Abstract

Waste management is a current and transversal problem in all production areas, including agriculture. Within this economic activity, wine production generates a large amount of waste, namely, that resulting from the winemaking activity itself, such as pomace and grape stalks, and waste resulting from the management of the vineyards, with operations such as vine pruning. The management of vine pruning residuals has traditionally been conducted by burning leftovers on-site, without any use for the energy produced. This research analyzed the potential for the valorization of residual biomass resulting from vine pruning by creating a business model based on value chains of local scale. For this analysis, several samples of residues resulting from the “Loureiro” vine variety planted in Ponte de Lima (northern Portugal) were collected and characterized. The objective of the small-scale business model created, in addition, to solving the environmental problems related to the disposal of waste from agricultural activities, a value chain can be established, contributing to increasing the income of the farmers while introducing a circular bioeconomy and sustainable rural development practices.

1. Introduction

The increasing demand for food products and other basic resources by a growing population has led to the intensification of agricultural and industrial activities []. Several studies have focused on this topic, highlighting the issue of waste products as a result of this intensification of agricultural and industrial activity, and its subsequent consumption [,,]. Tripathi et al. stated that agricultural waste is a burgeoning problem because their disposal, utilization and management practices are not efficiently or universally applied []. It is, therefore, a problem that can even exacerbate the worse consequences of the practices traditionally in use in the regions where these residues are produced. The same authors mentioned that, in many countries and regions, the current practices consist of these wastes being left in the fields to decompose or be burnt, resulting in significant environmental impacts, without any compensation for the release of greenhouse gases. In this way, all the practices that can contribute to avoiding the continuation of these traditional methods help to mitigate the negative impacts resulting from less sustainable waste from agricultural activity management practices [,,].

Over time, with technological evolutions, several methods have been applied as a way of valuing residual biomass []. The success rate of these practices is closely related, firstly, to the degree of maturity of the technologies used, which, due to the fact of them being more or less robust, may allow greater efficiency in the waste disposal process, and, secondly, to the heterogeneity of the waste to be processed []. Biomass waste, whether being of agricultural origin, from forest management operations, or even from the organic fraction of urban waste, has such a great diversity that its management using a single process becomes very difficult [,]. In this way, for example, processes such as anaerobic digestion are very efficient for the recovery of residues rich in cellulosic materials, whereas on the other hand, fermentation is more efficient when the residues have a large amount of carbon hydrates [,]. However, none of these processes are efficient when the residues are rich in lignin, as is the case, for example, of residues resulting from the pruning of fruit orchards, such as vineyards [,].

These woody biomasses have traditionally been valued through technologically more straightforward methods, such as combustion, but also through processes such as pyrolysis, with the production of biochar [,]. Although currently, both combustion and pyrolysis are processes standard in an industrial environment and considered advanced technology, their use dates back to ancient times []. Combustion is the oldest form of energy recovery that humanity has at its disposition, dating back to the times of Homo erectus, whereas the production of biochar, through an organized and intentionally carried out process, dates back at least to Ancient Egypt [,,]. Thus, and because there is such a long history of the use and recovery of woody waste through these processes, they continue to be the most used for the disposal, recovery and management of woody waste [].

The residues resulting from pruning operations in vineyards are a problem that presents some constraints for its resolution, mainly by the dispersion of materials, if this pruning operation is not planned correctly. For example, if since the early beginning of the operation, there is an aggregation of the materials that later facilitates the collection, or if the collection is carried out at the precise moment of the cut [,], when this logistical issue is overcome, the processes of valorization of vine pruning are diverse and have already been widely studied previously [,,,,,]. The potential to recover this type of waste is high, allowing great flexibility in its use, depending only on the intended final objective and the quantities available. The use of more complex processes, from a biorefinery perspective, to obtain products with higher added value allows, on the one hand, in a continuous and industrialized way, to process large amounts of waste, with production units located closer to the waste generating points. This way, it guarantees the supply of large quantities of raw materials, which can be stored and processed later [,,]. On the other hand, this type of process also allows the final products have higher added value, justifying investments in the construction of these waste recovery units []. Examples of this could be biomass gasification units, charcoal production units, biomass power plants, or biomass pellets production units [,,,,].

Regarding the Portuguese reality, which is also suitable for other countries in the Mediterranean region, such as Spain, Italy, or Greece, wherein parallel with large productions with very significative areas, capable of aggregating economies of scale that justify the investments necessary for these large and expensive technological solutions, there are myriad small vineyards, which mostly occupy only a few hectares, with wider territorial dispersion, and interspersed with other types of occupation and land uses []. This is the most recurrent situation in the Portuguese region that was selected for the present study, in which the owners of small vineyards are not able to find a solution for their waste [,]. In this way, as a solution for the large volume of waste generated, these are burnt on-site, without any use for the generated energy [].

Small-scale recovery, such as the use of this waste as firewood, namely in traditional processes, was mainly as an option, e.g., its use in bakery ovens or traditional roasted piglet restaurants, which are so common in several regions of Portugal []. However, with the advent of electric and gas-fueled ovens, these practices are less frequent and cannot handle the increasing amounts of waste. These traditional practices can show which possibilities may serve as a solution if adequately adapted to the current reality []. The amount of vine pruning waste can be an alternative to other types of fuel, especially in locations closer to waste production areas, creating value chains while contributing to the resolution of problems associated with the disposal processes of these wastes [,,,].

In the specific case of woody residues of agricultural origin, such as vine pruning materials, the management process presents some constraints, namely related to the logistics associated with the collection process in the vineyards, the storage and subsequent transportation []. The usual practice of the pruning process, which also depends a little on the way the vineyard is organized, means that the pruners cut the branches and drop them to the ground, where they can later be collected and baled or pilled and shredded on-site, with the biomass chips being spread over the soil []. These difficulties are not very different from those encountered in the management of waste resulting from forestry operations because they present the same type of constraints, such as low density, low heating value, high moisture content, a significant content of inert contaminants, and large dispersion over the production area []. All these factors negatively contribute to the success of the waste management logistical process [].

From the perspective of introducing sustainable practices and the circularization of the agrarian-based economy, efforts for the proper management of agricultural waste must be seen not from the perspective of a cost associated with the production process, but rather from the perspective of creating a value chain, which contributes to the success of the farm and the increase in business productivity []. Thus, the present research analyzes some forms of the recovery of residues from agricultural activity, specifically, the material resulting from vine pruning, through small-scale combustion processes, to create an innovative approach based on the creation of value chains of local or regional scale.

