Abstract

Agaricus bisporus is widely cultivated worldwide due to its considerable economic benefits. The increasingly prominent contradiction between production and labor shortage necessitates the urgent replacement of human workers with intelligent picking technology and equipment. Therefore, a pressure-stabilized flexible end-effector was designed to achieve the rapid and low-loss picking of Agaricus bisporus. The dimensions of the end-effector were determined by measuring the external parameters of Agaricus bisporus. A mechanics model of the end-effector was constructed to analyze the picking process theoretically, and the pre-experiments identified the key performance factors of the end-effector: the thickness of the flexible membrane, the particle filler material, and the pressure stability. A series of experiments were conducted to investigate the factors mentioned above concerning the performance of the end-effector. The results show that the adsorption effect is best when the thickness of the flexible membrane is 0.9 mm, and the particle diameter is 200 mesh quartz. To control the adsorption force of the end-effector accurately during the picking process, a low-cost adsorption force-adjustment system was designed, and the stability of the system was verified. The experimental results showed that the device improved the stability of the adsorption force during the operation of the picking system by 84.71%. An experiment was conducted on the picking of Agaricus bisporus using the designed end-effector. The success rate of picking with the end-effector was 98.50%, and the picking damage rate was 2.50%.

1. Introduction

Agaricus bisporus is an edible mushroom that has the advantages of low production cost, a short growth cycle, and a high economic benefit [1,2,3]. It is widely planted in China [4]. In production, over 90% of Agaricus bisporus is picked manually to ensure its excellent quality and intact appearance. Artificial picking has high labor intensity and costs [5]. Issues of labor shortages and rising costs increasingly challenge the sustainability of the mushroom industry. Mechanical or robotic systems are potential solutions to address this challenge [6,7,8]. As the core device of the picking robot, the end-effector plays a vital role in improving the picking quality [9]. The end-effector is categorized into two types: gripper type and suction type [10,11,12,13]. The gripper-type end-effector uses finger gripping to hold the Agaricus bisporus and completes the picking by a rotating or shearing action. The suction-type end-effector holds the Agaricus bisporus using negative pressure and picks it by a stretching or rotating action [14,15,16,17,18].

With the rapid development of material science, soft manipulators have become the focus of research worldwide [19,20,21]. Fei et al. [22] developed a mobile picking device. The end-effecter is equipped with a flexible chuck, and the picking process for robotic mushroom picking is simple and effective. The utilization of flexible clamping jaws can effectively decrease the rate of picking damage. However, in regions where Agaricus bisporus is densely grown, there might not be sufficient space for clamping. The adsorption-type top-picking end-effector effectively resolves this issue. Kurpaska et al. [23] conducted a study on the applicability of pneumatic end-effectors for picking commercial crops. The study examined the correlation between the pressure applied by the suction cup and the extent of fruit damage. Huang et al. [24] designed a suction-based robotic picking mechanism and built a laboratory-scale prototype to validate its performance. The mechanism, using corrugated suction cups as end-effectors, achieved a success rate of 94.2% in picking. The experimental results indicate a direct relationship between the negative pressure and the level of damage to Agaricus bisporus. Yang et al. [25] designed a vacuum-negative pressure end-effector, which utilizes flexible suction cups made of special silicone and a double-layer corrugated structure, providing multiple degrees of freedom and thereby reducing the harm to the mushroom. In a factory setting, the robot achieved a success rate of 88.2% and a damage rate of 2.9%. Huh et al. [26] presented a novel robot end-effector for gripping and haptic exploration. The end-effector is divided into four quadrants. During suction gripping, a trained LSTM network localized breaks in the suction seal between four quadrants with up to 97% accuracy and detected breaks in the suction seal early enough to prevent total grasp failure.

Compared to the gripper-type end-effector, the suction-type end-effector causes less damage to the Agaricus bisporus, has a faster response time, and is more effective in picking dense areas. However, when the shape of the Agaricus bisporus is irregular or the negative pressure is insufficient, the success rate of picking using the suction-type end-effector may be reduced. To address these problems, based on picking requirements and finite element simulations, this study designed a pressure-stabilized flexible end-effector and conducted experimental verification for its performance indicators and picking effectiveness.

2. Materials and Methods

2.1. Design of the End-Effector

2.1.1. Structural Design of the End-Effector

The sealing between the suction cup-type end-effector and the contact object directly affects the negative pressure inside the end-effector, thereby influencing the strength of the adsorption force. The ellipticity and surface curvature of individual Agaricus bisporus are different, and common suction cups do not form an effective seal with Agaricus bisporus during the picking process, resulting in the problems of loose grips and loss of mushrooms. To solve the above problems, an end-effector with flexible profiling was designed with appropriate profiling ability and operation mode to effectively reduce mechanical damage and not interfere with surrounding Agaricus bisporus.

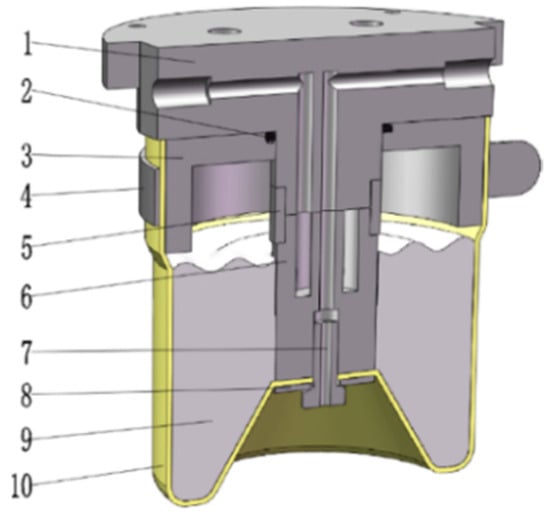

Figure 1 shows the three-dimensional cross-sectional view of the end-effector with flexible profiling. It was composed of a flexible film, particles, and metal attachments. These attachments included an end cap, a support element, a clamp, a connecting sleeve, a vent core, a vent screw, and a gasket. The main function of these accessories was to fix the flexible film and transmit negative pressure to the inside of the end-effector. Two ventilation pipes were arranged in the end cap for ventilation in the flexible film and negative-pressure transfer in the end-effector. To prevent particle leakage, a seal ring was installed between the end cap and the support element, and a filter screen was installed on the outer side of the vent core. The clamp fixed the flexible film on the support element, and the vent screw fixed the lower surface of the flexible film on the vent core.

Figure 1.

Cross section of the mechanical structure. 1. End cap; 2. seal ring; 3. support element; 4. clamp; 5. connecting sleeve; 6. vent core; 7. vent screw; 8. gasket; 9. particles; 10. and flexible film.

The working principle of the end-effector was as follows: under standard air pressure, particles exhibit fluid-like characteristics within a flexible film. When the particles are flowing, certain friction and interaction forces are generated between the particles, which leads to accumulation and blockage phenomena between the particles when the fluid force increases. Therefore, after the flexible film contacts the surface of the Agaricus bisporus, negative pressure appears inside the suction cup, and the Agaricus bisporus is held and squeezes the flexible film. In this process, the particles inside the flexible membrane first begin to flow and imitate the contour of the surface of the Agaricus bisporus according to the contour of the surface of the Agaricus bisporus, and when the pressure further increases, the particles form a blockage inside the flexible membrane. At this time, the suction of the Agaricus bisporus could be completed.

