2.2. Application of the VDI-2221 Design Methodology to Determine the Conceptual Design

The VDI-2221 guideline [

10] proposes a systematic approach to the process design of technical systems and products, which is very useful for the particular case of agriculture equipment. The methodology mainly consists of four phases: clarification of the problem, conceptual design, project development, and detailed design. The advantage of this guideline is the assessment of alternatives developed in each phase and the choice of the most optimal alternative on the basis of the designer’s criteria through their experience and knowledge.

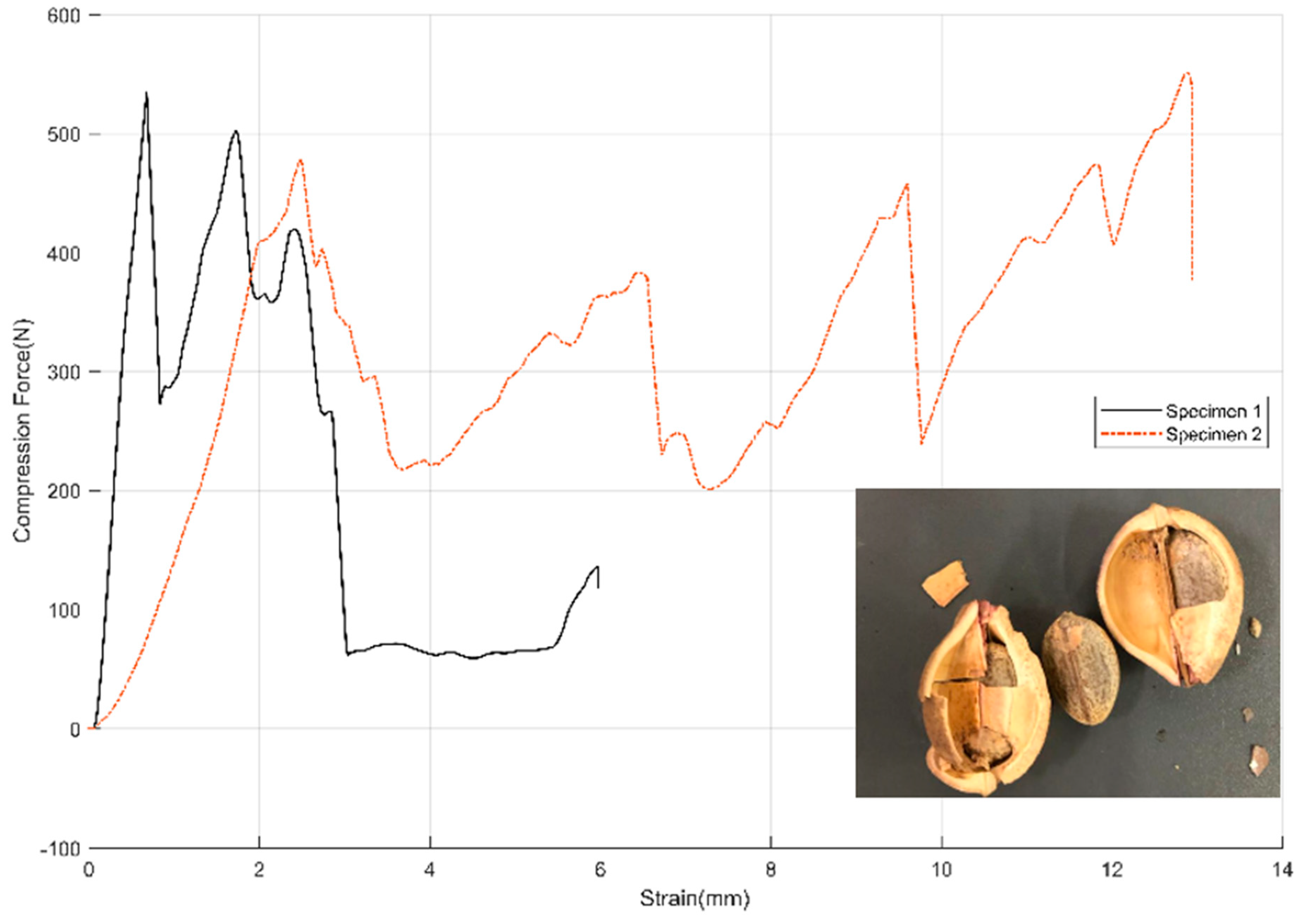

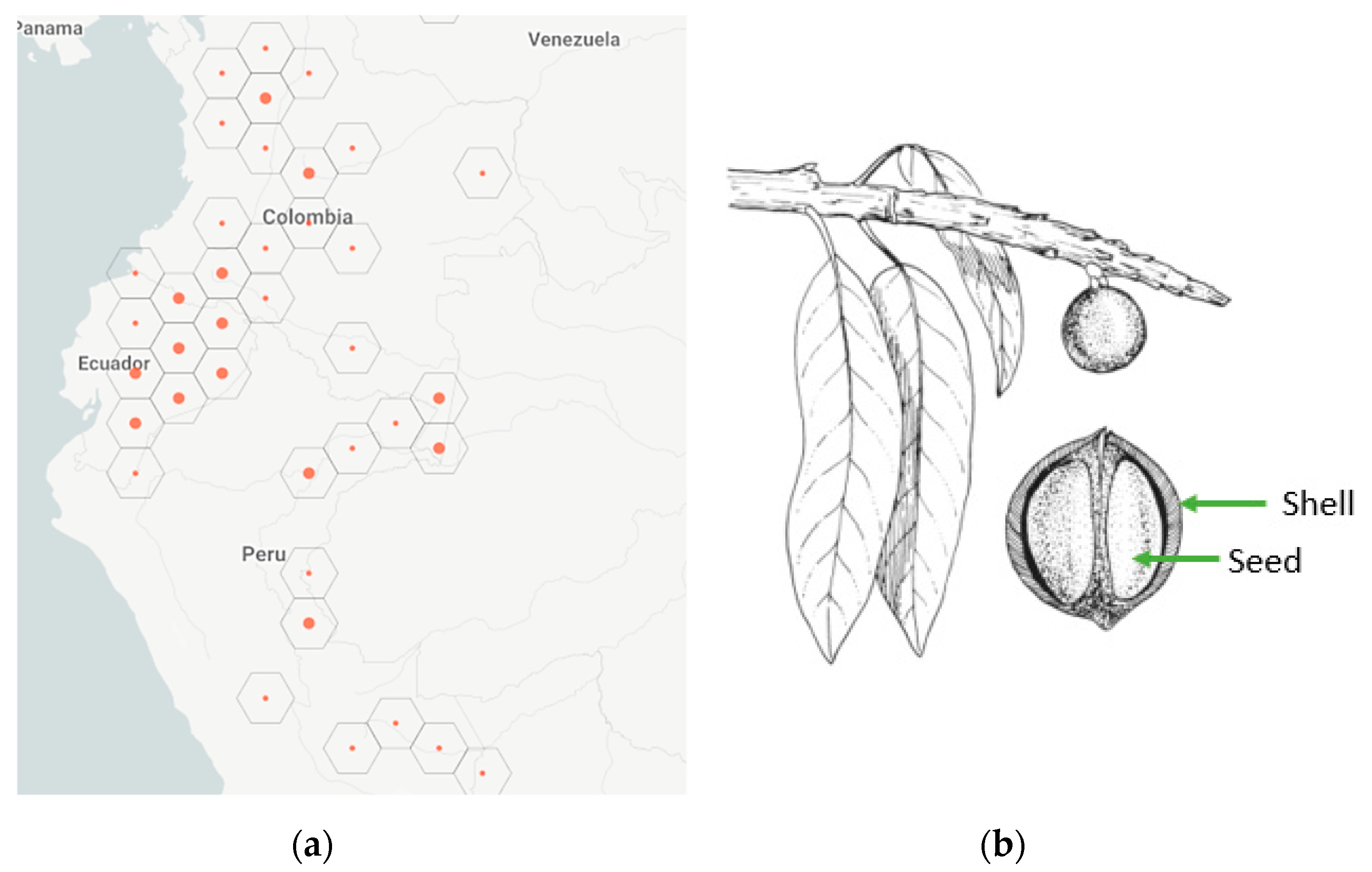

The first phase is achieved by making a requirement list and determining the state of the art. It involves the characteristics that the project needs to achieve and characteristics that could be achieved. In order to meet the production demand, the design requirements were established by entrepreneurs who needed to process 50 kg per hour. The machine function covered fruit feeding to the separation of shell and fruit seed. Allowed materials were established according to the standards from the Food and Agriculture Organization of the United Nations (FAO) and World Health Organization (WHO). Local security standards were followed to assure operator safety and ergonomic operation.

The next step was to gather information from research on technologies and machines with the main function of separating the shell and seeds of different nuts such as macadamia nuts [

11] in articles, patents, videos, and other information sources.

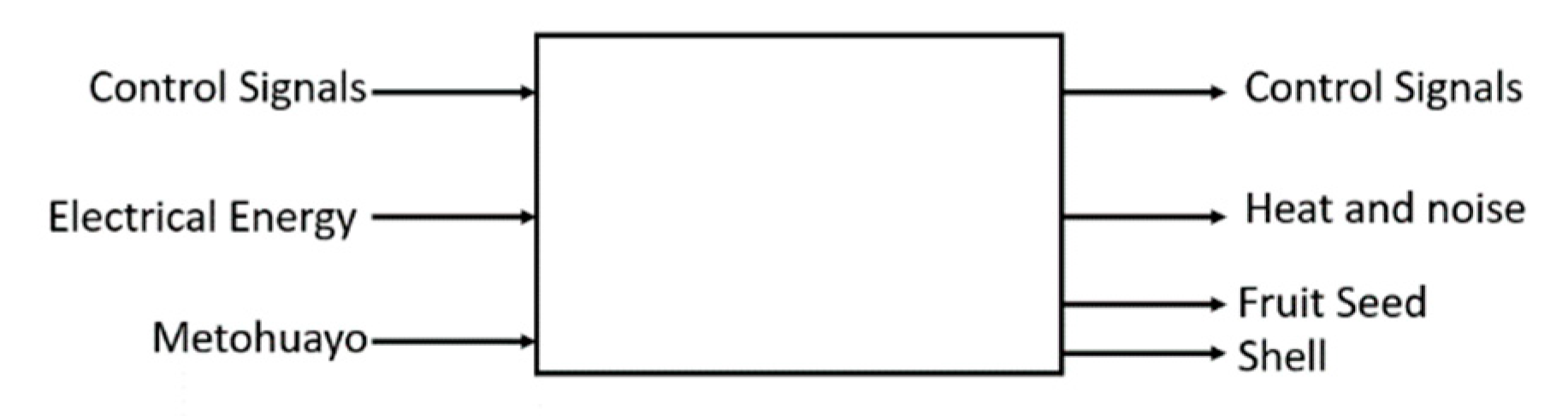

After the clarification of the problem, the phase of conceptual design was implemented to determine the optimal concept or solution principle. The machine is described as an overall function depicted as a black box in

Figure 4.

