Evaluation of a Fixed Spraying System for Phytosanitary Treatments in Heroic Viticulture in North-Eastern Italy

Abstract

:1. Introduction

2. Materials and Methods

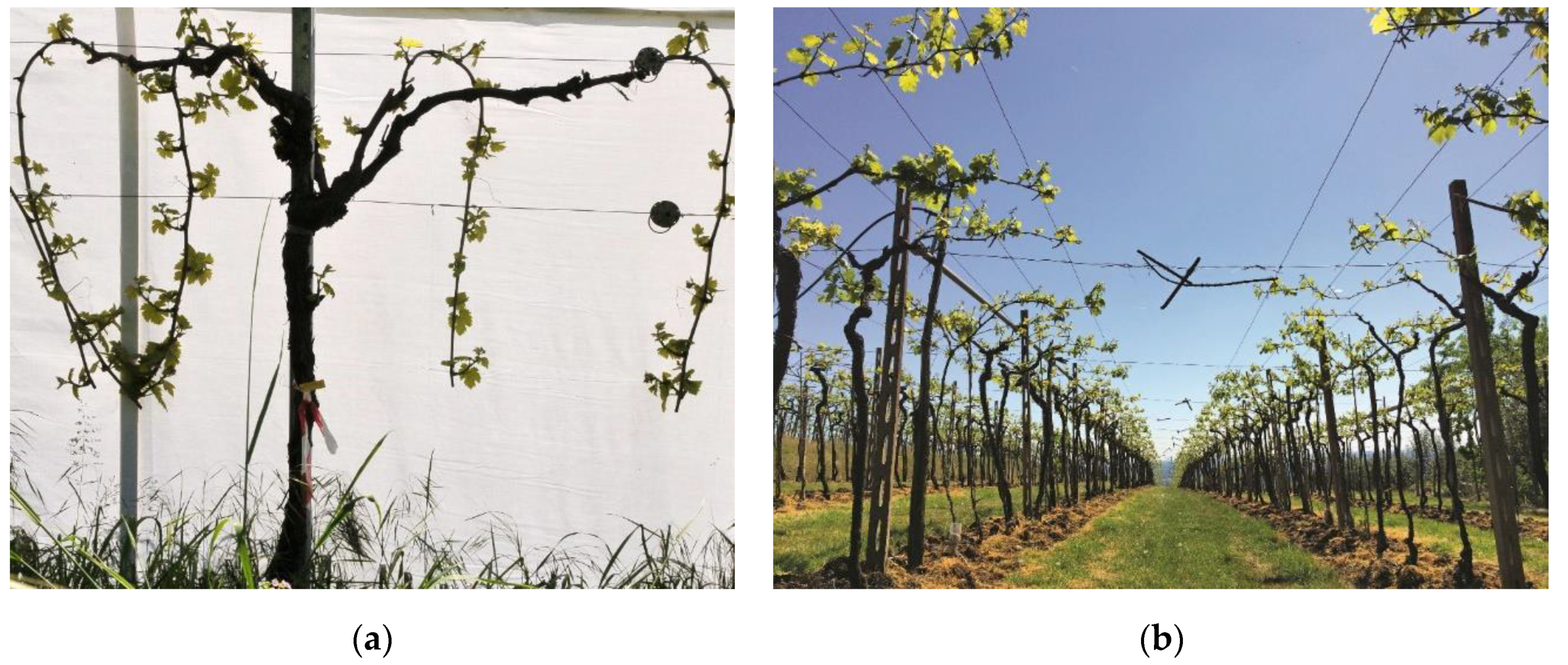

2.1. Experimental Areas

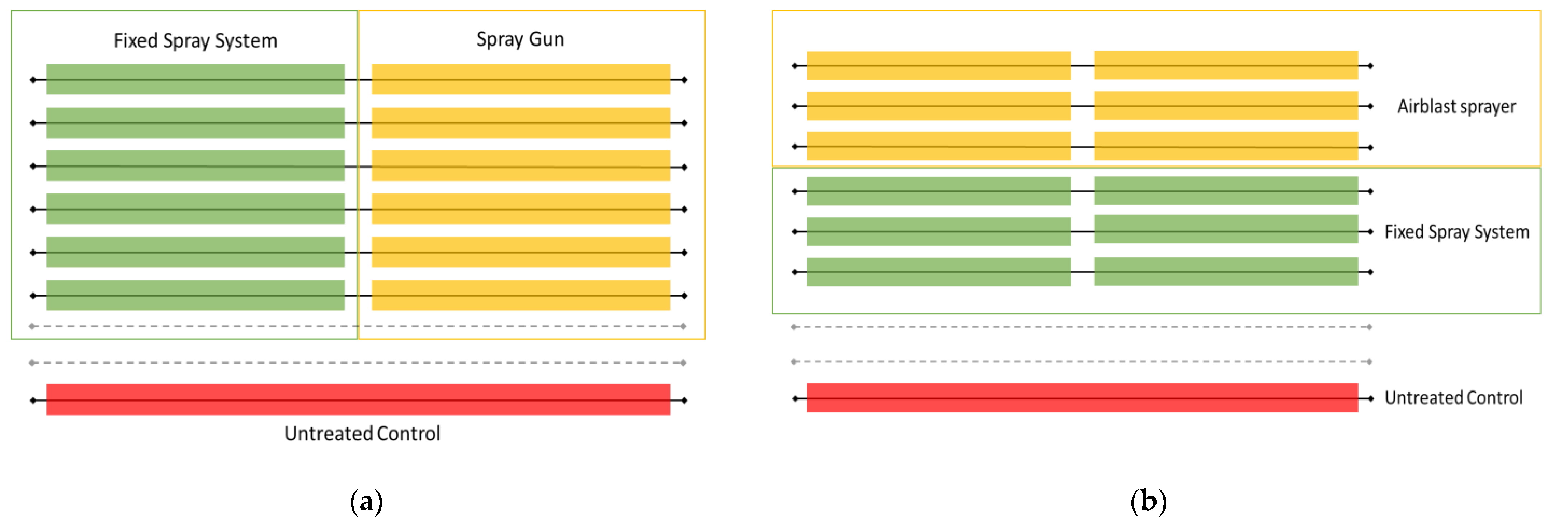

2.2. Experimental Design

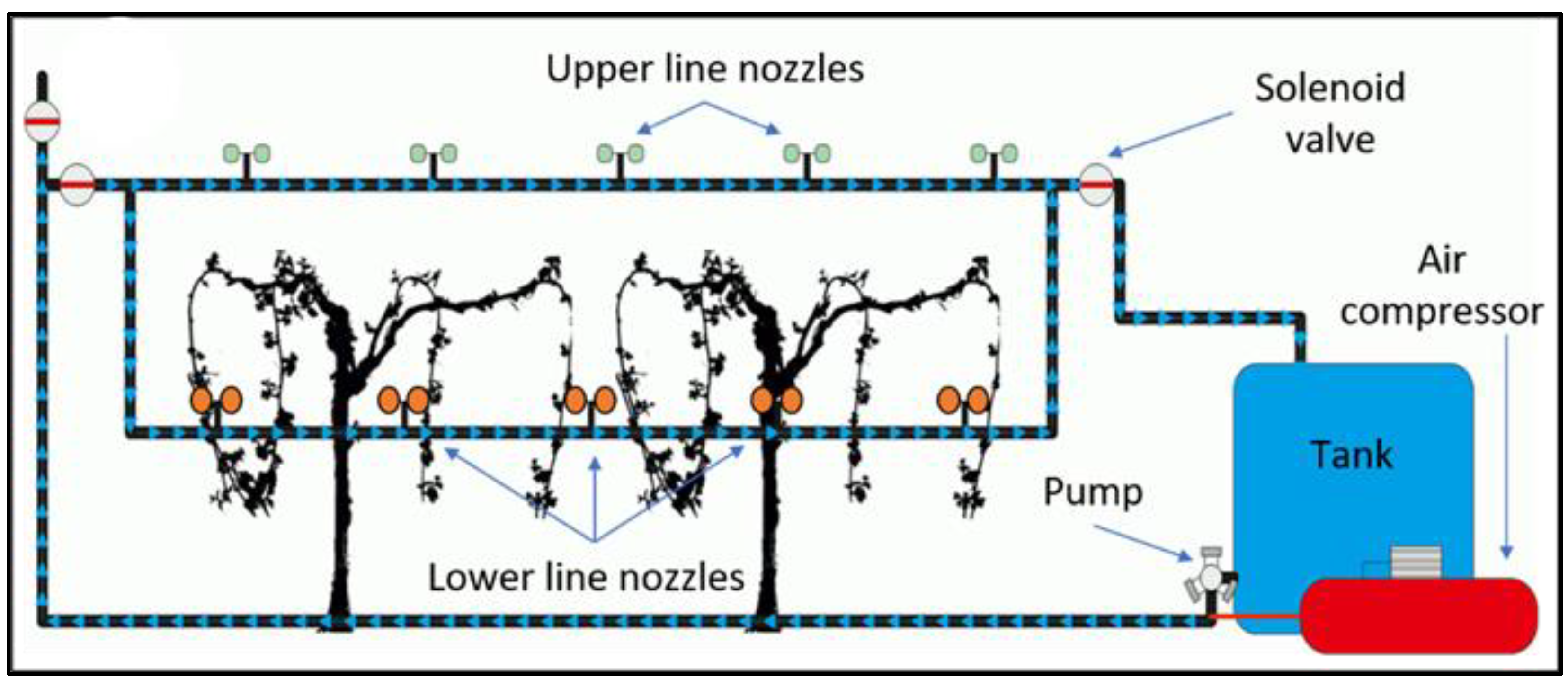

2.3. Fixed Spraying Systems

- the agrochemical mixture is circulated at low pressure in the system, with the solenoid valves of the row to be treated open, until the liquid completely fills the line; this step takes about 100 s;

- once the pipeline is fully replenished, the PLC closes the solenoid valve located at the end of the row; the pressure rises suddenly at 6 bar, the anti-drop valves open, and the nozzles start spraying, with virtually no delay between the opening of the first and last nozzle; after 15 s, the PLC opens the terminal row valve: the pressure drops immediately below 2 bar, anti-drop valves close, and the mixture flows through the collecting tube back to the tank;

- at the end of spraying, the pump is switched off and a solenoid valve lets compressed airflow at low pressure (<0.2 bar) into the supply line, thus emptying the mixture into the tank; after 70–80 s, the air pressure in the nozzle line increases due to the closing of the end-of-row valve, and the residual mixture in the nozzles is sprayed on the foliage;

- steps 2 and 3 are repeated for each row.

