index k could be given as the following.

where is the average fruit-to-shaker distance of the cluster (m).

2.5. Inside Fruit and Outside Fruit

For a cluster of litchi fruit, the inside fruit may be restricted by the outside fruit and induce a different motion and impact characteristics. In the current study, the outside fruit was defined as the outermost fruit of a cluster and all isolated fruit. The other fruits were regarded as inside fruit. As shown in Figure 3, the fruit in the red box were considered as the inside fruit and other fruit as the outside fruit.

Figure 3.

Inside fruit and outside fruit.

2.6. The Horizontal Throw Distance of Litchi Fruit

The horizontal throw distance of the fruit was important for designing a catching device for mechanical harvesting. In the present study, the detachment velocity and angle were calculated by analyzing the high-speed videos, which could be used to predict the horizontal throw distance.

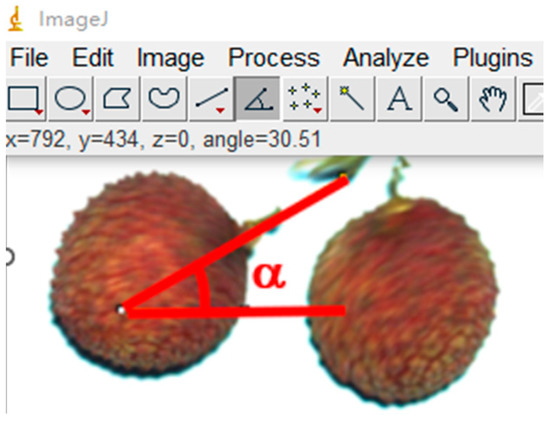

The average speed within 1/500 s (two consecutive frames) after the detachment was approximately considered as the detachment velocity. First, the two consecutive frames were extracted from a high-speed video, and the displacement of the certain fruit within the two frames was measured by the software ImageJ. Then, the average speed was calculated. As shown in Figure 4, the detachment angle of a fruit α was defined as the angle between the moving speed direction and the horizontal direction. The ImageJ software also measured this angle with the first frame after the detachment.

Figure 4.

Measurement of the detachment angle.

Due to the air viscous resistance, the detached fruit’s x-direction velocity will eventually decrease to zero if the drop height is adequate. In this case, the drop distance of the fruit reaches a maximum value and will not increase with the drop height anymore. This distance was defined as the extreme horizontal throw distance. However, if the drop height is insufficient, the fruit will drop nearer.

‘Guiwei’ litchi is subglobose in shape with a high sphericity degree [32]. When considering the fruit as a sphere, the air viscous resistance F can be written as the following.

where ρ is the air density (kg/m3), which was given as 1.154 kg/m3 at 30 °C; C is the air resistance coefficient (Pa∙s) under a normal temperature and pressure, where the C of a sphere object with a velocity smaller than 17.5 m/s can be considered as 0.5 Pa∙s [32]; A is the maximum cross-sectional area of the fruit (m2); and vt (vector) is the instantaneous velocity of the fruit (m/s).

The initial x-direction velocity of the fruit and the x-direction resistance can be given as the following.

where v0 (vector) is the detachment velocity of the fruit (m/s), vx is the initial x-direction velocity of the fruit (m/s), Fx is the initial x-direction air viscous resistance (N), and α is the detachment angle of the fruit (deg).

The detached fruit decelerates under the action of the air viscous resistance in the x-axis direction until the x-direction velocity of the fruit reduces to zero. Therefore, the movement of the fruit in the x-direction is a variably accelerated motion. The differential equation of the movement in the x-direction can be expressed as the following.

where vxt is the instantaneous x-direction velocity of the fruit (m/s) and m is the mass of the fruit (g).

Then, the replacement in the x-direction s can be given as the following.

where t1 is the moment that the x-direction velocity reduces to zero (s) and m is the mass of the fruit (kg).

Equations (7) and (8) were solved using MATLAB, and the fruit’s drop distance could be obtained. If the drop height was given, the drop time was calculated first, then the drop distance was determined also using these equations.

3. Results and Discussion

3.1. The Influence of the Vibrational Parameters on the Detachment and Impact Characteristics

3.1.1. The Fruit Detachment Percentage

The detachment percentages of fruit within the 4.364 s recording time are shown in Table 1. The results indicated that at the amplitude of 40 mm, the detachment percentage increased with the vibration frequency. Nevertheless, the detachment percentage at this amplitude was significantly lower than at other amplitudes at all three frequencies. Even at a frequency of 12 Hz, the detachment percentage of 64% was not sufficient for litchi harvesting. Hence, a frequency higher than 12 Hz was necessary to obtain an acceptable detachment percentage if the amplitude was smaller than 40 mm. All the fruit were detached at the parameter combinations of 95 Hz/60 mm, 9.5 Hz/80 mm, 12 Hz/60 mm, and 12 Hz/80 mm. Since the detachment percentage at the amplitude of 40 mm was too low, the results were not included in the following analyses (except for the one-factor analyses).

