Design and Test of Sensor for Monitoring Corn Cleaning Loss

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cleaning Discharge Composition Analysis

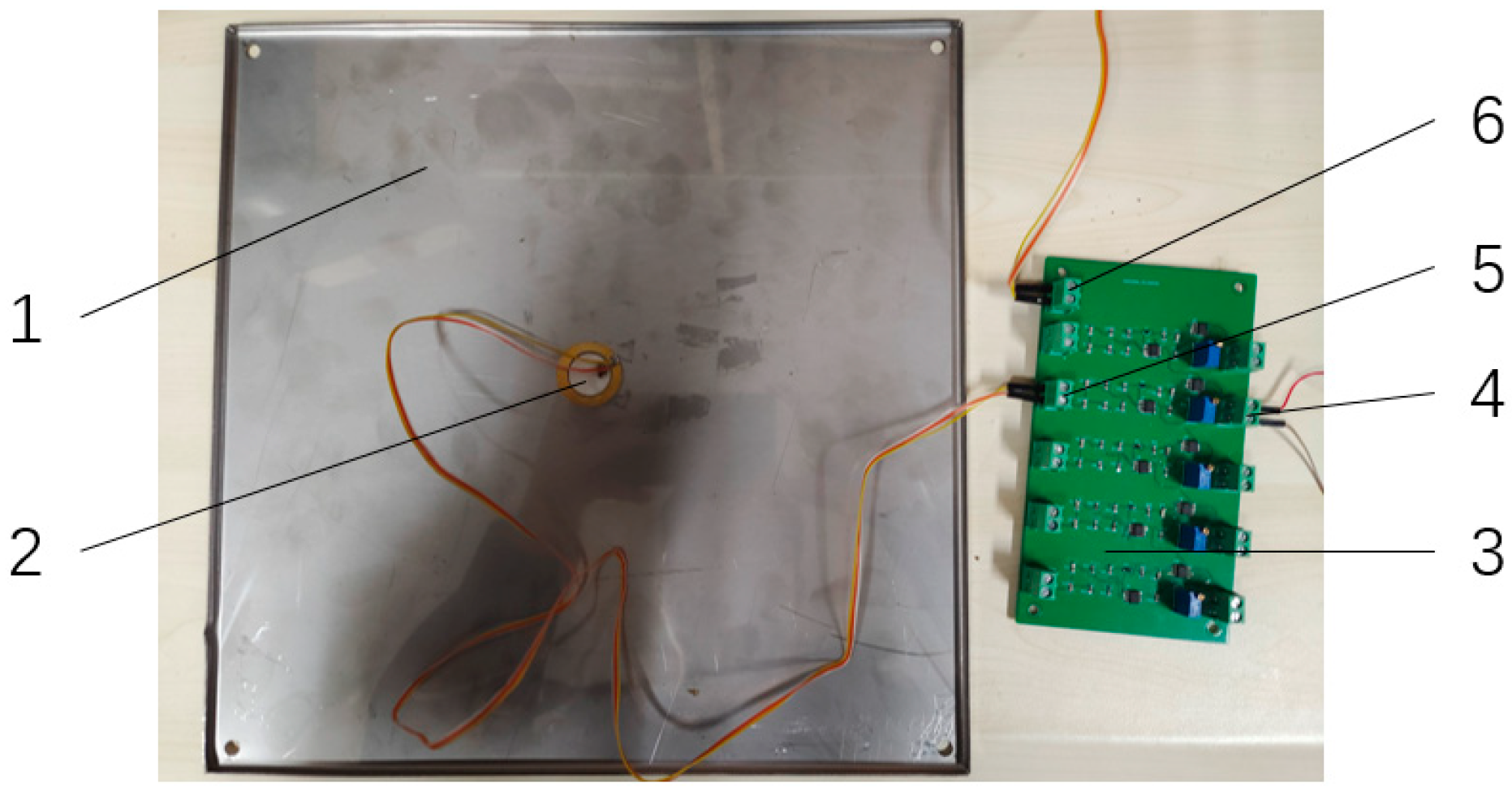