2.4. Application of Pesticides

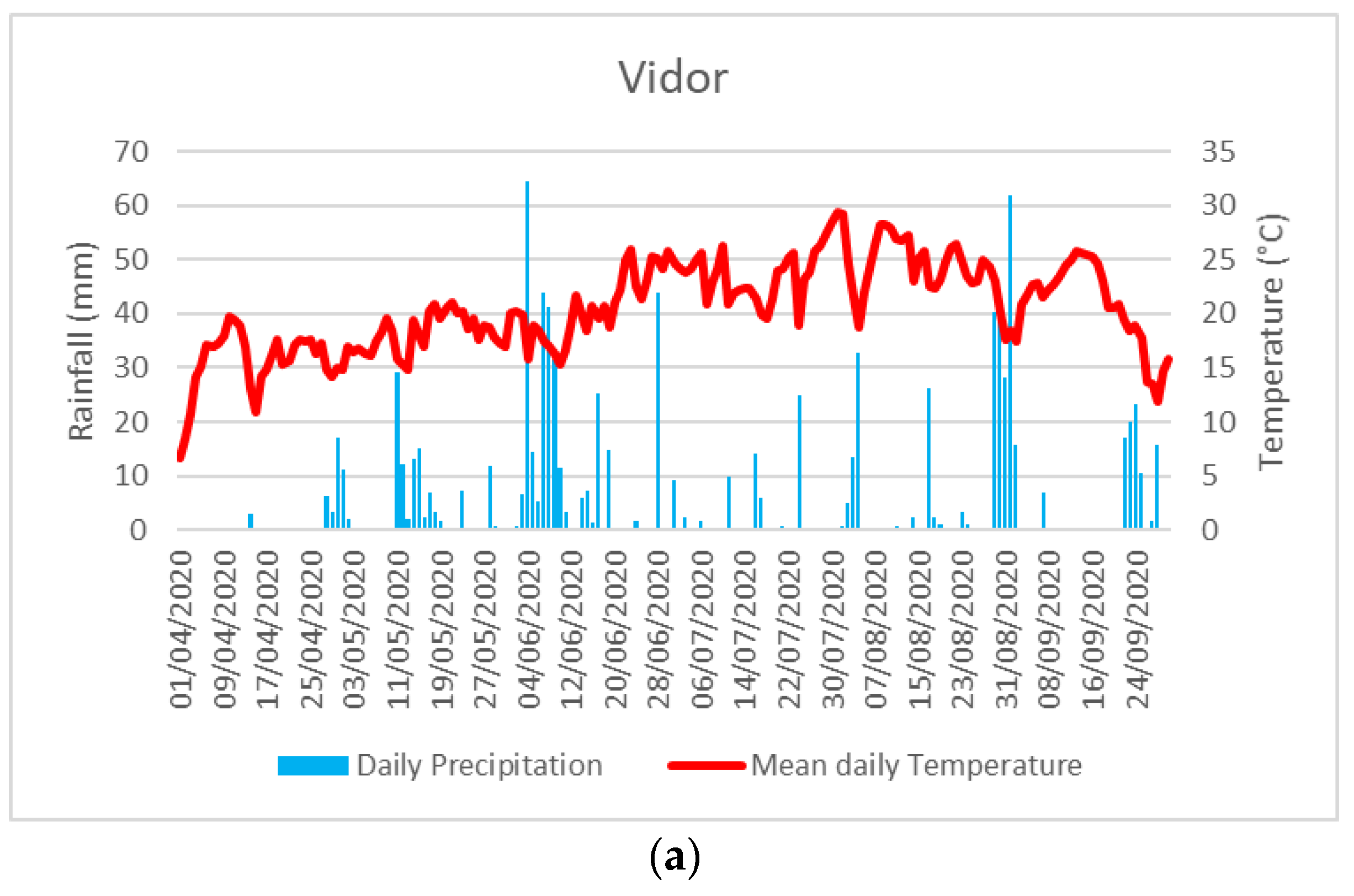

2.5. Meteorological Data

2.6. Evaluation of Disease Symptoms and Arthropods Abundance

2.7. Data Analysis

3. Results

3.1. Vidor

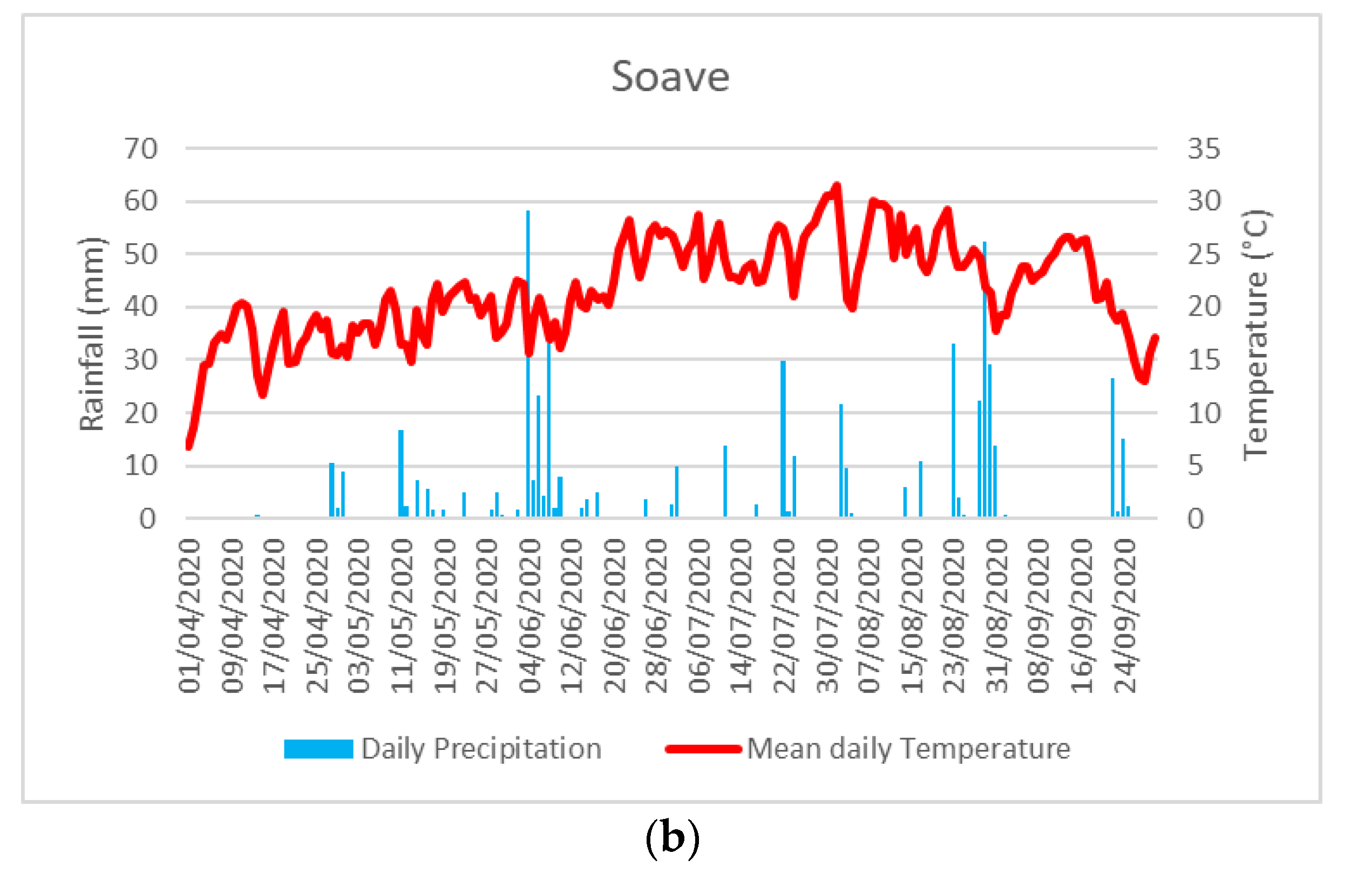

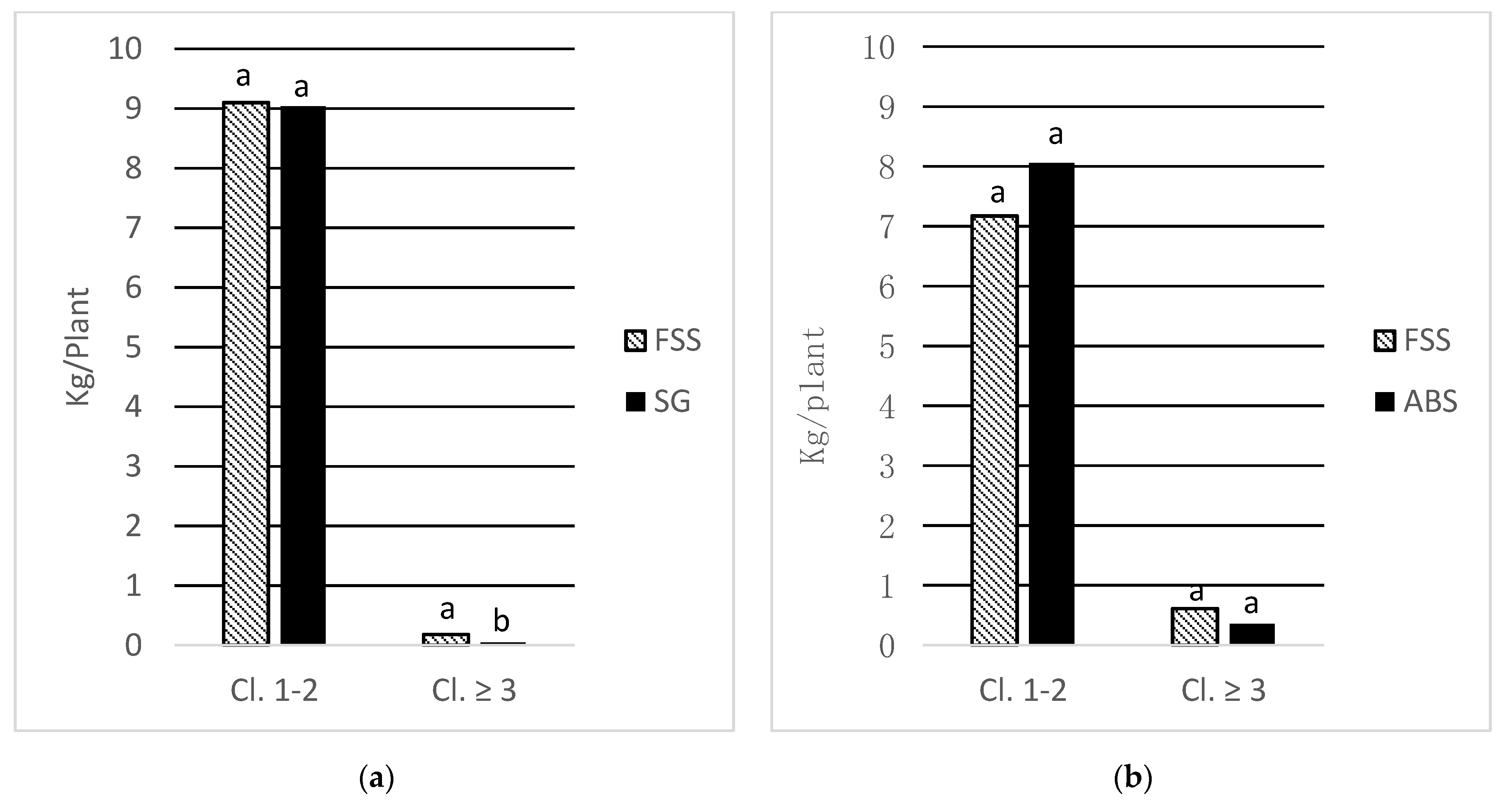

3.2. Soave

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- CERVIM 2021. Available online: http://www.cervim.org/en/mountain-and-steep-slope-vitigulture.aspx (accessed on 28 August 2021).

- Michael, C.; Gil, E.; Gallart, M.; Stavrinides, M.C. Evaluation of the effects of spray technology and volume rate on the control of grape berry moth in mountain viticulture. Agriculture 2021, 11, 178. [Google Scholar] [CrossRef]