3.1.2. The Fruit Detachment Time

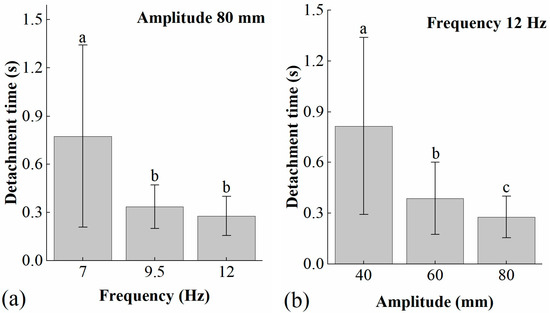

We conducted a one-factor analysis to analyze the separate effects of the frequency and amplitude on the detachment time. As shown in Figure 5, with the increasing frequency and amplitude, the average detachment time decreased, and the rate of reduction for the detachment time decreased. The average detachment times at 9.5 Hz and 12 Hz and 60 mm and 80 mm were shorter and closer than 7 Hz and 40 mm.

Figure 5.

One-factor analysis of the detachment time: (a) frequency factor; (b) amplitude factor. Error bars indicate the standard deviations. According to Duncan’s tests, the different letters indicate significant differences (p ≤ 0.05).

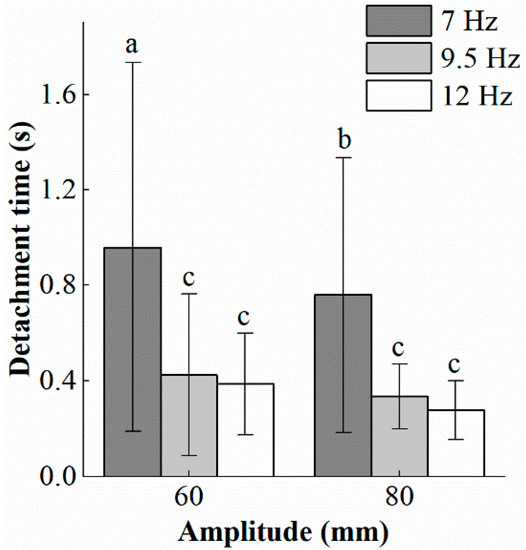

The fruit detachment time is a key index for mechanical harvesting. A short detachment time can increase the harvesting efficiency and shorten the shaking time of the harvester. The total shaking time and the shaking parameters are major factors determining the machine’s operational life (fatigue life). As shown in Figure 6, the average detachment time decreased as the frequency increased from 7 Hz to 12 Hz at the amplitude of 60 mm to 80 mm. However, the detachment times at 9.5 Hz and 12 Hz were not significantly different for both amplitudes. In these cases, the average shaking time was shorter than 0.43 s. Thus, the parameter combinations of 9.5 Hz/60 mm or 9.5 Hz/80 mm were sufficient to obtain efficient detachments depending on the experimental results.

Figure 6.

The detachment time at different amplitudes and frequencies. Error bars indicate the standard deviations. According to Duncan’s tests, the different letters indicate significant differences (p ≤ 0.05).

