Hazelnut Kernel Size and Industrial Aptitude

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material

2.2. Physical Traits of In-Shell Nut

2.3. Physical Traits of Shelled Nut

2.4. Chemical Composition

2.5. Statistical Analysis

3. Results

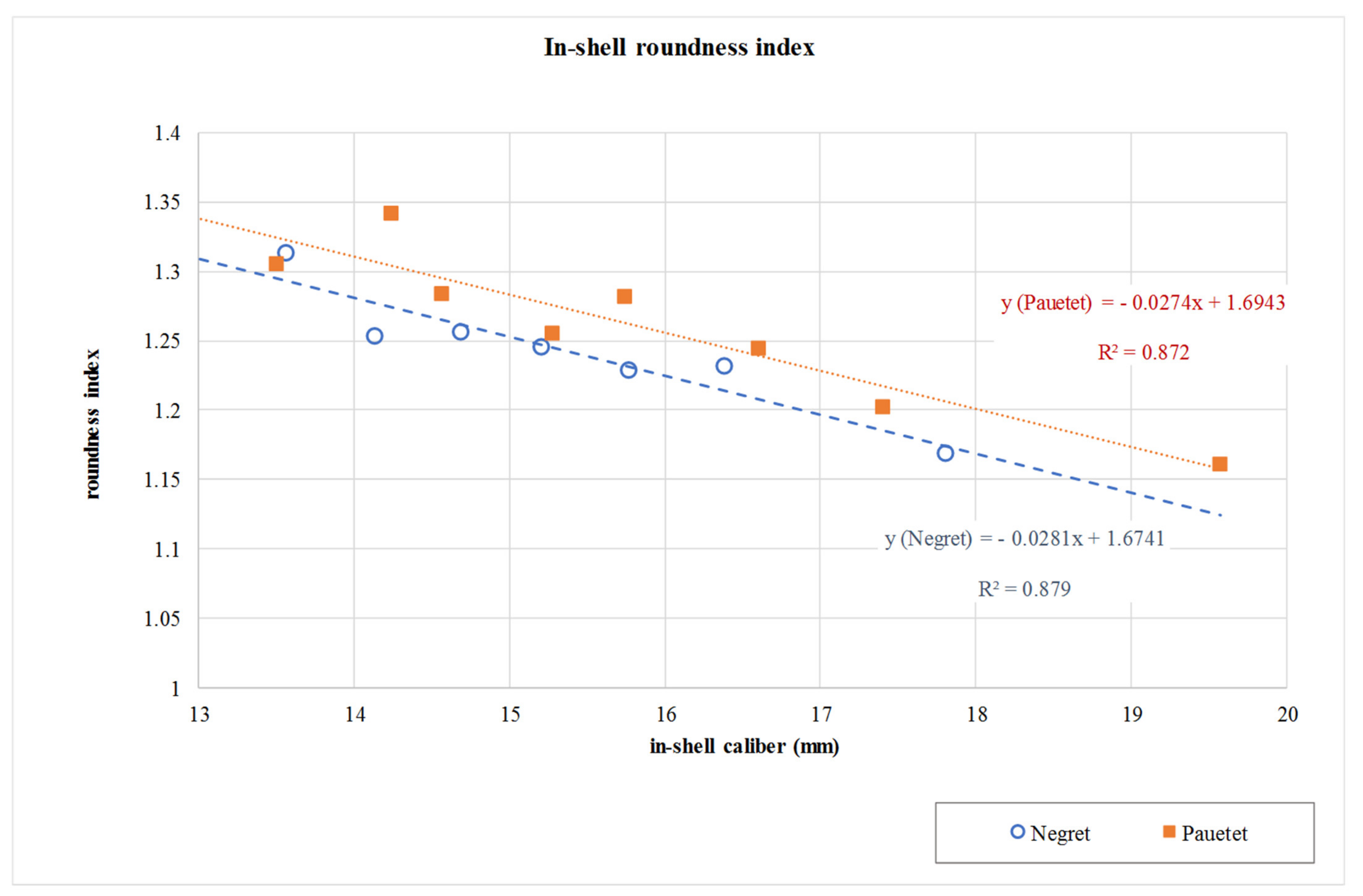

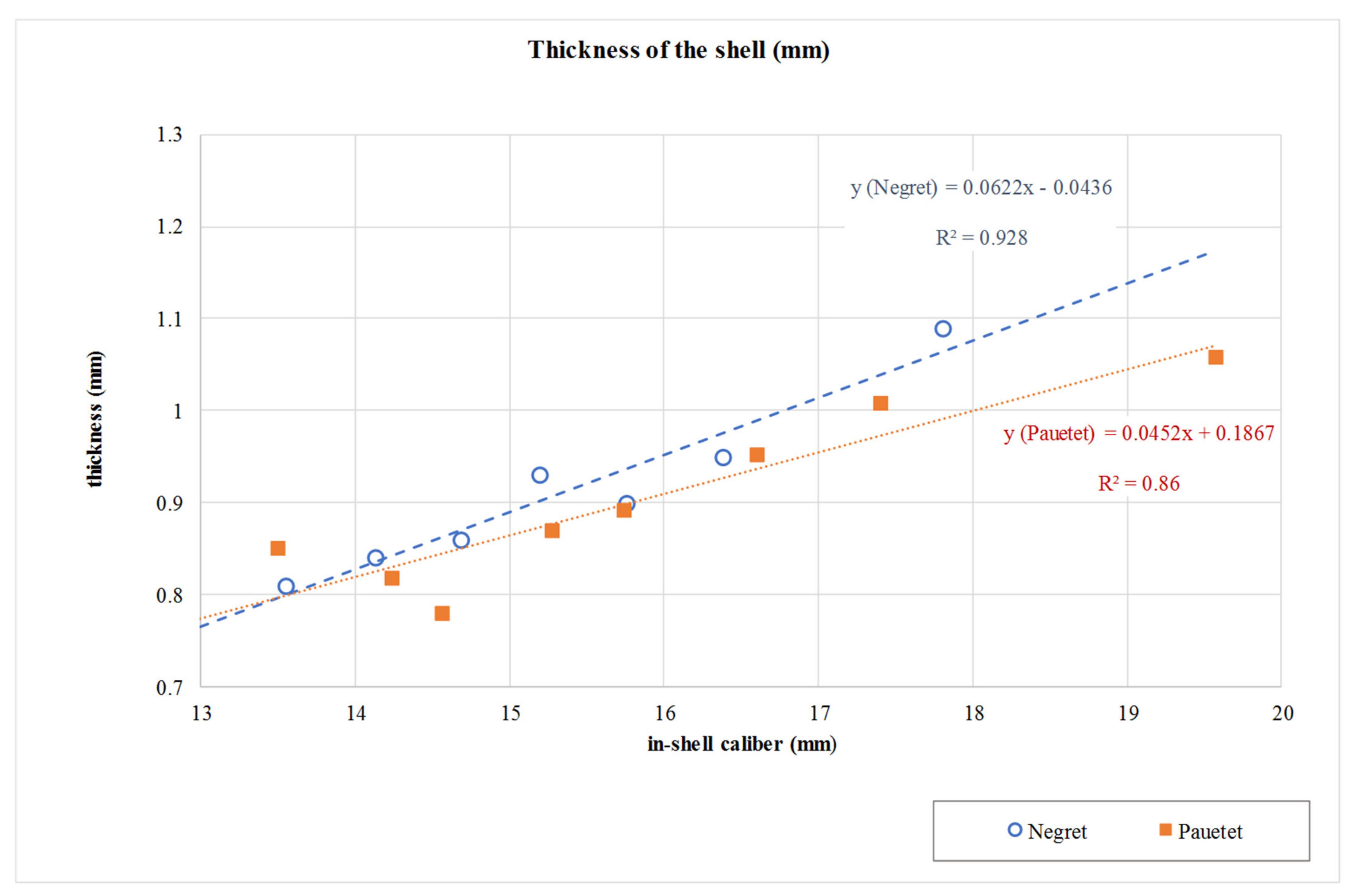

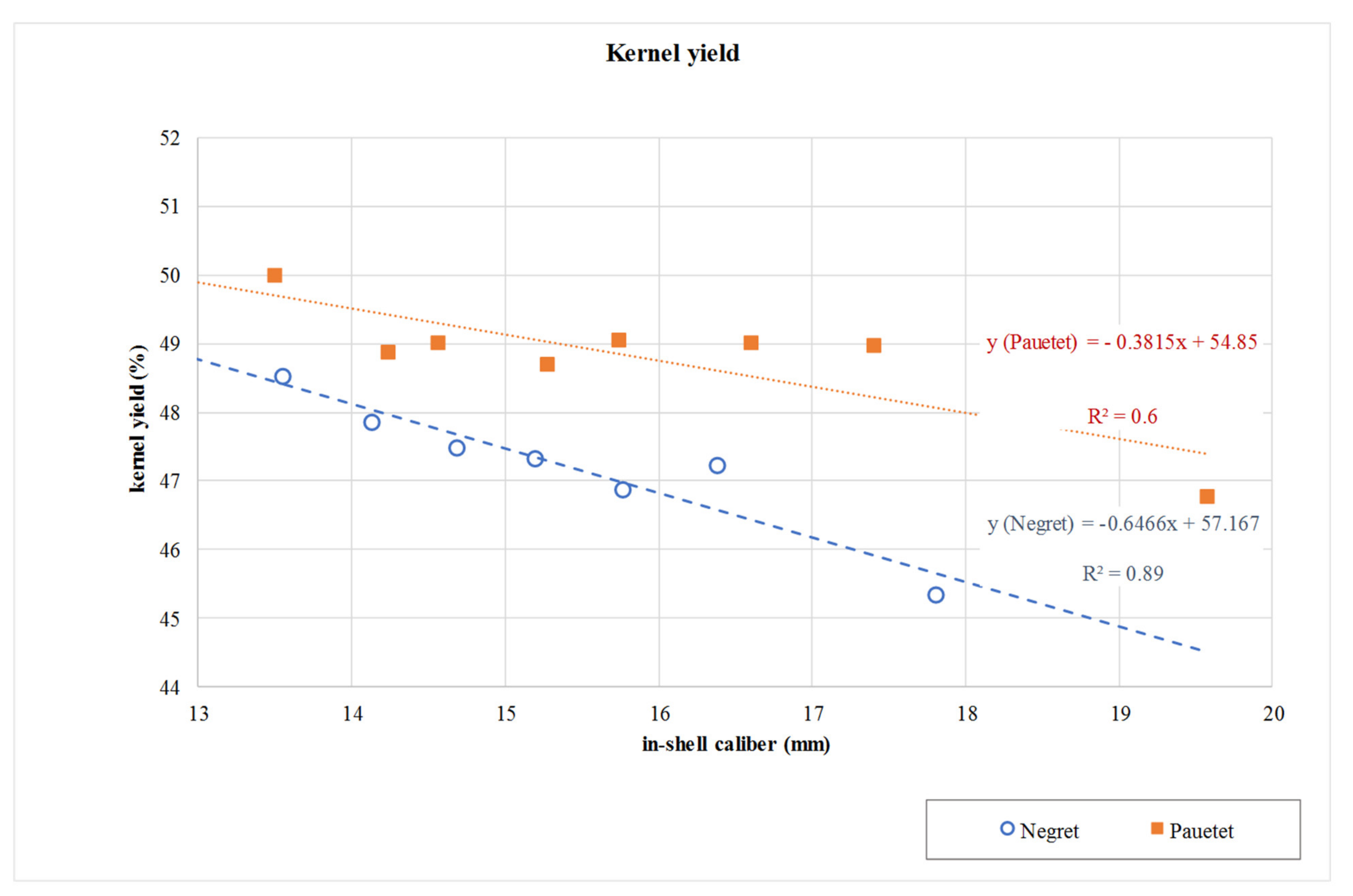

3.1. In-Shell Hazelnuts

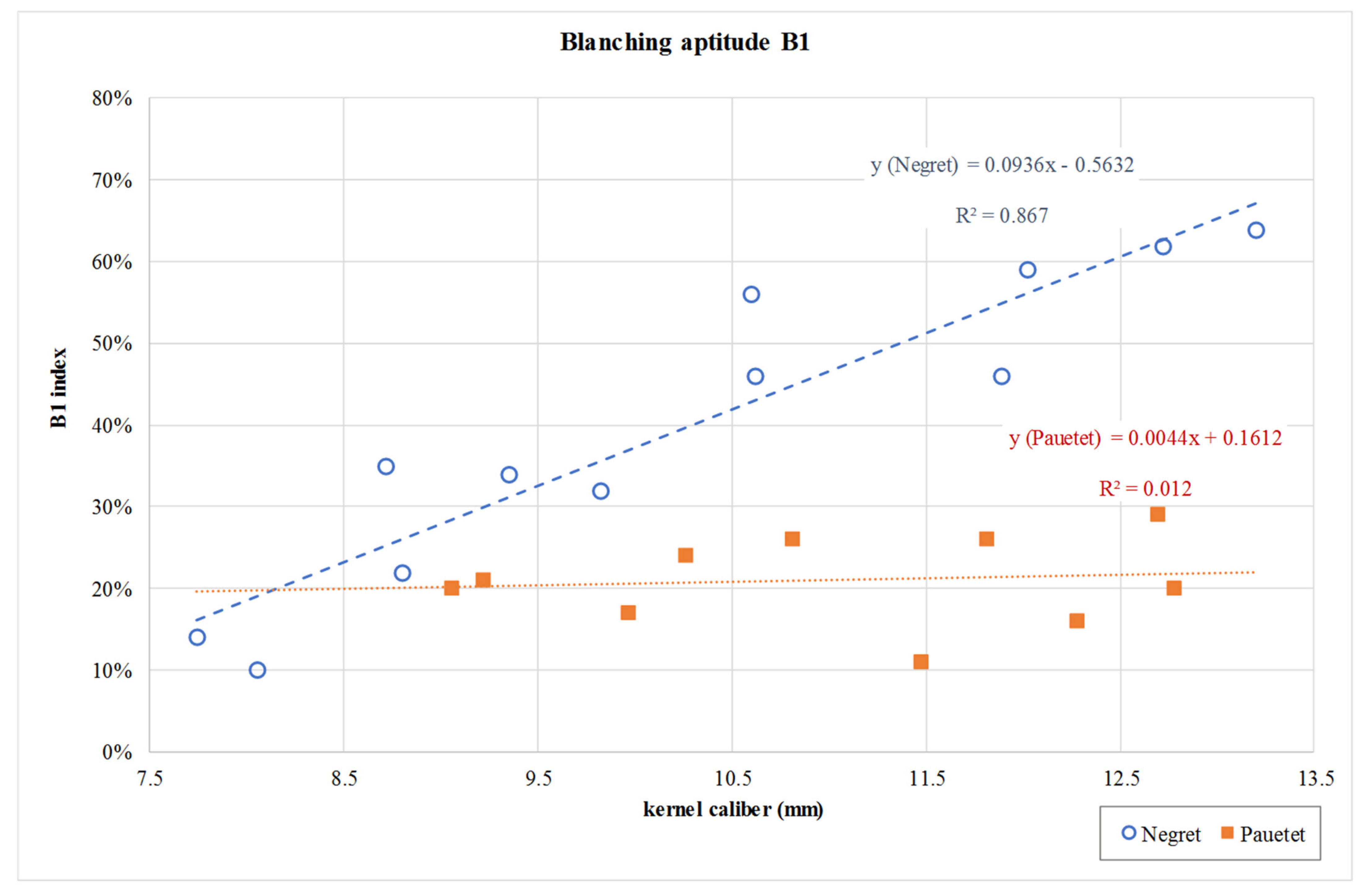

3.2. Shelled Hazelnuts

4. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Batlle, I.; Aletà, N.; Rovira, M.; Torguet, L.; Miarnau, X.; Romero, M. Retos de futuro de los frutos secos en España. Vida Rural. 2018, 442, 70–78. [Google Scholar]

- Romero, A.; Tous, J.; Plana, J.; Díaz, I.; Boatella, J.; García, J.; López, A. Commercial quality characterization of spanish “Negret” cultivar. Acta Hort. 1997, 445, 157–163. [Google Scholar] [CrossRef]

- Islam, A.; Özkutlu, F.; Tonkaz, T.; Cristofori, V.; Silvestri, C.; Pica, A.L.; Speranza, S.; Rovira, M.; Romero, A.; Batlle, I. Hazelnut Cultivation in Europe; Islam, V.C.A., Mercé, R., Eds.; MKB Halk Kütüphanesi Yayinevi: Istambul, Turkey, 2018. [Google Scholar]

- Radicati, L.; Romisondo, P.; Me, G. Le caratteristiche qualitative della nocciola in rapporto alle esigenze dell’industria dolciaria. In Atti del Convegno Nazionale Su il Miglioramento Della Coltura del Mandorlo e del Nocciolo. Aspetti Genetici e Tecnici; Regione Sicilia: Siracusa Messina, Messina, Italy, 1979; pp. 137–143. [Google Scholar]

- Garrone, W.; Vacchetti, M. La qualità delle nocciole in rapporto alle esigenze dell’industria dolciaria utilizzatrice. Acta Hortic. 1994, 351, 641–648. [Google Scholar] [CrossRef]

- Liepe, M. Taste variations for chocolate bars-filling mass, fruits, nuts. Zucker Suesswarenwirtschaft 1992, 45, 264–267. [Google Scholar]

