Development, Validation, and Application of Building Energy Simulation Models for Livestock Houses: A Systematic Review

Abstract

:1. Introduction

1.1. Background

1.2. Building Energy Simulation (BES) Models for Livestock Houses

1.3. Research Gap, Aim, and Contributions of This Work

- The presentation and thorough critical comparison of the BES models for livestock houses developed in recent years. By doing so, a pioneering and comprehensive overview of this specific area is provided.

- A critical examination of the validation procedures adopted in BES models for livestock houses accompanied by insightful recommendations to enhance and harmonize the validation process of future BES models. The final aim is to increase the reliability of these models.

- A critical discussion about the limitations that should be overcome to make BES models a standard practice, especially in industry.

2. Materials and Methods

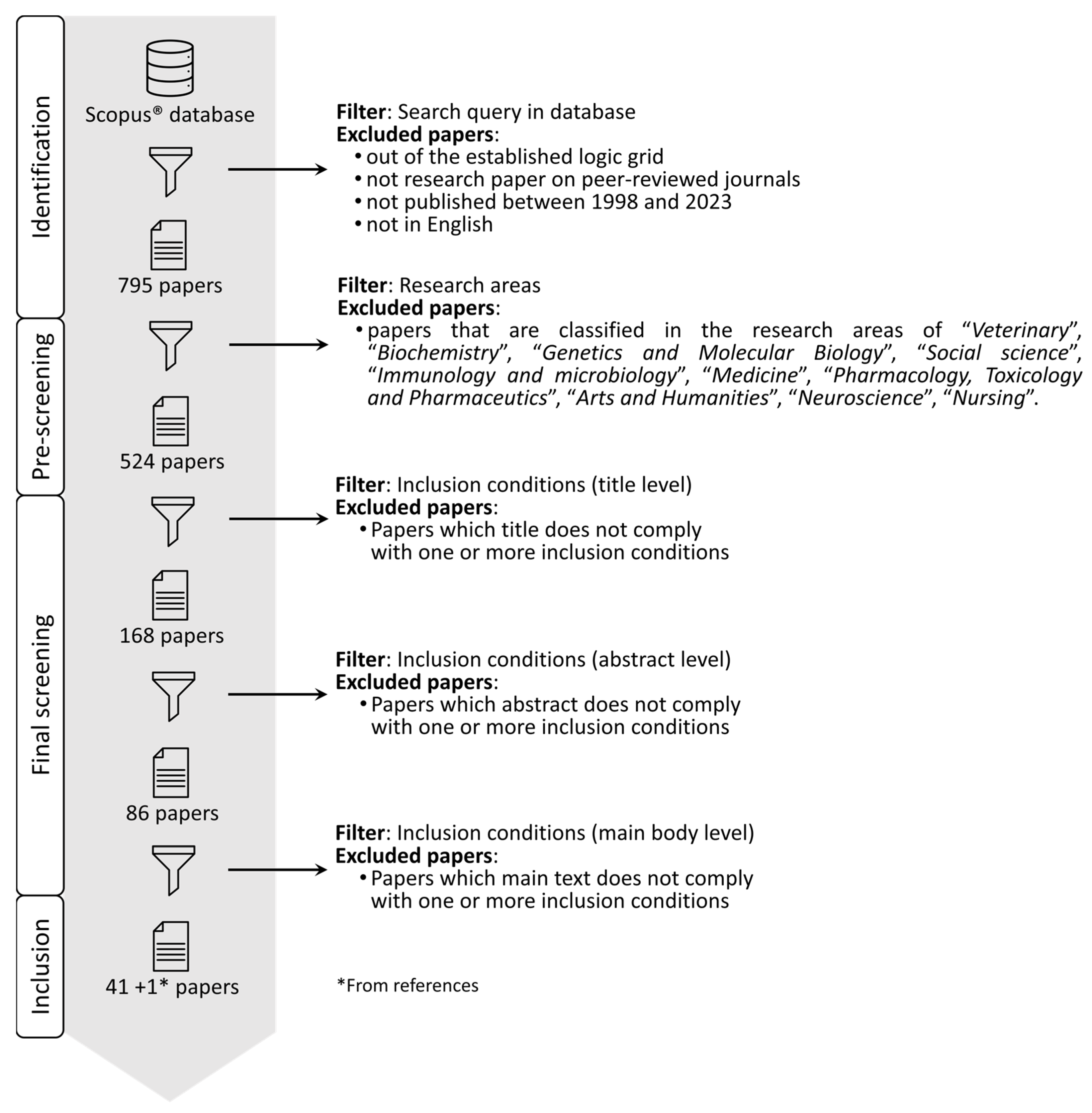

2.1. Review Methodology

2.1.1. Scope Delimiting

- The paper should be focused on livestock houses in intensive systems. Papers focused on other livestock systems (e.g., extensive or backyard systems) as well as on other farm structures (e.g., biodigesters or milking parlors) are out of the scope of this review.

- The paper should be focused on climate control and/or energy aspects. Papers focused on other topics, such as gaseous emissions and waste management, are out of the scope of this work.

- In the paper, a physics-based BES model for livestock houses should be adopted.

