Development and Experiment of an Online Measuring System for Spray Deposition

Abstract

:1. Introduction

| Services | Principle | Software or Sensor | Advantages | Disadvantages |

|---|---|---|---|---|

| Spray App | Processing water-sensitive paper based on image technology [23,24,25]. | DepositScan, Spray_imageI and II, SnapCard. | High measurement accuracy for droplet deposition density and droplet coverage area. | Consumables, expensive, long period. |

| Online Measuring System | Calculating deposition volume based on resistive and capacitive sensors [13,16,17]. | LWS capacitive sensor, resistive sensor. | Reusable, low cost, fast response. | Low measurement accuracy and few measurement parameters (only spray deposition quality). |

2. Materials and Methods

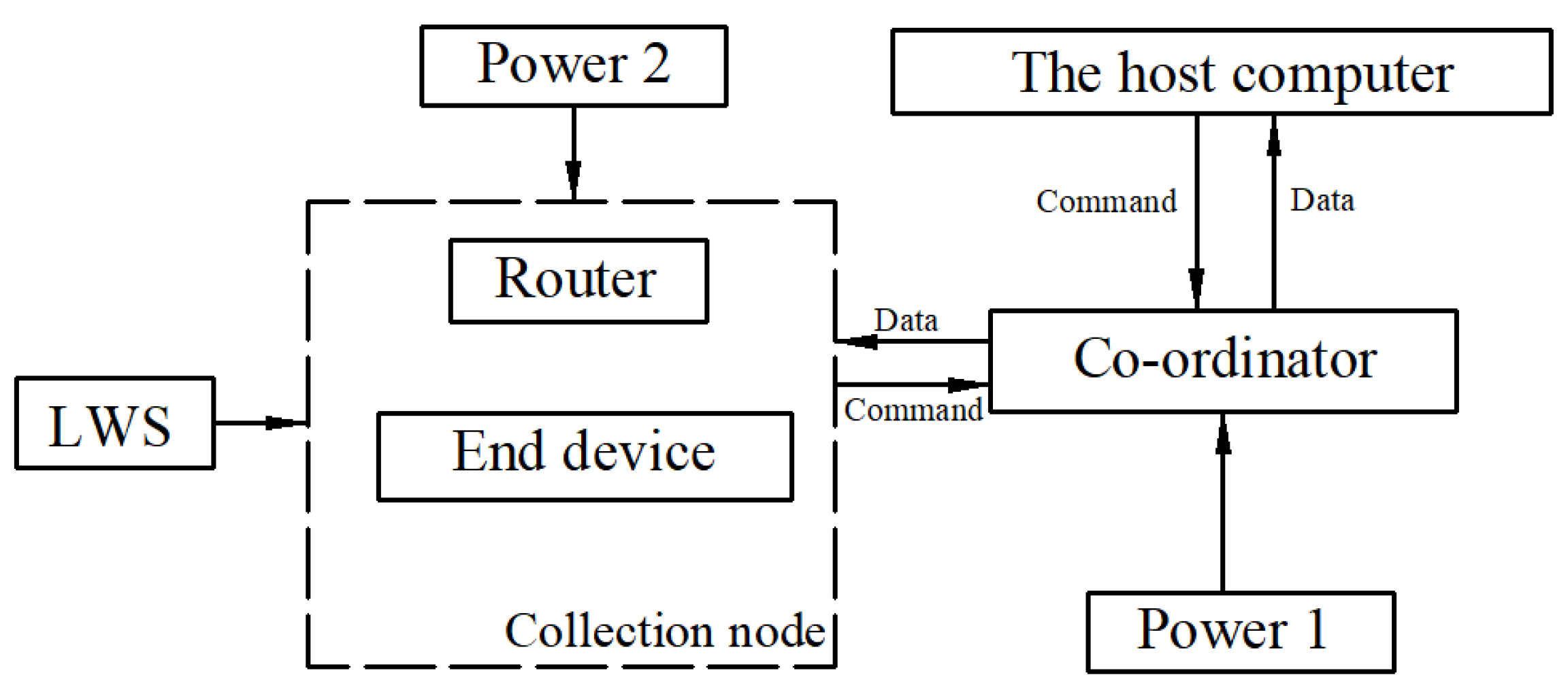

2.1. Online Measuring System

2.2. Analysis of Measuring Spray Coverage and Deposition Quality Based on LWS

2.3. Experimental Design

2.3.1. Calibration Tests Design

2.3.2. Homogeneity Check of the Measuring System

2.3.3. Outdoor Tests