- Voigt, J.; Wrann, D.; Heinrichs, H.; Biehl, B. The proteolytic formation of essential cocoa-specific aroma precursors depends on particular chemical structures of the vicilin-class globulin of the cocoa seeds lacking in the globular storage proteins of coconuts, hazelnuts and sunflower seeds. Food Chem. 1994, 51, 197–205. [Google Scholar] [CrossRef]

- Ebrahem, K.S.; Richardson, D.G.; Tetley, R.M. Effects of storage temperature, kernel intactness and roasting temperature on vitamin E, fatty acids and peroxide value of hazelnuts. Acta Hortic. 1994, 351, 677–684. [Google Scholar] [CrossRef]

- Perren, R.; Escher, F. Rösttechnologie von Haselnüssen, Teil 1: Einfluss von Produkttemperatur und Röstgrad auf die Oxidationsstabilität der gerösteten Nüsse. ZSV 1996, 1, 4. [Google Scholar]

- Richardson, D.G.; Ebrahem, K. Hazelnut quality as affected by roasting temperatures and duration. Acta Hortic. 1997, 445, 301–304. [Google Scholar] [CrossRef]

- Romero, A.; Tous, J.; Guerrero, L.; Gou, P.; Guardia, M.D. Aplicaciones del análisis sensorial en el tostado industrial de avellana en grano. Frutic. Prof. 1999, 104, 71–77. [Google Scholar]

- Demir, A.D.; Frías, J.M.; Cronin, K.; Abodayeh, K. Modelling of the kinetics of colour change in hazelnuts during air roasting. J. Food Eng. 2002, 53, 283–292. [Google Scholar] [CrossRef]

- Saklar, S.; Ungan, S.; Katnas, S. Microstructural changes in hazelnuts during roasting. Food Res. Int. 2003, 36, 19–23. [Google Scholar] [CrossRef]

- Ruggeri, S.; Cappelloni, M.; Gambelli, L.; Nicoli, S.; Carnovale, E. Chemical composition and nutritive value of nuts grown in Italy. Ital. J. Food Sci. 1998, 10, 243–252. [Google Scholar]

- Valentini, N.; Zeppa, G.; Rolle, L.; Me, G. Caratterizzazione chimico-fisica e sensoriale della nocciola Tonda Gentille delle Langhe. In Atti 2º Convegno Naz. Sul Nocciolo; Regione Campania, Ed.; Ottobre: Giffoni Valle Piana, Italy, 2002; pp. 279–287. [Google Scholar]

