Design of and Experiment on Open-and-Close Seedling Pick-Up Manipulator with Four Fingers

Abstract

:1. Introduction

2. Requirements and Scheme Design for Seedling Pick-Up

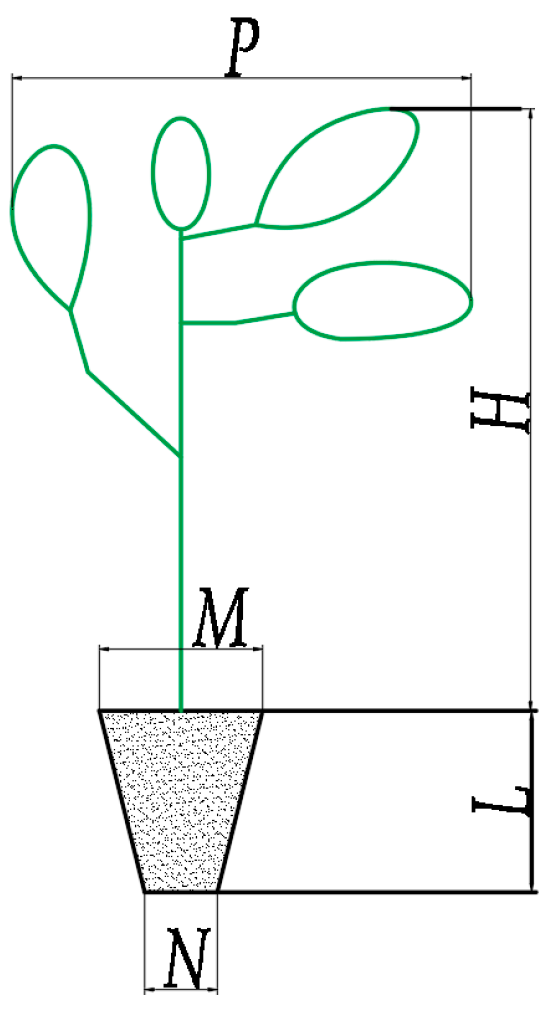

2.1. Physical Characteristics of Pepper Seedlings

2.2. Design Requirements for Manipulator

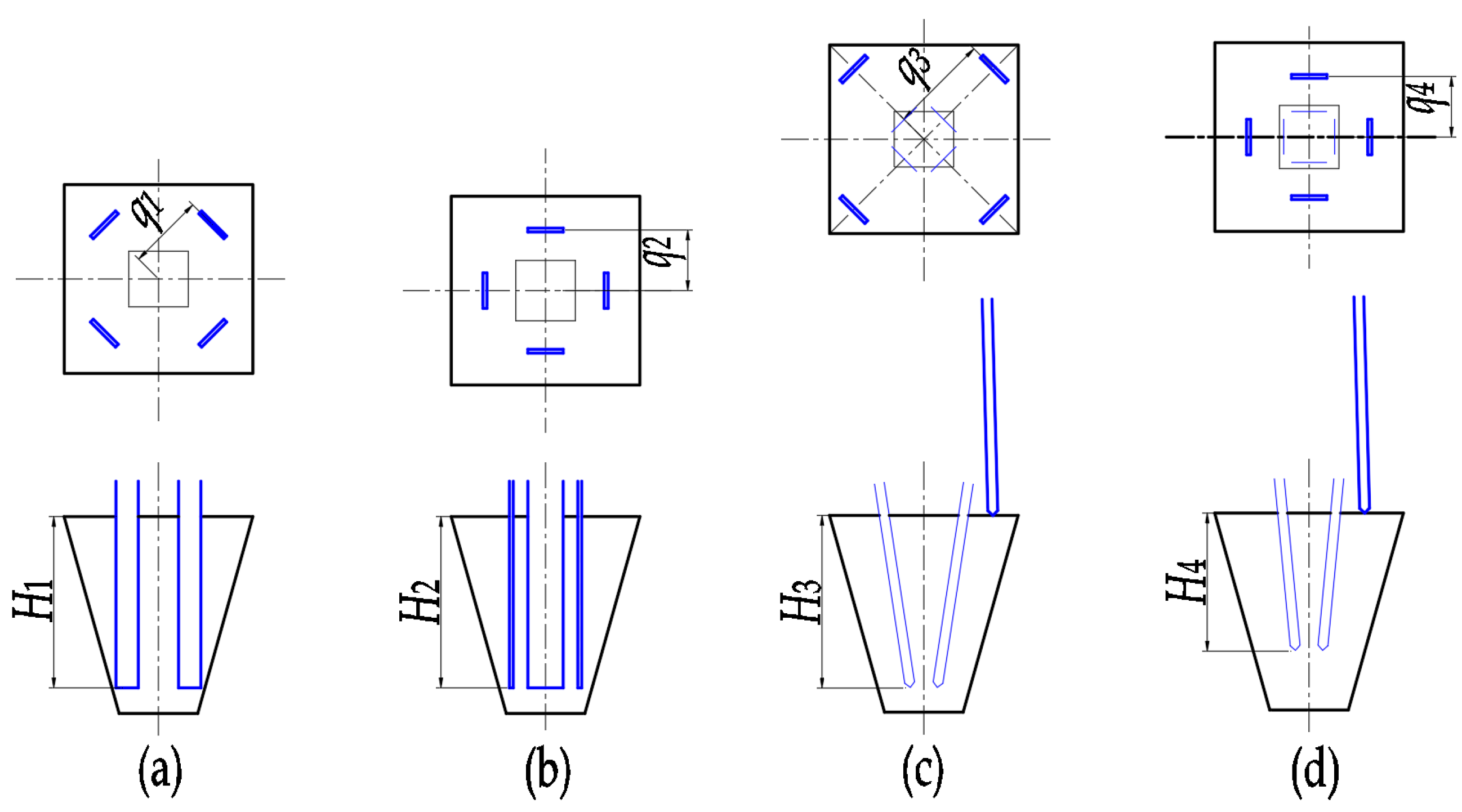

2.3. Design of Clamping Scheme

3. Design of Picking Up Seedling Manipulator

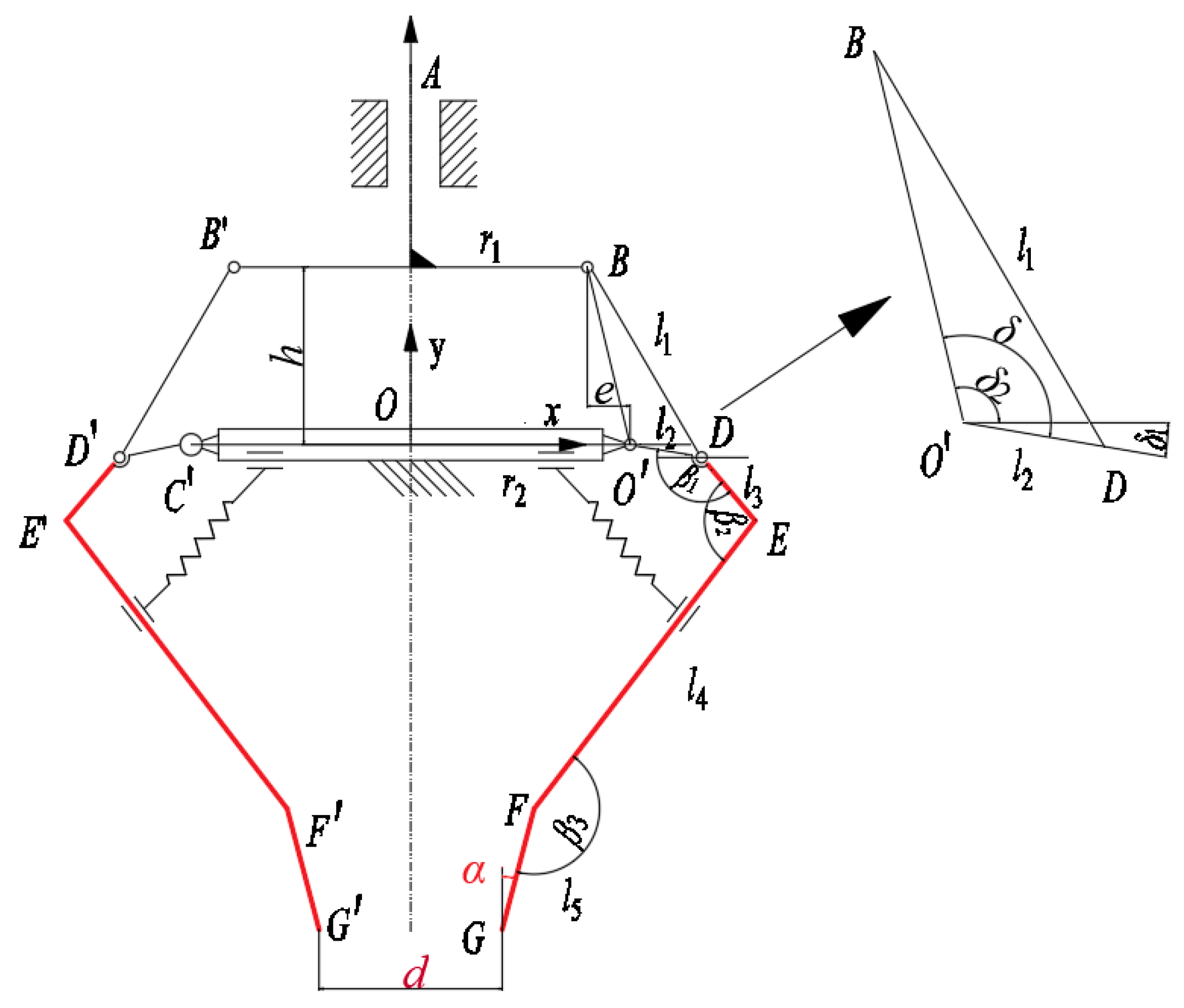

3.1. Working Principle of Picking Up Seedling Manipulator

3.2. Analysis of Linkage Clamping Mechanism

3.3. Motion Mathematical Model of Linkage Clamping Mechanism