2.4. Data Processing

2.4.1. Variation Coefficient Calculation

2.4.2. Spray Coverage Processing

3. Results

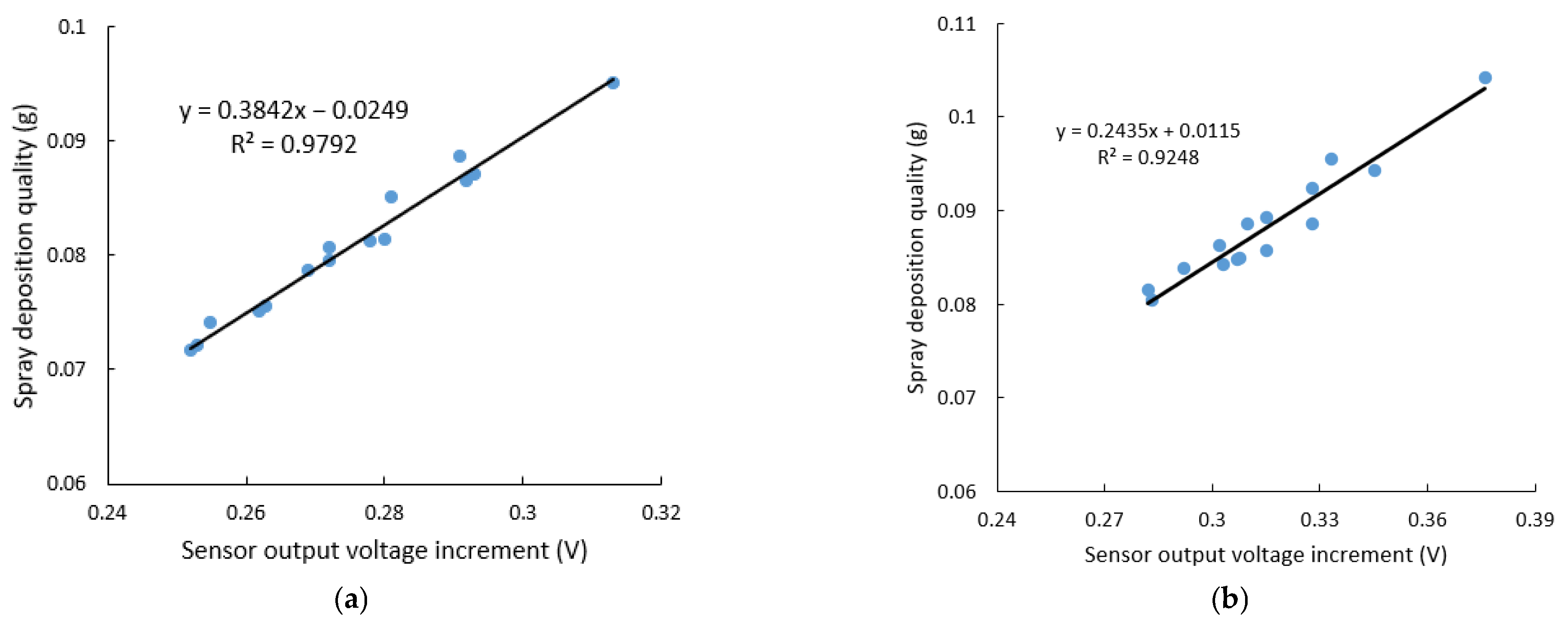

3.1. Calibration Curve

3.2. Homogeneity Check Results

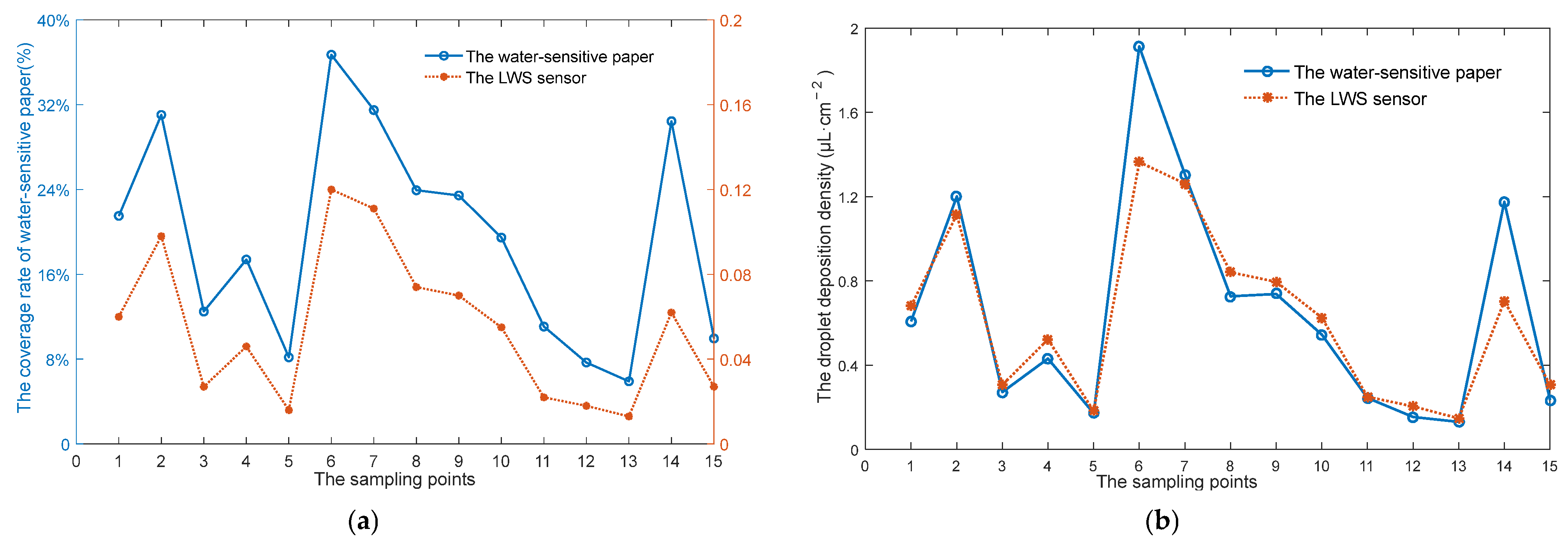

3.3. Outdoor Test Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chahal, G.S.; Jordan, D.L.; Brandenburg, R.L.; Shew, B.B.; Burton, J.D.; Danehower, D.; York, A.C. Interactions of agrochemicals applied to peanut; part 3: Effects on insecticides and prohexadione calcium. Crop Prot. 2012, 41, 150–157. [Google Scholar] [CrossRef]

- Zhang, C.; Shi, G.; Shen, J.; Rui-Fa, H.U. Productivity effect and overuse of pesticide in crop production in China. J. Integr. Agric. 2015, 14, 1903–1910. [Google Scholar] [CrossRef]

- Wu, S.; Liu, J.; Wang, J.; Hao, D.; Wang, R. The Motion of Strawberry Leaves in an Air-Assisted Spray Field and its Influence on Droplet Deposition. Trans. ASABE 2021, 64, 83–93. [Google Scholar] [CrossRef]

