Applying the Response Surface Methodology (RSM) Approach to Predict the Tractive Performance of an Agricultural Tractor during Semi-Deep Tillage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Measuring Unit

2.2. Data Attainment System

2.3. Field Trials

2.4. RSM Approach

3. Results and Discussion

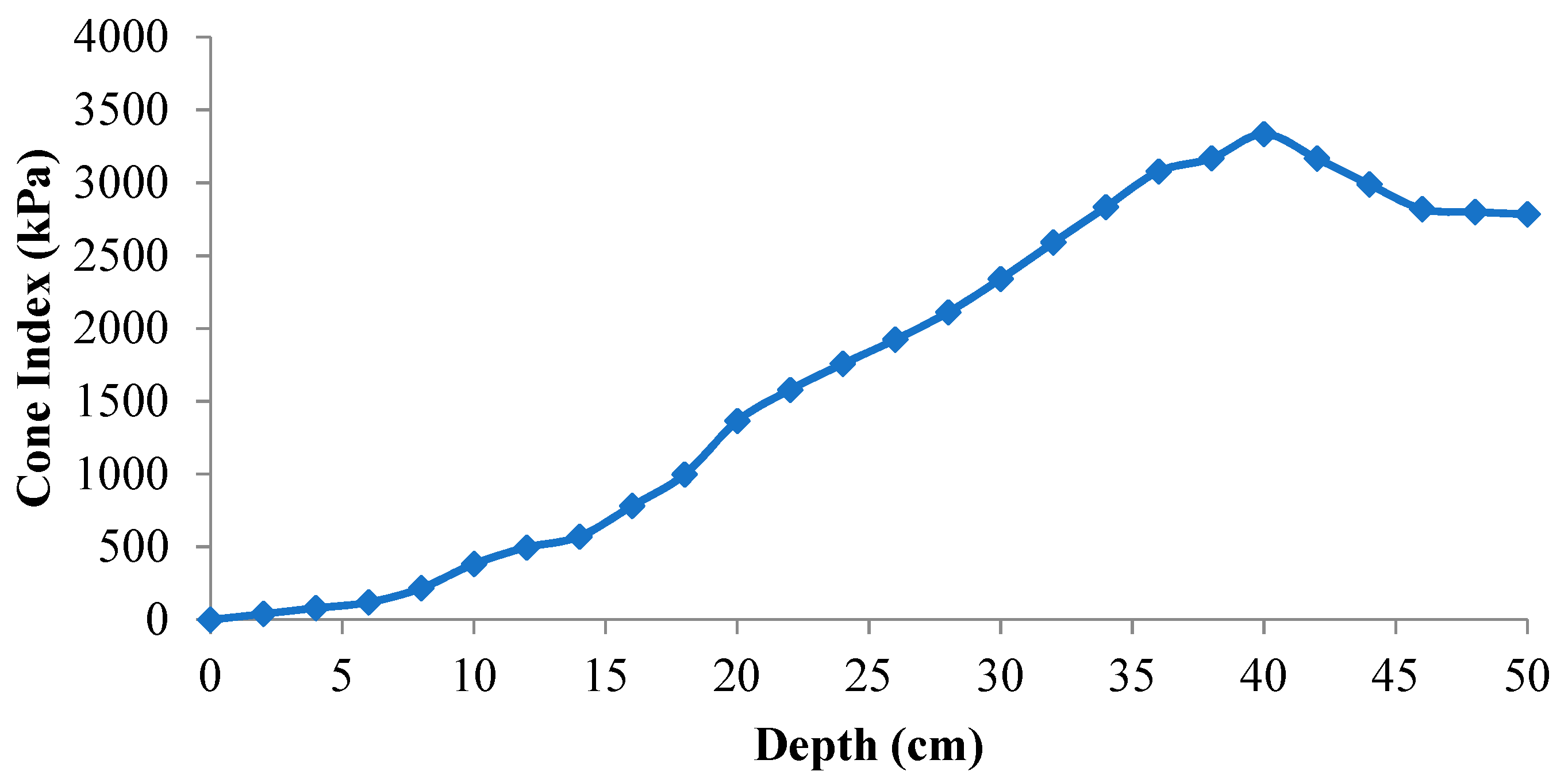

3.1. Field Data

3.1.1. Influence of Tine, Depth, Speed and Vertical Loads on the Slippage

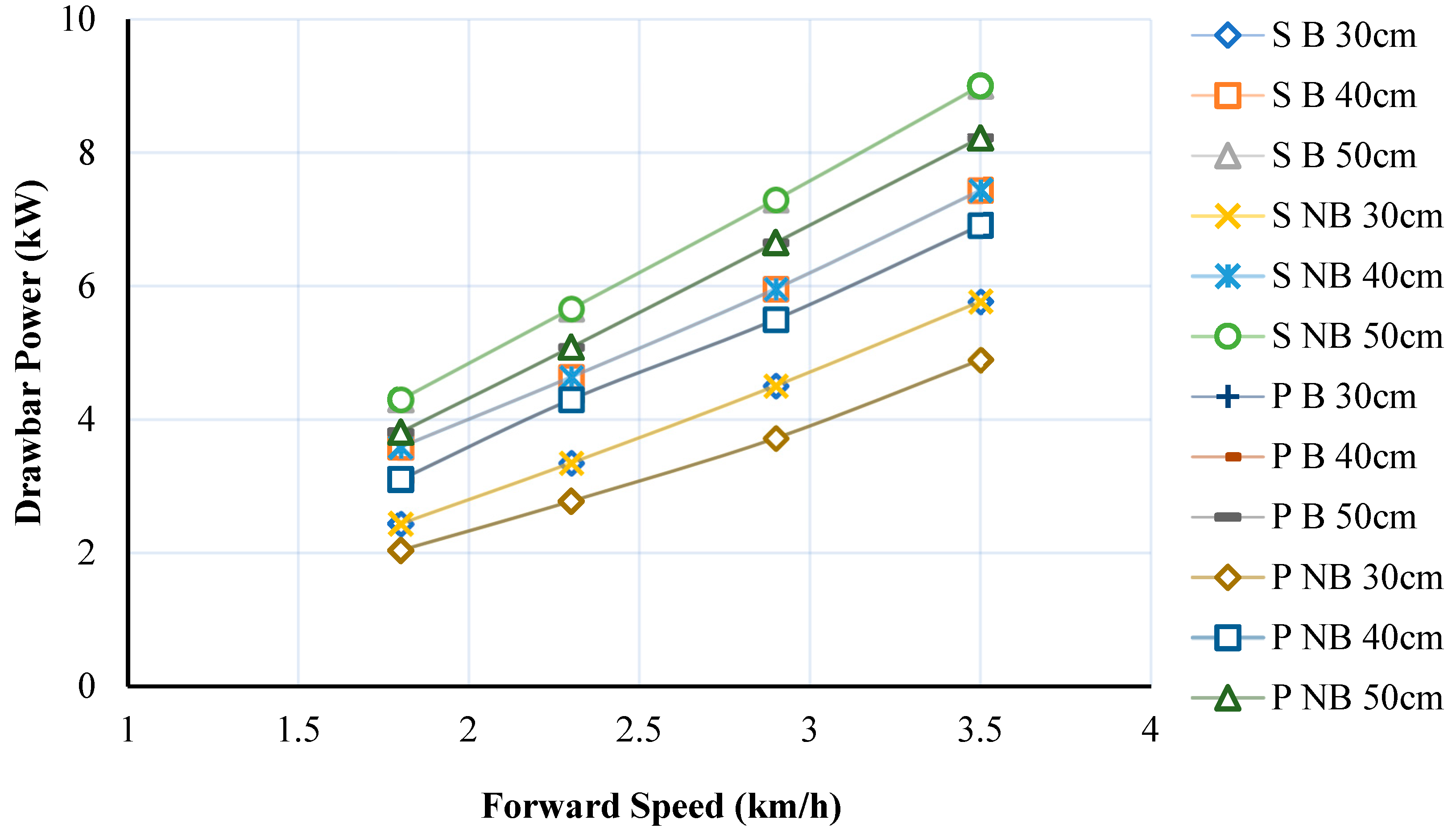

3.1.2. Influence of Tine, Depth, Speed and Ring Weights on the Drawbar Power

3.1.3. Influence of Tine, Depth, Speed and Ring Weights on the Traction Efficiency

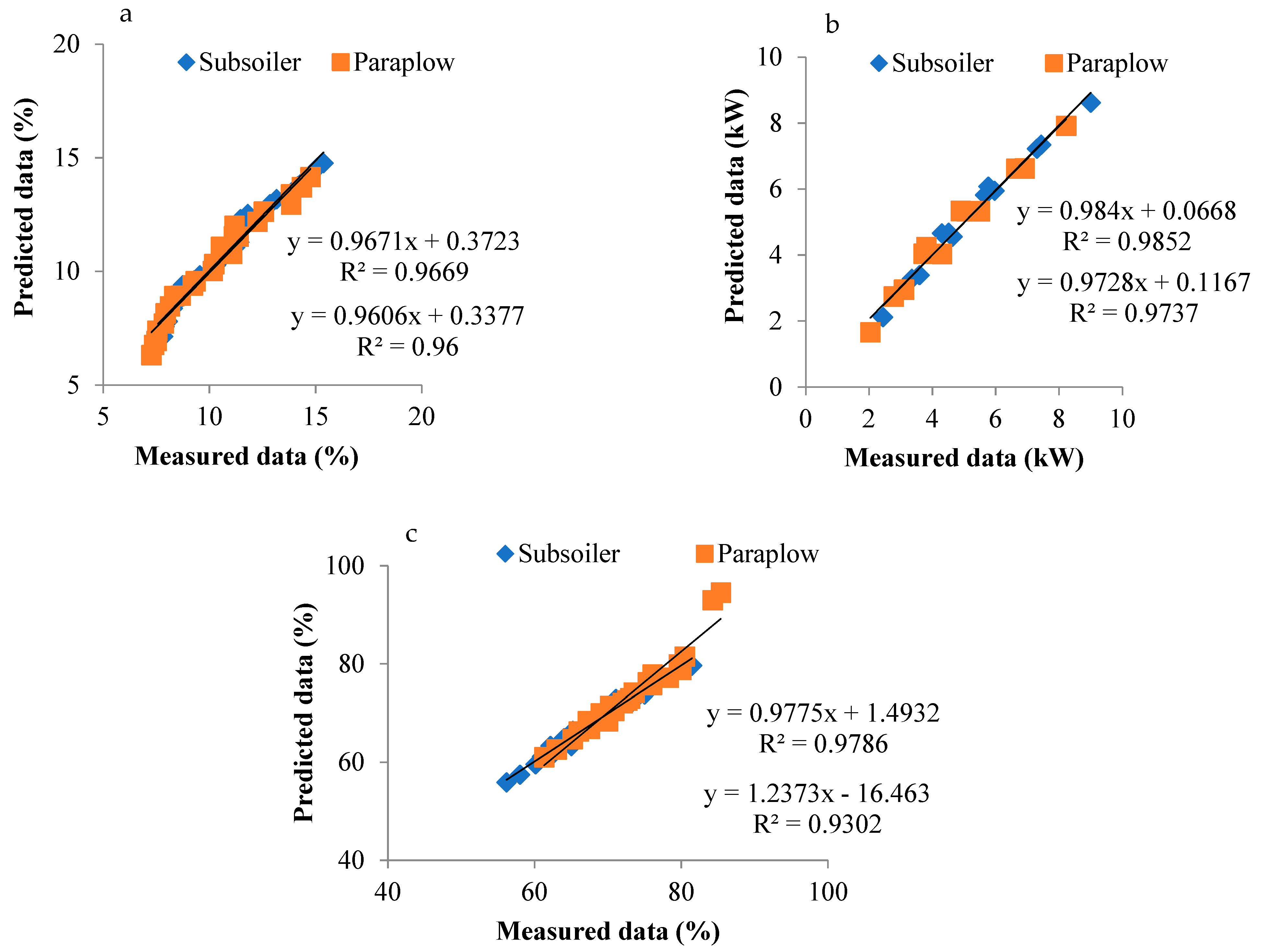

3.2. Regression Models and Accuracy

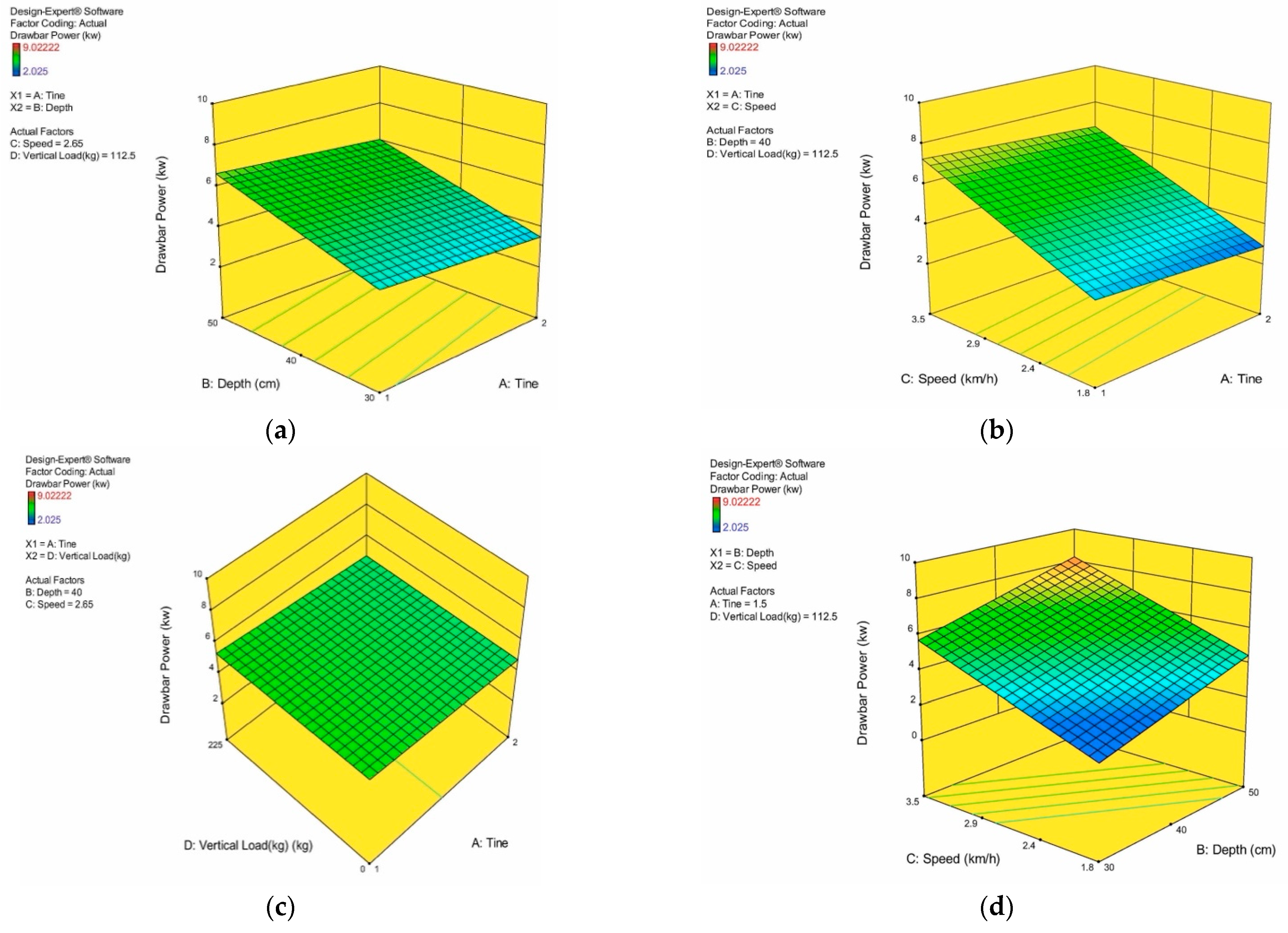

