Design and Test of Air-Assisted Seed-Guiding Device of Precision Hill-Seeding Centralized Seed-Metering Device for Sesame

Abstract

:1. Introduction

2. Materials and Methods

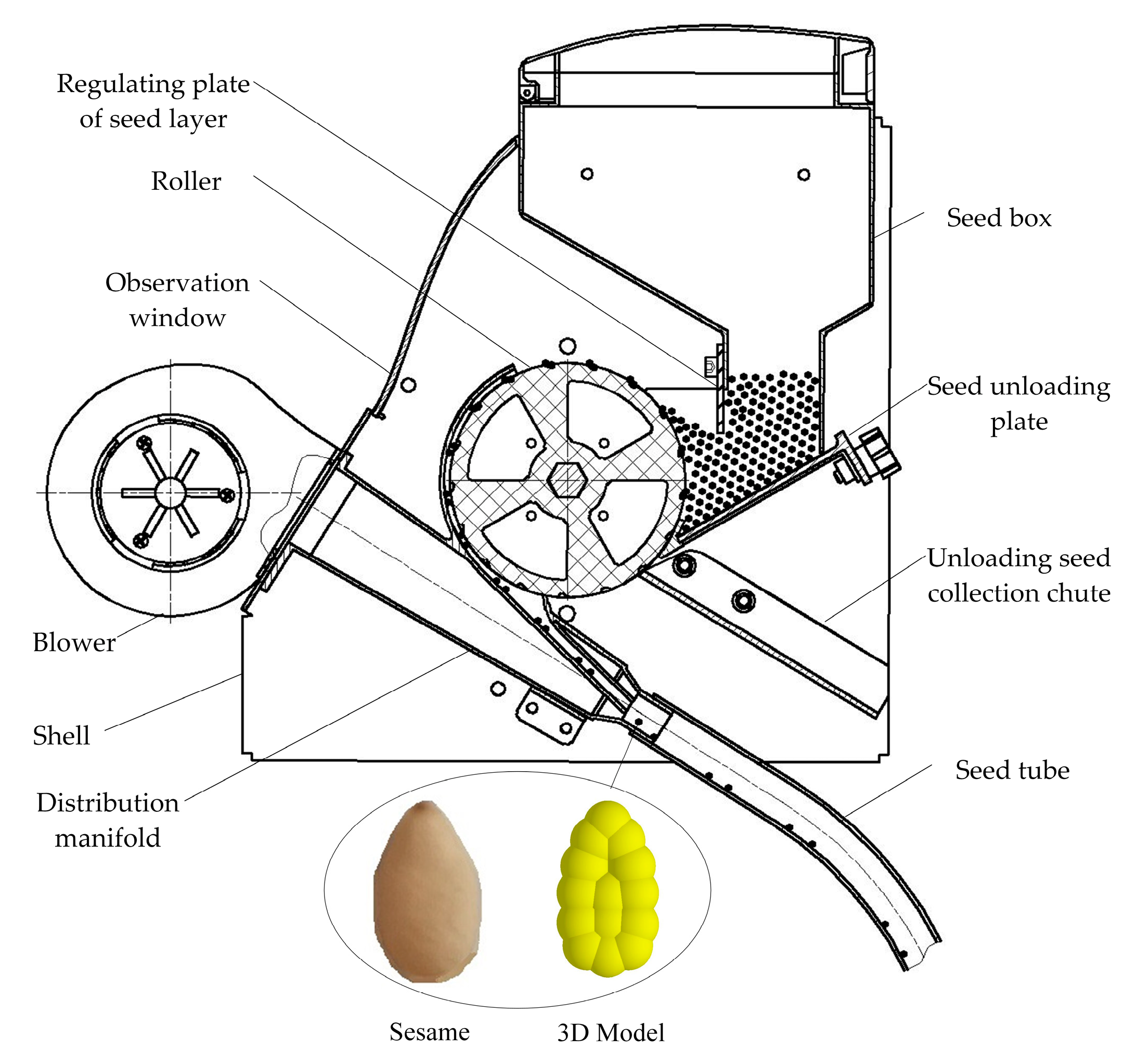

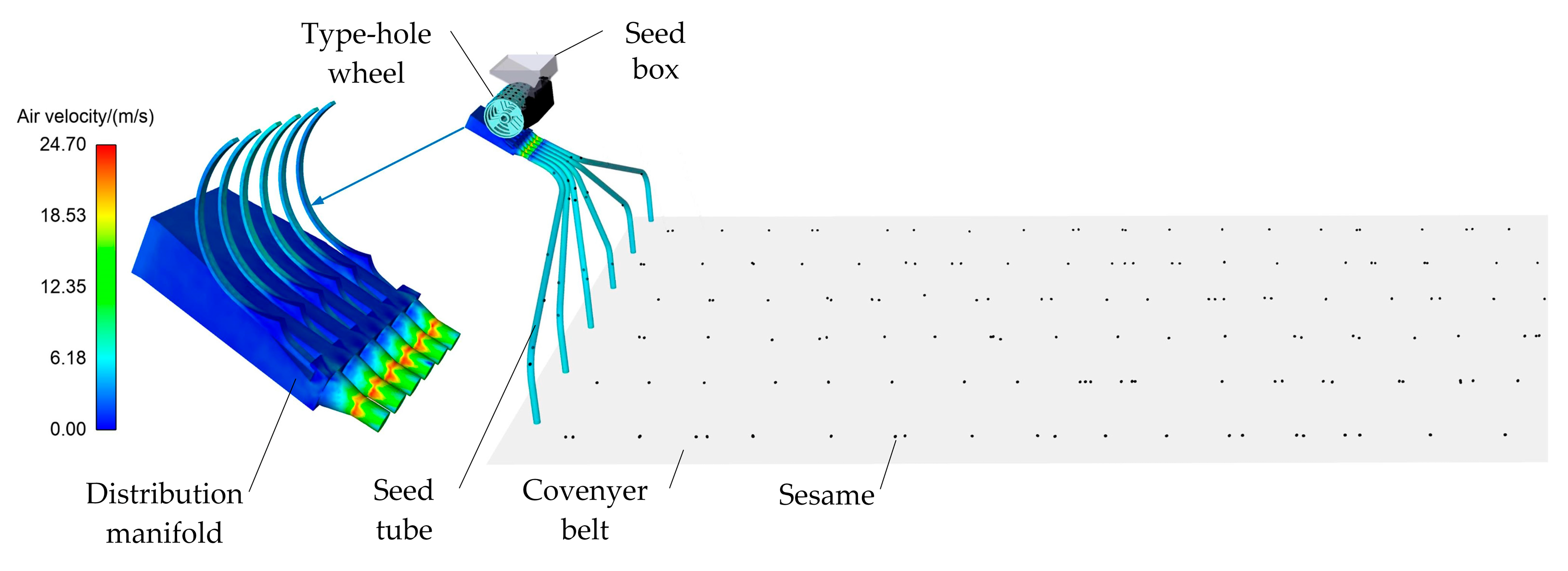

2.1. Overall Structure and Working Principle

2.1.1. Overall Structure

2.1.2. Working Principle of the Seeding System

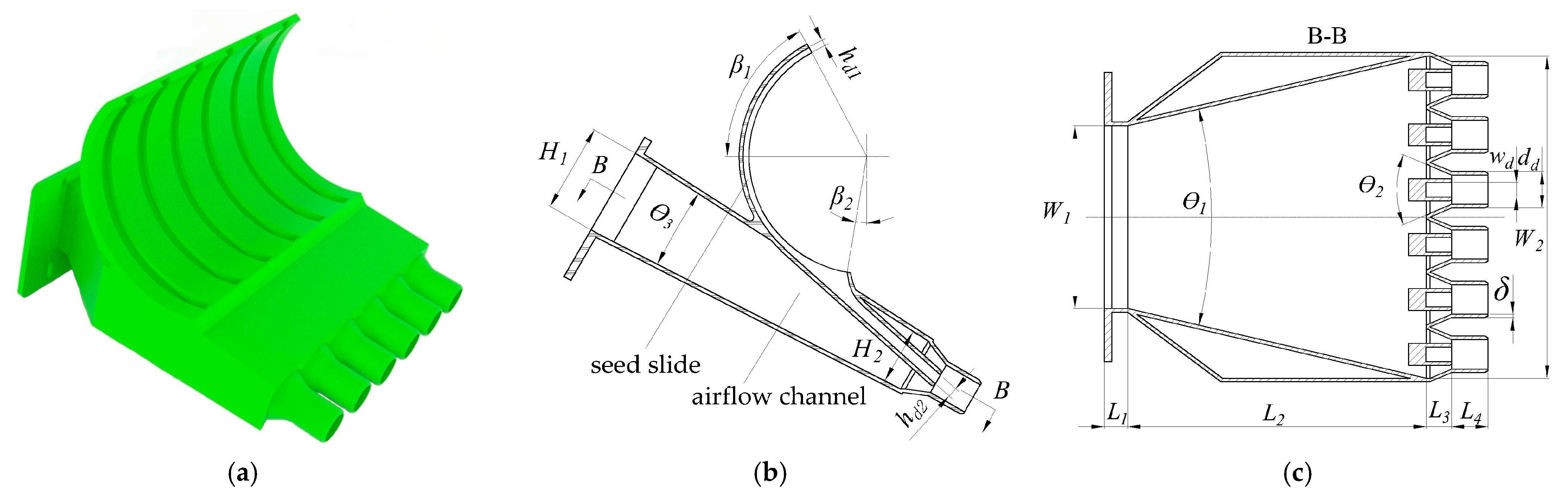

2.2. Design of Air-Assisted Seed-Guiding Device

2.2.1. Structural Design of the Distribution Manifold

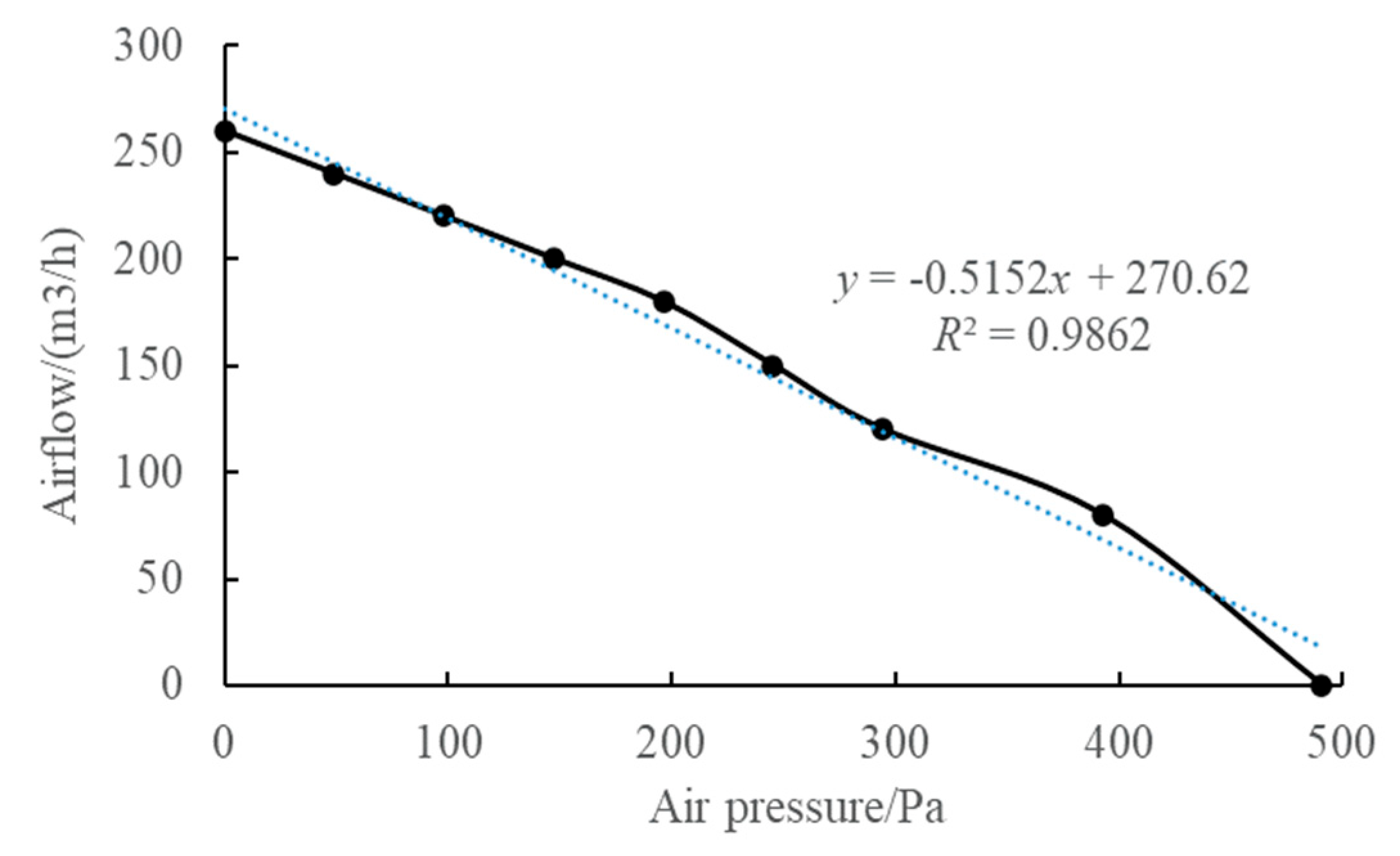

2.2.2. Analysis of the Airflow Parameters of the Distribution Manifold

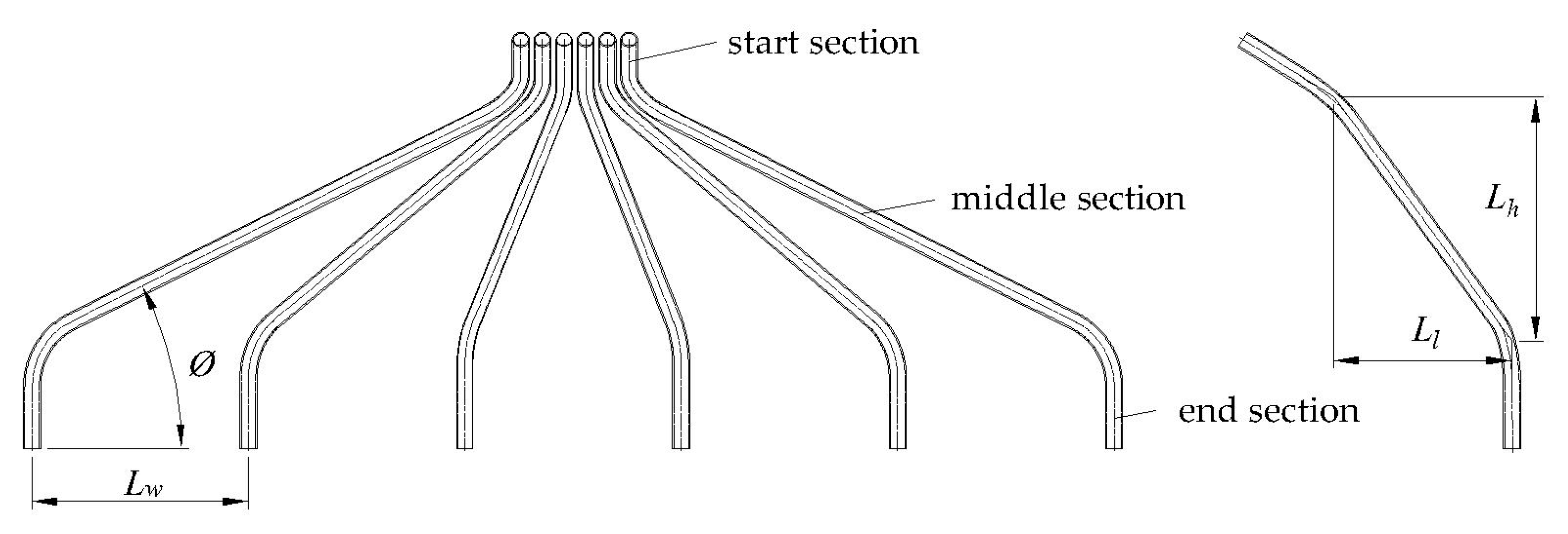

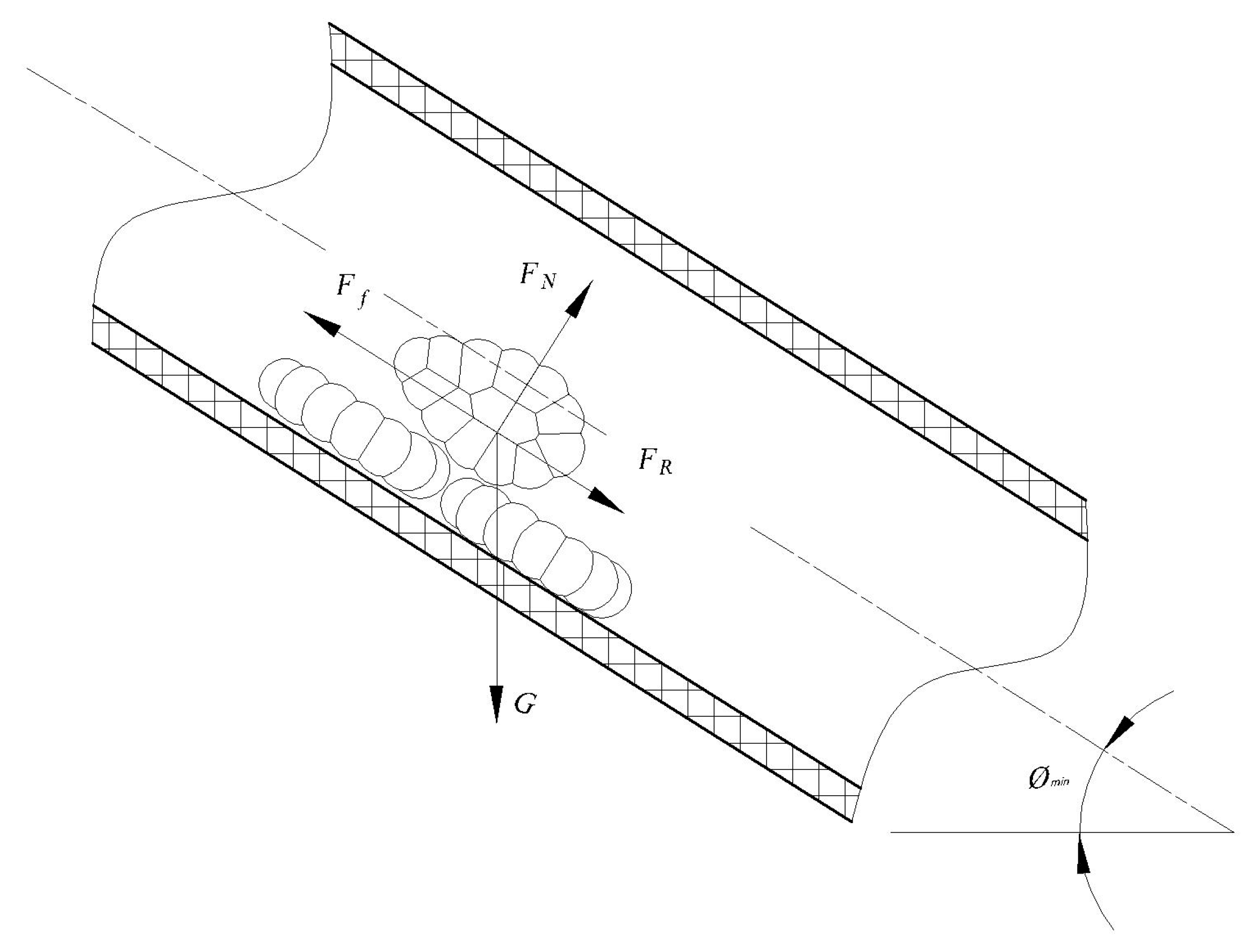

2.2.3. Structural Design of the Seed Tube

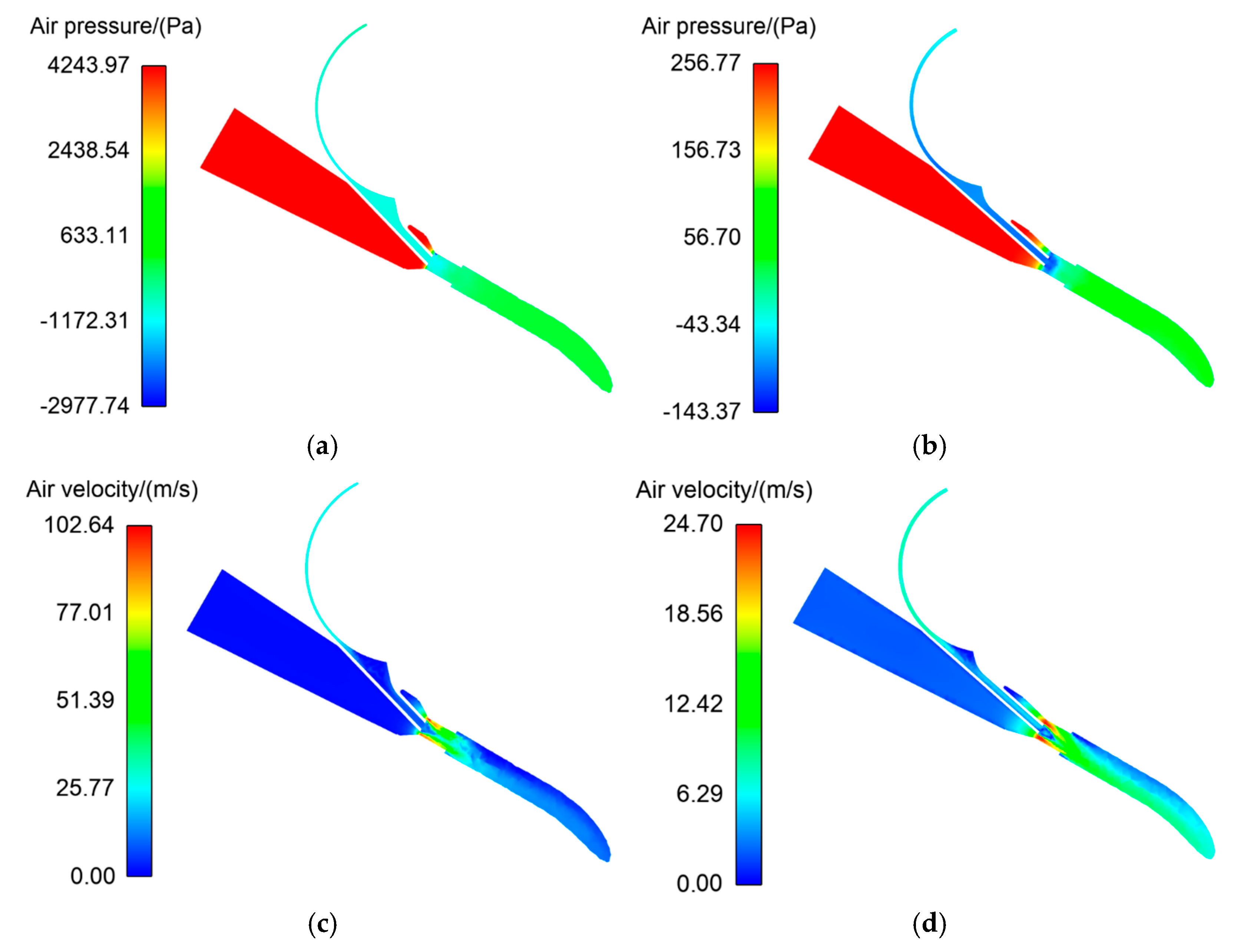

2.2.4. Analysis of the Airflow Parameters of the Seed Tube

2.3. Test Design

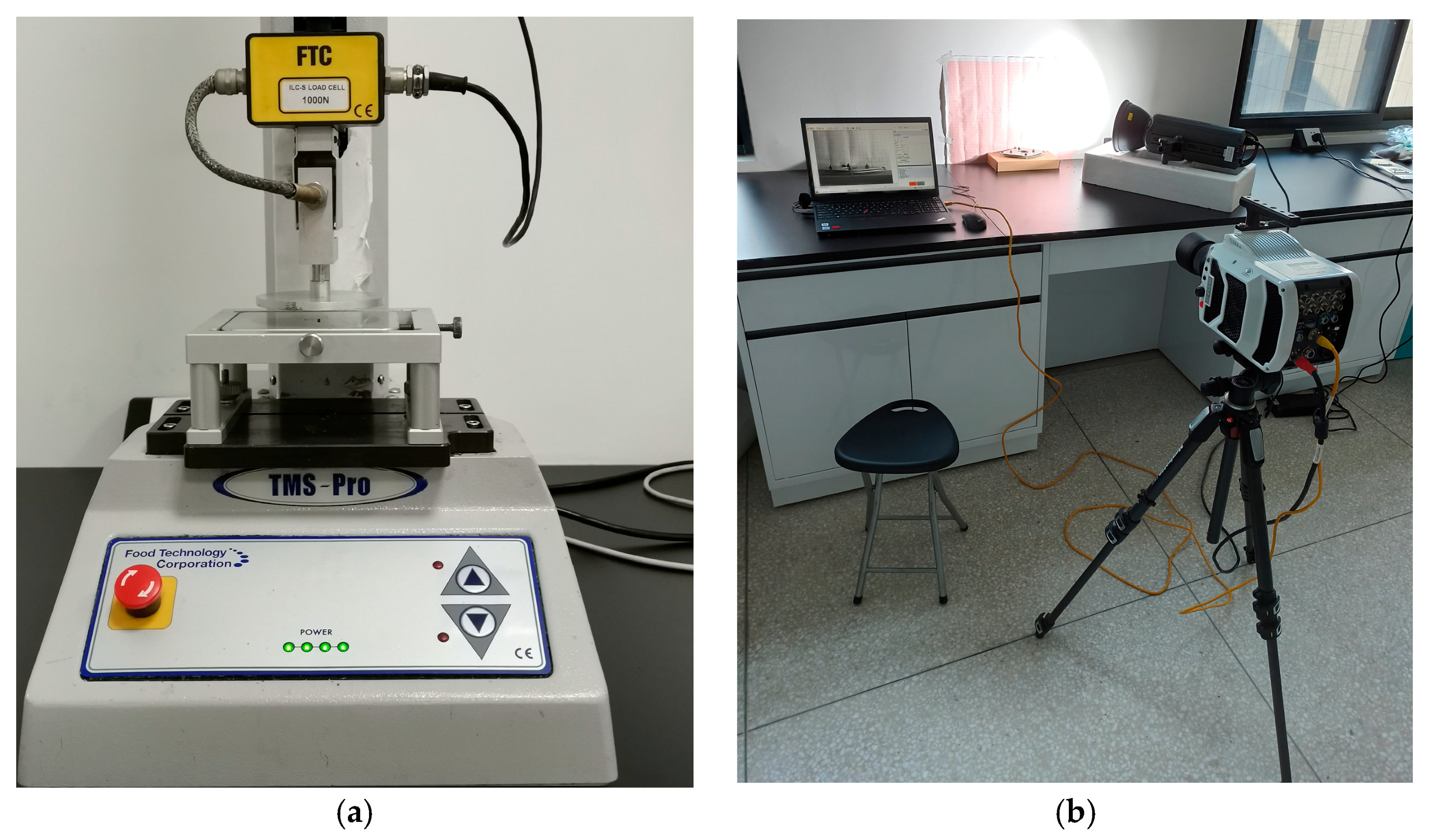

2.3.1. Establishment of CFD–DEM Coupling Simulation Model