- Sánchez-Hermosilla, J.; Páez, F.; Rincón, V.J.; Carvajal, F. Evaluation of the effect of spray pressure in hand-held sprayers in a greenhouse tomato crop. Crop Prot. 2013, 54, 121–125. [Google Scholar] [CrossRef]

- Appah, S.; Jia, W.; Ou, M.; Wang, P.; Asante, E.A. Analysis of potential impaction and phytotoxicity of surfactant-plant surface interaction in pesticide application. Crop Prot. 2020, 127, 104961. [Google Scholar] [CrossRef]

- Zhu, H.; Yu, Y.; Ozkan, H.E.; Derksen, R.C.; Krause, C.R. Influence of spray additives on droplet evaporation and residual patterns on wax and wax-free surfaces. In Proceedings of the 2008 ASABE Annual International Meeting, Providence, RI, USA, 29 June–2 July 2008. Paper No. 083752. [Google Scholar]

- Fox, R.D.; Derksen, R.C.; Cooper, J.A.; Krause, C.R.; Ozkan, H.E. Visual and image system measurement of spray deposits using water-sensitive paper. Appl. Eng. Agric. 2003, 19, 549. [Google Scholar]

- Hoffmann, W.C.; Hewitt, A.J. Comparison of three imaging systems for water-sensitive papers. Appl. Eng. Agric. 2005, 21, 961–964. [Google Scholar] [CrossRef]