2.2. Design and Development of Monitoring Sensor

2.2.1. Sensitive Plate Design

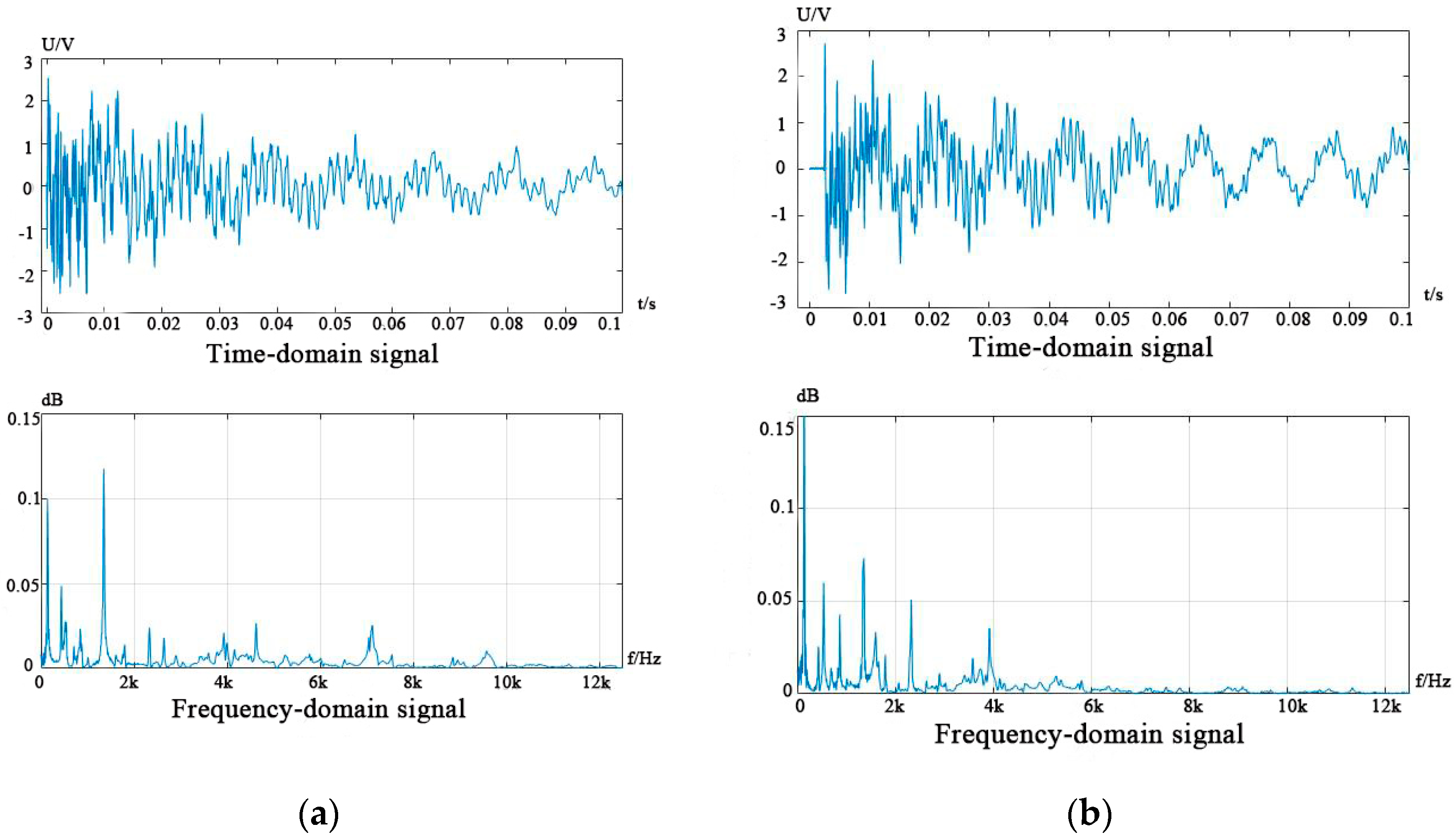

2.2.2. Signal Acquisition and Analysis