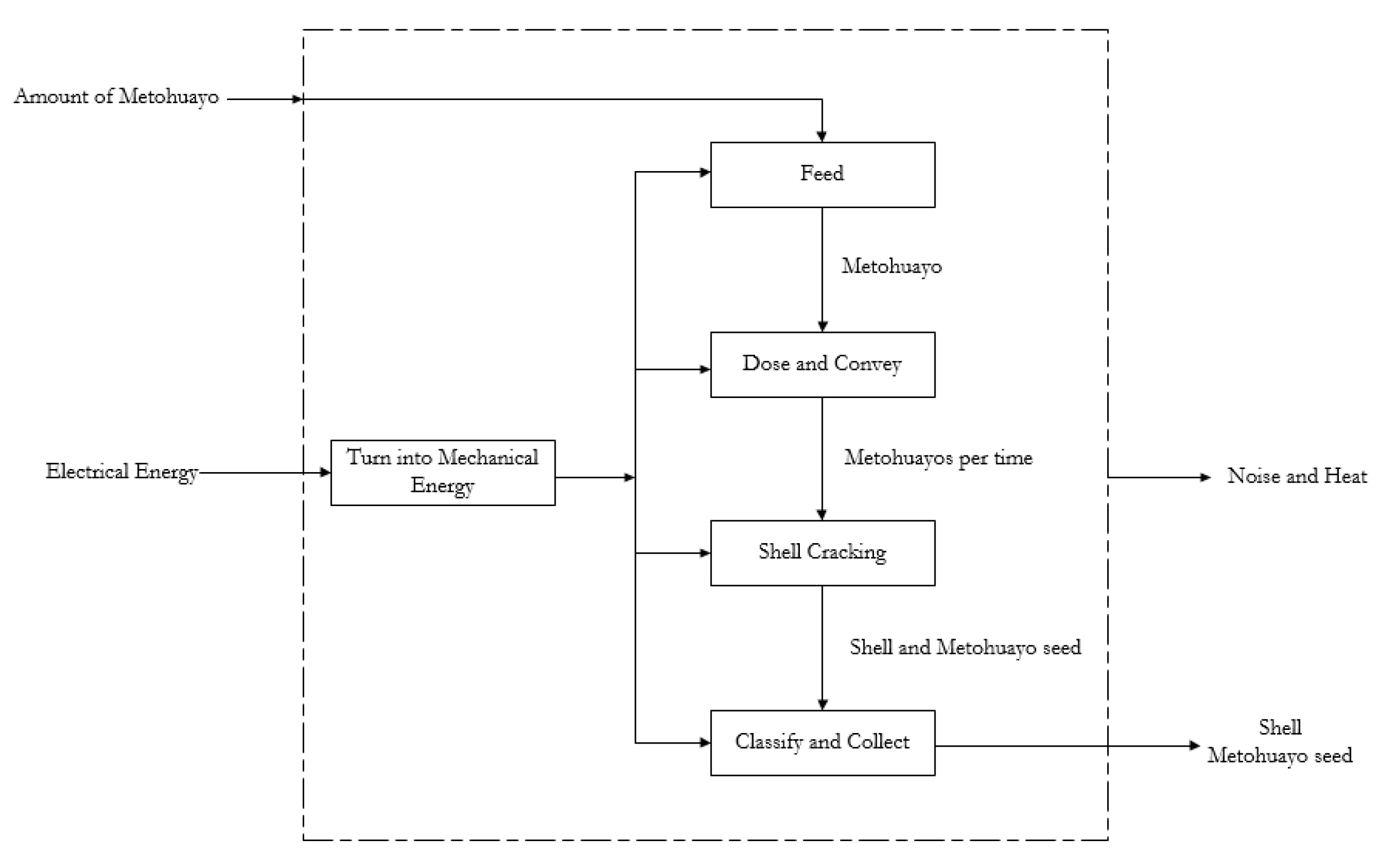

According to the aim, the strategy was to split the complex overall function into subfunctions. A sequence of operations was established to order the subfunctions. The function structure was represented in connected blocks due to the established sequence. Furthermore, some subfunctions could be grouped into one block which resulted in a number of alternative function structures.

Figure 5 shows the optimal function structure composed of both individual and group subfunction blocks. The individual subfunctions were feed and shell cracking. The group subfunctions were dose and convey, shell cracking, and classify and collect.

Then, the functional elements performing the abovementioned blocks were determined through the research of components or systems satisfying the solution principles [

12].

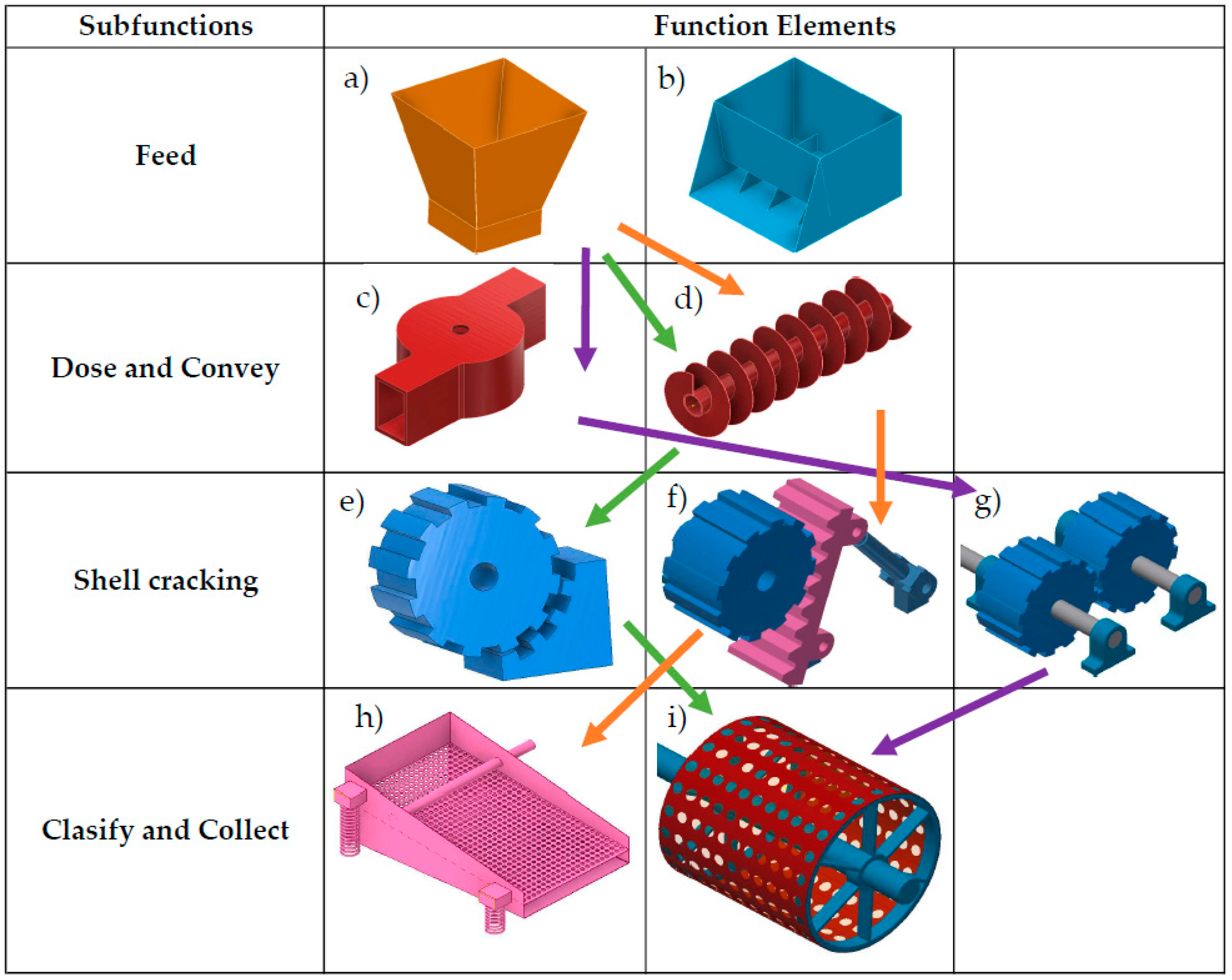

Figure 6 shows a morphological table in which the subfunctions are listed in the first column of the table and the functional elements are presented in each respective row. The elements are linked by arrows, resulting in alternative solution concepts. In this sense, the morphological table provides a large number of possible solutions which is both an advantage and a disadvantage of this method since the number of layouts must be reduced according to the requirements previously established [

