Abstract

In order to meet the sowing demand of the hybrid rice plug seedling, a horizontal rotary precision seed metering device was proposed. The key structure parameters were designed, the kinematics analysis of the seed-filling process was carried out, and the main influencing factors of the seeding performance evaluation index were determined. Taking motor speed, the eccentric distance of the disk, and seed layer thickness as test factors, and the taking qualification rate, repetition rate, and miss-seeding rate as seeding performance test indexes, the quadratic regression orthogonal rotation combination test was carried out, and the relationship between the test factors and evaluation indexes was approached by a quadratic polynomial. On the basis of discussing the influence of the test factors on the performance index, the regression surrogate mathematical model between the main performance index and the influencing factors was established. The value of the evaluation index of correlation degree p between the model variables was less than 0.01. Based on the regression surrogate mathematical model, the response surface of the qualified rate of the seeding performance evaluation index was established, and the test data were analyzed by multiple regression analysis. The rapid prediction of qualified rates under the influence of test factors was realized, and the optimum test parameters were obtained as follows: motor speed 165 r/min, an eccentric distance of disk 22 mm, seed layer thickness 28 mm, qualification rate 98.55%, miss-seeding rate 1.45%, and repetition rate 0%. According to the best combination of test parameters, the performance evaluation index test of the prototype was carried out, and the qualification rate, miss-seeding rate, and repetition rate were 98.34%, 1.66%, and 0%. The experimental results were in good agreement with the theoretical analysis, indicating that the horizontal rotary precision seed metering device can meet the agronomic requirements of hybrid rice. The research results could provide some reference for the design of a precision seeding device for industrialized plug seedlings.

1. Introduction

Hybrid rice technology is an independent innovation and global leading technology which has made great contributions to the food security of China [1,2]. Hybrid rice planting is mainly promoted by the planting mode of precision sowing and seedling transplanting, which requires the accurate control of sowing quantity and seed dropping position per unit area [3,4].

Precision sowing technology is an important way to realize the seedling and sowing of hybrid rice, and the seed metering device is the core component [5]. Developed countries, such as the United States, Italy, Australia, and so on, mainly focus on direct seeding technology, and there are few pieces of equipment with which to study seedlings and sowing. In Asia, Japan and South Korea have the highest level of sowing equipment. Kubota, Jingguan, Yangma, Mitsubishi, Toyo, and other companies have established sowing lines with good technology and a high degree of automation. However, most of them are developed for conventional rice, which can realize the sowing of 3–6 grains/hole or 4–8 grains/grid [6].

The existing precision of seed metering devices in China mainly includes mechanical type, vibration type, and pneumatic type [7]. The vibrating seed metering device usually has a large sowing quantity, which is suitable for conventional rice sowing and has the problems of seeding interruption and low efficiency [8,9,10]. The pneumatic seed metering device has good adaptability to seed size and can realize single seed sowing with low seed injury rates and high sowing precision, but no effective method has been found to solve the problem of blockage [11,12,13,14]. The mechanical seed metering device has the advantages of a simple structure, low price, and good stability, and has a large market share [15,16,17,18,19]. The device with a mechanical cavity is widely used for corn, soybean, and other regular shape seeds. For rice seeds, the filling process is extremely complex, and it is difficult to control the seed movement posture. Therefore, it is still difficult to ensure seeding accuracy and uniformity stability. To sum up, the existing precision seed metering device in China has poor adaptability to the precision requirements of 2 ± 1 grain/hole for hybrid rice. It is of great practical significance to study the precision metering device to develop the mechanized planting technology of hybrid rice.

In order to improve the seeding performance of the seed metering device with low seeding rates for the plug seedling raising of super hybrid rice, a piezoelectric vibration seed supply device was designed [20]. A rice pneumatic seeding metering device with an adjustable seeding rate was designed in this study. This seed metering device adopted multiple independent negative pressure flow paths to control the accuracy of the seed suction [21]. The scholars wanted to design the wedge-type churning device on the basis of a pneumatic cylinder-type seed metering device. As the shape of the rice seed is slender, long, and sharp, with edges, villus, and poor fluidity, the wedge-shaped churning device was designed to improve suction accuracy [22]. Generally speaking, a mechanical precision seed arranger for hybrid rice is rare. In view of this, the horizontal rotary precision seed metering device is innovatively designed. In this paper, taking Wanxiangyou 111 hybrid rice as an example, the working principle was analyzed theoretically, and the key parameters affecting the sowing index were found and optimized. Through the bench test verification, it was expected to provide a reference for the design of the precision metering device for hybrid rice.

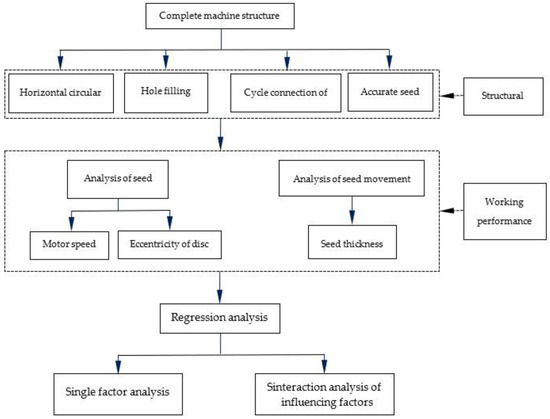

The roadmap of this study is shown in Figure 1.

Figure 1.