3.4. Speed and Acceleration Model of Mechanism

3.5. Analysis and Design of Key Parameters

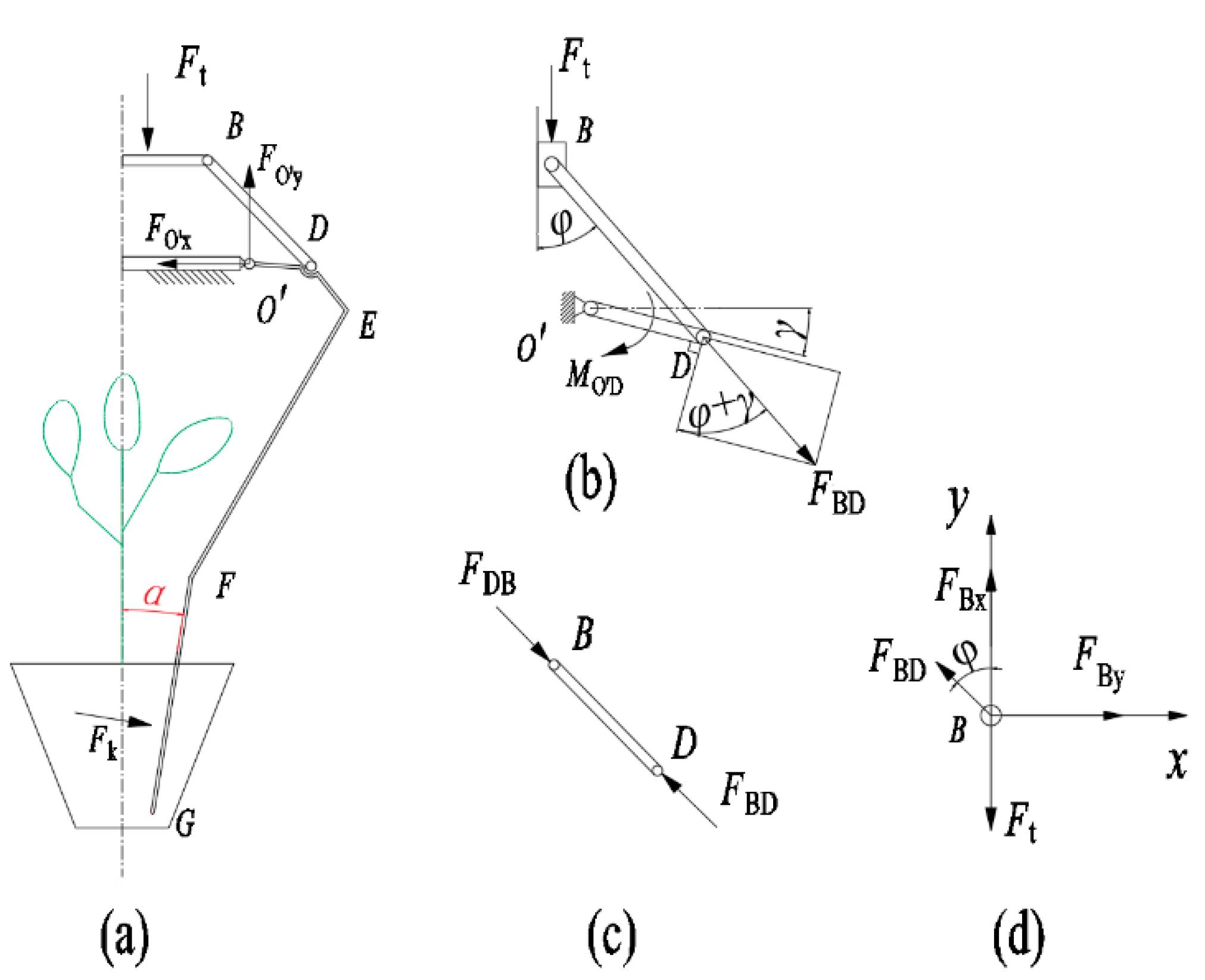

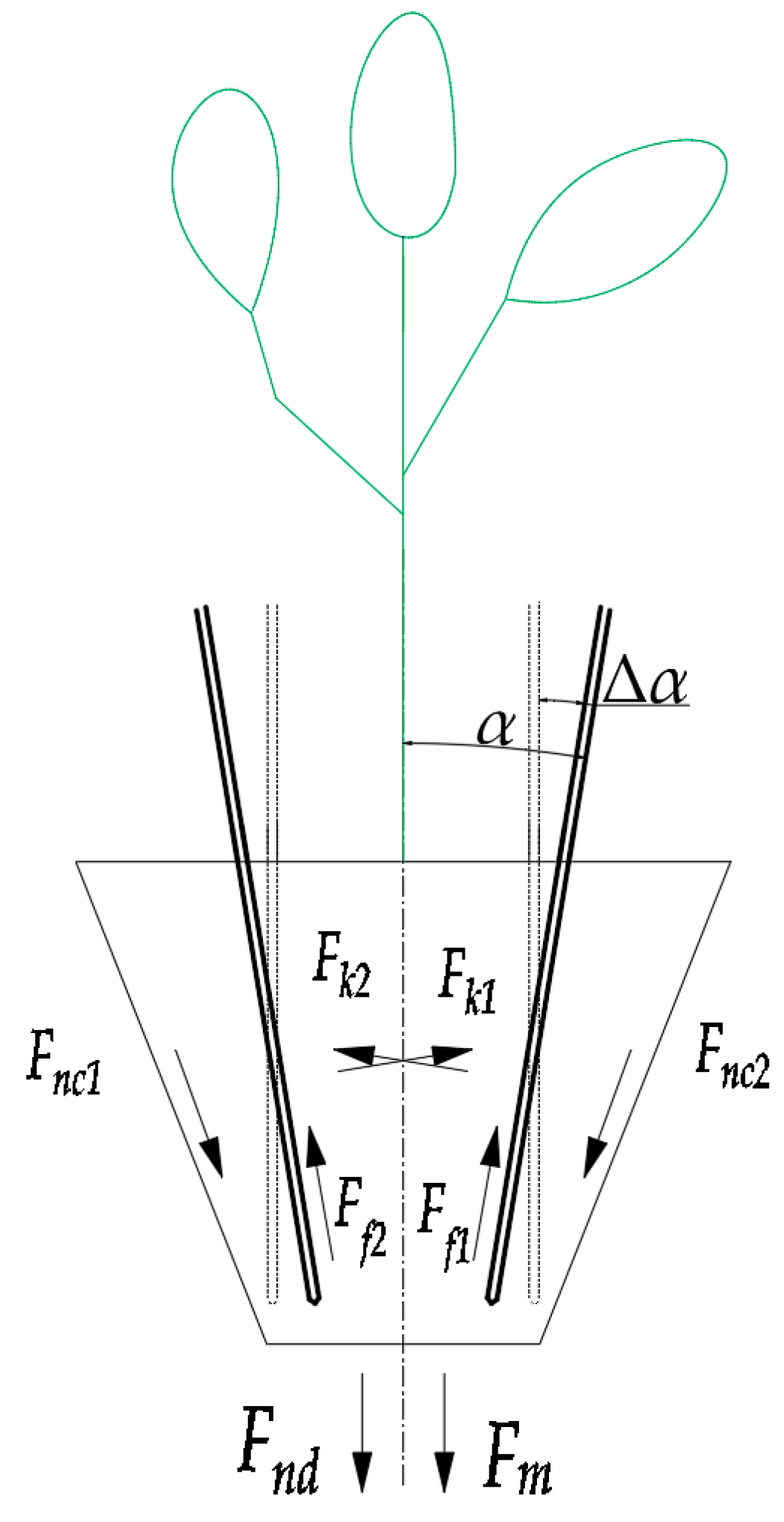

3.5.1. Force Analysis of Manipulator Mechanism

Force Transfer Analysis of Manipulator Mechanism

Force Analysis of the Interaction between Pot and Fingers

3.5.2. Structural Parameters Design of Manipulator

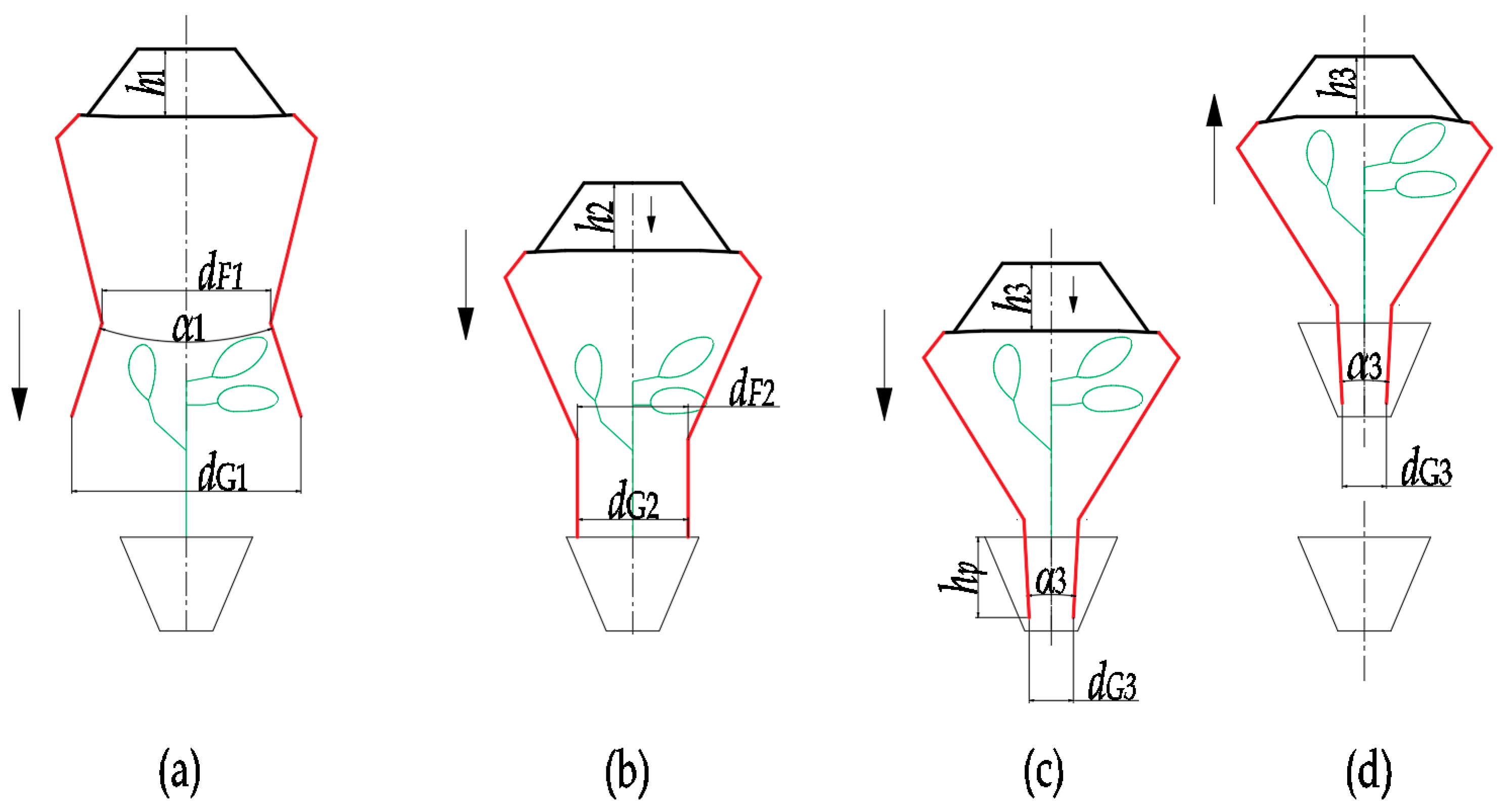

- (1)

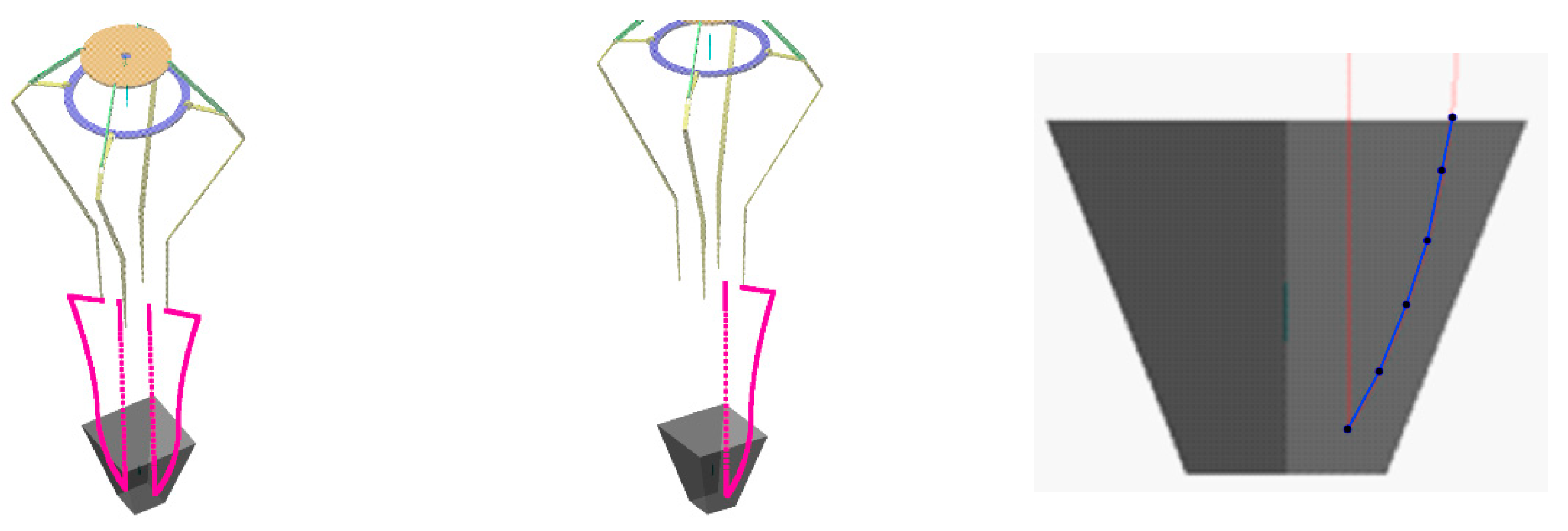

- At the beginning of the pick-up period, the pick-up manipulator keeps its fingers open. By setting the relative displacement between the middle moving block and the bottom frame as h1, the preset opening range is obtained. The initial angle between the fingers is α1, and dG1 > dF1 so as to avoid damaging the leaves as much as possible, as shown in Figure 7a;

- (2)

- Manipulator feeds are close to the tray seedling pot along the vertical direction. The four fingers are perpendicular to the upper surface of the tray before the manipulator reaches the picking point. The relative distance between the two fingers is dG2 = dF2 = d0. At this point, the relative displacement between the middle moving block and the bottom frame is h2, as shown in Figure 7b;

- (3)

- The manipulator continues to move vertically downward, and clamping fingers are inserted into the matrix, wrapped in the root, and clamped at an inserting depth of hp. At this point, the relative displacement between the middle moving block and the bottom frame is h3. The opening of the angle between the fingers is upward, the angle is α3, dG3 < dF3, and this is the clamping state, as shown in Figure 7c;

- (4)

- The four fingers keep the clamping state, and the manipulator lifts the pot seedling vertically, as shown in Figure 7d. In addition to overcoming the gravity of the pot seedling, the extraction force of this process is to remove of the adhesion force between the matrix block and the plug.