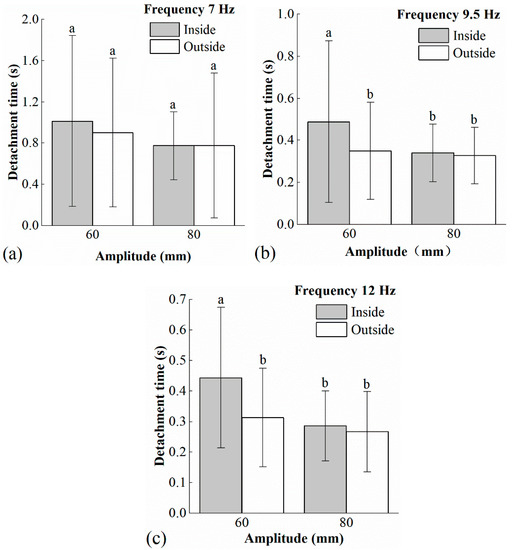

The differences in the detachment time between the inside and outside fruit are shown in Figure 7. At the frequencies of 9.5 Hz and 12 Hz, the detachment time of the inside fruit at 60 mm was longer than that of the outside fruit. Wang et al. [4] proposed that obtaining a large enough tilting angle was a major reason and the quickest way to detach fruit. Therefore, the results indicated that the outside fruit affected the inside fruit. The pendulum swing and tilt motions were restricted during the shaking process at the amplitude of 60 mm for 9.5 Hz and 12 Hz. Hence, the outside fruit was detached first, and then the restriction on the inside fruit was released, which would be detached afterward. In these cases, the total shaking time was determined by the detachment time of the inside fruit. However, at the frequency of 7 Hz and the amplitude of 60 mm, the average detachment time of the inside and outside fruit was close, and no significant difference was found. This was because, at a low frequency, the tilting angle of most of the fruit was relatively small, so the detachment efficiency of the outside fruit was also low [4]. The results in Figure 7 also show that at the amplitude of 80 mm, no significant differences in the detachment time were observed for all three frequencies. Thus, an appropriate increase in the amplitude is a feasible approach to minimize the inside and outside fruit effect on the detachment time, and thus increase the overall harvesting efficiency. It also explains why the standard deviations of 80 mm amplitude were much smaller than those of 60 mm amplitude at 9.5 Hz and 12 Hz, as shown in Figure 6. Based on this consideration, 9.5 Hz/80 mm was better than 9.5 Hz/60 mm for acquiring a stabler detachment speed.

Figure 7.

The detachment time of the inside fruit and the outside fruit at different vibrational parameters: (a) 7 Hz, (b) 9.5 Hz, and (c) 12 Hz. Error bars indicate the standard deviations. According to Duncan’s tests, the different letters indicate significant differences (p ≤ 0.05).

3.1.3. The Fruit-to-Fruit Impact

Impacts may cause obvious or potential damage to fruit and shorten their storage life. During the shaking harvesting of litchis, impacts may occur between the fruit or between the fruit and the shaker. The fruit-to-shaker impact was related to the shaking position and will be discussed in the next section. Observe the video shot by the high-speed camera with naked eyes and calculate the number of number of impacts.

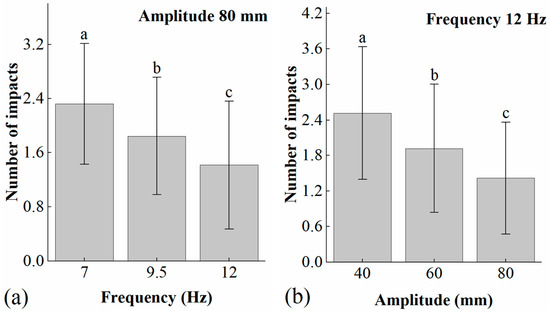

As shown in Figure 8, the frequency and amplitude had separate effects on the number of impacts. With the increase in the frequency and amplitude, the average number of impacts between the litchi decreased evenly, and the differences between the different parameters were obvious. When the parameter value (frequency or amplitude) reached the maximum, the number of impacts was the least.

Figure 8.

One-factor analysis of the number of impacts: (a) frequency factor; (b) amplitude factor. Error bars indicate the standard deviations. According to Duncan’s tests, the different letters indicate significant differences (p ≤ 0.05).

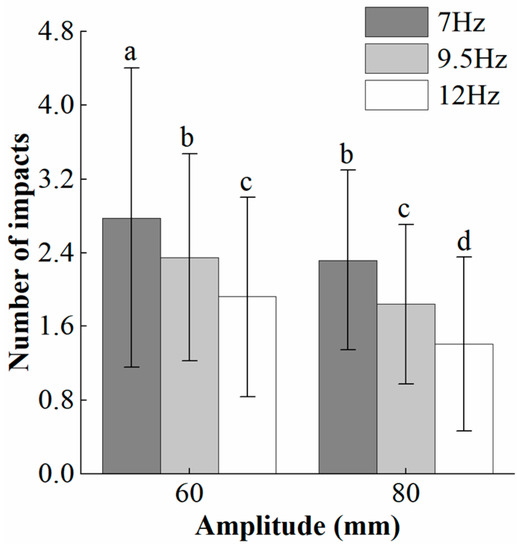

A previous study showed that the number of impacts was an important factor influencing the fruit damage level [7]. Reducing the number of impacts was conductive to decrease the fruit damage. As shown in Figure 9, the average number of impacts decreased with the increase in the amplitude and frequency, which agreed with previous studies [4,7]. This phenomenon was caused by the short detachment time at a high amplitude and frequency. With the parameter combinations of 12 Hz/60 mm, 9.5 Hz/80 mm, and 12 Hz/80 mm, the average number of impacts were all fewer than two times (respectively, 1.84, 1.92, and 1.41 times).

Figure 9.

The number of fruit–fruit impacts at the different amplitudes and frequencies. Error bars indicate the standard deviations. According to Duncan’s tests, the different letters indicate significant differences (p ≤ 0.05).