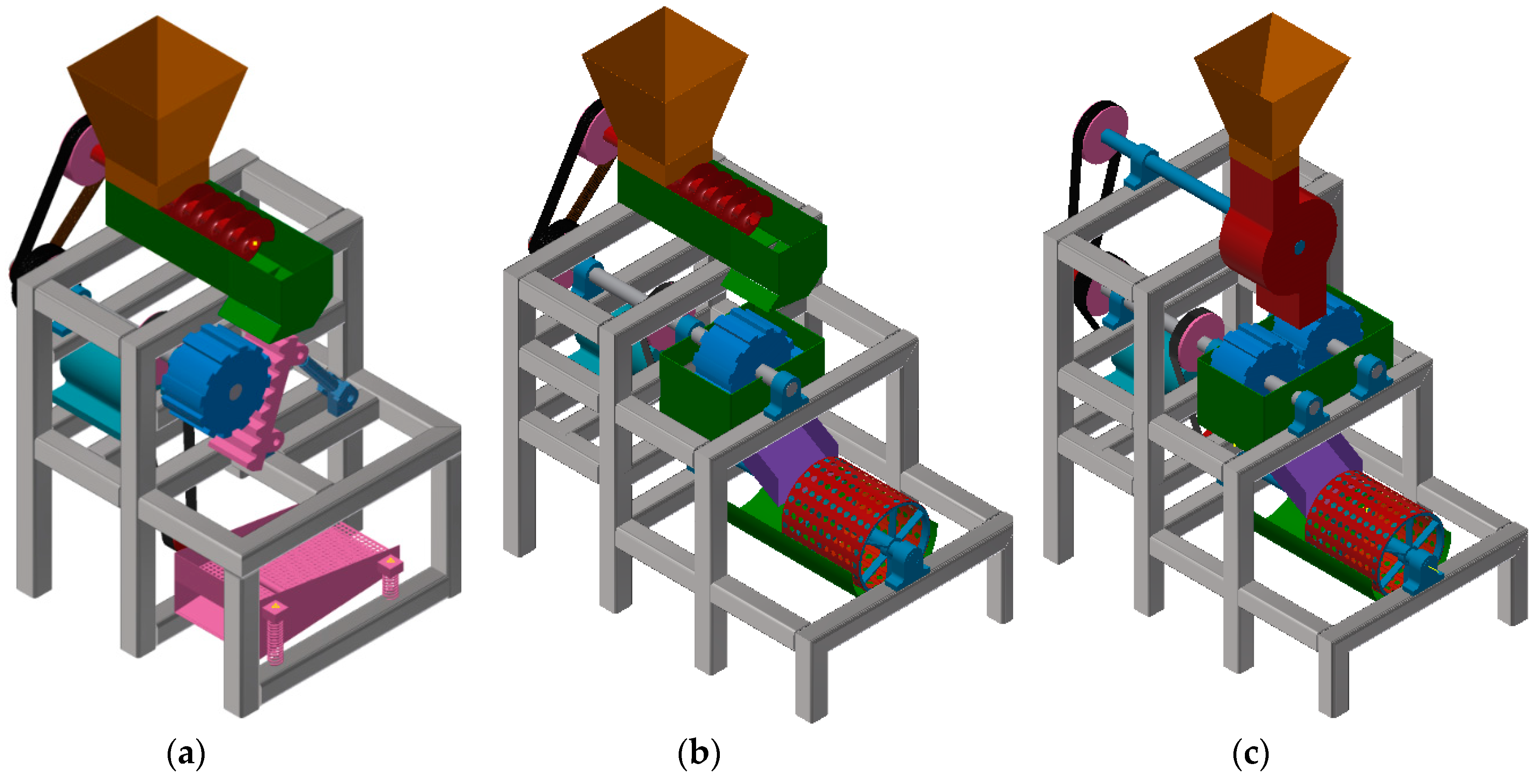

13]. In the current design, the best three concepts were chosen according to the requirements of farmers and the advantages of the functional elements presented as combinations. Three-dimensional (3D) freehand drawings were generated to visualize the alternatives. The schematic concepts made with the program Autodesk Inventor are shown in

Figure 7. The determination of the optimal concept was based on economic and technical criteria such as minimum components, fabrication feasibility, design safety, and requirement accomplishment.

Figure 7b shows the optimal solution concept consisting mainly of a chute (

Figure 6a), screw conveyor (

Figure 6d), toothed wheel with a tilted toothed wall (

Figure 6f), and rotating screen (

Figure 6i).

After the determination of the optimal solution concept, the phase of project development continued. The third phase was characterized by the development of preliminary layouts that differed from each other because of the power transmission and the arrangement of functional elements. Rough calculations according to the strength of materials were carried out in order to determine the dimensions of components, as well as the total power required by each component to determine the total power required by the electrical motor. This is discussed in

Section 2.3. Three-dimensional freehand drawings and three preliminary layouts were generated. The selection of the optimal preliminary layout depended on the technical and economic criteria listed in

Table 2 and

Table 3, respectively. This procedure allowed evaluating the solutions as a function of different criteria, where a better performance corresponded to a higher mark, and weighting factors were established for each criteria according to the project requirements [

13]. In

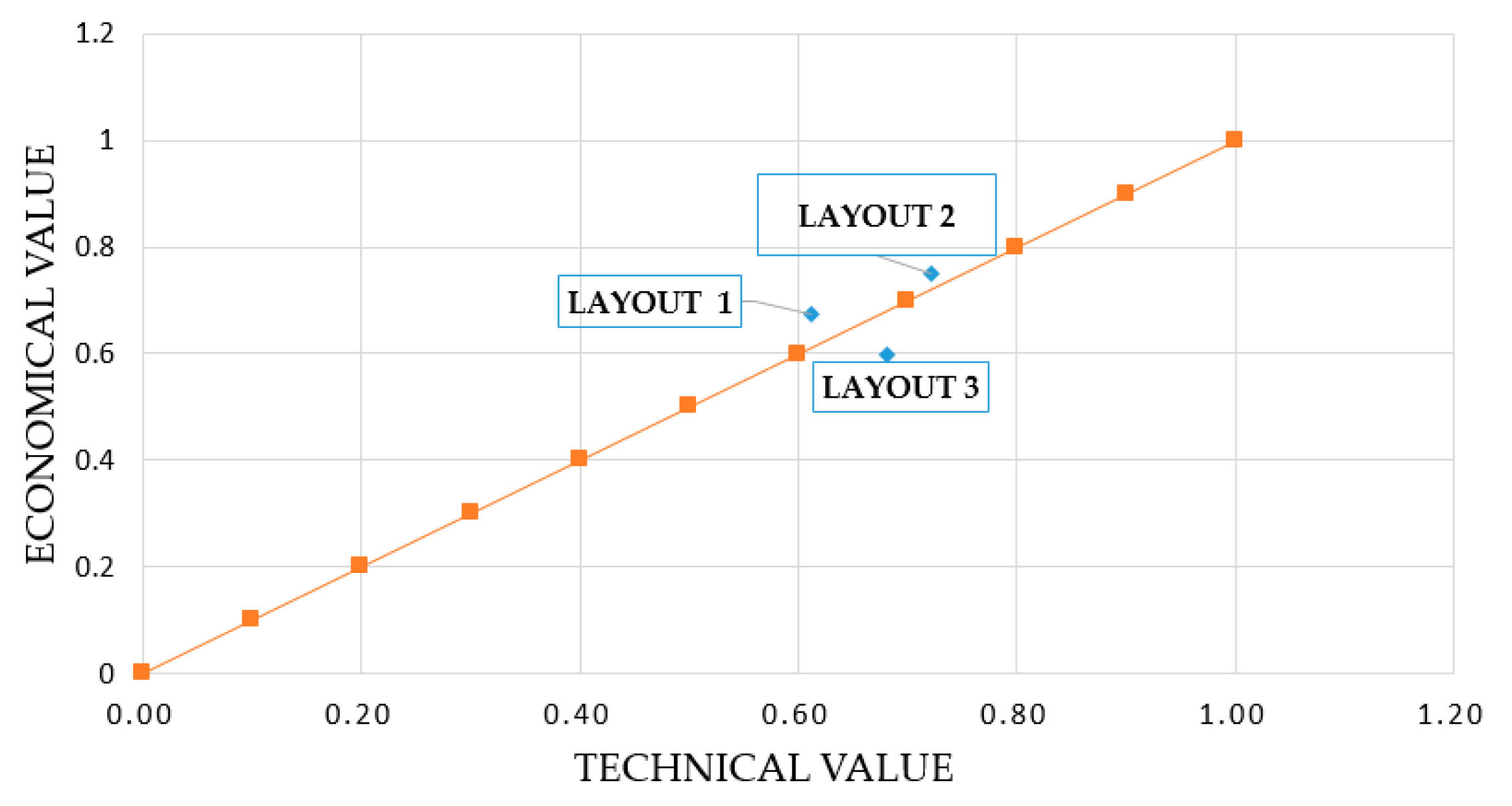

Table 2 and

Table 3,

g is the weighing factor,

p is the mark assigned from 0–4 depending on the performance achieved for each criterion, and

gp is their product. The ideal solution represents the maximum grade possible assigned as 4 for each criterion, whereas the ratios between the sum of

gp from the ideal solution column and the sum of

gp from the other solutions correspond to the technical value

xi or economic value

yi. The best solution results from an equilibrium between both technical and economic criteria, which corresponds to the nearest solution to the 45° line (

Figure 8). Then, the layout was improved since the location of the components, materials, frame, and dimensions was defined. The assembly of the components and the final project were carried out using the program Autodesk Inventor (

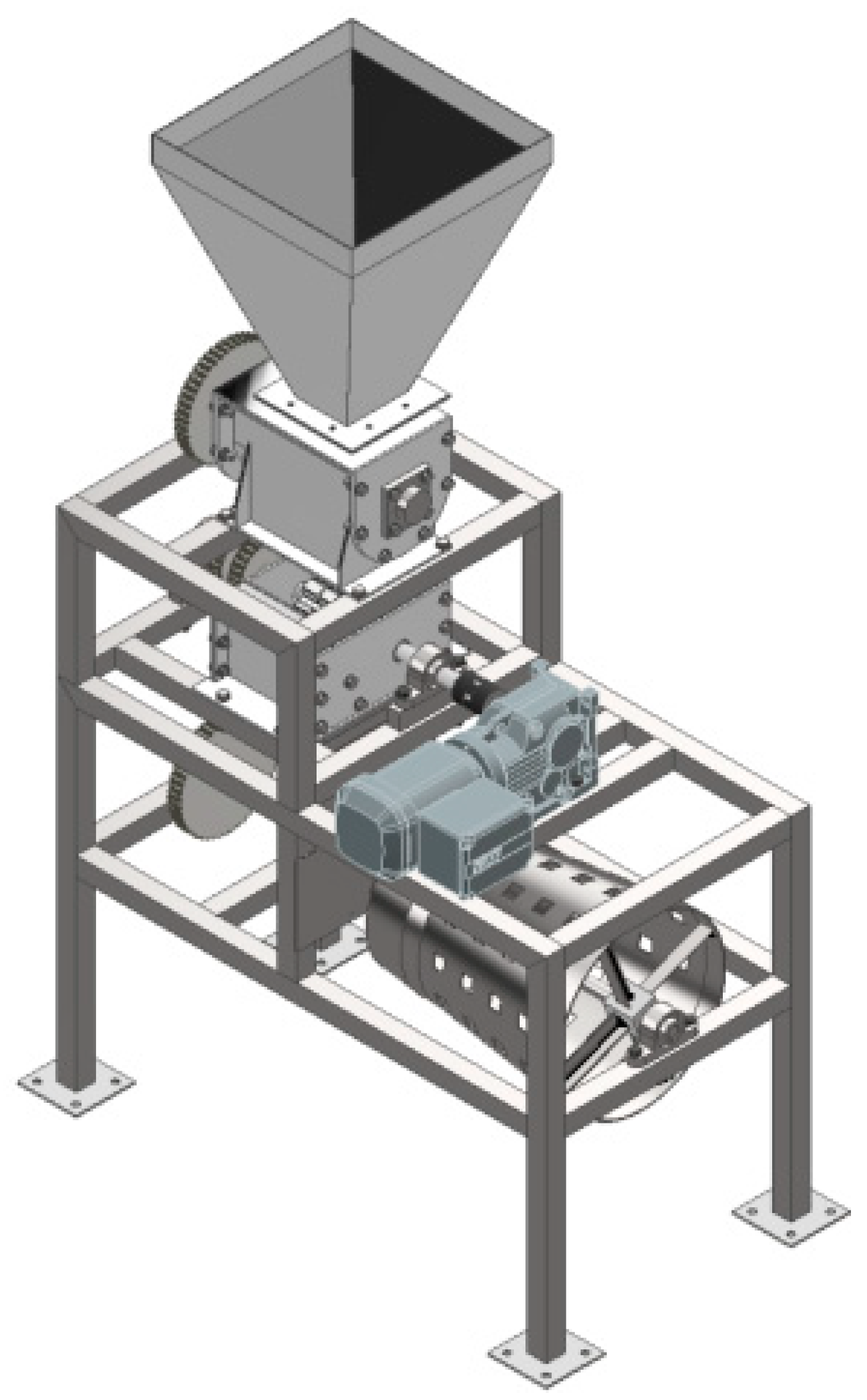

Figure 9).

