Design and Experiment of Real-Time Grain Yield Monitoring System for Corn Kernel Harvester

Abstract

1. Introduction

2. Materials and Methods

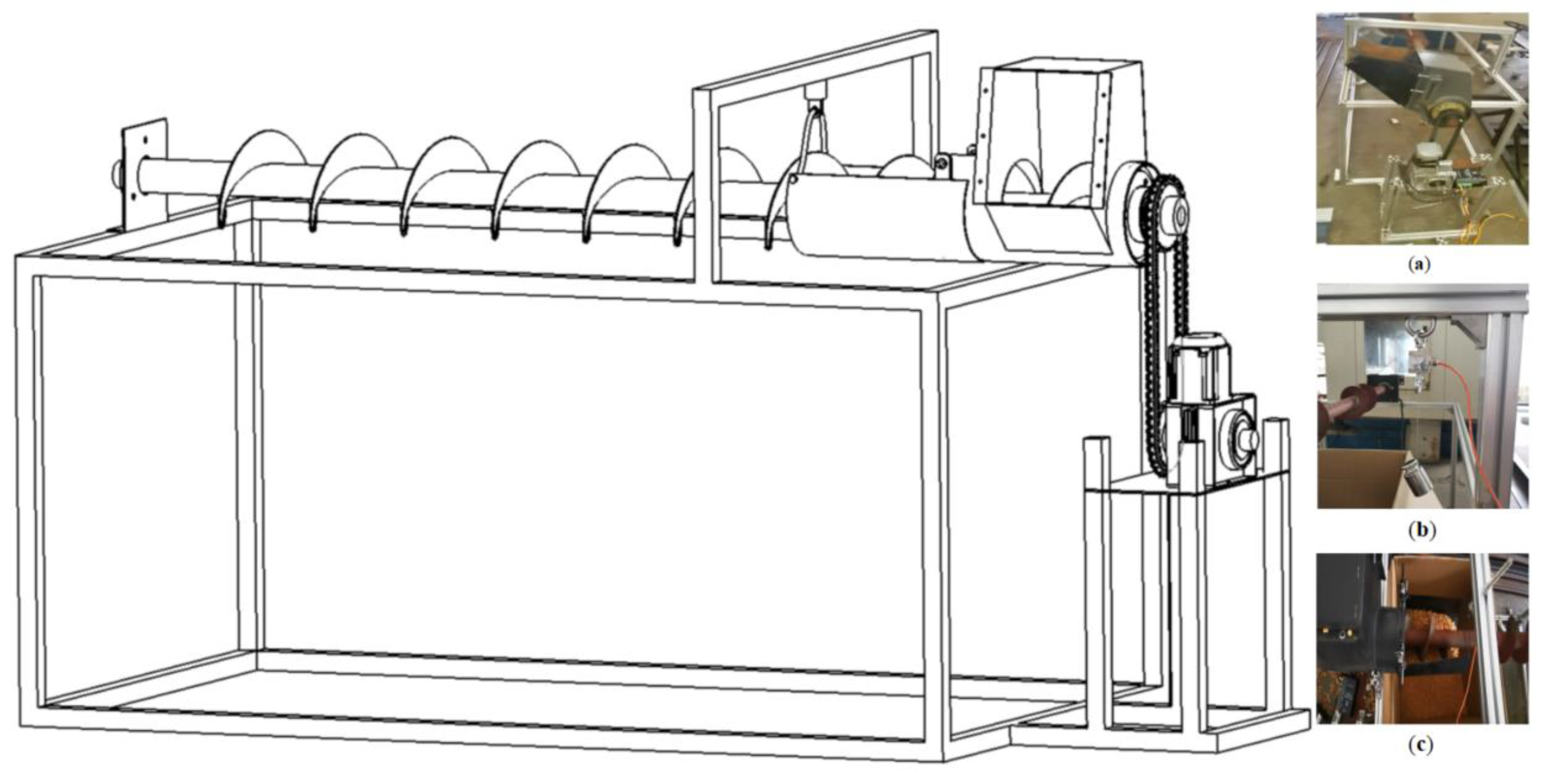

2.1. Grain Yield Monitoring System Development

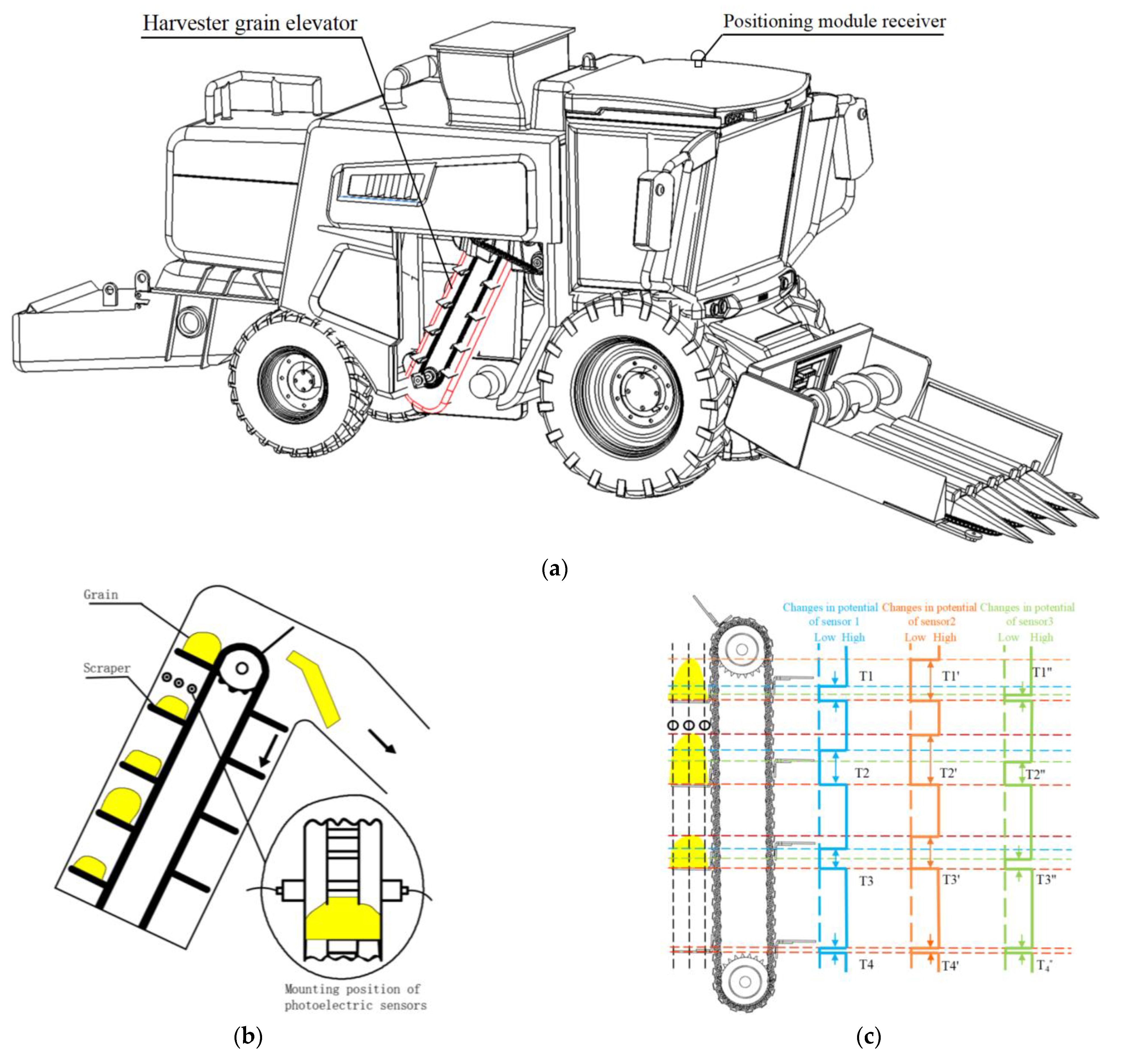

2.1.1. Grain Yield Monitoring Principle

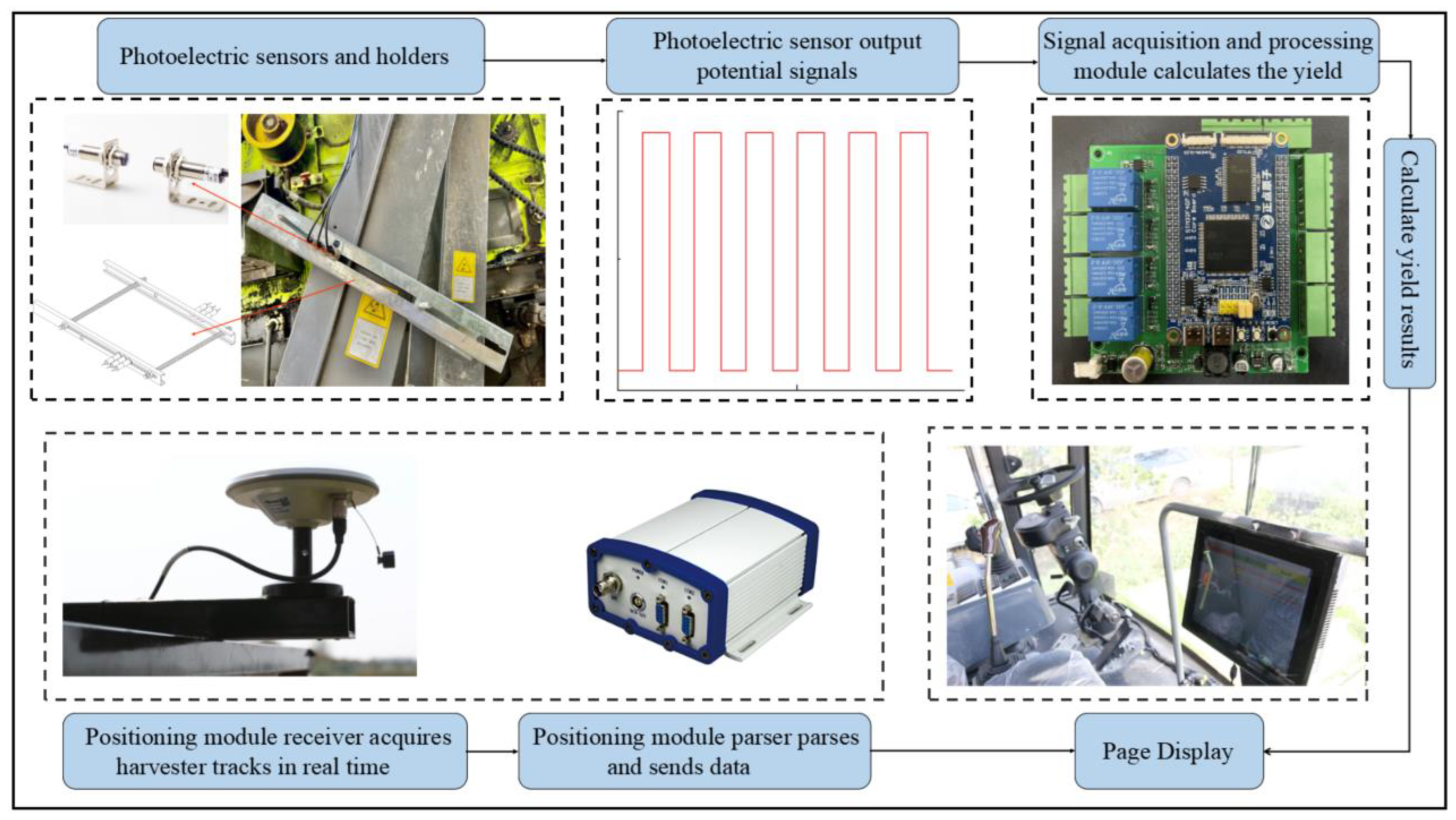

2.1.2. Grain Yield Monitoring System Design

2.2. Yield Calculation Model

2.2.1. Model Construction for Yield Calculation

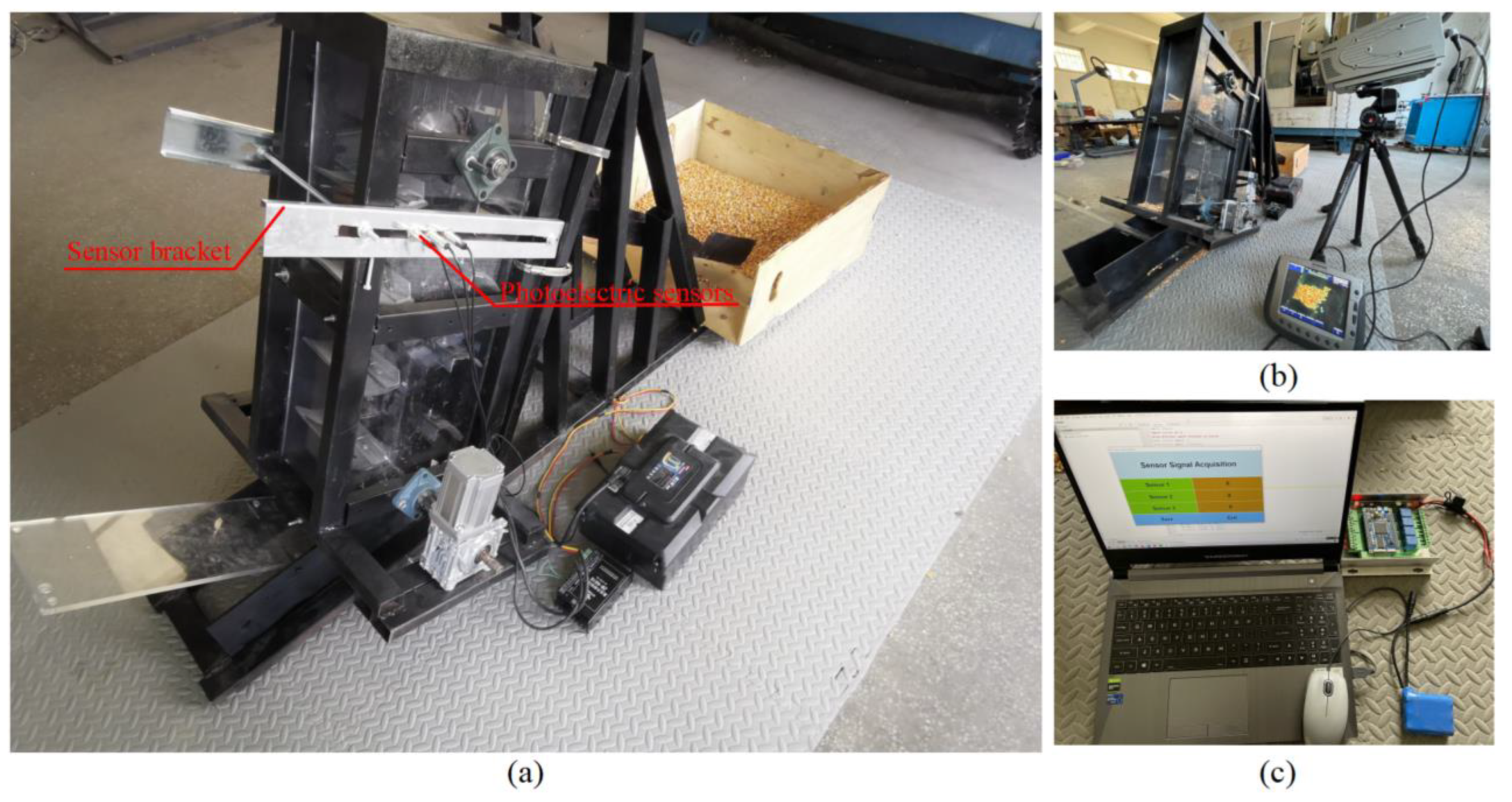

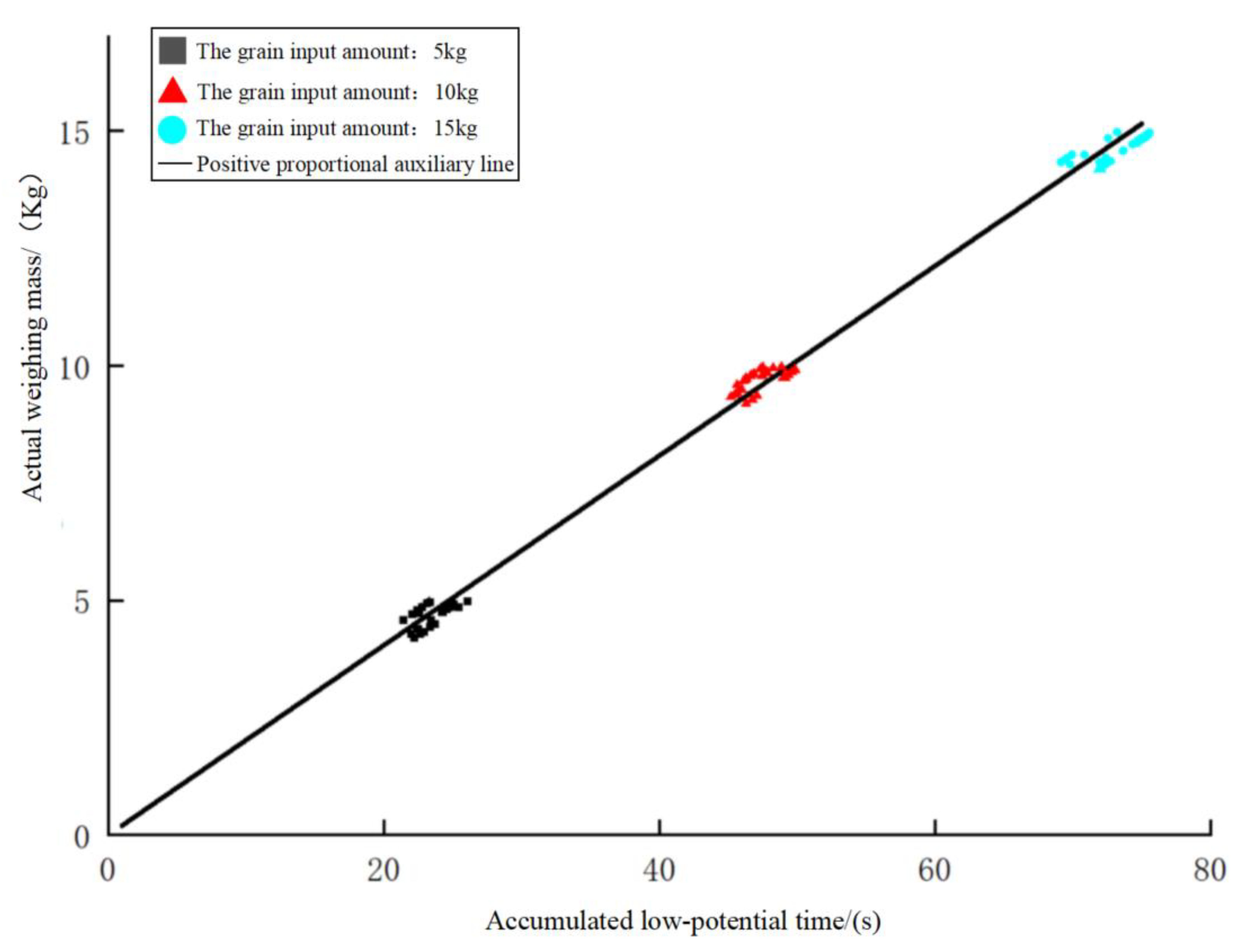

2.2.2. Determination of Model Coefficient Fitting for Yield Calculation

2.3. Validation of Yield Measurement Model Accuracy