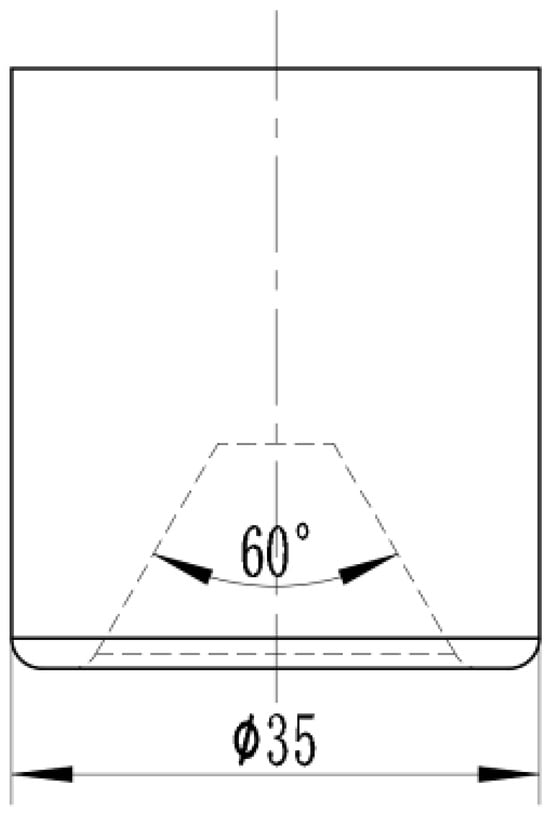

To shorten the profiling time, the shape of the end-effector was designed, as shown in Figure 2. According to the shape of the mushroom cap, prototype flexible films with opening angles of 60°, 90°, and 120° were produced, and a preliminary test was performed. One hundred Agaricus bisporus were picked using the end-effectors with the three opening angles, and the picking success rates were 92.00%, 88.00%, and 73.00%. The results showed that the success rate of end-effector picking was the highest when the opening angle of the flexible film was 60°, and thus, the opening angle was set to 60°.

Figure 2.

Schematic diagram of flexible film.

The size of the end-effector with flexible profiling was determined by the actual working space and the size of the mushroom cap. The outer diameter of the flexible film should be as small as possible without affecting the profiling function to reduce the possibility of interference with the surrounding Agaricus bisporus. According to the DB34/T 1277-2010 “Technical Regulations for Picking, Grading, and Pickling of Agaricus bisporus”, the optimal picking diameter for Agaricus bisporus is 25–35 mm. To reserve the margin for the opening diameter and ensure the profiling ability of the end-effector, the outer diameter of the flexible film was taken as 35 mm. In this study, the relationship between the inner diameter of the flexible film and the effective suction diameter of the end-effector was analyzed using a simulation to determine the best inner diameter of the flexible film. In addition, the stress changes in the end-effector with flexible profiling and the Agaricus bisporus during the process of adsorption profiling were analyzed.

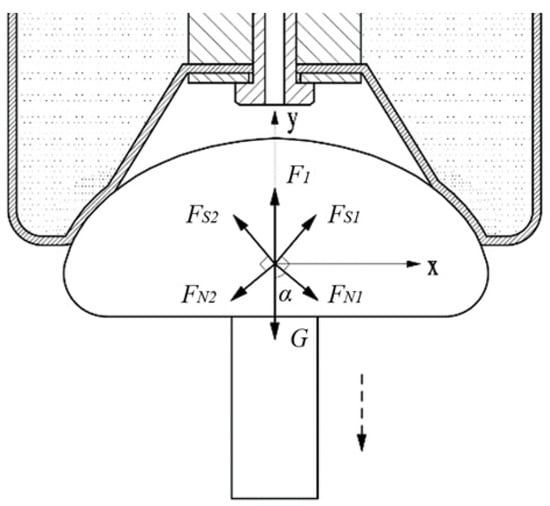

2.1.2. Material Determination

To investigate the effect of the contact surface on the adsorption force, a force analysis was conducted on Agaricus bisporus after being adsorbed by the end-effector with flexible profiling, as shown in Figure 3. The Agaricus bisporus was considered to have a centrally symmetrical regular shape. When an Agaricus bisporus was tightly adsorbed by the end-effector and showed a downward movement trend, a force analysis was conducted on the Agaricus bisporus, which was subjected to an upwards suction force F1, gravity G, support reaction forces FN1 and FN2 on the left and right sides, as well as friction forces FS1 and FS2.

Figure 3.

Force analysis of Agaricus bisporus after adsorption.

The adsorption force of the end-effector with flexible profiling was calculated using the following equation:

where

and where α is the angle between G and FN, deg; A is the adsorption area, m2; D is the adsorption diameter, m; p is the relative pressure, Pa; and fS is the friction coefficient.

According to Equations (1)–(4), the adsorption force of the end-effector is primarily composed of a suction force and friction forces, with the suction force significantly exceeding the friction force. In order to strengthen the linear relationship between the negative pressure and the adsorption force of the end-effector for precise control, the friction force is recognized as a disturbance factor and ought to be minimized. Table 1 compares the friction coefficients of latex and silicone film. Based on this comparison, the latex film was selected as the flexible film material because its friction coefficient was lower.

Table 1.

Comparison of friction coefficient.

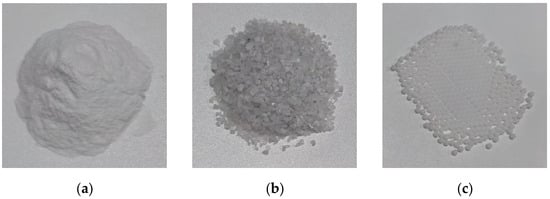

To analyze the influence of particle size and fluidity on the copying ability, packing density, and cost of particles in the flexible film, POM plastic balls with smooth surfaces and quartz sand with two different diameters were selected as particle fillers, as shown in Figure 4. Three types of particle fillers were used to make end-effectors, and comparative experiments were conducted on the profiling performance of the end-effectors.

Figure 4.

Particulate materials. (a) Fine quartz sand with diameters of 20 mesh; (b) coarse quartz sand with diameters of 200 mesh; and (c) POM plastic balls with diameters of 3 mm.

2.1.3. Finite Element Simulation of the End-Effector

To determine the optimal opening diameter of the flexible membrane and the stress distribution of the end-effector, finite element simulations of the profiling and adsorption processes of the effector using the static structure module in ANSYS finite element software (2021 R1 version) were conducted. A 3D modeling of the end-effector was performed using SolidWorks software (2020 SP5.0 version). Without affecting the simulation results, component parts unrelated to the simulation were removed to simplify the model as much as possible.

