The Carbon Footprint of a 5000-Milking-Head Dairy Operation in Central Texas

Abstract

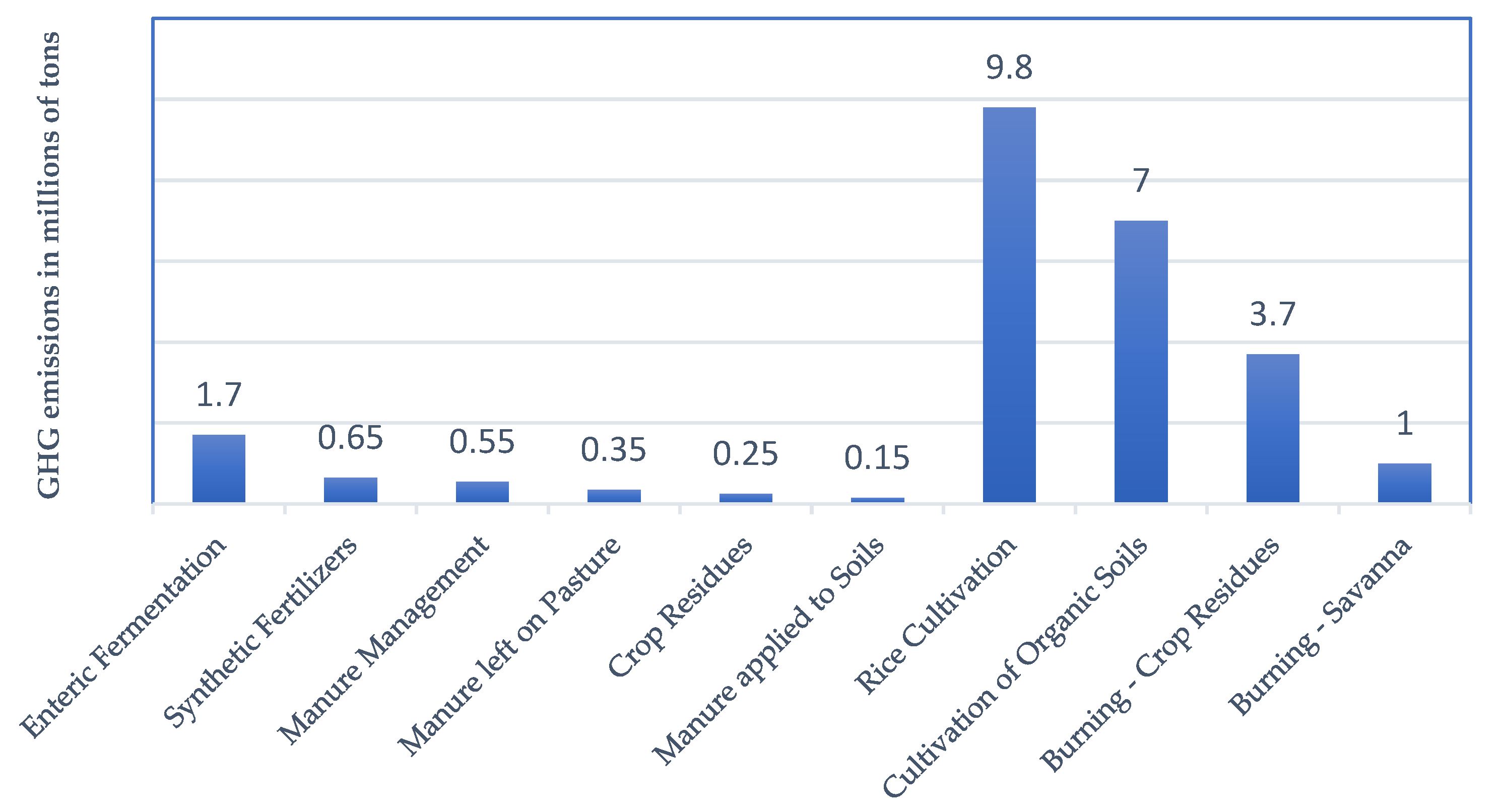

:1. Introduction

2. Materials and Methods

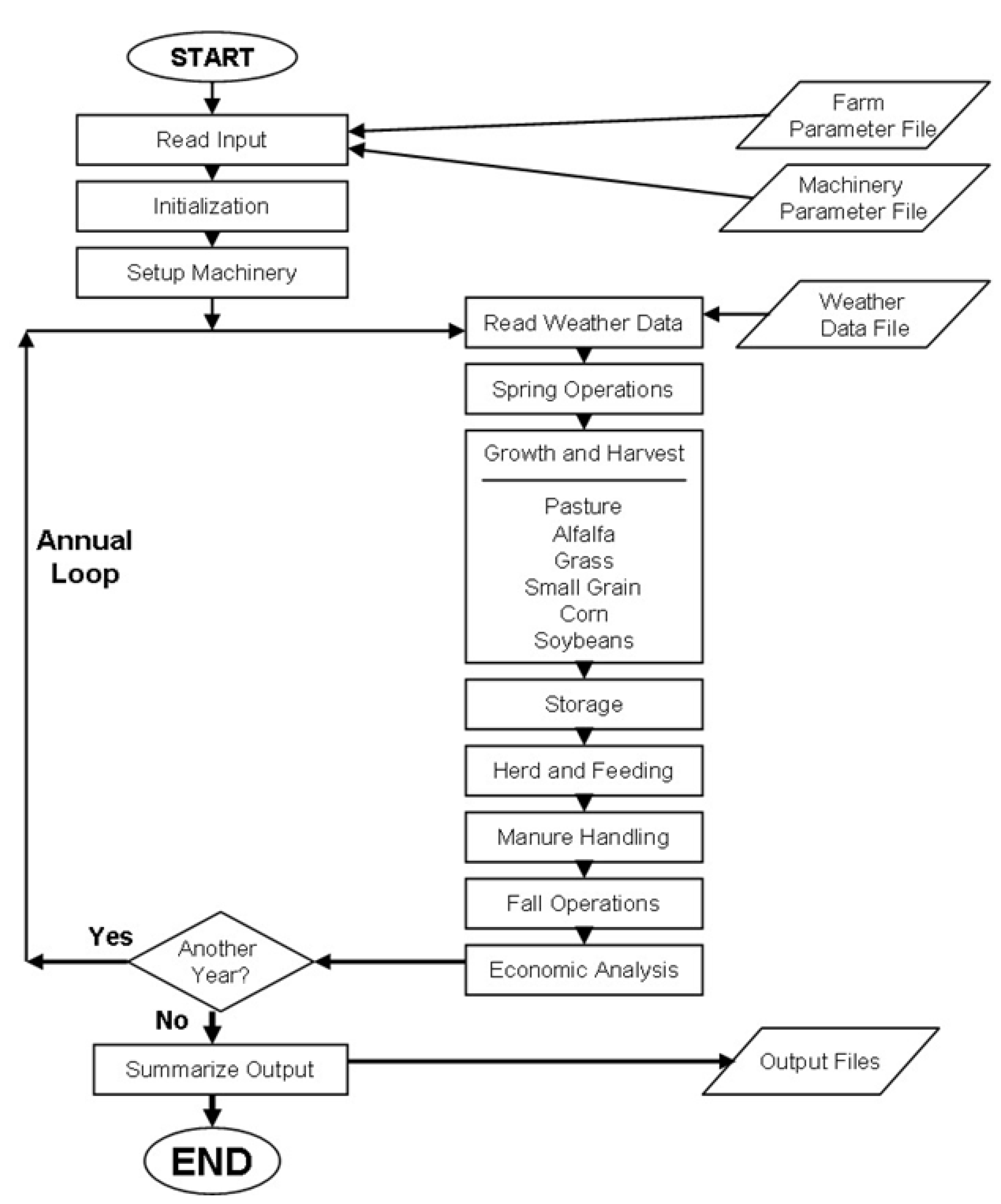

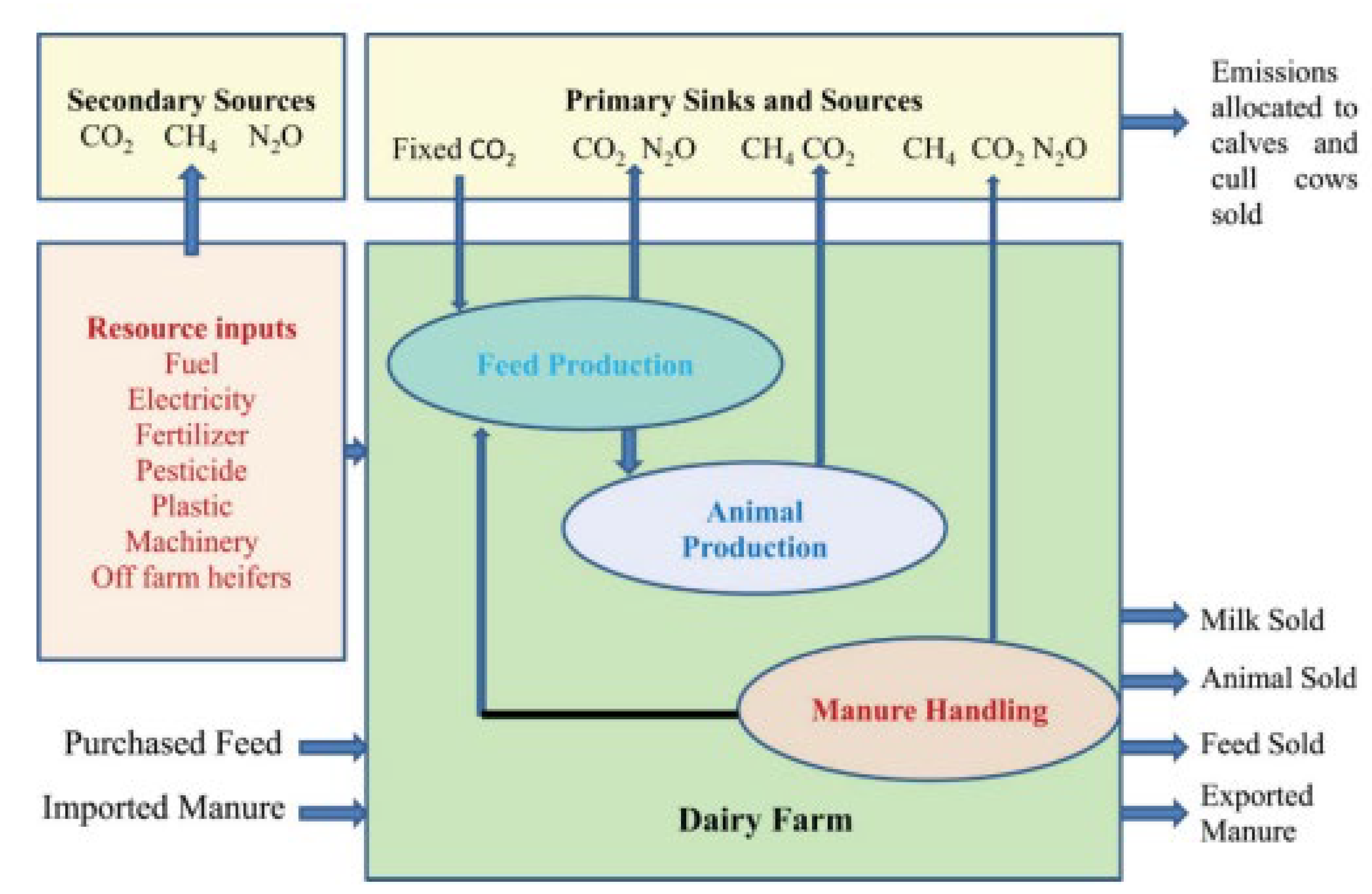

2.1. Integrated Farm System Model Version 4.7

2.1.1. IFSM 4.7 Model Input

2.1.2. IFSM 4.7 Model Output

2.1.3. IFSM 4.7 Model Algorithm

2.1.4. IFSM 4.7 Carbon Footprint

2.2. Data

2.2.1. Dairy Farm Input Parameters

2.2.2. Weather and Machinery Data

3. Results

3.1. Annual GHG Emissions

3.2. Carbon Footprint

3.3. Economic Results

4. Conclusions and Recommendations

4.1. Conclusions

4.2. Recommendations

4.3. Limitations of this Study

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vakilifard, N.; Williams, R.; Holden, P.; Turner, K.; Edwards, N.; Beerling, D. Impact of negative and positive CO2 emissions on global warming. Biogeosciences 2022, 19, 4249–4265. [Google Scholar] [CrossRef]