2.3.2. Experiment Methods and Appraisal Indices of CFD–DEM Coupling Simulation

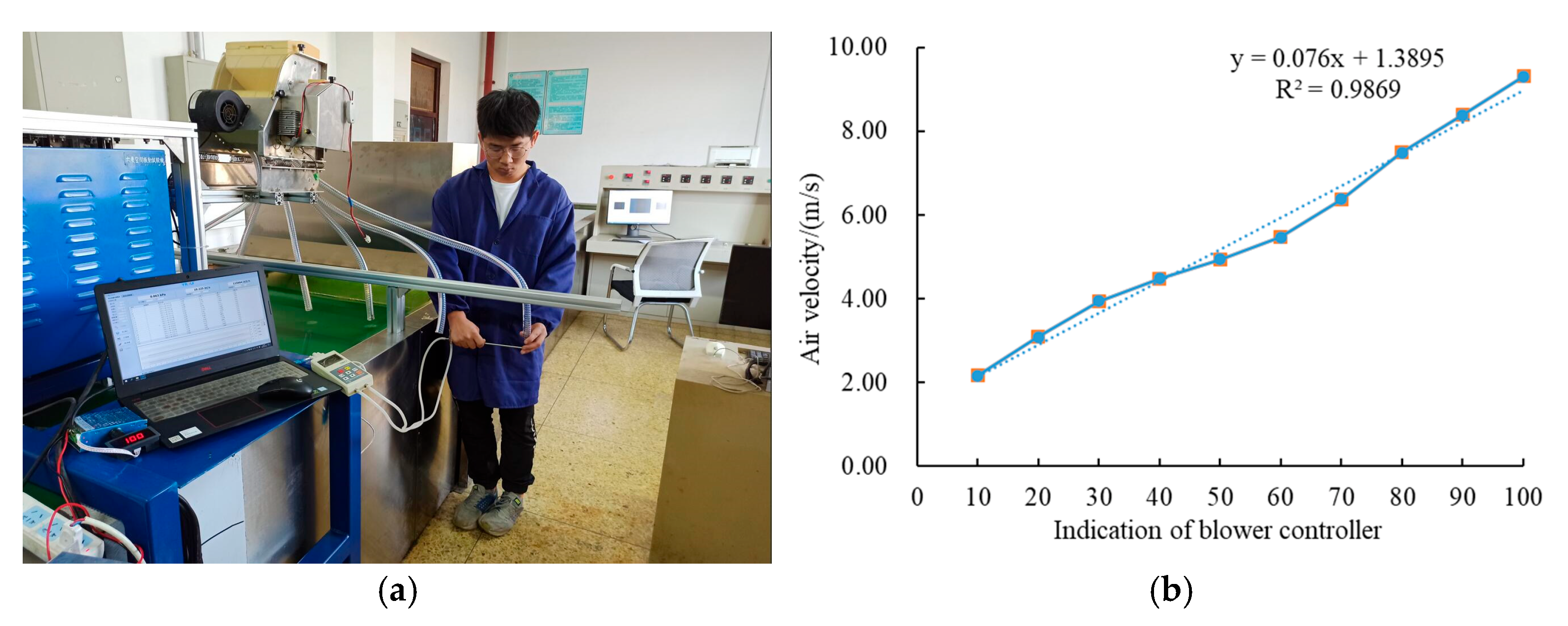

2.3.3. Bench Test Program

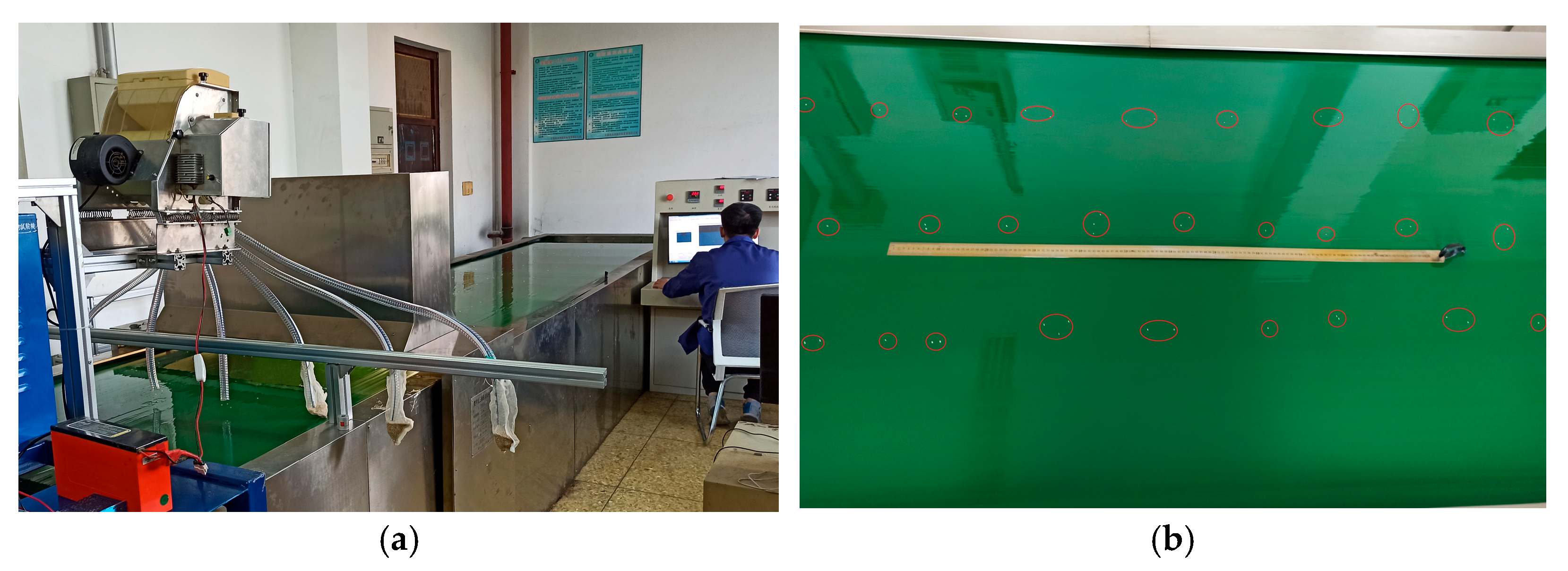

2.3.4. Field Experiment Program

3. Results and Discussion

3.1. Influence of Structure and Operation Parameters on Seeding Quality

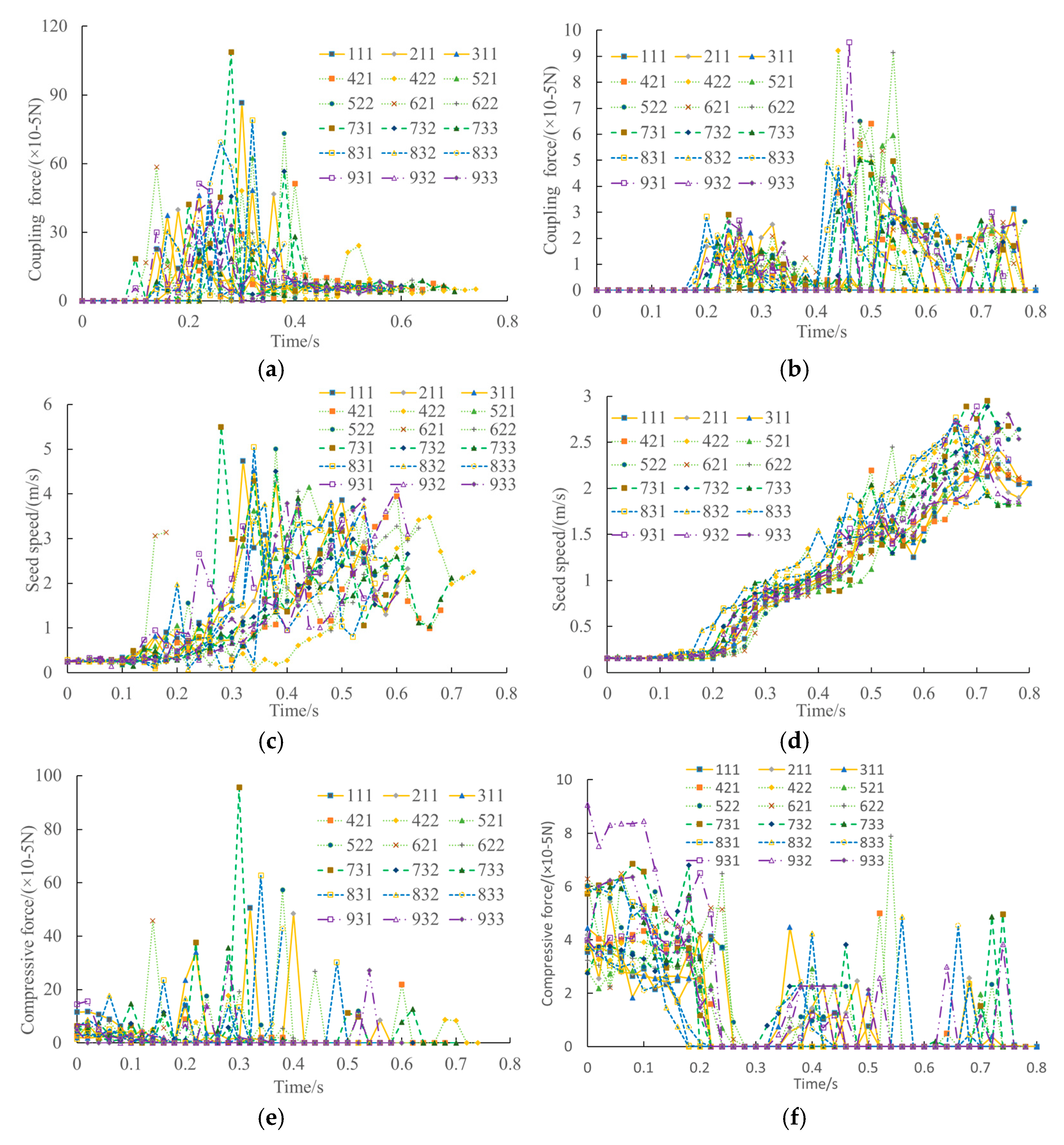

3.2. Analysis of Airflow Field Distribution and Sesame Movement Characteristics

3.3. Bench Test

3.4. Field Experiment

4. Conclusions

- (1)

- A precision hill-seeding centralized seed-metering device for sesame was designed. The design and experimental study focused on an air-assisted guiding device. The core of the air-assisted guiding device is a distribution manifold with tangential seed protection and seed guide function. Based on theoretical analysis, the parameter range of the distribution manifold was determined. The depth of seed slide, length of expansion contraction section, and length of contraction section are 1.58 mm–3.65 mm, 160 mm–188 mm, and 10 mm–20 mm, respectively. Moreover, the suitable airflow velocity range to achieve stable transport is 6.3 m/s–9.1 m/s.