- Cristofori, V.; Ferramondo, S.; Bertazza, G.; Bignami, C. Nut and kernel traits and chemical composition of hazelnut (Corylus avellana L.) cultivars. J. Sci. Food Agri. 2008, 88, 1091–1098. [Google Scholar] [CrossRef]

- Parcerisa, J.; Rafecas, M.; Castellote, A.I.; Codony, R.; Farràn, A.; Garcia, J.; Lopez, A.; Romero, A.; Boatella, J. Influence of variety and geographical origin on the lipid fraction of hazelnuts (Coryllus avellana L.) from spain: (II). triglyceride composition. Food Chem. 2014, 50, 245–249. [Google Scholar] [CrossRef]

- Ebrahem, K.S.; Richardson, D.G.; Tetley, R.M.; Mehlenbacher, S.A. Oil content, fatty acid composition and vitamin E concentration of 17 hazelnut varieties, compared to other types of nuts and oil seeds. Acta Hortic. 1994, 351, 685–692. [Google Scholar] [CrossRef]

- Ayfer, M.; Uzun, A.; Bas, F. Turkish Hazelnut Cultivars; Black Sea Region Hazelnut Exporters Union: Ankara, Turkey, 1986; p. 95. [Google Scholar]

- Król, K.; Gantner, M.; Piotrowska, A. Morphological traits, kernel composition and sensory evaluation of hazelnut (Corylus avellana L.) cultivars grown in Poland. Agronomy 2019, 9, 703. [Google Scholar] [CrossRef] [Green Version]

- Król, K.; Gantner, M.; Piotrowska, A.; Hallmann, E. Effect of climate and roasting on polyphenols and tocopherols in the kernels and skin of six hazelnut cultivars (Corylus avellana L.). Agriculture 2021, 10, 36. [Google Scholar] [CrossRef] [Green Version]

- Ciemniewska-Żytkiewicz, H.; Pasini, F.; Verardo, V.; Bryś, J.; Koczoń, P.; Caboni, M.F. Changes of the lipid fraction during fruit development in hazelnuts (Corylus avellana L.) grown in Poland. Eur. J. Lipid Sci. Technol. 2015, 117, 710–717. [Google Scholar] [CrossRef]