2.4. Field Test

2.4.1. Testing Conditions

2.4.2. Field Harvest Tests

2.5. System Real-Time Validation Tests

3. Results and Discussion

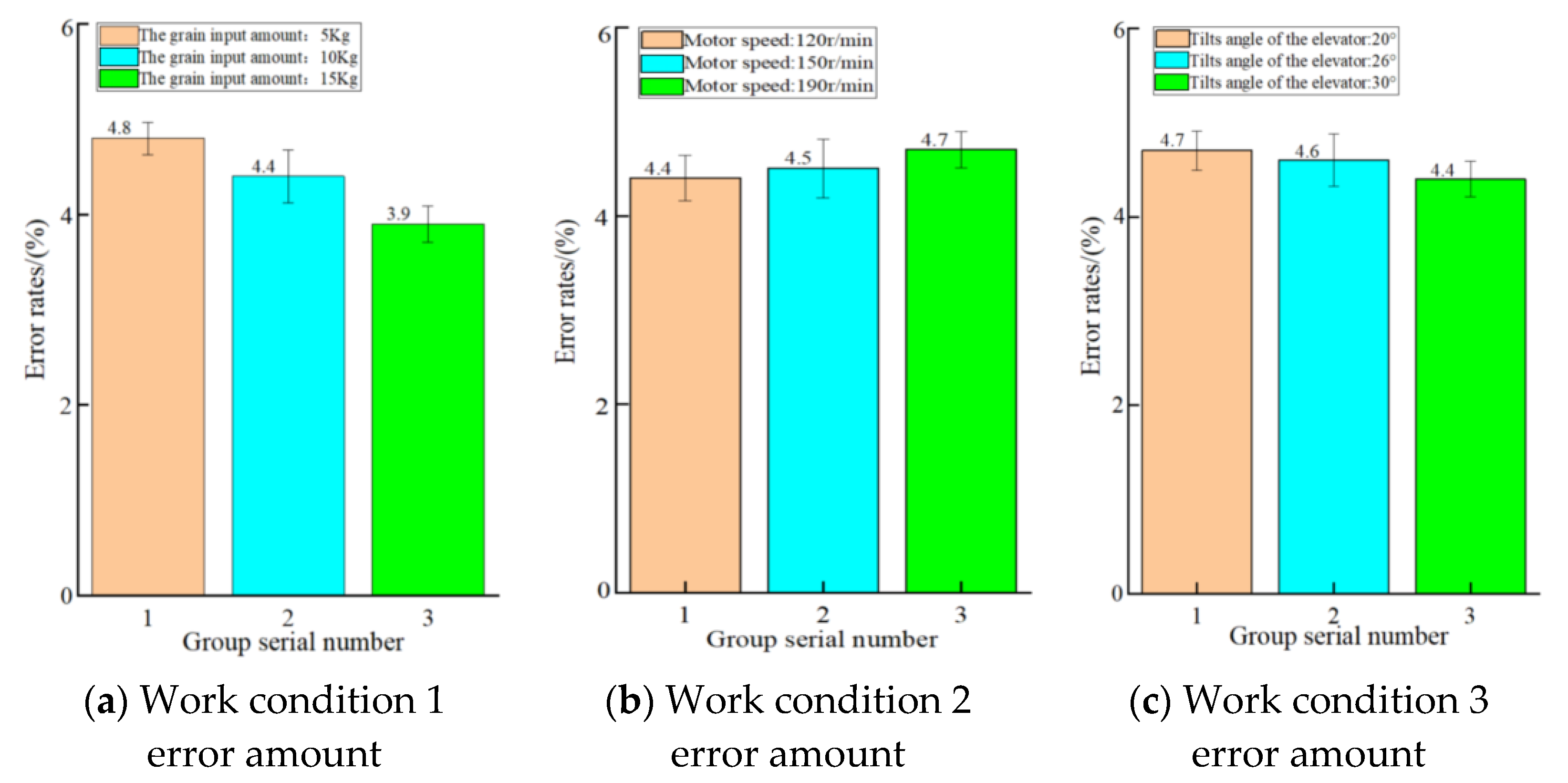

3.1. Validation Results of Yield Measurement Model Accuracy

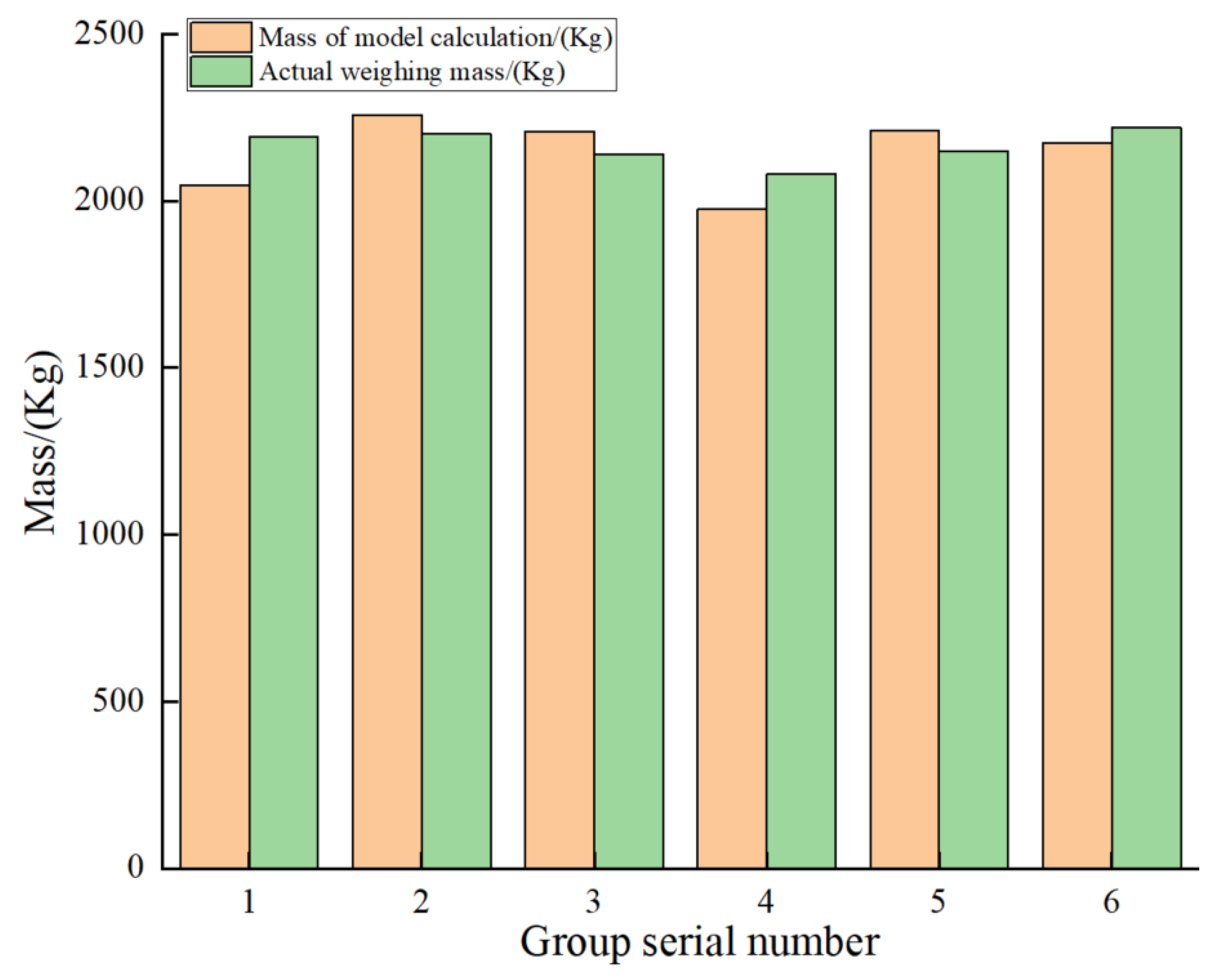

3.2. Field Trial Test Results

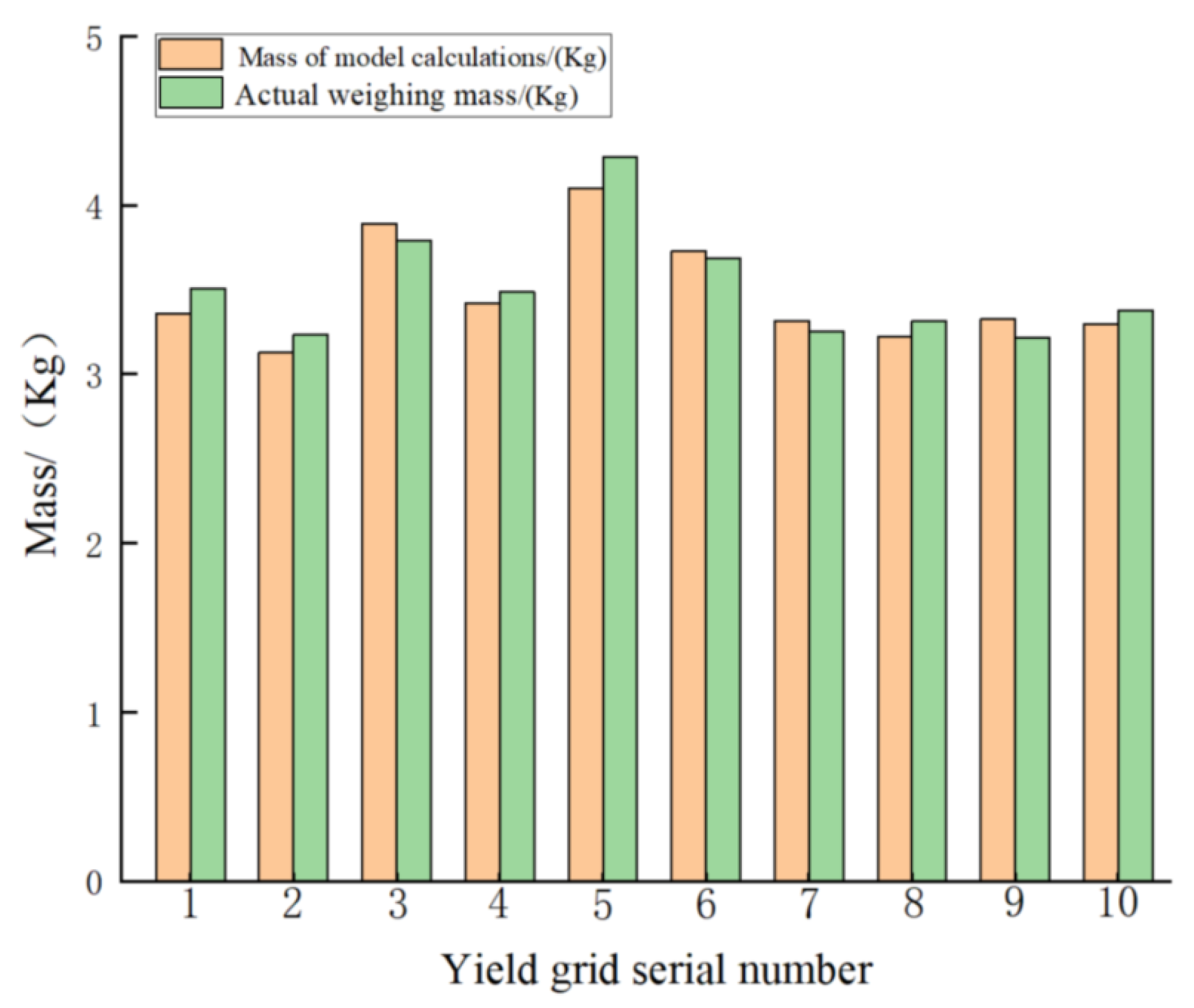

3.3. System Real-Time Validation Test Results

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, R.; Sun, Y.; Li, M.; Zhang, M. Development and application experiments of a grain yield monitoring system. Comput. Electron. Agric. 2022, 195, 106851. [Google Scholar] [CrossRef]