During the actual adsorption process, factors such as the loading position, the loading speed, and the friction coefficient between contact surfaces can affect the adsorption performance and stress distribution of the end-effector. To simplify the simulation, the following assumptions were made: The end-effector was assumed to be in contact with the Agaricus bisporus at its initial position. During the pressing process, the force was evenly applied to the top surface of the end-effector. The flexible film indicated that the surface of the Agaricus bisporus was smooth and flat, the material was uniform and continuous, and the material was accessible. According to the particle blocking principle, when the particles inside the flexible membrane are blocked, they behave as a continuous solid, a property that is independent of the physical properties of the particles themselves. Therefore, the filler inside the flexible membrane can be regarded as a continuous solid during simulation.

The flexible film material parameters were a density of 1000 kg/m3, a material constant C10 of 0.01 MPa, a material constant C20 of 0.001 MPa, and an incompressibility of 1.21 × 10−9 Pa−1. Quartz was chosen as the granular filling material in the flexible film. The axial modulus of elasticity of Agaricus bisporus is about 0.53 MPa, and the radial modulus of elasticity is about 0.33 MPa. In this study, the end actuator was apical suction, so the axial modulus of elasticity was used to calculate the deformation of Agaricus bisporus during the picking process. The average picking force was 5.14 N, the effective adsorption area was 4.91 × 10−4 m2, and the cap thickness was 1.5 cm. The action area of the suction cup was mainly at the top of the Agaricus bisporus, and 1/5 of the cap thickness was taken as the deformation area. The deformation of Agaricus bisporus in the adsorption process was about 0.06 mm, much smaller than that of the flexible film. When analyzing the stress distribution of the flexible film in the adsorption process, the Agaricus bisporus was regarded as an object of pressure application, and its small deformation did not affect the stress distribution of the flexible film. Therefore, the model of Agaricus bisporus was simplified. Polyethylene was chosen as the material for the model to simplify the computational effort of the simulation. The contact surface of the flexible film and Agaricus bisporus was taken as the main research object during the finite element simulation of the profile modeling process and the adsorption process. The lower surface of the flexible film and the upper surface of Agaricus bisporus were subjected to mesh-refinement treatment during mesh division to ensure the accuracy of the calculation. The mesh divisions of the flexible film and Agaricus bisporus were tetrahedral mesh types with a mesh size of 2 mm. The mesh on the lower surface of the flexible film and the upper surface of Agaricus bisporus were refined with a mesh size of 1 mm. The contact type between the lower surface of the flexible film and the upper surface of Agaricus bisporus was nonseparation. The lower surface of the flexible film was selected as the contact surface, and the upper surface of Agaricus bisporus was selected as the target surface. The formula algorithm option was set to the augmented Lagrangian algorithm type.

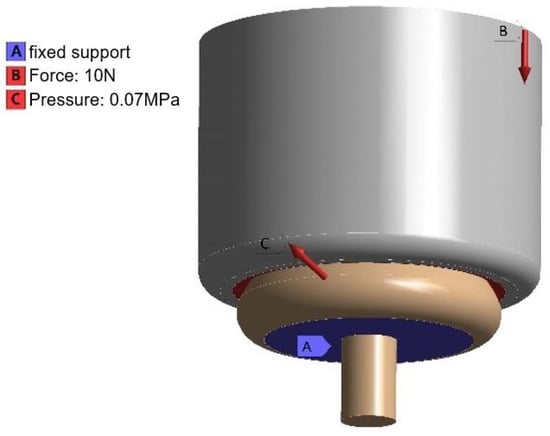

The finite element load loading setting of the end-effector is shown in Figure 5. To facilitate the analysis of stress changes in the end-effector and Agaricus bisporus, the adsorption process was divided into two steps. First, a fixed bracket was added to the lower surface of the mushroom cover, and a force of 10 N was evenly applied to the upper surface of the end-effector to simulate the fitting process during the picking process. Then, a negative vacuum pressure of 0.07 MPa was applied inside the end-effector to simulate the adsorption process. After setting the load, the large deformation option was turned on to solve the finite element model.

Figure 5.

Finite element load setting.

2.2. Adsorption Force Experiment

The performance index of the adsorption end-effector was the adsorption force of the end-effector to the object, and the adsorption force was directly related to the pull-off force. To investigate the influence of factors on the adsorption performance of the end-effector, flexible films with different thicknesses and particle fillers with different diameters were used to prepare end-effectors. Subsequently, the pull-off force was measured to verify the performance.

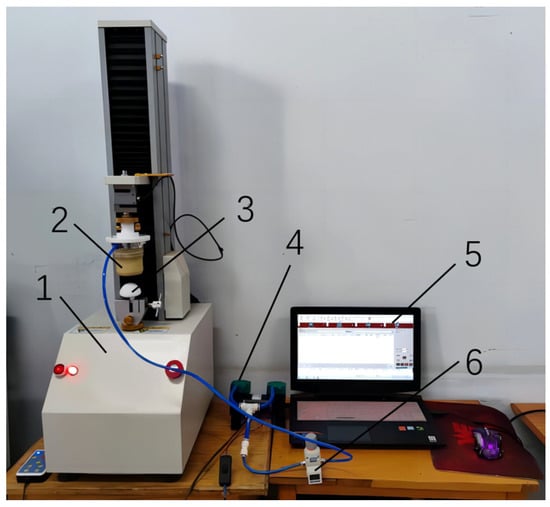

The experiment used a single-column electronic tensile-testing machine (Dongri Instrument Co., Ltd., Dongguan, China) to conduct a pull-out force test on the double-spore model, as shown in Figure 6. The end-effector was fixed to the movable end of the tensile-testing machine using a connector, while the Agaricus bisporus model was fixed to the fixed end with a clamp. The experimental material was a resin material model of Agaricus bisporus with a diameter of 25 mm. The 25 mm diameter flexible films had thicknesses of 0.70, 0.90, and 1.10 mm, and they were filled with quartz particles with a diameter of 200 and 20 mesh and plastic balls with a diameter of 3 mm.

Figure 6.

Experiment illustration. 1. Single-column electronic tensile tester; 2. end-effector; 3. Agaricus bisporus; 4. vacuum pump; 5. computer; 6. and flow valves.

2.2.1. Flexible Films of Different Thicknesses

The end-effector was completely blocked, the vacuum pump was turned on, and the negative pressure was manually adjusted using the proportional control valve. The opening and closing degrees of the proportional control valve remained unchanged, and then, the end-effector blockage was removed. The movable end of the tensile-testing machine was moved down to make the end actuator come in contact, profile, and adsorb the Agaricus bisporus model. The pull-off force test program for Agaricus bisporus was run on the PC end, and the movable end of the tensile-testing machine moved up at a speed of 10 mm/min, gradually separating from the Agaricus bisporus model until it reached its highest point and then returned to its initial position. During this process, the maximum force recorded on the PC end was the pull-out force of the end-effector. Quartz particles with a diameter of 200 mesh were selected as the filling material, flexible membranes with thicknesses of 0.70, 0.90, and 1.10 mm were replaced and installed, and pull-off force tests were conducted on a model mushroom with a 25 mm diameter. The tensile-testing machine was operated to perform the pull-out force test procedure for Agaricus bisporus, and each test was repeated 20 times.