2. Materials and Methods

2.1. Location and Characterization of the Area under Study

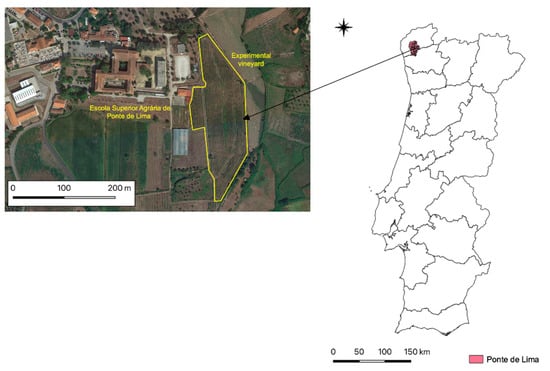

For the collection of samples to proceed with the characterization of the materials, an area dedicated to the production of vines was selected, located in the parish of Refóios do Lima, in the municipality of Ponte de Lima (northern Portugal). In the “Vinhos Verdes” demarcated wine region, in the “Lima” sub-region. In the selected area, the entire vineyard used for the present study is composed of the local “Loureiro” variety, which is perfectly adapted to the soil and climate conditions of the territory in question. Figure 1 shows the location of the area under study and an image of the vineyard where the samples were collected.

Figure 1.

Location of the vineyard where the samples were collected, in the experimental vineyard of the Escola Superior Agrária of the Instituto Politécnico de Viana do Castelo (Refóios do Lima, Ponte de Lima, Portugal).

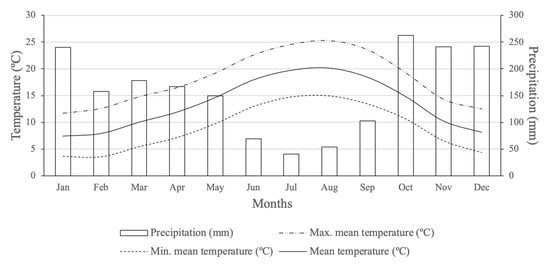

It is a region with a temperate Mediterranean-type climate with a strong Atlantic influence, where the summer is mild and dry, and the sky is usually not very cloudy []. On the other hand, the winter is cooler, with high precipitation, and usually cloudy. Throughout the year, in general, the temperature varies from 7 °C to 26 °C (average temperatures) and is rarely below 2 °C or above 35 °C. Figure 2 shows the average distribution of temperature and precipitation throughout the year for the Ponte de Lima region.

Figure 2.

Annual average distribution of temperature and precipitation in the region of Ponte de Lima (https://www.meteoblue.com/pt/tempo/semana/ponte-de-lima_portugal_2736041, accessed on 12 February 2022).

2.2. Sampling and Material Preparation

In the area under study, vine pruning is usually carried out during January, always after all the vine leaves have fallen. This time, after the pruning was carried out in January 2022, samples of these same prunings were collected to quantify the biomass production capacity of the vineyard and collect samples for the laboratory characterization of the materials from a perspective of energy recovery. Ten sampling points were selected for the collection of samples as representative of the entire area covered by the vineyard. Namely, they were collected among the different types of soil existing in the place and represented the different altitudes at which the vines are planted. The ten selected collection points constituted the plants between supports, usually three in number, so each selected point provided three samples. Figure 3 shows one of these sample collection units, consisting of the two mainstays supporting the vine with the three plants.

Figure 3.

Vine support system with three plants.

After pruning, residual materials were collected and weighed. After weighing, they were dried for one week. This drying took place by natural direct exposure to air. After seven days, the materials were weighed to assess the evolution of the moisture loss of the materials. Figure 4 shows the vine pruning bales during the natural drying process.

Figure 4.

Drying process of bales collected from vine pruning.

In the year prior to the procedure described, in January 2021, a smaller-scale collection of material was carried out to obtain samples for laboratory characterization. Thus, several samples of vine pruning were collected, which were cut using electric pruning shears in dimensions between 2 and 5 cm, as shown in Figure 5.

Figure 5.

Aspect of the samples already cut for carrying out the laboratory characterization tests.

2.3. Laboratorial Characterization

The objective was to analyze the properties of materials from a perspective of energy recovery; therefore, the laboratory characterization of the collected materials was carried out according to the sequence presented in the standard ENPlus ®, enabling a direct comparison with other solid fuels derived from biomass, such as is the case of wood pellets produced from Pinus pinaster. Table 1 presents the list of standards referred to in the standard ENPlus ® and where the laboratory procedures used are described.

Table 1.

Standards used in the laboratory characterization tests.

Elemental analysis (CHNO) was performed in LECO CHN628 apparatus, in which the operating principle consists of weighing a sample in a tin foil that is later placed in the autoloader and then introduced into the furnace containing pure oxygen, with carbon, hydrogen, and nitrogen being completely oxidized and the CHN contents calculated. Oxygen content on a dry basis is calculated by difference. Thermogravimetric analysis (TGA) was performed using ELTRA THERMOSTEP equipment. One gram of each sample was introduced into crucibles and placed inside an oven, along with an empty reference crucible. As the temperature increased, crucibles were weighed on a precision scale. Moisture, volatile, and fixed carbon contents were determined throughout the heating process. Lastly, the final residue represented the ash content. A TITROLINE 7000 titrator from SI Analytics was used to determine the chlorine content. For this procedure, sample preparation involves previous digestion of the sample, performed in a SINEO MDS-6G microwave since titration requires a liquid sample. Chlorine content determination is achieved by potentiometric titration. The lower and higher heating values were determined using an adiabatic bomb calorimeter, model 6400 Automatic Isoperibol Calorimeter, by PARR INSTRUMENT. After each procedure, the equipment provides the corrected temperature increase that is later used to determine the heating value. The determination of ash fusibility consists of monitoring the behavior of ash melting along a temperature ramp. The samples, converted to ashes, were subsequently placed in a plastic dish, where two drops of ethyl alcohol were added and homogenized. Then, this paste was transferred to a mold, where a cylinder is compacted. Subsequently, the cylinders were placed on a zirconia lamella and then placed inside the chamber of the ash fusibility furnace, which in this specific case was a SYLAB IF 2000 g device. Inductively coupled plasma optical emission spectrometry (ICP-OES) was used to determine trace elements and sulphur. The equipment used was a THERMO SCIENTIFIC (iCAP 6000 series). A peristaltic pump delivered the digested samples to an analytical nebulizer and introduced them into the plasma flame that broke down the samples into charged ions, releasing radiation with specific wavelengths.

