Gradient Cleaning Method of Potato Based on Multi-Step Operation of Dry-Cleaning and Wet Cleaning

Abstract

:1. Introduction

2. Materials and Methods

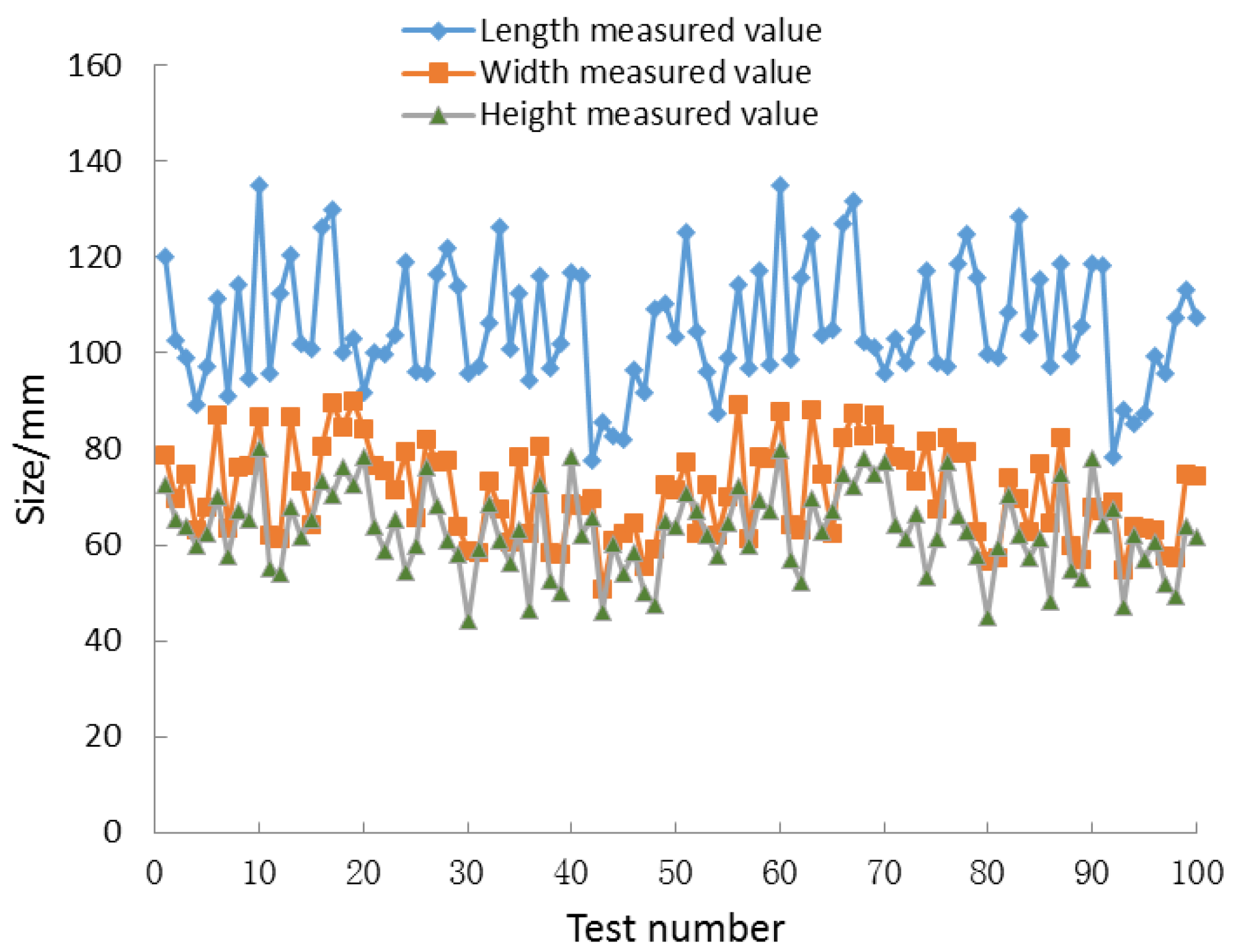

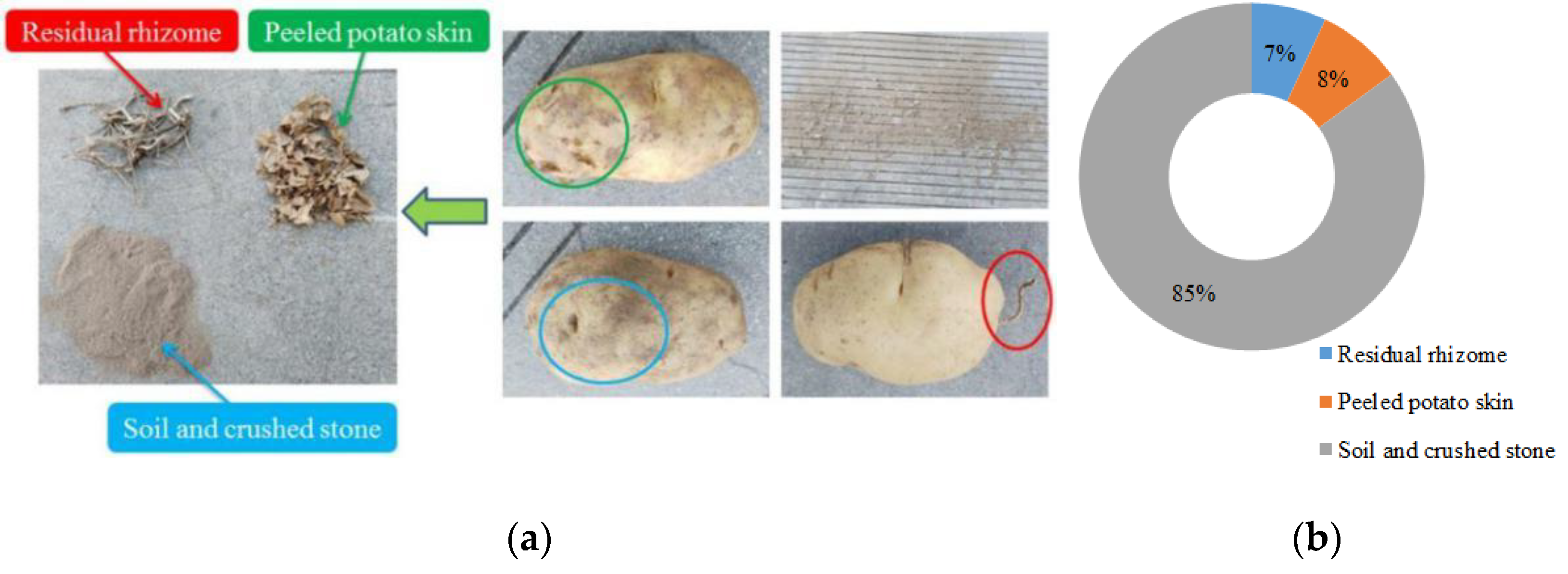