2.2.2. Particle Fillers of Different Species

The above experimental conditions were unchanged. A flexible film with a thickness of 0.90 mm was selected, quartz particles with diameters of 200 and 20 mesh and plastic balls with diameters of 3 mm were used, and pull-off force tests were conducted using a model mushroom with a 25 mm diameter. The tensile-testing machine was operated to perform the Agaricus bisporus pull-out force test procedure, and each test was repeated 20 times.

2.3. Design of the Adsorption Force Adjustment System

2.3.1. Principle of Adsorption Force Adjustment

From Formula (2), it can be inferred that the adsorption force was mainly determined by the adsorption area and negative adsorption pressure. The adsorption area was related to the inner diameter of the flexible membrane and the diameter of the Agaricus bisporus. Considering that this factor was not easily changed, the main factor affecting the adsorption force was the size of the negative adsorption pressure.

Due to the different size, shape, and surface roughness of each Agaricus bisporus, when picking different mushrooms, the negative pressure inside the end-effector with flexible profiling was different under a constant vacuum pump flow. To achieve precise control and real-time adjustment of the adsorption force during the picking process of Agaricus bisporus, a low-cost negative-pressure control system was established. The system adopted pneumatic feedback closed-loop control, which could achieve the conversion of adsorption force and negative pressure. During the picking process, when the negative pressure value measured using the pressure sensor deviated from the expected negative pressure, the negative-pressure adjustment system began to adjust the negative pressure, thereby adjusting the adsorption force.

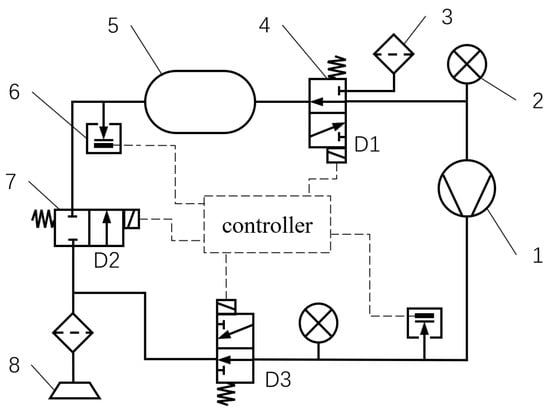

2.3.2. Design of the Adjustment System

A schematic diagram of the negative-pressure regulation system is shown in Figure 7. The pneumatic loop of the system was comprised of a vacuum pump, a negative-pressure gauge, a two-position three-way electromagnetic valve, an air storage tank, an air pressure sensor, a two-position two-way electromagnetic valve, and an end-effector. The air pressure sensor measured the air pressure in the pneumatic circuit and transmitted it to the controller. The controller adjusted the negative pressure by controlling the switch of the solenoid valve. The vacuum pump, electromagnetic valve D1, pressure stabilizing tank, negative pressure sensor, electromagnetic valve D2, and end-effector formed a negative pressure loop that was used to adsorb the Agaricus bisporus. The vacuum pump, air pressure sensor, electromagnetic valve D3, and end-effector formed a positive pressure loop that was used to rapidly blow Agaricus bisporus off the end-effector after it was picked. When the electromagnetic valve D1 was opened, the end executor was connected to the vacuum pump to continuously increase the negative pressure, and when the electromagnetic valve D1 was closed, the end executor was connected to the air inlet to reduce the negative pressure. Thus, the effect of adjusting the negative pressure was achieved by quickly adjusting the on–off time proportions of solenoid valve D1, and the air storage tank was used to stabilize the air pressure fluctuation generated by the switch of the solenoid valve to obtain stable negative pressure.

Figure 7.

Negative-pressure control system of the end-effector. 1. Vacuum pump; 2. pressure gauge; 3. filter; 4. two-position three-way solenoid valve; 5. surge tank; 6. negative-pressure sensor; 7. two-position two-way solenoid valve; and 8. end-effector.

Because the picking force of Agaricus bisporus was small, a miniature vacuum pump was selected for pumping and inflating; the maximum flow rate was 20 L/min, and the maximum vacuum was −70 kPa. The capacity of the air storage tank was 1 L. The pneumatic circuit control system used an ESP32 module as the main controller and communicated with the computer through a serial port. An XGZP6847a air pressure sensor module was selected as the air pressure sensor to monitor the negative pressure of the pneumatic circuit in real-time, and the detection range of the air pressure sensor module was −100~100 kPa.

Through testing, the response time of the designed negative-pressure regulating system was between 2 and 3 s, and it could provide any stable blocking negative pressure between −50 and 0 KPa. The negative pressure required for Agaricus bisporus picking was usually around −20 KPa, so the system met the picking requirements.

2.4. Performance Evaluation of the Adjustment System

2.4.1. Negative-Pressure Stability Comparison

The performance index of the adsorption force regulation system was the stability of the negative adsorption pressure and the error between the negative adsorption pressure and the expected negative pressure. The performance of the adsorption force regulation system was verified by measuring the internal negative pressure of the end-effector. The experimental preparation was as follows: The end-effector in the pneumatic circuit of the non-adsorption regulating system was completely blocked, the proportional regulating valve was manually adjusted to make the negative pressure value reach −10 KPa, the proportion of the regulating valve was maintained, and the blockage of the end-effector was removed. The negative pressure of the pneumatic circuit with the adsorption force regulating system was set to −10 kPa. Ten groups of Agaricus bisporus with different sizes, shapes, and surface roughness values were tested using two kinds of pressure loops, and each group of tests was repeated 10 times. After the start of adsorption, there was a waiting time of 3 s to stabilize the negative pressure, and then, the negative pressure value inside the sucker was read using the air pressure sensor.

2.4.2. Correlation Experiment

To verify the relationship between the negative pressure and the adsorption force inside the end-effector, an end-effector with a diameter of 25 mm (flexible film thickness of 0.90 mm and particle diameter of 20 mesh) and an Agaricus bisporus model with a diameter of 25 mm were selected to conduct the pull-off force test, and the end-effector was installed on the tensile-testing machine to obtain a stable negative pressure through the negative-pressure regulation system. The pull-out force was measured at negative pressures from −70 to −10 kPa with a pressure interval of 10 kPa, and each test was repeated 20 times.

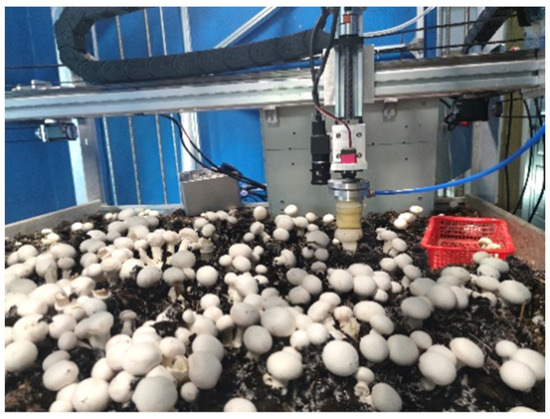

2.5. Experiment on Harvesting Agaricus bisporus

To verify the actual picking effect of the designed end-effector with flexible profiling, a picking experiment was conducted at Henan Luoyang Ojite Edible Fungi Co., Ltd. (Luoyang, China), and the picking effect was compared with that of a common silicone suction cup. A photograph of the two devices is shown in Figure 8. The experiment used an end-effector with flexible profiling with a diameter of 25 mm and common suction cups with diameters of 25, 35, and 45 mm. The picking process is shown in Figure 9. White Agaricus bisporus mushrooms were selected for the picking experiments, with cap diameters ranging from 25 to 50 mm and weights ranging from 15 to 35 g. The experiment on picking was carried out by progressively amplifying the negative pressure for blocking. The initial setting for the negative pressure for blocking was −5 KPa. If the picking failed, the negative pressure for blocking was increased by 1 KPa each time until the picking succeeded. If the negative pressure for blocking increased to −15 KPa and the picking remained unsuccessful, it was deemed a failure.

