Design of Rice Straw Fiber Crusher and Evaluation of Fiber Quality

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Materials and Equipment

2.2. Design and Simulation of Straw Fiber Crusher

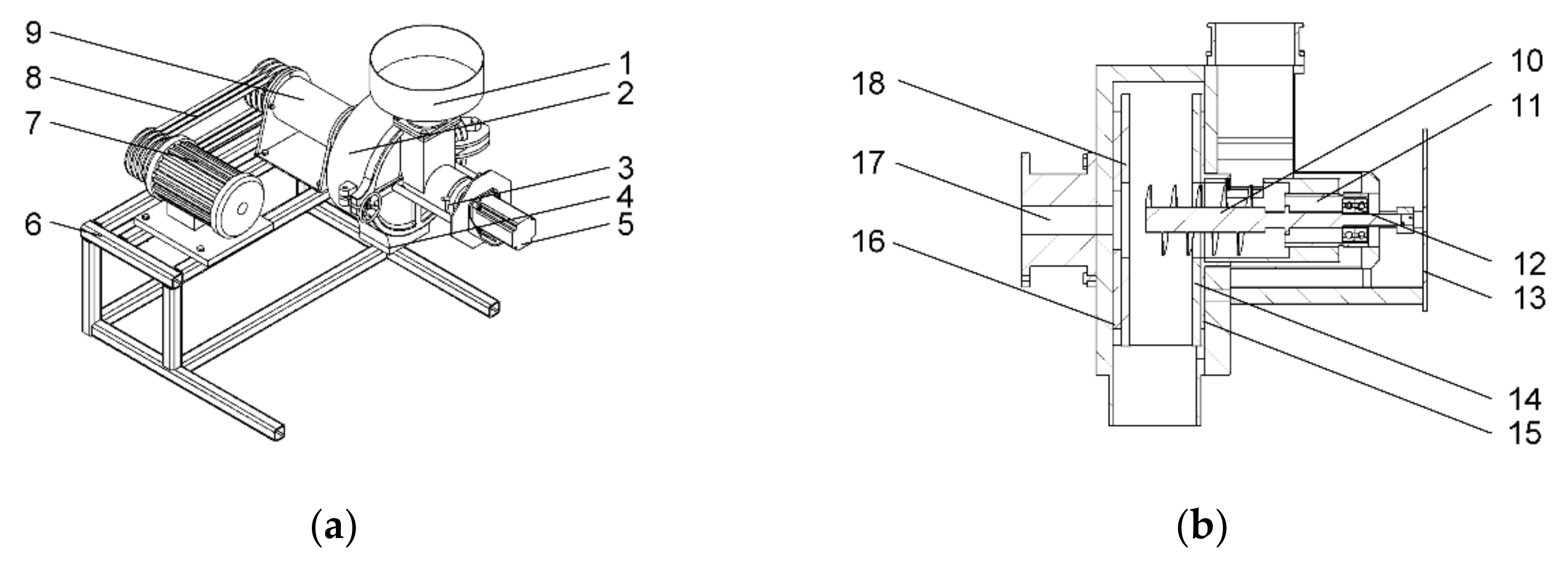

2.2.1. Overall Design of Straw Fiber Crusher

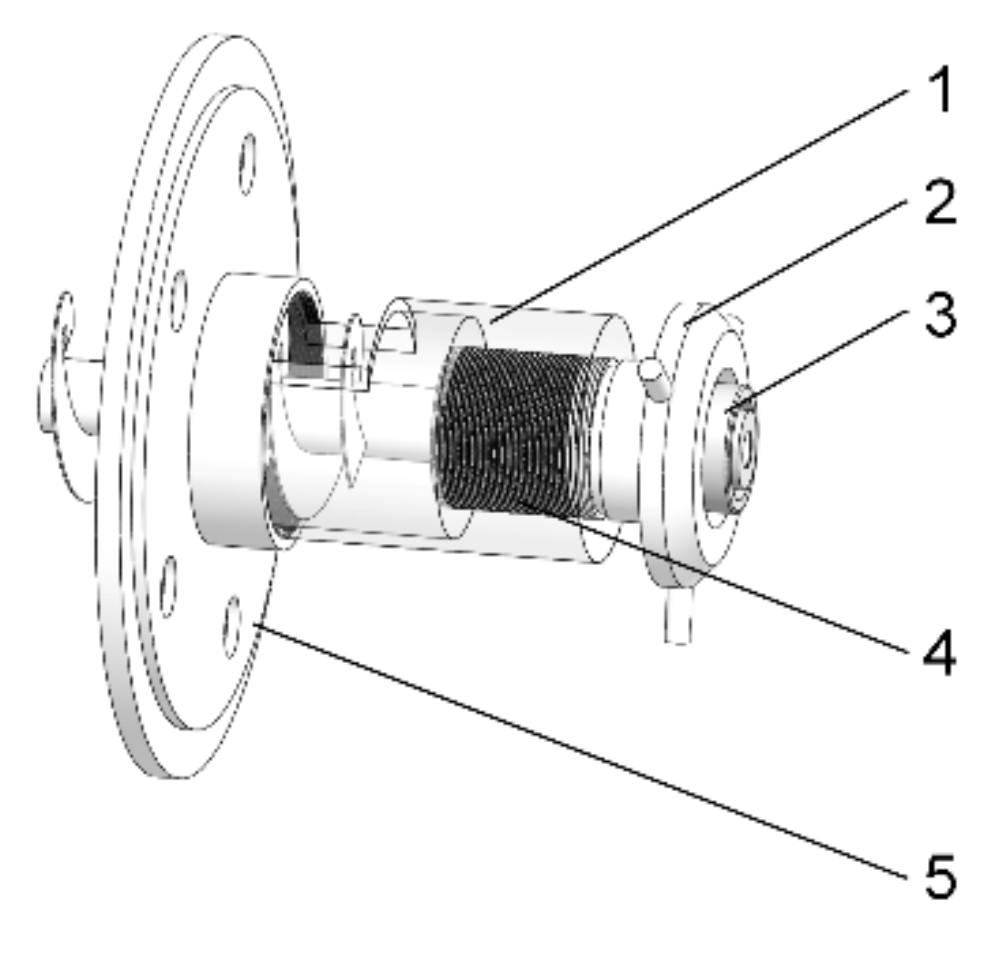

2.2.2. Design of Grinding Wheel Clearance Adjustment Device

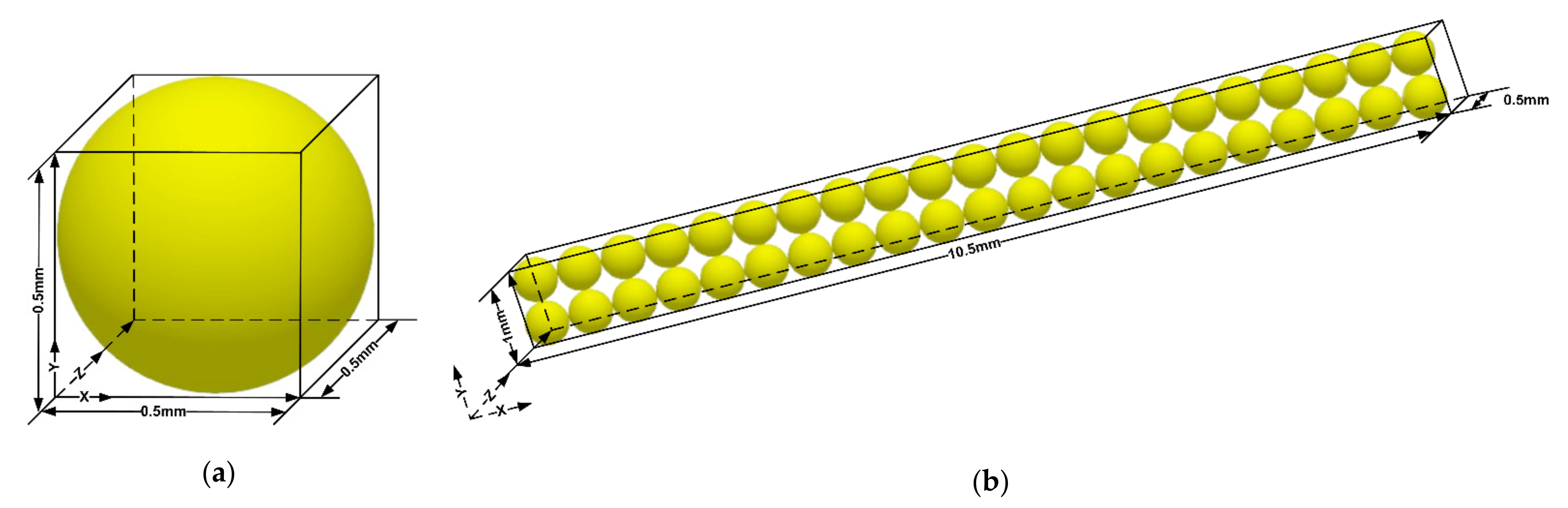

2.2.3. Construction of the Simulation Model

2.3. Straw Fiber Prepartion and Test Procedure