Workflow of this article.

2. Working Principle and Key Parameter Setting

2.1. Structure and Working Principle

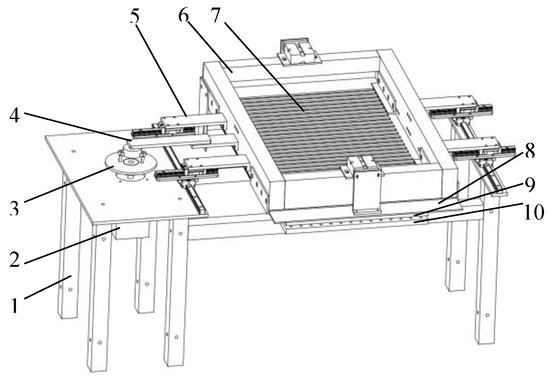

The structure of the whole machine is shown in Figure 2, which is mainly composed of the frame, motor, eccentric disc, connecting plate, support plate, seed filling box, upper plate, lower plate, seed guiding device, and tray.

Figure 2.

Structure of horizontal rotary precision seed metering device. 1. Frame; 2. Motor; 3. Eccentric disc; 4. Connecting plate; 5. Support plate; 6. Seed filling box; 7. Upper plate; 8. Lower plate; 9. Seed guiding device; 10. Tray.

The working process can be divided into four parts: horizontal circular feeding, mechanical hole filling, the cycle connection of filling and metering, and accurate seed guiding. The details are as follows: firstly, the motor transmits the power to the seed filling box through the eccentric disc, connecting the plate and support plate, and drives the seed filling box to make continuous circular translational motions, and the seeds are evenly dispersed. Secondly, the upper plate is in the open state, the lower plate is in the closed state, and the seed posture is adjusted adaptively so as to fall into the shaped hole. Thirdly, the upper plate is closed, the lower plate is open, and the seeds enter the seed guiding device. Finally, the seeds fall into the tray through the internal path of the seed guiding device.

2.2. Horizontal Circular Feeding

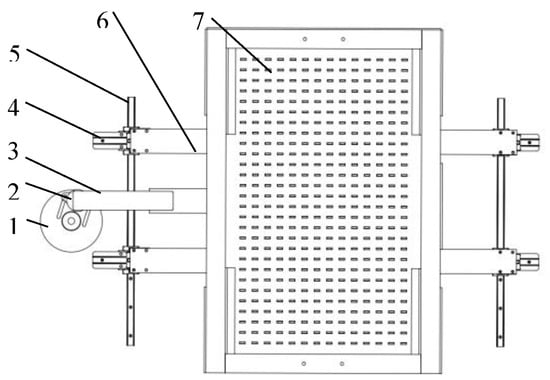

As shown in Figure 3, the horizontal rotary seed feeding assembly is driven by the motor, and its main structure includes an eccentric disc, bearing, connecting plate, first slide rail, second slide rail, support plate, and seed-filling box. When working, the seed filling box makes a horizontal circular motion. The hinge center of the motor and eccentric disc does not coincide with the hinged center of the connecting plate and the eccentric disc. The movement state of the seeds can be changed by adjusting the speed of the motor and the distance between the two hinge centers so as to meet the needs of the hybrid rice seeds.

Figure 3.

Structure of drive components. 1. Eccentric disc; 2. Bearing; 3. Connecting plate; 4. First slide rail; 5. Second slide rail; 6. Support plate; 7. Seed filling box.

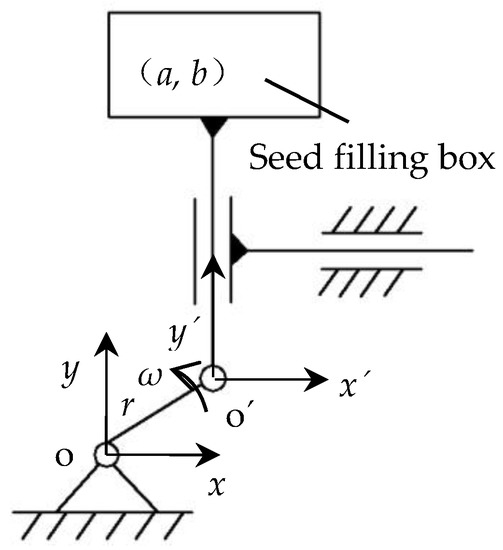

The motion of the seed-filling box can be simplified, as shown in Figure 4. The dynamic part is simplified as crank oo’, and the seed-filling box can be regarded as a rigid body. The track shape of all the position points on it is the same, and all points have the same velocity and acceleration at the same moment. oxy is the reference coordinate system; o’x´y´ is the connected coordinate system; ω is the angular velocity of the motor, rad/s; r is the eccentricity between the hinge center of the motor and the hinge center of the connecting plate on the eccentric disc (referred to as the disc eccentricity), mm. The position of any point on the seed filling box can be determined by its invariant vector in the connected coordinate system. It is supposed that the coordinates of the seed filling box in the connected coordinate system are (a, b) at some point.

Figure 4.

Motion diagram of driving components and seed filling box mechanism.

The displacement equation of any point on the seed filling box in the reference coordinate system is as follows:

The velocity equation is as follows:

It can be seen from Formulas (1) and (2) that the speed is directly related to the motor speed and the disc eccentricity, thus affecting the movement characteristics of the seeds. According to the preliminary experimental observation, the motor speed range is 50–400 r/min, and the disc eccentricity is adjustable in the range of 5–45 mm.