Figure 8.

Common suction cups and an end-effector with flexible profiling.

Figure 9.

Picking test process.

3. Results and Discussion

3.1. Analysis of the Simulation Results

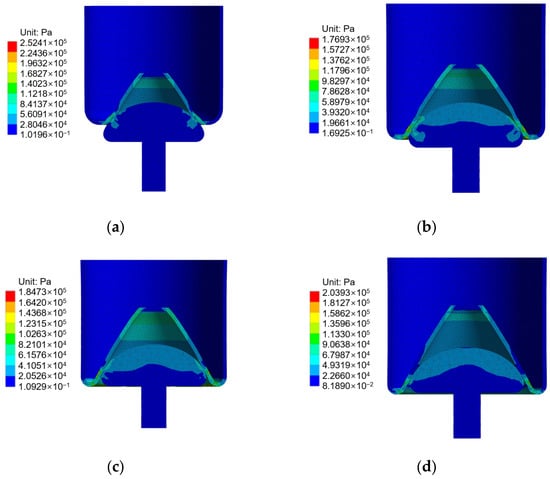

Diagrams of the profiling process from finite element simulations of four different inner diameter flexible films and a 25 mm diameter Agaricus bisporus are shown in Figure 10. When the inner diameter of the flexible film was small, the position in contact with Agaricus bisporus was at the top of the mushroom cover, and the equivalent adsorption area was mainly limited by the inner diameter of the flexible film. As the inner diameter of the flexible film increased, the contact position between the flexible film and Agaricus bisporus gradually decreased from the top of the mushroom cover until the cover was completely wrapped. Afterward, the equivalent adsorption area was mainly limited by the diameter of the mushroom cover.

Figure 10.

Diagrams from simulations of flexible films with different inner diameters. (a) 20.00 mm; (b) 22.50 mm; (c) 25.00 mm; and (d) 27.50 mm.

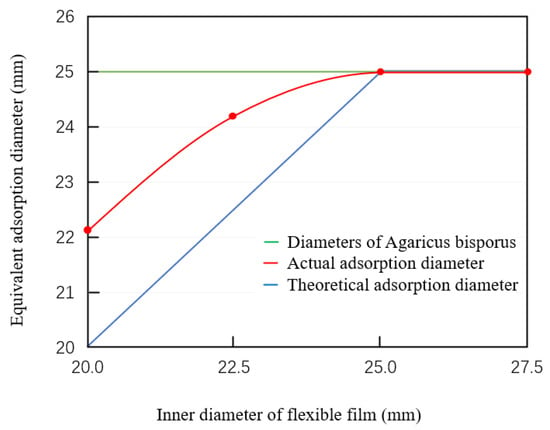

As shown in Figure 11, the equivalent adsorption diameters of flexible membranes with inner diameters of 20.00, 22.50, 25.00, and 27.50 mm were measured on the Agaricus bisporus ANSYS workbench with a diameter of 25 mm, and the results were 22.10, 24.20, 25.00, and 25.00 mm, respectively. The results showed that when the diameter of the mushroom cover was fixed, the equivalent adsorption diameter gradually increased with increasing inner diameter of the flexible membrane and remained unchanged after reaching the maximum value. The maximum value was the diameter of the mushroom cover. When the inner diameter of the flexible membrane was 25 mm, the equivalent adsorption diameter reached the maximum value, and thus, the outer diameter of the flexible membrane was chosen as 25 mm.

Figure 11.

Curve of effective adsorption diameter.

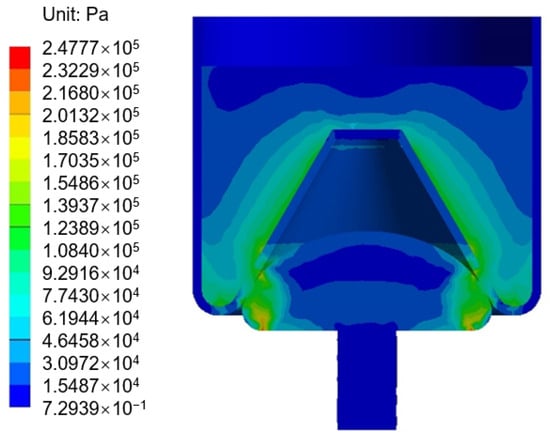

Figure 12 shows that the stress was smaller on the surface of the flexible membrane than on the internal particles. This was because the flexible membrane material was soft and deformed in the direction of stress after being subjected to stress, thereby transferring stress to particles; the outer particles were the main load-bearing component.

Figure 12.

Overall stress diagram.

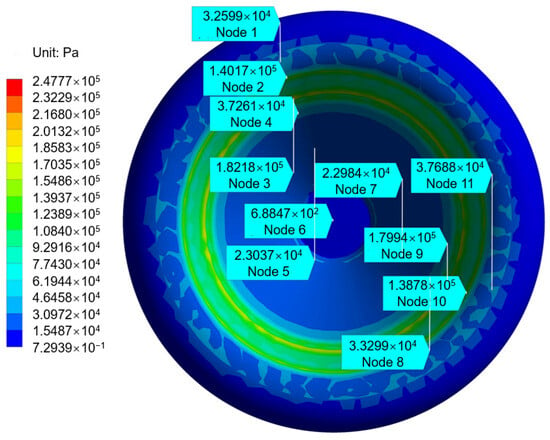

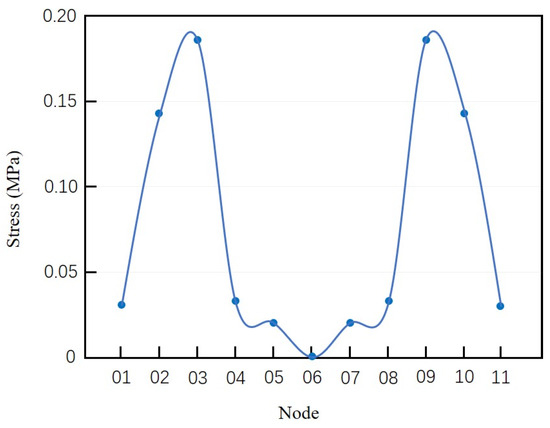

To more intuitively study the change in stress at each point on the bottom surface of the end-effector, 11 points along the diameter of the end-effector were taken using the finite element software (2021 R1 version)probe on the equivalent stress diagram to obtain the von Mises stress values, and the von Mises stress curve of the end-effector was drawn.