2.1.2. Logic Grid Creation

2.1.3. Definitions of the Literature Database, Search Rules, and Screening Criteria

2.1.4. Database Search

2.1.5. Identification, Pre-Screening, and Final Screening

2.2. Analysis Methodology

2.3. Bias Risk and Limitations

3. Results

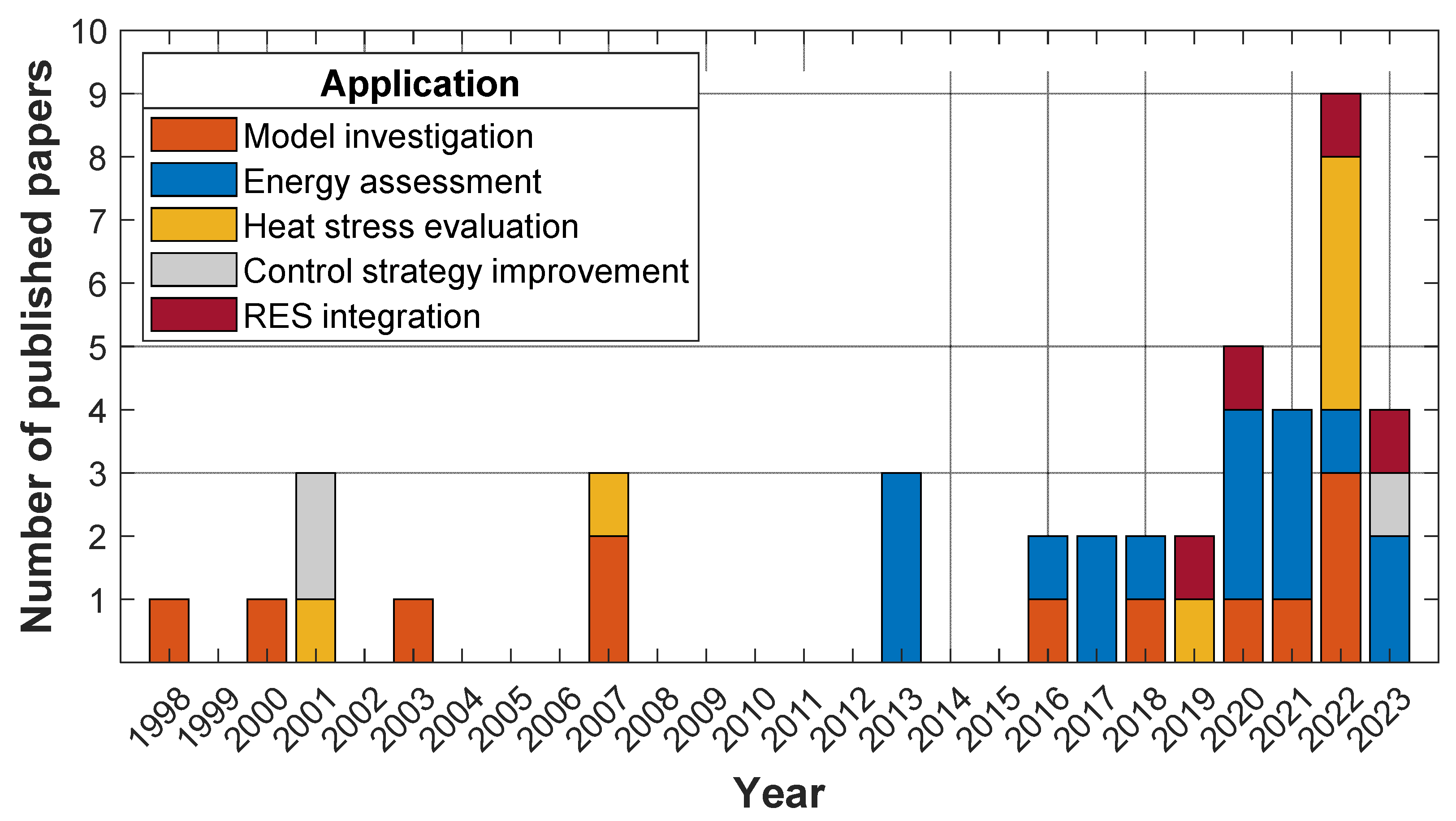

3.1. BES Models for Livestock Houses: Applications

- Model investigation;

- Energy assessment;

- Heat stress evaluation;

- Control strategy improvement;

- Renewable Energy Source (RES) integration.

| Application | Reference | Livestock House (Type of Ventilation) | Journal | Publication Year |

|---|---|---|---|---|

| Model investigation | Lee et al. [59] | Duck house (N) | Biosystems Engineering | 2022 |

| Shin et al. [43] | Piglet house (M) | Biosystems Engineering | 2022 | |

| Costantino et al. [31] | Fattening pig house (M) | Applied Energy | 2022 | |

| Nguyen-Ky and Pentillä [60] | Dairy barn (N) | Applied Engineering in Agriculture | 2021 | |

| Lee et al. [42] | Duck house (M) | Biosystems Engineering | 2020 | |

| Costantino et al. [63] | Broiler house (M) | Energy and Buildings | 2018 | |

| Hamilton et al. [64] | Broiler house (M) | Advances in Mechanical Engineering | 2016 | |

| Liberati and Zappavigna [41] | Generic house (N/M) | Transactions of the ASABE | 2007 | |

| Silva et al. [65] | Broiler house (M) | Revista Brasileira de Engenharia Agrícola e Ambiental | 2007 | |

| Wagenberg et al. [66] | Fattening pig house (M) | Biosystems Engineering | 2003 | |

| Schauberger et al. [67] | Fattening pig house (M) | International Journal of Biometeorology | 2000 | |

| Cooper et al. [40] | Generic house (N/M) | Journal of Agricultural Engineering Research | 1998 | |

| Energy assessment | Si et al. [49] | Fattening pig house (M) | Science of the Total Environment | 2023 |

| Qi et al. [44] | Nursery + fattening pig house (M) | Agriculture | 2023 | |

| Nawalany and Sokołowski [45] | Broiler house (M) | Energies | 2022 | |

| Costantino et al. [17] 1 | Broiler house (M) | Journal of Cleaner Production | 2021 | |

| Kwak et al. [20] 2 | Piglet house (M) | Energy Strategy Reviews | 2021 | |

| Panagakis et al. [68] 1 | Broiler house (M) | CIGR Journal | 2021 | |

| Costantino et al. [69] | Broiler house (M) | Biosystems Engineering | 2020 | |

| Izar-Tenorio et al. [46] | Broiler house (M) | Journal of Cleaner Production | 2020 | |

| Wang et al. [57] | Laying hen house (M) | Computers and Electronics in Agriculture | 2020 | |

| Jackson et al. [16] | Fattening pig house (M) | Biosystems Engineering | 2018 | |

| Jackson et al. [70] | Fattening pig house (M) | Energy and Buildings | 2017 | |

| Axaopoulos et al. [47] 1 | Fattening pig house (M) | Transactions of the ASABE | 2017 | |

| Wang and Xue [48] 1 | Piglet house (N) | Transactions of the ASABE | 2016 | |

| Zhao et al. [58] | Laying hen house (M) | Biosystems Engineering | 2013 | |

| Menconi et al. [61] 1 | Sheepfold (M) | Journal of Agricultural Engineering | 2013 | |

| Park et al. [71] | Fattening pig house (M) | Computers and Electronics in Agriculture | 2013 | |

| Heat stress evaluation | Scherllin-Pirscher et al. [72] | Fattening pig house (M) | Atmosphere | 2022 |

| Cho et al. [73] | Broiler house (M) | Agriculture | 2022 | |

| Schauberger et al. [51] | Fattening pig house (M) | Agronomy | 2022 | |

| Gonçalves et al. [52] | Broiler house (N) | Revista Brasileira de Engenharia Agrícola e Ambiental | 2022 | |

| Mikovits et al. [50] | Fattening pig house (M) | International Journal of Biometeorology | 2019 | |

| Haeussermann et al. [74] | Fattening pig house (M) | Transactions of the ASABE | 2007 | |

| Turnpenny et al. [62] | Generic house (M) | Global Change Biology | 2001 | |

| Control strategy improvement | Shin et al. [53] | Piglet house (M) | Energy | 2023 |

| Lambert et al. [54] | Fattening pig house (M) | Canadian Biosystems Engineering | 2001 | |

| Gates et al. [75] | Broiler house (M) | Computers and Electronics in Agriculture | 2001 | |

| RES 3 integration | Tyris et al. [19] 4 | Broiler house (M) | Energies | 2023 |

| Tan et al. [21] 5 | Broiler house (M) | Energy | 2022 | |

| Omar et al. [56] 5 | Broiler house (N) | Renewable Energy | 2020 | |

| Manolakos et al. [55] 4 | Broiler house (M) | Computers and Electronics in Agriculture | 2019 |