2.2.3. Signal Processing Circuit Design

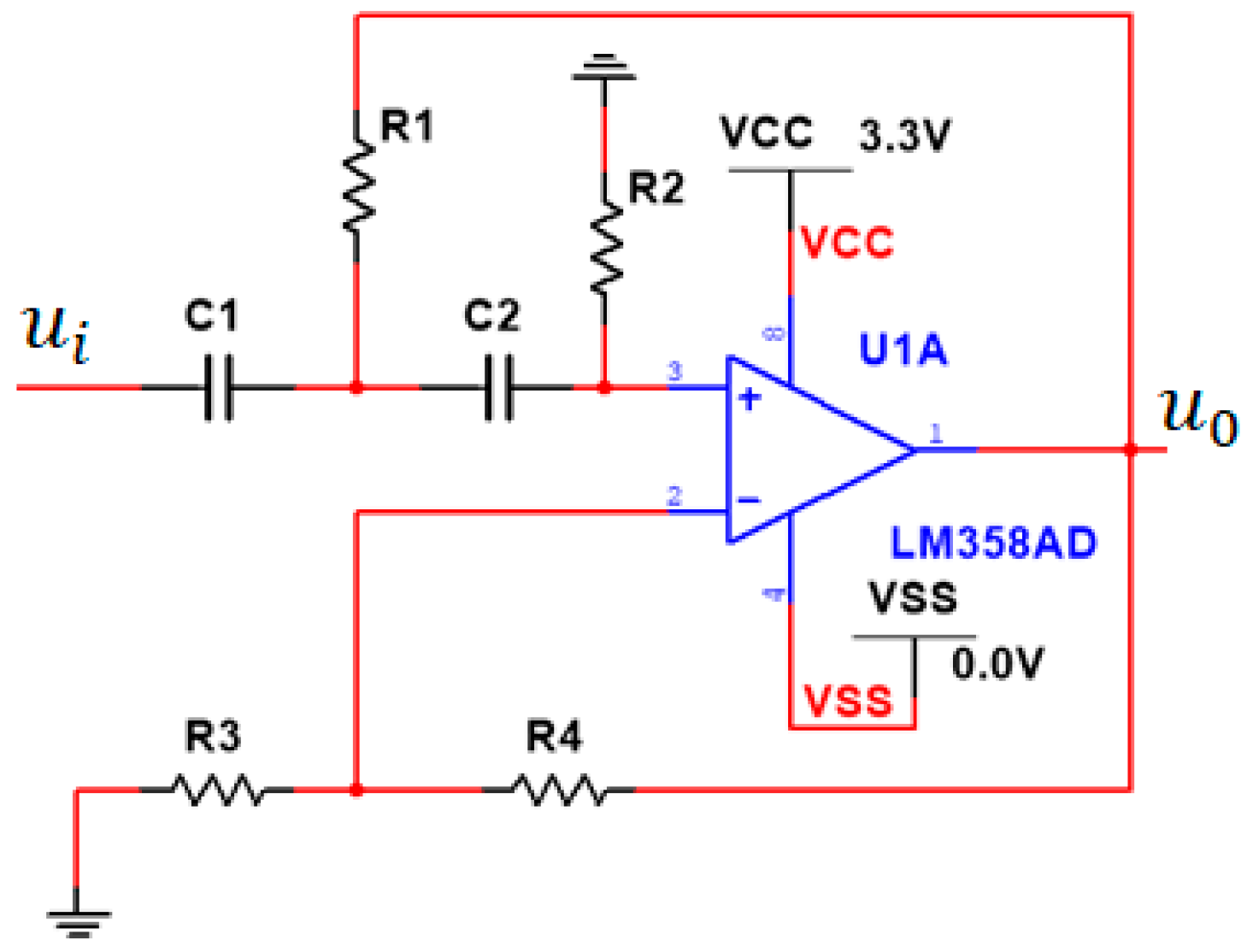

- (1)

- High-pass filter circuit design

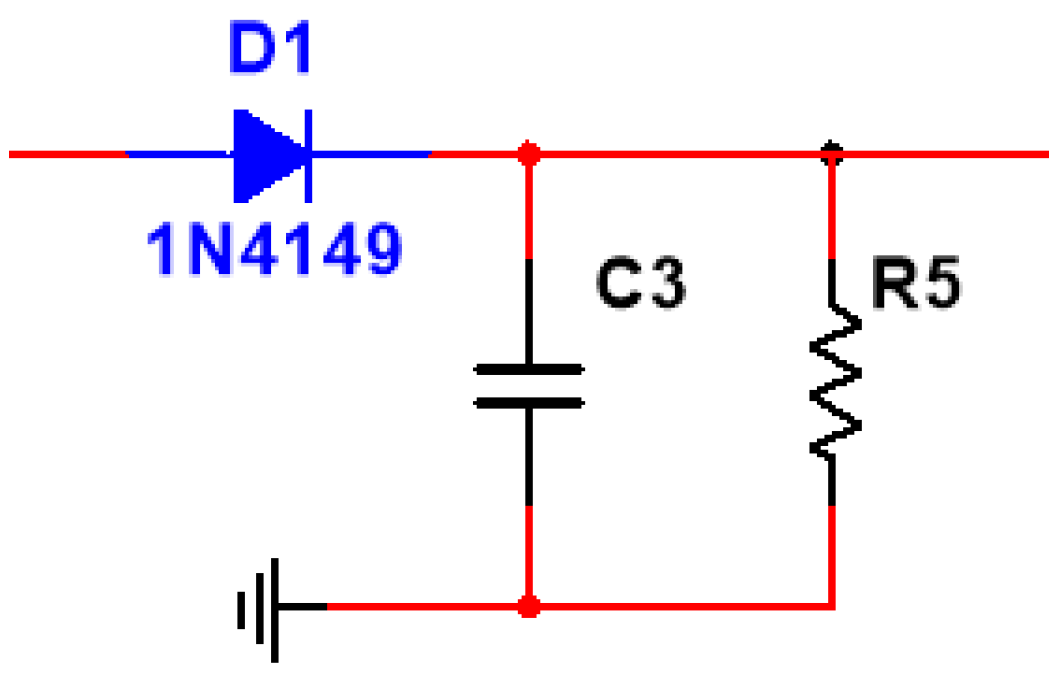

- (2)