2.3. Mechanical Hole Filling-Shaped Hole Design

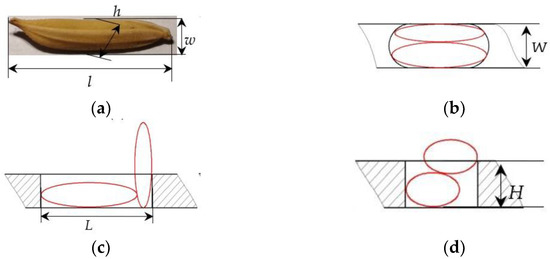

The top of the filling box is open, and there are square array holes on the bottom plate. The parameters of the shaped hole directly affect the seed-filling performance. Taking Wanxiangyou 111 as the research object, the seed shape is similar to the spindle, and there may be three states of falling into the mold hole: lying flat, lying on the side, and upright. According to the probability method, the probability of lying flat and lying on the side is much greater than that of standing up. At the same time, lying flat is the most possible stable state of hybrid rice seeds due to the principle of minimum potential energy. In order to contain only one seed in the mold hole, considering its shape, average size, and processing difficulty, the shaped hole is designed as a rounded rectangle. The schematic diagram of the three-circumference size of the seed and the limit size of the shape is shown in Figure 5.

Figure 5.

Schematic diagram of the seed and limit dimension of the hole: (a) 3-D seed size; (b) Limited width of the shaped hole; (c) Limited length of the shaped hole; (d) Limited height of the shaped hole.

The design of L should ensure that the shaped hole can accommodate the seeds lying on the bottom and avoid seeds lying horizontally and vertically at the same time; W should be designed to avoid two seeds lying on the side; meanwhile, the design of H should ensure that the center of gravity for the second seed lying flat is not in the hole, as follows:

where l is the average length of the seeds, mm; w is the average width of the seeds, mm; h is the average height of the seeds, mm; L is the length of the shaped hole, mm; W is the width of the shaped hole, mm; and H is the height of the shaped hole, mm.

A total of 100 seeds of Wanxiangyou 111 were randomly selected for three-dimensional measurements. The average length, width, and height of the seeds were 11.98 mm, 2.64 mm, and 2.08 mm, respectively. According to Formula (3), the length, width, and height of the shaped hole were determined to be 13, 3, and 3 mm, respectively.

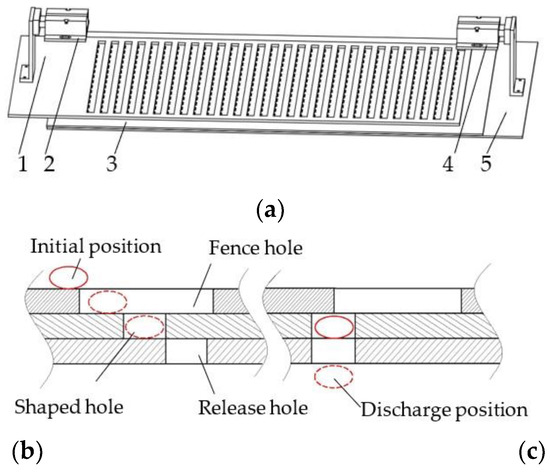

2.4. Cycle Connection of Filling and Metering

The first cylinder and the second cylinder are used to drive the upper plate and the lower plate to move parallel in a straight line. The structure diagram is shown in Figure 6a. The upper plate is provided with a fence hole, and the lower plate is set with a release hole. The upper and lower plates are, respectively, close to the bottom plate of the seed filling box, which can be opened and closed by two cylinders. The schematic diagram is shown in Figure 6b,c.

Figure 6.

Schematic diagram of connection principle of filling and discharging seeds: (a) Structural diagram of filling and metering cycle connection; (b) Seed filling state; (c) Seed metering state. 1. Upper plate; 2. First cylinder; 3. Bottom plate of the seed filling box; 4. Second cylinder; 5. Lower plate.

In the seed-filling state, the upper plate is opened, the lower plate is closed, and the seeds fall into the seed-filling box-shaped hole through the fence hole of the upper plate; in the seed-metering state, the lower plate is open, and the upper plate is partially closed to reduce seed clamping and seed damage. At this time, the seeds fall into the release hole of the lower plate from the filling box hole.

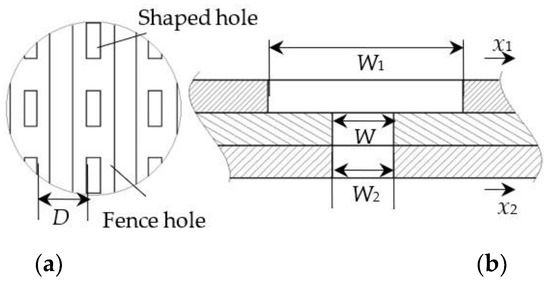

The key dimension is shown in Figure 7: the width of the fence hole W1 should be greater than the average length of the seeds l to ensure that seeds can rotate 360° above the hole. The width of the release hole W2 should be greater than the shaped hole W. The stroke of the two cylinders should ensure that there is no seed in and out when the upper and lower plates are closed and that this does not hinder the seeds from entering and leaving when opening. Referring to the working principle of the seed guiding device in the following, the range of the eccentric disc is fully considered for the spacing of the hole so as to ensure a one-to-one correspondence between the shaped hole and the inner pipe of the seed guiding device.