- Blunden, J.; Boyer, T. State of the Climate in 2021. Bull. Am. Meteorol. Soc. 2022, 103, S1–S465. [Google Scholar] [CrossRef]

- Verbič, M.; Satrovic, E.; Mujtaba, A. Assessing the Driving Factors of Carbon Dioxide and Total. Int. J. Environ. Res. 2022, 16, 105. [Google Scholar] [CrossRef]

- Johnson, J.; Franzluebbers, A.; Weyers, S.; Reicosky, D. Agricultural opportunities to mitigate greenhouse gas emissions. Environ. Pollut. 2007, 150, 107–124. [Google Scholar] [CrossRef] [PubMed]

- Koushki, R.; Sharma, S.; Warren, J.; Foltz, M. Life cycle greenhouse has emissions for irrigated corn production in the U.S. great plains. Environ. Chall. 2023, 13, 100750. [Google Scholar] [CrossRef]

- MakeWay. CO2 Equivalents. Climate Change Connection. 23 June 2020. Available online: https://climatechangeconnection.org/emissions/co2-equivalents/ (accessed on 3 October 2023).

- Lamb, W.; Weidmann, T.; Pongratz, J.; Andrew, R.; Crippa, M.; Olivier, J.; House, J. A review of trends and drivers of greehouse has emissions by sector from 1990 to 2018. Environ. Res. Lett. 2021, 16, 073005. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M.; Rosado, P. CO2 and Greenhouse Gas Emissions. 2022. Available online: https://ourworldindata.org/co2-and-greenhouse-gas-emissions (accessed on 3 October 2023).

- USDA. Annual Dairy Review Texas and U.S. Inventory and Production. Texas Field Office, USDA-NASS. nass.usda.gov; 2022. Available online: https://www.nass.usda.gov/Statistics_by_State/Texas/Publications/Current_News_Release/2022_Rls/tx-dairy-review-2022.pdf (accessed on 3 October 2023).

- Food and Agriculture Organization of the United Nations (FAO). FAOSTAT Database. 2018. Available online: http://www.fao.org/faostat/en/#data/EL (accessed on 3 October 2023).

- Rotz, A.; Stout, R.; Leytem, A.; Feyereisen, G.; Waldrip, H.; Thoma, G.; Kleinman, P. Environmental assessment of United States dairy farms. J. Clean. Prod. 2021, 315, 128153. [Google Scholar] [CrossRef]

- EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2015; Environmental Protection Agency: Washington, DC, USA, 2017.

- Smith, P.; Bustamante, M.; Ahammad, H.; Clark, H.; Dong, H.; Elsiddig, E.; Tubiello, F. Agriculture, Forestry and Other Land Use (AFOLU). In Climate Change; Cambridge University Press: Cambridge, UK, 2014; pp. 811–922. [Google Scholar]

- Place, S.; McCabe, C.; Mitloehner, F. Symposium review: Defining a pathway to climate neutrality for US dairy cattle production. J. Dairy Sci. 2022, 105, 8558–8568. [Google Scholar] [CrossRef]