The final phase was the design consisting of the development of engineering drawings and the 3D model with the use of computer-aided design (CAD) and computer-aided engineering (CAE) software, as discussed in detail in

Section 2.5 and

Section 2.6, respectively.

2.4. Dynamic Modeling of the Machine

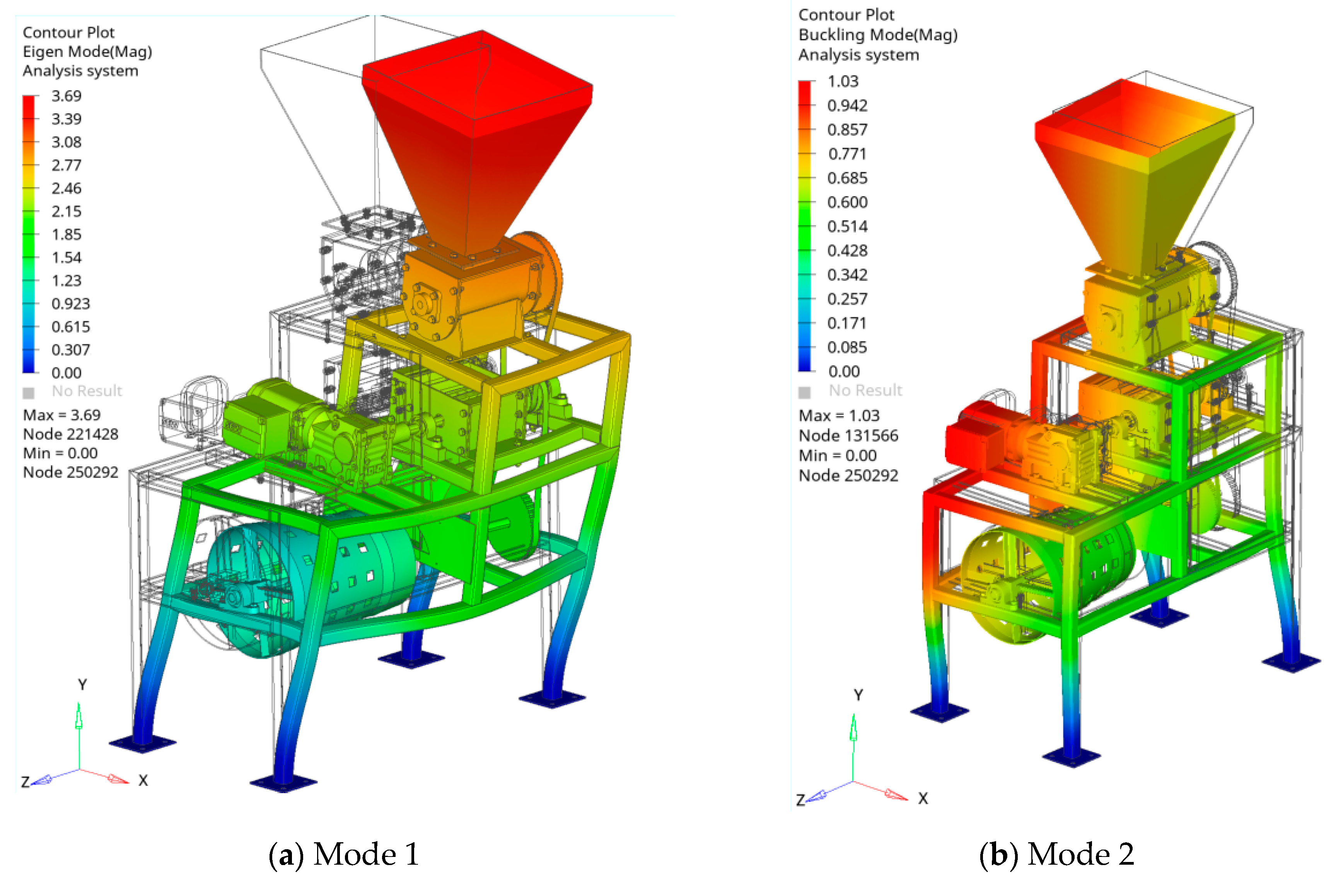

For each material’s mechanical properties, a system has its own dynamical characteristics depending on mass, stiffness, damping, and boundary conditions. These parameters together establish the natural frequencies of the system, in this case, the machine. If there is an excitation force near to one of these natural frequencies, high vibration amplitudes are produced and, when both coincide, a phenomenon known as resonance occurs [

15]. In this sense, it must be verified that each excitation frequency is sufficiently far from the natural frequency. In the same way, the forces related to each excitation frequency must not occur in the plane of their respective modal shape.

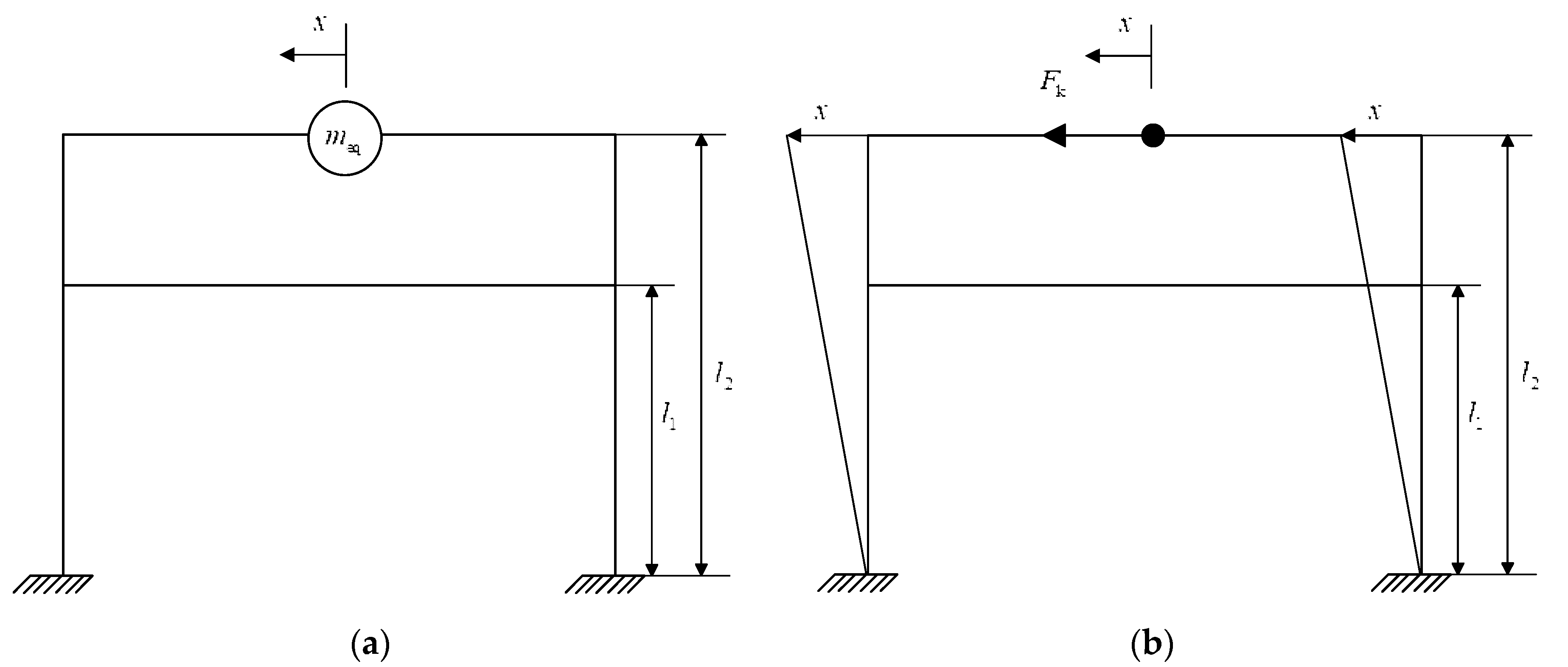

In order to calculate the natural frequency of the machine designed, an analytical model was proposed. In the first approach, a one degree of freedom (1DOF) model was developed (

Figure 11a). The equivalent mass

meq corresponded to the sum of mass above the second level of the structure because of the mass distribution along the machine. The frame for the machine was modeled as four columns united by eight beams, with four on each level. Damping was neglected in this model, and small displacements

were assumed on the second level on top of the structure.

In the operational conditions of the machine, dynamical forces are produced through the interaction between mass equivalent and frame. In order to analyze the dynamics corresponding to the horizontal direction, the stiffness in this direction needed to be calculated. The stiffness is the relationship between a force applied and the displacement produced in that direction. In this sense, a force

Fk produced a displacement

in the horizontal direction (

Figure 11b). The displacement was calculated using the beam deflection theory. The columns were analyzed as fixed beams, with the upper and lower beams producing a force because of their interaction with the columns; thus, the superposition principle was used, resulting in Equation (11), where

E is the Young modulus of the material in MPa,

I is the inertial moment from the section of the column used in m

4,

l1 is the length from the ground to the lower beam in m, and

l2 is the length from the ground to the upper beam in m.

Then, the stiffness

keq in N/m corresponding to the horizontal direction is the relationship between

Fk and

x (Equation (12)).

The differential equation representing the movement of the machine along the horizontal direction with no external forces had the form shown in Equation (13), where

meq is the equivalent mass in kg, and

keq is the equivalent stiffness corresponding to the displacement

x. The natural frequency of the machine

ω modeled with 1-DOF was estimated using Equation (14).

2.5. Computer-Aided Design (CAD) of the Machine

According to the basic specifications and calculations developed and exposed in previous points, a detailed three-dimensional computer-aided model of the complete machine and the support was modeled. Autodesk Inventor software was considered to create a digital prototype of a general 3D mechanical solid modeling application, commonly used in the design of machinery for different sectors, such as the construction, automotive, or agriculture sectors. All components of the machine (structural profiles, mechanical devices, and standard and commercial components) were assembled and positioned in a unique model, where the geometric and manufacturing information was obtained, such as part and assembly drawings, bill of materials, or models to generate toolpaths in manufacturing applications (CAM software). The software also allowed the export of geometry in standard formats recognized by CAE software.