Figure 7.

Key dimension diagram of seed-filling and discharging connection device: (a) Partial top view; (b) Partial front sectional view.

The details are as follows:

where W1 is the width of the fence hole, mm; W2 is the width of the release hole, mm; D is the distance between the holes, mm; x1 is the stroke of the first cylinder, mm; x2 is the stroke of the second cylinder, mm.

According to Formula (4), the value range of the key dimensions is obtained. From the perspective of ensuring the flatness of the upper and lower plates and reducing the cylinder stroke, and improving the stability, it is determined that the width of the fence hole is 14 mm, the width of the release hole is 4 mm, the stroke of the first cylinder is 9 mm, the stroke of the second cylinder is 3 mm, and the distance between the holes is 50 mm.

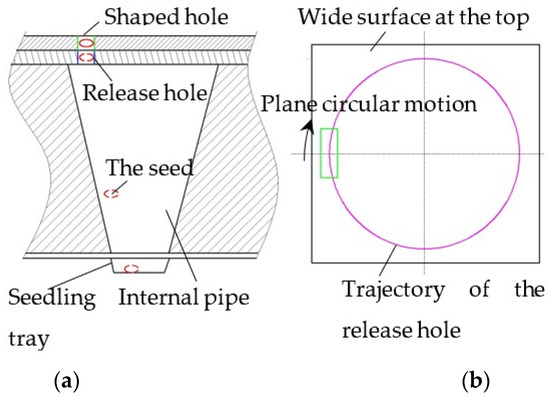

2.5. Accurate Seed Guiding

The principal diagram is shown in Figure 8. The seed guiding device is made of PVC material. The inner channel is wide at the top and narrows at the bottom. The upper part corresponds to the shaped hole, and the lower part corresponds to the seedling tray. During the operation, the upper part needs to accommodate the movement track of the hole so that the seeds always fall into the internal pipe. At the same time, the arrangement of the shaped hole should refer to the size distribution of the upper part so as to ensure the one-to-one correspondence between the shaped hole and the internal pipe.

Figure 8.

Working principal diagram of the seed guiding device: (a) Partial front sectional view; (b) Partial top view.

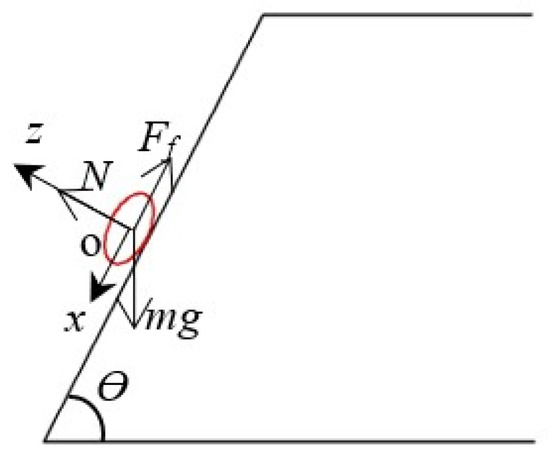

The slope of the seed guiding channel is designed to avoid seeds from staying still on the slope. Regardless of the bouncing and overturning phenomenon of the seeds on the inclined plane, when the seed centroid is taken to be the origin o of the coordinate system, the x-axis square is parallel to the inclined plane downward, and the z-axis square is perpendicular to the inclined plane upward. The force analysis of the seeds is shown in Figure 9 below.

Figure 9.

Stress analysis diagram of seed on slope of seed guiding channel.

The conditions of seed sliding on the slope are as follows:

where ϴ is the inclination angle of the slope; mg is the gravity of the seed, N; N is the support force of the slope, N; Ff is the sliding friction force between the seed and the slope, N; Fx is the resultant force in the x-axis direction, N; Fz is the resultant force in the z-axis direction, N; and μ is the static friction coefficient between the seed and the bottom of seed-filling box.

From Formula (5), it can be concluded that:

The inclination angle θ should be greater than the maximum static friction angle of 37° [23] so as to ensure the relative movement between the seeds and the inclined plane and provide the necessary conditions for the seeds to fall into the seedling tray accurately.

3. Analysis of Seed Filling Process

3.1. Analysis of Seed Filling Conditions

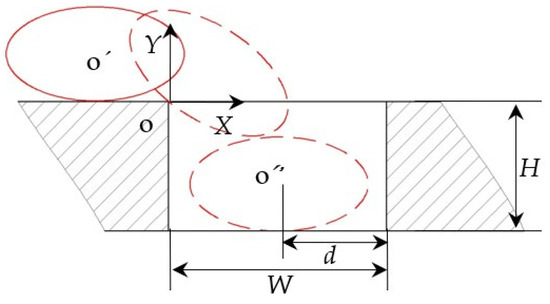

In the process of seed-filling, the gravity of the seeds, the pressure between the seeds, the positive pressure between the seeds and the bottom of the seed-filling box, rolling friction, and sliding friction constitute a complex dynamic mechanical system. The speed of the bottom seed is lower than that of the seed-filling box, and the bottom seed transfers the velocity to the upper seed and finally transfers the movement to the whole seeds. As shown in Figure 10, o is the origin of the coordinate system, X and Y are the coordinate axes, o’ is the center of mass for the seed’s initial position, and o’’ is the center of mass for the seeds falling into the shaped hole. The relative velocity vr between the seed and the shaped hole is a necessary condition for seed filling, but if the relative velocity is too high, it cannot guarantee the filling time, which is easy to cause missed sowing. Therefore, in order to achieve good seeding performance, it is necessary to research the maximum limit speed.