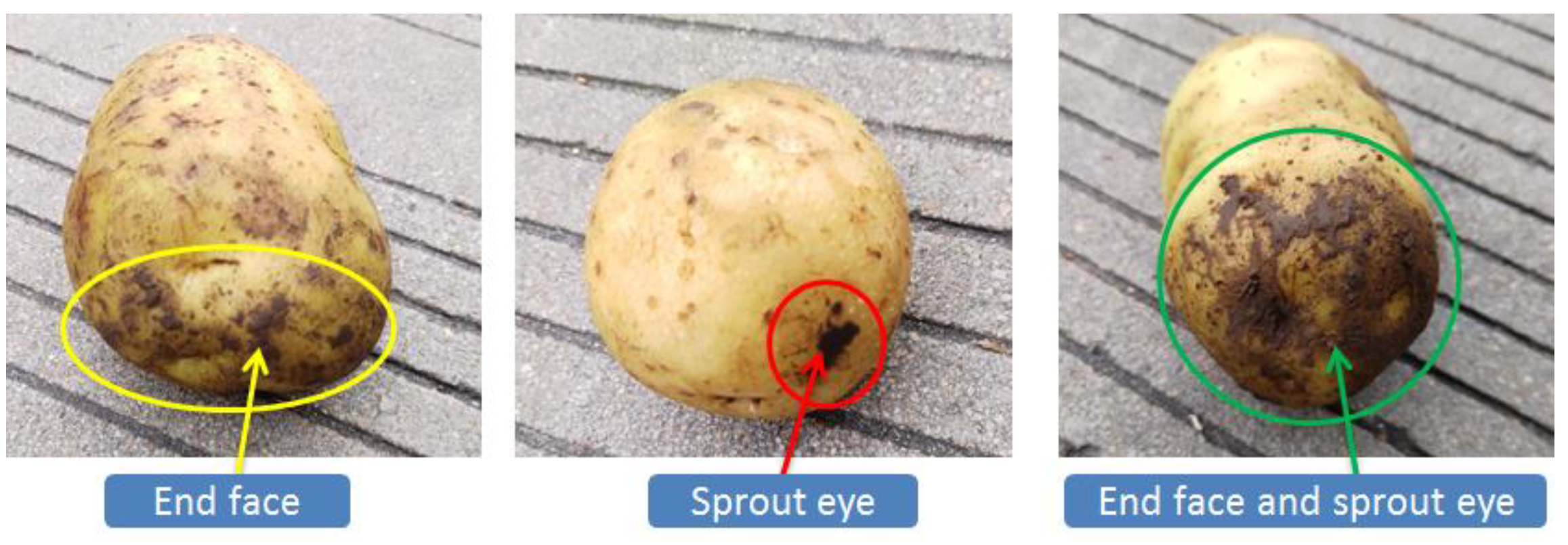

2.1. Determination of Basic Sizes and Types of Potato Tuber Impurities

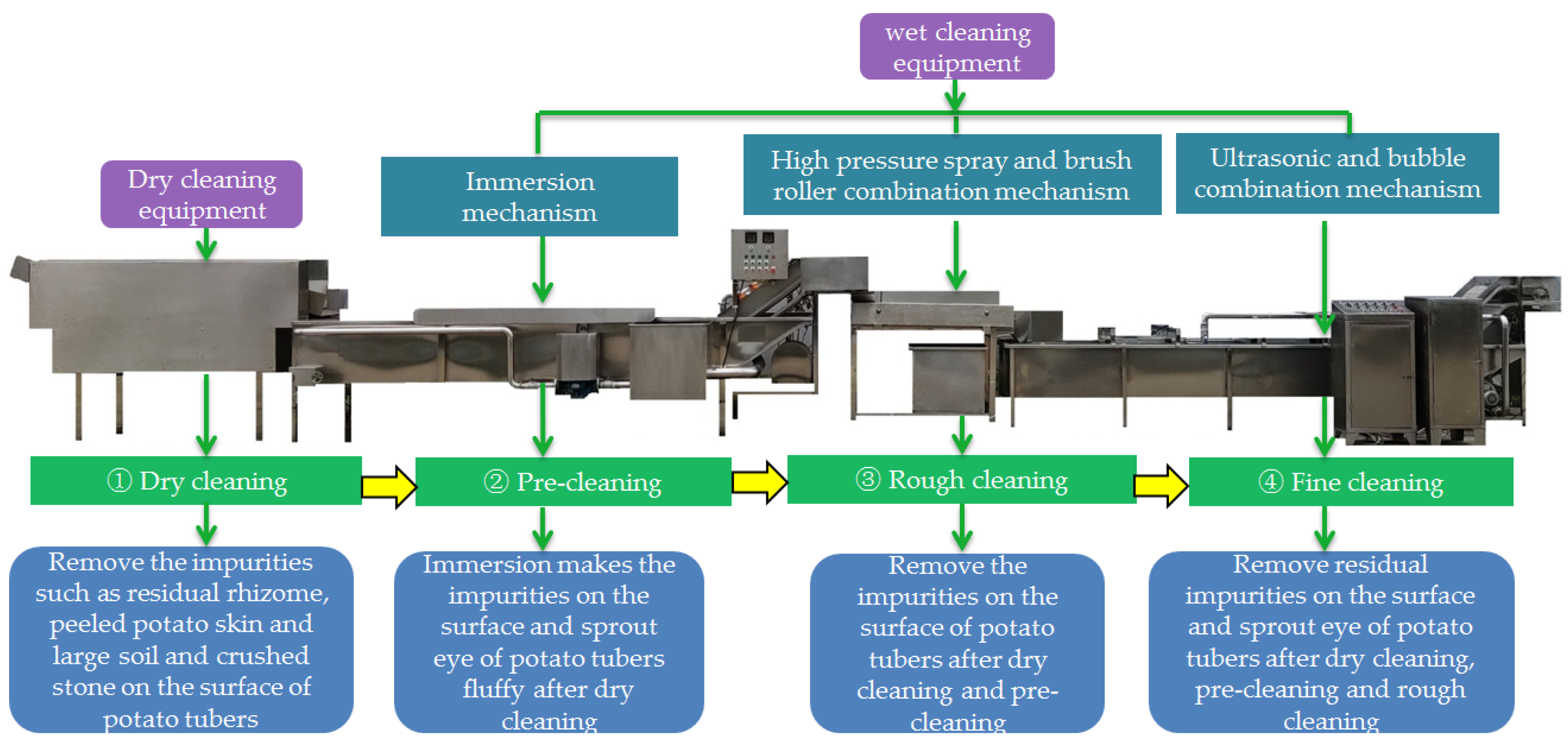

2.2. Overall Process Flow and Selection of Key Operation Parameters for Cleaning Method