3.6. Trajectory Analysis of Finger End

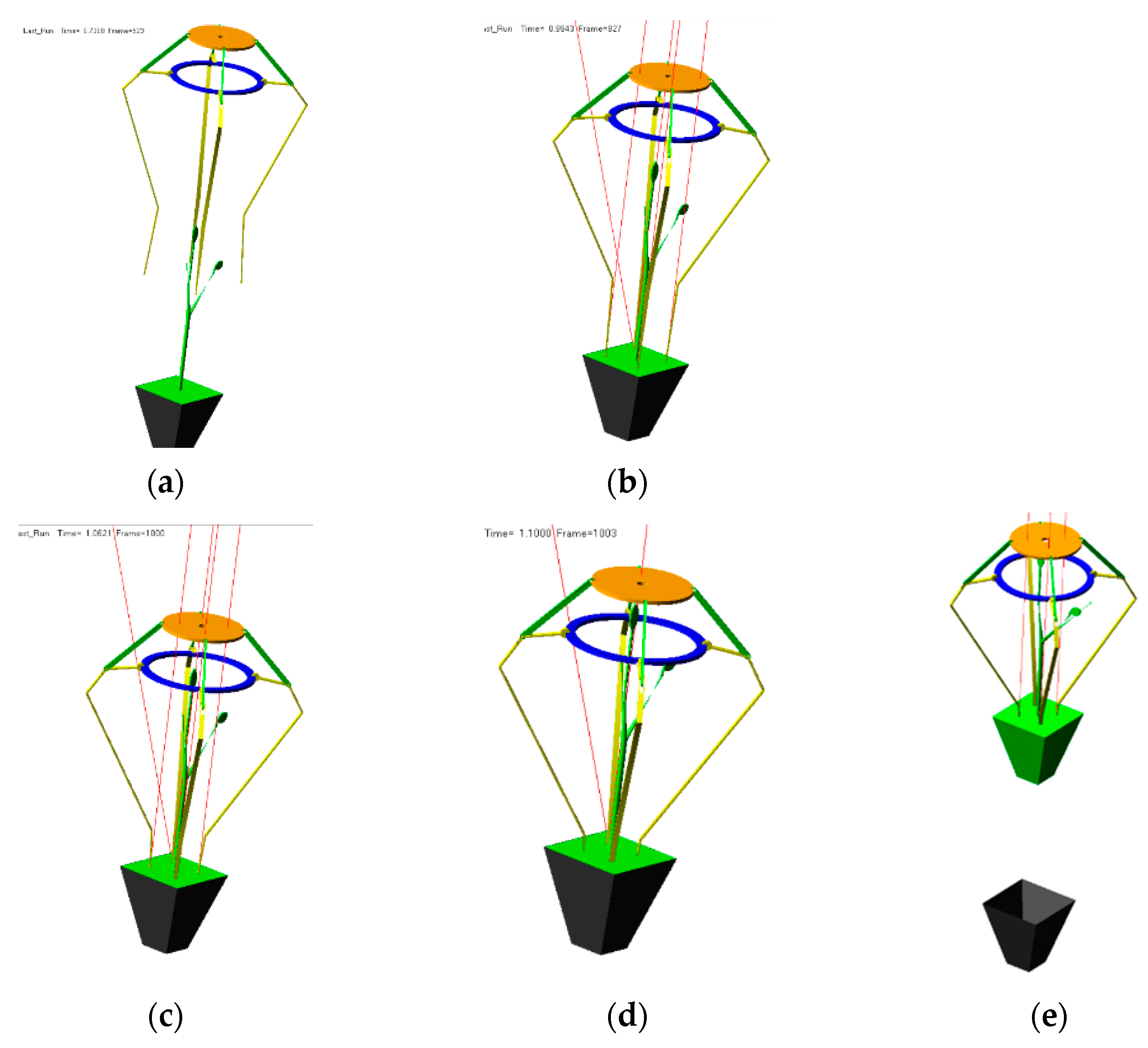

4. Motion Analysis of Virtual Prototype Simulation

4.1. Virtual Prototype Model

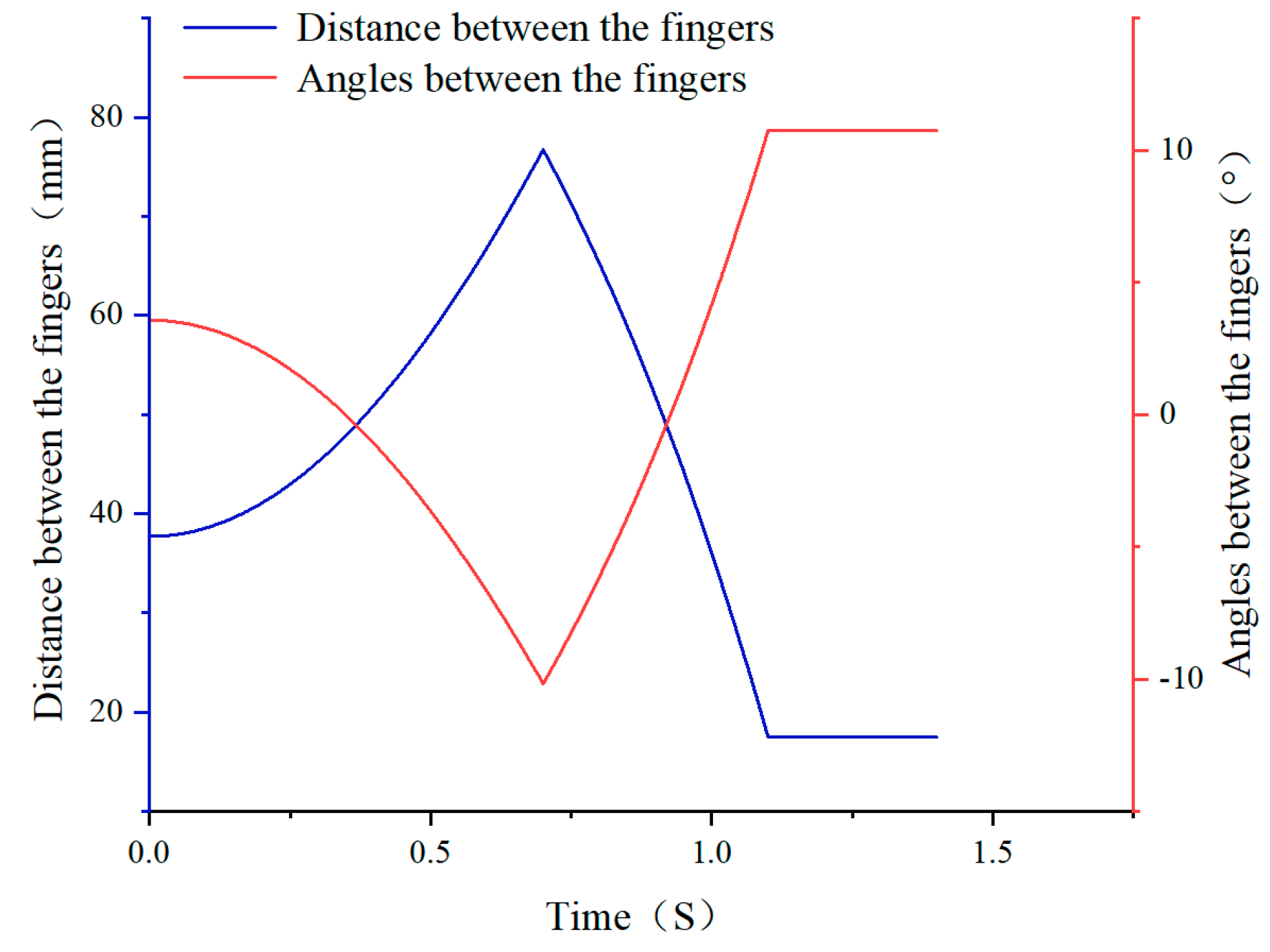

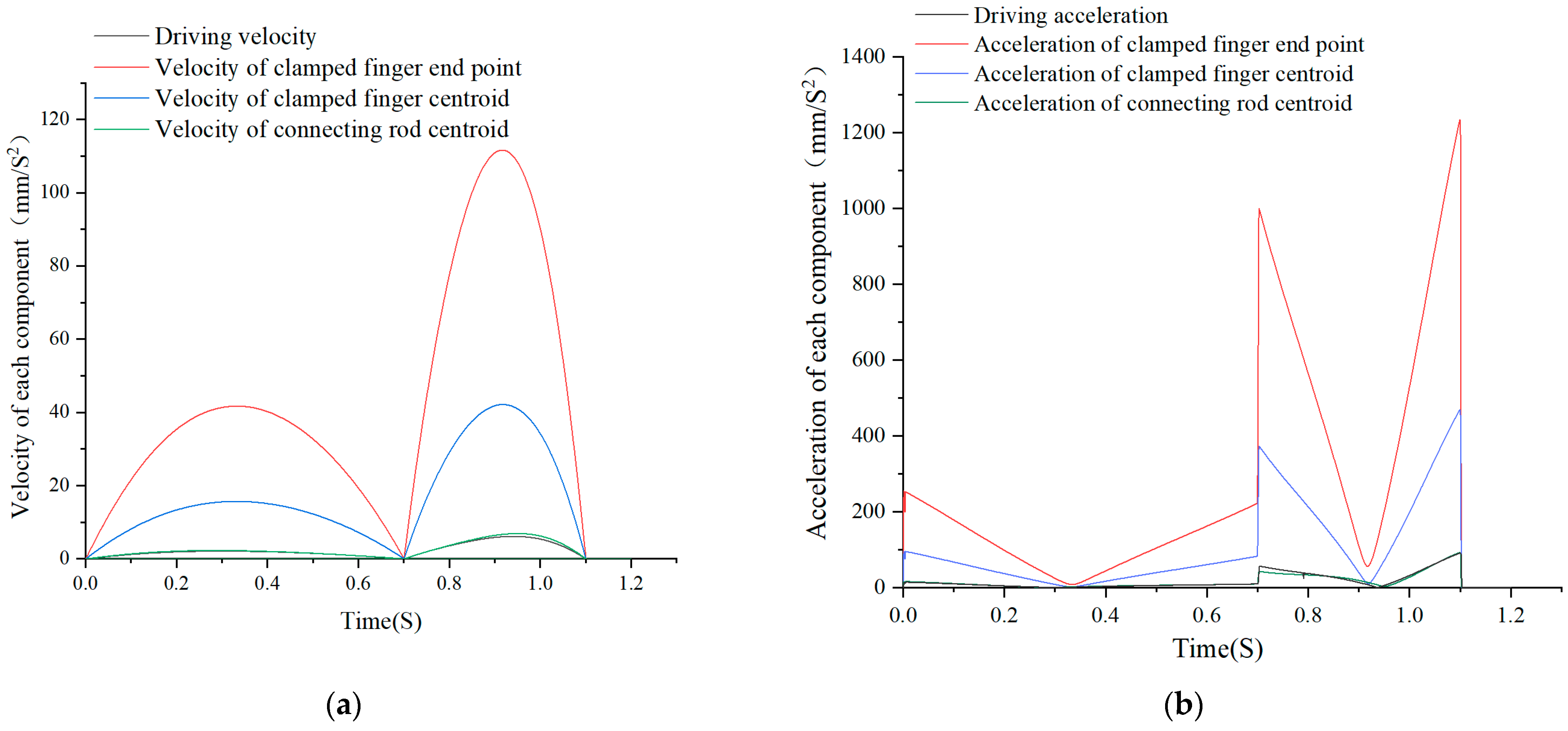

4.2. Motion Simulation Analysis and Verification

5. Picking Seedling Experiment

5.1. Test Conditions and Methods

5.2. Experiment Factors and Levels

5.3. Test Evaluation Index

5.4. Analysis of Test Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wen, Y.S.; Zhang, J.X.; Yuan, T. Current situation and analysis of automatic pick-up technology for vegetable plug seedlings. J. China Agric. Univ. 2021, 26, 128–142. [Google Scholar]

- Zhang, N.; Zhang, G.Z. Research status and prospect of rice planting mechanization. Hubei Agric. Sci. 2020, 59, 5–10. [Google Scholar]

- Hu, Q.L.; Zhang, Q.S.; Li, X.Z. Design and parameter analysis of seedling collection device of rapeseed substrate block seedlings transplanter machine. Trans. Chin. Soc. Agric. Eng. 2021, 37, 18–27. [Google Scholar]

- Feng, S.J.; Wu, M.L.; Yan, B.; Quan, W. Design and test of eject lifting type pot seedling detaching device. Trans. Chin. Soc. Agric. Eng. 2020, 36, 50–58. [Google Scholar]

- Ma, X.X.; Li, H.; Cao, W.B. Optimization and experiment of working parameters of automatic seedling picking device for tomato seedlings transplanting. Trans. Chin. Soc. Agric. Eng. 2020, 36, 46–55. [Google Scholar]

- Liao, Q.X.; Zhang, Z.; Hu, Q.L. Design and trajectory analysis of pneumatic picking-up mechanism for rape paper pot seedling. Trans. Chin. Soc. Agric. Mach. 2017, 48, 70–78. [Google Scholar]

- Xu, C.L.; Lv, Z.J.; Xin, L. Optimization design and experiment of full-automatic strawberry potted seedling transplanting mechanism. Trans. Chin. Soc. Agric. Mach. 2019, 50, 97–106. [Google Scholar]