- Ciemniewska-Zytkiewicz, H.; Verardo, V.; Pasini, F.; Bry’s, J.; Koczo´n, P.; Caboni, M.F. Determination of lipid and phenolic fraction in two hazelnut (Corylus avellana L.) cultivars grown in Poland. Food Chem. 2015, 168, 615–622. [Google Scholar] [CrossRef] [PubMed]

- Botta, R.; Gianotti, C.; Richardson, D.; Suwanagul, A.; Sanz, C.L. Hazelnut variety organic acids, sugars, and total lipid fatty acids. Acta Hortic. 1994, 351, 693–699. [Google Scholar] [CrossRef]

- Rovira, M.; Romero, A.; Botta, R.; Di Giammatteo, V.; Duval, H.; Drogoudi, P.; Spera, A.; Silva, D.; Solar, A.; Bacchetta, L. Biochemical analysis in almond and hazelnut European cultivars. Ann. Nutr. Metab. 2013, 62, 82. [Google Scholar]

- Rovira, M.; Hermoso, J.F.; Romero, A. Performance of hazelnut cultivars from Oregon, Italy, and Spain, in Northeastern Spain. HortTechnology 2017, 27, 631–638. [Google Scholar] [CrossRef] [Green Version]

- Sarraquigne, J.P. Hazelnut production in France. Acta Hort. 2004, 686, 669–672. [Google Scholar] [CrossRef]

- Parcerisa, J.; Boatella, J.; Codony, R.; Rafecas, M.; Castellote, A.I.; García, J.; López, A.; Romero, A. Comparison of fatty acid and triacylglycerol composition of different hazelnut varieties (Corylus avellana L.) cultivated in Catalonia (Spain). J. Agric. Food Chemistry 1995, 43, 13–16. [Google Scholar] [CrossRef]

- Parcerisa, J.; Rafecas, M.; Castellote, A.I.; Codony, R.; Farràn, A.; García, J.; Gonzalez, C.; López, A.; Romero, A.; Boatella, J. Influence of variety and geographical origin on the lipid fraction of hazelnuts (Corylus avellana L.) from Spain: (III) Oil stability, tocopherol content and some mineral contents (Mn, Fe, Cu). Food Chem. 1995, 53, 71–74. [Google Scholar] [CrossRef]

- Silvestri, C.; Bacchetta, L.; Bellincontro, A.; Cristofori, V. Advances in cultivar choice, hazelnut orchard management, and nut storage to enhance product quality and safety: An overview. J. Sci. Food Agric. 2021, 101, 27–43. [Google Scholar] [CrossRef] [PubMed]

- Fattahi, R.; Mohammadzedeh, M.; Khadivi-Khub, A. Influence of different pollen sources on nut and kernel characteristics of hazelnut. Sci. Hortic. 2014, 173, 15–19. [Google Scholar] [CrossRef]

- Kodad, O.; Estopañán, G.; Juan, T.; Rafel Socias i Company. Xenia effects on oil content and fatty acid and tocopherol concentrations in autogamous almond cultivars. J. Agric. Food Chem. 2009, 57, 10809–10813. [Google Scholar] [CrossRef]

- Rasouli, M.; Imani, A. Effect of supplementary pollination by different pollinizers on fruit set and nut physicochemical traits of ‘Supernova’, a self-compatible almond. Fruits 2016, 71, 299–306. [Google Scholar] [CrossRef] [Green Version]

- Alizadeh-Salte, S.; Farhadi, N.; Arzani, K.; Khoshghalb, H. Almond oil quality as related to the type of pollen source in Iranian self-incompatible cultivars. Int. J. Fruit Sci. 2018, 18, 29–36. [Google Scholar] [CrossRef]

- Kämper, W.; Thorp, G.; Wirthensohn, M.; Brooks, P.; Trueman, S.J. Pollen Paternity Can Affect Kernel Size and Nutritional Composition of Self-Incompatible and New Self-Compatible Almond Cultivars. Agronomy 2021, 11, 326. [Google Scholar] [CrossRef]

- Zhang, X.-H.; Yuan, D.-Y.; Zou, F.; Fan, X.-M.; Tang, J.; Zhu, Z.-J. Studies on the pollen xenia of Castanea henryi. Acta Hortic. 2016, 43, 61–70. [Google Scholar] [CrossRef]

- Acar, I.; Eti, S. Nut quality of ‘Kirmizi’, ‘Siirt’ and ‘Ohadi’ pistachio cultivars as affected by different pollinators. Acta Hortic. 2011, 912, 81–86. [Google Scholar] [CrossRef]

- Richards, T.E.; Kämper, W.; Trueman, S.J.; Wallace, H.M.; Ogbourne, S.M.; Brooks, P.R.; Nichols, J.; Hosseini Bai, S. Relationships between nut size, kernel quality, nutritional composition and levels of outcrossing in three macadamia cultivars. Plants 2020, 9, 228. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Etheridge, R.D.; Pesti, G.M.; Foster, E.H. A comparison of nitrogen values obtained utilizing the Kjeldahl nitrogen and Dumas combustion methodologies (Leco CNS 2000) on samples typical of an animal nutrition analytical laboratory. Anim. Feed. Sci. Technol. 1998, 73, 21–28. [Google Scholar] [CrossRef]

- AOCS Official Method Ce 8-89. Determination of tocopherols and tocotrienols in vegetable oils and fats by HPLC. In Official Methods and Recommended Practices of the American Oil Chemists’ Society; AOCS Press: Champaign, IL, USA, 1997; p. 20. [Google Scholar]

- Bacchetta, L.; Aramiri, M.; Zini, A.; Di Giammatteo, V.; Spera, D.; Drogiudi, P.; Rovira, M.; Silva, A.P.; Solar, A.; Botta, R. Fatty acids and alpha-tocopherol composition in hazelnut (Corylus avellana L.): A chemotrofic approach to emphasize the quality of European germplasm. Euphytica 2013, 191, 57–73. [Google Scholar] [CrossRef]

- Klockmann, S.; Reiner, E.; Bachmann, R.; Hackl, T.; Fischer, M. Food Fingerprinting: Metabolomic Approaches for Geographical Origin Discrimination of Hazelnuts (Corylus avellana) by UPLC-QTOFMS. J. Agric. Food Chem. 2016, 64, 9253–9262. [Google Scholar] [CrossRef] [PubMed]

- Thompson, M.M.; Lagerstedt, H.B.; Mehlenbacher, S.A. Hazelnuts. In Fruit Breeding, Volume III: Nuts; Jules, J., James, N., Eds.; Moore: New York, NY, USA, 1996; pp. 125–184. [Google Scholar]

- Romero, A.; Tous, J.; Plana, J.; Guardia, M.D.; Díaz, I. How cultivar choice affects Spanish consumers’ acceptance of marzipan and chocolates made with almonds. Acta Hortic. 2001, 591, 117–123. [Google Scholar] [CrossRef]

- Romero, A.; Tous, J.; Plana, J. How cultivar choice affects Spanish consumers’ acceptance of chocolates, bonbons and hard turron made with hazelnuts. Acta Hortic. 2005, 686, 577–584. [Google Scholar] [CrossRef]

- Couzens, P.J.; Wille, H.J. Fat migration in composite confectionery products. Manuf. Confect. 1997, 77, 45–47. [Google Scholar]