- Envelope detection circuit design

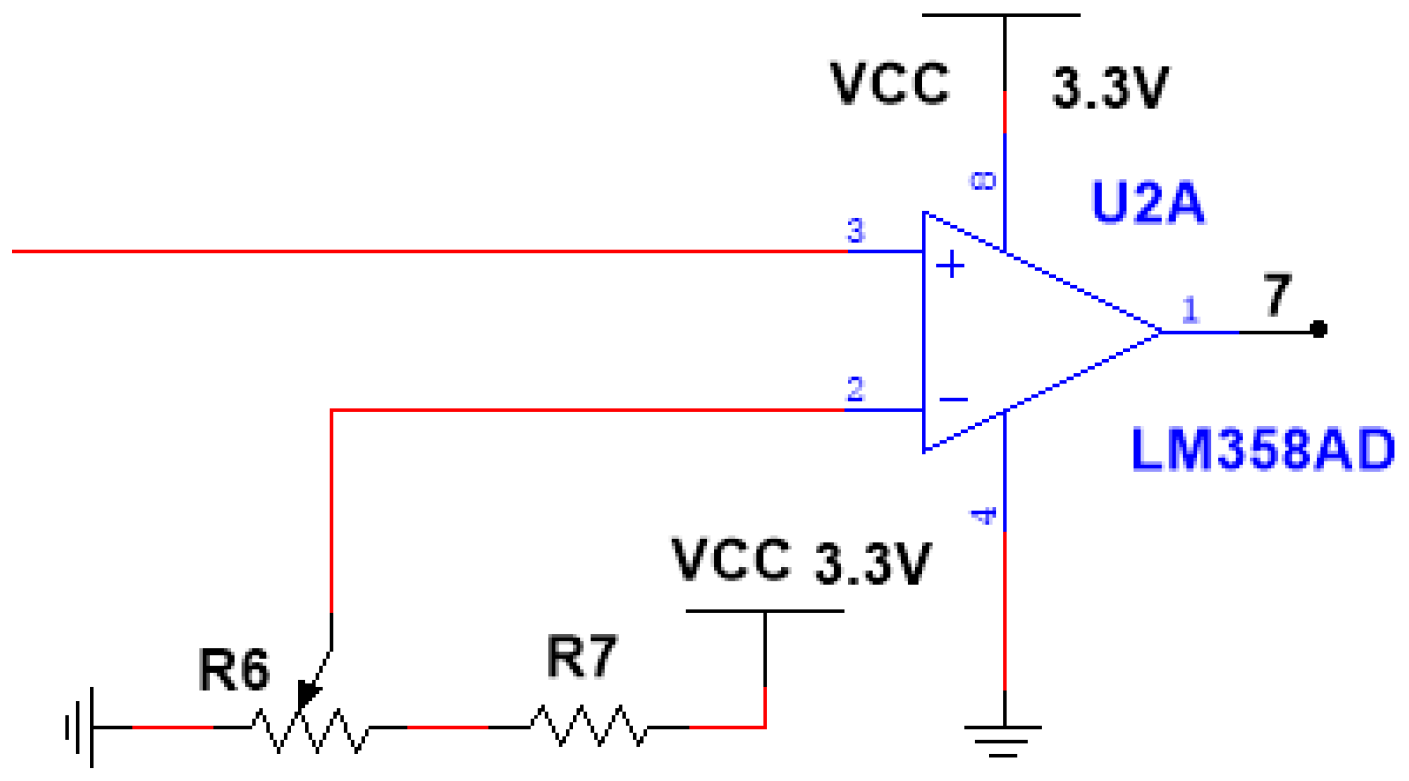

- (3)

- Voltage comparison circuit design

- (4)