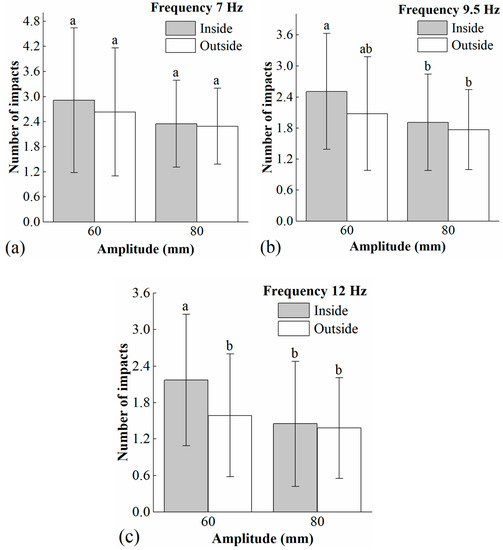

Figure 10 highlights the number of impacts between the inside and outside fruit at the different vibrational parameters. At the 60 mm amplitude, the average number of impacts of the inside fruit were higher than that of the outside fruit for all three frequencies. The difference became more significant as the frequency increased from 7 Hz to 12 Hz. The inside fruit was more likely to be impacted due to the adjacent fruit on both sides. However, at an amplitude of 80 mm, the number of impacts on the inside fruit and outside fruit had no significant differences. Therefore, a relatively low and stable impact time could be achieved at the 9.5 Hz/80 mm and 12 Hz/80 mm parameter combinations.

Figure 10.

The number of fruit–fruit impacts of the inside fruit and outside fruit at the different vibrational parameters: (a) 7 Hz, (b) 9.5 Hz, and (c) 12 Hz. Error bars indicate the standard deviations. According to Duncan’s tests, the different letters indicate significant differences (p ≤ 0.05).

3.2. The Influence of the Shaking Position and Fruit Mass on the Detachment and Impact Characteristics

3.2.1. The Relationship between the Shaking Position and Detachment Time

A longer fruit-to-shaker distance negatively influences the detachment time since the fruit receives low excitation energy [28]. However, it is beneficial to avoid the impact between the fruit and the shaker. Apart from the fruit-to-shaker distance, the total fruit mass is another factor that may affect the detachment speed of the fruit. In this section, we attempt to build an acceptable relationship between the detachment time and the morphological characteristics of the litchi clusters.

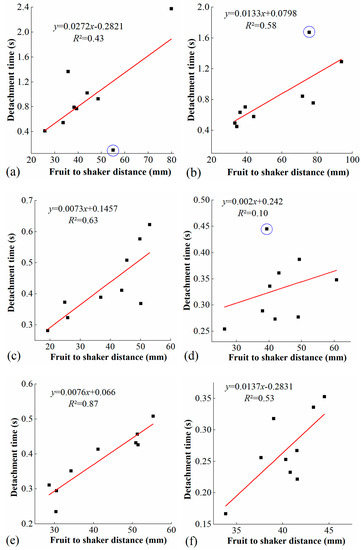

The relationship between the average detachment time and the average fruit-to-shaker distance of a litchi cluster at different vibrational parameters is shown in Figure 11. The overall trend revealed that the detachment time increased with the fruit-to-shaker distance. The coefficients of determination R2 of the linear regression model were 0.43, 0.58, 0.63, 0.10, 0.87, and 0.53, respectively, at six different vibrational parameter combinations. There were good correlations between the fruit-to-shaker distance and the detachment time for all the parameter combinations except for those shown in Figure 11d. Nevertheless, some of the data deviated significantly from the line of best fit, such as the data points in the blue circles.

Figure 11.

The relationship between the detachment time and the fruit-to-shaker distance: (a) 7 Hz/60 mm, (b) 7 Hz/80 mm, (c) 9.5 Hz/60 mm, (d) 9.5 Hz/80 mm, (e) 12 Hz/60 mm, and (f) 12 Hz/80 mm.

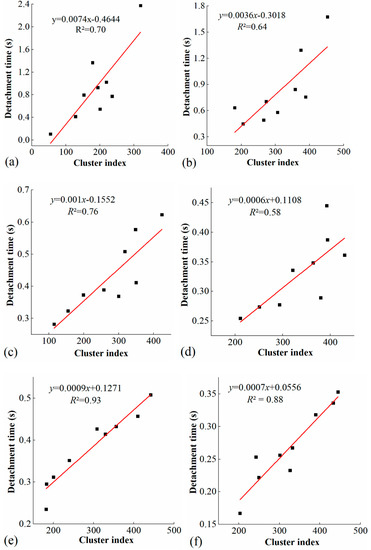

The cluster index, which contains both the fruit-to-shaker distance and the total mass information, was introduced to describe the overall fruiting characteristics of a litchi cluster. The relationship between the cluster index and the detachment time is shown in Figure 12. The trend lines in the figure show that the detachment time also increased with the cluster index at all the parameter combinations. The coefficients of determination R2 of the linear regression model were 0.70, 0.64, 0.76, 0.58, 0.93, and 0.88, respectively. The R2 values at all the parameter combinations improved compared to those in Figure 11. The detachment time had a much stronger correlation with the cluster index than the fruit-to-shaker distance. Therefore, the cluster index was a better morphological parameter for predicting the detachment time. Increasing the fruit-to-shaker distance and the number of fruit in a cluster resulted in a larger cluster index and increased the detachment time. In a machine vision-based shaking harvesting system, it is possible to estimate the cluster index and then predict the harvesting time for each cluster or even select the appropriate shaking parameters.