3.3. RSM Model

3.4. Optimization Using RSM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Šmerda, T.; Čupera, J. Tire inflation and its influence on drawbar characteristics and performance-energetic indicators of a tractor set. J. Terramech. 2010, 47, 395–400. [Google Scholar] [CrossRef]

- Battiato, A.; Diserens, E. Influence of tyre inflation pressure and wheel load on the traction performance of a 65 kW MFWD tractor on a cohesive soil. J. Agric. Sci. 2013, 5, 197–215. [Google Scholar] [CrossRef]

- Lee, J.H.; Gard, K. Vehicle-soil interaction: Testing, modeling, calibration and validation. J. Terramech. 2014, 52, 9–21. [Google Scholar] [CrossRef]

- Taghavifar, H.; Mardani, A. On the modeling of energy efficiency indices of agricultural tractor driving wheels applying adaptive neuro-fuzzy inference system. J. Terramech. 2014, 56, 37–47. [Google Scholar] [CrossRef]

- Janulevicius, A.; Damanauskas, V. How to select air pressures in the tires of MFWD (mechanical front-wheel drive) tractor to minimize fuel consumption for the case of reasonable wheel slip. Energy 2015, 90, 691–700. [Google Scholar] [CrossRef]

- Zoz, F.M.; Grisso, R.D. Traction and Tractor Performance; ASAE Distinguished Lecture Series No. 27; ASAE: St Joseph, MI, USA, 2003. [Google Scholar]

- Ranjbarian, S.; Askari, M.; Jannatkhah, J. Performance of tractor and tillage implements in clay soil. J. Saudi Soc. Agric. Sci. 2017, 16, 154–162. [Google Scholar] [CrossRef] [Green Version]