- Mann, M.L.; Warner, J.M. Ethiopian wheat yield and yield gap estimation: A spatially explicit small area integrated data approach. Field Crops Res. 2017, 201, 60–74. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, I.; Saeed, U.; Fahad, M. Yield forecasting of spring maize using remote sensing and crop modeling in Faisalabad-Punjab Pakistan. J. Indian Soc. Remote Sens. 2018, 46, 1701–1711. [Google Scholar] [CrossRef]

- Chen, Y.; Mo, W.; Mo, J.; Ding, M. Monitoring of sugarcane growth based on the fused remote sensing NDVI series and ground seeding survey. Trans. Asabe 2021, 63, 1795–1804. [Google Scholar] [CrossRef]

- Gumma, M.K.; Kadiyala, M.; Panjala, P. Assimilation of remote sensing data into crop growth model for yield estimation: A case study from India. J. Indian Soc. Remote Sens. 2022, 50, 257–270. [Google Scholar] [CrossRef]

- Young, L.J. Agricultural Crop Forecasting for Large Geographical Areas. Annu. Rev. Stat. Its Appl. 2019, 6, 173–196. [Google Scholar] [CrossRef]

- Djurfeldt, G.; Hall, O.; Jirström, M.; Archila Bustos, M.; Holmquist, B.; Nasrin, S. Using panel survey and remote sensing data to explain yield gaps for maize in sub-Saharan Africa. J. Land Use Sci. 2018, 13, 344–357. [Google Scholar] [CrossRef]

- Pi, W.; Du, J.; Bi, Y. 3D-CNN based UAV hyperspectral imagery for grassland degradation indicator ground object classification research. Ecol. Inform. 2021, 62, 101278. [Google Scholar] [CrossRef]