2.2.1. Overall Process Flow of Cleaning Method

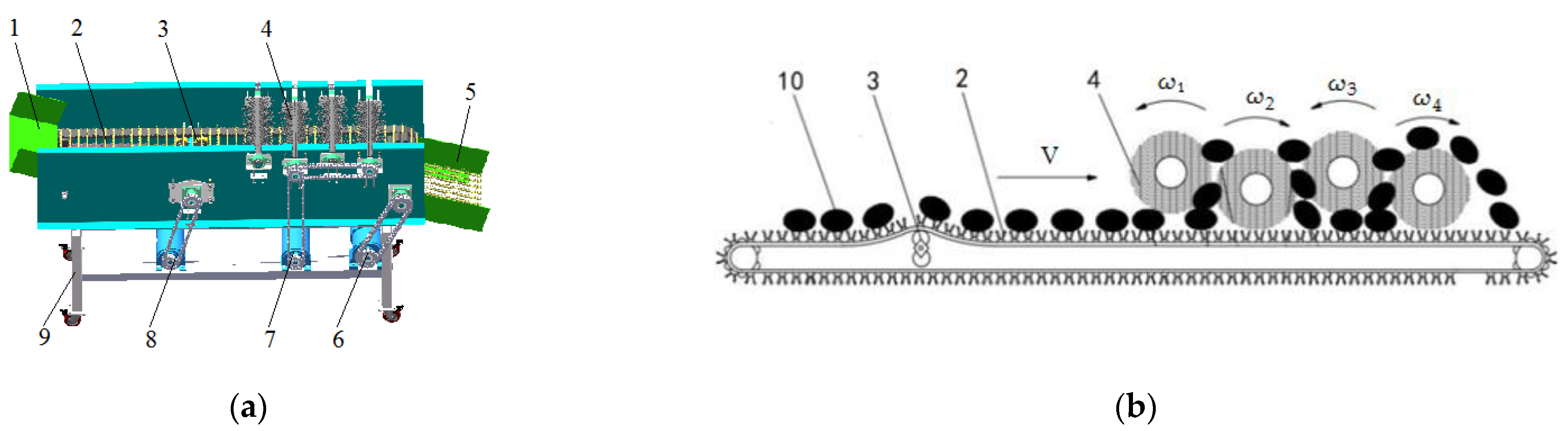

2.2.2. Constructional Features, Operating Principle, and Parameters Selection of Dry-Cleaning Equipment

- (1)