2.4. Selection of Experimental Factors

2.5. Straw Fiber Evaluation Method

2.5.1. Straw Fiber Tensile Index

- Y is tensile strength index, N·m·g−1;

- F is pattern tensile strength, N;

- Ls is pattern width, cm;

- s is pattern thickness, cm;

- g is volumetric weight, g/cm3.

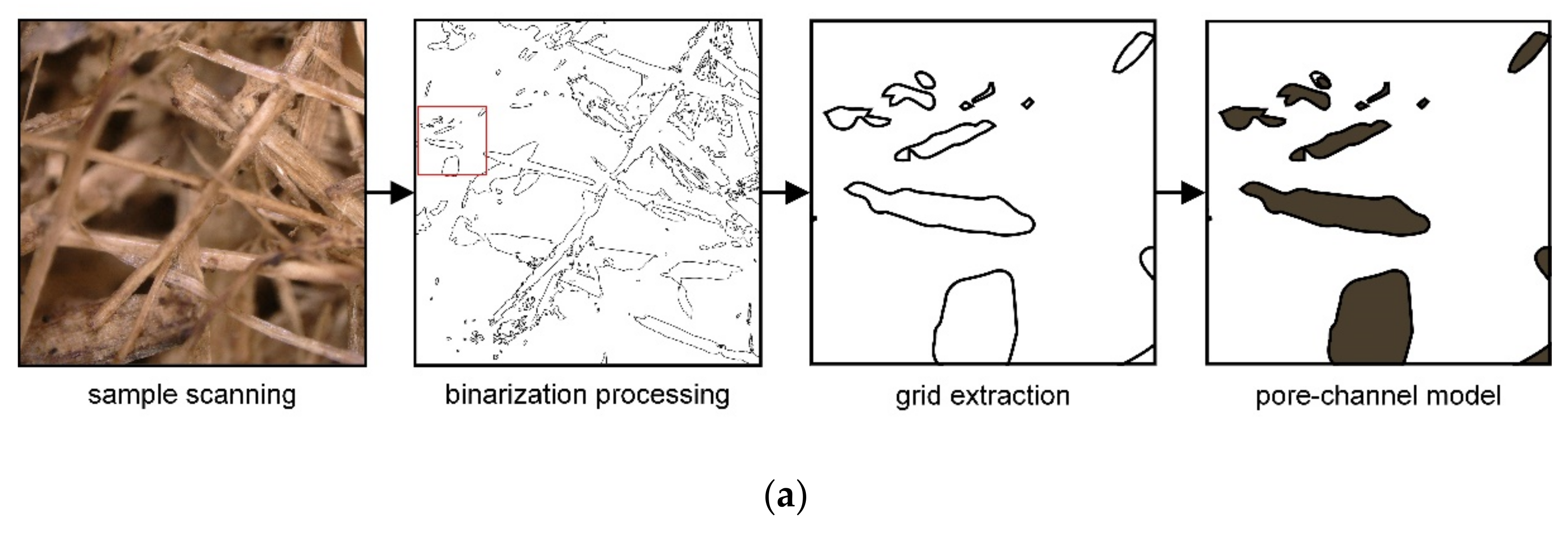

2.5.2. Straw Fiber Pore Channel Coefficient Ratio

- P is specimen pore coefficient ratio;

- St is specimen image area, cm2;

- Sp is pore area of specimen, cm2.