- Nasi, R.; Viljanen, N.; Kaivosoja, J. Estimating biomass and nitrogen amount of barley and grass using UAV and aircraft based spectral and photogrammetric 3D features. Remote Sens. 2018, 10, 1082. [Google Scholar] [CrossRef]

- Ballesteros, R.; Ortega, J.F.; Hernandez, D. Combined use of agro-climatic and very high-resolution remote sensing information for crop monitoring. Int. J. Appl. Earth Obs. Geoinf. 2018, 72, 66–75. [Google Scholar] [CrossRef]

- Fan, J.; Zhou, J.; Wang, B. Estimation of maize yield and flowering time using multi-temporal UAV-based hyperspectral data. Remote Sens. 2022, 14, 3052. [Google Scholar] [CrossRef]

- Habte, A.; Worku, W.; Gayler, S. Model-based yield gap analysis and constraints of rainfed sorghum production in Southwest Ethiopia. J. Agric. Sci. 2020, 158, 855–869. [Google Scholar] [CrossRef]

- Fu, Y.; Huang, J.; Shen, Y. A satellite-based method for national winter wheat yield estimating in China. Remote Sens. 2021, 13, 4680. [Google Scholar] [CrossRef]

- Begueria, S.; Maneta, M.P. Qualitative crop condition survey reveals spatiotemporal production patterns and allows early yield prediction. Proc. Natl. Acad. Sci. USA 2020, 117, 18317–18323. [Google Scholar] [CrossRef]

- Zhao, Y.; Vergopolan, N.; Baylis, K. Comparing empirical and survey-based yield forecasts in a dryland agro-ecosystem. Agric. For. Meteorol. 2018, 262, 147–156. [Google Scholar] [CrossRef]

- Wang, J.C.; Holan, S.H.; Nandram, B. A Bayesian Approach to Estimating Agricultural Yield Based on Multiple Repeated Surveys. J. Agric. Biol. Environ. Stat. 2012, 17, 84–106. [Google Scholar] [CrossRef]

- Basso, B.; Liu, L. Seasonal crop yield forecast: Methods, applications, and accuracies. Adv. Agron. 2019, 154, 201–225. [Google Scholar]

- Liu, L.; Basso, B. Linking field survey with crop modeling to forecast maize yield in smallholder farmers’ fields in Tanzania. Food Secur. 2020, 12, 537–548. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, Y.; Pan, J. Yield gap analysis of county level irrigated wheat in Hebei province, China. Agron. J. 2019, 111, 2245–2254. [Google Scholar] [CrossRef]