- (2)

- CFD–DEM coupling simulation obtained an optimal parameter combination for the air-assisted guiding device. When the depth of seed slide, diameter of seed tube, airflow velocity, rotation speed of the roller, length of expansion contraction section, and length of contraction section are 2.62 mm, 19 mm, 6.3 m/s, 25 r/min, 188 mm, and 20 mm, respectively, the seeding quality of the air-assisted guiding device is better. At this time, the qualified rate of seed numbers per hill and miss-seed rate are 88.33% and 5.00%, respectively. Bench test verifies the accuracy of simulation results.

- (3)

- The field experiment results showed that the qualified rate is 83.45% (2 ± 1 plants per hill) and the miss-seeding rate is 8.51% (0 plants per hill). The air-assisted guiding device of the precision hill-seeding centralized seed-metering device meets the requirements of sesame seeding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Zhou, Q.; Dossou, S.S.K.; Zhou, R.; Zhao, Y.; Zhou, W.; Zhang, Y.; Li, D.; You, J.; Wang, L. Genome-wide association study uncovers loci and candidate genes underlying phytosterol variation in sesame (Sesamum indicum L.). Agriculture 2022, 12, 392. [Google Scholar] [CrossRef]

- Parsaeian, M.; Rahimi, M.; Rohani, A.; Lawson, S.S. Towards the modeling and prediction of the yield of oilseed crops: A multi-machine learning approach. Agriculture 2022, 12, 1739. [Google Scholar] [CrossRef]

- Ryu, L.H.; Kim, K.U. Design of roller type metering device for precision planting. Trans. ASAE 1998, 41, 923–930. [Google Scholar] [CrossRef]

- Barut, Z.B. Seed Coating and tillage effects on sesame stand establishment and planter performance for single seed sowing. Appl. Eng. Agric. 2008, 24, 565–571. [Google Scholar] [CrossRef]

- Topakci, M.; Karayel, D.; Canakci, M.; Furat, S.; Uzun, B. Sesame hill dropping performance of a vacuum seeder for different tillage practices. Appl. Eng. Agric. 2011, 27, 203–209. [Google Scholar] [CrossRef]