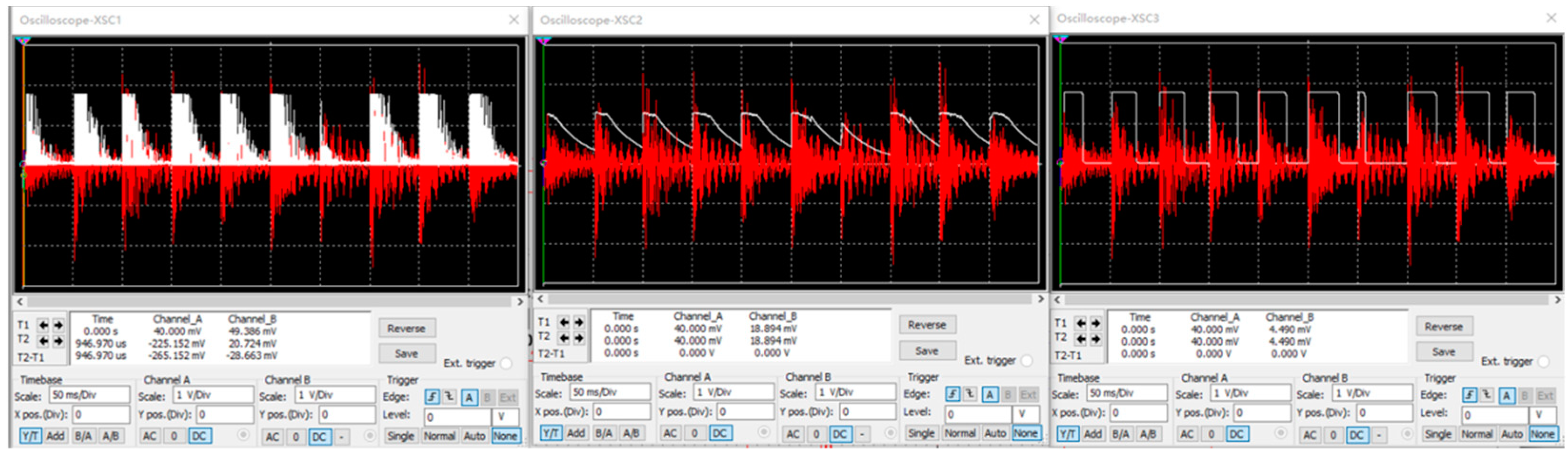

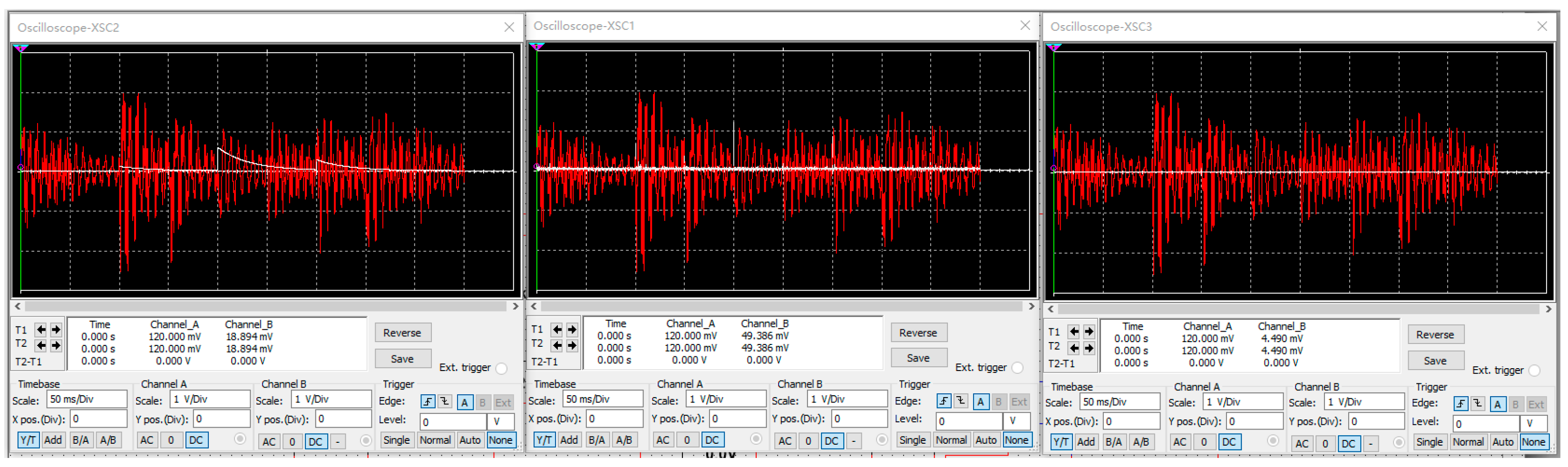

- Simulation and test

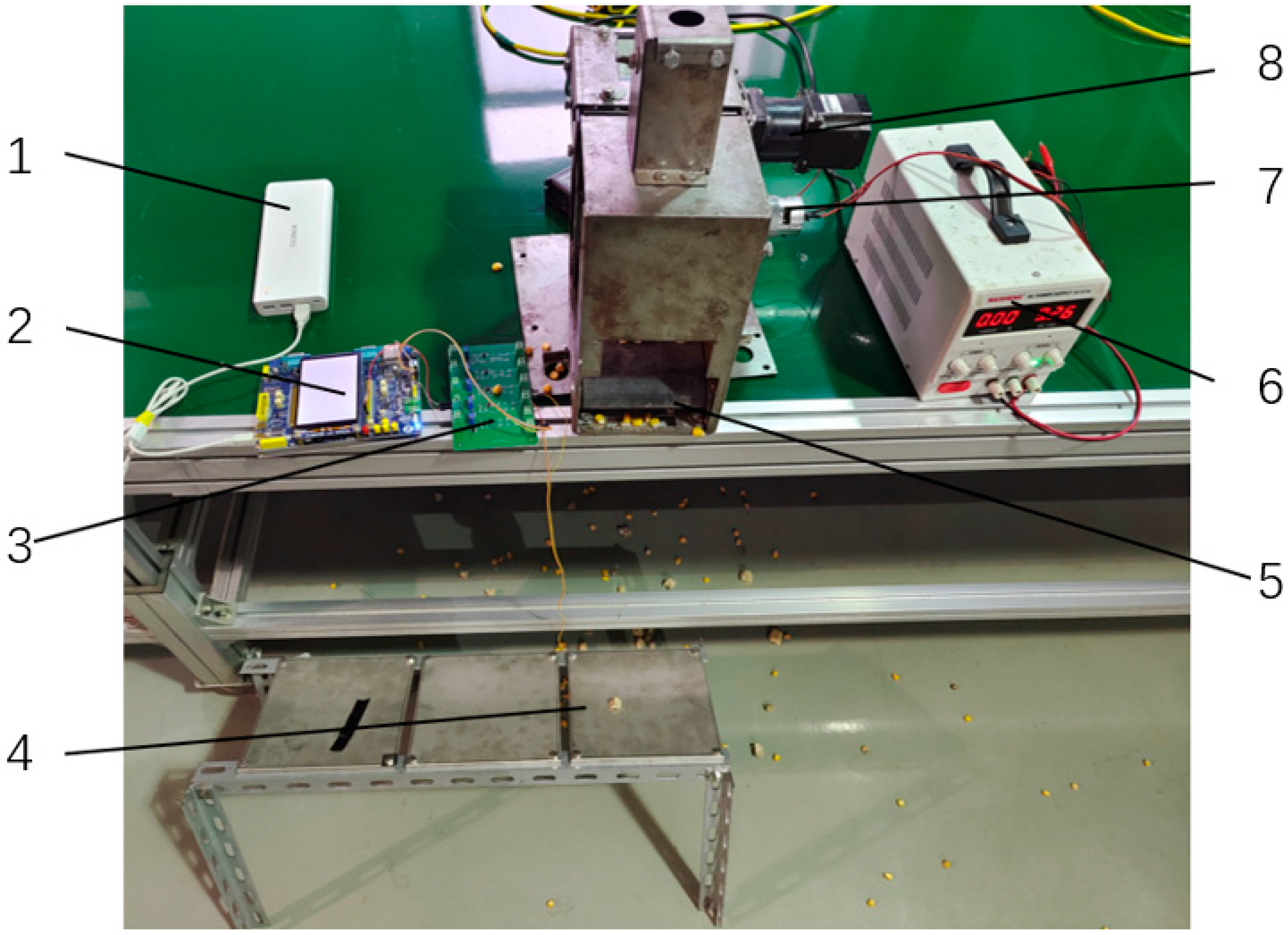

2.3. Sensor Test

2.3.1. Test Conditions

2.3.2. Test Method

3. Results and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z. Design of Threshing and Separating Device about Corn Grain Harvester and Automatic Control System of Entrainment Loss; Jiangsu University: Zhenjiang, China, 2021. [Google Scholar]

- Guo, Y.; Zhan, P.; Li, X.; Zhu, J. Study on yield loss of maize during harvesting in China—Based on the surveys in 5 counties of 5 provinces. J. Maize Sci. 2018, 26, 130–136. [Google Scholar]

- Zhang, M.; Jiang, L.; Wu, C.; Wang, G. Design and test of cleaning loss kernel recognition system for corn combine harvester. Agronomy 2022, 12, 1145. [Google Scholar] [CrossRef]

- Edwin, M.N.; David, L.M.; Lyle, S.J. Grain Loss Monitor. U. S. Patent 3935866, 3 February 1976. [Google Scholar]

- Osselaere Guy, H.J. Offset Grain Loss Sensor for Combine Harvesters. U.S. Patent 4540003, 10 September 1985. [Google Scholar]

- Diekhans, N.; Willi, B. Lost-Grain Detector for Harvesting Machine. U.S. Patent 4902264, 20 February 1990. [Google Scholar]

- Thomas, G.K. Acoustic Grain Flow Rate Monitor. U. S. Patent 4004289, 18 January 1977. [Google Scholar]

- Hiregoudar, S.; Udhaykumar, R.; Ramappa, K.T.; Shreshta, B.; Meda, V.; Anantachar, M. Artificial Neural Network for Assessment of Grain Losses for Paddy Combine Harvester a Novel Approach; Springer: Berlin/Heidelberg, Germany, 2011; pp. 221–231. [Google Scholar]

- Gilbert, J.; Strubbe, I. Grain Loss Monitors for Harvesting Machines. U. S. Patent 5046362, 10 September 1991. [Google Scholar]

- Wang, X.; Zhang, S. Grain impact dynamics analysis of combine harvester grain loss sensor. J. Agric. Mech. Res. 1997, 2, 57–60. [Google Scholar]