- Zandonadi, R.S.; Stombaugh, T.S.; Shearer, S.A. Laboratory performance of a mass flow sensor for dry edible bean harvesters. Appl. Eng. Agric. 2009, 26, 11–20. [Google Scholar] [CrossRef]

- Veal, M.w.; Shearer, S.A.; Fulton, J.P. Development and performance assessment of a grain combine feeder house-based mass flow sensing device. Trans. ASABE 2010, 53, 339–348. [Google Scholar] [CrossRef]

- Mcnaull, R.P. Development of a Real-time Algorithm for Automation of the Grain Yield. Monitor Calibration. PhD Dissertion, Lowa State University, Ames, IW, USA, 2016. [Google Scholar]

- Shoji, K.; Matsumoto, L.; Kawamura, T. Impact-by-impact sensing of grain flow on jidatsu combine. Eng. Agric. Environ. Food 2011, 4, 1–6. [Google Scholar] [CrossRef]

- Nelson, S.O.; Trabelsi, S.; Lewis, M.A. Microwave sensing of moisture content and bulk density in flowing grain and seed. Trans. Asabe 2016, 59, 429–433. [Google Scholar]

- Development of a grain yield monitoring system for 55 kW full-type multi-purpose combines. PhD. Dissertion, Chungnam National University, Daejeon, Korea, 2016.

- Sirikun, C.; Samseemoung, G.; Soni, P. A grain yield sensor for yield mapping with local rice combine harvester. Agriculture 2021, 11, 897. [Google Scholar] [CrossRef]

- Chung, S.-O.; Choi, M.-C.; Lee, K.-H. Sensing Technologies for Grain Crop Yield Monitoring Systems: A Review. J. Biosyst. Eng. 2016, 41, 408–417. [Google Scholar] [CrossRef]

- Jin, C.; Cai, Z.; Yang, T. Design and Experiment of Yield Monitoring System of Grain Combine. Trans. Chin. Soc. Agric. Mach. 2022, 53, 1–17. [Google Scholar]

| Area Values in Image Processing /(cm2) | Calculated Values for Area in Method 1 | Calculated Values for Area in Method 2 | The Difference Between the Area Value in the Image Processing and the Calculated Area Value/(%) | ||

|---|---|---|---|---|---|

| Calculation Formula: (L1 + L3) × L/2 | Calculation Formula: (L1 + 2L2 +L3) × L/4 | Method 1 | Method 2 | ||

| Side profile1 1 | 71 | 73.4 | 71.6 | 3.3 | 0.85 |

| Side profile1 2 | 75 | 77.6 | 76.1 | 2.1 | 0.93 |

| Side profile1 3 | 81 | 79.1 | 80.2 | 2.3 | 0.94 |

| Comparison of Bench Test Results under Different Working Conditions of Grain Input Amount | ||||

|---|---|---|---|---|

| Grain input amount/(kg) | The average error of the tests in this study/(%) | Average error in weighing tests/(%) | The research [26] did not carry out bench test | The research [28] did not carry out bench test |

| 5 | 5.1 | 8.2 | / | / |

| 10 | 4.4 | 7.9 | / | / |

| 15 | 4.5 | 6.8 | / | / |

| Comparison of bench test results at different motor speeds | ||||

| Motor speed of the bench/(r/min) | The average error of the tests in this study/(%) | Average error in weighing tests/(%) | The research [26] did not carry out bench test | Average error of tests in the research [28]/(%) |

| 150 | 4.6 | 7.2 | / | / |

| 190 | 4.4 | 6.9 | / | 6.76 |

| 287 | / | / | / | 7.74 |

| Comparison of field test results | ||||

| Average error of field tests in this study/(%) | Weighing method of yield measurement without field tests | Research [26] average error in field tests/(%) | Research [28] average error in field tests/(%) | |

| 3.72 | / | 16.38 | 3.83 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, S.; Han, H.; Qi, J.; Ma, Q.; Liu, J.; An, D.; Yang, Y. Design and Experiment of Real-Time Grain Yield Monitoring System for Corn Kernel Harvester. Agriculture 2023, 13, 294. https://doi.org/10.3390/agriculture13020294

Cheng S, Han H, Qi J, Ma Q, Liu J, An D, Yang Y. Design and Experiment of Real-Time Grain Yield Monitoring System for Corn Kernel Harvester. Agriculture. 2023; 13(2):294. https://doi.org/10.3390/agriculture13020294

Chicago/Turabian StyleCheng, Shangkun, Huayu Han, Jian Qi, Qianglong Ma, Jinghui Liu, Dong An, and Yang Yang. 2023. "Design and Experiment of Real-Time Grain Yield Monitoring System for Corn Kernel Harvester" Agriculture 13, no. 2: 294. https://doi.org/10.3390/agriculture13020294

APA StyleCheng, S., Han, H., Qi, J., Ma, Q., Liu, J., An, D., & Yang, Y. (2023). Design and Experiment of Real-Time Grain Yield Monitoring System for Corn Kernel Harvester. Agriculture, 13(2), 294. https://doi.org/10.3390/agriculture13020294