- Ryu, K.H.; Kim, G.; Han, J.S. Automation and emerging technologies: Development of a robotic transplanter for bedding plants. J. Agric. Eng. Res. 2001, 78, 141–146. [Google Scholar] [CrossRef]

- Choi, W.C.; Kim, D.C.; Ryu, I.; Kim, K.U. Development of a Seedling Pick-up Device for Vegetable Transplanters. Trans. ASAE 2002, 45, 13–19. [Google Scholar]

- Islam, M.N.; Iqbal, M.Z.; Ali, M. Kinematic Analysis of a Clamp-Type Picking Device for an Automatic Pepper Transplanter. Agriculture 2020, 10, 627. [Google Scholar] [CrossRef]

- Li, H.; Ma, X.X.; Cao, W.B. Design and experiment of seedling picking mechanism by stem clipping for tomato plug seedling. Trans. Chin. Soc. Agric. Eng. 2020, 36, 39–48. [Google Scholar]

- Tong, J.H.; Shi, H.F.; Wu, C.Y. Simulation and test of seedling pot grabbing by spade end-effector. Trans. Chin. Soc. Agric. Mach. 2019, 50, 107–116. [Google Scholar]

- Jiang, Z.H.; Jiang, H.Y.; Tong, J.H. Optimal design of end-effector on automatic plug seedling transplanter. J. Zhejiang Univ. Eng. Sci. 2017, 51, 1119–1125. [Google Scholar]

- Liang, X.F.; Xiao, X.Z.; Zhu, Y.H. Design and experiment on pot-seedling supplementing end-effector for vegetables in cotyledon phase. Trans. CSAE 2018, 34, 49–57. [Google Scholar]

- Xie, S.Y.; Yang, S.H.; Liu, J. Development of the seedling taking and throwing device with oblique insertion and plug clipping for vegetable transplanters. Trans. Chin. Soc. Agric. Eng. 2020, 36, 1–10. [Google Scholar]

- Han, L.H.; Mao, H.P.; Yan, L. Pincette-type end-effector using two fingers and four pins for picking up seedlings. Trans. Chin. Soc. Agric. Mach. 2015, 46, 23–30. [Google Scholar]

- Han, B.; Shen, D.S.; Guo, C. Design and experiment of adjustable end-effector of cabbage seedings. Trans. Chin. Soc. Agric. Mach. 2019, 50, 111–120. [Google Scholar]

- Wang, M.M.; Song, J.N.; Liu, C.L. Design and experiment of crank rocker type clamp seedlings mechanism of vegetable transplanter. Trans. CSAE 2015, 31, 49–57. [Google Scholar]

- Han, C.J.; Xiao, L.Q.; Xu, Y. Design and experiment of the automatic transplanter for chili plug seedlings. Trans. CSAE 2021, 37, 20–29. [Google Scholar]

- Han, C.J.; Zhao, X.W.; Guo, H. Experimental study on determination of pepper plug seedling morphological characteristic. Chin. Agric. Mech. 2015, 37, 191–193. [Google Scholar]

- Ma, Y.F.; Wang, W.B.; Feng, J.A. Experimental study on compression properties transplanted tomato plug seedlings pot. Chin. J. Agric. Mach. Chem. 2020, 41, 64–71. [Google Scholar]

- Wang, Y.; Chen, J.N.; Wu, J.W. Mechanics property experiment of broccoli seedling oriented to mechanized planting. Trans. Chin. Soc. Agric. Eng. 2014, 30, 1–10. [Google Scholar]

- Hu, J.; Han, L.H.; Wen, Y.F. Mechanical properties of different vegetable plug seedlings as related to automatic transplanting. J. Agric. Mech. Res. 2018, 40, 132–136. [Google Scholar]

- Miao, X.H.; Mao, H.P.; Han, L.H. Analysis of influencing factors on force of picking plug seedlings and pressure resistance of plug seedlings. Trans. Chin. Soc. Agric. Mach. 2013, 44, 27–32. [Google Scholar]

- Han, L.H.; Mao, H.P.; Hu, J.P. Experiment on mechanical property of seedling pot for automatic transplanter. Trans. Chin. Soc. Agric. Eng. 2013, 29, 24–29. [Google Scholar]

- Wang, Y.Y.; Yu, H.Y. Experiment and analysis of impact factors for soil matrix intact rate of manipulator for picking-up plug seedlings. Trans. Chin. Soc. Agric. Eng. 2015, 31, 65–71. [Google Scholar]

- Hu, J.P.; Pan, J.; Chen, F. Simulation and Optimization Design of Finger-clamping Seedling Picking Claw Based on EDEM-RecurDyn. Trans. Chin. Soc. Agric. Mach. 2022, 53, 75–85, 301. [Google Scholar]

- Shen, T.H.; Feng, J.A.; Wang, W.B. Virtual design and parameter optimization of the transplanter’s end-effector based on ADAMS. J. Mach. Des. 2019, 36, 46–51. [Google Scholar]

- Tong, J.H.; Meng, Q.X.; Gu, S. Design and experiment of high-speed sparse transplanting mechanism for hydroponics pot seedlings in greenhouses. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–9. [Google Scholar]

- Jin, X.; Li, S.J.; Yang, X.J. Motion analysis and parameter optimization for pot seedling planting mechanism based on up-film transplanting. Trans. Chin. Soc. Agric. Mach. 2012, 43, 29–34. [Google Scholar]

- Tian, S.B.; Zhao, C.X.; Hu, X. Design and experiment on automatic feeding-seedling device of vegetable transplanter. J. Shenyang Agric. Univ. 2020, 51, 586–592. [Google Scholar]

- Wang, C.; Liu, C.L.; Li, Y.L. Design and Experiment of pneumatic punching high-speed seedling picking device for vegetable transplanter. Trans. Chin. Soc. Agric. Mach. 2021, 52, 35–43, 51. [Google Scholar]