As shown in Figure 13 and Figure 14, during the adsorption process, the contact stress between the end-effector and the Agaricus bisporus was relatively high, and the center stress of the end-effector was relatively small. The stress distribution from the edge position to the center position was parabolic. The stress distribution at the edge of the end-effector was approximately symmetrical relative to the center position, and the stress concentration area was circular, indicating that the stress distribution between the end-effector and the higher ellipticity of the Agaricus bisporus was relatively uniform.

Figure 13.

Equivalent force diagram of the end-effector.

Figure 14.

Von Mises stress curve of the end-effector.

3.2. Analysis of Adsorption Force Experimental Results

3.2.1. Impact Analysis from Film Thickness

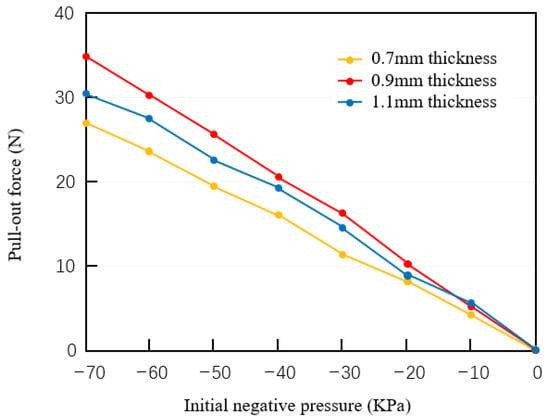

As shown in Figure 15, there is a nonlinear relationship between the thickness of the flexible film and the pull-off force. Under the same initial negative pressure, the pull-off force of the flexible film with a thickness of 0.90 mm was the largest, followed by 1.10 mm and 0.70 mm, which was the worst. A higher pull-off force implies superior sealing and profiling effects. The profiling effect of flexible films that were too thin or too thick was not good. The reason may have been that a thin, flexible film lacked stability, and wrinkles easily formed and affected the sealing performance of the profile. A thick, flexible film was too hard, making it difficult to complete the profiling process, and gaps easily formed between the contact surfaces that affected sealing performance during profiling.

Figure 15.

Pull-off force for different flexible film thicknesses.

3.2.2. Impact Analysis from Particle Species

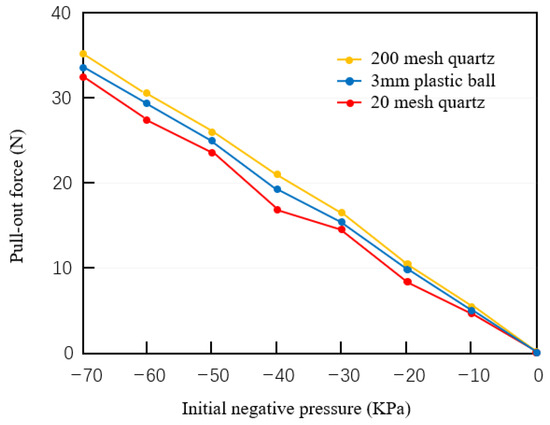

As shown in Figure 16, there was a negative correlation between the particle diameter of the filler and the pull-off force. Under the same initial negative pressure, the pulling force was largest for fine quartz with a particle diameter of 200 mesh, followed by plastic balls with a diameter of 3 mm, and coarse quartz with a diameter of 20 mesh was the worst. The reason may have been that fine quartz with a diameter of 200 mesh was in powder form, with the smallest gap between the particles. After the surface contour of the particles and Agaricus bisporus was completed, there was good sealing between the contact surfaces. The plastic balls had smooth surfaces with a diameter of 3 mm and could quickly profile the surface of the mushroom after the end-effector came in contact with it. However, due to the large gaps between the plastic balls, their profiling ability was less than that of fine quartz, and the seal between the contact surfaces was also weaker than that of fine quartz. Quartz particles with a diameter of 20 mesh had larger diameters and irregular shapes. The particles moved slowly, and there were large gaps between the particles, resulting in the weakest profiling ability and the sealing between the contact surfaces.

Figure 16.

Pull-off force for different particle diameters.

3.3. Evaluation of the Adsorption Force Adjustment System

3.3.1. Evaluation of Negative-Pressure Stability

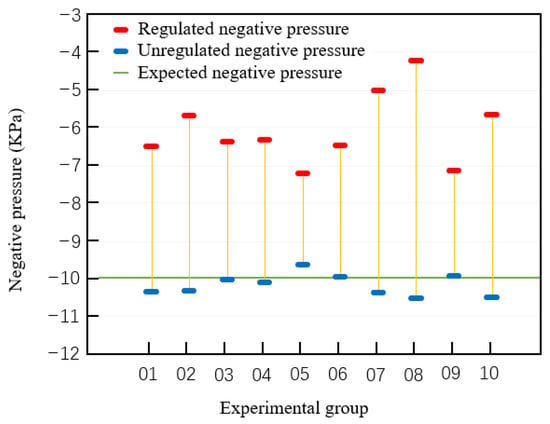

The experimental results for negative pressure stability are shown in Figure 17. The average negative adsorption pressure of the pneumatic circuit without the negative-pressure regulation system was −6.13 KPa, with a maximum deviation of 5.82 KPa from the expected negative pressure. The maximum difference in negative pressure when adsorbing different Agaricus bisporus was 2.99 KPa. The average negative adsorption pressure of the pneumatic circuit with the negative pressure regulation system was −10.10 kPa, with a maximum deviation of 0.45 kPa from the expected negative pressure. The maximum difference in negative pressure when adsorbing different Agaricus bisporus was 0.89 kPa.

Figure 17.

Stability test results of two pneumatic circuits.

The experimental results showed that the negative pressure stability of Agaricus bisporus was correlated with the surface flatness of Agaricus bisporus. The negative pressure stability of Agaricus bisporus with good surface flatness was higher, while the negative pressure stability of Agaricus bisporus with poor surface flatness was lower. In addition, the negative pressure values in the pneumatic circuit without the negative-pressure regulation system were lower than the expected negative pressure values. This was because the contact position between the end-effector and Agaricus bisporus was not completely sealed, resulting in air pressure leakage. In addition, Agaricus bisporus itself had breathability. In a pneumatic circuit with the adsorption force adjustment system, after the end-effector adsorbed the twin mushrooms, the adjustment system quickly compensated the negative pressure difference, thereby increasing the negative pressure value to the expected negative pressure value. Comparing different experimental groups showed that there was a significant difference in negative pressure values when adsorbing individual Agaricus bisporus with different shapes, sizes, and surface roughness values without an adsorption force regulation system. The main reason for these differences was that the profiling ability of the end-effector with flexible profiling differed for individual Agaricus bisporus, especially for some Agaricus bisporus with surface defects. The pneumatic circuit with the adsorption force adjusting system actively adjusted the flow rate of the airflow in the end-effector in real time after adsorption to compensate for the air pressure leakage caused by insufficient sealing, and thus, the negative pressure value stabilized near the expected negative pressure value. In this experiment, the adsorption force adjustment system reduced the fluctuation of negative adsorption pressure by 84, 71% of which showed that the system effectively improved the stability of adsorption under negative pressure.