- Constructional features and operating principle

- (2)

- Parameter selection

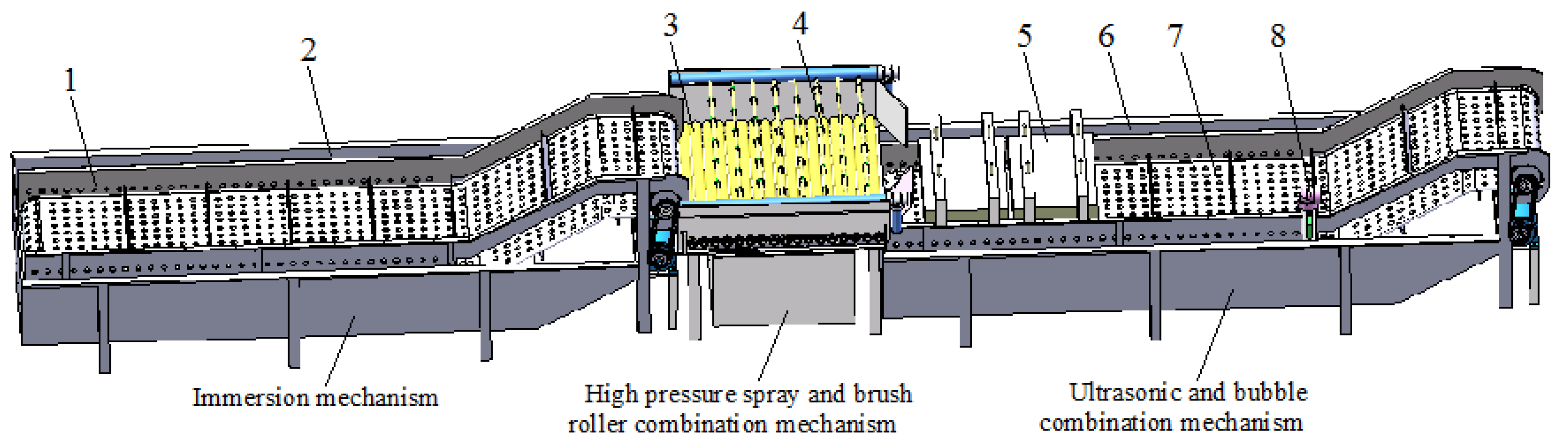

2.2.3. Constructional Features, Operating Principle, and Parameters Selection of Wet Cleaning Equipment

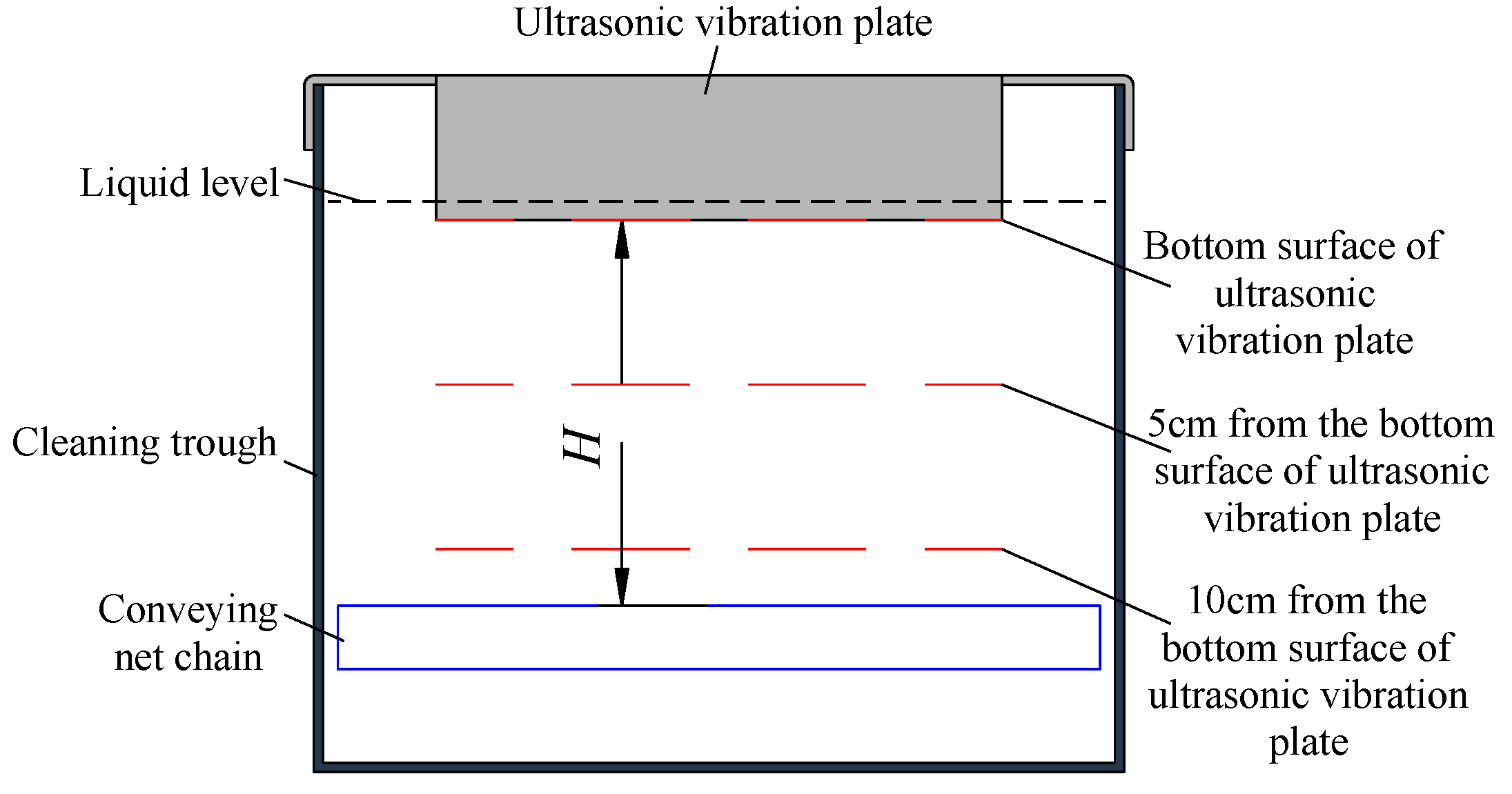