- Ma, Z.H.; Rao, Y.C.; Tong, J.H. Sparse Transplanting Mechanism Design with Double Row Mechanical Arms and Work Time Sequence Optimization for Hydroponics Pot Seedlings in Greenhouse. Trans. Chin. Soc. Agric. Mach. 2022, 53, 60–69. [Google Scholar]

| Parameters | Value (mm) | Parameters | Value |

|---|---|---|---|

| r1 | 26 | l4 | 100/mm |

| r2 | 36 | l5 | 55/mm |

| l1 | 45 | θ1 | 130/° |

| l2 | 21.5 | θ2 | 118/° |

| l3 | 20 | θ3 | 153.48/° |

| Num. | Constraint Parts | Type of Joint | Constraints Name | Driving Force |

|---|---|---|---|---|

| 1 | drive, rod1 | Revolute | Rdrive_rod1 | |

| 2 | drive, rod3 | Revolute | Rdrive_rod3 | |

| 3 | fix, drive | Translational | T_drive_fix | drive_fixMotion |

| 4 | finger1, rod1 | Revolute | R_fin1_rod1 | |

| 5 | finger2, rod2 | Revolute | R_fin2_rod2 | |

| 6 | finger3, rod3 | Revolute | R_fin3_rod3 | |

| 7 | finger4, rod4 | Revolute | R_fin4_rod4 | |

| 8 | finger1, fix | Revolute | R_fin1_fix | |

| 9 | finger2, fix | Revolute | R_fin2_fix | |

| 10 | finger3, fix | Revolute | R_fin3_fix | |

| 11 | finger4, fix | Revolute | R_fin4_fix | |

| 12 | pot, ground | Translational | T_pot_ground | |

| 13 | fix, ground | Translational | T_fix_ground | fix_grouMotion |

| 14 | seedling50, fix | Translational | Tseedl_fix | fix_seedlMotion |

| 15 | drive, rod2 | Revolute | Rdrive_rod2 | |

| 16 | drive, rod4 | Revolute | Rdrive_rod4 |

| Name of Drive Source | Motion Expression |

|---|---|

| drive_fixMotion | IF (time-0.7: -10 * time, -10 * time, IF (time-1.1:10 * time, 10 * time, 0)) |

| fix_grouMotion | IF (time-0.7:0, -410 * time, IF (time-1.1: -410 * time, -410 * time, 410 * time)) |

| fix_seedlMotion | IF (time-0.7:0, -410 * time, IF (time-1.1: -410 * time, -410 * time, 0)) |

| Name of Drive Source | Motion Expression |

|---|---|

| drive_fixMotion | STEP (time, 0, 0, 0.7, −2.42206) + STEP (time, 0.70001, 0, 0.92680, 1.81315) + STEP (time, 0.92681, 0, 1.10007, 1.75891) |

| fix_grouMotion | STEP (time, 0, 0, 0.7, 0) + STEP (time, 0.70001, 0, 0.92680, −100) + STEP (time, 0.92681, 0, 1.10007, −45) + STEP (time, 1.10008, 0, 1.2, 145) |

| fix_seedlMotion | STEP (time, 0, 0, 0.7, 0) − STEP (time, 0.70001, 0, 0.92680, −100) − STEP (time, 0.92681, 0, 1.10007, −45) + STEP (time, 1.10008, 0, 1.2, 0) |

| Levels | Factors | ||

|---|---|---|---|

| Moisture Content of Pots (A) (%) | Frequency of Picking Up Seedlings (B) (Trees·min−1) | Materials of Clampers (C) | |

| 1 | 45 | 16 | Q235A |

| 2 | 58 | 20 | Nylon 7100 |

| 3 | 71 | 24 | Q235A |

| Test No. | Experimental Factors | S1 (%) | S2 (%) | ||||

|---|---|---|---|---|---|---|---|

| Moisture Content of Pots (A) | Frequency of Picking Up Seedlings (B) | Empty | Materials of Clampers (C) | ||||

| 1 | 1 | 1 | 1 | 1 (1) | 2.62 | 100 | |

| 2 | 1 | 2 | 2 | 2 (2) | 3.11 | 95 | |

| 3 | 1 | 3 | 3 | 3 (1) | 2.53 | 100 | |

| 4 | 2 | 1 | 2 | 3 (1) | 3.81 | 100 | |

| 5 | 2 | 2 | 3 | 1 (1) | 3.39 | 100 | |

| 6 | 2 | 3 | 1 | 2 (2) | 7.16 | 90 | |

| 7 | 3 | 1 | 3 | 2 (2) | 7.78 | 85 | |

| 8 | 3 | 2 | 1 | 3 (1) | 3.95 | 100 | |

| 9 | 3 | 3 | 2 | 1 (1) | 4.21 | 95 | |

| S1 | k1 | 2.75 | 4.74 | 4.58 | 3.42 | ||

| k2 | 4.79 | 3.48 | 3.71 | 6.02 | |||

| k3 | 5.31 | 4.63 | 4.57 | ||||

| R | 2.56 | 1.25 | 0.87 | 2.60 | |||

| S2 | k1 | 98.33 | 95.00 | 96.67 | 99.17 | ||

| k2 | 96.67 | 98.33 | 96.67 | 90.00 | |||

| k3 | 93.33 | 95.00 | 95.00 | ||||

| R | 5.00 | 3.33 | 1.67 | 9.17 | |||

| Indicators | Source | Degree of Freedom | Sum of Squares | Mean Square | F Value | p-Value |

|---|---|---|---|---|---|---|

| S1 | A | 2 | 10.97 | 14.43 | 53,004.53 | <0.0001 ** |

| B | 2 | 2.90 | 1.45 | 5333.92 | <0.0001 ** | |

| C | 1 | 13.50 | 13.50 | 49,601.65 | <0.0001 ** | |

| Error | 3 | 0.0008 | 0.00027 | |||

| Total | 8 | 28.83 | ||||

| S2 | A | 2 | 238.89 | 119.44 | 86 | <0.01 ** |

| B | 2 | 38.89 | 11.11 | 8 | <0.025 * | |

| C | 1 | 22.22 | 168.06 | 121 | <0.01 * | |

| Error | 3 | 4.17 | 1.39 | |||

| Total | 8 | 238.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, N.; Zhang, G.; Liu, H.; Liu, W.; Wei, J.; Tang, N. Design of and Experiment on Open-and-Close Seedling Pick-Up Manipulator with Four Fingers. Agriculture 2022, 12, 1776. https://doi.org/10.3390/agriculture12111776

Zhang N, Zhang G, Liu H, Liu W, Wei J, Tang N. Design of and Experiment on Open-and-Close Seedling Pick-Up Manipulator with Four Fingers. Agriculture. 2022; 12(11):1776. https://doi.org/10.3390/agriculture12111776

Chicago/Turabian StyleZhang, Ni, Guozhong Zhang, Haopeng Liu, Wanru Liu, Jia Wei, and Nanrui Tang. 2022. "Design of and Experiment on Open-and-Close Seedling Pick-Up Manipulator with Four Fingers" Agriculture 12, no. 11: 1776. https://doi.org/10.3390/agriculture12111776

APA StyleZhang, N., Zhang, G., Liu, H., Liu, W., Wei, J., & Tang, N. (2022). Design of and Experiment on Open-and-Close Seedling Pick-Up Manipulator with Four Fingers. Agriculture, 12(11), 1776. https://doi.org/10.3390/agriculture12111776