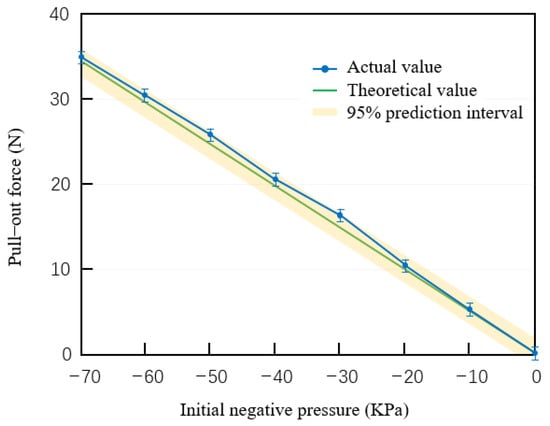

3.3.2. Evaluation of the Relevance

As shown in Figure 18, the experimental values of the adsorption force were generally greater than the theoretical values, which may have been caused by the friction force between the flexible profiling end-effector and Agaricus bisporus, as the calculation of the theoretical values ignored the influence of the friction force. In addition, the real adsorption force-negative pressure relationship curve was very close to the theoretical relationship, and the maximum deviation between the theoretical and experimental values was only 1. 50 N in the whole pressure range of −70~0 kPa. This indicated that the friction force between the end-effector with flexible profiling and Agaricus bisporus had little effect on the adsorption force. In other words, within the acceptable error range, there was a linear relationship between the suction pressure and suction force, which indicated that adjusting the suction pressure was completely feasible.

Figure 18.

Relationship between the pull-out force and initial negative pressure.

3.4. Evaluation of Actual Picking Results

The results of the picking experiment are shown in Table 2. The success rate of the end-effector with flexible profiling was 98.50%, and the success rates of the common suction cups of diameters 25, 35, and 45 mm were 90.50%, 92.50%, and 86%, respectively. The average air pressure for picking with the end-effector with flexible profiling was −9.20 kPa, while the average air pressures for picking with the common suction cups of 25, 35, and 45 mm were −10.30, −9.80, and −11.70 kPa, respectively. The experimental results showed that when picking the same batch of Agaricus bisporus, the negative pressure required by the end-effector with flexible profiling was lower, and the success rate of picking was higher than that for the common suction cups. Some of these Agaricus bisporus were found to have malformed shapes or surface defects, and there were large gaps between the common suction cups and the contact surfaces of these Agaricus bisporus, which could not be adsorbed. The end-effector with flexible profiling was likewise unable to complete the profiling of severely deformed or defective Agaricus bisporus, which resulted in picking failure.

Table 2.

Results of the picking test.

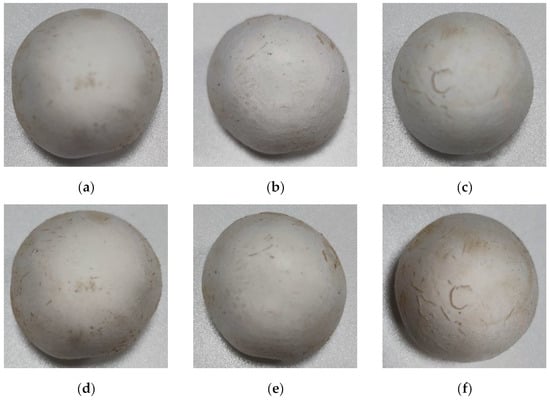

After picking, the damage detection of the picked Agaricus bisporus was analyzed. The test results are shown in Table 3. There was no significant damage to the surfaces of the Agaricus bisporus that were picked manually or using the end-effector with flexible profiling; only very few Agaricus bisporus showed slight damage. The common suction cup picking method left slight suction marks on the surfaces of some Agaricus bisporus, while a few Agaricus bisporus had obvious suction marks on the surface. Based on a comprehensive evaluation, the picking damage rate was 1% for manual picking, 2.50% for an end-effector with flexible profiling, and 21% for common suction cups.

Table 3.

Damage detection results.

One sample was randomly taken from Agaricus bisporus picked with each of the three methods, as shown in Figure 19. Two hours after the Agaricus bisporus were picked, the surfaces of those that were picked manually and using an end-effector with flexible profiling were basically intact, without obvious signs of damage. The surfaces of the Agaricus bisporus that were picked with the common suction cups had arc-shaped suction marks. After 24 h, the mycelium on the surface of Agaricus bisporus oxidizes to a light brown color in the air. The surfaces of the Agaricus bisporus that were picked manually and using the end-effector with flexible profiling remained basically unchanged, while the suction marks on the surfaces of the Agaricus bisporus that were picked with common suction cups deepened in color.

Figure 19.

Changes in samples after picking. (a) 2 h after manual picking; (b) 2 h after picking using the end-effector with flexible profiling; (c) 2 h after picking by a common suction cup; (d) 24 h after manual picking; (e) 24 h after picking using the end-effector with flexible profiling; and (f) 24 h after picking by a common suction cup.

The results of the picking experiment showed that, compared to common suction cups, the end-effector with flexible profiling had a higher picking success rate and a lower picking damage rate of 98.50% and 2.50%, respectively. The picking effect and control performance of the end-effector with flexible profiling were superior to those of common suction cups. We compared the results of the picking experiment with existing research, focusing on the picking success rate and picking damage rate. Table 4 shows the specific comparison data.

Table 4.

Comparison of existing research results.

Through comparison, it can be understood that the picking success rate and picking damage rate of this study are superior to existing Agaricus bisporus picking research work, which is due to the excellent structure design and stable pressure control. In the next step of research work, we will study and analyze the relationship between the diameter of the cap of Agaricus bisporus and the required picking force, and we will further study the pressure change during the adsorption and shedding process. Through these studies, we hope to realize the automatic setting and adjustment of the pressure during the picking process to prevent the shedding caused by insufficient pressure and the damage caused by too much pressure.

4. Conclusions

An end-effector with flexible profiling was designed, and a set of adsorption force adjustment systems was established for the effector. A series of experiments was conducted to verify their performance. The following conclusions were drawn:

- (1)

- In this experiment, when the thickness of the flexible film was 0.90 mm, and the film was filled with a quartz diameter of 200 mesh, the flexible profiling end-effector achieved a good profiling effect;

- (2)

- The relationship between the adsorption force and negative suction pressure was linear. Within an acceptable error range, the influence of friction on suction could be ignored. Therefore, it was feasible to control the adsorption force by controlling the negative pressure;

- (3)

- The designed flexible profiling end actuator was used to harvest Agaricus bisporus with diameters in the range of 25–50 mm. The success rate of harvesting was 98.50%, and the damage rate was 2.50%.

In conclusion, the designed flexible profiling end-effector demonstrated the advantages of strong adaptability, stable grasping, and low damage rate, and it can meet the needs of producers for automatic picking of Agaricus bisporus.