- Dubuis, P.-H.; Monod, V.; Gindro, K. Pulvérisateurs de type gun et canon: Étude de littérature sur leur utilisation et les risques spécifiques. Rev. Suisse Vitic. Arboric. Hortic. 2019, 51, 300–305. [Google Scholar]

- Michael, C.; Gil, E.; Gallart, M.; Stavrinides, M.C. Influence of spray technology and application rate on leaf deposit and ground losses in mountain viticulture. Agriculture 2020, 10, 615. [Google Scholar] [CrossRef]

- Merlo, R. Consorzio di Tutela del Conegliano Valdobbiadene Prosecco Superiore DOCG. Personal communication, 2021. [Google Scholar]

- Strub, L.; Loose, S.M. The cost disadvantage of steep slope viticulture and strategies for its preservation. Oeno One 2021, 55, 49–68. [Google Scholar] [CrossRef]

- Landers, A.; Agnello, A.; Shayya, W. Engineering challenges in the development of a fixed spraying system for high-density apple trees. In Proceedings of the III workshop on Spray Application Techniques—Fruit Growing, Barcelona, Spain, 9–12 July 2005. [Google Scholar]

- Verpont, F.; Favareille, J.; Zavagli, F. Fixed spraying system: A future potential way to apply pesticides in an apple orchard? In Proceedings of the Workshop on Spray Application in Fruit Growing, Lake Constance, Germany, 15–18 July 2015; pp. 53–54. [Google Scholar]

- Sinha, R.; Ranjan, R.; Bahlol, H.Y.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.J. Development and performance evaluation of a pneumatic solid set canopy delivery system for high-density apple orchards. Trans. ASABE 2020, 63, 37–48. [Google Scholar] [CrossRef]

- Niemann, S.M.; Whiting, M.D. Spray coverage in apple and cherry orchards using a solid set canopy delivery system. Acta Hortic. 2016, 1130, 647–653. [Google Scholar] [CrossRef]