2.4. Further Analysis

In addition to the materials collected for the laboratory characterization tests, more samples were also collected and prepared, as shown in Figure 5, to carry out combustion tests. This way, to conduct these combustion tests, 30 kg was collected in 2022, which also served to analyze the available diameters present in the materials to complement the comparative study with wood pellets. Thus, an amount of material was separated, totalizing 183 fragments, whose diameters were measured.

3. Results and Discussion

3.1. Characterization of Vine Pruning Samples

3.1.1. Laboratorial Results

The results obtained in the laboratory characterization are presented in the following tables. Table 2 presents the results of the elemental analysis, with the determination of the percentual contents of carbon (C), hydrogen (H), nitrogen (N), oxygen (O), sulphur (S) and chlorine (Cl). Table 3 presents the results of the thermogravimetric analysis (TGA), with the determination of percentual moisture content (%), volatile content (%), ash content (%) and fixed carbon (%). Table 4 presents the heating values (low and high) by calorimetry. Table 5 presents the results obtained in determining the fusibility temperatures of the ashes. Table 6 shows the content (mg·kg−1) of the major elements, and Table 7 shows the content (mg·kg−1) of the minor elements.

Table 2.

Elemental analysis (CHNO).

Table 3.

Thermogravimetric analysis (TGA).

Table 4.

Determination of lower (LHV) and higher (HHV) heating value.

Table 5.

Fusibility of the ashes. IDT—initial deformation temperature (°C); ST—softening temperature (°C); HT—hemispherical temperature (°C); FT—fluid temperature (°C).

Table 6.

Analysis of the contents of major elements by ICP-OES.

Table 7.

Analysis of minor elements content by ICP-OES.

The elemental analysis shows that the carbon content presented an average value of 46.27 ± 0.95%, the hydrogen content presented an average value of 6.28 ± 0.20%, the nitrogen content presented an average value of 0.54 ± 0.23%, and the oxygen content presented an average value of 46.89 ± 1.37%. From the determination of the sulfur and chlorine contents, it was found that the mean values were 0.0185 ± 0.0005% and 0.0005 ± 0.0003%, respectively.

The thermogravimetric analysis showed that the average moisture content was 3.67 ± 0.14%, the volatile content presented an average value of 77.80 ± 0.07%, the ash content presented an average value of 1.42 ± 0.01%, and the fixed carbon showed a content of 19.58 ± 0.17%. The moisture content obtained during the laboratory characterization was significantly low because the samples were subjected to a forced drying process in a laboratory oven during the sample preparation process for the remaining laboratory tests. This way, this moisture content should not be considered in the analysis of the thermal and combustibility properties of the materials under analysis.

The heating value determined for the vine pruning samples presented a value of 18.95 ± 0.006 MJ·kg−1 for the higher heating value and 17.58 ± 0.000 MJ·kg−1 for the lower heating value.

The analysis of the ash fusibility, produced by calcination of the vine pruning samples, showed an average IDT of 882 ± 22 °C, an average ST of 1527 ± 47 °C, an average HT of 1576 ± 4 °C and an FT of 1584 ± 4 °C.

The analysis of the major elements showed an average content of 60.55 ± 12.12 mg·kg−1 for aluminum, an average content of 7445.35 ± 54 mg·kg−1 for calcium, an average content of 34.00 ± 4.00 mg·kg−1 for iron, an average content of 1359.30 ± 48.12 mg·kg−1 for magnesium, an average content of 1095.81 ± 16.14 mg·kg−1 for phosphorus, an average content of 8244.37 ± 174.86 mg·kg−1 for potassium, an average content of 152.65 ± 31.46 mg·kg−1 for silicon, an average content of 421.79 ± 19.84 mg·kg−1 for sodium, and an average content of 3.01 ± 0.41 mg·kg−1 for titanium.

The analysis of minor elements showed an average content of 0.73 ± 0.15 mg·kg−1 for arsenic, an average content of 0.44 ± 0.13 mg·kg−1 for cadmium, an average content of 0.31 ± 0.10 mg·kg−1 for cobalt, an average content of 0.29 ± 0.22 mg·kg−1 for chromium, an average content of 24.93 ± 1.67 mg·kg−1 for copper, an average content of 41.34 ± 1.93 mg·kg−1 for manganese, an average content of 0.39 ± 0.25 mg·kg−1 for nickel, an average content of 0.16 ± 0.11 mg·kg−1 for lead, and an average content of 15.53 ± 2.02 mg·kg−1 for zinc. For mercury (Hg), the samples always presented a value lower than the minimum detection limit of the equipment used in the analysis.

3.1.2. Statistical Analysis of the Laboratorial Results

Using the Friedman one-way repeated measure analysis of variance by ranks, significant differences between the different parameters of the chemical analysis performed on the vine pruning were checked. For the results obtained for the elemental analysis, the mean values for the contents of C, H, N and O were 3.67, 2.00, 1.00 and 3.33, respectively. The Friedman test returned a p < 0.05; thus, the null hypothesis was rejected, i.e., there were differences between the mean ranks. This result indicates that, because the oxygen content is calculated from the sum of C, H and N, this content is directly dependent on the result of the other elements. The difference between the mean ranks for hydrogen and nitrogen contents tends to be low, as confirmed by Kendall’s concordance coefficient (0.042), i.e., p < 0.05 confirms the rejection of the null hypothesis and supports the difference between the mean ranks of the parameters for the two pairs of elements, C-O and N-H, respectively. When the elemental analysis was performed together with the results of sulfur and chlorine contents, there was a change in the mean ranks of the parameters, which became 5.67, 4.00, 3.00, 5.33, 2.00 and 1.00 for C, H, N, O, S and Cl, respectively. However, in this case, the Friedman test presented p < 0.05, confirming differences between the mean ranks, as also confirmed by the Kendall’s concordance coefficient, which also presented p < 0.05, which justified the rejection of the null hypothesis.

The thermogravimetric analysis also showed a similar trend to that observed for elemental analysis. The mean ranks for moisture, volatiles, ashes and fixed carbon were 2.00, 4.00, 1.00 and 3.00, respectively, with the Friedman test showing p < 0.05, indicating the differences between the mean ranks of these parameters, confirmed by the coefficient of agreement of Kendall, also with p < 0.05, and that rejected the null hypothesis.

The major elements Al, Ca, Fe, Mg, P, K, Si, Na and Ti presented mean ranks of 3.00, 8.00, 2.00, 7.00, 6.00, 5.00, 4.00, 5.00 and 1.00, respectively, also with the Friedman test showing p < 0.05, as well as p < 0.05 for Kendall’s concordance coefficient, once again rejecting the null hypothesis and confirming the differences between the mean ranks of this set of parameters. On the other hand, the minor elements As, Cd, Co, Cr, Cu, Mn, Ni, Pb and Zn presented mean ranks of 5.50, 4.33, 2.65, 2.50, 8.00, 9.00, 4.67, 1.33 and 7.00, respectively, with the Friedman test showing p < 0.05. This situation indicated that this set of parameters had equal mean ranks, confirmed by Kendall’s concordance coefficient, which also had p < 0.05.