3. Results and Analysis

3.1. Simulation Analysis of Straw Fiber Crushing Process

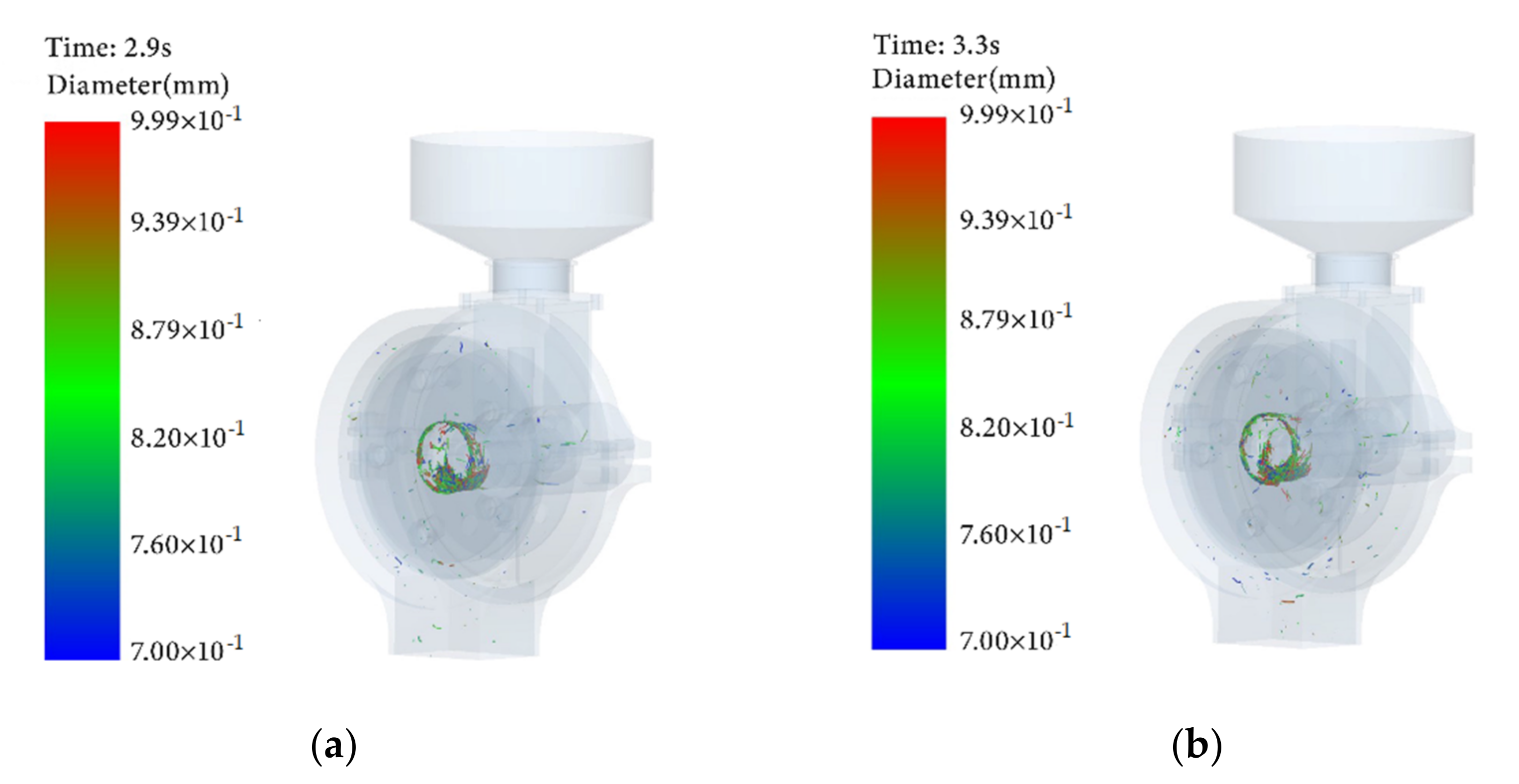

3.1.1. Particle Distribution during Straw Fiber Crushing

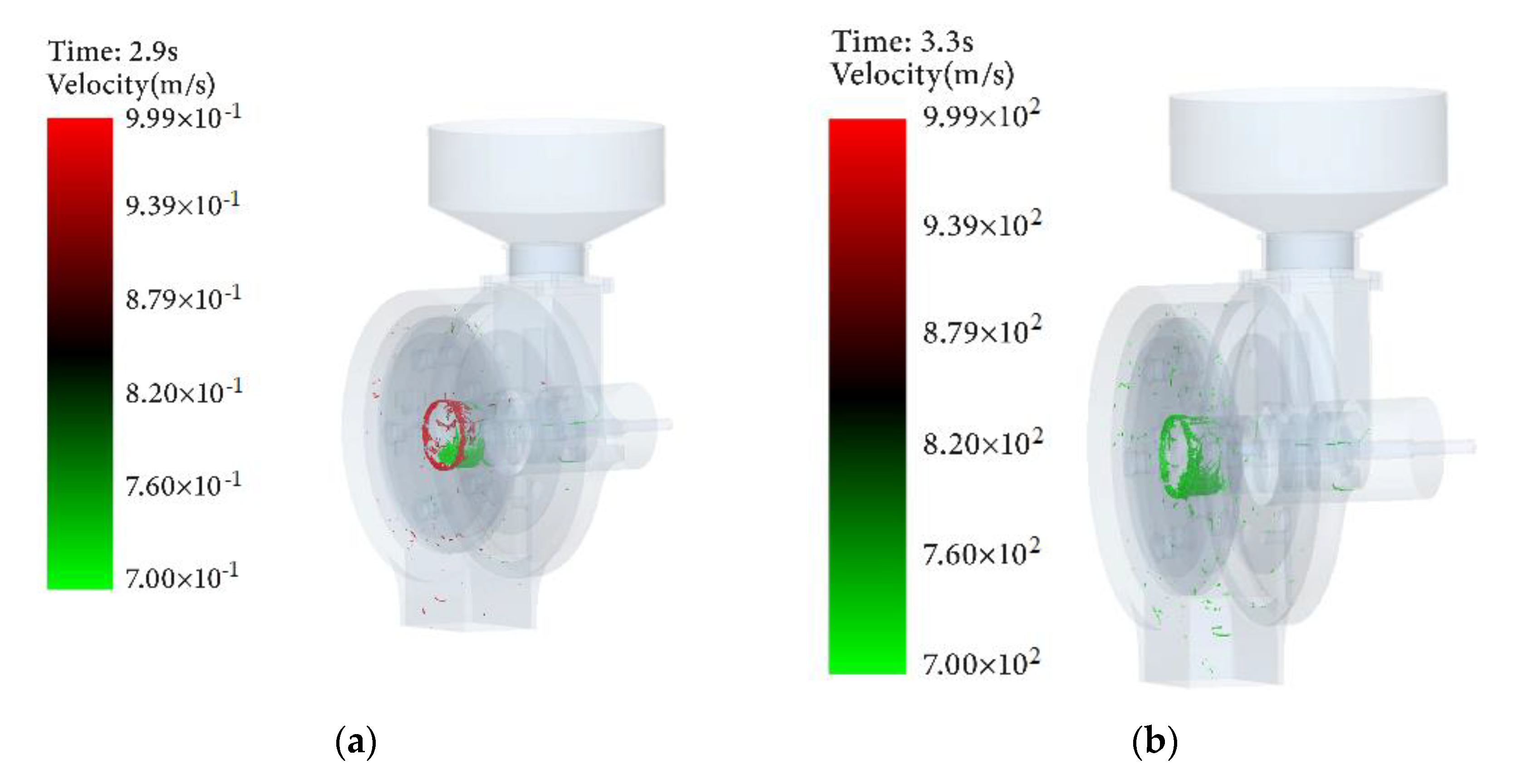

3.1.2. Particle Velocity Distribution during Straw Fiber Crushing