- Owen-Smith, P.; Wise, J.; Grieshop, M.J. Season long pest management efficacy and spray characteristics of a solid set canopy delivery system in high density apples. Insects 2019, 10, 193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bondesan, D.; Rizzi, C.; Dorigoni, A.; Pasqualini, J.; McHeli, F. First assessments of fixed spray application systems in narrow-wall apple orchards. Asp. Appl. Biol. 2016, 132, 411–414. [Google Scholar]

- Otto, S.; Loddo, D.; Schmid, A.; Roschatt, C.; Venturelli, M.; Innerebner, G. Droplets deposition pattern from a prototype of a fixed spraying system in a sloping vineyard. Sci. Total Environ. 2018, 639, 92–99. [Google Scholar] [CrossRef]

- Baldoin, C.; Causin, R.; Loddo, D.; Otto, S.; Duso, C.; Zanin, G. Design and first testing of a prototype of a fixed spraying system for sloping vineyards. Asp. Appl. Biol. 2016, 132, 397–404. [Google Scholar]

- Innerebner, G.; Roschatt, C.; Schmid, A. Efficacy of fungicide treatments on grapevines using a fixed spraying system. Crop Prot. 2020, 138, 105324. [Google Scholar] [CrossRef]

- Sinha, R.; Ranjan, R.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.J. Comparison of within canopy deposition for a solid set canopy delivery system (SSCDS) and an axial–fan airblast sprayer in a vineyard. Crop Prot. 2020, 132, 105124. [Google Scholar] [CrossRef]

- Sinha, R.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.J.; Bahlol, H. Feasibility of a Solid set canopy delivery system for efficient agrochemical delivery in vertical shoot position trained vineyards. Biosyst. Eng. 2019, 179, 59–70. [Google Scholar] [CrossRef]

- UNESCO Le Colline del Prosecco di Conegliano e Valdobbiadene. Available online: https://whc.unesco.org/en/list/1571/ (accessed on 28 August 2021).

- FAO Soave Traditional Vineyards, Italy. Available online: http://www.fao.org/giahs/giahsaroundtheworld/designated-sites/europe-and-central-asia/soave-traditional-vineyards/en/ (accessed on 28 August 2021).

- Agnello, A.; Landers, A.; Savira, F.; Suharsono, Y. Optimization of a Fixed Spraying System for Commercial High-Density Apple Plantings Final Report 2007; Department of Entomology, Cornell University: Geneva, NY, USA, 2007; Volume 1. [Google Scholar]

- Agnello, A.; Landers, A. In-Canopy Fixed Spraying System for High-Density Apple Orchards. In Proceedings of the Communication at Interpoma 2014 Congress, Bolzano, Italy, 20–22 November 2014. [Google Scholar]

- Commission of the European Communities Commission regulation (EC) no 889/2008 of 5 September 2008 laying down detailed rules for the implementation of council regulation (EC) no 834/2007 on organic production and labelling of organic products with regard to organic production, labelling and co. Off. J. Eur. Union 2008, L 250, 1–84.

- Townsend, G.K.; Heuberger, J.W. Methods for Estimating Losses Caused by Diseases in Fungicide Experiments. Plant Dis. Report. 1943, 27, 340–343. [Google Scholar]

- Regione del Veneto Decreto 34 del 4 Giugno 2020. Available online: https://veneto.coldiretti.it/wp-content/uploads/2020/06/FD-Decreto-34-del-4_6_2020.pdf (accessed on 28 August 2021).

- Niemann, S.M.; Whiting, M.D.; Hanrahan, I. Efficacy of a solid set canopy delivery system (SSCDS) in sweet cherry and apple. Acta Hortic. 2016, 1130, 145–150. [Google Scholar] [CrossRef]

- Owen-Smith, P.; Perry, R.; Wise, J.; Jamil, R.Z.R.; Gut, L.; Sundin, G.; Grieshop, M. Spray coverage and pest management efficacy of a solid set canopy delivery system in high density apples. Pest Manag. Sci. 2019, 75, 3050–3059. [Google Scholar] [CrossRef] [PubMed]

- Chuche, J.; Thiéry, D. Biology and ecology of the Flavescence dorée vector Scaphoideus titanus: A review. Agron. Sustain. Dev. 2014, 34, 381–403. [Google Scholar] [CrossRef] [Green Version]

- Tirello, P.; Marchesini, E.; Gherardo, P.; Raniero, D.; Rossetto, F.; Pozzebon, A.; Duso, C. The control of the american leafhopper erasmoneura vulnerata (Fitch) in european vineyards: Impact of synthetic and natural insecticides. Insects 2021, 12, 85. [Google Scholar] [CrossRef]

- Fornasiero, D.; Pavan, F.; Pozzebon, A.; Picotti, P.; Duso, C. Relative infestation level and sensitivity of grapevine cultivars to the leafhopper empoasca vitis (Hemiptera: Cicadellidae). J. Econ. Entomol. 2016, 109, 416–425. [Google Scholar] [CrossRef] [PubMed]