3.2. BES Models for Livestock Houses: Development

3.3. BES Models for Livestock Houses: Validation

- “✓” signifies the validation was performed for that parameter;

- “☓” denotes the validation was omitted for that parameter;

- “-” indicates the validation was not possible for that parameter because it cannot be estimated by the simulation model.

4. Discussion

4.1. Toward BES Models as a Standard Practice in the Livestock Sector

4.2. Recommendations for BES Model Validation

4.2.1. Perform Model Validation

4.2.2. Prefer Empirical Validation

4.2.3. Choose GoF Indexes with Defined Thresholds

4.3. BES Models for a More Environmentally Sustainable and Resilient Livestock Sector

5. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

| Acronym/Variable | Definition |

|---|---|

| ANalysis Of VAriance | |

| Coefficient of Variation | |

| Coefficient of Variation of the Root Mean Square Error | |

| Goodness Of Fit | |

| Interquartile Range | |

| Fisher’s Least Significant Difference | |

| Arithmetic mean of the monitored values | |

| i-th measured value | |

| Mean Absolute Error | |

| Mean Absolute Percentage Error | |

| Maximum value | |

| Maximum Absolute Error | |

| Maximum Relative Error | |

| Mean Bias Error | |

| Minimum value | |

| Mean Percentage Error | |

| Dataset cardinality | |

| Normalized Mean Bias Error | |

| Correlation coefficient | |

| Coefficient of determination | |

| Root Mean Square Error | |

| Arithmetic mean of the simulated values | |

| i-th simulated value | |

| Standard Error | |

| Arithmetic mean of values | |

| Standard deviation |

References

- Mottet, A.; de Haan, C.; Falcucci, A.; Tempio, G.; Opio, C.; Gerber, P. Livestock: On Our Plates or Eating at Our Table? A New Analysis of the Feed/Food Debate. Glob. Food Sec. 2017, 14, 1–8. [Google Scholar] [CrossRef]

- Mpofu, I. Chapter 7—Ecosystem Services from Different Livestock Management Systems. In The Role of Ecosystem Services in Sustainable Food Systems; Rusinamhodzi, L., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 135–140. ISBN 978-0-12-816436-5. [Google Scholar]

- ASHRAE. 2011 ASHRAE Handbook: HVAC Applications; ASHRAE: Atlanta, GA, USA, 2011; ISBN 9781936504077. [Google Scholar]

- Costantino, A.; Fabrizio, E.; Calvet, S. The Role of Climate Control in Monogastric Animal Farming: The Effects on Animal Welfare, Air Emissions, Productivity, Health, and Energy Use. Appl. Sci. 2021, 11, 9549. [Google Scholar] [CrossRef]

- Daramola, J.O.; Abioja, M.O.; Onagbesan, O.M. Heat Stress Impact on Livestock Production BT—Environmental Stress and Amelioration in Livestock Production. In Environmental Stress and Amelioration in Livestock Production; Sejian, V., Naqvi, S.M.K., Ezeji, T., Lakritz, J., Lal, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 53–73. ISBN 978-3-642-29205-7. [Google Scholar]

- Grieve, D. Heat Stress in Commercial Layers and Breeders. Tech. Bull. Hy-Line Int. 2003, 19, 1–3. [Google Scholar]

- Moreno, I.; Ladero, L.; Cava, R. Effect of the Iberian Pig Rearing System on Blood Plasma Antioxidant Status and Oxidative Stress Biomarkers. Livest. Sci. 2020, 235, 104006. [Google Scholar] [CrossRef]

- Lu, Q.; Wen, J.; Zhang, H. Effect of Chronic Heat Exposure on Fat Deposition and Meat Quality in Two Genetic Types of Chicken. Poult. Sci. 2007, 86, 1059–1064. [Google Scholar] [CrossRef]

- Costantino, A.; Fabrizio, E.; Biglia, A.; Cornale, P.; Battaglini, L. Energy Use for Climate Control of Animal Houses: The State of the Art in Europe. Energy Procedia 2016, 101, 184–191. [Google Scholar] [CrossRef]

- van Horne, P.L.M. Economics of Broiler Production Systems in the Netherlands; Economic Aspects within the Greenwell Sustainability Assessment Model; Wageningen Economic Research: Wageningen, The Netherlands, 2020. [Google Scholar]

- Karaman, S.; Taşcıoğlu, Y.; Bulut, O.D. Profitability and Cost Analysis for Contract Broiler Production in Turkey. Animals 2023, 13, 2072. [Google Scholar] [CrossRef]

- Costantino, A.; Calvet, S.; Fabrizio, E. The Use of Renewable Energy Sources as a Driver to Reduce the Carbon Footprint of the Livestock Sector. In Technology for Environmentally Friendly Livestock Production; Bartzanas, T., Ed.; Springer International Publishing: Cham, Switzerland, 2023; pp. 217–250. ISBN 978-3-031-19730-7. [Google Scholar]

- Paris, B.; Vandorou, F.; Tyris, D.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in the EU Livestock Sector: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 2142. [Google Scholar] [CrossRef]

- IRENA; FAO. Renewable Energy for Agri-Food Systems—Towards the Sustainable Development Goals and the Paris Agreement; IRENA and FAO: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- FAO. Energy-Smart Food for People and Climate—Issue Paper; FAO: Rome, Italy, 2011. [Google Scholar]

- Jackson, P.; Guy, J.H.; Sturm, B.; Bull, S.; Edwards, S.A. An Innovative Concept Building Design Incorporating Passive Technology to Improve Resource Efficiency and Welfare of Finishing Pigs. Biosyst. Eng. 2018, 174, 190–203. [Google Scholar] [CrossRef]

- Costantino, A.; Calvet, S.; Fabrizio, E. Identification of Energy-Efficient Solutions for Broiler House Envelopes through a Primary Energy Approach. J. Clean. Prod. 2021, 312, 127639. [Google Scholar] [CrossRef]