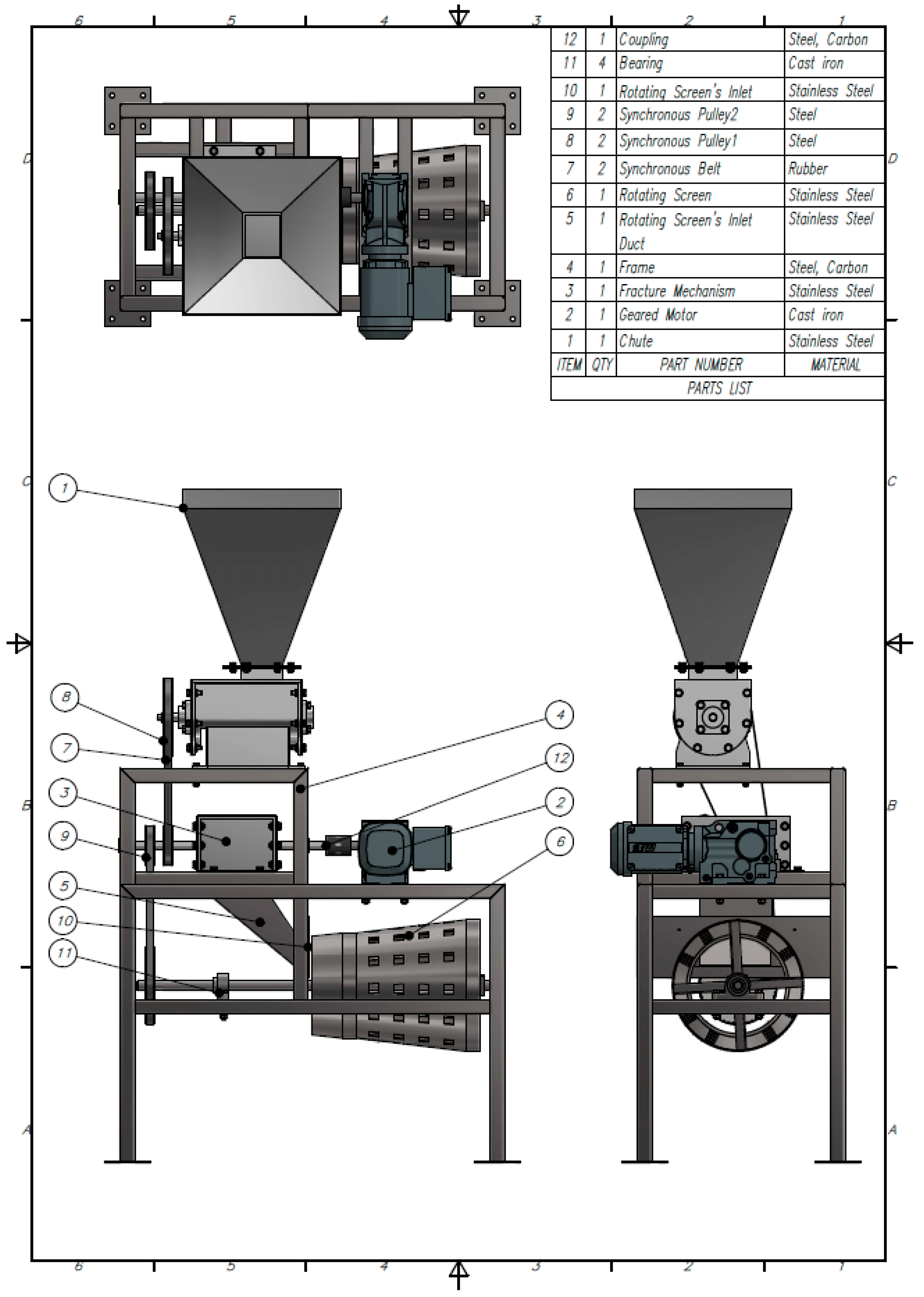

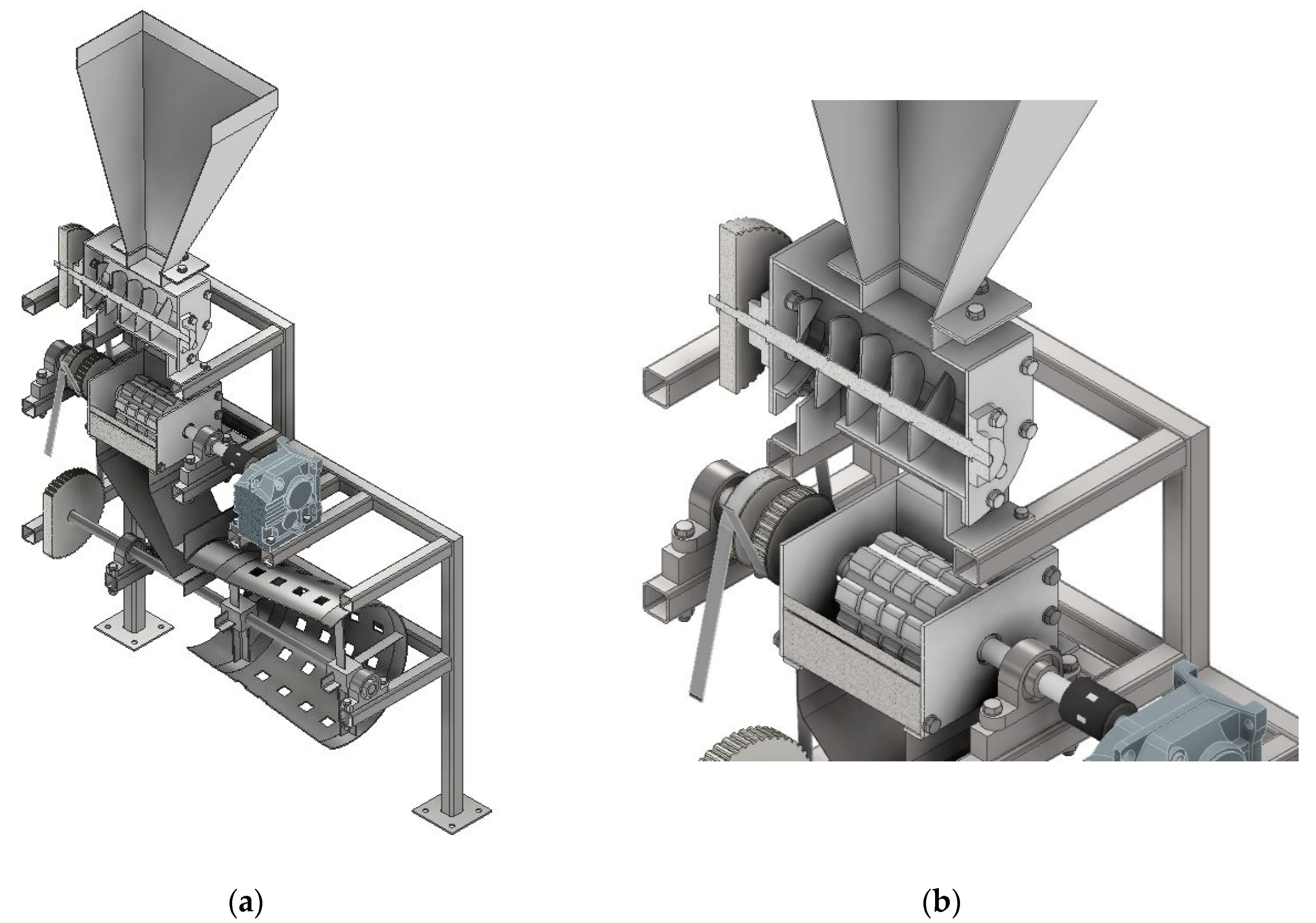

Figure 12 shows the assembly plan of the shell cracking machine and its four main components.

Figure 13 shows main views of the machine. Each was developed by following the structure of functions in the conceptual design phase. As can be seen, a modular design was favorable in order to facilitate fabrication, maintenance, and assembly.

Figure 14 shows a section of the machine describing the Metohuayo fruit processing. The operation started with Metohuayo fruits being fed through a chute fed. The screw conveyor controlled the quantity and velocity of processing according to the capacity 50 kg/h. Fruits were then sent to the fracture mechanism composed of a toothed cylinder and a toother wall with variable clearance provided by the wall tilt. This allowed processing different dimensions of Metohuayo fruits according to the sample analyzed.

When the fruits were cracked, they were divided into shell and seed, which needed to be separated in order to get only the seeds. Under the fracture mechanism, there was a duct leading the cracked fruits to the rotating screen. This rotating screen had a truncated cone shape to generate a tilt for the shells to drop to the end.

2.6. Computer-Aided Engineering (CAE) of the Machine

Conventionally, the engineering product development process employed a design–build–test philosophy, where the “optimum” solution was reached via a trial-and-error sequence, and where the experience of the designer related to the product was decisive. Simulation-based design methods, as defined in [

16], considerably reduced this design process, in terms of time and cost, and the concept of concurrent engineering, for example, is today considered in product design. In these techniques, the task of carrying out experimental tests is displaced by the simulation through numerical techniques of the different physics involved in the problem which is the object of study by the designer.