- Lin, P.; Liao, Q.; Wang, L.; Wang, B.; Liu, H. Seed suction performance and experiment of sesame precision hole seeding metering device. J. Huazhong Agric. Univ. 2021, 40, 195–206. [Google Scholar]

- Lei, X.; Yang, W.; Liu, L.; Liu, H.; Ren, W.; Chen, Y. Design and experiment of seed hill feeding device in pneumatic centralized metering device for hybrid rice. Trans. Chin. Soc. Agric. Mach. 2018, 49, 58–67. [Google Scholar]

- Luo, X.; Wang, Z.; Jiang, E.; Li, J.; Li, Q.; Chen, W. Design of disassemble rubber guard device for cell wheel feed. Trans. Chin. Soc. Agric. Mach. 2008, 39, 60–63. [Google Scholar]

- Lei, X.; Hu, H.; Wu, W.; Liu, H.; Liu, L.; Yang, W.; Zhou, Z.; Ren, W. Seed motion characteristics and seeding performance of a centralised seed metering system for rapeseed investigated by DEM simulation and bench testing. Biosyst. Eng. 2021, 203, 22–33. [Google Scholar] [CrossRef]

- Tang, H.; Xu, F.; Xu, C.; Zhao, J.; Wang, Y. The influence of a seed drop tube of the inside-filling air-blowing precision seed-metering device on seeding quality. Comput. Electron. Agric. 2023, 204, 107555. [Google Scholar] [CrossRef]

- Abdolahzare, Z.; Mehdizadeh, S.A. Real time laboratory and field monitoring of the effect of the operational. Comput. Electron. Agric. 2018, 145, 187–198. [Google Scholar] [CrossRef]

- Yan, B.; Wu, G.; Fu, W.; Gao, N.; Meng, Z.; Zhu, P. Influencing factors of corn implantation distribution for high-height planting based on EDEM. Trans. Chin. Soc. Agric. Mach. 2020, 51, 47–54. [Google Scholar]

- Liao, Y.; Li, C.; Liao, Q.; Wang, L. Research progress of seed guiding technology and device of planter. Trans. Chin. Soc. Agric. Mach. 2020, 51, 1–14. [Google Scholar]

- Zhang, C.; Kang, J.; Peng, Q.; Zhang, N.; Wang, X.; Jian, S. Design and test of secondary seed feeding mechanism of air-suction roller dibbler for cotton. Trans. Chin. Soc. Agric. Mach. 2021, 52, 106–116. [Google Scholar]