- Ni, J.; Mao, H.; Li, P. Design of lntelligent grain cleaning losses monitor based on array piezocrystals. Trans. Chin. Soc. Agric. Mach. 2010, 41, 175–177. [Google Scholar]

- Mao, H.; Ni, J. Finite element analysis and measurement for array piezocrystals grain losses sensor. Trans. Chin. Soc. Agric. Mach. 2008, 39, 123–126. [Google Scholar]

- Zhou, X. Study on the Monitoring System for Cleaning Loss of the Grain Combine Harvester; Northwest A&F University: Yangling, China, 2010. [Google Scholar]

- Wei, C. Study on the Monitoring Method and Device for Cleaning Loss of the Rapeseed Combine Harvester; Jiangsu University: Zhenjiang, China, 2018. [Google Scholar]

- Chun, W.; Ming, L.; Liangjun, Y.; Zhu, L. Research on loss monitoring of grain cleaning in combine harvester based on kalman filter. J. Agric. Mech. Res. 2016, 38, 23–27. [Google Scholar]

- Zhang, G.; Jin, C.; Yang, T.; Liu, Z.; Chen, M.; Zhou, D. Design and implementation of cleaning loss rate monitoring system for combine harvester. J. Chin. Agric. Mech. 2019, 40, 146–150. [Google Scholar]

- Yanhan, W.; Xiaoyu, L.; Enrong, M.; Du, Y.; Yang, F. Design and development of monitoring device for corn grain cleaning loss based on piezoelectric effect. Comput. Electron. Agric. 2020, 179, 105793. [Google Scholar]

- Wei, C.; Li, Y.; Xu, L.; Liang, Z.; Wang, J. Design and experimental study of large feed quantity crawler full feeding rice combine harvester. J. Agric. Mech. Res. 2018, 8, 70–74. [Google Scholar]

- Liang, Z.; Li, Y.; Zhao, Z.; Xu, L.; Tang, Z. Monitoring mathematical model of grain cleaning losses on longitudinal-axial flow combine harvester. Trans. Chin. Soc. Agric. Mach. 2015, 46, 106–111. [Google Scholar]

- Wang, J.; Li, F. Signal processing methods in fault diagnosis of machinery—Analyses in frequency doman. Noise Vib. Control. 2013, 33, 173–180. [Google Scholar]

- Wang, J.; Li, F. Review of signal processing methods in fault diagnosis for machinery. Noise Vib. Control. 2013, 33, 128–132. [Google Scholar]