- Askari, M.; Abbaspour-Gilandeh, Y. Assessment of adaptive neuro-fuzzy inference system and response surface methodology approaches in draft force prediction of subsoiling tines. Soil Tillage Res. 2019, 194, 104338. [Google Scholar] [CrossRef]

- Karuppaiya, M.; Sasikumar, E.; Viruthagiri, T.; Vijayagopal, V. Optimization of process variables using response surface methodology (RSM) for ethanol production from cashew apple juice by Saccharomycescerevisiae. Asian J. Food Agro-Ind. 2010, 3, 462–473. [Google Scholar]

- Betiku, E.; Adesina, O.A. Optimization of sweet potato starch hydrolyzate production and its potential utilization as substrate for citric acid production. Br. Biotechnol. J. 2013, 3, 169–182. [Google Scholar] [CrossRef]

- Managamuri, U.; Vijayalakshm, V.; Poda, S.; Gandur, V.S.; Babu, R.S. Optimization of culture conditions by response surface methodology and unstructured kinetic modeling for bioactive metabolite production by Nocardiopsis litoralisVSM-8. 3 Biotech 2016, 6, 219–231. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, P.; Chen, C.; Li, H. Investigation of Hydraulic Performance Based on Response Surface Methodology for an Agricultural Chemigation Proportional Injector. Water 2020, 12, 3155. [Google Scholar] [CrossRef]

- Jiang, Q.; He, Z.; Wang, Y.; Wang, J. Optimizing the working performance of a boat-type tractor using central composite rotatable design and response surface method. Comput. Electron. Agric. 2021, 181, 105944. [Google Scholar] [CrossRef]