- Oliver, J.; Ray, L.; Workman, K. Best Management Practices for Dairy Producers to Reduce Their GHG Emissions from Manure; Progressive Dairy: Oakdale, CA, USA, 2023; pp. 1–3. [Google Scholar]

- Thoma, G.; Popp, J.; Nutter, D.; Shonnard, D.; Ulrich, R.; Matlock, M.; Adom, F. Greenhouse gas emissions from milk production and consumption in the United States: A cradle-to-grave life cycle assessment circa 2008. Int. Dairy J. 2013, 31, S3–S14. [Google Scholar] [CrossRef]

- Rotz, A. Symposium review: Modeling greenhouse gas emissions from dairy farms. J. Dairy Sci. 2018, 101, 6675–6690. [Google Scholar] [CrossRef]

- Dillion, J.; Stackhouse-Lawson, K.; Thoma, G.; Gunter, S.; Rotz, C.; Kebreab, E.; Mueller, N. Current state of enteric methane and the carbon footprint of beef and dairy cattle in the United States. Anim. Front. 2021, 11, 57–68. [Google Scholar] [CrossRef] [PubMed]

- Dairymen, T.A. Economics. 7 November 2022. Available online: https://www.milk4texas.org/issues/economics/ (accessed on 3 October 2023).

- Minton, L. The Thriving Texas Dairy Industry. July 2021. Available online: https://www.idfa.org/dairydelivers (accessed on 3 October 2023).

- IDFA. The Economic Impact of Dairy Products in the United States. International Dairy Foods Association. milk4texas.org. 7 November 2022. Available online: https://milk4texas.org/issues/economics/ (accessed on 3 October 2023).

- Son, M.; Richard, J.; Lambert, D.U.S. Dairy Farm Transition and Exits, 1987–2017. J. Agric. Appl. Econ. 2022, 54, 242–261. [Google Scholar] [CrossRef]

- Odom, D. Dairy Industry. Handbook of Texas. 9 March 2023. Available online: https://www.tshaonline.org/handbook/entries/dairy-industry (accessed on 3 October 2023).

- Ledbetter, K. High Plains Takes over as Leader in Texas Dairy Industry. Texas A&M AgriLife. 7 October 2011. Available online: https://agrilifetoday.tamu.edu/2011/10/07/high-plains-takes-over-as-leader-in-texas-dairy-industry/ (accessed on 3 October 2023).

- Guerrero, B.; Owens, R.; Amosson, S.; Sukcharoen, K.; Richeson, J.; Almas, L. Assessing Economic Changes Due to an Expanding Dairy Industry in the Texas High Plains. J. Am. Water Resour. Assoc. 2019, 55, 670–679. [Google Scholar] [CrossRef]

- Bechtel, W. High Plains Boom States. Dairy Herd Management. 7 January 2015. Available online: https://www.dairyherd.com/news/business/high-plains-boom-states (accessed on 3 October 2023).

- Schulte, K. Dairy Profit Projection Model for the High Plains Region. Ph.D. Thesis, Kansas State University, Manhattan, KS, USA, 2011. [Google Scholar]

- U.S. Department of Agriculture. Census of Agriculture. 1987–2017. Available online: https://www.nass.usda.gov/AgCensus/ (accessed on 2 October 2023).

- Rotz, C.; Thoma, G. Assessing Carbon Footprints of Dairy Production Systems, 3rd ed.; American Dairy Society Association: Champaign, IL, USA, 2017. [Google Scholar]

- Vida, E.; Tedesco, D. The carbon footprint of integrated milk production and renewable energy systems—A case study. Sci. Total Environ. 2017, 609, 1286–1294. [Google Scholar] [CrossRef] [PubMed]

- Uddin, M.; Aguirre-Villegas, H.; Larson, R.; Wattiaux, M. Carbon footprint of milk from Holstein and Jersey cows fed low or high forage diet with alfalfa silage or corn silage as the main forage source. J. Clean. Prod. 2021, 298, 126720. [Google Scholar] [CrossRef]