- Alberti, L.; Antelmi, M.; Angelotti, A.; Formentin, G. Geothermal Heat Pumps for Sustainable Farm Climatization and Field Irrigation. Agric. Water Manag. 2018, 195, 187–299. [Google Scholar] [CrossRef]

- Tyris, D.; Gkountas, A.; Bakalis, P.; Panagakis, P.; Manolakos, D. A Dynamic Heat Pump Model for Indoor Climate Control of a Broiler House. Energies 2023, 16, 2770. [Google Scholar] [CrossRef]

- Kwak, Y.; Shin, H.; Kang, M.; Mun, S.-H.; Jo, S.-K.; Kim, S.-H.; Huh, J.-H. Energy Modeling of Pig Houses: A South Korean Feasibility Study. Energy Strat. Rev. 2021, 36, 100672. [Google Scholar] [CrossRef]

- Tan, H.; Yan, W.; Ren, Z.; Wang, Q.; Mohamed, M.A. Distributionally Robust Operation for Integrated Rural Energy Systems with Broiler Houses. Energy 2022, 254, 124398. [Google Scholar] [CrossRef]

- Chong, A.; Gu, Y.; Jia, H. Calibrating Building Energy Simulation Models: A Review of the Basics to Guide Future Work. Energy Build 2021, 253, 111533. [Google Scholar] [CrossRef]

- Costantino, A.; Fabrizio, E. Envisioning an Energy Performance Certificate for Livestock Houses: A General Methodological Development and a Specific Application to Growing-Finishing Pig Houses. J. Clean. Prod. 2023, 429, 139279. [Google Scholar] [CrossRef]

- Harish, V.S.K.V.; Kumar, A. A Review on Modeling and Simulation of Building Energy Systems. Renew. Sustain. Energy Rev. 2016, 56, 1272–1292. [Google Scholar] [CrossRef]

- Barone, G.; Buonomano, A.; Forzano, C.; Palombo, A. Building Energy Performance Analysis: An Experimental Validation of an In-House Dynamic Simulation Tool through a Real Test Room. Energies 2019, 12, 4107. [Google Scholar] [CrossRef]

- Coakley, D.; Raftery, P.; Keane, M. A Review of Methods to Match Building Energy Simulation Models to Measured Data. Renew. Sustain. Energy Rev. 2014, 37, 123–141. [Google Scholar] [CrossRef]

- Fabrizio, E.; Monetti, V. Methodologies and Advancements in the Calibration of Building Energy Models. Energies 2015, 8, 2548–2574. [Google Scholar] [CrossRef]

- Choi, K.; Park, S.; Joe, J.; Kim, S.-I.; Jo, J.-H.; Kim, E.-J.; Cho, Y.-H. Review of Infiltration and Airflow Models in Building Energy Simulations for Providing Guidelines to Building Energy Modelers. Renew. Sustain. Energy Rev. 2023, 181, 113327. [Google Scholar] [CrossRef]

- Hong, T.; Chen, Y.; Belafi, Z.; D’Oca, S. Occupant Behavior Models: A Critical Review of Implementation and Representation Approaches in Building Performance Simulation Programs. Build. Simul. 2018, 11, 1–14. [Google Scholar] [CrossRef]

- Shin, M.; Haberl, J.S. Thermal Zoning for Building HVAC Design and Energy Simulation: A Literature Review. Energy Build 2019, 203, 109429. [Google Scholar] [CrossRef]

- Costantino, A.; Comba, L.; Cornale, P.; Fabrizio, E. Energy Impact of Climate Control in Pig Farming: Dynamic Simulation and Experimental Validation. Appl. Energy 2022, 309, 118457. [Google Scholar] [CrossRef]

- Song, W.; Zhang, Z.; Chen, Z.; Wang, F.; Yang, B. Thermal Comfort and Energy Performance of Personal Comfort Systems (PCS): A Systematic Review and Meta-Analysis. Energy Build. 2022, 256, 111747. [Google Scholar] [CrossRef]

- Arakawa Martins, L.; Soebarto, V.; Williamson, T. A Systematic Review of Personal Thermal Comfort Models. Build Environ. 2022, 207, 108502. [Google Scholar] [CrossRef]

- Bournet, P.-E.; Rojano, F. Advances of Computational Fluid Dynamics (CFD) Applications in Agricultural Building Modelling: Research, Applications and Challenges. Comput. Electron. Agric. 2022, 201, 107277. [Google Scholar] [CrossRef]

- Rong, L.; Nielsen, P.V.; Bjerg, B.; Zhang, G. Summary of Best Guidelines and Validation of CFD Modeling in Livestock Buildings to Ensure Prediction Quality. Comput. Electron. Agric. 2016, 121, 180–190. [Google Scholar] [CrossRef]

- Singh, M.; Sharston, R. A Literature Review of Building Energy Simulation and Computational Fluid Dynamics Co-Simulation Strategies and Its Implications on the Accuracy of Energy Predictions. Build. Serv. Eng. Res. Technol. 2022, 43, 113–138. [Google Scholar] [CrossRef]

- Shan, X.; Luo, N.; Sun, K.; Hong, T.; Lee, Y.-K.; Lu, W.-Z. Coupling CFD and Building Energy Modelling to Optimize the Operation of a Large Open Office Space for Occupant Comfort. Sustain. Cities Soc. 2020, 60, 102257. [Google Scholar] [CrossRef]

- Corrado, V.; Fabrizio, E. Chapter 5—Steady-State and Dynamic Codes, Critical Review, Advantages and Disadvantages, Accuracy, and Reliability. In Handbook of Energy Efficiency in Buildings; Asdrubali, F., Desideri, U., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 263–294. ISBN 978-0-12-812817-6. [Google Scholar]

- Chen, Y.; Guo, M.; Chen, Z.; Chen, Z.; Ji, Y. Physical Energy and Data-Driven Models in Building Energy Prediction: A Review. Energy Rep. 2022, 8, 2656–2671. [Google Scholar] [CrossRef]

- Cooper, K.; Parsons, D.J.; Demmers, T. A Thermal Balance Model for Livestock Buildings for Use in Climate Change Studies. J. Agric. Eng. Res. 1998, 69, 43–52. [Google Scholar] [CrossRef]

- Liberati, P.; Zappavigna, P. A Dynamic Computer Model for Optimization of the Internal Climate in Swine Housing Design. Trans. ASABE 2007, 50, 2179–2188. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Lee, I.-B.; Kim, R.-W.; Yeo, U.-H.; Kim, J.-G.; Kwon, K.-S. Dynamic Energy Modelling for Analysis of the Thermal and Hygroscopic Environment in a Mechanically Ventilated Duck House. Biosyst. Eng. 2020, 200, 431–449. [Google Scholar] [CrossRef]