- Kheiralla, A.F. Modeling of power and energy forces for tillage implements operating in Serdang sandy clay loam, Malaysia. Soil Tillage Res. 2003, 78, 21–34. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Haghighat-Shishvan, S. Extended octagonal ring transducers for measurement of tractor-implement force. Instrum. Exp. Tech. 2011, 54, 137–141. [Google Scholar] [CrossRef]

- Upadhyaya, S.K.; Collins, N.E.; Kemble, L.J.; Williams, T.H. Energy requirement for chiseling in coastal plain soils. Trans. ASAE 1984, 27, 1643–11649. [Google Scholar] [CrossRef]

- Upadhyaya, S.K.; Ma, T.X.; Chancellor, W.J.; Zhao, Y.M. Dynamics of soil-tool interaction. Soil Tillage Res. 1987, 9, 187–206. [Google Scholar] [CrossRef]

- ASABE Standard. Soil Cone Penetrometer; ASABE Standard No. S313.3 (R2013); American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 1999. [Google Scholar]

- McKenzie, N.J.; Jacquier, D.; Isbell, R.F.; Brown, K. Australian Soils and Landscapes: An Illustrated Compendium; CSIRO Publishing, CSIRO, Research Way: Clayton, VIC, Australia, 2004. [Google Scholar] [CrossRef]

- ASABE Standard. Agricultural Machinery Management Data Standard; ASABE Standard No. D497.7 (R2020); American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2011. [Google Scholar]

- ASABE Standard. General Terminology for Traction of Agricultural Traction and Transport Devices and Vehicles; ASABE Standard No. S296.5 (R2018); American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2003. [Google Scholar]

- Khuri, A.I.; Cornell, J.A. Response Surfaces: Designs and Analyses; CRC Press: New York, NY, USA, 1987. [Google Scholar]

- Xie, Y.; Chen, L.; Liu, R. Oxidation of AOX and organic compounds in pharmaceutical wastewater in RSM-optimized-Fenton system. Chemosphere 2016, 155, 217–224. [Google Scholar] [CrossRef] [PubMed]

- Askari, M.; Shahgholi, G.; Abbaspour-Gilandeh, Y.; Tash-Shamsabadi, H. The effect of new wings on subsoiler performance. Appl. Eng. Agric. 2016, 32, 1–10. [Google Scholar] [CrossRef]

- Danbaba, N.; Nkama, I.; Badau, M.H.; Ukwungwu, M.N.; Maji, A.T.; Abo, M.E.; Hauwawu, H.; Fati, K.I.; Oko, A.O. Optimization of rice parboiling process for optimum head rice yield: A response surface methodology (RSM) approach. Int. J. Agric. For. 2014, 4, 154–165. [Google Scholar]