Figure 10.

Schematic diagram of the seed falling into the shaped hole.

When the seed centroid point o’ moves above the coordinate origin o, the seed starts to fall freely and, at the same time, produces a rotation motion around the o point; then, the motion equation of the seed centroid is as follows:

where x is the horizontal distance of the seed centroid passing through, mm; y is the vertical distance of the seed centroid passing through, mm; d is the horizontal distance between the seed centroid and the back wall of the shaped hole, mm; vr is the relative velocity of the seed and the shaped hole, m/s; t is the time of the seed falling into the shaped hole, s; and g is the acceleration of gravity, m/s2.

From Formula (7), it can be concluded that the relative velocity should satisfy the following relationship:

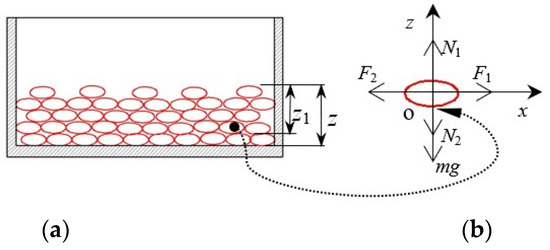

3.2. Analysis of Seed Movement in Population

According to the theory of agricultural materials science, the pressure on the side wall of the container depends on the height of the seed layer and the specific gravity of the seeds, and the effect of the pressure on the horizontal plane increases the coefficient of lateral pressure. As shown in Figure 11, taking the center of gravity of the seed as the origin o, the movement direction of the seed-filling box at a certain moment is the positive direction of the x-axis, and the vertical direction of the bottom of the box is the positive direction of the z-axis.

Figure 11.

Force analysis of the bottom seed: (a) Height of the seed layer; (b) Stress analysis of the seed.

The differential equation of seed motion is as follows:

where: γ is the specific gravity, kg/m3; Ω1 is the surface area of the studied seed layer, m2; μ1 is the sliding friction coefficient between the seeds and the bottom of the seed-filling box; μ2 is the sliding friction coefficient between the seeds; F1 is the friction between the seeds and the bottom of the seed-filling box, N; F2 is the friction between the upper and the lower layer seeds, N; N1 is the supporting force of the bottom, N; N2 is the vertical pressure of the upper layer seeds on the bottom layer seeds, N; mg is the gravity of the seed, N; z is the total height of the seed layer, m; and z1 is the height of the upper layer, m.

By solving Equation (9), it can be concluded that:

According to Formula (10), the change in the seed layer thickness can affect the relative velocity and then affect the filling process. In conclusion, the motor speed, disc eccentricity, and seed layer thickness are the main factors affecting the performance of the seed metering device.

4. Working Performance Test

Through the comparative study of the preface, it can be obtained that the precision sowing device of corn, soybeans, and other seeds with a regular and nearly round shape has been widely applied in the design of seed arrangement devices. However, rice is a heteromorphic seed, and the filling process is extremely complicated, so it is still difficult to ensure the accuracy, uniformity, and stability of seeding. So, this paper proposes a new horizontal rotary precision seed metering device for hybrid rice, after which the working performance test can be carried out.

4.1. Test Conditions

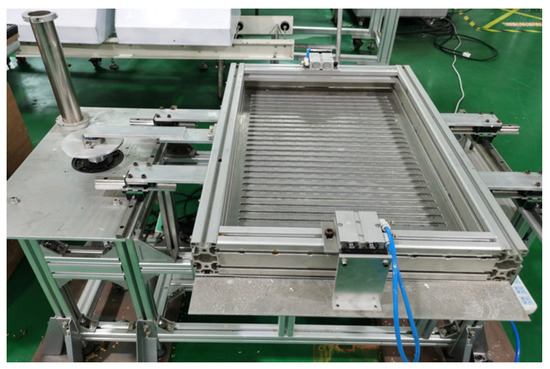

The prototype of the horizontal rotary precision seed metering device with a low sowing rate for hybrid rice is shown in Figure 12. The hybrid rice variety Wanxiangyou 111 was used in the experiment, the seed moisture content was about 13.5%, and the 1000-grain weight was 21.36 g.

Figure 12.

Model machine of horizontal rotary precision seed metering device.

4.2. Test Conditions

In order to explore the influence of the motor speed, disc eccentricity, and seed layer thickness on the performance of the seed metering device, they were taken as the three factors of the test, and the qualification rate, repetition rate, and miss-seeding rate were selected as the evaluation indexes on which to carry out the quadratic regression general rotary combination test. The expression of each index is as follows:

where N is the total number of holes; n1 is the number of holes in 2 ± 1 seeds; n2 is the number of holes greater than or equal to four seeds; and n0 is the number of seedless holes.

According to the design principle of the secondary rotation combination test, the coding coefficient is 1.682 [24], and the coding results are shown in Table 1.

Table 1.

Code of test factors.