- Shin, H.; Kwak, Y.; Jo, S.-K.; Kim, S.-H.; Huh, J.-H. Calibration of Building Energy Simulation Model for a Mechanically Ventilated Livestock Facility. Biosyst. Eng. 2022, 217, 115–130. [Google Scholar] [CrossRef]

- Qi, F.; Li, H.; Zhao, X.; Huang, J.; Shi, Z. Investigation on Minimum Ventilation, Heating, and Energy Consumption of Pig Buildings in China during Winter. Agriculture 2023, 13, 319. [Google Scholar] [CrossRef]

- Nawalany, G.; Sokołowski, P. Interaction between a Cyclically Heated Building and the Ground, for Selected Locations in Europe. Energies 2022, 15, 7493. [Google Scholar] [CrossRef]

- Izar-Tenorio, J.; Jaramillo, P.; Griffin, W.M.; Small, M. Impacts of Projected Climate Change Scenarios on Heating and Cooling Demand for Industrial Broiler Chicken Farming in the Eastern U.S. J. Clean. Prod. 2020, 255, 120306. [Google Scholar] [CrossRef]

- Axaopoulos, P.; Panagakis, P.; Axaopoulos, I. Optimization of Exterior Wall and Roof Insulation Thickness of a Growing-Finishing Piggery Building. Trans. ASABE 2017, 60, 489–495. [Google Scholar] [CrossRef]

- Wang, K.; Xue, H. Effects of Roof and Wall Insulation on Thermal Performance of Piglet Building Using Dynamic Simulation and Life Cycle Cost Analysis. Trans. ASABE 2016, 59, 915–922. [Google Scholar] [CrossRef]

- Si, B.; Wang, C.; Cheng, S.; Ma, X.; Xu, W.; Wang, Z.; Li, B.; Wang, Y.; Shi, Z.; Jiang, W. Carbon and Water Footprint Analysis of Pig Farm Buildings in Northeast China Using Building-Information-Modeling Enabled Assessment. Sci. Total Environ. 2023, 888, 164088. [Google Scholar] [CrossRef]

- Mikovits, C.; Zollitsch, W.; Hörtenhuber, S.J.; Baumgartner, J.; Niebuhr, K.; Piringer, M.; Anders, I.; Andre, K.; Hennig-Pauka, I.; Schönhart, M.; et al. Impacts of Global Warming on Confined Livestock Systems for Growing-Fattening Pigs: Simulation of Heat Stress for 1981 to 2017 in Central Europe. Int. J. Biometeorol. 2019, 63, 221–230. [Google Scholar] [CrossRef]

- Schauberger, G.; Schönhart, M.; Zollitsch, W.; Hörtenhuber, S.J.; Kirner, L.; Mikovits, C.; Baumgartner, J.; Piringer, M.; Knauder, W.; Anders, I.; et al. Reduction of the Economic Risk by Adaptation Measures to Alleviate Heat Stress in Confined Buildings for Growing-Fattening Pigs Modelled by a Projection for Central Europe in 2030. Agronomy 2022, 12, 248. [Google Scholar] [CrossRef]

- Gonçalves, I.C.M.; Turco, S.H.N.; Lopes Neto, J.P.; do Nascimento, J.W.B.; de Lima, V.L.A.; Borges, V.P. Thermal Performance of Aviary Located in the Semiarid Region of Pernambuco Based on Computer Simulation. Rev. Bras. Eng. Agríc. E Ambient. 2022, 26, 533–540. [Google Scholar] [CrossRef]

- Shin, H.; Kwak, Y.; Jo, S.-K.; Kim, S.-H.; Huh, J.-H. Development of an Optimal Mechanical Ventilation System Control Strategy Based on Weather Forecasting Data for Outdoor Air Cooling in Livestock Housing. Energy 2023, 268, 126649. [Google Scholar] [CrossRef]

- Lambert, M.; Lemay, S.P.; Barber, E.M.; Crowe, T.G.; Chénard, L. Humidity Control for Swine Buildings in Cold Climate—Part I: Modelling of Three Control Strategies. Can. Biosyst. Eng./Le Genie Des Biosyst. Au Can. 2001, 43, 529–536. [Google Scholar]

- Manolakos, D.; Panagakis, P.; Bartzanas, T.; Bouzianas, K. Use of Heat Pumps in HVAC Systems for Precise Environment Control in Broiler Houses: System’s Modeling and Calculation of the Basic Design Parameters. Comput. Electron. Agric. 2019, 163, 104876. [Google Scholar] [CrossRef]

- Omar, M.N.; Samak, A.A.; Keshek, M.H.; Elsisi, S.F. Simulation and Validation Model for Using the Energy Produced from Broiler Litter Waste in Their House and Its Requirement of Energy. Renew. Energy 2020, 159, 920–928. [Google Scholar] [CrossRef]

- Wang, Y.; Li, B.; Liang, C.; Zheng, W. Dynamic Simulation of Thermal Load and Energy Efficiency in Poultry Buildings in the Cold Zone of China. Comput. Electron. Agric. 2020, 168, 105127. [Google Scholar] [CrossRef]

- Zhao, Y.; Xin, H.; Shepherd, T.A.; Hayes, M.D.; Stinn, J.P. Modelling Ventilation Rate, Balance Temperature and Supplemental Heat Need in Alternative vs. Conventional Laying-Hen Housing Systems. Biosyst. Eng. 2013, 115, 311–323. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Lee, I.-B.; Yeo, U.-H.; Kim, J.-G.; Kim, R.-W.; Kwon, K.-S. Dynamic Energy Model of a Naturally Ventilated Duck House and Comparative Analysis of Energy Loads According to Ventilation Type. Biosyst. Eng. 2022, 219, 218–234. [Google Scholar] [CrossRef]

- Nguyen-Ky, S.; Penttilä, K. Indoor climate and energy model calibration with monitored data of a naturally ventilated dairy barn in a cold climate. Appl. Eng. Agric. 2021, 37, 851–859. [Google Scholar] [CrossRef]

- Menconi, M.E.; Chiappini, M.; Grohmann, D. Implementation of a Genetic Algorithm for Energy Design Optimization of Livestock Housing Using a Dynamic Thermal Simulator. J. Agric. Eng. 2013, 44, 191–196. [Google Scholar] [CrossRef]