3.2. Straw Fiber Crushing Test Results and Analysis

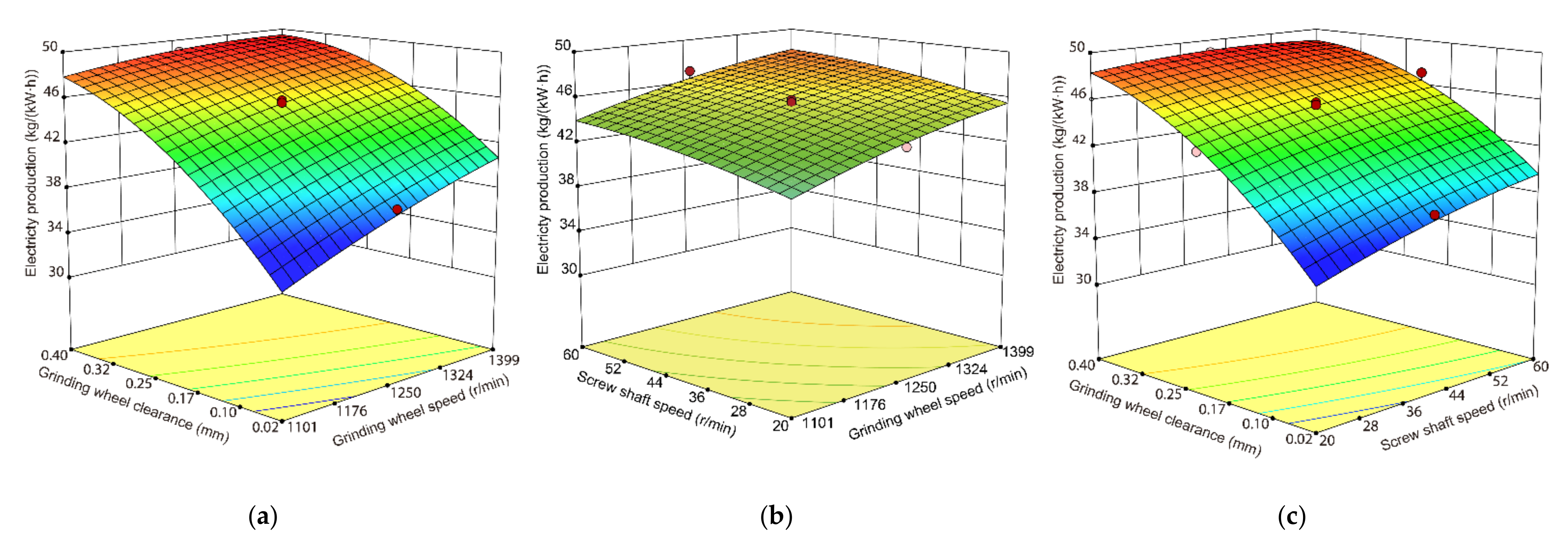

3.2.1. Experimental Results and Analysis of Power Output in kW·h

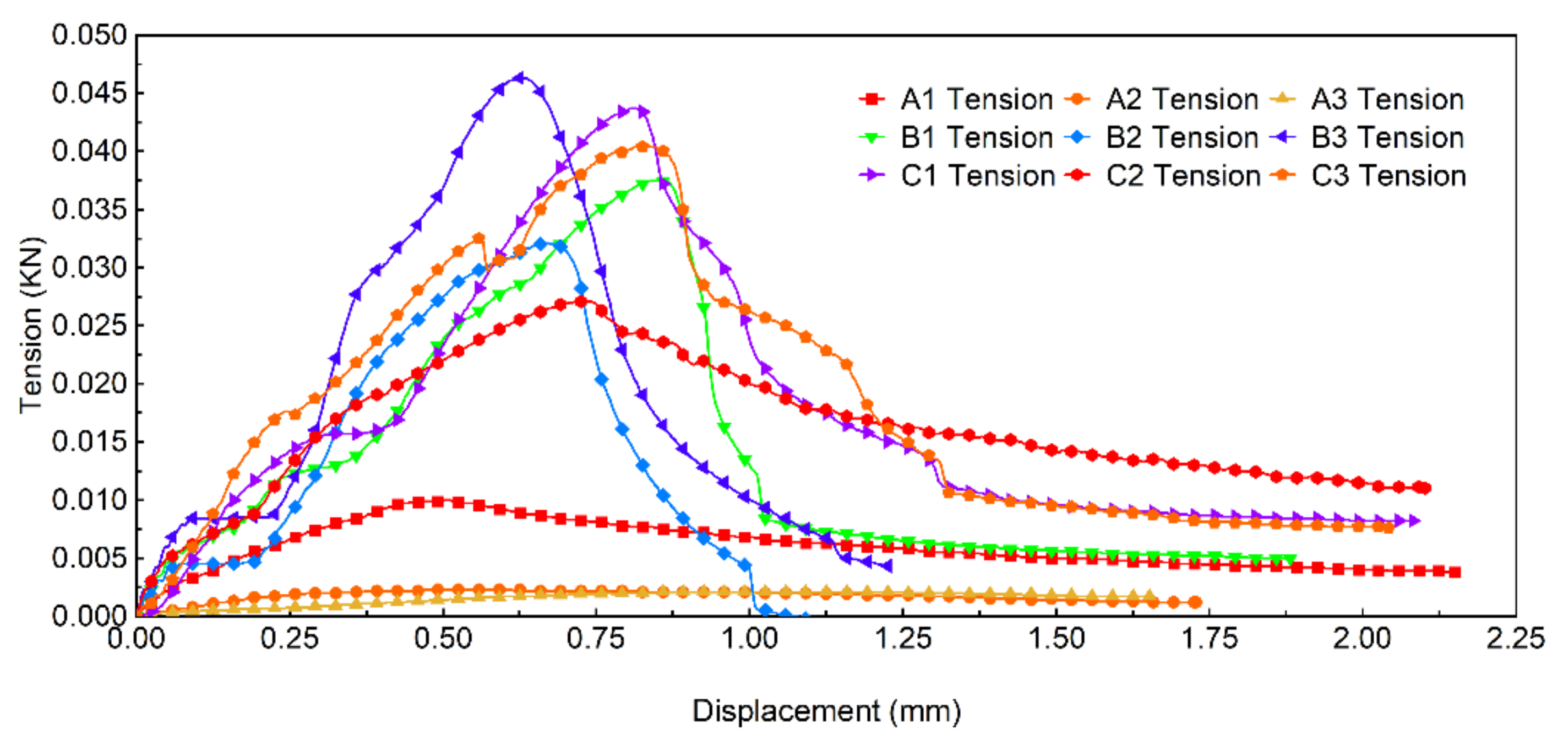

3.2.2. Experimental Results and Analysis of Tensile Index of Straw Fiber