- Zhu, H.; Salyani, M.; Fox, R.D. A portable scanning system for evaluation of spray deposit distribution. Comput. Electron. Agric. 2011, 76, 38–43. [Google Scholar] [CrossRef]

- Cunha, J.P.A.R.; Farnese, A.C.; Olivet, J.J. Computer programs for analysis of droplets sprayed on water sensitive papers. Planta Daninha 2013, 31, 715–720. [Google Scholar] [CrossRef] [Green Version]

- Fritz, B.K.; Hoffmann, W.C.; Jank, P. A fluorescent tracer method for evaluating spray transport and fate of field and laboratory spray applications. J. ASTM Int. 2011, 8, 1–9. [Google Scholar] [CrossRef]

- Hoffmann, W.C.; Kirk, I.W. Spray deposition and drift from two “medium” nozzles. Trans. ASAE 2005, 48, 5–11. [Google Scholar] [CrossRef]

- Salyani, M.; Serdynski, J. Development of a sensor for spray deposition assessment. Trans. ASAE 1990, 33, 1464. [Google Scholar] [CrossRef]

- Crowe, T.G.; Downey, D.; Giles, D.K. Digital device and technique for sensing distribution of spray deposition. Trans. ASAE 2005, 48, 2085–2093. [Google Scholar] [CrossRef]

- Melissa, A.; Joe, D.; Michael, P. Development and Preliminary Evaluation of a Spray Deposition Sensing System for Improving Pesticide Application. Sensors 2015, 15, 31965–31972. [Google Scholar]

- Wang, P.; Yu, W.; Ou, M.; Gong, C.; Jia, W. Monitoring of the Pesticide Droplet Deposition with a Novel Capacitance Sensor. Sensors 2019, 19, 537. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.; Chen, L.; Lan, Y.B.; Xu, G.; Kan, J.; Zhang, D. Development of a Deposit Sensing System for Aerial Spraying Application. Trans. Chin. Soc. Agric. Mach. 2014, 45, 123–127. [Google Scholar]

- Sun, C.; Qiu, W.; Ding, W.; Gu, J. Design and Experiment of a Real-Time Droplet Accumulating Mass Measurement System. Trans. ASABE 2017, 60, 615–624. [Google Scholar] [CrossRef]

- Wu, Y.; Qi, L.; Zhang, Y.; Elizabeth, M.; Li, S.; Cheng, Z. Design and test of real-time monitoring of droplet evaporation system based on standing wave and ZigBee. Trans. Chin. Soc. Agric. Eng. 2017, 33, 128–135. [Google Scholar]

- Wu, Y.; Qi, L.; Zhang, Y.; Gao, C.; Li, S.; Elizabeth, M. Design and experiment of pesticide droplet deposition detection system based on principle of standing wave ratio. Trans. Chin. Soc. Agric. Eng. 2017, 33, 64–71. [Google Scholar]

- Foqué, D.; Dekeyser, D.; Langenakens, J.; Nuyttens, D. Evaluating the usability of a leaf wetness sensor as a spray tech monitoring tool. Int. Adv. Pestic. Appl. 2018, 137, 191–200. [Google Scholar]

- Wei, Y.; Ziyuan, H.; Minzan, L.; Xu, Z. Detecting System Design of Droplet Deposition on Fruit Leaves. Trans. Chin. Soc. Agric. Mach. 2017, 48, 8–14. [Google Scholar]

- Nansen, C.; Ferguson, J.C.; Moore, J.; Groves, L.; Emery, R.; Garel, N.; Hewitt, A. Optimizing pesticide spray coverage using a novel web and smartphone tool, SnapCard. Agron. Sustain. Dev. 2015, 35, 1075–1085. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, R.; Chen, L. Assessing the Ability of Image Processing Methods of Droplets Sprayed on Water Sensitive Papers for Aerial Application; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Cunha, M.; Carvalho, C.; Marcal, A.R.S. Assessing the ability of image processing software to analyse spray quality on water-sensitive papers used as artificial targets. Biosyst. Eng. 2012, 111, 11–23. [Google Scholar] [CrossRef] [Green Version]

- Sama, M.P.; Weiss, A.M.; Benedict, E.K. Validating Spray Coverage Rate Using Liquid Mass on a Spray Card. Trans. ASABE 2018, 61, 887–895. [Google Scholar] [CrossRef]

- Yunyan, L.; Chuangrong, H. Experiment Design and Data Processing; Chemical Industry Press: Beijing, China, 2014; p. 257. [Google Scholar]