- Groves, R. Fat migration through chocolate. Candy Ind. 1999, 164, 28. [Google Scholar] [CrossRef]

| Nut Trait | Cultivar | Linear Models | Test for Slope | Test for Cultivar | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Intercept | Slope | R2 | F Model | P Model | F Slope | P Slope | F Cultivar | P Cultivar | ||||||

| Kernel yield (%) | Negret | 57.17 | ± | 1.53 | −0.6466 | ± | 0.0993 | 0.895 | 42.44 | 0.0013 | 2.70 | 0.1283 | 41.07 | <0.0001 |

| Pauetet | 54.85 | ± | 1.69 | −0.3815 | ± | 0.1062 | 0.683 | 12.92 | 0.0114 | |||||

| Thickness of the shell (mm) | Negret | −0.043 | ± | 0.118 | 0.0622 | ± | 0.0077 | 0.929 | 65.08 | 0.0005 | 2.17 | 0.1684 | 0.23 | 0.6387 |

| Pauetet | 0.186 | ± | 0.117 | 0.0452 | ± | 0.0074 | 0.862 | 37.49 | 0.0009 | |||||

| Shell moisture (%) | Negret | 14.32 | ± | 1.04 | −0.0297 | ± | 0.0678 | 0.037 | 0.19 | 0.6799 | 3.69 | 0.0808 | 16.91 | 0.0017 |

| Pauetet | 11.04 | ± | 1.50 | 0.2310 | ± | 0.0942 | 0.500 | 6.01 | 0.0497 | |||||

| In-shell length (mm) | Negret | 6.899 | ± | 0.820 | 0.6984 | ± | 0.0533 | 0.972 | 171 | <0.0001 | 0.49 | 0.4977 | 30.58 | 0.0002 |

| Pauetet | 8.334 | ± | 0.982 | 0.6340 | ± | 0.0615 | 0.947 | 106 | <0.0001 | |||||

| In-shell thickness (mm) | Negret | 0.910 | ± | 0.514 | 0.7930 | ± | 0.0334 | 0.991 | 565 | <0.0001 | 2.03 | 0.1821 | 44.51 | <0.0001 |

| Pauetet | 1.191 | ± | 0.403 | 0.7319 | ± | 0.0253 | 0.993 | 840 | <0.0001 | |||||

| In-shell roundness (mm) | Negret | 1.674 | ± | 0.071 | −0.0281 | ± | 0.0047 | 0.879 | 36.36 | 0.0018 | 0.01 | 0.9254 | 0.04 | 0.8520 |

| Pauetet | 1.694 | ± | 0.068 | −0.0274 | ± | 0.0043 | 0.873 | 41.19 | 0.0007 | |||||

| Nut Trait | Cultivar | Linear Models | Test for Slope | Test for Cultivar | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Intercept | Slope | R2 | F Model | P Model | F Slope | P Slope | F Cultivar | P Cultivar | ||||||

| Kernel length (mm) | Negret | 8.5987 | ± | 0.6457 | 0.4231 | ± | 0.0618 | 0.824 | 46.82 | <0.0001 | 0.98 | 0.3348 | 0.07 | 0.7917 |

| Pauetet | 7.3151 | ± | 1.0799 | 0.5386 | ± | 0.1013 | 0.739 | 28.28 | 0.0003 | |||||

| Kernel thickness (mm) | Negret | 1.9348 | ± | 0.5645 | 0.7402 | ± | 0.0540 | 0.949 | 187 | <0.0001 | 2.99 | 0.0991 | 2.31 | 0.1442 |

| Pauetet | 0.3774 | ± | 0.3848 | 0.8546 | ± | 0.0361 | 0.982 | 560 | <0.0001 | |||||

| Kernel roundness | Negret | 2.0824 | ± | 0.076 | −0.0730 | ± | 0.0073 | 0.909 | 100 | <0.0001 | 0.07 | 0.8007 | 0.38 | 0.5427 |

| Pauetet | 2.0521 | ± | 0.1151 | −0.0697 | ± | 0.0107 | 0.807 | 41.75 | <0.0001 | |||||

| L* | Negret | 26.07 | ± | 2.67 | 0.1124 | ± | 0.2554 | 0.019 | 0.19 | 0.6692 | 0.03 | 0.8652 | 5.08 | 0.0356 |

| Pauetet | 24.56 | ± | 7.67 | −0.0151 | ± | 0.7191 | 0.000 | 0.00 | 0.9836 | |||||

| a* | Negret | 6.9783 | ± | 0.7856 | 0.0997 | ± | 0.0752 | 0.149 | 1.76 | 0.2147 | 0.08 | 0.7821 | 2.80 | 0.1098 |

| Pauetet | 6.9774 | ± | 2.0004 | 0.0444 | ± | 0.1876 | 0.006 | 0.06 | 0.8125 | |||||

| b* | Negret | 13.86 | ± | 1.45 | −0.0841 | ± | 0.1396 | 0.035 | 0.36 | 0.5602 | 0.05 | 0.8228 | 2.79 | 0.1104 |

| Pauetet | 13.69 | ± | 4.69 | −0.1859 | ± | 0.4404 | 0.017 | 0.18 | 0.6829 | |||||

| Hue angle (°) | Negret | 1.1065 | ± | 0.0441 | −0.0086 | ± | 0.0042 | 0.291 | 4.11 | 0.0700 | 0.00 | 0.9500 | 1.75 | 0.2023 |

| Pauetet | 1.0953 | ± | 0.08 | −0.0090 | ± | 0.0075 | 0.128 | 1.47 | 0.2536 | |||||

| Chroma | Negret | 15.48 | ± | 1.51 | −0.0208 | ± | 0.1447 | 0.002 | 0.02 | 0.8886 | 0.06 | 0.8127 | 2.89 | 0.1048 |

| Pauetet | 15.33 | ± | 4.98 | −0.1346 | ± | 0.4670 | 0.008 | 0.08 | 0.7790 | |||||

| Nut Trait | Cultivar | Linear Models | Test for Slope | Test for Cultivar | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Intercept | Slope | R2 | F Model | P Model | F Slope | P Slope | F Cultivar | P Cultivar | ||||||

| Roasting aptitude R1 (%) | Negret | 0.0241 | ± | 0.1747 | 0.0619 | ± | 0.0167 | 0.578 | 13.71 | 0.0041 | 5.25 | 0.0342 | 7.88 | 0.0117 |

| Pauetet | 0.4953 | ± | 0.1397 | 0.0059 | ± | 0.0126 | 0.027 | 0.22 | 0.6486 | |||||

| Roasting aptitude R2 (%) | Negret | 0.9317 | ± | 0.0582 | 0.0027 | ± | 0.0056 | 0.022 | 0.23 | 0.6424 | 0.11 | 0.7470 | 22.69 | 0.0002 |

| Pauetet | 0.8233 | ± | 0.0934 | 0.0059 | ± | 0.0084 | 0.059 | 0.50 | 0.4986 | |||||

| Blanching aptitude B1 (%) | Negret | −0.5632 | ± | 0.1206 | 0.0936 | ± | 0.0115 | 0.868 | 65.64 | <0.0001 | 22.07 | 0.0002 | 46.54 | <0.0001 |

| Pauetet | 0.1612 | ± | 0.1538 | 0.0044 | ± | 0.0138 | 0.013 | 0.10 | 0.7574 | |||||

| Blanching aptitude B2 (%) | Negret | 0.1168 | ± | 0.2376 | 0.0648 | ± | 0.0227 | 0.448 | 8.11 | 0.0173 | 0.03 | 0.8620 | 48.41 | <0.0001 |

| Pauetet | −0.2084 | ± | 0.1944 | 0.0589 | ± | 0.0179 | 0.574 | 10.76 | 0.0112 | |||||

| Oil acidity (% ocelic acid) | Negret | 0.3219 | ± | 0.1109 | −0.0094 | ± | 0.0106 | 0.073 | 0.79 | 0.3961 | 1.56 | 0.2291 | 1.18 | 0.2918 |

| Pauetet | 0.7559 | ± | 0.3366 | −0.0436 | ± | 0.0297 | 0.234 | 2.14 | 0.1865 | |||||

| Water activity (aw) | Negret | 0.6695 | ± | 0.0297 | −0.0033 | ± | 0.0028 | 0.117 | 1.33 | 0.2764 | 0.61 | 0.4433 | 4.97 | 0.0374 |

| Pauetet | 0.0441 | ± | 0.0561 | 0.0013 | ± | 0.0053 | 0.006 | 0.06 | 0.8078 | |||||

| Nut Trait | Cultivar | Linear Models | Test for Slope | Test for Cultivar | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Intercept | Slope | R2 | F Model | P Model | F Slope | P Slope | F Cultivar | P Cultivar | ||||||