3.2.3. Experimental Optimization and Validation

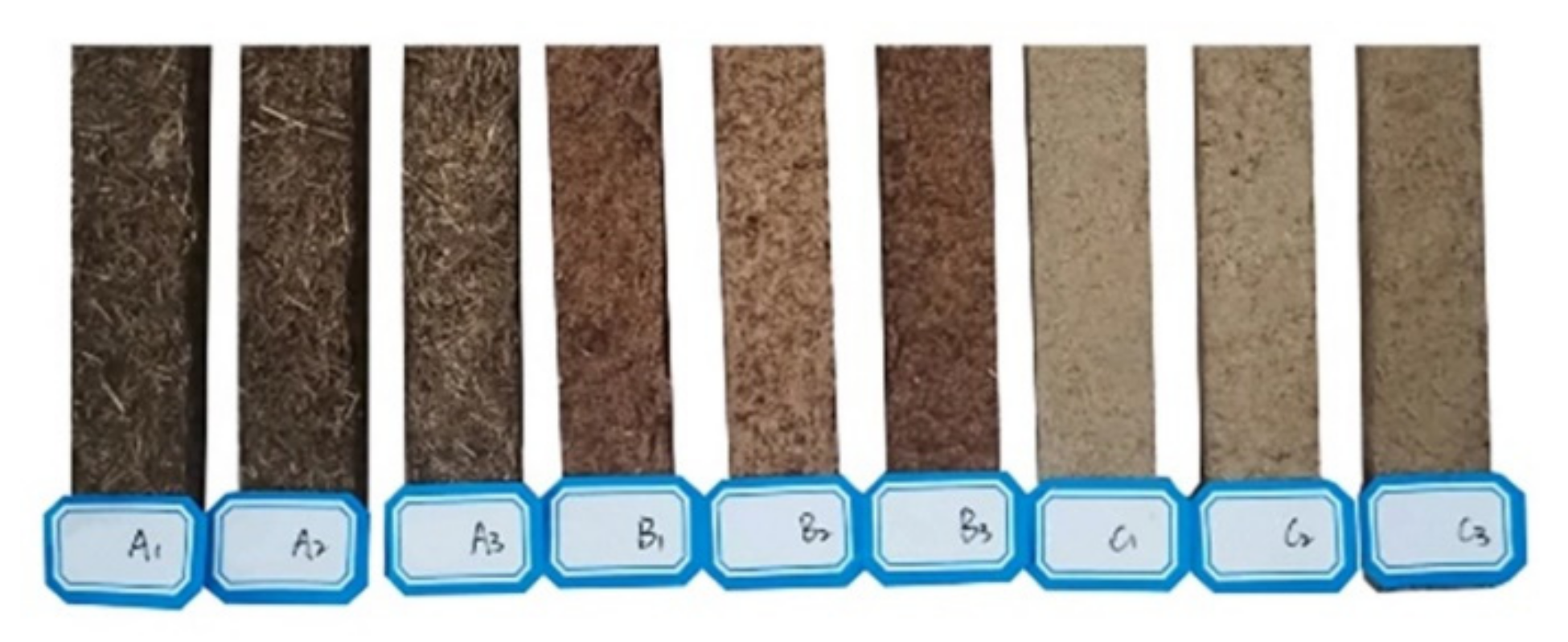

3.3. Straw Fiber Quality Evalution Analysis

3.3.1. Effect of Straw Fiber Tensile Index on Fiber Quality

3.3.2. Effect of Pore Channel Coefficient Ratio on Fiber Quality

4. Discussion

5. Conclusions

- (1)