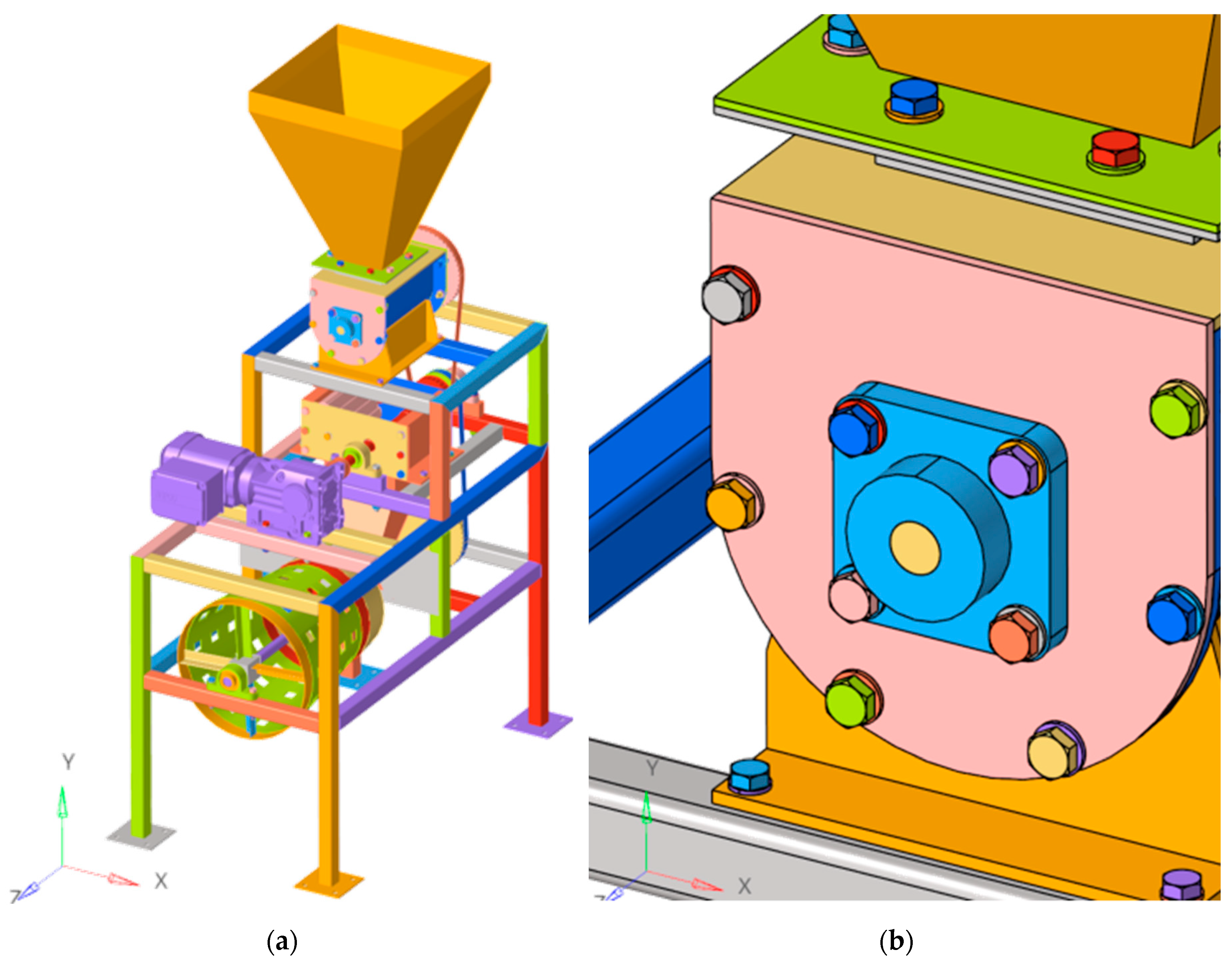

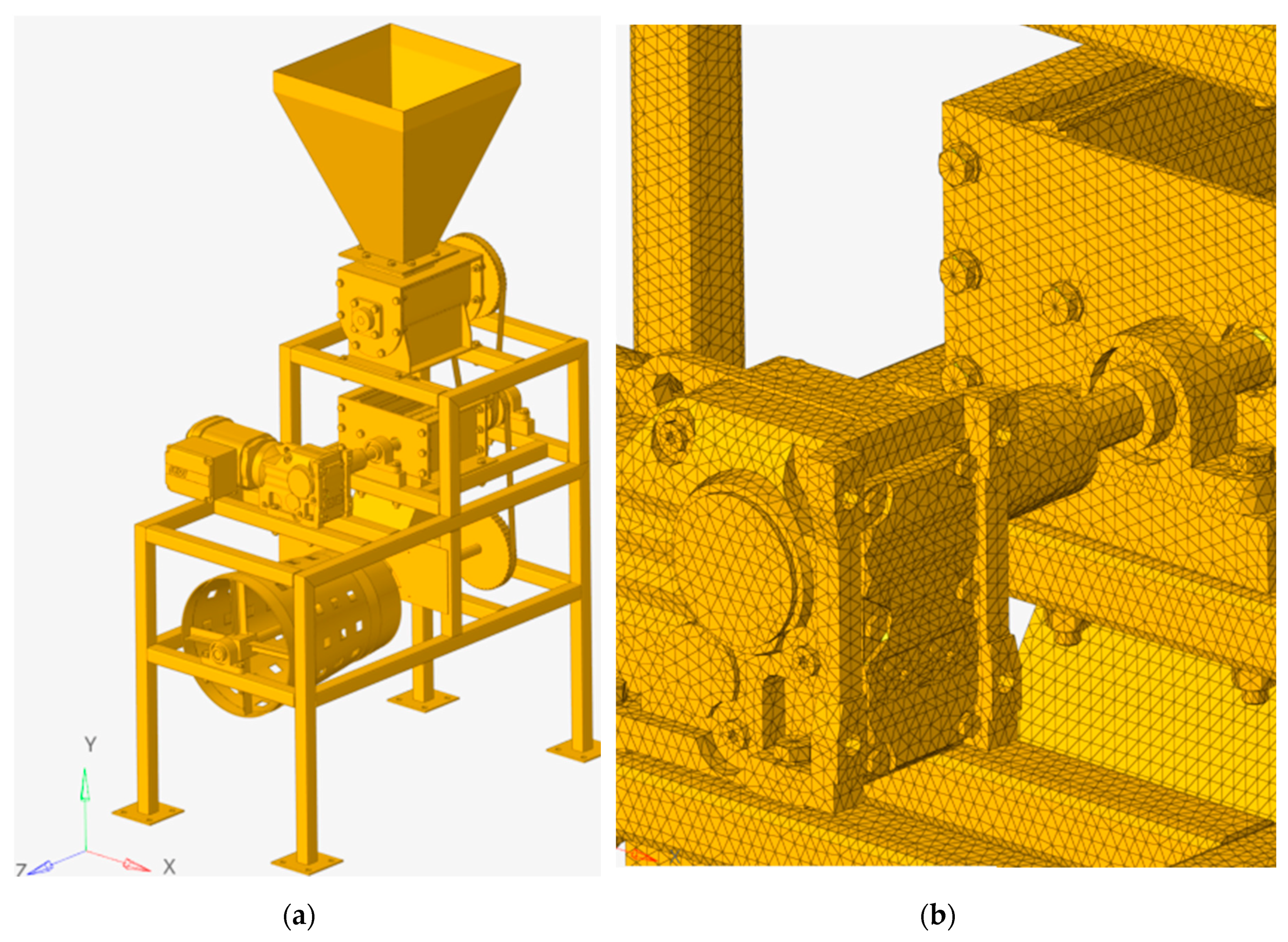

For the CAE simulation, the Altair Hyperworks simulation platform was considered, in which the preprocessing and postprocessing stages were addressed. The CAD three-dimensional model was taken as a starting point (

Figure 15a), whose components were pre-dimensioned and selected according to basic calculations. In this model, some simplifications were implemented in the bearing supports (

Figure 15b), since these subsets included all the elements that made them up (balls, cages, raceways, seals, etc.), which complicated their analysis. The difference in results at the level of the overall behavior of the structure was imperceptible.