Concerning the analysis of the chemical properties of vine pruning, it can be seen from the results obtained that there is no direct relationship between the different parameters. In other words, the variation in the content of a given element is not dependent on the variation in any other element, except for the oxygen content, determined by the differences between the carbon, nitrogen, and hydrogen contents, which can also include the sulfur and chlorine contents. On the other hand, when the carbon content was related to the LHV with the Pearson test, a positive correlation between the two parameters was verified (0.963) with p = 0.174, i.e., p > 0.05, which led to the acceptance of the null hypothesis, confirming the correlation between the two parameters. This condition justifies the high calorific value presented by the vine pruning, which, as has been seen, is directly related to the high carbon content.

3.1.3. Fuel Comparative Analysis

The results obtained for the characterization of the collected samples demonstrate that the quality of this residual biomass fits as a fuel that can be used in energy recovery processes. In fact, this finding has already been confirmed by several previous studies [,,,]. Table 8 shows a comparison between the results obtained for the vine pruning with the values obtained for a characterization presented by Nunes et al. for wood pellets certified to the ENPlus ® standard [].

Table 8.

Comparison of the parameters obtained for vine pruning with the limits imposed by the ENPlus ® standard and with the values normally presented by wood pellets produced with Pinus pinaster (adapted from []).

The results obtained are mainly within the limits established by the standard ENPlus ® and are very similar to those usually found in wood pellets produced with Pinus pinaster. Exception was made for the ash content, which with a value of 1.42% exceeded the limits imposed for categories A1 and A2, and could only be used to produce wood pellets to fit in category B. The same happened for the nitrogen content, which, with 0.536%, only enables its use in the production of category B wood pellets. On the other hand, in the case of copper, the value significantly exceeded the established limit by almost 2.5 times; therefore, it cannot be used exclusively as the only raw material to produce wood pellets subject to certification. This high level of copper may, however, have an explanation that is not related to the intrinsic properties of the biomass itself, but should instead be related to the use of Bordeaux mixture as a fungicidal treatment, which is commonly applied to vineyards in the region in two treatments, the first being applied in the last week of July, and the second during the third week of August. This situation can be extrapolated to calcium, which, although not part of the ENPlus ® list, also exhibited a high value, even compared with the remaining major elements, with an average value of 7445.35 ± 44.54 mg·kg−1. This situation should also be related to the application of a treatment, this time based on quicklime and sulphate, which are used to combat powdery mildew. This high content of calcium may act as a fondant for the ashes.

Although these parameters exceed the limits imposed by the ENPlus ® standard and make it impossible to produce wood pellets exclusively with vine pruning, their incorporation into mixtures seems to be possible. In the case of mixtures incorporating 50% of vine pruning, the authors indicate that copper levels continue to be an impediment to the use of these materials in the production of certified wood pellets. When the mixture only incorporated 25% of vine pruning, the authors indicate that only the ash content remains above the limits imposed by the standard ENPlus ® for products certified in category A1, but allows the production of wood pellets of category A2. With mixtures incorporating 10% of vine pruning, wood pellets can be certified in category A1. In this way, the possibility of incorporating these residual biomasses can be seen as an excellent possibility for the recovery of large amounts of waste, while using already established value chains, which can even have a double role from point to point from an environmental point of view and the management of forest resources, because they would allow significant savings in virgin raw materials.

3.2. Combustibility and Energy Recovery

As the laboratory characterization tests indicated, the thermal properties and the combustibility of the vine pruning are comparable with other commonly used fuels. They can be presented as a suitable product, both from the perspective of being used as raw material for incorporation in the production of wood pellets, combined with other biomasses, and to be used as a single fuel in applications such as firewood. As seen in Figure 5, the material cutting can be adjusted so that the final product is longer or smaller and looks similar to that of wood pellets. However, if the length is not an issue because it can be adjusted, the diameter can vary greatly.

From the granulometric analysis performed, it appears that the values obtained vary between a minimum of 2.65 mm and a maximum of 19.67 mm, with an average value of 7.78 ± 3.10 mm, with a variance of 9.67 mm. Compared with wood pellets that have a fixed value diameter, which can be 6 mm for pellets commonly used in domestic applications, and 8 mm, more frequently used in industrial applications, and with length to be limited by the standard ENPlus ® at a minimum value of 3.15 mm and a maximum value of 35.0 mm, seems to present significant differences in dimensions. This difference in dimensions should not be a problem for industrial-type applications, which use high-throughput equipment, where the fuel feed augers are capable of processing both wood pellets and woodchips, thus having greater agility to process materials of different dimensions. On the other hand, domestic equipment, such as boilers and stoves, normally do not have this capacity, so the use of fuels in this equipment that does not present a certain homogeneity normally leads to clogging of the supply systems, damaging the equipment, and causing frequent cleaning interventions.

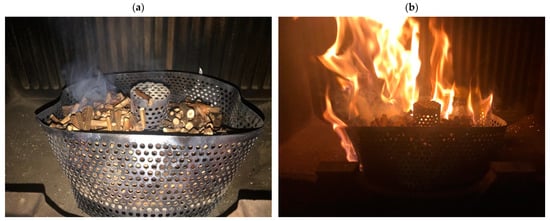

The use of vine pruning cut in dimensions between 20 and 50 mm for direct use in domestic fireplaces, with or without the use of an adapter, depending on the size of the openings of the bottom grate fireplace, can be a very viable alternative for domestic applications with several advantages. Figure 6 shows some aspects of the tests carried out in a domestic fireplace using an adapter.

Figure 6.

Use of vine pruning as firewood in a fireplace with an adapter for domestic heat recovery. (a) Initiation of combustion; (b) combustion of vine pruning.

This use of vine pruning as firewood presents several advantages. It allows many people who currently consume firewood as heating fuel to replace the purchase of traditional firewood, preferably produced with the wood of species such as oaks or pines, avoiding the exploitation of forest resources. At the same time, because vine pruning biomass is expected to have a significantly lower cost for the consumer than traditional firewood, this replacement will imply a significant reduction in heating costs for the consumer, thus contributing to mitigating energy poverty. This subject has been widely discussed in Portugal, and mainly affects populations living in rural environments, who are often older and without the financial capacity to bear the costs of heating their homes during the coldest and wettest period of the year. Finally, regarding the advantages of using vine pruning such as firewood, the question of storage in the domestic space arises; because they can be bagged, similar to what happens with wood pellets, it allows a more accessible accommodation of the fuel in basements or domestic storage rooms, taking up less space. Additionally, because the material can be bagged, it allows the consumer to purchase it in a way that is more in line with their needs, avoiding bulk purchase, which often exceeds the absolute need for the consumption of the year, leaving leftovers for the following year, with the corresponding equity tie for such a long period.