- Through SOLIDWORKS software modeling and discrete element simulation, the designed straw fiber crusher principle is feasible, the structure is reasonable, and the straw can be prepared after straw soaking. Through the Central Composite experimental design of grinding wheel speed, spiral feed shaft speed, and grinding wheel clearance, the best parameters for the kW·h output and straw fiber quality are optimized as follows: a grinding wheel speed of 1250 r·min−1, a screw feed shaft speed of 40 r·min−1, a grinding wheel clearance of 0.21 mm. The power output reached 45.8 kg/(kW·h), and the obtained straw fiber tensile index could reach 112.5 N·m·g−1.

- (2)

- The response surface analysis of straw fiber crushing showed that the interaction of grinding wheel speed, screw feed shaft speed, and grinding wheel clearance had a significant effect on the kW·h output of the machine, in which the grinding wheel speed and grinding wheel clearance were the key factors to determine the kW·h output of the device. In contrast, the quality of straw fiber showed a strong correlation directly with the grinding wheel clearance, without interaction.

- (3)

- The specimen was scanned through the section image, MATLAB image binarization processing, grid extraction, local magnification, and other methods to establish the pore channel model and the relationship between the basis model pore channel coefficient ratio and the straw fiber specimen tensile index, proving that the technique of pressing the straw fiber into specimens to test the tensile index to evaluate the quality of straw fiber is feasible and reliable. The method is simple and easy to operate.

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ren, J.Q.; Yu, P.X.; Xu, X.H. Straw Utilization in China-Status and Recommendations. Sustainability 2019, 11, 1762. [Google Scholar] [CrossRef] [Green Version]

- Ginni, G.; Kavitha, S.; Kannah, R.Y.; Bhatia, S.K.; Kumar, S.A.; Rajkumar, M.; Kumar, G.; Pugazhendhi, A.; Chi, N.T.L.; Banu, J.R. Valorization of Agricultural Residues: Different Biorefinery Routes. J. Environ. Chem. Eng. 2021, 9, 4. [Google Scholar] [CrossRef]

- Li, L.X.; Wang, C.; Zhang, X.Y.; Li, G.Y. Improvement and Optimization of Preparation Process of Seedling-Growing Bowl Tray Made of Paddy Straw. Int. J. Agric. Biol. Eng. 2014, 7, 13–22. [Google Scholar] [CrossRef]

- Zhang, S.C. Study on the Preparation Process of Rice Straw Fiberboard for Packaging. In Proceedings of the International Conference on Construction, Aerotropolis, Aviation and Environmental Engineering (ICCAE), Taoyuan, Taiwan, 12–25 November 2019. [Google Scholar]

- Rossi, G.; Conti, L.; Fiorineschi, L.; Marvasi, M.; Monti, M.; Rotini, F.; Togni, M.; Barbari, M. A New Eco-Friendly Packaging Material Made of Straw and Bioplastic. J. Agric. Eng. 2020, 51, 185–191. [Google Scholar] [CrossRef]

- Dahy, H. Efficient Fabrication of Sustainable Building Products from Annually Generated Non-Wood Cellulosic Fibres and Bioplastics with Improved Flammability Resistance. Waste Biomass Valorization 2019, 10, 1167–1175. [Google Scholar] [CrossRef]

- Jafarpour, M.; Jalalizand, A.; Eghbalsaied, S. High Fiber Media as the Most Efficient Substrates for Pleurotus Florida Culture. Arch. Biol. Sci. 2011, 63, 889–895. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Q.J.; Gao, S.; Liu, S.; Li, L.H.; Chen, H.T. Optimization of Technological Parameters of Straw Fiber-Based Plant Fiber Seedling Pot Raw Materials. Appl. Sci. 2021, 11, 7152. [Google Scholar] [CrossRef]

- Ming, X.L.; Li, Q.C.; Feng, J.L.; Jiang, W. Analysis and Optimization of Process Parameters of the Degradable Fiber Mulch Paper Made from Pineapple Leaf and Rice Straw by Response Surface Method. BioResources 2021, 16, 3454–3468. [Google Scholar] [CrossRef]

- Shi, J.Y.; Wang, G.Y. The Preparation and Performance of Biomass Cushioning Packaging Material Prepared by Sunflower Stalk Pith. In Proceedings of the International Conference of Environment Materials and Environment Management, Harbin, China, 24–25 July 2010. [Google Scholar]

- Thomsen, M.H.; Thygesen, A.; Thomsen, A.B. Hydrothermal Treatment of Wheat Straw at Pilot Plant Scale Using a Three-Step Reactor System Aiming at High Hemicellulose Recovery, High Cellulose Digestibility and Low Lignin Hydrolysis. Bioresour. Technol. 2008, 99, 4221–4228. [Google Scholar] [CrossRef]

- Periyasamy, S.; Karthik, V.; Senthil Kumar, P.S.; Isabel, J.B.; Temesgen, T.; Hunegnaw, B.M.; Melese, B.B.; Mohamed, B.A.; Vo, D.-V.N. Chemical, Physical and Biological Methods to Convert Lignocellulosic Waste into Value-Added Products. A Review. Environ. Chem. Lett. 2022, 20, 1129–1152. [Google Scholar] [CrossRef]

- Wang, Q.Q.; Zhu, Q.Q.; Xu, J.X.; Sun, J.Z. Combined Mechanical Destruction and Alkaline Pretreatment of Wheat Straw for Enhanced Enzymatic Saccharification. BioResources 2014, 9, 6841–6850. [Google Scholar] [CrossRef]

- Feng, N.J.; Fu, Y.; Wang, C.H.; Wu, Q. An Effective Modification with Mild Alkali Pretreatment for Enhancing the Biodegradation of Wheat Straw by Pycnoporus Sanguineus Nfzh-1. BioResources 2018, 13, 704–714. [Google Scholar] [CrossRef]