- Zhao, S.; Chen, J.; Wang, J.; Chen, J.; Yang, C.; Yang, Y. Design and experiment on V-groove dialing round type guiding-seed device. Trans. Chin. Soc. Agric. Mach. 2018, 49, 146–158. [Google Scholar]

- Liu, R.; Liu, L.; Li, Y.; Liu, Z.; Zhao, J.; Liu, Y.; Zhang, X. Numerical simulation of seed-movement characteristics in new maize delivery device. Agriculture 2022, 12, 1944. [Google Scholar] [CrossRef]

- Lei, X.; Liao, Y.; Wang, L.; Wang, D.; Yao, L.; Liao, Q. Simulation of gas-solid two-phase flow and parameter optimization of pressurized tube of air-assisted centralized metering device for rapeseed and wheat. Trans. Chin. Soc. Agric. Eng. 2017, 33, 67–75. [Google Scholar]

- Zhang, X.; Wang, Y.; Zhang, L.; Peng, C.; Fan, G. Design and experiment of wheat pneumatic centralized seeding distributing system. Trans. Chin. Soc. Agric. Mach. 2018, 49, 59–67. [Google Scholar]

- Hu, H.; Zhou, Z.; Wu, W.; Yang, W.; Li, T.; Chang, C.; Ren, W.; Lei, X. Distribution characteristics and parameter optimisation of an air-assisted centralised seed-metering device for rapeseed using a CFD-DEM coupled simulation. Biosyst. Eng. 2021, 208, 246–259. [Google Scholar] [CrossRef]

- Yatskul, A.; Lemiere, J.P.; Cointault, F. Influence of the divider head functioning conditions and geometry on the seed’s distribution accuracy of the air-seeder. Biosyst. Eng. 2017, 161, 120–134. [Google Scholar] [CrossRef]

- Lei, X.; Liao, Y.; Cong, J.; Lei, W.; Zhang, Q.; Liao, Q. Parameter optimization and experiment of air-assisted centralized seed-metering device of direct seeding machine for rape and wheat. Trans. Chin. Soc. Agric. Eng. 2018, 34, 16–26. [Google Scholar]

- Wang, B.; Wu, C.; Cao, M.; Liao, Q. Design and test of seeding wheels of precision hole-seeding centralized metering device for small particle size seeds. Trans. Chin. Soc. Agric. Mach. 2022, 53, 64–75+119. [Google Scholar]

- Luo, X.; Liu, T.; Jiang, E.; Li, Q. Design and experiment of hill sowing wheel of precision rice direct-seeder. Trans. Chin. Soc. Agric. Eng. 2007, 23, 108–112. [Google Scholar]

- China Academy of Agricultural Mechanization Science. Manual for Design of Agricultural Machinery; Agricultural Science and Technology Press: Beijing, China, 2007; p. 353. [Google Scholar]

- Wang, L.; Liao, Y.; Wan, X.; Wang, B.; Hu, Q.; Liao, Q. Design and test on mixing component of air-assisted centralized metering device for rapeseed and wheat. Trans. Chin. Soc. Agric. Mach. 2022, 53, 68–79+97. [Google Scholar]

- Wu, Y.; Wang, F. Engineering Fluid Dynamics Pump and Fan, 2nd ed.; Chemical Industry Press: Beijing, China, 2016; pp. 123–129. [Google Scholar]

- Yatskul, A.; Lemiere, J.P. Establishing the conveying parameters required for the air-seeders. Biosyst. Eng. 2018, 166, 1–12. [Google Scholar] [CrossRef]

- Wang, X.; Bian, B.; Tuluhong, T.; Zhang, L. Experiments and parameter optimization of almond shell and kernel air separation device. Trans. Chin. Soc. Agric. Eng. 2021, 37, 299–306. [Google Scholar]

- Yang, L.; Xie, Y. Pneumatic Conveying Engineering, 1st ed.; China Machine Press: Beijing, China, 2015; pp. 84–88. [Google Scholar]

- Ma, Y. Physical Properties of Bio-Materials, 1st ed.; Chemical Industry Press: Beijing, China, 2015; pp. 80–82. [Google Scholar]

- Lei, X.; Liao, Y.; Zhang, W.; Li, S.; Wang, D.; Liao, Q. Simulation and experiment of gas-Solid flow in seed conveying tube for rapeseed and wheat. Trans. Chin. Soc. Agric. Mach. 2017, 48, 57–68. [Google Scholar]

- Wang, L.; Liao, Y.; Wan, X.; Xiao, W.; Wang, B.; Qingxi, L. Design and test on distributor device of air-assisted centralized metering device for rapeseed and wheat. Trans. Chin. Soc. Agric. Mach. 2021, 52, 43–53. [Google Scholar]

- Kong, L. Engineering Fluid Mechanics, 4th ed.; China Electric Power Press: Beijing, China, 2014; pp. 106–107. [Google Scholar]

- Huang, Y.; Zhao, M. Optimization design of performance test of cyclone separator sand sampler based on numerical simulation and wind erosion tunnel experiment. Trans. Chin. Soc. Agric. Eng. 2015, 31, 50–56. [Google Scholar]

- Li, Y.; Liu, R.; Liu, C.; Liu, L. Simulation and test of seed velocity coupling in seed tube of pneumutic seed metering device. Trans. Chin. Soc. Agric. Mach. 2021, 52, 54–61+133. [Google Scholar]

- Lei, X.; Yang, W.; Yang, L.; Liu, L.; Liao, Q.; Ren, W. Design and experiment of seed hill-seeding centralized metering device for rapeseed. Trans. Chin. Soc. Agric. Mach. 2020, 51, 54–64. [Google Scholar]

- Shi, L.; Sun, W.; Zhao, W.; Yang, X.; Feng, B. Parameter determination and validation of discrete element model of seed potato mechanical seeding. Trans. Chin. Soc. Agric. Eng. 2018, 34, 35–42. [Google Scholar]

- Yu, Q.; Liu, Y.; Chen, X.; Sun, K.; Lai, Q. Calibration and experiment of simulation parameters for Panax notoginseng seeds based on DEM. Trans. Chin. Soc. Agric. Mach. 2020, 51, 123–132. [Google Scholar]

| Items | Sesame | ABS | PVC Steel Wire Hose | Rubber |

|---|---|---|---|---|

| Density/(kg·m−3) | 930 | 1060 | 1500 | 1350 |

| Poisson’s ratio | 0.48 | 0.39 | 0.40 | 0.47 |

| Shear modulus/Pa | 2.5 × 106 | 8.96 × 108 | 1.5 × 109 | 2.9 × 109 |

| Coefficient of restitution (between with sesame) | 0.278 | 0.36 | 0.42 | 0.001 |

| Coefficient of static friction (between with sesame) | 0.57 | 0.49 | 0.92 | 1 |

| Coefficient of rolling friction (between with sesame) | 0.01 | 0.03 | 0.01 | 1 |

| No. | Depth of the Circular Section of Seed Slide/mm | Length of Expansion Contraction Section/mm | Length of Contraction Section/mm | Diameter of the Seed Tube/mm | Airflow Velocity/ (m/s) | Rotation Speed of the Roller/(r/min) | Qualified Rate/% | Miss- Seeding Rate/% | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.58 | 160 | 10 | 16 | 6.3 | 10 | 68.00 | 22.67 | |