- Hanping, M.; Wei, L.; Han, L.; Xiaodong, Z. Design of intelligent monitoring system for grain cleaning losses based on symmetry sensors. Trans. Chin. Soc. Agric. Eng. 2012, 28, 34–39. [Google Scholar]

- Zhou, L.; Zhang, X.; Liu, Y.; Yuan, Y. Design of PVDF sensor array for grain loss measuring. Trans. Chin. Soc. Agric. Mach. 2010, 41, 167–171. [Google Scholar]

- Zheng, Y.; Yang, Y.; Jia, D.; Xing, L.; Zhu, Y. Optimal Design of Voltage-controlled Voltage Source Second-order Unit Gain Butterworth High-pass Filter. Electron. Technol. 2012, 39, 33. [Google Scholar]

- Williams, A.B. Analog Filter and Circuit Design Manual; Electronics Industry Press: Beijing, China, 2015; pp. 108–131. [Google Scholar]

- Ma, X.; Cheng, X.; Hou, W. Simulation of diode peak value envelope detector based on Multisim 10.1. Exp. Technol. Manag. 2012, 29, 85–87. [Google Scholar]

- Zhou, H.; Lv, Z.; Ma, G.; Hu, J. Experimental study of voltage comparator. Exp. Technol. Manag. 2012, 29, 42–44. [Google Scholar]

| Component | Weight/(g) | Weight Percentage/(%) | Quantity | Quantity Percentage/(%) |