- Pan, M.Z.; Zhou, D.G.; Zhou, X.Y.; Lian, Z.N. Improvement of Straw Surface Characteristics Via Thermomechanical and Chemical Treatments. Bioresour. Technol. 2010, 101, 7930–7934. [Google Scholar] [CrossRef] [PubMed]

- Sun, E.H.; Zhang, Y.; Yong, C.; Qu, P.; Huang, H.Y.; Xu, Y.D. Biological Fermentation Pretreatment Accelerated the Depolymerization of Straw Fiber and Its Mechanical Properties as Raw Material for Mulch Film. J. Clean. Prod. 2021, 284, 9. [Google Scholar] [CrossRef]

- Li, B.; Chen, K.J.; Gao, X.; Zhao, C.; Shao, Q.J.; Sun, Q.; Li, H. Influence of Steam Explosion on Rice Straw Fiber Content. J. Bi-obased Mater. Bioenergy 2015, 9, 596–608. [Google Scholar] [CrossRef]

- Kellersztein, I.; Shani, U.; Zilber, I.; Dotan, A. Sustainable Composites from Agricultural Waste: The Use of Steam Explosion and Surface Modification to Potentialize the Use of Wheat Straw Fibers for Wood Plastic Composite Industry. Polym. Compos. 2019, 40, E53–E61. [Google Scholar] [CrossRef]

- Matsakas, L.; Nitsos, C.; Raghavendran, V.; Yakimenko, O.; Persson, G.; Olsson, E.; Rova, U.; Olsson, L.; Christakopoulos, P. A Novel Hybrid Organosolv: Steam Explosion Method for the Efficient Fractionation and Pretreatment of Birch Biomass. Biotechnol. Biofuels 2018, 11, 160. [Google Scholar] [CrossRef]

- Han, G.P.; Deng, J.; Zhang, S.Y.; Bicho, P.; Wu, Q.L. Effect of Steam Explosion Treatment on Characteristics of Wheat Straw. Ind. Crop. Prod. 2010, 31, 28–33. [Google Scholar] [CrossRef]

- Cui, L.; Liu, Z.; Si, C.L.; Hui, L.F.; Kang, N.; Zhao, T. Influence of Steam Explosion Pretreatment on the Composition and Structure of Wheat Straw. BioResources 2012, 7, 4202–4213. [Google Scholar]

- Xia, W.D.; Song, J.; Tarverdi, K.; Kang, Y.G. Wheat Straw and Wheat Flour Biocomposites Prepared by Extrusion Process. J. Biobased Mater. Bioenergy 2010, 4, 172–180. [Google Scholar] [CrossRef]

- Theng, D.; Arbat, G.; Delgado-Aguilar, M.; Ngo, B.; Labonne, L.; Evon, P.; Mutje, P. Comparison between Two Different Pretreatment Technologies of Rice Straw Fibers Prior to Fiberboard Manufacturing: Twin-Screw Extrusion and Digestion Plus Defibration. Ind. Crops Prod. 2017, 107, 184–197. [Google Scholar] [CrossRef] [Green Version]

- Evon, P.; Labonne, L.; Khan, S.U.; Ouagne, P.; Pontalier, P.Y.; Rouilly, A. Twin-Screw Extrusion Process to Produce Renewable Fiberboards. J. Vis. Exp. 2021, 167, e62072. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.F.; Zhang, Y.; Cao, Y.Y.; Xiao, W.H.; Han, L.J. Effect of Ultrafine Grinding Pretreatment on the Cellulose Fibers and Nanocrystals from Wheat Straw. J. Biobased Mater. Bioenergy 2020, 14, 369–375. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, B.; Guo, L.; Kong, L.Z.; Zhao, C.; Yu, X.Z.; Luo, W.J.; Kan, Z. Performance Test and Process Parameter Optimization of 9ff Type Square Bale Straw Crusher. Int. J. Agric. Biol. Eng. 2021, 14, 232–240. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, M.Q.; Liu, F.; Tian, H.Q.; Wulan, T.Y.; Yue, Y.; Li, D.P. A Discrete Element Method Model of Corn Stalk and Its Mechanical Characteristic Parameters. BioResources 2020, 15, 9337–9350. [Google Scholar] [CrossRef]

- Chen, L.Q.; Zhang, J.Q.; Kong, X.L. Genetic Optimal Design of Straw Crusher Based on Adams. In Proceedings of the International Conference on Manufacturing Engineering and Automation, Guangzhou, China, 7–9 December 2011. [Google Scholar]

- Yang, W.; Zhao, J.F.; Liu, X.Y.; Xi, L.Q.; Liao, J. Simulation and Test of “Separated Burying Device” of Green Manure Returning Machine Based on the EDEM Software. Agriculture 2022, 12, 569. [Google Scholar] [CrossRef]

- Saeed, H.A.M.; Liu, Y.; Lucia, L.A.; Chen, H.L. Evaluation of Sudanese Sorghum and Bagasse as a Pulp and Paper Feedstock. BioResources 2017, 12, 5212–5222. [Google Scholar] [CrossRef] [Green Version]

- Kamoga, O.L.M.; Kirabira, J.B.; Byaruhanga, J.K.; Godiyal, R.D.; Anupam, K. Characterisation and Evaluation of Pulp and Paper from Selected Ugandan Grasses for Paper Industry. Cell Chem. Technol. 2016, 50, 275–284. [Google Scholar]

- Zhang, Y.; Chen, H.T.; Liu, S.; Rokayya, S.; He, Y.Y. Optimization of Process Parameters for Preparing Straw Fiber from Corn Stalk Rind. BioResources 2020, 15, 923–934. [Google Scholar] [CrossRef]