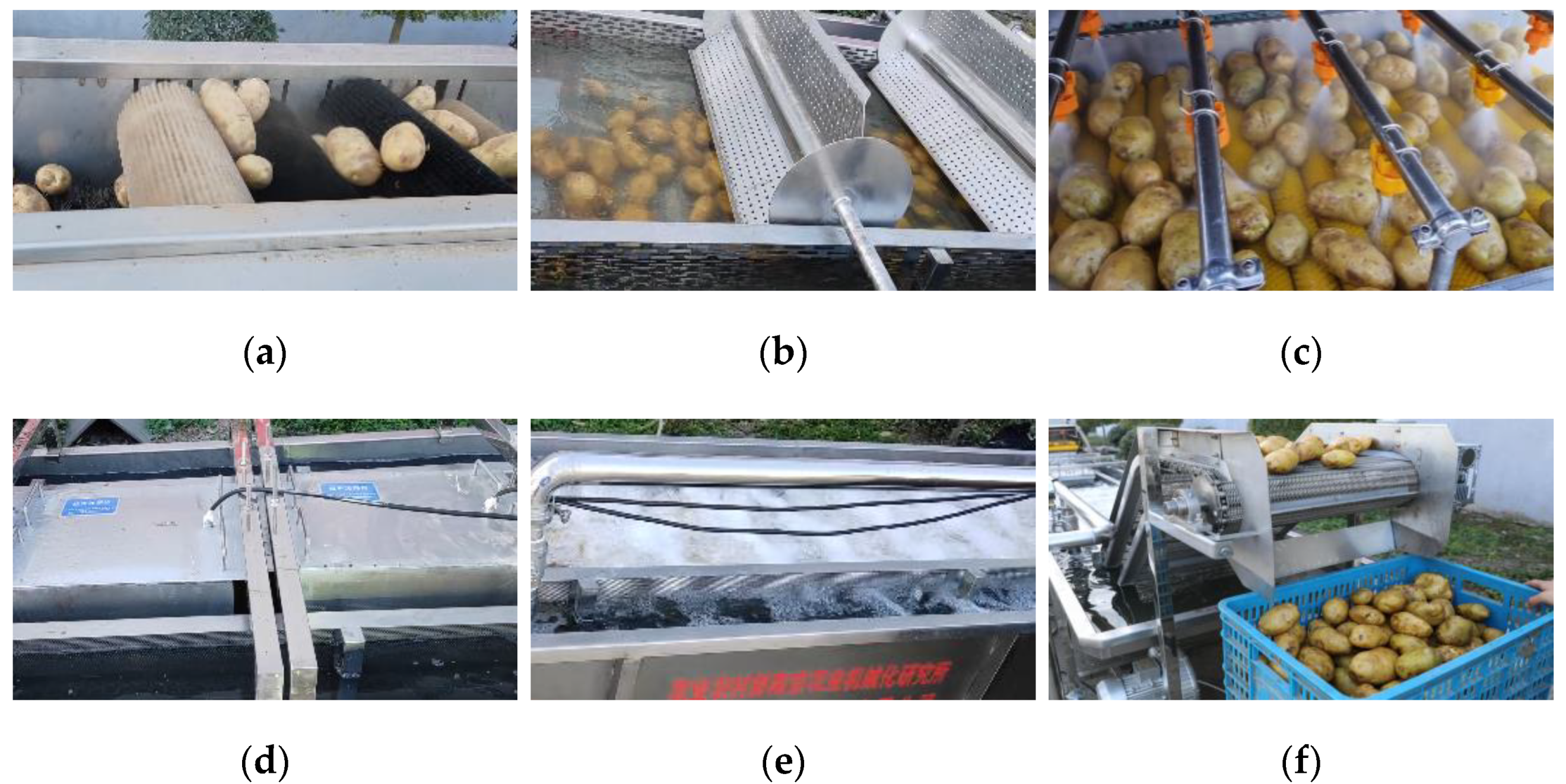

- (1)

- Constructional features and operating principle

- (2)

- Parameter selection

2.3. Gradient Cleaning Test of Potato

2.3.1. Test Conditions

2.3.2. Test Factors and Indicators

- (1)

- Test factors

- (2)