Figure 12.

The relationship between the detachment time and the cluster index: (a) 7 Hz/60 mm, (b) 7 Hz/80 mm, (c) 9.5 Hz/60 mm, (d) 9.5 Hz/80 mm, (e) 12 Hz/60 mm, and (f) 12 Hz/80 mm.

3.2.2. The Fruit-to-Shaker Impact

If an aluminum shaker hit the fruit during the shaking process, serious damage could be induced. Thus, decreasing the number of fruit–shaker impacts is important to reduce the damage degree of the fruit.

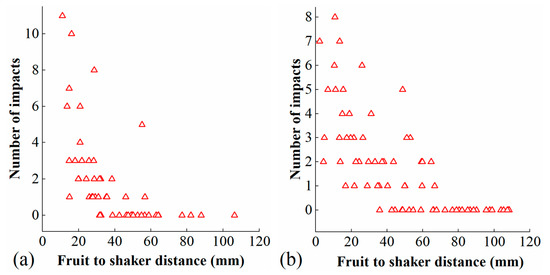

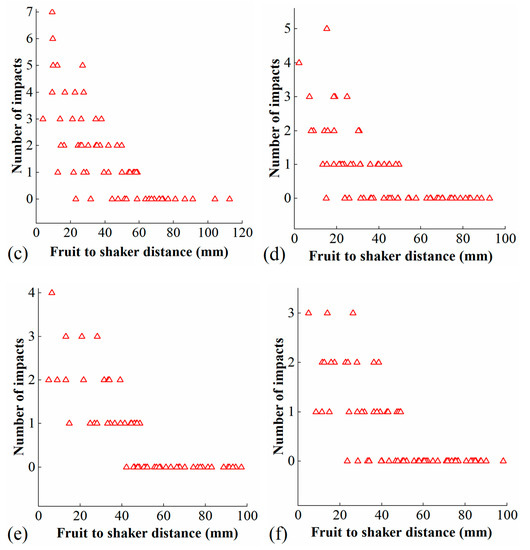

Normally, the fruit and shaker impacts occurred when the fruit was swung to an upper position, which was more easily induced under high amplitudes and frequencies. However, a shorter detachment time would decrease the impact possibility simultaneously. The experimental results showed that the average number of impacts between the fruit and the shaker were 1.78, 1.72, 1.62, 0.75, 0.78, and 0.60 times, respectively, at the parameter combinations of 7 Hz/60 mm, 7 Hz/80 mm, 9.5 Hz/60 mm, 9.5 Hz/80 mm, 12 Hz/60 mm, and 12 Hz/80 mm. Hence, fewer impacts were observed at the high vibrational parameters. As shown in Figure 13, the fruit-to-shaker distance was another major factor affecting the number of fruit–shaker impacts. It was found that the number of impacts between the fruit and the shaker decreased with the increase in the fruit-to-shaker distance at all six vibrational parameter combinations. When the fruit-to-shaker distance reached 40 mm, the percentages of the fruit that the impact time was equal to or fewer than one time were 95.7%, 82.9%, 96.8%, 100%, 100%, and 100%, respectively, for the six different vibrational conditions. The percentages of the fruit that had no impact were 87.0%, 70.7%, 86.1%, 78.6%, and 86.4%, respectively. With a fruit-to-shaker distance of 50 mm, all the fruit was free from the fruit-to-shaker impact at 9.5 Hz/80 mm, 12 Hz/60 mm, and 12 Hz/80 mm. When the fruit-to-shaker distance increased to 60 mm, almost all the fruit had no impact with the shaker at 7.5 Hz/60 mm, 7.5 Hz/80 mm, and 95 Hz/60 mm. Only two exceptions occurred at 75 Hz/80 mm, where the percentage of non-impact fruit was 98.9%. Therefore, a fruit-to-shaker distance of 50 mm or 60 mm was a good choice for selecting the shaking position depending on the shaking parameters to avoid fruit-to-shaker impacts. To obtain a higher detachment speed, a fruit-to-shaker distance of 40 mm was also acceptable.

Figure 13.