|---|---|---|---|---|

| Light impurity | 286.52 | 5.41 | —— | —— |

| Large-sized broken corncobs | 2149.16 | 40.56 | 1446 | 32.33 |

| Medium-sized broken corncobs | 1465.42 | 27.66 | 1077 | 24.08 |

| Small-sized broken corncobs | 1283.07 | 24.22 | 1604 | 35.86 |

| Corn grains | 113.93 | 2.15 | 346 | 7.73 |

| Items | Parameter | Items | Parameter |

|---|---|---|---|

| Length | 200 mm | Material | 304 stainless steel |

| Width | 200 mm | Fixing method | Bolting |

| Thickness | 1 mm | Other processing | Four-sided bending |

| Parameters | Symbol | Numerical Values |

|---|---|---|

| Coupling coefficient | kp | 0.68 |

| Relative permittivity (F/m) | ε | 1700 |

| Piezoelectric constant (C/N) | d31 | 195 |

| Elastic flexibility coefficient(m2/N) | S33 | 19.2 |

| Quality factor | Qm | 50 |

| Dielectric loss | tg | 0.02 |

| Thickness (mm) | d | 0.2 |

| Radius (mm) | r | 9 |

| Levels | Installation Angle A/(°) | Installation Height B/(cm) |

|---|---|---|

| −1.414 | 24 | 26 |

| −1 | 30 | 30 |

| 0 | 45 | 40 |

| 1 | 60 | 50 |

| 1.414 | 66 | 54 |

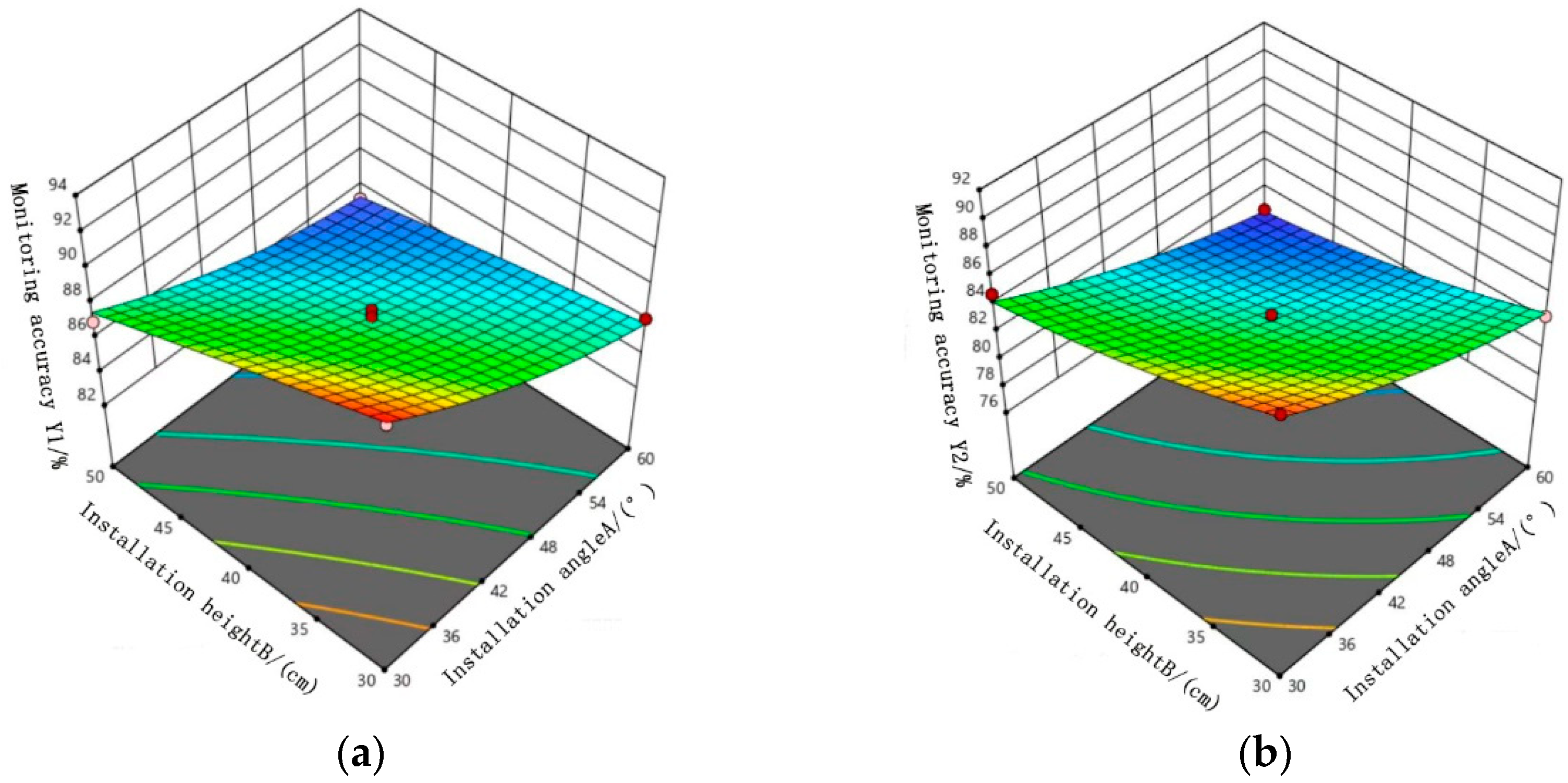

| No. | Installation Angle A/(°) | Installation Height B/(cm) | Monitoring Accuracy Y1/% | Monitoring Accuracy Y2/% |

|---|---|---|---|---|

| 1 | 30 | 50 | 87.04 | 84.86 |

| 2 | 30 | 30 | 92.82 | 90.07 |

| 3 | 60 | 50 | 83.17 | 78.33 |

| 4 | 60 | 30 | 86.17 | 82.50 |

| 5 | 66 | 40 | 84.02 | 79.35 |

| 6 | 24 | 40 | 92.56 | 88.05 |

| 7 | 45 | 26 | 89.30 | 87.32 |

| 8 | 45 | 54 | 84.35 | 79.75 |

| 9 | 45 | 40 | 86.80 | 82.47 |

| 10 | 45 | 40 | 87.09 | 82.94 |

| 11 | 45 | 40 | 86.63 | 83.03 |

| Source of Variance | Monitoring Accuracy Y1/% | Monitoring Accuracy Y2/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Degree of Freedom | Mean Square | F Value | p Value | Sum of Squares | Degree of Freedom | Mean Square | F Value | p Value | |

| Model | 100.31 | 5 | 20.06 | 86.72 | <0.0001 | 142.43 | 5 | 28.49 | 139.03 | <0.0001 |

| A | 63.78 | 1 | 63.78 | 275.74 | <0.0001 | 87.20 | 1 | 87.20 | 425.58 | <0.0001 |

| B | 31.16 | 1 | 31.16 | 134.71 | <0.0001 | 50.39 | 1 | 50.39 | 245.94 | <0.0001 |

| A × B | 1.93 | 1 | 1.93 | 8.35 | 0.0233 | 0.27 | 1 | 0.27 | 1.32 | 0.2884 |

| A × A | 3.31 | 1 | 3.31 | 14.30 | 0.0069 | 2.90 | 1 | 2.90 | 14.18 | 0.0070 |

| B × B | 0.02 | 1 | 0.02 | 0.07 | 0.8033 | 2.21 | 1 | 2.21 | 10.77 | 0.0135 |

| Residual | 1.62 | 7 | 0.23 | 1.43 | 7 | 0.20 | ||||

| Lack of fit | 0.86 | 3 | 0.29 | 1.50 | 0.3432 | 0.78 | 3 | 0.26 | 1.58 | 0.3265 |

| Pure error | 0.76 | 4 | 0.19 | 0.66 | 4 | 0.16 | ||||

| Correct total | 101.93 | 12 | 143.87 | 12 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, D.; Wu, C.; Jiang, L.; Wang, G.; Chen, H. Design and Test of Sensor for Monitoring Corn Cleaning Loss. Agriculture 2023, 13, 663. https://doi.org/10.3390/agriculture13030663

Wei D, Wu C, Jiang L, Wang G, Chen H. Design and Test of Sensor for Monitoring Corn Cleaning Loss. Agriculture. 2023; 13(3):663. https://doi.org/10.3390/agriculture13030663

Chicago/Turabian StyleWei, Dexin, Chongyou Wu, Lan Jiang, Gang Wang, and Hui Chen. 2023. "Design and Test of Sensor for Monitoring Corn Cleaning Loss" Agriculture 13, no. 3: 663. https://doi.org/10.3390/agriculture13030663

APA StyleWei, D., Wu, C., Jiang, L., Wang, G., & Chen, H. (2023). Design and Test of Sensor for Monitoring Corn Cleaning Loss. Agriculture, 13(3), 663. https://doi.org/10.3390/agriculture13030663