| Property | Value |

|---|---|

| Organic matter | 0.5% |

| pH | 7.1 |

| Electrical conductivity (EC) | 0.41 dS m−1 |

| Dry bulk density | 1230 kg m−3 |

| Soil moisture content (db) (0–25 cm) | 9.3% |

| Soil moisture content (db) (25–50 cm) | 10.8% |

| Source of Variation | Degree of Freedom | Mean Square | ||

|---|---|---|---|---|

| A | B | C | ||

| T | 1 | 13.031 ** | 16.016 ** | 1190.52 ** |

| D | 2 | 452.78 ** | 106.41 ** | 2172.47 ** |

| S | 3 | 44.47 ** | 131.28 ** | 1002.63 ** |

| W | 1 | 4.29 ** | 29.30 ns | 121.19 ** |

| T × D | 2 | 0.156 ** | 0.19 ** | 0.098 ns |

| T × S | 3 | 0.043 ** | 0.18 ** | 0.062 ns |

| T × W | 1 | 0.133 ** | 0.02 ns | 0.263 * |

| D × S | 6 | 5.184 ** | 1.64 ** | 8.01 ** |

| D × W | 2 | 0.544 ** | 0.036 ns | 3.645 ** |

| S × W | 3 | 0.035 ** | 0.097 ns | 3.16 ** |

| T × D × S | 6 | 0.015 ** | 0.044 ** | 0.062 ns |

| T × D × W | 2 | 0.507 ** | 0.033 ns | 0.131 ns |

| T × S × W | 3 | 0.036 ** | 0.041 ns | 0.152 ns |

| D × S × W | 6 | 0.015 ** | 0.033 ns | 0.925 ** |

| T × D × S × W | 6 | 0.017 ** | 0.30 ns | 0.148 * |

| Error | 144 | 0.001 | 0.000 | 0.064 |

| Total | 191 | |||

| Parameter | Tine | Model |

|---|---|---|

| Slippage (%) | Subsoiler Paraplow | –3.309 + 0.269 D + 1.323 S − 0.001 W |

| –3.364 + 0.262 D + 1.263 S − 0.002 W | ||

| Drawbar Power (kW) | –5.877 + 0.127 D + 2.327 S | |

| –6.096 + 0.129 D + 2.162 S | ||

| Traction Efficiency (%) | 106.758 − 0.584 D − 6.194 S + 0.007 W | |

| 111.303 − 0.577 D − 6.117 S + 0.007 W |

| Response Variable | Equation | R2 Value | Adj R2 | Pred. R2 | C.V. (%) |

|---|---|---|---|---|---|

| Slippage (%) | −2.85456 − 0.52104 × Tine + 1.293 × Speed + 1.33 ×10−3 × vertical load | 0.9638 | 0.9630 | 0.9615 | 4.36 |

| Drawbar Power (kW) | −5.12 − 0.57763 × Tine + 0.12838 × Depth + 2.24469 × Speed | 0.9792 | 0.9789 | 0.9782 | 5.25 |

| Traction Efficiency (%) | 103.14873 + 4.98021 × Tine − 0.58042 × Depth − 6.15519 × Speed | 0.9813 | 0.9810 | 0.9803 | 1.33 |

| Tine | Speed (km h−1) | Depth (cm) | VL (kg) | S (%) | DP (kW) | TE (%) | Desirability |

|---|---|---|---|---|---|---|---|

| Paraplow | 2.077 | 30.00 | 0.010 | 6.758 | 2.238 | 82.912 | 0.843 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Askari, M.; Abbaspour-Gilandeh, Y.; Taghinezhad, E.; El Shal, A.M.; Hegazy, R.; Okasha, M. Applying the Response Surface Methodology (RSM) Approach to Predict the Tractive Performance of an Agricultural Tractor during Semi-Deep Tillage. Agriculture 2021, 11, 1043. https://doi.org/10.3390/agriculture11111043

Askari M, Abbaspour-Gilandeh Y, Taghinezhad E, El Shal AM, Hegazy R, Okasha M. Applying the Response Surface Methodology (RSM) Approach to Predict the Tractive Performance of an Agricultural Tractor during Semi-Deep Tillage. Agriculture. 2021; 11(11):1043. https://doi.org/10.3390/agriculture11111043

Chicago/Turabian StyleAskari, Mohammad, Yousef Abbaspour-Gilandeh, Ebrahim Taghinezhad, Ahmed Mohamed El Shal, Rashad Hegazy, and Mahmoud Okasha. 2021. "Applying the Response Surface Methodology (RSM) Approach to Predict the Tractive Performance of an Agricultural Tractor during Semi-Deep Tillage" Agriculture 11, no. 11: 1043. https://doi.org/10.3390/agriculture11111043

APA StyleAskari, M., Abbaspour-Gilandeh, Y., Taghinezhad, E., El Shal, A. M., Hegazy, R., & Okasha, M. (2021). Applying the Response Surface Methodology (RSM) Approach to Predict the Tractive Performance of an Agricultural Tractor during Semi-Deep Tillage. Agriculture, 11(11), 1043. https://doi.org/10.3390/agriculture11111043