4.3. Results and Discussion

4.3.1. Regression Analysis

The test results are shown in Table 2. The sum of the qualified rate and the miss-seeding rate is equal to 100%, so the regression model of the miss-seeding rate and the influence law of factors are consistent with the conclusion of the qualification rate analysis. Therefore, this paper only analyzes the qualified rate. Design expert 8.0.6 software is used to process the test data, and a quadric model is used to establish the regression surrogate mathematical model. The results of the variance analysis for the qualified rate are shown in Table 3.

Table 2.

Test results.

Table 3.

Analysis of variance of qualified rate.

According to the analysis, the coefficient of X1, X2, X3, X1X2, X1X3, X12, and X22 reaches a significant level (p < 0.1). The p-value of the regression model is less than 0.01, while the p-value of the unmatched item is 0.1085, which indicates that the regression model is extremely significant and the mismatch is not significant, and the regression is effective. After deleting the non-significant items, the regression second-order surrogate mathematical model equation for the qualified rate was obtained.

According to the F value in Table 3, the disk eccentricity has a highly significant impact on the qualification rate, and the motor speed and seed layer thickness had a significant impact, which verified the theoretical analysis results. The influence of the three factors from large to small is disc eccentricity, motor speed, and seed layer thickness. The interaction between the motor speed and disc eccentricity is highly significant, and the interaction between motor speed and seed layer thickness is significant. The interaction of factors cannot be ignored. The interaction between the disc eccentricity and seed layer thickness is not significant, and the interaction of factors can be ignored.

4.3.2. Influence of Single Factor on Response Value

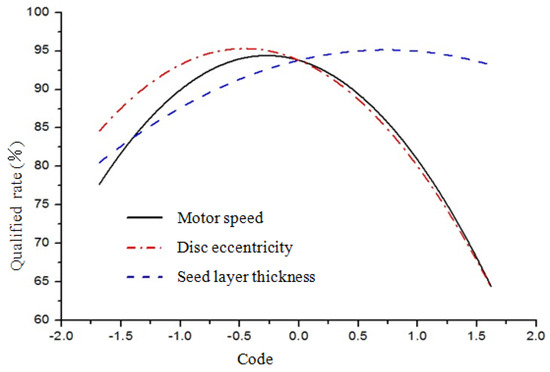

In this paper, the dimension reduction method was adopted, and other factors were fixed at zero level according to the second-order surrogate mathematical model [25]. The specific results are shown in Figure 13.

Figure 13.

Influence of the single factor on the qualified rate.

The results show that the relationship between the three factors and the qualified rate is a concave curve, which has a positive effect before the extreme value point and a negative effect after the extreme value point. The extreme value of the motor speed is −0.27 (actual value 197 r/min), the extreme value point of disc eccentricity is −0.46 (actual value is 19.5 mm), and the extreme value point of the seed layer thickness is 0.73 (actual value is 22.3 mm). The slope of the curve corresponding to the motor speed and disc eccentricity is higher, which indicates that the change in this factor has a greater disturbance on the qualified rate. The curve corresponding to the thickness of the seed layer is gentle, which indicates that the disturbance of this factor on the qualified rate was relatively small.

4.3.3. Response Surface Analysis of Interaction between Factors

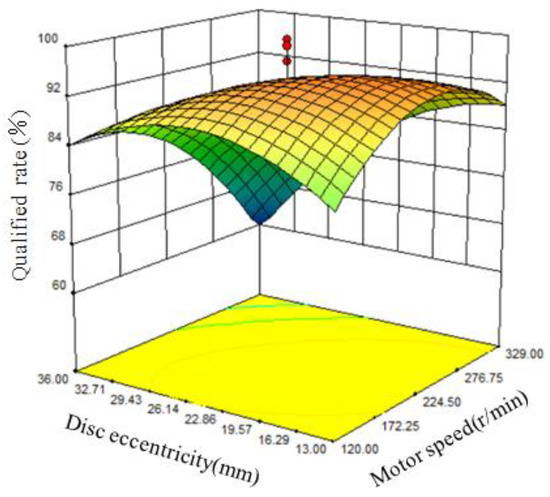

The influence of the interaction between motor speed and disc eccentricity on the qualification rate is shown in Figure 14. When the motor speed is low, the qualified rate increases first and then decreases with the increase in the disc eccentricity, but the range of variation is small. When the motor speed is high, the qualified rate decreases sharply with the increase in disc eccentricity.

Figure 14.

Interaction between motor speed and disc eccentricity.

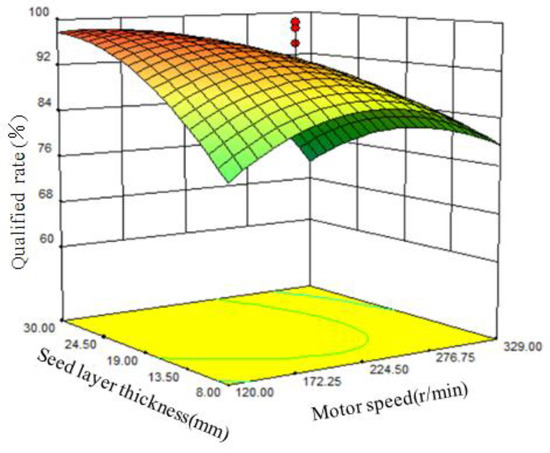

Figure 15 shows the effect of the interaction between the motor speed and seed layer thickness on the qualification rate. When the motor speed is low, the qualified rate increases with the increase in the seed layer thickness because the increase in the seed layer thickness at a low speed increases the positive pressure of the seed in the bottom layer of the seed-filling box, which increases the probability of the seed filling into the hole. When the motor speed is high, the qualified rate first increases and then decreases with the increase in the seed layer thickness, and the change range is small. The change in the seed layer thickness is relatively low, and the influence of the low-speed area on the qualified rate is not obvious.