- Test indicators

2.3.3. Test Methods

3. Results

3.1. Determination of Basic Sizes and Types of Potato Tubers Impurities

3.2. Selection of Key Operation Parameters of Cleaning Method

3.2.1. Parameter Selection of the Dry-Cleaning Equipment

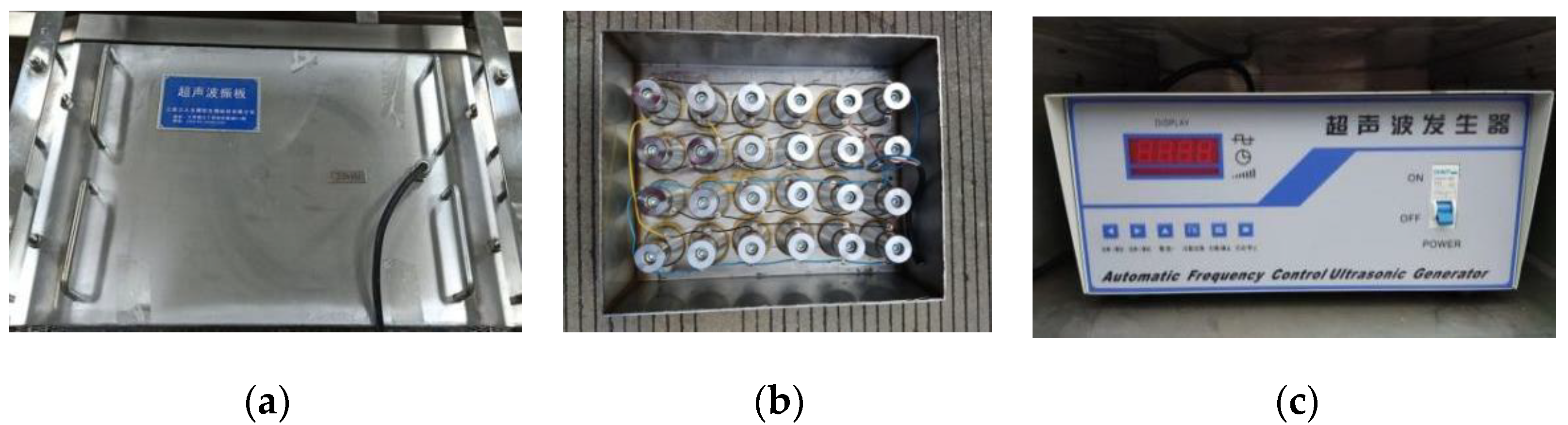

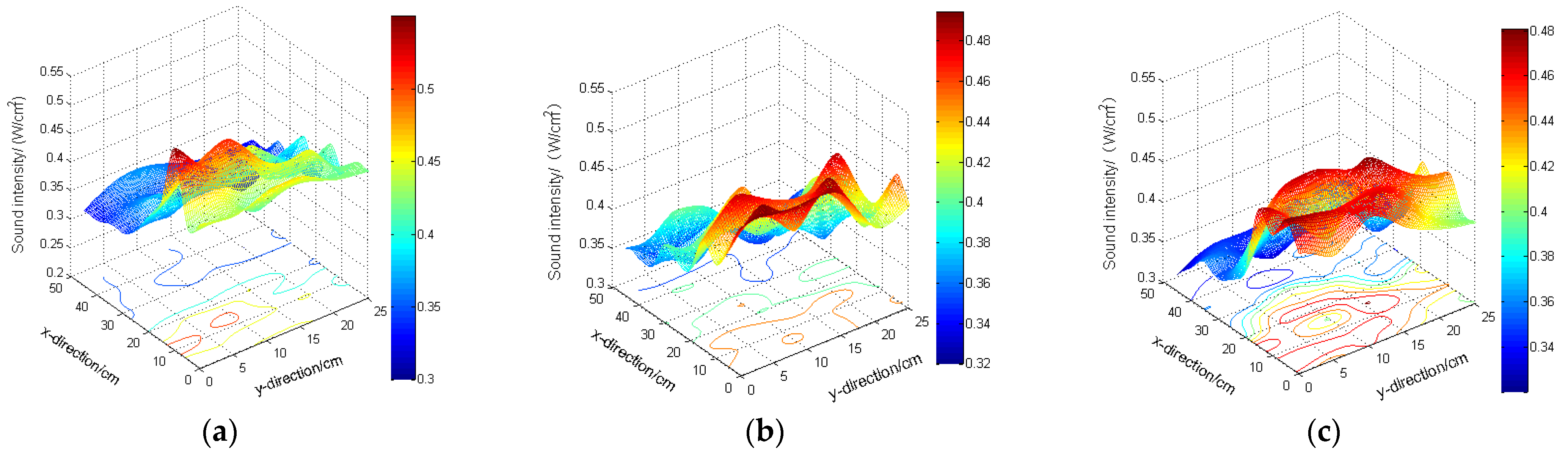

3.2.2. Parameter Selection of Wet Cleaning Equipment

- (1)

- Selection of key parameters of immersion mechanism

- (2)

- Selection of key parameters of high-pressure spray and brush roller combination mechanism

- (3)