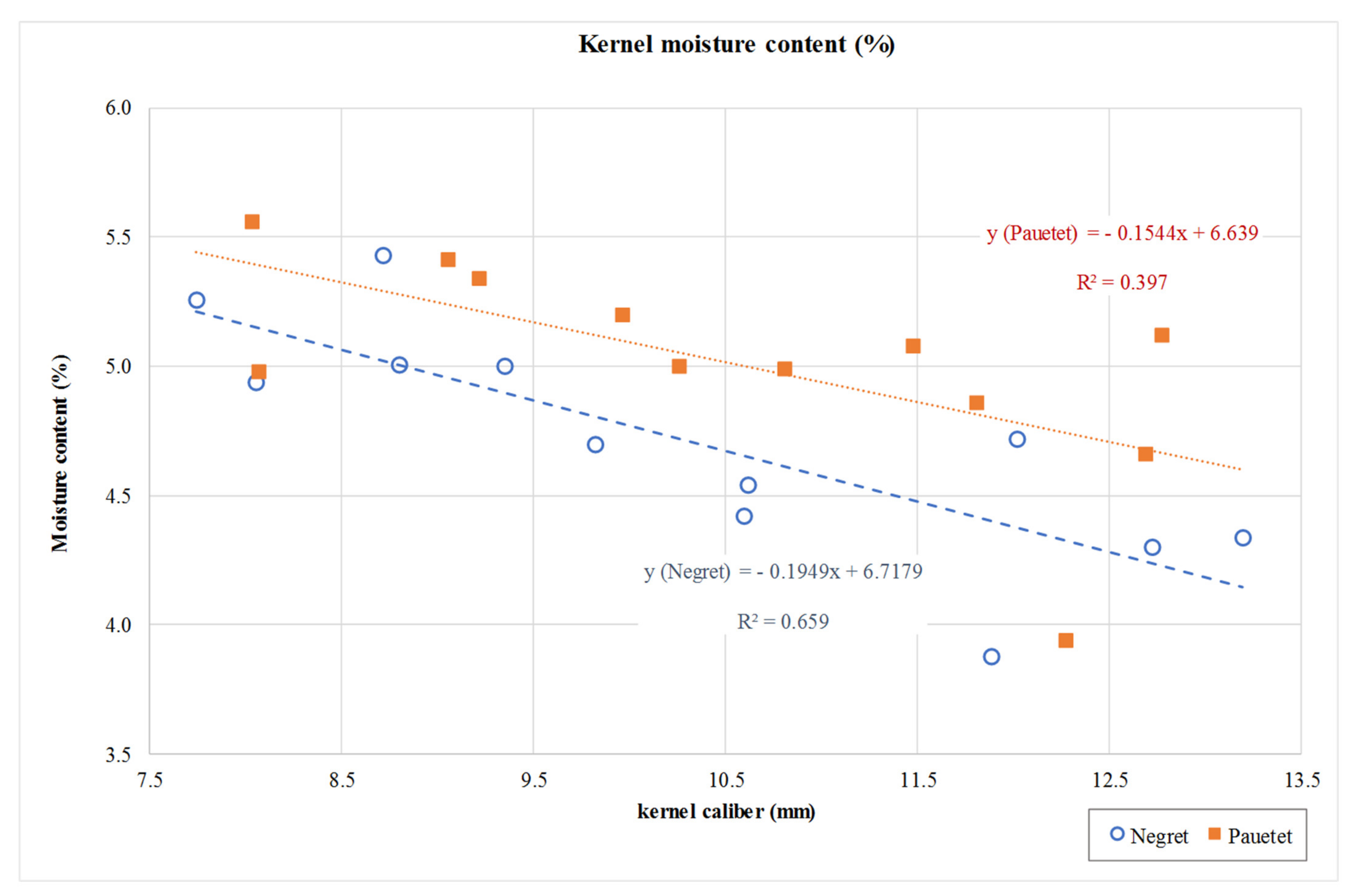

| Moisture content (%) | Negret | 6.7179 | ± | 0.4626 | −0.1949 | ± | 0.0443 | 0.659 | 19.36 | 0.0013 | 0.30 | 0.5905 | 5.72 | 0.0267 |

| Pauetet | 6.639 | ± | 0.6408 | −0.1544 | ± | 0.0600 | 0.398 | 6.60 | 0.0279 | |||||