- Duso, C.; Van Leeuwen, T.; Pozzebon, A. Improving the compatibility of pesticides and predatory mites: Recent findings on physiological and ecological selectivity. Curr. Opin. Insect Sci. 2020, 39, 63–68. [Google Scholar] [CrossRef] [PubMed]

| Date | Product Name | Rate/ha | Active Ingredient | Target |

|---|---|---|---|---|

| 2 May | Polyram DF | 1500 g | Metiram | Downy and powdery mildew |

| Dimethomorph | 400 mL | Dimethomorph | Downy and powdery mildew | |

| Sulfur | 3000 mL | Sulfur | Powdery mildew | |

| 14 May | Polyram DF | 1500 g | Metiram | Downy and powdery mildew |

| Dimethomorph | 400 mL | Dimethomorph | Downy and powdery mildew | |

| Sulfur | 3000 mL | Sulfur | Powdery mildew | |

| 21 May | Sercadis | 150 mL | Fluxapyroxad | Powdery mildew |

| Enervin TOP | 2500 g | Ametoctradin + metiram | Downy mildew | |

| 1 June | Sercadis | 150 mL | Fluxapyroxad | Powdery mildew |

| Zorvec Zelavin | 1500 mL | Oxathiapiprolin | Downy mildew | |

| 12 June | Lieto SC | 450 g | Cymoxanil + zoxamide | Downy mildew |

| Quantum | 500 mL | Dimethomorph | Downy and powdery mildew | |

| Score 25 EC | 200 mL | Difenoconazole | Powdery mildew and black rot | |

| 23 June | Enervin Duo | 1000 mL | Ametoctradin + dimethomorph | Downy mildew |

| Vivando | 200 mL | Metrafenone | Powdery mildew | |

| Kestrel | 400 mL | Acetamiprid | Leafhoppers | |

| 6 July | Lieto SC | 450 g | Cymoxanil + zoxamide | Downy mildew |

| Vivando | 200 mL | Metrafenone | Powdery mildew | |

| 14 July | Ridomil GOLD R WG | 5000 g | Metalaxyl + copper oxychloride | Powdery mildew |

| Zorvec Zelavin | 300 mL | Oxathiapiprolin | Downy mildew | |

| Brionflo 100 SC | 1000 mL | Cyazofamid | Downy mildew | |

| Kestrel | 400 mL | Acetamiprid | Leafhoppers | |

| 21 July | Ridomil GOLD R WG | 5000g | Metalaxyl + copper oxychloride | Powdery mildew |

| Champ 20 | 1000 g | Copper hydroxide | Downy mildew | |

| Sulfur | 3000 mL | Sulfur | Powdery mildew | |

| 30 July | Curame bordeaux | 5000 g | Copper sulfate + cymoxanil | Downy mildew |

| Mavrik smart | 300 mL | Tau-fluvalinate | Leafhoppers | |

| Zolvis | 4000 g | Sulfur | Powdery mildew |

| Thesis | Nozzle Type | Number of Nozzles | Operating Pressure (bar) | Air Pressure (bar) | Flow Rate @ 3.0 bar (L min−1) | Forward Speed (km h−1) | Volume Rate (L ha−1) | |

|---|---|---|---|---|---|---|---|---|

| FSS | Upper line | Netafim Coolnet Pro mod. 075 | 1 nozzle every 0.8 m | 3.5 | 8 | 0.43 | - | 1000 |

| Lower line | TeeJet TXR TXR800053VK (hollow cone) | A couple every 1.2 m | 5—5.5 | 8 | 0.21 | - | ||