- Lauer, M.; Hansen, J.; Lamers, P.; Thrän, D. Making money from waste: The economic viability of producing biogas and biomethane in the Idaho dairy industry. Appl. Energy 2018, 222, 621–636. [Google Scholar] [CrossRef]

- Powell, J.; Russelle, M.; Martin, N. Trends in the dairy industry and their implications for producers and the environment. In Livestock in a Changing Landscape: Experiences and Regional Perspectives; Island Press: Washington, DC, USA, 2010; Volume 2, pp. 115–139. [Google Scholar]

- Aguirre-Villegas, H.; Larson, R. Evaluating greenhouse gas emissions from dairy manure management practices using survey data and lifecycle tools. J. Clean. Prod. 2017, 143, 169–179. [Google Scholar] [CrossRef]

- O’Connor, S.; Ehimen, E.; Pillai, S.; Lyons, G.; Bartlett, J. Economic and environmental analysis of small-scale anaerobic digestion plants on Irish dairy farms. Energies 2020, 13, 637. [Google Scholar] [CrossRef]

- Rotz, A.; Corson, M.; Chianese, D.; Montes, F.; Hafner, S.; Bonifacio, H.; Coiner, C. The Integrated Farm Systen Model Refernce Manual 4.7. Pasture Systems and Watershed Management Research Unit. 28 February 2022. Available online: https://www.ars.usda.gov/ARSUserFiles/80700500/Reference%20Manual.pdf (accessed on 3 October 2023).

- Alvarez-Hess, P.; Little, S.; Moate, P.; Jacobs, J.; Beauchemin, K.; Eckard, R. A partial life cycle assessment of the greenhouse gas mitigation potential of feeding 3-nitrooxypropanol and nitrate to cattle. Agric. Syst. 2019, 169, 14–23. [Google Scholar] [CrossRef]

- Sejian, V.; Prasadh, R.; Lees, A.M.; Lees, J.C.; Al-Hosni, Y.; Sullivan, M.L.; Gaughan, J.B. Assessment of the carbon footprint of four commercial dairy production systems in Australia suing an integrated farm system model. Carbon Manag. 2018, 9, 57–70. [Google Scholar] [CrossRef]

- ASAE. Agricultural Machinery Management Standards, 47th ed.; ASAE: St. Joseph, MI, USA, 2000. [Google Scholar]

- McGeough, E.; Little, S.; Janzen, H.; McAllister, T.; McGinn, S.; Beauchemin, K. Life-cycle assessment of greenhouse gas emissions from dairy production in eastern Canada: A case study. J. Dairy Sci. 2012, 95, 5164–5175. [Google Scholar] [CrossRef] [PubMed]

- Aguirre-Villegas, H.; Passos-Fonseca, T.; Reinemann, D.; Armentano, L.; Wattiaux, M.; Cabrera, V.; Larson, R. Green cheese: Partial life cycle assessment of greenhouse gas emissions and energy intensity of integrated dairy production and bioenergy systems. J. Dairy Sci. 2015, 98, 1571–1592. [Google Scholar] [CrossRef] [PubMed]