The relationship between the number of impacts and the fruit-to-shaker distance: (a) 7 Hz/60 mm, (b) 7 Hz/80 mm, (c) 9.5 Hz/60 mm, (d) 9.5 Hz/80 mm, (e) 12 Hz/60 mm, and (f) 12 Hz/80 mm.

3.3. The Horizontal Throw Distance of the Fruit

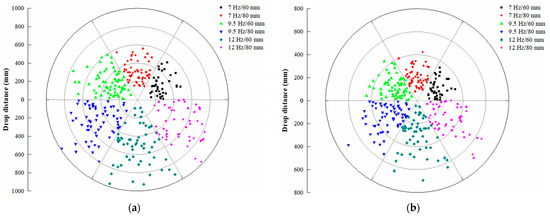

To design a proper catching device for the mechanical harvesting system, the horizontal throw distance of the fruit needs to be investigated. A fruit can reach an extreme drop distance with enough height under a certain initial velocity and angle. In real situations, the height from the fruit to the catching surface is normally certain, so the fruit may drop on the surface before it reaches the extreme drop distance. Although the branches and leaves of the litchi trees may change the motion path for some of the detached fruit, the calculated horizontal throw distance can reflect the real range to a large extent. If there was no limit to the drop height, the maximum extreme drop distance would be 525 mm, 564 mm, 769 mm, 986 mm, 969 mm, and 979 mm, respectively, at the six different vibrational parameter combinations. When the drop height was 400 mm, the maximum extreme drop distance was 345 mm, 424 mm, 447 mm, 714 mm, 695 mm, and 704 mm, respectively, at the six different vibrational parameter combinations.

Figure 14 shows the calculated extreme drop distance and the drop distance with a drop height of 400 mm for all the fruit in the shaking tests. The drop distance increased with the frequency and the amplitude. A disc-shaped catching surface with a corresponding size radius was needed to catch all the fruit. Suppose the desired collecting percentage was 90%, then the radius of the disc would be 475 mm, 489 mm, 591 mm, 741 mm, 844 mm, and 832 mm, respectively. If the drop height was 400 mm, the maximum extreme drop distance was 349 mm, 424 mm, 447 mm, 714 mm, 695 mm, and 703 mm, respectively.

Figure 14.

The calculated drop distance of all the fruit at the different vibrational parameters: (a) extreme drop distance; (b) drop distance at a drop height of 400 mm. The data dots in the figure only represent the distance from the center.

Similarly, discs with a radius of 321 mm, 328 mm, 395 mm, 493 mm, 554 mm, and 547 mm were required to collect 90% of all the fruit at the different parameter combinations. Therefore, the fixed 400 mm interval from the catching surface to the fruit could effectively reduce the horizontal throw distance. A closer catching interval would further reduce the horizontal throw distance. Designing a catching device close to the fruit that moves with the shaker in a real application is feasible.

4. Conclusions

The detachment time and the number of fruit–fruit impacts decreased as the frequency and amplitude increased. However, the detachment times at the parameter combinations of 9.5 Hz/60 mm, 9.5 Hz/80 mm, 12 Hz/60 mm, and 12 Hz/80 mm were all shorter than 0.42 s and had no significant differences. The average number of impacts at 12 Hz/60 mm, 9.5 Hz/80 mm, and 12 Hz/80 mm were fewer than two times. The position of the fruit affected the detachment time and the number of impacts to some degree. At 9.5 Hz/60 mm and 12 Hz/60 mm, the detachment times of the inside fruit were significantly higher than that of the outside fruit. At 12 Hz/60 mm, the number of fruit–fruit impacts of the inside fruit were significantly higher than the outside fruit. The combination of 9.5 Hz/80 mm was the optimal parameter considering all the aspects. The fruit-to-shaker impacts decreased with the increase in the fruit-to-shaker distance. Depending on the shaking parameters, a fruit-to-shaker distance of 50 mm to 60 mm was recommended so that a majority of fruit could avoid impacts with the shaker. The determination of optimal vibration parameter combination and the fruit-to-shaker distance can improve the mechanical harvesting efficiency and reduce the damage to litchi.

The overall trends showed that the detachment time increased with the fruit-to-shaker distance and the cluster index. However, the cluster index had a much stronger correlation with the detachment time. It indicated that the shaking position and the total fruit mass affected the detachment speed. The detachment time could be predicted using the cluster index. On the basis of being longer than the fruit-to-shaker distance, the optimum vibration position of the litchi cluster could be determined by further research on the cluster index and the number of fruit in the cluster.

With a high enough drop height, a disc-shaped catching surface with a radius of 475 mm, 489 mm, 591 mm, 741 mm, 844 mm, and 832 mm, respectively, could collect 90% of all the fruit at the six different vibrational parameter combinations. A closer catching surface to the fruit could effectively reduce the horizontal throw distance. The determination of the horizontal throw distance of litchi provides a theoretical foundation for the subsequent design of a litchi collecting device.