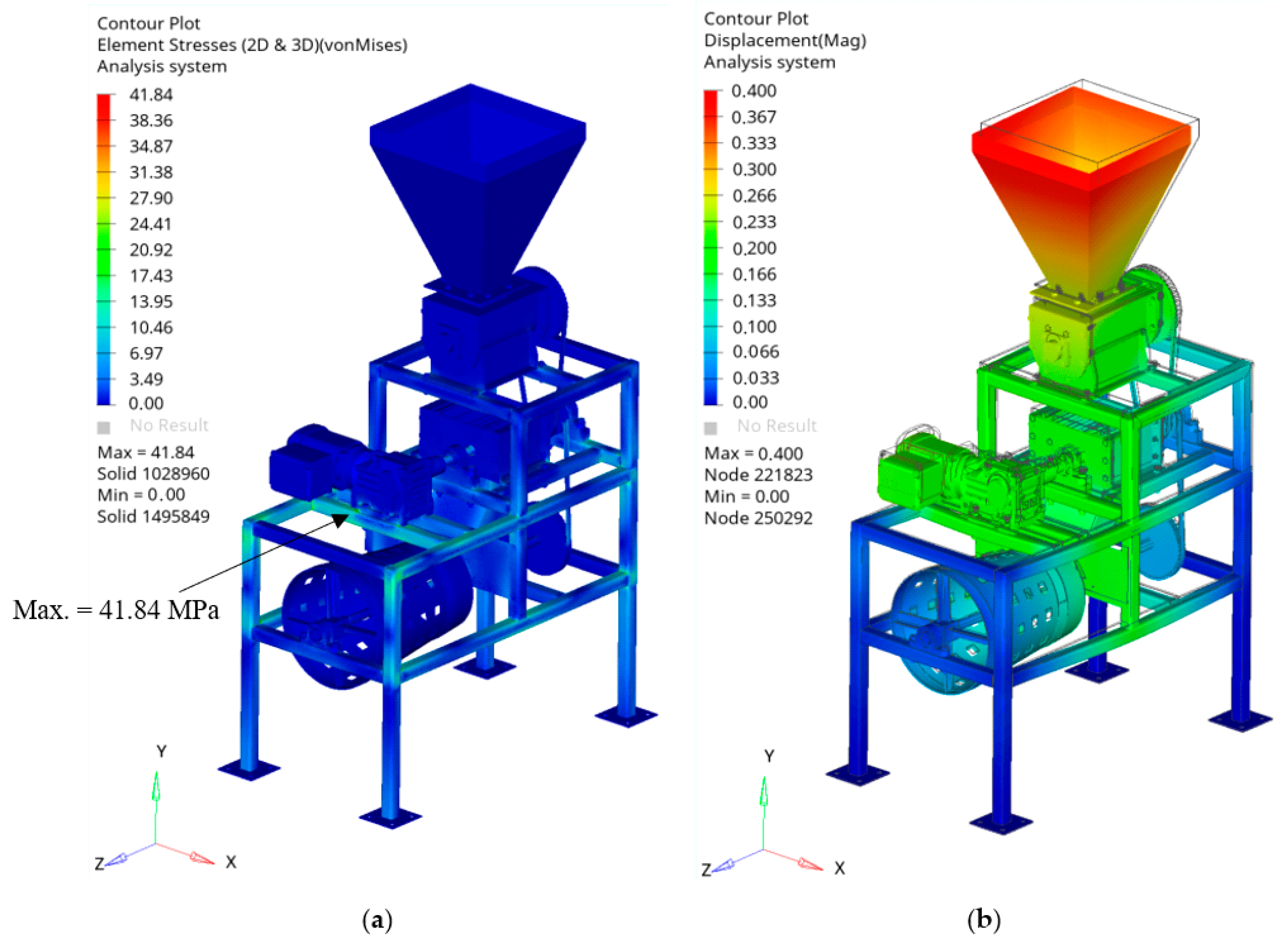

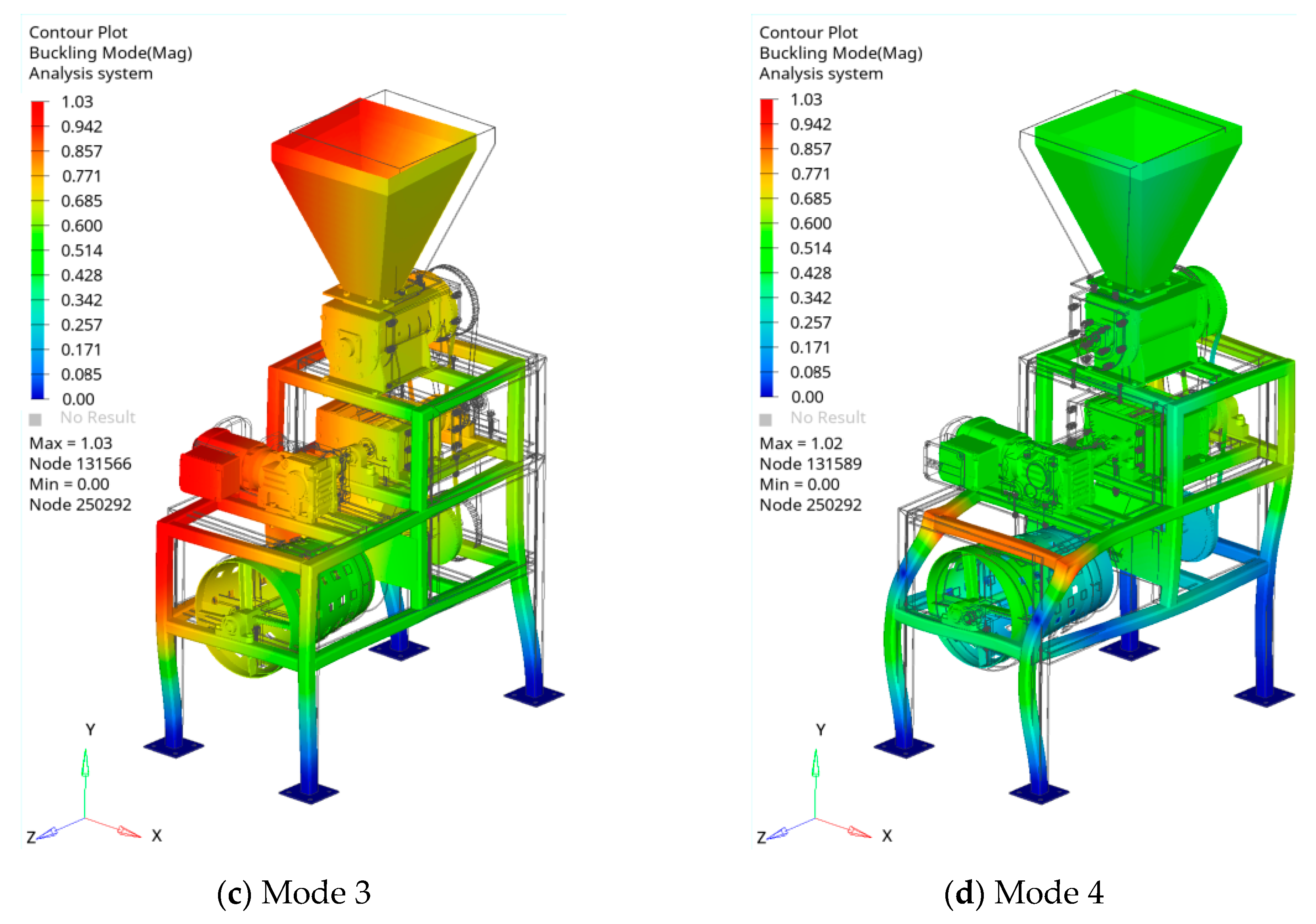

The subdivision of the geometry into discrete approximations, known as meshing, was automatically done by the software. In calculations that consider only stiffness, as is the case of the analysis of buckling modes and vibration modes, the influence of the mesh on the results is very small; thus, two different sizes were considered and the values obtained were equal or very similar, guaranteeing the mesh independence of the calculations. However, in stress analysis, a coarse mesh can yield inaccurate results; thus, it was necessary to carry out a mesh convergence study in order to achieve reliable results. The convergence method considered in static analysis was the adaptative method, through the iterative reduction of the mesh in the stress concentration zone until the difference between two consecutive iterations was affordable. The definitive mesh of the model (

Figure 16a,b) was made up of 281,128 nodes and 864,095 elements. Solid second-order tetrahedrons were considered in the meshing calculation. Finally, the interaction between elements making up different parts of the machine was carried out through the kinematic conditions of the three relative degrees of freedom between the surfaces in contact (similar conditions to a welded connection); this assumption was valid because the loads were relatively small and the focus was on the parts to be connected. Additional conditions such as bolt prestress were not considered, further reinforcing this hypothesis.

In the part in contact with the fruit, A304 stainless-steel components were considered, in order to comply with the national hygiene and health regulations. For the other components, A500 steel (yielding strength = 250 MPa) for hollow structural sections was considered, and A36 steel profiles were considered for the sheet metal elements (yielding strength = 250 MPa), both easily found on the national market. The Young modulus of the materials considered was 200 GPa. The material properties used for modeling are listed in

Table 4. Loads and boundary conditions correspond to the machine working,

Figure 17a shows the boundary condition applied to each support and

Figure 17b shows the loads applied to the structure by each component support.