Figure 15.

Interaction between motor speed and seed layer thickness.

4.4. Parameter Optimization and Verification Test

In order to find the optimal combination of the influencing factors within the scope of constraints, the qualified rate y1 is taken as the evaluation index, and the mathematical model is established by combining the boundary conditions of each factor. The objective function and constraint conditions are as follows:

Design expert 8.0.6 was used to optimize the test parameters. The results show that the optimal parameter combination of the maximum qualification rate and the minimum hole rate is a motor speed of 165 r/min, disc eccentricity of 22 mm, and seed layer thickness of 28 mm. The predicted qualification rate is 98.55%, and the miss-seeding rate is 1.45%.

The optimized results are verified by the experiments. The same batch of Wanxiangyou 111 was selected and repeated 10 times. The qualified rate of the (2 ± 1) hole was 98.34%, and there were no more than three holes. The miss-seeding rate was 1.66%, which is basically consistent with the optimization results.

5. Conclusions

In order to meet the needs of hybrid rice sowing, a horizontal and ratation motional seed metering device with a higher sowing rate was designed in this paper. The key structure and parameters were designed, the corresponding prototype was developed, the dynamic analysis of the seed filling conditions was carried out, and the design parameters affecting the seeding performance were determined as motor speed, disc eccentricity, and seed layer thickness.

Taking the motor speed, disc eccentricity, and seed layer thickness as experimental factors and taking the qualified rate, miss-seeding rate, and repetition rate as seeding performance indexes, the regression surrogate mathematical model between the main performance indexes and influencing factors was established. The results showed that the p-value was less than 0.01, which indicated that the regression surrogate mathematical model had high precision and satisfied the mathematical modeling of the seeding performance index. Based on the surrogate mathematical model, the influence law of test factors on the test indexes was discussed. The order of importance for the factors affecting the qualified rate was disc eccentricity, motor speed, and seed layer thickness, and the interaction between the factors can not be ignored.

Based on the surrogate mathematical model of the seeding performance evaluation index, the qualified rate was optimized. When the motor speed was 165 r/min, the disc eccentricity was 22 mm, and the seed layer thickness was 28 mm; the qualified rate was 98.55%, the miss-seeding rate was 1.45%, and the repetition rate was 0%. The prototype test showed that the qualified rate, miss-seeding rate, and repetition rate were 98.34%, 1.66%, and 0%, respectively. The theoretical and experimental results showed that the performance evaluation index of the device designed in this paper could meet the requirements of a low sowing rate. The surrogate mathematical model could provide some reference for the design of a precision seed metering device for factory plug seedlings.

This paper is carried out under the support of the Jiangsu Provincial Natural Science Foundation of China, the Jiangsu Province Agricultural Science and Technology Independent Innovation Fund, the National Key Research and Development Program of China, and the Special Fund for Basic Scientific Research Business of Chinese Academy of Agricultural Sciences. Compared to the existing seeding structure, this paper proposes a new horizontal rotary precision seed metering device for hybrid rice. The research in this paper can provide some reference for the design of precision seed metering devices for factory plug seedlings. This paper can also lay a foundation for the structure optimization design of an automatic seeder.

Author Contributions

Conceptualization, Q.X. and B.Q.; methodology, Q.X.; software, Y.W.; validation, Q.X., B.Q. and Y.W.; formal analysis, W.Z.; investigation, W.Z.; resources, W.Z.; data curation, Q.X.; writing—original draft preparation, Q.X.; writing—review and editing, B.Q.; visualization, Y.W.; supervision, W.Z.; project administration, W.Z.; funding acquisition, B.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Jiangsu Provincial Natural Science Foundation of China (Grant No. BK20211021), the Jiangsu Province Agricultural Science and Technology Independent Innovation Fund (Grant No. CX(21)3143), the National Key Research and Development Program of China (Grant No. 2021YFD2000401), and the Special Fund for Basic Scientific Research Business of Chinese Academy of Agricultural Sciences (Grant No. SR202104).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Acknowledgments

We would like to thank the three anonymous reviewers for their helpful suggestions to improve the manuscript.

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Peng, S. Dilemma and Way-out of Hybrid Rice during the Transition Period in China. Acta Agron. Sin. 2016, 42, 313. [Google Scholar] [CrossRef]

- Longping, Y. The Strategy for Hybrid Rice Development. Hybrid Rice 2018, 33, 1–2. [Google Scholar]

- Li, Z.; Ma, X.; Xie, J.; Chen, G.; Zhen, Z.; Tan, Y.; Huang, Y. Experiment on precision seedling raising and mechanized transplanting of hybrid rice under low sowing rate in double cropping area. Trans. Chin. Soc. Agric. Eng. 2014, 30, 17–27. [Google Scholar]

- Zhang, W.; Zhu, D.; Lin, X. The effects of different sowing densities and raising materials on seedling quality of mechanical transplanting rice. J. Yangzhou Univ. 2007, 28, 45–48. [Google Scholar]