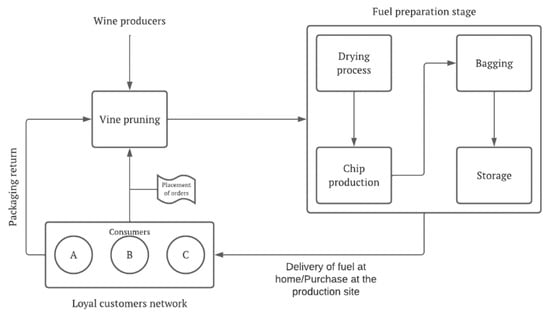

Despite all these advantages that are easily understood, perhaps the most significant advantage of all is the possibility of creating value chains at a local level or regional proximity, in which vineyards managers may place a new product on the market through the direct sale of vine pruning, creating a new value chain. This business model, in which producers sell the bagged fuel directly to the final consumer, can earn farmers more income. At the same time, from an environmental perspective, they eliminate the waste produced without resorting to less appropriate practices, as is the burning of leftovers, where the energy produced is not used. This business model can be even more efficient if, for example, fuel producers create customer loyalty networks, in which, by yearly production estimations, fuels are reserved for a customer portfolio, which knows in advance that have its firewood needs covered at a specific price. This model may also include a system for exchanging packaging, giving preference to reusable bags with the return, such as sackcloth, thus avoiding plastic. Models that include home delivery can also be considered, with previously agreed dates and quantities. Figure 7 shows a flowchart with the proposed business model.

Figure 7.

Business model for the sale of firewood from vine pruning from a local or regional proximity value chain perspective.

Although a fuel preparation stage is presented, which involves drying the collected material and the production of woodchips, the costs associated with this processing can be considered low and do not significantly impact production cost estimations. The drying process considered in this business model is carried out naturally, with the vine pruning bales being stored preferentially in a covered place to avoid exposure to rain, thus allowing the material to dry as much as possible []. Preferably, in an ideal scenario where the producer has available space, the material collected in January, at the time of pruning the vines, is only available for consumption at the beginning of the following autumn. In September or October of the same year, the humidity of the materials naturally reaches 15–25%. In the case of woodchip production, the process considered in this business model was the use of small-scale shredding equipment, such as a woodchipper adaptable onto a tractor, usually with a shaft with a slipping clutch, or an organic waste electric shredder, which are types of equipment usually already available in agricultural facilities. This operation, as mentioned above, must be carried out when the sales period begins to avoid long periods of storage of the shredded material to avoid the risk of fermentation and its perishability.

In this way, a value chain is created in which the following aspects stand out:

- There is a prospect of valuing waste resulting from agricultural production—in this case, wine production—where the disposal of waste is carried out in line with the reduction in the carbon footprint, associated, for example, with the burning of leftovers, through the reduction in greenhouse gas emissions without using the energy;

- There is value creation resulting from the commercialization of waste, now transformed into fuel;

- There is a contribution to the preservation of forest resources as a result of the substitution of firewood of forest origin for others of residual origin;

- There is an effective contribution to improvements in the economic and social conditions of rural populations as a result of the creation of a new direct value chain established between producers and final consumers, with obvious advantages for both;

- Finally, there is a compelling valuation of endogenous resources with the application of a circular bioeconomy model, intending to increase the sustainability of the agricultural sector and promote rural development.

3.3. Residual Biomass Production Capacity

The amount of biomass produced per hectare of vineyard depends on the soil and climate conditions where the vineyard is located, the variety of the vine, the compass and density of the plantation and its age []. The planting compass is characterized by the distance of the vines between the rows and the distance of the vines in the row, expressed by the distance between rows (m) × distance in the row (m), whose product corresponds approximately to the area occupied by each plant (m2). The planting density corresponds to the number of plants per hectare, which is calculated by dividing the area of one hectare, which corresponds to 10,000 m2, by the area occupied by each of the plants, expressed in m2. The most common vine planting densities may vary from 952 plants·ha−1 to 2222 plants·ha−1, in accordance with the different types of compasses normally used in the vineyards of the demarcated region of Vinhos Verdes (available at https://viticultura.vinhoverde.pt, accessed on 12 February 2022). In the area selected for the present study, the following results were obtained in weighing residual biomass production per plant, shown in Table 9.

Table 9.

Results obtained in weighing the biomass produced per plant, in which each sampling point corresponds to a set of three plants between supports (each one the sampling points, corresponding to the vines planted between the support systems, supplied three samples).

From the results, at the time of cut, an average value of 2.83 ± 0.94 kg is obtained for each sample. However, after a drying period of seven days, this value decreases by 10%, with an average weight per plant of 2.61 ± 0.89 kg. The drying process tends to occur homogeneously, and the material has a high capacity for moisture loss after cutting, ranging from approximately 32% moisture to 20–25% after drying for one week. This result is in line with those usually found in firewood produced with other species such as oaks, acacias, or pines. Based on these results, using the values obtained after drying over a period of seven days, the values shown in Table 10 were obtained, calculated from the combination of the vine planting densities and the average values of biomass produced per plant after drying.

Table 10.

Potential biomass production (kg·ha−1) and estimated revenues ((EUR·ha−1) for the most common vine planting densities.

Bearing in mind the available amounts on average, calculated for vineyards planted with the “Loureiro” variety, in the Ponte de Lima region, it appears that it is possible to produce significant amounts of residual biomass, which may vary between a maximum of 5799 ± 1978 kg·year−1·ha−1, for densities of 2222 plants·ha−1, and a minimum of 2485 ± 847 kg·year−1·ha−1, for densities of 952 plants·ha−1. The average yield for the region should be close to 3500 kg·ha−1, corresponding to the density of 1333 plants·ha−1, which can be considered as corresponding to the mode because it is the most frequently used in the region where the present study was carried out. However, there is a high variance directly related to the possible planting densities, which can range from 952 to 2222 plants·ha−1. The results presented in Table 9 seem to follow a normal distribution, because the one-sample Kolmogorov–Smirnov test resulted in p > 0.05, so the null hypothesis was accepted. This framework may help to understand the fact that the median of the distribution is closer to 3500 kg·ha−1, so the value resulting from the mode of vine planting density in the region where the study was carried out is accepted, and which corresponds to the value most commonly used in vine planting, as the most likely value for the quantification of the biomass produced. This analysis was based on a survey on Google Forms (https://forms.gle/erpGfC4tNYb9DrG36, accessible between 1 April 2022, and 12 April 2022) submitted by email to winemaking cooperatives in the region, with the request for distribution to its associates and contacts. A total of 92 answers were obtained, among which was the question “What is the planting density that you use in your vineyard?”, to which 41 participants answered “1333 plants·ha−1”. In other words, about 45% of the winegrowers in the region point to this planting density as the most commonly used, highlighting it among the other possibilities. These estimated biomass yields enable calculations of the potential revenue, based on a price per ton of firewood of 90 EUR·t−1, as presented in Table 10.