Author Contributions

Conceptualization, X.C., W.W. and H.F.; methodology, X.C., C.H. and Y.W.; writing—original draft, X.C.; visualization, X.C. and W.W.; resources, X.C. and W.W.; investigation, X.C., W.W. and Y.W.; software, X.C. and W.W.; validation, W.W. and J.L.; writing—review and editing, X.C. and W.W.; supervision, J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the China Agriculture Research System of MOF and MARA (Grant No. CARS-32-14) and the Special Project of the Rural Vitalization Strategy of the Guangdong Academy of Agricultural Sciences (Grant No. TS-1-4).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of the data; in the writing of the manuscript; or in the decision to publish the results.

References

- Su, Z.; Yang, S.; Chen, J. Analysis of the production situation for litchi in main planting areas of China in 2020. J. South. Agric. 2020, 51, 1598–1605. (In Chinese) [Google Scholar]

- Wang, W.; Lu, H.; Yang, Z.; Li, J.; Lv, E.; Wang, W. Investigation and analysis on mechanization status of litchi and longan orchards. J. Agric. Mech. Res. 2012, 34, 237–241. (In Chinese) [Google Scholar] [CrossRef]

- Wang, W.; Lu, H.; Mo, C.; Yang, Z.; Hohimer, C.J.; Qiu, G. Experiments on the Mechanical Harvesting of Litchi and its Effects on Litchi Storage. Trans. ASABE 2017, 60, 1529–1535. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Fu, H.; Yang, Z.; Lu, H. Detachment patterns and impact characteristics of litchi fruit during vibrational harvesting. Sci. Hortic. 2022, 295, 110836. [Google Scholar] [CrossRef]

- Kumar, V.; Purbey, S.K.; Anal, A.D. Losses in litchi at various stages of supply chain and changes in fruit quality parameters. Crop Prot. 2016, 79, 97–104. [Google Scholar] [CrossRef]

- Bryant, P. Optimizing the Post Harvest Management of Lychee (Litchi chinensis Sonn.)—A Study of Mechanical Injury and Desiccation. Ph.D. Thesis, The University of Sydney, Seney, Australia, 2004. [Google Scholar]

- Wang, W.; Lu, H.; Zhang, S.; Yang, Z. Damage caused by multiple impacts of litchi fruits during vibration harvesting. Comput. Electron. Agric. 2019, 162, 732–738. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, S.; Fu, H.; Lu, H.; Yang, Z. Evaluation of litchi impact damage degree and damage susceptibility. Comput. Electron. Agric. 2020, 173, 105409. [Google Scholar] [CrossRef]

- Erdoǧan, D.; Güner, M.; Dursun, E.; Gezer, I. Mechanical Harvesting of Apricots. Biosyst. Eng. 2003, 85, 19–28. [Google Scholar] [CrossRef]

- Polat, R.; Gezer, I.; Guner, M.; Dursun, E.; Erdogan, D.; Bilim, H.C. Mechanical harvesting of pistachio nuts. J. Food Eng. 2007, 79, 1131–1135. [Google Scholar] [CrossRef]

- Santos, F.L.; De Queiroz, D.M.; Pinto, F.D.A.D.C.; De Resende, R.C. Efeito da frequência e amplitude de vibração sobre a derriça de frutos de café. Rev. Bras. Eng. Agrícola Ambient. 2010, 14, 426–431. [Google Scholar] [CrossRef]

- Xu, F.; Liu, S.; Liu, Y.; Wang, S. Effect of mechanical vibration on postharvest quality and volatile compounds of blueberry fruit. Food Chem. 2021, 349, 129216. [Google Scholar] [CrossRef]

- Lu, F.; Xu, F.; Li, Z.; Liu, Y.; Wang, J.; Zhang, L. Effect of vibration on storage quality and ethylene biosynthesis-related enzyme genes expression in harvested apple fruit. Sci. Hortic. 2019, 249, 1–6. [Google Scholar] [CrossRef]

- Leili, A.; Taymaz, H.; Arash, T.; Reza, E.; Louise, F.; Sergio, C. Mechanical harvesting of selected temperate and tropical fruit and nut trees. Hortic. Rev. 2021, 49, 171–242. [Google Scholar] [CrossRef]

- Castro-Garcia, S.; Blanco-Roldán, G.L.; Gil-Ribes, J.A. Frequency response of Pinus pinea L. for selective cone harvesting by vibration. Trees 2011, 25, 801–808. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, T.; Inagaki, T.; Chen, Y.; Hu, G.; Wang, Z.; Chen, Q.; Gao, Z.; Zhou, J.; Wang, M.; et al. Parameter Optimization of Vibrating and Comb-Brushing Harvesting of Lycium barbarum L. Based on FEM and RSM. Horticulturae 2021, 7, 286. [Google Scholar] [CrossRef]