Author Contributions

Conceptualization, K.Z., Q.L. and J.J.; software, M.L.; validation, Y.H., J.L. and S.X.; formal analysis, H.L.; investigation, K.Z. and H.L.; writing—review and editing, H.L. and M.L.; supervision, K.Z. and Q.L.; project administration, J.J. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Major Project of Longmen Laboratory/Major Science and Technology Project of Henan Province (Grant No. 231100220200), the International Science and Technology Cooperation Project of Henan Province Key Research and Development Projects (Grant No. 232102521006), and the National Natural Science Foundation of China (Grant No. 51975186).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author. The data are not publicly available.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Erjavec, J.; Kos, J.; Ravnikar, M.; Dreo, T.; Saboti, J. Proteins of higher fungi—From forest to application. Trends Biotechnol. 2012, 30, 259–273. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Pu, Y.; Sun, D. Recent advances in quality preservation of postharvest mushrooms (Agaricus bisporus): A review. Trends Food Sci. Technol. 2018, 78, 72–82. [Google Scholar] [CrossRef]

- Perez-Montes, A.; Rangel-Vargas, E.; Lorenzo, J.M.; Romero, L.; Santos, E.M. Edible mushrooms as a novel trend in the development of healthier meat products. Curr. Opin. Food Sci. 2021, 37, 118–124. [Google Scholar] [CrossRef]

- Mleczek, M.; Rzymski, P.; Budka, A.; Siwulski, M.; Jasińska, A.; Kalač, P.; Poniedziałek, B.; Gąsecka, M.; Niedzielski, P. Elemental characteristics of mushroom species cultivated in China and Poland. J. Food Compos. Anal. 2018, 66, 168–178. [Google Scholar] [CrossRef]

- Yin, H.; Yi, W.; Hu, D. Computer vision and machine learning applied in the mushroom industry: A critical review. Comput. Electron. Agric. 2022, 198, 107015. [Google Scholar] [CrossRef]

- Reed, J.N.; Miles, S.J.; Butler, J.; Baldwin, M.; Noble, R. AE—Automation and Emerging Technologies. J. Agric. Eng. Res. 2001, 78, 15–23. [Google Scholar] [CrossRef]

- Zhang, Y.; Geng, W.; Shen, Y.; Wang, Y.; Dai, Y. Edible Mushroom Cultivation for Food Security and Rural Development in China: Bio-Innovation, Technological Dissemination and Marketing. Sustainability 2014, 6, 2961–2973. [Google Scholar] [CrossRef]

- Zhang, B.; Xie, Y.; Zhou, J.; Wang, K.; Zhang, Z. State-of-the-art robotic grippers, grasping and control strategies, as well as their applications in agricultural robots: A review. Comput. Electron. Agric. 2020, 177, 105694. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Weltzien, C.; Hameed, I.A.; Yule, I.; Grift, T.E.; Balasundram, S.K.; Pitonakova, L.; Ahmad, D.; Chowdhary, G.V. Research and development in agricultural robotics: A perspective of digital farming. Int. J. Agric. Biol. Eng. 2018, 11, 1–14. [Google Scholar] [CrossRef]

- Mu, L.; Cui, G.; Liu, Y.; Cui, Y.; Fu, L.; Gejima, Y. Design and simulation of an integrated end-effector for picking kiwifruit by robot. Inf. Process. Agric. 2020, 7, 58–71. [Google Scholar] [CrossRef]

- Wei, B.; He, J.; Shi, Y.; Jiang, G.; Zhang, X.; Ma, Y. Design and experiment of underactuated end-effector for citrus picking. Trans. Chin. Soc. Agric. Mach. 2021, 52, 120–128. [Google Scholar] [CrossRef]

- Guo, T.; Zheng, Y.; Bo, W.; Liu, J.; Pi, J.; Chen, W.; Deng, J. Research on the Bionic Flexible End-Effector Based on Tomato Harvesting. J. Sens. 2022, 2022, 2564952. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Z.; Wang, Y.; Bao, R.; Chen, X.; Fu, S.; Tian, M.; Zhang, Y. Research on Flexible End-Effectors with Humanoid Grasp Function for Small Spherical Fruit Picking. Agriculture 2023, 13, 123. [Google Scholar] [CrossRef]

- Yue, H.; Guo, X.; Zhang, W.; Yang, W.Y.; Zhou, Y. Discussion on the application of picking robot in agriculture. Xinjiang Agricult. Mech. 2016, 1, 31–34. [Google Scholar] [CrossRef]

- Binghe, L.; Takanori, U.; Takuya, F.; Shinsuke, Y.; Takashi, S.; Kazuo, I. Development of end-effector for harvesting tomato using suction and cutting mechanism. In Proceedings of the of JSME Annual Conference on Robotics and Mechatronics (Robomec), Tokyo, Japan, 10–13 November 2017; pp. 1A1–D06. [Google Scholar] [CrossRef]

- Hu, X.; Wang, C.; Yu, T. Design and application of visual system in the Agaricus bisporus picking robot. J. Phys. Conf. Ser. 2019, 1187, 32–34. [Google Scholar] [CrossRef]

- Masoudian, A.; Mcisaac, K.A. Application of support vector machine to detect microbial spoilage of mushrooms. In Proceedings of the 2013 International Conference on Computer and Robot Vision, Regina, SK, Canada, 28–31 May 2013; pp. 281–287. [Google Scholar] [CrossRef]

- Huang, M.; He, L.; Choi, D.; Pecchia, J.A.; Li, Y. Picking dynamic analysis for robotic harvesting of Agaricus bisporus mushrooms. Comput. Electron. Agric. 2021, 185, 106145. [Google Scholar] [CrossRef]

- Elango, N.; Faudzi, A. A review article: Investigations on soft materials for soft robot manipulations. Int. J. Adv. Manuf. Technol. 2015, 80, 1027–1037. [Google Scholar] [CrossRef]

- Park, W.; Seo, S.; Bae, J. A Hybrid Gripper with Soft Material and Rigid Structures. IEEE Robot. Autom. Lett. 2019, 4, 65–72. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, X.; Huang, Y.; Cao, L.; Liu, J. A review of soft manipulator research, applications, and opportunities. J. Field Robot. 2021, 39, 281–311. [Google Scholar] [CrossRef]

- Fei, Y.; Wang, J.; Pang, W. A novel fabric-based versatile and stiffness-tunable soft gripper integrating soft pneumatic fingers and wrist. Soft Robot. 2019, 6, 1–20. [Google Scholar] [CrossRef]

- Kurpaska, S.; Sobol, Z.; Pedryc, N.; Hebda, T.; Nawara, P. Analysis of the pneumatic system parameters of the suction cup integrated with the head for harvesting strawberry fruit. J. Sens. 2020, 20, 4389. [Google Scholar] [CrossRef]

- Huang, M.; Jiang, X.; He, L.; Choi, D.; Pecchia, J.; Li, Y. Development of a robotic harvesting mechanism for button mushrooms. Trans. ASABE 2021, 64, 565–575. [Google Scholar] [CrossRef]

- Yang, S.; Ji, J.; Cai, H.; Chen, H. Modeling and Force Analysis of a Harvesting Robot for Button Mushrooms. IEEE Access 2022, 10, 78519–78526. [Google Scholar] [CrossRef]

- Huh, T.M.; Sanders, K.; Danielczuk, M.; Li, M.S.; Goldberg, K.; Stuart, H.S. A Multi-Chamber Smart Suction Cup for Adaptive Gripping and Haptic Exploration. In Proceedings of the 2021 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Prague, Czech Republic, 27 September–1 October 2021; pp. 1786–1793. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).