- Özlüoymak, Ö.B.; Bolat, A. Development and assessment of a novel imaging software for optimizing the spray parameters on water-sensitive papers-sciencedirect. Comput. Electron. Agric. 2020, 168, 105104. [Google Scholar] [CrossRef]

- Utstumo, T.; Urdal, F.; Brevik, A.; Dørum, J.; Netland, J.; Overskeid, Ø.; Berge, T.W.; Gravdahl, J.T. Robotic in-row weed control in vegetables. Comput. Electron. Agric. 2018, 154, 36–45. [Google Scholar] [CrossRef]

- Longworth, L.; Post, S.; Jermy, M.; Hendrickson, H.; Steel, J.; Cannon, E.; Brown, S. Evaluating capacitive wetness sensors for measuring deposition in electrostatically charged spraying operations-ScienceDirect. Comput. Electron. Agric. 2020, 179, 105829. [Google Scholar] [CrossRef]

- Thacker, J.R.M.; Hall, F.R. The effects of drop size and formulation upon the spread of pesticide droplets impacting on water-sensitive papers. J. Environ. Sci. Health Part B 1991, 26, 631–651. [Google Scholar] [CrossRef]

- Yu, Y.; Zhu, H.; Frantz, J.M.; Reding, M.E.; Chan, K.C.; Ozkan, H.E. Evaporation and coverage area of pesticide droplets on hairy and waxy leaves. Biosyst. Eng. 2009, 104, 324–334. [Google Scholar] [CrossRef]

- Zhu, H.; Yu, Y.; Ozkan, H.E. Influence of spray formulation and leaf surface structures on droplet evaporation and wetted area. Asp. Appl. Biol. 2010, 99, 333–340. [Google Scholar]

| Group Number | Nozzle Type | Flow Rate (MPa) | Test Type |

|---|---|---|---|

| 1 | Lechler ST110−03 | 0.3 | A |

| 2 | Lechler ST110−03 | 0.4 | A |

| 3 | Lechler ST110−01 | 0.3 | B |

| 4 | Lechler ST110−03 | 0.3 | B |

| 5 | Lechler ST110−03 | 0.4 | B |

| Group Number | Fα (1, n − 2) | Significance | |

|---|---|---|---|

| 1 | 4069.32 | 9.07 | ** |

| 2 | 2584.75 | 9.07 | ** |

| Group Number | Fα (1, n − 2) | Significance | |

|---|---|---|---|

| 3 | 90.33 | 9.07 | ** |

| 4 | 1654.60 | 9.07 | ** |

| 5 | 1213.25 | 9.07 | ** |

| Test Number | Coefficient of Variation | Relative Error | |

|---|---|---|---|

| Measuring System | Weighing | ||

| 1 | 4.92% | 4.80% | 0.12% |

| 2 | 7.35% | 7.16% | 0.19% |

| 3 | 7.06% | 6.95% | 0.11% |

| 4 | 4.11% | 3.95% | 0.16% |

| 5 | 5.88% | 5.61% | 0.27% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, S.; Wang, M.; Ou, M.; Zhou, H.; Jia, W.; Gao, R.; Wang, C.; Wang, G.; Li, Z.; Chen, H. Development and Experiment of an Online Measuring System for Spray Deposition. Agriculture 2022, 12, 1195. https://doi.org/10.3390/agriculture12081195

Dai S, Wang M, Ou M, Zhou H, Jia W, Gao R, Wang C, Wang G, Li Z, Chen H. Development and Experiment of an Online Measuring System for Spray Deposition. Agriculture. 2022; 12(8):1195. https://doi.org/10.3390/agriculture12081195

Chicago/Turabian StyleDai, Shiqun, Ming Wang, Mingxiong Ou, Huitao Zhou, Weidong Jia, Ronghua Gao, Chenyang Wang, Guanqun Wang, Ziyu Li, and Hong Chen. 2022. "Development and Experiment of an Online Measuring System for Spray Deposition" Agriculture 12, no. 8: 1195. https://doi.org/10.3390/agriculture12081195

APA StyleDai, S., Wang, M., Ou, M., Zhou, H., Jia, W., Gao, R., Wang, C., Wang, G., Li, Z., & Chen, H. (2022). Development and Experiment of an Online Measuring System for Spray Deposition. Agriculture, 12(8), 1195. https://doi.org/10.3390/agriculture12081195