- Roka, F.M.; Ehsani, R.J.; Futch, S.H.; Hyman, B.R. Citrus Mechanical Harvesting Systems-Continuous Canopy Shakers; Food and Economic Resources Department, UF/IFAS Extension: Gainesville, FL, USA, 2014. [Google Scholar]

- Zhou, J.; He, L.; Zhang, Q.; Du, X.; Chen, D.; Karkee, M. Evaluation of the influence of shaking frequency and duration in mechanical harvesting of sweet cherry. Appl. Eng. Agric. 2013, 29, 607–612. [Google Scholar] [CrossRef]

- Lenker, D.H.; Hedden, S.L. Optimum shaking action for citrus fruit harvesting. Trans. ASABE 1968, 11, 347–349. [Google Scholar] [CrossRef]

- Ortiz, C.; Torregrosa, A. Determining Adequate Vibration Frequency, Amplitude, and Time for Mechanical Harvesting of Fresh Mandarins. Trans. ASABE 2013, 56, 15–22. [Google Scholar] [CrossRef]

- Alzoheiry, A.; Ghonimy, M.; El Rahman, E.A.; Abdelwahab, O.; Hassan, A. Improving olive mechanical harvesting using appropriate natural frequency. J. Agric. Eng. 2020, 51, 148–154. [Google Scholar] [CrossRef]

- Blanco, G.L.; Gil, J.A.; Kouraba, K.; Castro, S. Effects of trunk shaker duration and repetitions on removal efficiency for the harvesting of oil olives. Appl. Eng. Agric. 2009, 25, 329–334. [Google Scholar] [CrossRef]

- Roka, F.M.; House, L.H.; Mosley, K.R. Analyzing Production Records of Commercial Sweet Orange Blocks to Measure Effects of Mechanical Harvesting on Long-Term Production and Tree Health; Food and Economic Resources Department, UF/IFAS Extension: Gainesville, FL, USA, 2014. [Google Scholar]

- Sola-Guirado, R.R.; Jimenez-Jimenez, F.; Blanco-Roldan, G.L.; Castro-Garcia, S.; Castillo-Ruiz, F.J.; Gil-Ribes, J.A. Vibration parameters assessment to develop a continuous lateral canopy shaker for mechanical harvesting of traditional olive trees. Span. J. Agric. Res. 2016, 14, e0204. [Google Scholar] [CrossRef]

- Ortiz, C.; Torregrosa, A.; Castro-García, S. Comparison of a Lightweight Experimental Shaker and an Orchard Tractor Mounted Trunk Shaker for Fresh Market Citrus Harvesting. Agriculture 2021, 11, 1092. [Google Scholar] [CrossRef]

- Cardona, C.I.; Tinoco, H.A.; Perdomo-Hurtado, L.; López-Guzmán, J.; Pereira, D.A. Vibrations Analysis of the Fruit-Pedicel System of Coffea arabica var. Castillo Using Time–Frequency and Wavelets Techniques. Appl. Sci. 2021, 11, 9346. [Google Scholar] [CrossRef]

- Zhou, J.; He, L.; Zhang, Q.; Karkee, M. Effect of excitation position of a handheld shaker on fruit removal efficiency and damage in mechanical harvesting of sweet cherry. Biosyst. Eng. 2014, 125, 36–44. [Google Scholar] [CrossRef]

- He, L.; Fu, H.; Karkee, M.; Zhang, Q. Effect of fruit location on apple detachment with mechanical shaking. Biosyst. Eng. 2017, 157, 63–71. [Google Scholar] [CrossRef]

- Castro-Garcia, S.; Sola-Guirado, R.R.; Gil-Ribes, J.A. Vibration analysis of the fruit detachment process in late-season ‘Valencia’ orange with canopy shaker technology. Biosyst. Eng. 2018, 170, 130–137. [Google Scholar] [CrossRef]

- Zhou, J.; He, L.; Whiting, M.; Amatya, S.; Larbi, P.A.; Karkee, M.; Zhang, Q. Field evaluation of a mechanical-assist cherry harvesting system. Eng. Agric. Environ. Food 2016, 9, 324–331. [Google Scholar] [CrossRef]

- Zhou, J.; He, L.; Karkee, M.; Zhang, Q. Analysis of shaking-induced cherry fruit motion and damage. Biosyst. Eng. 2016, 144, 105–114. [Google Scholar] [CrossRef]

- Zhou, Y.; Ye, Z.; Wu, Z. Calculation and Analysis of Air Resistance in Ball Games. Phys. Eng. 2002, 12, 55–59. (In Chinese) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).