| 2 | 1.58 | 160 | 10 | 16 | 7.7 | 25 | 61.33 | 27.67 | |

| 3 | 1.58 | 160 | 10 | 16 | 9.1 | 40 | 49.33 | 47.33 | |

| 4 | 1.58 | 174 | 15 | 19 | 6.3 | 10 | 71.33 | 16.00 | |

| 5 | 1.58 | 174 | 15 | 19 | 7.7 | 25 | 77.00 | 13.00 | |

| 6 | 1.58 | 174 | 15 | 19 | 9.1 | 40 | 74.00 | 20.67 | |

| 7 | 1.58 | 188 | 20 | 22 | 6.3 | 10 | 72.33 | 14.67 | |

| 8 | 1.58 | 188 | 20 | 22 | 7.7 | 25 | 77.33 | 15.00 | |

| 9 | 1.58 | 188 | 20 | 22 | 9.1 | 40 | 82.00 | 16.00 | |

| 10 | 2.62 | 160 | 15 | 22 | 6.3 | 25 | 83.67 | 7.67 | |

| 11 | 2.62 | 160 | 15 | 22 | 7.7 | 40 | 80.00 | 16.67 | |

| 12 | 2.62 | 160 | 15 | 22 | 9.1 | 10 | 66.67 | 16.00 | |

| 13 | 2.62 | 174 | 20 | 16 | 6.3 | 25 | 81.33 | 13.33 | |

| 14 | 2.62 | 174 | 20 | 16 | 7.7 | 40 | 79.67 | 19.33 | |

| 15 | 2.62 | 174 | 20 | 16 | 9.1 | 10 | 65.33 | 25.67 | |

| 16 | 2.62 | 188 | 10 | 19 | 6.3 | 25 | 87.33 | 5.33 | |

| 17 | 2.62 | 188 | 10 | 19 | 7.7 | 40 | 80.33 | 15.33 | |

| 18 | 2.62 | 188 | 10 | 19 | 9.1 | 10 | 77.33 | 8.33 | |

| 19 | 3.65 | 160 | 20 | 19 | 6.3 | 40 | 81.00 | 16.33 | |

| 20 | 3.65 | 160 | 20 | 19 | 7.7 | 10 | 68.33 | 16.33 | |

| 21 | 3.65 | 160 | 20 | 19 | 9.1 | 25 | 77.00 | 14.00 | |

| 22 | 3.65 | 174 | 10 | 22 | 6.3 | 40 | 80.00 | 18.00 | |

| 23 | 3.65 | 174 | 10 | 22 | 7.7 | 10 | 72.67 | 13.00 | |

| 24 | 3.65 | 174 | 10 | 22 | 9.1 | 25 | 77.67 | 12.33 | |

| 25 | 3.65 | 188 | 15 | 16 | 6.3 | 40 | 80.00 | 17.33 | |

| 26 | 3.65 | 188 | 15 | 16 | 7.7 | 10 | 69.00 | 17.67 | |

| 27 | 3.65 | 188 | 15 | 16 | 9.1 | 25 | 71.00 | 21.67 | |

| Qualified rate | k1 | 70.30 | 70.59 | 72.67 | 69.44 | 78.33 | 70.11 | ||

| k2 | 77.96 | 75.44 | 74.74 | 77.07 | 73.96 | 77.07 | |||

| k3 | 75.19 | 77.41 | 76.04 | 76.93 | 71.15 | 76.26 | |||

| R | 7.67 | 6.81 | 3.37 | 7.63 | 7.19 | 6.96 | |||

| Miss-seeding rate | k1 | 21.44 | 20.52 | 18.89 | 23.63 | 14.59 | 16.70 | ||

| k2 | 14.19 | 16.81 | 16.30 | 13.93 | 17.11 | 14.44 | |||

| k3 | 16.30 | 14.59 | 16.74 | 14.37 | 20.22 | 20.78 | |||

| R | 7.26 | 5.93 | 2.59 | 9.70 | 5.63 | 6.33 | |||

| Variance Source | Qualified Rate | Miss-Seeding Rate | ||||||

|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Degree of Freedom | F Value | p Value | Sum of Squares | Degree of Freedom | F Value | p Value | |

| Model | 0.14 | 12 | 5.51 | 0.002 ** | 0.13 | 12 | 6.00 | 0.001 ** |

| A | 0.027 | 2 | 6.48 | 0.010 * | 0.025 | 2 | 6.87 | 0.008 ** |

| B | 0.022 | 2 | 5.29 | 0.019 * | 0.016 | 2 | 4.41 | 0.033 * |

| C | 0.005 | 2 | 1.24 | 0.319 | 0.003 | 2 | 0.95 | 0.411 |

| D | 0.034 | 2 | 8.18 | 0.004 ** | 0.054 | 2 | 14.79 | 0.000 ** |

| E | 0.024 | 2 | 5.64 | 0.016 * | 0.014 | 2 | 3.92 | 0.045 * |

| F | 0.026 | 2 | 6.23 | 0.012 * | 0.019 | 2 | 5.07 | 0.022 * |

| Residual | 0.029 | 14 | 0.026 | 14 | ||||

| Cor Total | 0.17 | 26 | 0.16 | 26 | ||||

| Test Indicators | Coupling Force/(×10−5 N) | Velocity of Sesame/(m/s) | Compressive Force/(×10−5 N) | Time of Guiding Process/s | Velocity of Sesame at the End of Seed Tube/(m/s) |

|---|---|---|---|---|---|

| Test 3 | 8.13 ± 13.18 | 1.31 ± 1.16 | 2.92 ± 8.29 | 0.57 ± 0.13 | 2.39 ± 0.55 |

| Optimal result | 0.79 ± 1.39 | 1.10 ± 0.81 | 1.35 ± 2.00 | 0.77 ± 0.02 | 2.24 ± 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Liao, Q.; Wang, L.; Shu, C.; Cao, M.; Du, W. Design and Test of Air-Assisted Seed-Guiding Device of Precision Hill-Seeding Centralized Seed-Metering Device for Sesame. Agriculture 2023, 13, 393. https://doi.org/10.3390/agriculture13020393

Wang B, Liao Q, Wang L, Shu C, Cao M, Du W. Design and Test of Air-Assisted Seed-Guiding Device of Precision Hill-Seeding Centralized Seed-Metering Device for Sesame. Agriculture. 2023; 13(2):393. https://doi.org/10.3390/agriculture13020393

Chicago/Turabian StyleWang, Baoshan, Qingxi Liao, Lei Wang, Caixia Shu, Mei Cao, and Wenbin Du. 2023. "Design and Test of Air-Assisted Seed-Guiding Device of Precision Hill-Seeding Centralized Seed-Metering Device for Sesame" Agriculture 13, no. 2: 393. https://doi.org/10.3390/agriculture13020393

APA StyleWang, B., Liao, Q., Wang, L., Shu, C., Cao, M., & Du, W. (2023). Design and Test of Air-Assisted Seed-Guiding Device of Precision Hill-Seeding Centralized Seed-Metering Device for Sesame. Agriculture, 13(2), 393. https://doi.org/10.3390/agriculture13020393