| Data Input Parameter | Value | Units |

|---|---|---|

| Herd/facility parameters | ||

| Animal type | Holstein | |

| Number of lactating animals | 5000 | |

| Number of young stock (over 1 year) | 1150 | |

| Number of young stock (under 1 year) | 400 | |

| Milk production | ||

| Target milk production per cow | 26,285 | lb/cow/year |

| Target milk production—TOTAL | 131,524,000 | lb/year |

| Animal facilities | ||

| Milking center | Double twenty-four parlor | |

| Cow housing | Free stall barn, mechanically ventilated | |

| Heifer housing | Calf hutches | |

| Dry cows/older heifers | Open lot | |

| Feed facility | Commodity shed | |

| Labor for milking and animal handling | 10 | minutes/cow/day |

| Feeding | ||

| Grain | Loader and mixer wagon | |

| Silage | Loader and mixer wagon | |

| Hay | Tub grinder | |

| Ration constituents | ||

| Minimum dry hay in rations | 50% of forage | |

| Relative forage to grain ratio | Low | |

| Crude protein supplement | Cotton seed meal | |

| Undegradable protein supplement | Distillers grain | |

| Phosphorus feeding level in rations | ||

| Early lactation | 0.39% | |

| Mid lactation | 0.42% | |

| Late lactation | 0.42% | |

| Dry cow | 0.30% | |

| Young heifer | 0.42% | |

| Older heifer | 0.38% | |

| Protein feeding level in rations | ||

| Early lactation | 16.60% | |

| Mid lactation | 17.20% | |

| Late lactation | 17.20% | |

| Dry cow | 15% | |

| Young heifer | 14.20% | |

| Older heifer | 13.20% |

| Statistic | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average monthly maximum air temp (°C) | 14.74 | 16.18 | 20.71 | 25.36 | 28.81 | 32.59 | 34.95 | 35.31 | 31.45 | 26.26 | 20.15 | 14.95 |

| Average monthly min air temp (°C) | 0.33 | 2.42 | 6.8 | 10.96 | 16.04 | 20.13 | 21.52 | 21.35 | 17.52 | 11.69 | 6.15 | 0.90 |

| Monthly average standard deviation of daily max temp (°C) | 6.58 | 7.24 | 5.84 | 4.56 | 3.60 | 2.43 | 2.11 | 2.53 | 3.6 | 4.52 | 5.65 | 6.46 |

| Monthly average standard deviation of daily min temp (°C) | 4.39 | 4.82 | 4.90 | 4.36 | 3.55 | 2.02 | 1.32 | 1.58 | 3.61 | 4.57 | 5.21 | 4.88 |

| Average monthly precipitation (mm) | 43.4 | 53.4 | 67.9 | 60.6 | 114.9 | 104.4 | 51.6 | 61.4 | 67.8 | 80 | 53.8 | 41.8 |

| Monthly standard deviation of daily precipitation (mm) | 4.51 | 4.93 | 5.66 | 5.42 | 8.30 | 8.49 | 4.84 | 5.34 | 6.07 | 7.02 | 4.62 | 3.58 |

| Monthly skew coefficient for daily precipitation | 3.6 | 3.3 | 3.1 | 3.1 | 2.8 | 3.1 | 3.6 | 3.2 | 3.1 | 3.3 | 3.3 | 3.3 |

| Monthly probability of wet day after dry day | 0.089 | 0.109 | 0.13 | 0.13 | 0.129 | 0.114 | 0.096 | 0.106 | 0.105 | 0.103 | 0.085 | 0.099 |

| Monthly probability of wet day after wet day | 0.098 | 0.108 | 0.122 | 0.109 | 0.182 | 0.159 | 0.108 | 0.119 | 0.123 | 0.137 | 0.125 | 0.108 |

| Average number days of rain per month (days) | 6.0 | 6.7 | 8.1 | 7.3 | 10.0 | 8.6 | 6.6 | 7.2 | 7.2 | 7.4 | 6.6 | 6.6 |