For the end user, the acquisition of this residual biomass at a price of 90 EUR·t−1 presents itself as a significant benefit, because the market value of wood pellets varies between EUR 3.49 and EUR 3.99 for each 15 kg bag, which corresponds to an average price of EUR 3.74 per bag []. Thus, the cost per ton of these wood pellets is EUR 250, including VAT. This significant difference in prices is justified because preparing the biomass from vine pruning does not involve significant industrial processing, and the proposed bagging format is also the responsibility of the end-user, thus reducing the cost of bagging. On the other hand, the production of wood pellets is a complex industrial process which involves energy-intensive steps, such as, in addition to shredding, the use of refining mills and drying. Packaging can also be an additional factor of unnecessary costs considering this proximity business model.

Compared with other types of firewood, the price may not be the most attractive factor because the lowest market value was used as a reference for assigning a value to the material resulting from vine pruning, which varied, depending on the type of firewood and the place of delivery, between 90 EUR·t−1 and 150 EUR·t−1. The main advantage can be attributed to the fact that the consumer can purchase smaller quantities at each purchase, avoiding the availability of capital in a single time. However, mainly the occupation of space for storage, because the acquisition of firewood in the traditional method implies the purchase of a certain minimum quantity, as a way of including the transport and storage of firewood, which generally corresponds to 1 ton. Another factor that can be considered is the willingness to pay by the consumers, who may understand that in this way, they are actively reducing their ecological footprint by contributing to the creation of a circular bioeconomy system.

4. Conclusions

The residues resulting from the fruit tree pruning operations can be considered an environmental problem because, in most cases, its elimination is processed through the burning of the leftovers in the field. In this way, the valorization of vine pruning through energy recovery seems to be an exciting possibility, mainly if it is associated with creating small-scale value chains. In this study, it was demonstrated that vine pruning as firewood for domestic consumption could be viable. As verified by the obtained results, vine pruning as firewood for domestic applications is comparable to conventional firewood, both in terms of heating value and general quality, referring to other parameters. Additionally, from an economic point of view, vine pruning is competitive with other types of firewood and may even present more advantageous conditions. In addition to contributing to the elimination/management of waste generated in agricultural activity, this solution contributes to creating a local-scale business model, which creates value for farmers in a circular bioeconomy and sustainable rural development perspective.

Author Contributions

Conceptualization, A.I.F., A.C.R. and L.J.R.N.; methodology, A.I.F., A.C.R. and L.J.R.N.; validation, A.I.F., A.C.R. and L.J.R.N.; formal analysis, A.I.F., A.C.R. and L.J.R.N.; investigation, T.F., A.I.F., A.C.R. and L.J.R.N.; resources, A.C.R. and L.J.R.N.; data curation, A.I.F., A.C.R. and L.J.R.N.; writing—original draft preparation, T.F., A.I.F., A.C.R. and L.J.R.N.; writing—review and editing, T.F., A.C.R., A.I.F. and L.J.R.N.; visualization, A.I.F. and L.J.R.N.; supervision, L.J.R.N.; project administration, L.J.R.N. and A.C.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research is a result of the project TECH—Technology, Environment, Creativity and Health—Norte-01-0145-FEDER-000043, supported by Norte Portugal Regional Operational Program (NORTE 2020), under the PORTUGAL 2020 Partnership Agreement, through the European Regional Development Fund (ERDF). L.J.R.N. was supported by proMetheus, Research Unit on Energy, Materials and Environment for Sustainability—UIDP/05975/2020, funded by national funds through FCT—Fundação para a Ciência e Tecnologia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to thank José Durão, Agricultural Engineer responsible for the management of the Experimental Vineyard of the Escola Superior Agrária de Ponte de Lima, of the Polytechnic Institute of Viana do Castelo, for collaborating in the collection of biomass samples for this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jhariya, M.K.; Meena, R.S.; Banerjee, A. Ecological intensification of natural resources towards sustainable productive system. In Ecological Intensification of Natural Resources for Sustainable Agriculture; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–28. [Google Scholar]

- Tripathi, N.; Hills, C.D.; Singh, R.S.; Singh, J.S. Offsetting anthropogenic carbon emissions from biomass waste and mineralised carbon dioxide. Sci. Rep. 2020, 10, 958. [Google Scholar] [CrossRef] [PubMed]

- Hills, C.D.; Tripathi, N.; Singh, R.S.; Carey, P.J.; Lowry, F. Valorisation of agricultural biomass-ash with CO2. Sci. Rep. 2020, 10, 13801. [Google Scholar] [CrossRef] [PubMed]

- Devi, S.; Gupta, C.; Jat, S.L.; Parmar, M. Crop residue recycling for economic and environmental sustainability: The case of India. Open Agric. 2017, 2, 486–494. [Google Scholar] [CrossRef]

- Tripathi, N.; Hills, C.D.; Singh, R.S.; Atkinson, C.J. Biomass waste utilisation in low-carbon products: Harnessing a major potential resource. NPJ Clim. Atmos. Sci. 2019, 2, 35. [Google Scholar] [CrossRef] [Green Version]

- Sharma, B.; Vaish, B.; Singh, U.K.; Singh, P.; Singh, R.P. Recycling of organic wastes in agriculture: An environmental perspective. Int. J. Environ. Res. 2019, 13, 409–429. [Google Scholar] [CrossRef]

- Piñeiro, V.; Arias, J.; Dürr, J.; Elverdin, P.; Ibáñez, A.M.; Kinengyere, A.; Opazo, C.M.; Owoo, N.; Page, J.R.; Prager, S.D. A scoping review on incentives for adoption of sustainable agricultural practices and their outcomes. Nat. Sustain. 2020, 3, 809–820. [Google Scholar] [CrossRef]