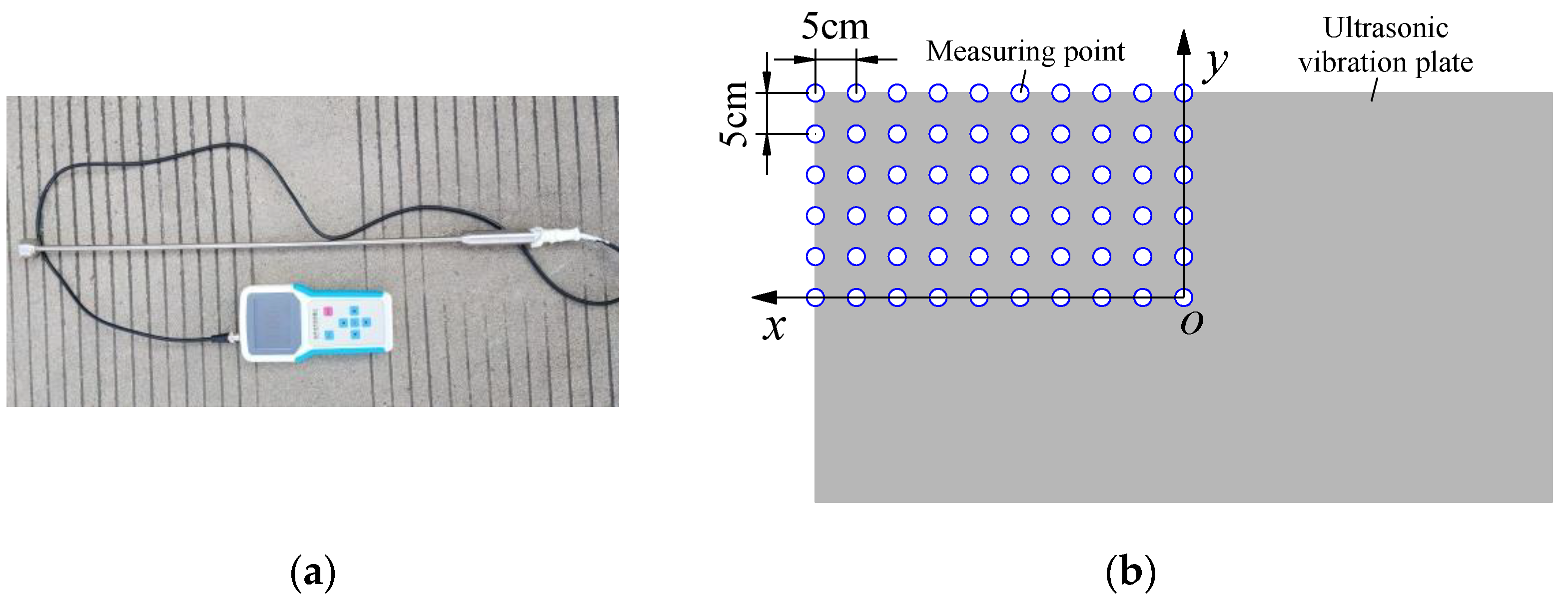

- Selection of key parameters of ultrasonic and bubble combination mechanism

3.3. Gradient Cleaning Test of Potato

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, N.; Zhang, H.L.; Zhang, R.H.; Xu, Y.K. Current situation and prospect of potato planting in China. Chin. Potato J. 2021, 35, 81–96. [Google Scholar]

- He, J.Y. Status quo and suggestions of China’s potato industry development. Agric. Outlook 2020, 16, 34–39. [Google Scholar]

- Li, Z.H.; Wen, X.Y.; Lv, J.Q.; Li, J.C.; Yi, S.J.; Qiao, D. Analysis and prospect of research progress on key technologies and equipments of mechanization of potato planting. Trans. CSAM 2019, 50, 1–16. [Google Scholar]

- Yang, H.G.; Hu, Z.C.; Wang, B.; Peng, B.L.; Wang, G.P. Research progress of harvesting mechanization technology of potato. J. Chin. Agric. Mech. 2019, 40, 27–34. [Google Scholar] [CrossRef]

- Wang, X.Y.; Sun, J.B.; Xu, Y.C.; Li, X.Q.; Cheng, P.F. Design and experiment of potato cleaning and sorting machine. Trans. CSAM 2017, 48, 316–322. [Google Scholar]

- Lv, J.Q.; Yu, J.Y.; Feng, X.; Li, Z.H.; Li, J.C.; Liu, Z.Y. Design and experiment of roller potato grading machine. Trans. CSAM 2019, 50, 323–332. [Google Scholar]

- Yang, H.G.; Xie, H.X.; Yan, J.C.; Wei, H.; Wang, H.O.; Zhang, H.J. Overview of mechanized cleaning technology of post-harvest potato. J. Chin. Agric. Mech. 2020, 41, 115–120. [Google Scholar]

- Bai, L.; Chen, X.; Sun, J.; Zhang, X.Y. Development of potato processing industry in China from perspective of industrial integration. Trans. CSAE 2019, 35, 316–322. [Google Scholar]

- Ji, L.L.; Xie, H.X.; Yan, J.C.; Wei, H.; Yang, H.G. Research status and prospect of potato cleaning equipment. J. Chin. Agric. Mech. 2020, 41, 98–104. [Google Scholar]

- Cai, W.; Zhang, Y.; Liang, D. Mechanical design and test based water jet potato cleaning. J. Agric. Mech. Res. 2013, 35, 169–172. [Google Scholar]