| SG | - | TeeJet TXA8004VK (hollow cone) | 1 | 20 | - | 1.58 | 2.5 | 1000 |

| Date | Product Name | Active Ingredient | Rate/ha | Target |

|---|---|---|---|---|

| 2 May | Mexiram Hi Bio | Copper hydroxide | 1.5 Kg/ha | Downy mildew |

| Tiovit Jet | Sulfur | 3 kg/ha | Powdery mildew | |

| 9 May | Mexiram Hi Bio | Copper hydroxide | 1.5 Kg/ha | Downy mildew |

| Tiovit Jet | Sulfur | 3 kg/ha | Powdery mildew | |

| 14 May | Mexiram Hi Bio | Copper hydroxide | 1.5 Kg/ha | Downy mildew |

| Tiovit Jet | Sulfur | 3 kg/ha | Powdery mildew | |

| 21 May | Mexiram Hi Bio | Copper hydroxide | 1 Kg/ha | Downy mildew |

| 29 May | Tiovit Jet | Sulfur | 3 kg/ha | Powdery mildew |

| Mexiram Hi Bio | Copper hydroxide | 1.5 Kg/ha | Downy mildew | |

| 3 June | Tiovit Jet | Sulfur | 3 kg/ha | Powdery mildew |

| Mexiram Hi Bio | Copper hydroxide | 1.5 Kg/ha | Downy mildew | |

| 5 June | Tiovit Jet | Sulfur | 3 kg/ha | Powdery mildew |

| Mexiram Hi Bio | Copper hydroxide | 1.5 Kg/ha | Downy mildew | |

| 8 June | Tiovit Jet | Sulfur | 3 kg/ha | Powdery mildew |

| Mexiram Hi Bio | Copper hydroxide | 1.5 Kg/ha | Downy mildew | |

| 15 June | Tiovit Jet | Sulfur | 3 kg/ha | Powdery mildew |

| Mexiram Hi Bio | Copper hydroxide | 1.5 Kg/ha | Downy mildew | |

| 25 June | Microthiol Disperss | Sulfur | 4 kg/ha | Powdery mildew |

| Mexiram Hi Bio | Copper hydroxide | 0.5 kg/ha | Downy mildew | |

| 7 July | Microthiol Disperss | Sulfur | 6 kg/ha | Powdery mildew |

| Neemik Ten | Azadirachtin | 2.6 L/ha | Leafhoppers | |

| 15 July | Microthiol Disperss | Sulfur | 8 kg/ha | Powdery mildew |

| 28 July | Mexiram Hi Bio | Copper hydroxide | 400 g/hl | Downy mildew |

| Microthiol Disperss | Sulfur | 800 g/hl | Powdery mildew | |

| 18 August | Poltiglia Disperss | Bordeaux mixture | 2 kg/ha | Downy mildew |

| Microthiol Disperss | Sulfur | 4 kg/ha | Powdery mildew | |

| Surround Wp | Kaolin | 15 kg/ha |

| Thesis | Nozzle Type | Number of Nozzles | Operating Pressure (bar) | Air Pressure (bar) | Flow Rate @ 3.0 bar (L min−1) | Forward Speed (km h−1) | Volume Rate (L ha−1) | |

|---|---|---|---|---|---|---|---|---|

| FSS | Upper line | NETAFIM Gyronet 58 SR | 1 nozzle every 2.5 m | 6 | 10 | 0.83 | - | 750 |

| Lower line | TeeJet TXR TXR800053VK (hollow cone) | A couple every 1 m | 6 | 10 | 0.21 | - | ||

| ABS | - | TeeJet TXB8003VK (hollow cone) | 6 | 20 | - | 1.18 | 5.3 | 750 |

| Pathogen | Evaluation Day | Application Method | Incidence (ID) (%) | Severity (Ic) (%) |

|---|---|---|---|---|

| Downy mildew | 23 July 2020 | Fixed spray system | 25.5 a | 9.07 b |

| Spray gun | 13.00 b | 3.07 a | ||

| Untreated control | 42.47 a | 29.80 c | ||

| p-value | 0.0181 * | 0.0072 ** | ||

| Downy mildew | 11 September 2020 | Fixed spray system | 4.00 a | 1.35 b |

| Spray gun | 4.00 a | 0.85 a | ||

| Untreated control | 44.00 b | 21.00 c | ||

| p-value | 0.0053 ** | 0.0089 ** |

| Pathogen | Evaluation Day | Application Method | Incidence (ID) (%) | Severity (Ic) (%) |

|---|---|---|---|---|

| Powdery mildew | 26 September 2020 | Fixed spray system | 4.00 a | 2.85 a |

| Airblast sprayer | 6.66 b | 3.04 a | ||

| Untreated control | 6.67 b | 3.61 a | ||

| p-value | 0.0456 * | 0.8068 | ||

| Grey mildew | 26 September 2020 | Fixed spray system | 27.33 a | 10.38 a |

| Airblast sprayer | 34.04 a | 13.06 a | ||

| Untreated control | 32.00 a | 16.28 a | ||

| p-value | 0.3932 | 0.2019 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imperatore, G.; Ghirardelli, A.; Strinna, L.; Baldoin, C.; Pozzebon, A.; Zanin, G.; Otto, S. Evaluation of a Fixed Spraying System for Phytosanitary Treatments in Heroic Viticulture in North-Eastern Italy. Agriculture 2021, 11, 833. https://doi.org/10.3390/agriculture11090833

Imperatore G, Ghirardelli A, Strinna L, Baldoin C, Pozzebon A, Zanin G, Otto S. Evaluation of a Fixed Spraying System for Phytosanitary Treatments in Heroic Viticulture in North-Eastern Italy. Agriculture. 2021; 11(9):833. https://doi.org/10.3390/agriculture11090833

Chicago/Turabian StyleImperatore, Gaetano, Aurora Ghirardelli, Luca Strinna, Cristiano Baldoin, Alberto Pozzebon, Giuseppe Zanin, and Stefan Otto. 2021. "Evaluation of a Fixed Spraying System for Phytosanitary Treatments in Heroic Viticulture in North-Eastern Italy" Agriculture 11, no. 9: 833. https://doi.org/10.3390/agriculture11090833

APA StyleImperatore, G., Ghirardelli, A., Strinna, L., Baldoin, C., Pozzebon, A., Zanin, G., & Otto, S. (2021). Evaluation of a Fixed Spraying System for Phytosanitary Treatments in Heroic Viticulture in North-Eastern Italy. Agriculture, 11(9), 833. https://doi.org/10.3390/agriculture11090833