- Turnpenny, J.R.; Parsons, D.J.; Armstrong, A.C.; Clark, J.A.; Cooper, K.; Matthews, A.M. Integrated Models of Livestock Systems for Climate Change Studies. 2. Intensive Systems. Glob. Chang. Biol. 2001, 7, 163–170. [Google Scholar] [CrossRef]

- Costantino, A.; Fabrizio, E.; Ghiggini, A.; Bariani, M. Climate Control in Broiler Houses: A Thermal Model for the Calculation of the Energy Use and Indoor Environmental Conditions. Energy Build. 2018, 169, 110–126. [Google Scholar] [CrossRef]

- Hamilton, J.; Negnevitsky, M.; Wang, X. Thermal Analysis of a Single-Storey Livestock Barn. Adv. Mech. Eng. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- Silva, M.P.; Baêta, F.C.; Tinôco, I.F.F.; Zolnier, S.; Ribeiro, A. Evaluation of a Simplified Model for Estimating Energy Balance in Broilers Production Housing. Rev. Bras. Eng. Agric. E Ambient. 2007, 11, 532–536. [Google Scholar] [CrossRef]

- Van Wagenberg, A.V.; Vranken, E.; Berckmans, D. Simulation and Validation of the Evaporation of Water from Liquid Manure Using Ventilation Exhaust Air: Linking of Two Simulation Models. Biosyst. Eng. 2003, 84, 31–43. [Google Scholar] [CrossRef]

- Schauberger, G.; Piringer, M.; Petz, E. Steady-State Balance Model to Calculate the Indoor Climate of Livestock Buildings, Demonstrated for Finishing Pigs. Int. J. Biometeorol. 2000, 43, 154–162. [Google Scholar] [CrossRef]

- Panagakis, P.; Manolakos, D.; Axaopoulos, P. Optimal Financial Insulation Thickness of a Broiler House. Agric. Eng. Int. CIGR J. 2021, 23, 99–110. [Google Scholar]

- Costantino, A.; Fabrizio, E.; Villagrá, A.; Estellés, F.; Calvet, S. The Reduction of Gas Concentrations in Broiler Houses through Ventilation: Assessment of the Thermal and Electrical Energy Consumption. Biosyst. Eng. 2020, 199, 135–148. [Google Scholar] [CrossRef]

- Jackson, P.; Guy, J.; Edwards, S.A.; Sturm, B.; Bull, S. Application of Dynamic Thermal Engineering Principles to Improve the Efficiency of Resource Use in UK Pork Production Chains. Energy Build. 2017, 139, 53–62. [Google Scholar] [CrossRef]

- Park, J.H.; Peters, T.M.; Altmaier, R.; Sawvel, R.A.; Renée Anthony, T. Simulation of Air Quality and Cost to Ventilate Swine Farrowing Facilities in Winter. Comput. Electron. Agric. 2013, 98, 136–145. [Google Scholar] [CrossRef] [PubMed]

- Scherllin-Pirscher, B.; Mikovits, C.; Baumann-Stanzer, K.; Piringer, M.; Schauberger, G. Are Adaptation Measures Used to Alleviate Heat Stress Appropriate to Reduce Ammonia Emissions? Atmosphere 2022, 13, 1786. [Google Scholar] [CrossRef]

- Cho, J.-H.; Lee, I.-B.; Lee, S.-Y.; Park, S.-J.; Jeong, D.-Y.; Decano-Valentin, C.; Kim, J.-G.; Choi, Y.-B.; Jeong, H.-H.; Yeo, U.-H.; et al. Development of Heat Stress Forecasting System in Mechanically Ventilated Broiler House Using Dynamic Energy Simulation. Agriculture 2022, 12, 1666. [Google Scholar] [CrossRef]

- Haeussermann, A.; Vranken, E.; Aerts, J.-M.; Hartung, E.; Jungbluth, T.; Berckmans, D. Evaluation of Control Strategies for Fogging Systems in Pig Facilities. Trans. ASABE 2007, 50, 265–274. [Google Scholar] [CrossRef]

- Gates, R.S.; Chao, K.; Sigrimis, N. Identifying Design Parameters for Fuzzy Control of Staged Ventilation Control Systems. Comput. Electron. Agric. 2001, 31, 61–74. [Google Scholar] [CrossRef]

- European Commission. Farm to Fork Strategy—For a Fair, Healthy and Environmentally-Friendly Food System. 2020. Available online: https://food.ec.europa.eu/system/files/2020-05/f2f_action-plan_2020_strategy-info_en.pdf (accessed on 19 September 2023).

- EN ISO 13790; Energy Performance of Buildings–Calculation of Energy Use for Space Heating and Cooling. European Committee for Standardisation: Brussels, Belgium, 2008.

- U.S. Department of Energy Energy Plus. Available online: https://energyplus.net/ (accessed on 19 September 2023).

- Thermal Energy System Specialists TRNSYS—Transient System Simulation Tool. Available online: https://www.trnsys.com/ (accessed on 19 September 2023).

- Crawley, D.B.; Hand, J.W.; Kummert, M.; Griffith, B.T. Contrasting the Capabilities of Building Energy Performance Simulation Programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef]

- University of Strathclyde: Energy Systems Research Unit—ESP-r (Environmental Systems Performance—Research). Available online: https://www.esru.strath.ac.uk/applications/esp-r/ (accessed on 19 September 2023).

- Fraunhofer IBP WUFI. Available online: https://wufi.de/en/software/wufi-plus/ (accessed on 19 September 2023).

- EQUA Simulation AB IDA Indoor Climate and Energy. Available online: https://www.equa.se/en/ida-ice (accessed on 20 September 2023).

- Yan, D.; Xia, J.; Tang, W.; Song, F.; Zhang, X.; Jiang, Y. DeST—An Integrated Building Simulation Toolkit Part I: Fundamentals. Build. Simul. 2008, 1, 95–110. [Google Scholar] [CrossRef]

- Baxevanou, C.; Fidaros, D.; Bartzanas, T.; Kittas, C. Energy Consumption and Energy Saving Measures in Poultry. Environ. Eng. 2017, 5, 29–36. [Google Scholar] [CrossRef]

- ASHRAE. Measurement of Energy and Demand Savings; ANSI/ASHRAE ASHRAE Guideline 14-2002; American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2002. [Google Scholar]

- ASHRAE. ASHRAE Handbook—Fundamentals (SI Edition); ASHRAE: Atlanta, GA, USA, 2017; ISBN 978-1-936504-46-6. [Google Scholar]

- Federal Energy Management Program. M&V Guidelines: Measurement and Verification for Performance-Based Contracts Version 4.0; U.S. Department of Energy: Washington, DC, USA, 2015.