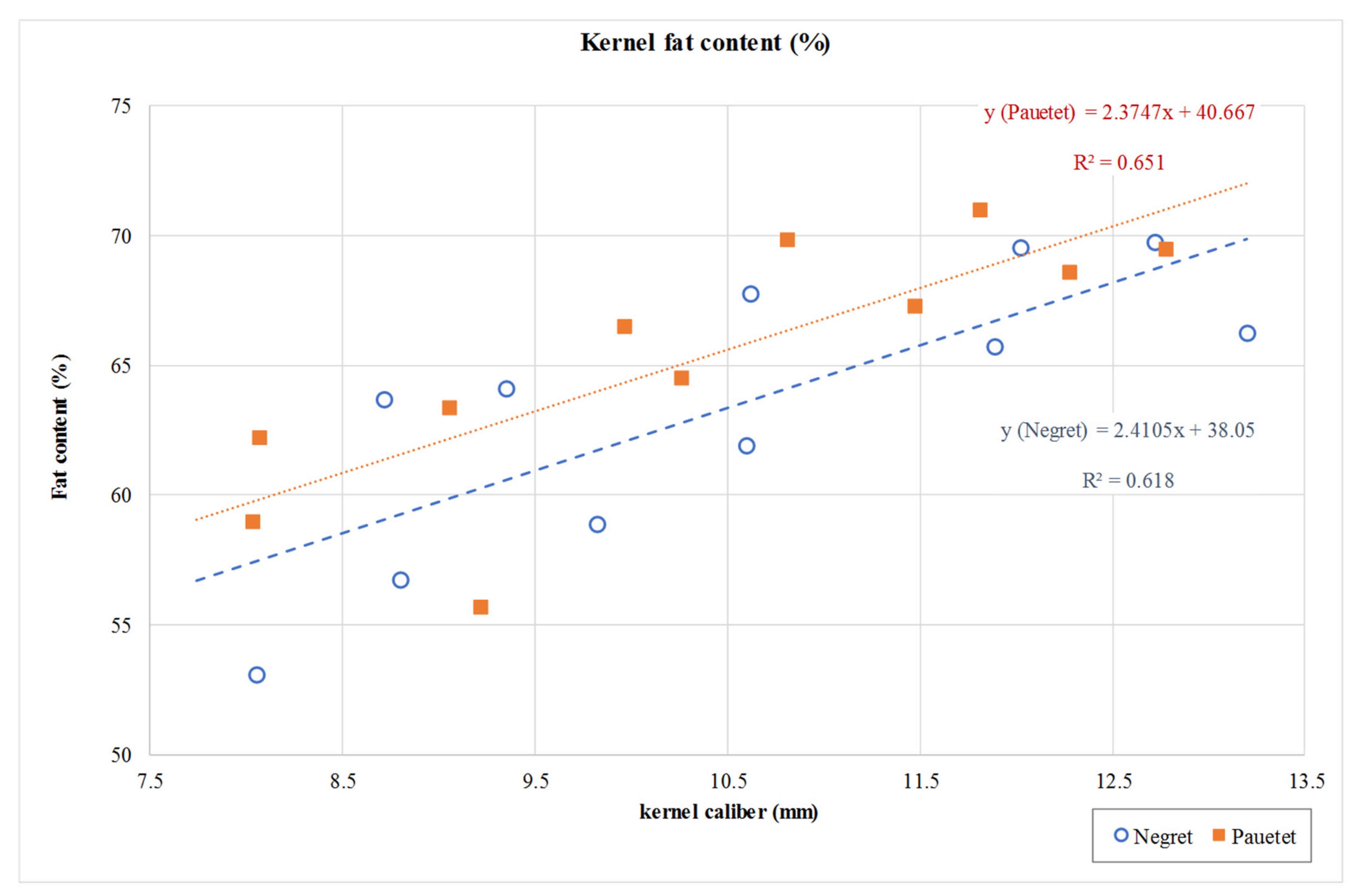

| Fat content (%) | Negret | 38.05 | ± | 6.72 | 2.4105 | ± | 0.6308 | 0.619 | 14.60 | 0.0041 | 0.00 | 0.9673 | 1.70 | 0.2086 |

| Pauetet | 40.67 | ± | 6.06 | 2.3747 | ± | 0.5795 | 0.651 | 16.79 | 0.0027 | |||||

| Protein (%) | Negret | 16.06 | ± | 0.97 | −0.1059 | ± | 0.0903 | 0.314 | 1.38 | 0.3254 | 3.28 | 0.1202 | 0.24 | 0.6439 |

| Pauetet | 20.29 | ± | 1.74 | −0.4268 | ± | 0.1588 | 0.707 | 7.22 | 0.0746 | |||||

| Crude fiber (%) | Negret | 14.6116 | ± | 2.6437 | −0.2714 | ± | 0.2419 | 0.290 | 1.23 | 0.3488 | 4.99 | 0.0669 | 0.01 | 0.9360 |

| Pauetet | 5.0274 | ± | 3.4554 | 0.6109 | ± | 0.3130 | 0.559 | 3.81 | 0.1460 | |||||

| Sugars (%) | Negret | 5.2274 | ± | 0.7489 | −0.2109 | ± | 0.0694 | 0.755 | 9.24 | 0.0559 | 0.51 | 0.5027 | 3.34 | 0.1173 |

| Pauetet | 5.6912 | ± | 1.2988 | −0.3061 | ± | 0.1187 | 0.689 | 6.65 | 0.0818 | |||||

| Minerals (%) | Negret | 2.2106 | ± | 0.4259 | −0.0135 | ± | 0.0395 | 0.038 | 0.12 | 0.7543 | 0.86 | 0.3903 | 0.12 | 0.7424 |

| Pauetet | 1.4651 | ± | 0.6650 | 0.0522 | ± | 0.0607 | 0.197 | 0.74 | 0.4538 | |||||

| Nut Trait | Cultivar | Linear Models | Test for Slope | Test for Cultivar | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Intercept | Slope | R2 | F Model | P Model | F Slope | P Slope | F Cultivar | P Cultivar | ||||||

| Palmitic acid (C16:0 %) | Negret | 5.5462 | ± | 0.1404 | 0.0109 | ± | 0.0132 | 0.071 | 0.69 | 0.4291 | 4.16 | 0.0582 | 70.57 | <0.0001 |

| Pauetet | 5.2791 | ± | 0.1826 | 0.0566 | ± | 0.0161 | 0.638 | 12.32 | 0.0099 | |||||

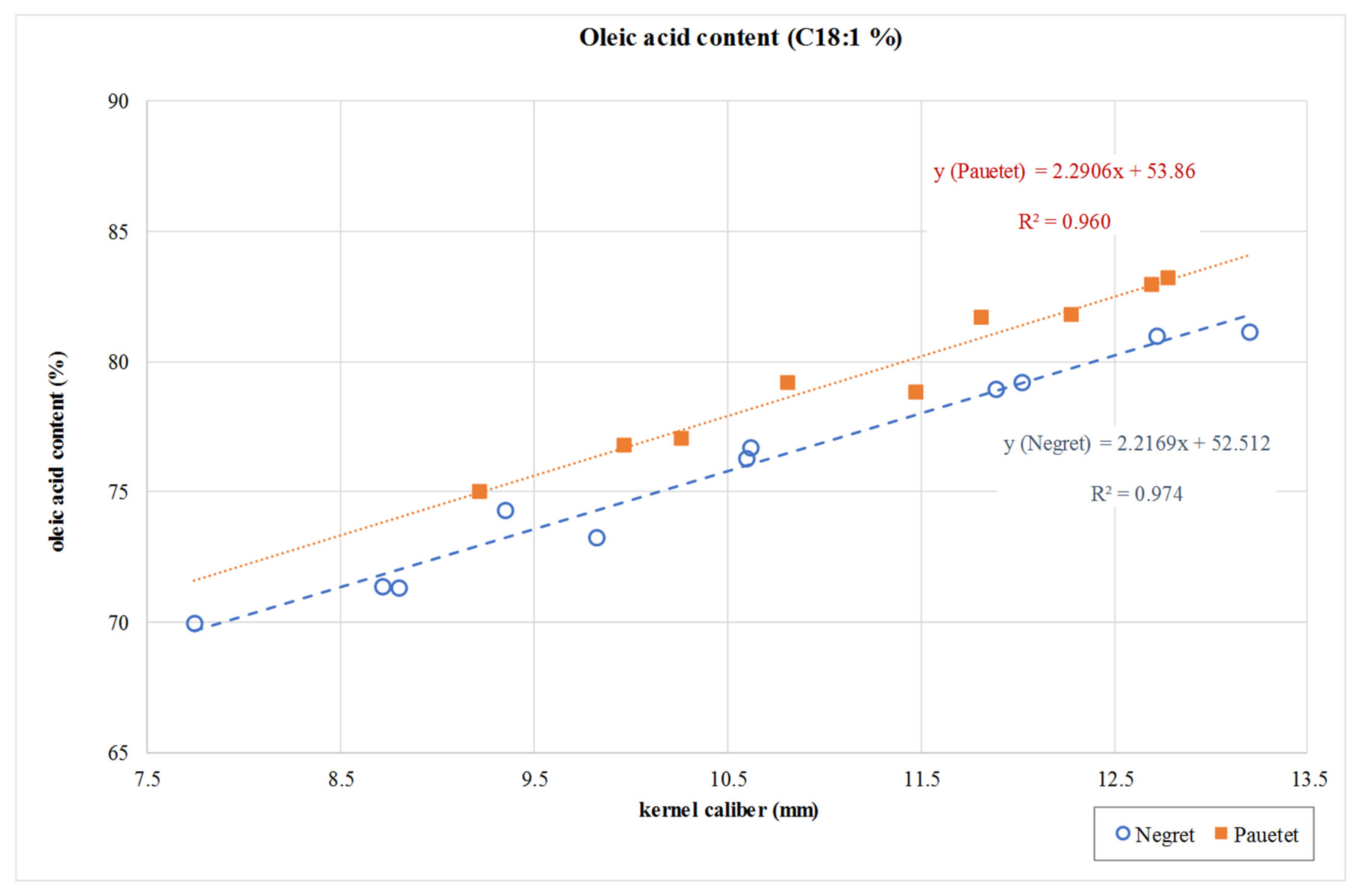

| Oleic acid (C18:1 %) | Negret | 52.51 | ± | 1.26 | 2.2169 | ± | 0.1186 | 0.975 | 349 | <0.0001 | 0.12 | 0.7375 | 172 | <0.0001 |