| Total Annual GHG Allocation and Emissions | ||

|---|---|---|

| lb/Cow | lb | |

| Ammonia | ||

| Housing facility | 99.9 | 499,699 |

| Manure storage | 104.5 | 522,334 |

| Field application | 16.9 | 84,411 |

| Total farm | 221.3 | 1,106,444 |

| Hydrogen sulfide | ||

| Housing facility | 0.7 | 3600 |

| Manure storage | 0.1 | 283 |

| Field application | 0.6 | 2892 |

| Total farm | 1.4 | 6775 |

| Ozone forming VOC | ||

| Silo face | 5.4 | 26,911 |

| Silage feeding | 12.4 | 61,967 |

| Housing manure | 0.9 | 4491 |

| Manure storage | 0.5 | 2687 |

| Field application | 1 | 4953 |

| Total farm | 20.2 | 101,009 |

| Methane | ||

| Animal | 307.2 | 1,535,836 |

| Housing manure | 11.2 | 56,095 |

| Manure storage | 120.4 | 602,181 |

| Field application | 0.1 | 587 |

| Total farm | 438.9 | 2,194,699 |

| Nitrous oxide | ||

| Animal | 0.4 | 1904 |

| Housing manure | 2.1 | 10,579 |

| Manure storage | 2.8 | 14,120 |

| Farmland | 0.5 | 2394 |

| Indirect sources | 3 | 15,243 |

| Total farm | 8.8 | 44,240 |

| Biogenic CO2 | ||

| Housing facility | 13,484.70 | 67,423,288 |

| Manure storage | 132.3 | 661,682 |

| Net land and feed | −24,476.10 | −122,380,680 |

| Total farm | −10,859.10 | −54,295,724 |

| Anthropogenic CO2 | 397.50 | 1,987,294 |

| Greenhouse Gas Emissions (CO2-eq) | ||

|---|---|---|

| Unit | Mean | |

| Animal emissions | lb | 43,508,036 |

| Manure emissions | lb | 24,993,304 |

| Direct and indirect land emissions | lb | 4,673,748 |

| Net biogenic CO2 emissions | lb | −54,295,740 |

| Anthropogenic CO2 emissions | lb | 1,987,294 |

| Production of resource inputs | lb | 34,022,084 |

| Not allocated to milk production | lb | −8,695,361 |

| Carbon footprint without biogenic CO2 | lb/lb FPCM | 0.83 |

| Carbon footprint with biogenic CO2 | lb/lb FPCM | 0.40 |

| Carbon footprint without biogenic CO2 | lb/131,524,000 FPCM | 43,508,036 |

| Carbon footprint with biogenic CO2 | lb/131,524,000 FPCM | 24,993,304 |

| Annual Production Costs and Return to Management for a 25-Year Analysis | |||

|---|---|---|---|

| Unit | Mean | Standard Deviation | |

| Equipment cost | USD | 1,199,412 | 43,405 |

| Facilities cost | USD | 1,067,856 | 1843 |

| Energy cost | USD | 717,094 | 5282 |

| Labor cost | USD | 3,826,504 | 5073 |

| Seed, fertilizer, and chemical cost | USD | 342,622 | - |

| Net purchased feed and bedding cost | USD | 7,599,146 | 142,711 |

| Animal purchase and livestock expense | USD | 2,433,500 | - |

| Milk hauling and marketing fees | USD | 1,313,446 | 3506 |

| Property tax | USD | 106,746 | - |

| Total Cost | USD | 18,606,326 | |

| Income from milk sales | USD | 24,037,520 | 64,162 |

| Income from animal sales | USD | 1,787,436 | - |

| Return to management and unpaid factors | USD | 7,218,630 | 157,819 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woolery, S.; Osei, E.; Yu, M.; Guney, S.; Lovell, A.; Jafri, H. The Carbon Footprint of a 5000-Milking-Head Dairy Operation in Central Texas. Agriculture 2023, 13, 2109. https://doi.org/10.3390/agriculture13112109

Woolery S, Osei E, Yu M, Guney S, Lovell A, Jafri H. The Carbon Footprint of a 5000-Milking-Head Dairy Operation in Central Texas. Agriculture. 2023; 13(11):2109. https://doi.org/10.3390/agriculture13112109

Chicago/Turabian StyleWoolery, Sadie, Edward Osei, Mark Yu, Selin Guney, Ashley Lovell, and Hussain Jafri. 2023. "The Carbon Footprint of a 5000-Milking-Head Dairy Operation in Central Texas" Agriculture 13, no. 11: 2109. https://doi.org/10.3390/agriculture13112109

APA StyleWoolery, S., Osei, E., Yu, M., Guney, S., Lovell, A., & Jafri, H. (2023). The Carbon Footprint of a 5000-Milking-Head Dairy Operation in Central Texas. Agriculture, 13(11), 2109. https://doi.org/10.3390/agriculture13112109