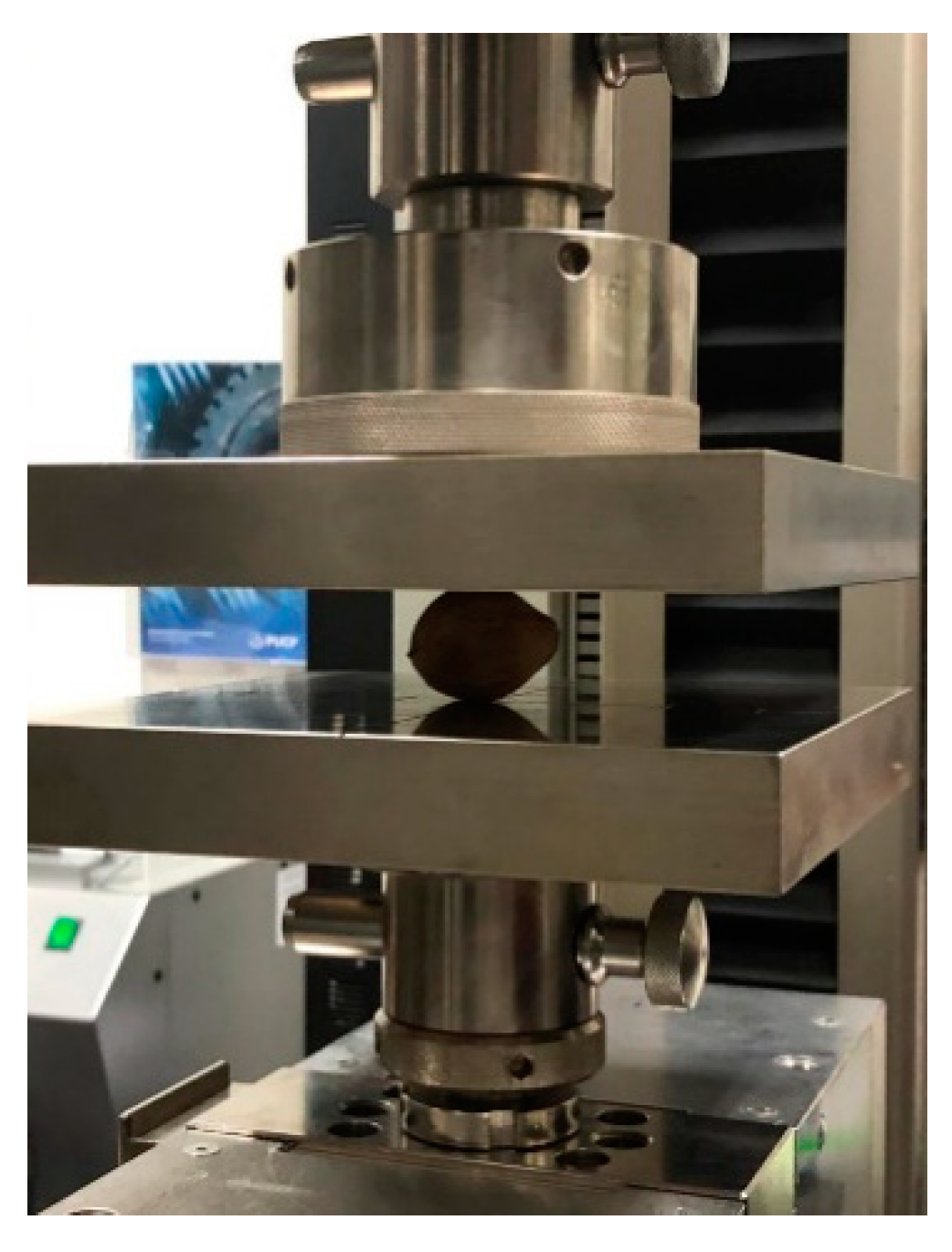

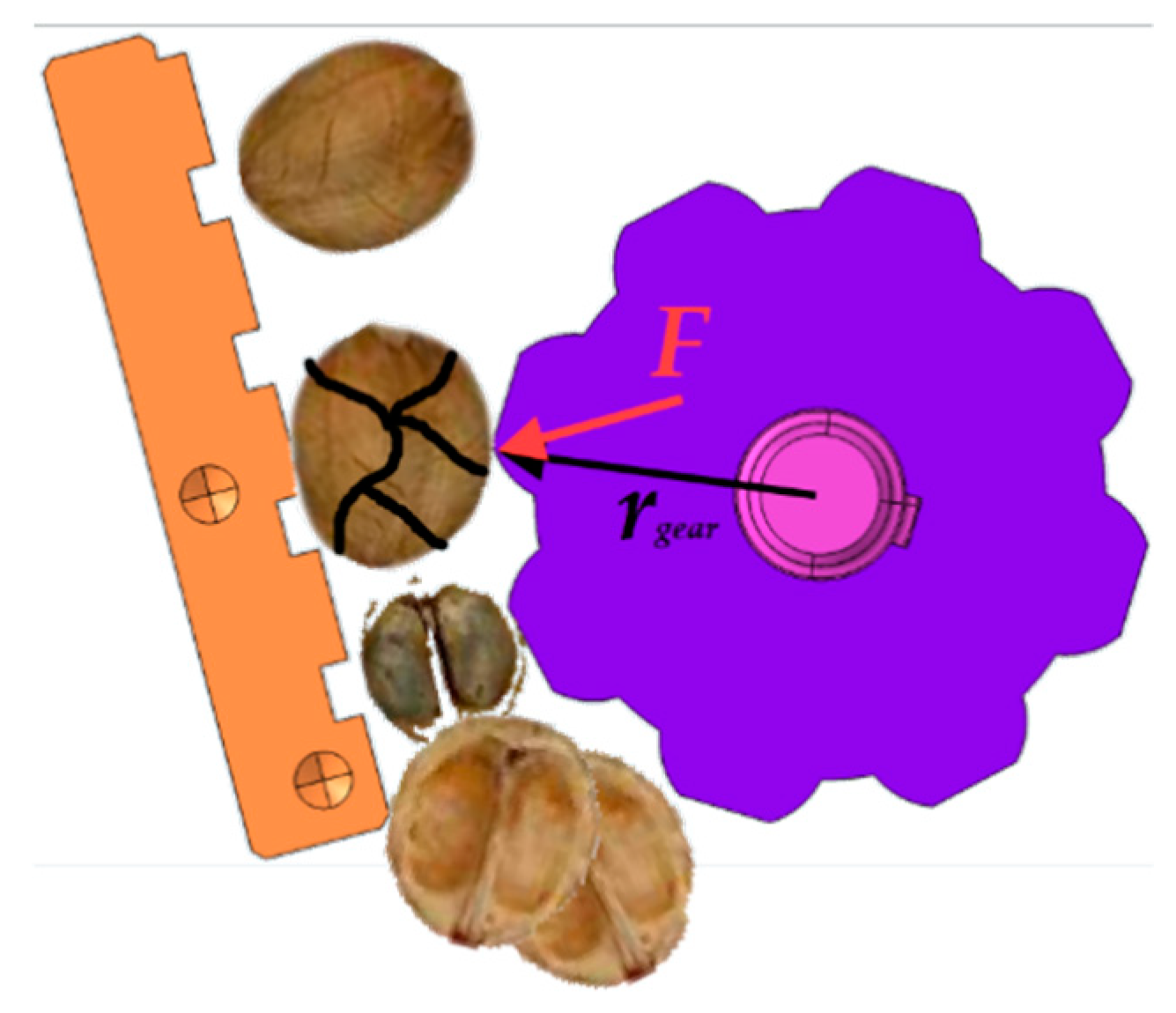

In addition to the analytic calculations of the machine structure, a static analysis corresponding to the worst condition of the components and structure of the machine was simulated. This condition was the blocking produced if the mechanism fracture could not crack the fruit or the stone inside.

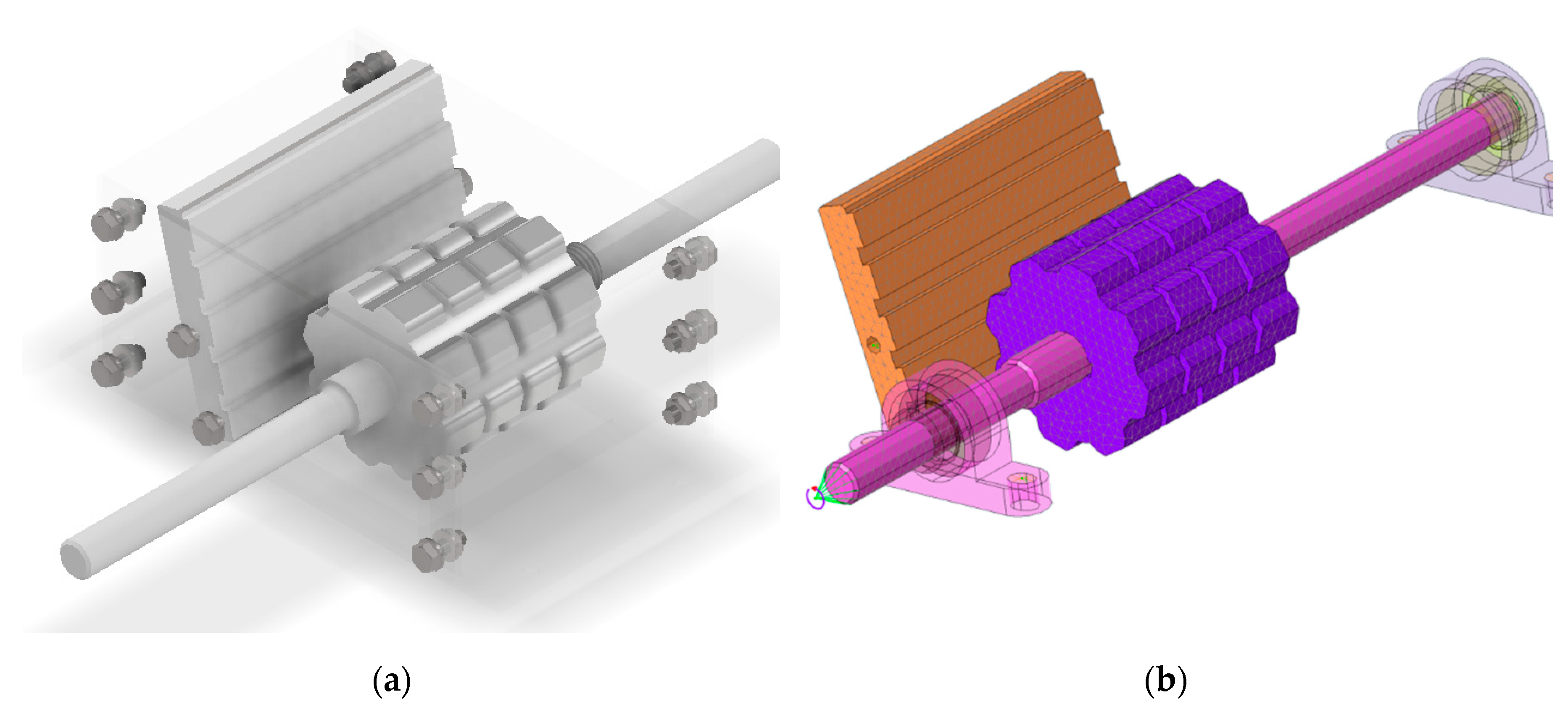

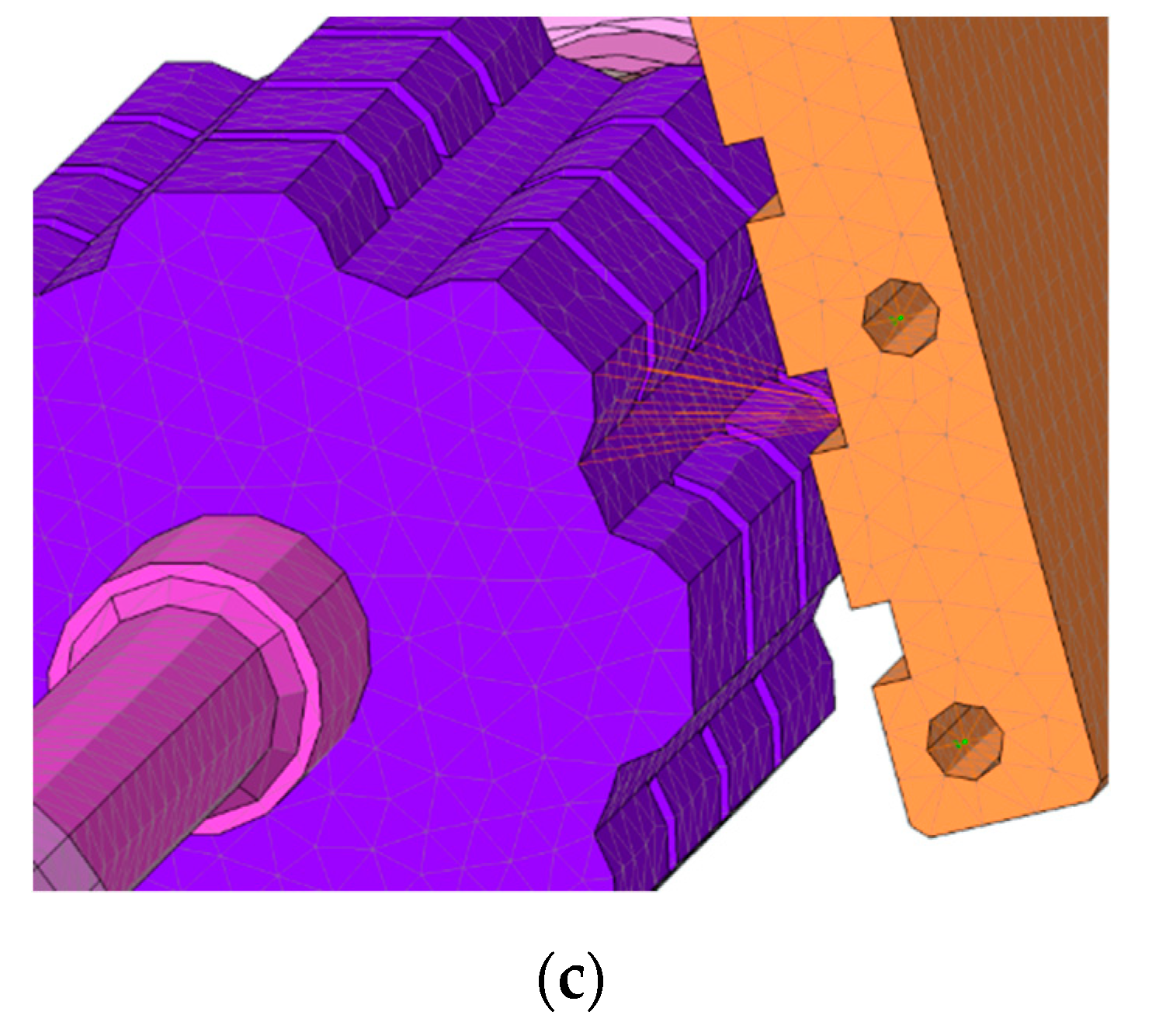

Figure 18a shows the fracture mechanism of the Metohuayo fruits analyzed,

Figure 18b shows the mesh used, and

Figure 18c is a detailed form of the mesh.

It was considered that this blocking would produce the maximum torque in the transmission, with a value of 2.4 corresponding to the nominal torque according to the electrical motor datasheet (144.8 Nm). Boundary conditions of the lateral supports corresponded to a sliding contact. All bolt connections were modeled as MPC (multipoint constraint) elements, which allowed connecting the nodes for which restrictions could be defined; hence, the behavior of these nodes was compatible with the boundary conditions established. Similarly, for the forced applied, a torque transmission proportional to the position of nodes in the outer surface was considered. The transmission from the toothed wheel to the Metohuayo cracking work plane was generated with RBE (rigid body elements).