| Pauetet | 53.86 | ± | 1.99 | 2.2906 | ± | 0.1763 | 0.960 | 168 | <0.0001 | |||||

| Linoleic acid (C18:2 %) | Negret | 40.54 | ± | 1.31 | −2.3228 | ± | 0.1129 | 0.975 | 356 | <0.0001 | 0.28 | 0.6048 | 205 | <0.0001 |

| Pauetet | 39.33 | ± | 1.96 | −2.4385 | ± | 0.1729 | 0.966 | 198 | <0.0001 | |||||

| Linolenic acid (C18:3 %) | Negret | 0.1787 | ± | 0.0112 | −0.0085 | ± | 0.0011 | 0.878 | 64.67 | <0.0001 | 0.18 | 0.6789 | 14.10 | 0.0017 |

| Pauetet | 0.1679 | ± | 0.0134 | −0.0077 | ± | 0.0012 | 0.858 | 42.30 | 0.0003 | |||||

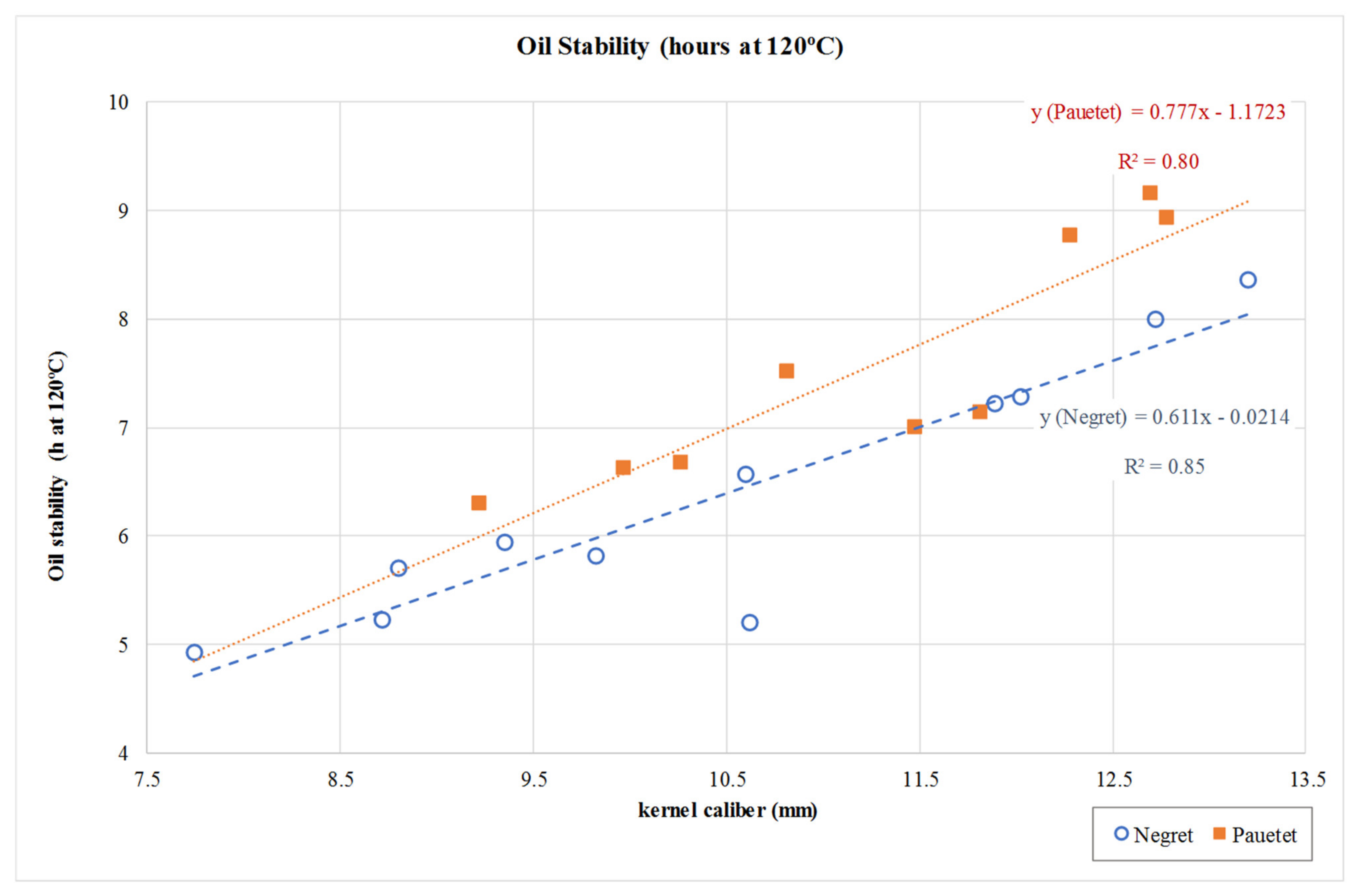

| Stability (h at 120 °C) | Negret | −0.0214 | ± | 0.8942 | 0.6109 | ± | 0.0841 | 0.854 | 52.80 | <0.0001 | 1.02 | 0.3269 | 28.01 | <0.0001 |

| Pauetet | −1.1723 | ± | 1.6516 | 0.7770 | ± | 0.1459 | 0.802 | 28.35 | 0.0011 | |||||

| α-tocopherol (mg/kg) | Negret | 98.78 | ± | 16.24 | 8.4429 | ± | 1.5048 | 0.913 | 31.49 | 0.0112 | 1.98 | 0.2090 | 0.46 | 0.5241 |

| Pauetet | 173.14 | ± | 51.69 | 1.8664 | ± | 4.7236 | 0.049 | 0.16 | 0.7195 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero-Aroca, A.; Rovira, M.; Cristofori, V.; Silvestri, C. Hazelnut Kernel Size and Industrial Aptitude. Agriculture 2021, 11, 1115. https://doi.org/10.3390/agriculture11111115

Romero-Aroca A, Rovira M, Cristofori V, Silvestri C. Hazelnut Kernel Size and Industrial Aptitude. Agriculture. 2021; 11(11):1115. https://doi.org/10.3390/agriculture11111115

Chicago/Turabian StyleRomero-Aroca, Agusti, Mercè Rovira, Valerio Cristofori, and Cristian Silvestri. 2021. "Hazelnut Kernel Size and Industrial Aptitude" Agriculture 11, no. 11: 1115. https://doi.org/10.3390/agriculture11111115

APA StyleRomero-Aroca, A., Rovira, M., Cristofori, V., & Silvestri, C. (2021). Hazelnut Kernel Size and Industrial Aptitude. Agriculture, 11(11), 1115. https://doi.org/10.3390/agriculture11111115