- Cailing, L.; Chao, W.; Jiannong, S.; Xin, D.; Fuyin, Z. Design and Seed-filling Test of Cell-type Precision Seed-metering Device with Vibration Technology. Trans. Chin. Soc. Agric. Mach. 2018, 49, 108–115. [Google Scholar]

- Li, Y.; Bingxin YA, N.; Dongxing, Z.; Tianliang, Z.; Yunxia, W.; Tao, C. Research Progress on Precision Planting Technology of Maize. Trans. Chin. Soc. Agric. Mach. 2016, 47, 38–48. [Google Scholar]

- Zehua, L.; Xu, M.; Xiuhao, L.; Lintao, C.; Hongwei, L.; Zhicheng, Y. Research Progress of Rice Transplanting Mechanization. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–20. [Google Scholar]

- Zhiwei, L.; Yaojian, S. Study and Test of Electromagnetic Vibrating Type Rice Seeder for Hill Seedling Nursery Box. Trans. Chin. Soc. Agric. Mach. 2000, 32–34. [Google Scholar]

- Peixiang, H.; Mingjin, Y.; Zhonghui, C. Study on Photoelectric Controlled Precision Seeder. Trans. Chin. Soc. Agric. Mach. 2003, 34, 47–49. [Google Scholar]

- Jian, Y.; Wang, Y.; Gaofeng, W.; Zhiling, L. Optimization experiments on electromagnetic vibrated seeder of rice bud-seed for field seedling raising. Trans. Chin. Soc. Agric. Eng. 2012, 28, 32–38. [Google Scholar]

- Wei, S.; Fu-lin, W.; Hai-tao, C.; Qing-hui, L. Vacuum and Air Flow for 2QXP-1 Vacuum Precision Seed Metering. J. Northeast Agric. Univ. 2013, 20, 61–64. [Google Scholar]

- Singh, R.C.; Singh, G.; Saraswat, D.C. Optimisation of Design and Operational Parameters of a Pneumatic Seed Metering Device for Planting Cottonseeds. Biosyst. Eng. 2005, 92, 429–438. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.H.; Li, Y.M.; Gong, Z.Q. Analysis of Suction Height and Seed-adding Device for Suction-vibration Precision Seeder. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2013, 44, 67–71. [Google Scholar]

- Qi, B.; Zhang, W.Y.; Yu, S.S.; Ji, Y.; Li, K.; Zhang, S.Y. Establishment of Seeding Amount Control Model for Centralized Pneumatic Metering System for Rice. Trans. Chin. Soc. Agric. Mach. 2018, 49, 125–131. [Google Scholar]

- Zhou, H.B.; Ma, X.; Yao, Y.L. Research advances and prospects in the seeding technology and equipment for tray nursing seedlings of rice. Trans. Chin. Soc. Agric. Eng. 2008, 24, 301–306. [Google Scholar]

- Kumar, G.P.; Srivastava, B.; Nagesh, D.S. Modeling and optimization of parameters of flow rate of paddy rice grains through the horizontal rotating cylindrical drum of drum seeder. Comput. Electron. Agric. 2009, 65, 26–35. [Google Scholar] [CrossRef]

- Hongchang, L.; Fang, G.; Zhan, Z.; Wei, L. Domestic and overseas research status and development trend of precision seed-metering device. J. Chin. Agric. Mech. 2014, 35, 12–16+56. [Google Scholar]

- Cui, Q.; Hou, H.; Zheng, D.; Wu, Z. Design and test of tilt dise-type fine and small-amount seed metering device for foxtail millet. Trans. Chin. Soc. Agric. Eng. 2016, 32, 17–23. [Google Scholar]

- Haibo, Z. Research and application on key technologies of precision seeder for tray nursing seedlings of rice. Ph.D. Thesis, College of Biological and Agricultura, Changchun, China, 2009. [Google Scholar]

- Jianming, K.; Shujun, L.; Xuejun, Y. Structure parameters optimization of sine exponential curve type ditching blade. Trans. Chin. Soc. Agric. Mach. 2016, 47, 91–99. [Google Scholar]

- Hao, Y.; Cailing, L.; Jiannong, S.; Xin, D.; Meng, J.; Weihao, L. Piezoelectric Vibration Seed Supply Device of Precision Meteing Device for Plug Seedling of Super Hybrid Rice. Trans. Chin. Soc. Agric. Mach. 2020, 51, 31–40. [Google Scholar]

- He, X.; Ying, Z.; Zaiman, W.; Xiwen, L.; Juan, P.; Siyu, H.; Peng, X.; Shuncai, L. Design and parameter optimization of rice pneumatic seeding metering device with adjustable seeding rate. Trans. Chin. Soc. Agric. Eng. 2019, 35, 20–28. [Google Scholar]

- Cailing, L.; Yali, W.; Xin, D. Filling performance analysis and verification of cell-belt rice precision seed-metering based on friction and repeated filling principle. Trans. Chin. Soc. Agric. Eng. 2019, 35, 29–36. [Google Scholar]

- Guixiang, T.; Shujuan, Y.; Chun, W. Performance experiments of bowl dish precision seeder for rice in filling processing. Trans. Chin. Soc. Agric. Eng. 2013, 29, 44–50. [Google Scholar]

- Baolong, W.; Zaiman, W.; Xiwen, L.; Minghua, Z.; Longyu, F.; Shuncai, L.; Peng, X. Design and experiment of wedge churning device for pneumatic cylinder-type seed metering device for hybrid rice. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–8. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).