- Bizikova, L.; Nkonya, E.; Minah, M.; Hanisch, M.; Turaga, R.M.R.; Speranza, C.I.; Karthikeyan, M.; Tang, L.; Ghezzi-Kopel, K.; Kelly, J. A scoping review of the contributions of farmers’ organizations to smallholder agriculture. Nat. Food 2020, 1, 620–630. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Sarsaiya, S.; Patel, A.; Juneja, A.; Singh, R.P.; Yan, B.; Awasthi, S.K.; Jain, A.; Liu, T.; Duan, Y. Refining biomass residues for sustainable energy and bio-products: An assessment of technology, its importance, and strategic applications in circular bio-economy. Renew. Sustain. Energy Rev. 2020, 127, 109876. [Google Scholar] [CrossRef]

- De Almeida, S.T.; Borsato, M. Assessing the efficiency of End of Life technology in waste treatment—A bibliometric literature review. Resour. Conserv. Recycl. 2019, 140, 189–208. [Google Scholar] [CrossRef]

- Tsui, T.-H.; Wong, J.W. A critical review: Emerging bioeconomy and waste-to-energy technologies for sustainable municipal solid waste management. Waste Dispos. Sustain. Energy 2019, 1, 151–167. [Google Scholar] [CrossRef] [Green Version]

- Demirbas, A. Waste management, waste resource facilities and waste conversion processes. Energy Convers. Manag. 2011, 52, 1280–1287. [Google Scholar] [CrossRef]

- Nishio, N.; Nakashimada, Y. Recent development of anaerobic digestion processes for energy recovery from wastes. J. Biosci. Bioeng. 2007, 103, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Najafi, E.; Castro, E.; Karimi, K. Biorefining for olive wastes management and efficient bioenergy production. Energy Convers. Manag. 2021, 244, 114467. [Google Scholar] [CrossRef]

- Momayez, F.; Karimi, K.; Taherzadeh, M.J. Energy recovery from industrial crop wastes by dry anaerobic digestion: A review. Ind. Crops Prod. 2019, 129, 673–687. [Google Scholar] [CrossRef]

- Siwal, S.S.; Zhang, Q.; Devi, N.; Saini, A.K.; Saini, V.; Pareek, B.; Gaidukovs, S.; Thakur, V.K. Recovery processes of sustainable energy using different biomass and wastes. Renew. Sustain. Energy Rev. 2021, 150, 111483. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Sarsaiya, S.; Wainaina, S.; Rajendran, K.; Awasthi, S.K.; Liu, T.; Duan, Y.; Jain, A.; Sindhu, R.; Binod, P. Techno-economics and life-cycle assessment of biological and thermochemical treatment of bio-waste. Renew. Sustain. Energy Rev. 2021, 144, 110837. [Google Scholar] [CrossRef]

- Akhtar, A.; Krepl, V.; Ivanova, T. A combined overview of combustion, pyrolysis, and gasification of biomass. Energy Fuels 2018, 32, 7294–7318. [Google Scholar] [CrossRef]

- Kershaw, A.; Bush, M.; Hope, G.; Weiss, K.; Goldammer, J.; Sanford, R. Centre for Palynology and Palaeoecology Department of Geography and Environmental Science. Sediment Rec. Biomass Burn. Glob. Chang. 2013, 51, 413. [Google Scholar]

- Pausas, J.G.; Keeley, J.E. A burning story: The role of fire in the history of life. BioScience 2009, 59, 593–601. [Google Scholar] [CrossRef] [Green Version]

- Yargicoglu, E.N.; Sadasivam, B.Y.; Reddy, K.R.; Spokas, K. Physical and chemical characterization of waste wood derived biochars. Waste Manag. 2015, 36, 256–268. [Google Scholar] [CrossRef]

- Laurent, C.; Oger, B.; Taylor, J.A.; Scholasch, T.; Metay, A.; Tisseyre, B. A review of the issues, methods and perspectives for yield estimation, prediction and forecasting in viticulture. Eur. J. Agron. 2021, 130, 126339. [Google Scholar] [CrossRef]

- de Souza, L.L.P.; Hamedani, S.R.; Lora, E.E.S.; Palacio, J.C.E.; Comodi, G.; Villarini, M.; Colantoni, A. Theoretical and technical assessment of agroforestry residue potential for electricity generation in Brazil towards 2050. Energy Rep. 2021, 7, 2574–2587. [Google Scholar] [CrossRef]

- Nunes, L.J.; Loureiro, L.M.; Sá, L.C.; Matias, J.C.; Ferraz, A.I.; Rodrigues, A.C. Energy Recovery of Agricultural Residues: Incorporation of Vine Pruning in the Production of Biomass Pellets with ENplus® Certification. Recycling 2021, 6, 28. [Google Scholar] [CrossRef]

- Moreira, M.M.; Barroso, M.F.; Porto, J.V.; Ramalhosa, M.J.; Švarc-Gajić, J.; Estevinho, L.; Morais, S.; Delerue-Matos, C. Potential of Portuguese vine shoot wastes as natural resources of bioactive compounds. Sci. Total Environ. 2018, 634, 831–842. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Romaní, A.; Michelin, M.; Domingues, L.; Teixeira, J.A. Valorization of wastes from agrofood and pulp and paper industries within the biorefinery concept: Southwestern Europe scenario. In Waste Biorefinery; Elsevier: Amsterdam, The Netherlands, 2018; pp. 487–504. [Google Scholar]

- Brito, P.S.; Oliveira, A.S.; Rodrigues, L.F. Energy valorization of solid vines pruning by thermal gasification in a pilot plant. Waste Biomass Valorization 2014, 5, 181–187. [Google Scholar] [CrossRef]

- Silvestri, S.; Cristoforetti, A.; Mescalchin, E.; Spinelli, R. Recovery of pruining waste for energy use: Agronomic, economic and ecological aspects. In Proceedings of the Mitteleuropäische Biomassekonferenz 2011= Central European Biomass Conference, Graz, Austria, 26–29 January 2011; p. 31. [Google Scholar]

- Shankar Tumuluru, J.; Sokhansanj, S.; Hess, J.R.; Wright, C.T.; Boardman, R.D. A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef] [Green Version]

- Dávila, I.; Robles, E.; Egüés, I.; Labidi, J.; Gullón, P. The biorefinery concept for the industrial valorization of grape processing by-products. In Handbook of Grape Processing By-Products; Elsevier: Amsterdam, The Netherlands, 2017; pp. 29–53. [Google Scholar]