- IPMVP Technical Committee. International Performance Measurement & Verification Protocol—Concepts and Options for Determining Energy and Water Savings—Volume I; IPMVP: Washington, DC, USA, 2002. [Google Scholar]

- Federal Energy Management Program. M&V Guidelines: Measurement and Verification for Federal Energy Projects Version 3.0; U.S. Department of Energy: Washington, DC, USA, 2008.

- IPMVP New Construction Subcommittee. International Performance Measurement & Verification Protocol: Concepts and Option for Determining Energy Savings in New Construction, Volume III; IPMVP: Washington, DC, USA, 2003. [Google Scholar]

- Efficiency Valuation Organization. International Performance Measurement and Verification Protocol (IPMVP)—Core Concepts; Efficiency Valuation Organization: Washington, DC, USA, 2016. [Google Scholar]

- Ecim-Djuric, O.; Topisirovic, G. Energy Efficiency Optimization of Combined Ventilation Systems in Livestock Buildings. Energy Build 2010, 42, 1165–1171. [Google Scholar] [CrossRef]

- Izhboldina, O.; Mylostyvyi, R.; Khramkova, O.; Pavlenko, O.; Kapshuk, N.; Chernenko, O.; Matsyura, A.; Hoffmann, G. Effectiveness of Additional Mechanical Ventilation in Naturally Ventilated Dairy Housing Barns during Heat Waves. Ukr. J. Ecol. 2020, 10, 56–62. [Google Scholar]

- Zhai, Z.J.; Chen, Q.Y. Performance of Coupled Building Energy and CFD Simulations. Energy Build 2005, 37, 333–344. [Google Scholar] [CrossRef]

- Barbason, M.; Reiter, S. Coupling Building Energy Simulation and Computational Fluid Dynamics: Application to a Two-Storey House in a Temperate Climate. Build. Environ. 2014, 75, 30–39. [Google Scholar] [CrossRef]

- Nawalany, G.; Sokołowski, P. Improved Energy Management in an Intermittently Heated Building Using a Large Broiler House in Central Europe as an Example. Energies 2020, 16, 1371. [Google Scholar] [CrossRef]

- Ruiz, G.R.; Bandera, C.F. Validation of Calibrated Energy Models: Common Errors. Energies 2017, 10, 1587. [Google Scholar] [CrossRef]

- Thacker, B.H.; Doebling, S.W.; Hemez, F.M.; Anderson, M.C.; Pepin, J.E.; Rodriguez, E.A. Concepts of Model Verification and Validation; Los Alamos National Laboratory: Los Alamos, NM, USA, 2004. [Google Scholar]

- ANSI/ASHRAE. ANSI/ASHRAE 140-2020—Method Of Test For Evaluating Building Performance Simulation Software; ANSI: Washington, DC, USA, 2020. [Google Scholar]

- Costantino, A.; Ballarini, I.; Fabrizio, E. Comparison between Simplified and Detailed Methods for the Calculation of Heating and Cooling Energy Needs of Livestock Housing: A Case Study. In Proceedings of the Building Simulation Applications, Bozen-Bolzano, Italy, 8–10 February 2017; pp. 193–200. [Google Scholar]

- Wen, X.; Jaxa-Rozen, M.; Trutnevyte, E. Accuracy Indicators for Evaluating Retrospective Performance of Energy System Models. Appl. Energy 2022, 325, 119906. [Google Scholar] [CrossRef]

- Riahi, K.; van Vuuren, D.P.; Kriegler, E.; Edmonds, J.; O’Neill, B.C.; Fujimori, S.; Bauer, N.; Calvin, K.; Dellink, R.; Fricko, O.; et al. The Shared Socioeconomic Pathways and Their Energy, Land Use, and Greenhouse Gas Emissions Implications: An Overview. Glob. Environ. Chang. 2017, 42, 153–168. [Google Scholar] [CrossRef]

- St-Pierre, N.R.; Cobanov, B.; Schnitkey, G. Economic Losses from Heat Stress by US Livestock Industries. J. Dairy Sci. 2003, 86, E52–E77. [Google Scholar] [CrossRef]

- Minister of Agriculture. Code of Welfare: Layer Hens; Minister of Agriculture: Wellington, New Zealand, 2018.

- National Farm Animal Care Council (NFACC). Code of Practice for the Care and Handling of Pullets and Laying Hens; National Farm Animal Care Council: Ottawa, CA, USA, 2017. [Google Scholar]

| Livestock | Hous * | Energ * | Model * |

|---|---|---|---|

| Animal | Building | Simulation | Simulation |

| Poultry | Room | Therm * | Assessment |

| Broiler | Barn | Dynamic | |

| Hen | Facilit * | ||

| Duck | Farm * | ||

| Swine | |||

| Pig * | |||

| Farrow * | |||

| Cattle | |||

| Dairy | |||

| Cow |

| Reference | Model Type | Type of Analysis | Simulation Time Step | ) Estimation | Estimated Energy Parameter 1 | Model Validation |