- Miao, N. Optimization Research on the D-200 Crop Straw Fiber Extruder. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2015. [Google Scholar]

| Project | Parameter |

|---|---|

| Grain density (kg/m3) | 750 |

| Density of steel (kg/m3) | 7850 |

| Particle Poisson’s ratio | 0.4 |

| Poisson’s ratio of steel | 0.3 |

| Particle shear modulus (Pa) | 1 × 106 |

| Steel shear modulus (Pa) | 1 × 1010 |

| Particle and particle recovery coefficient | 0.485 |

| Particle and steel recovery coefficient | 0.663 |

| Particle-to-particle static friction coefficient | 0.142 |

| Static friction coefficient between particles and steel | 0.526 |

| Particle-to-particle rolling friction coefficient | 0.078 |

| Coefficient of rolling friction between particles and steel | 0.419 |

| Normal stiffness coefficient (N·m−1) | 8.5 × 109 |

| Tangential stiffness coefficient (N·m−1) | 8.2 × 109 |

| Critical normal stress (Pa) | 8.1 × 108 |

| Critical tangential stress (Pa) | 8.1 × 108 |

| Bonding radius (mm) | 0.52 |

| Code Value | Grinding Wheel Speed A/(r·min−1) | Screw Shaft Speed B/(r·min−1) | Grinding Wheel Clearance C/mm |

|---|---|---|---|

| −1.682 | 1000 | 20 | 0.02 |

| −1 | 1101 | 28 | 0.10 |

| 0 | 1250 | 40 | 0.21 |

| 1 | 1399 | 52 | 0.32 |

| 1.682 | 1500 | 60 | 0.40 |

| Number | Grinding Wheel Speed A/(r·min−1) | Screw Shaft Speed B/(r·min−1) | Grinding Wheel Clearance C/(mm) | Electricity Production Y1/(kg/(kW·h)) |

|---|---|---|---|---|

| 1 | 1250 | 40 | 0.21 | 45.2 |

| 2 | 1250 | 40 | 0.21 | 45.8 |

| 3 | 1000 | 40 | 0.21 | 40.6 |

| 4 | 1250 | 40 | 0.21 | 45.3 |

| 5 | 1250 | 20 | 0.21 | 43.3 |

| 6 | 1250 | 40 | 0.21 | 45.4 |

| 7 | 1250 | 40 | 0.40 | 48.9 |

| 8 | 1399 | 52 | 0.32 | 49.1 |

| 9 | 1101 | 28 | 0.32 | 46.1 |

| 10 | 1101 | 52 | 0.10 | 38.8 |

| 11 | 1101 | 28 | 0.10 | 36.5 |

| 12 | 1101 | 52 | 0.32 | 46.5 |

| 13 | 1500 | 40 | 0.21 | 48.2 |

| 14 | 1399 | 28 | 0.32 | 48.6 |

| 15 | 1250 | 40 | 0.02 | 38.2 |

| 16 | 1250 | 40 | 0.21 | 45.6 |

| 17 | 1250 | 60 | 0.21 | 47.1 |

| 18 | 1399 | 28 | 0.10 | 42.6 |

| 19 | 1399 | 52 | 0.10 | 44.2 |

| 20 | 1250 | 40 | 0.21 | 45.8 |

| Source | Sum of Squares | Degrees of Freedom | Mean Square Error | F Value | p Value |

|---|---|---|---|---|---|

| model | 245.17 | 9 | 27.24 | 131.83 | <0.0001 |

| A | 63.21 | 1 | 63.21 | 305.89 | <0.0001 |

| B | 9.17 | 1 | 9.17 | 44.38 | <0.0001 |

| C | 156.26 | 1 | 156.26 | 756.16 | <0.0001 |

| AB | 0.0450 | 1 | 0.0450 | 0.2178 | 0.6508 |

| AC | 5.12 | 1 | 5.12 | 24.78 | 0.0006 |

| BC | 1.13 | 1 | 1.13 | 5.44 | 0.0418 |

| A2 | 2.93 | 1 | 2.93 | 14.16 | 0.0037 |

| B2 | 0.4057 | 1 | 0.4057 | 1.96 | 0.1914 |

| C2 | 8.13 | 1 | 8.13 | 39.35 | <0.0001 |

| Residual | 2.07 | 10 | 0.2066 | - | - |

| Loss of quasi item | 1.74 | 5 | 0.3476 | 5.29 | 0.0457 |

| Pure error | 0.3283 | 5 | 0.0657 | - | - |

| Aggregate | 247.24 | 19 | - | - | - |

| Source | Sum of Squares | Degrees of Freedom | Mean Square Error | F Value | p Value |

|---|---|---|---|---|---|

| model | 7702.54 | 3 | 2567.51 | 21.81 | <0.0001 |

| A | 28.60 | 1 | 28.60 | 0.2430 | 0.6288 |

| B | 12.76 | 1 | 12.76 | 0.1084 | 0.7463 |

| C | 7661.18 | 1 | 7661.18 | 65.09 | <0.0001 |

| residual | 1883.26 | 16 | 117.70 | - | - |

| Loss of quasi item | 1260.15 | 11 | 114.56 | 0.9193 | 0.5809 |

| Pure error | 623.11 | 5 | 124.62 | - | - |

| aggregate | 9585.80 | 19 | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Q.; Wang, J.; Liu, K.; Chao, J.; Liu, D. Design of Rice Straw Fiber Crusher and Evaluation of Fiber Quality. Agriculture 2022, 12, 729. https://doi.org/10.3390/agriculture12050729

Cheng Q, Wang J, Liu K, Chao J, Liu D. Design of Rice Straw Fiber Crusher and Evaluation of Fiber Quality. Agriculture. 2022; 12(5):729. https://doi.org/10.3390/agriculture12050729

Chicago/Turabian StyleCheng, Qian, Jiaxin Wang, Kun Liu, Junqi Chao, and Dejun Liu. 2022. "Design of Rice Straw Fiber Crusher and Evaluation of Fiber Quality" Agriculture 12, no. 5: 729. https://doi.org/10.3390/agriculture12050729

APA StyleCheng, Q., Wang, J., Liu, K., Chao, J., & Liu, D. (2022). Design of Rice Straw Fiber Crusher and Evaluation of Fiber Quality. Agriculture, 12(5), 729. https://doi.org/10.3390/agriculture12050729