- Feng, Z.R. Design and Experimental Study of Cleaning Machine of the Squirrel Cage Potato. Master’s Thesis, Gansu Agricultural University, Lanzhou, China, 2018. [Google Scholar]

- Ji, L.L. Experiment and Optimization of Potato Dry-Type Brush Roller Cleaning Device. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2021. [Google Scholar]

- Ji, L.L.; Xie, H.X.; Yang, H.G.; Wei, H.; Yan, J.C.; Shen, H.Y. Simulation analysis of potato dry soil cleaning device based on EDEM-Recurdyn coupling. J. Chin. Agric. Mech. 2021, 42, 109–115. [Google Scholar]

- Wang, L.; Chen, Q.C. Experimental study on cleaning cherry tomatoes with submerged jets mechanism. Trans. CSAE 2007, 23, 86–90. [Google Scholar]

- Mulugeta, E.; Geyer, M. Characterising the washing processes of vegetables and potatoes. Biosyst. Eng. 2005, 91, 441–453. [Google Scholar] [CrossRef]

- Wang, H.O.; Hu, Z.C.; Wu, F.; Cao, S.F.; Xie, H.X.; Zhong, T. Design and test of ultrasonic ozone combined fruit and vegetable cleaner. Trans. CSAM 2011, 42, 165–169. [Google Scholar]

- Sam, L.H.; Son, T.A. A study on application of ultrasonic wave and ozone micro-bubbles in leafy vegetables washing. Key Eng. Mater. 2020, 963, 79–84. [Google Scholar] [CrossRef]

- Ma, H.L.; Sun, B.S.; He, R.H.; Luo, L.; Zhen, B.W. Process optimization of dimethoate pesticide degradation by ultrasound in aqueous solution. Trans. CSAM 2012, 43, 169–173. [Google Scholar]

- Ma, S.H.; Zhang, X.J. Working parameters optimization of ultrasonic cleaning machine for jujube. Trans. CSAE 2012, 28, 215–220. [Google Scholar]

- Roknul Azam, S.M.; Ma, H.L.; Xu, B.G.; Devi, S.; Bakar Siddique, M.A.; Stanley, S.L.; Bhandari, B.; Zhu, J.S. Efficacy of ultrasound treatment in the removal of pesticide residues from fresh vegetables: A review. Trends Food Sci. Technol. 2020, 97, 417–432. [Google Scholar] [CrossRef]

- Wang, X.H.; Mao, H.L.; Huang, Z.F. Measurement of cavitating intensity in a washing trough under the effect of ultrasonic wave. Appl. Acoust. 2005, 24, 188–191. [Google Scholar]

- Wang, H.O.; Hu, Z.C.; Wang, J.N.; Wu, F.; Xie, H.X.; Lv, X.L. Effects of connection mode between transducer and tank on ultrasonic field distribution. Trans. CSAE 2011, 27, 26–31. [Google Scholar]

- Ding, X.M.; Wang, L. Study on washing vegetables with air bubble flow washer. J. Agric. Mech. Res. 2007, 12, 119–123. [Google Scholar]

- Yang, H.B.; Ding, W.M.; Chen, K.J.; Li, Y.N.; Wang, H.P. Research and development of a new-style washer of vegetable. Trans. CSAE 2005, 21, 92–96. [Google Scholar]

- Standardization Administration of China. Code of Practice for Grading and Inspecting of Commercial Potatoes: GB/T 31784-2015; Standards Press of China: Beijing, China, 2015. [Google Scholar]

- Ministry of Agriculture and Rural Affairs of the People’s Republic of China. Vegetable Cleaning Machine: DG/T 125-2019; Standards Press of China: Beijing, China, 2019. [Google Scholar]

| Test No. | Impurity Removal Rate/% | Damage Rate/% |

|---|---|---|

| 1 | 99.13 | 2.25 |

| 2 | 99.36 | 2.71 |

| 3 | 98.67 | 2.49 |

| Mean | 99.05 | 2.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Yan, J.; Wei, H.; Wu, H.; Wang, S.; Ji, L.; Xu, X.; Xie, H. Gradient Cleaning Method of Potato Based on Multi-Step Operation of Dry-Cleaning and Wet Cleaning. Agriculture 2021, 11, 1139. https://doi.org/10.3390/agriculture11111139

Yang H, Yan J, Wei H, Wu H, Wang S, Ji L, Xu X, Xie H. Gradient Cleaning Method of Potato Based on Multi-Step Operation of Dry-Cleaning and Wet Cleaning. Agriculture. 2021; 11(11):1139. https://doi.org/10.3390/agriculture11111139

Chicago/Turabian StyleYang, Hongguang, Jianchun Yan, Hai Wei, Huichang Wu, Shenying Wang, Longlong Ji, Xiaowei Xu, and Huanxiong Xie. 2021. "Gradient Cleaning Method of Potato Based on Multi-Step Operation of Dry-Cleaning and Wet Cleaning" Agriculture 11, no. 11: 1139. https://doi.org/10.3390/agriculture11111139

APA StyleYang, H., Yan, J., Wei, H., Wu, H., Wang, S., Ji, L., Xu, X., & Xie, H. (2021). Gradient Cleaning Method of Potato Based on Multi-Step Operation of Dry-Cleaning and Wet Cleaning. Agriculture, 11(11), 1139. https://doi.org/10.3390/agriculture11111139