|---|---|---|---|---|---|---|

| Si et al. [49] | Custom | SS | n.a. 2 | ✓ | ☓ | |

| Tyris et al. [19] | Custom | D | n.a. | ✓ | 3 | ☓ |

| Qi et al. [44] | Custom | SS | 1 h | ✓ | ✓ | |

| Shin et al. [53] | Tool (E+) | D | 1 h | ☓ | ✓ | |

| Scherllin-Pirscher et al. [72] | Same of [67] | SS | 1 h | ✓ | - | ☓ |

| Cho et al. [73] | Tool (E+) | D | 5 min | ✓ | - | ✓ |

| Nawalany and Sokołowski [45] | Tool (WUFI) | D | 1 h | ☓ | ✓ | |

| Tan et al. [21] | Custom | D | 1 h | ☓ | ☓ | |

| Lee et al. [59] | Tool (TRNSYS) | D | 5 min | ✓ | ✓ | |

| Shin et al. [43] | Tool (E+) | D | 1 h | ☓ | ✓ | |

| Costantino et al. [31] | Custom | D | 1 h | ✓ | ✓ | |

| Schauberger et al. [51] | Same of [67] | SS | 1 h | ✓ | - | ☓ |

| Gonçalves et al. [52] | Tool (E+) | D | 1 h | ✓ | - | ✓ |

| Costantino et al. [17] | Same of [63] | D | 1 h | ✓ | in [63] | |

| Kwak et al. [20] | Tool (E+) | D | 1 h | ✓ | ☓ | |

| Nguyen-Ky and Pentillä [60] | Tool (IDA ICE) | D | 1 h | ✓ | ✓ | |

| Panagakis et al. [68] | Tool (TRNSYS) | D | 1 h | ✓ | ☓ | |

| Lee et al. [42] | Tool (TRNSYS) | D | 5 min | ✓ | ✓ | |

| Costantino et al. [69] | Same of [63] | D | 1 h | ✓ | in [63] | |

| Omar et al. [56] | Custom | SS | 1 h | ☓ | ✓ | |

| Izar-Tenorio et al. [46] | Adaptation of [64] | SS | 1 h | ☓ | ☓ | |

| Wang et al. [57] | Tool (DeST) | D | 1 h | ✓ | ✓ | |

| Manolakos et al. [55] | Custom | SS | 1 h | ✓ | ✓ | |

| Mikovits et al. [50] | Same of [67] | SS | 1 h | ✓ | - | ☓ |

| Jackson et al. [16] | Same of [70] | D | 1 h | ☓ | - | in [70] |

| Costantino et al. [63] | Custom | D | 1 h | ✓ | ✓ | |

| Jackson et al. [70] | Tool (E+) | D | 1 h | ☓ | - | ✓ |

| Axaopoulos et al. [47] | Tool (TRNSYS) | D | 1 h | ☓ | - | ☓ |

| Hamilton et al. [64] | Custom | SS | 1 h | ✓ | ✓ | |

| Wang and Xue [48] | Tool (E+) | D | 1 h | ☓ | ☓ | |

| Zhao et al. [58] | Custom | SS | 1 h | ☓ | ✓ | |

| Menconi et al. [61] | Tool (E+) | D | 1 h | ☓ | ☓ | |

| Park et al. [71] | Custom | D | n.a. | ✓ | ☓ | |

| Liberati and Zappavigna [41] | Custom | D | 1 h | ✓ | - | ✓ |

| Silva et al. [65] | Custom | SS | 2 h | ✓ 4 | - | ✓ |

| Haeussermann et al. [74] | Custom | D | 3 s | ✓ | ✓ | |

| Wagenberg et al. [66] | Custom | D | 3 s | ✓ | ☓ | |

| Lambert et al. [54] | Custom | SS | 1 h | ✓ | ☓ | |

| Turnpenny et al. [62] | Adaptation of [40] | SS | 1 h | ✓ | ☓ | |

| Gates et al. [75] | Custom | D | 30 s | ☓ | - | ☓ |

| Schauberger et al. [67] | Custom | SS | 30 min | ✓ | - | ☓ |

| Cooper et al. [40] | Custom | SS | 1 h | ✓ | - | ✓ |

| Validation Parameters (Sample Size) | |||||||

|---|---|---|---|---|---|---|---|

| Reference | Validation Period | GoF Indexes 1 | Thresholds | ||||

| Qi et al. [44] | ✓ (n.a.) | ✓ (n.a.) | ☓ | - | 14 days | , , , | ☓ |

| Shin et al. [53] | ✓ (504) | - | - | ✓ (504) | 21 days | , | [86] |

| Cho et al. [73] | ✓ (2016) | ✓ (2016) | - | - | 7 days | , , , | [87,88,89] |

| Nawalany and Sokołowski [45] | ✓ (8760) | - | - | - | 365 days | , | Custom |

| Lee et al. [59] | ✓ (2016) | ✓ (2016) | - | - | 7 days | , , | ☓ |

| Shin et al. [43] | ✓ (504) | - | - | ✓ (21) | 21 days | , , | [86] |

| Costantino et al. [31] | ✓ (744) | ✓ (744) | ☓ | ✓ (744) | 37 days | , , | [86,90,91] |

| Gonçalves et al. [52] | ✓ (48) | ✓ (48) | - | - | 2 days | , , | ☓ |

| Nguyen-Ky and Pentillä [60] | ✓ (4416) | ✓ (2928) | ✓ 3 (2) | - | 184/122/197 days 2 | , , | [86,88,92] Custom |

| Lee et al. [42] | ✓ (2016) | ✓ (2016) | - | - | 7 days | , , | ☓ |

| Omar et al. [56] | ✓ (144) | - | - | - | 6 days | ☓ | |

| Wang et al. [57] | ✓ (168) | ✓ (168) | - | - | 7 days | , , | ☓ |

| Manolakos et al. [55] | ☓ | ☓ | ✓ 4 (1) | ☓ | 365 days | ☓ | |

| Costantino et al. [63] | ✓ (1200) | ✓ (1200) | ✓ (1) | ✓ (1) | 50 days | , , , | [86] |

| Jackson et al. [70] | ✓ (240) | - | - | - | 10 days | ☓ | ☓ |

| Hamilton et al. [64] | ✓ (840) | ✓ (840) | - | - | 35 days | ☓ | |

| Zhao et al. [58] | ☓ | - | ✓ (1) | - | 152 days | Custom | |

| Liberati and Zappavigna [41] | ✓ (48) | ✓ (48) | - | - | 48 h | ☓ | |

| Silva et al. [65] | ✓ (34) | ✓ 5 (34) | - | - | 68 h | Custom | |

| Haeussermann et al. [74] | ✓ (17,280) | ✓ (17,280) | ☓ | ☓ | 180 days | , , , , | Custom |

| Cooper et al. [40] | ✓ (168) | ☓ | - | - | 7 days | , 6 | ☓ |

| GoF Index | Threshold Interval | Time Step of the Validation Dataset | Source |

|---|---|---|---|

| 1 | Hour | [86,88] | |

| Month | [86,88] | ||

| Month | [89] | ||

| Hour | [86,88] | ||

| Hour | [89] | ||

| Month | [86,90] | ||

| Month | [91] | ||

| Hour | [87,88] | ||

| Hour | [45] | ||

| 2 | Hour/Entire period | [60] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costantino, A. Development, Validation, and Application of Building Energy Simulation Models for Livestock Houses: A Systematic Review. Agriculture 2023, 13, 2280. https://doi.org/10.3390/agriculture13122280

Costantino A. Development, Validation, and Application of Building Energy Simulation Models for Livestock Houses: A Systematic Review. Agriculture. 2023; 13(12):2280. https://doi.org/10.3390/agriculture13122280

Chicago/Turabian StyleCostantino, Andrea. 2023. "Development, Validation, and Application of Building Energy Simulation Models for Livestock Houses: A Systematic Review" Agriculture 13, no. 12: 2280. https://doi.org/10.3390/agriculture13122280

APA StyleCostantino, A. (2023). Development, Validation, and Application of Building Energy Simulation Models for Livestock Houses: A Systematic Review. Agriculture, 13(12), 2280. https://doi.org/10.3390/agriculture13122280