- Gullón, P.; Gullón, B.; Dávila, I.; Labidi, J.; Gonzalez-Garcia, S. Comparative environmental Life Cycle Assessment of integral revalorization of vine shoots from a biorefinery perspective. Sci. Total Environ. 2018, 624, 225–240. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zacharof, M.-P. Grape winery waste as feedstock for bioconversions: Applying the biorefinery concept. Waste Biomass Valorization 2017, 8, 1011–1025. [Google Scholar] [CrossRef] [Green Version]

- Fermoso, F.G.; Serrano, A.; Alonso-Farinas, B.; Fernandez-Bolanos, J.; Borja, R.; Rodriguez-Gutierrez, G. Valuable compound extraction, anaerobic digestion, and composting: A leading biorefinery approach for agricultural wastes. J. Agric. Food Chem. 2018, 66, 8451–8468. [Google Scholar] [CrossRef]

- Nunes, L.J.; Rodrigues, A.M.; Matias, J.C.; Ferraz, A.I.; Rodrigues, A.C. Production of biochar from vine pruning: Waste recovery in the wine industry. Agriculture 2021, 11, 489. [Google Scholar] [CrossRef]

- Biagini, E.; Barontini, F.; Tognotti, L. Gasification of agricultural residues in a demonstrative plant: Vine pruning and rice husks. Bioresour. Technol. 2015, 194, 36–42. [Google Scholar] [CrossRef] [PubMed]

- Allesina, G.; Pedrazzi, S.; Puglia, M.; Morselli, N.; Allegretti, F.; Tartarini, P. Gasification and wine industry: Report on the use vine pruning as fuel in small-scale gasifiers. In Proceedings of the European Biomass Conference and Exhibition, Copenhagen, Denmark, 14–18 May 2018; pp. 722–725. [Google Scholar]

- Calcan, S.I.; Pârvulescu, O.C.; Ion, V.A.; Răducanu, C.E.; Bădulescu, L.; Dobre, T.; Egri, D.; Moț, A.; Popa, V.; Crăciun, M.E. Valorization of Vine Prunings by Slow Pyrolysis in a Fixed-Bed Reactor. Processes 2022, 10, 37. [Google Scholar] [CrossRef]

- Sapir, A. Globalization and the reform of European social models. JCMS J. Common Mark. Stud. 2006, 44, 369–390. [Google Scholar] [CrossRef]

- Pattara, C.; Raggi, A.; Cichelli, A. Life cycle assessment and carbon footprint in the wine supply-chain. Environ. Manag. 2012, 49, 1247–1258. [Google Scholar] [CrossRef]

- Brandão, A.S.; Santos, J.M. Rural regions as key locations for the Circular Bioeconomy: Insights from the northern interior of Portugal. Bioresour. Technol. Rep. 2022, 17, 100955. [Google Scholar] [CrossRef]

- Chen, T.-C.; Lin, C.-F. Greenhouse gases emissions from waste management practices using Life Cycle Inventory model. J. Hazard. Mater. 2008, 155, 23–31. [Google Scholar] [CrossRef]

- Razeghi, S.M.; Shabanali Fami, H.; Rezaei, R. Factors Affecting Biomass Energy Utilization by Small Holder Farmers in Iran. Int. J. Agric. Manag. Dev. 2020, 10, 45–57. [Google Scholar]

- Vecino, X.; Rodríguez-López, L.; Gudiña, E.J.; Cruz, J.; Moldes, A.; Rodrigues, L. Vineyard pruning waste as an alternative carbon source to produce novel biosurfactants by Lactobacillus paracasei. J. Ind. Eng. Chem. 2017, 55, 40–49. [Google Scholar] [CrossRef] [Green Version]

- Devesa-Rey, R.; Vecino, X.; Varela-Alende, J.; Barral, M.; Cruz, J.; Moldes, A. Valorization of winery waste vs. the costs of not recycling. Waste Manag. 2011, 31, 2327–2335. [Google Scholar] [CrossRef]

- Giorio, C.; Pizzini, S.; Marchiori, E.; Piazza, R.; Grigolato, S.; Zanetti, M.; Cavalli, R.; Simoncin, M.; Soldà, L.; Badocco, D. Sustainability of using vineyard pruning residues as an energy source: Combustion performances and environmental impact. Fuel 2019, 243, 371–380. [Google Scholar] [CrossRef]

- Giampietro, M.; Ulgiati, S.; Pimentel, D. Feasibility of large-scale biofuel production. BioScience 1997, 47, 587–600. [Google Scholar] [CrossRef] [Green Version]

- Demirbaş, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Mishenin, Y.; Yarova, I.; Koblianska, I. Ecologically Harmonized Agricultural Management for Global Food Security. In Ecological Intensification of Natural Resources for Sustainable Agriculture; Springer: Berlin/Heidelberg, Germany, 2021; pp. 29–76. [Google Scholar]

- Fraga, H.; Malheiro, A.; Moutinho-Pereira, J.; Santos, J. Climate factors driving wine production in the Portuguese Minho region. Agric. For. Meteorol. 2014, 185, 26–36. [Google Scholar] [CrossRef]

- Nunes, L.J.; Matias, J.C.; Loureiro, L.M.; Sá, L.C.; Silva, H.F.; Rodrigues, A.M.; Causer, T.P.; DeVallance, D.B.; Ciolkosz, D.E. Evaluation of the potential of agricultural waste recovery: Energy densification as a factor for residual biomass logistics optimization. Appl. Sci. 2020, 11, 20. [Google Scholar] [CrossRef]

- Tregambi, C.; Montagnaro, F.; Salatino, P.; Solimene, R. Solar-driven torrefaction of a lignin-rich biomass residue in a directly irradiated fluidized bed reactor. Combust. Sci. Technol. 2019, 191, 1609–1627. [Google Scholar] [CrossRef]

- Rasam, S.; Haghighi, A.M.; Azizi, K.; Soria-Verdugo, A.; Moraveji, M.K. Thermal behavior, thermodynamics and kinetics of co-pyrolysis of binary and ternary mixtures of biomass through thermogravimetric analysis. Fuel 2020, 280, 118665. [Google Scholar] [CrossRef]

- Raitila, J.; Tsupari, E. Feasibility of solar-enhanced drying of woody biomass. BioEnergy Res. 2020, 13, 210–221. [Google Scholar] [CrossRef] [Green Version]

- Manzone, M.; Paravidino, E.; Bonifacino, G.; Balsari, P. Biomass availability and quality produced by vineyard management during a period of 15 years. Renew. Energy 2016, 99, 465–471. [Google Scholar] [CrossRef]

- Nunes, L.J.; Casau, M.; Ferreira Dias, M. Portuguese Wood Pellets Market: Organization, Production and Consumption Analysis. Resources 2021, 10, 130. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).