Osteo-Compatibility of 3D Titanium Porous Coating Applied by Direct Energy Deposition (DED) for a Cementless Total Knee Arthroplasty Implant: In Vitro and In Vivo Study

Abstract

:1. Introduction

2. Materials and Methods

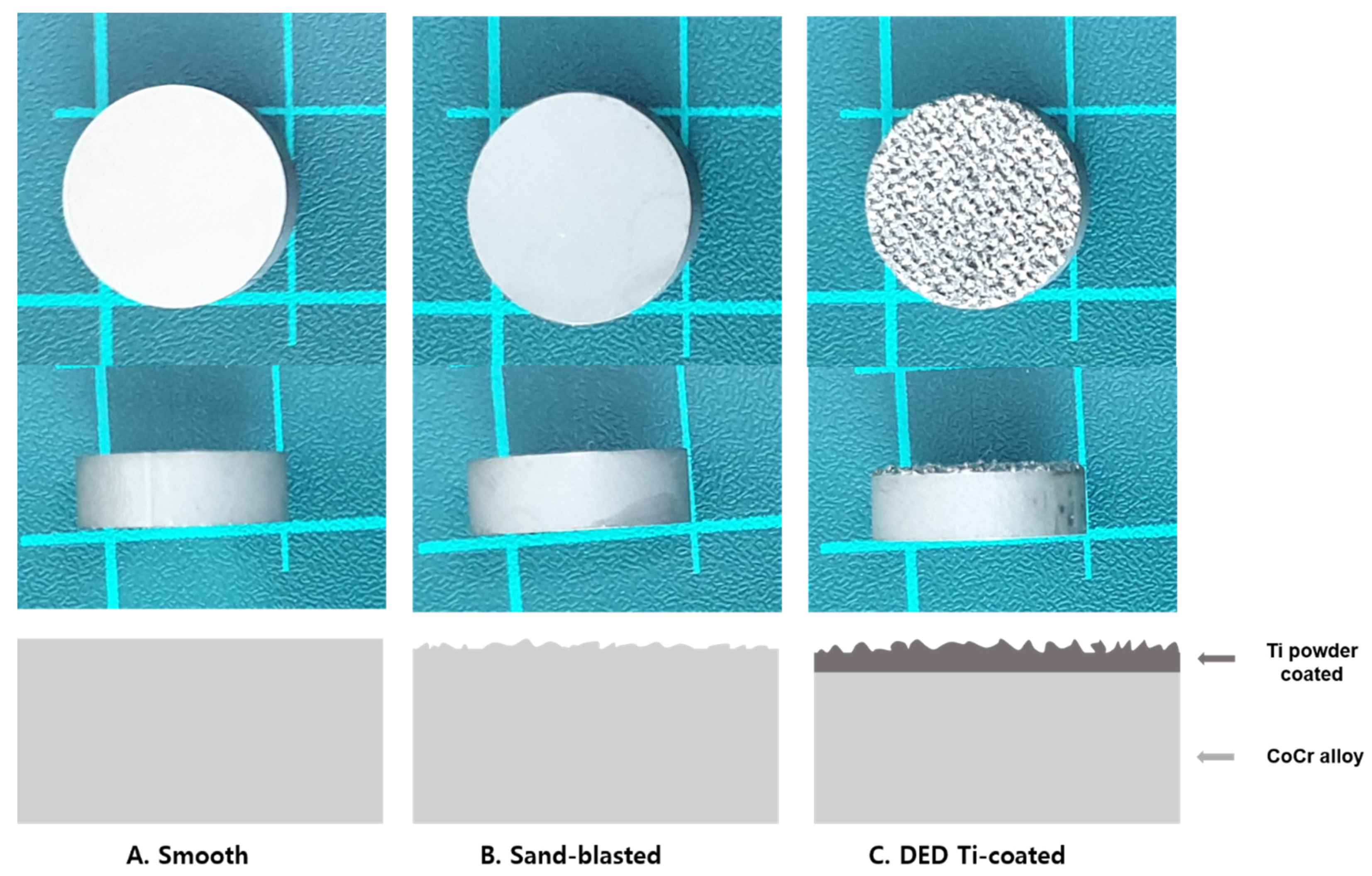

2.1. Preparation of Specimens

2.2. Sample Preparation and Test Groups

2.3. In Vitro Preparation

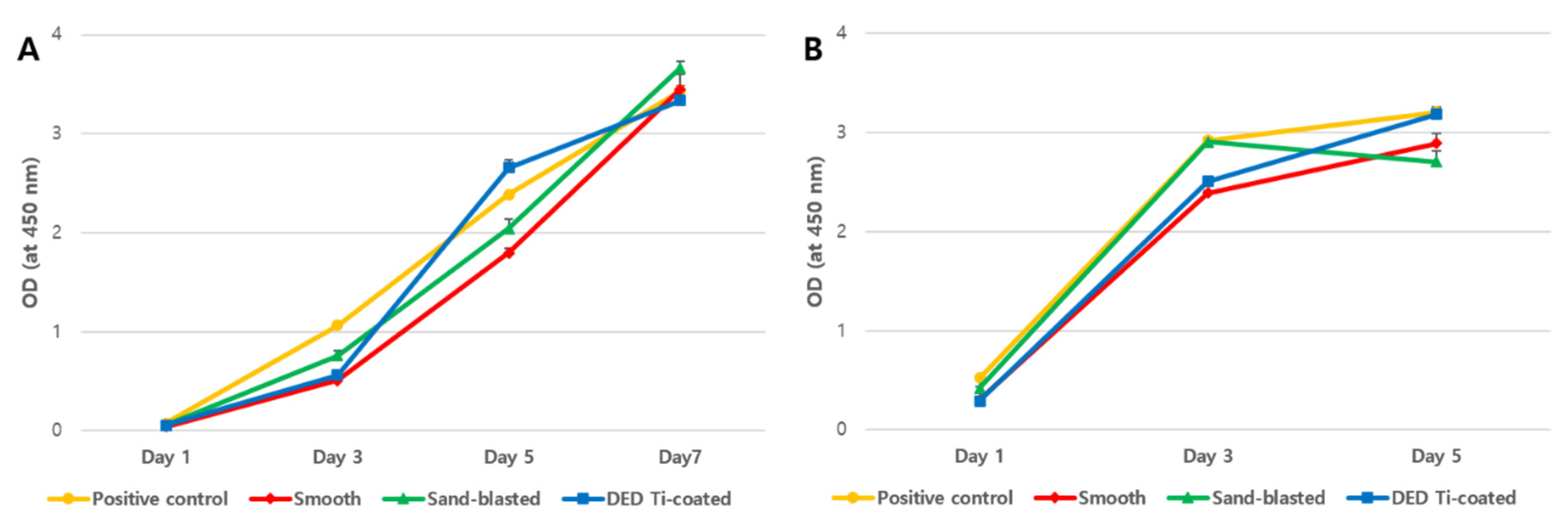

2.3.1. CCK-8 Viability Analysis of Cultured Osteoblast

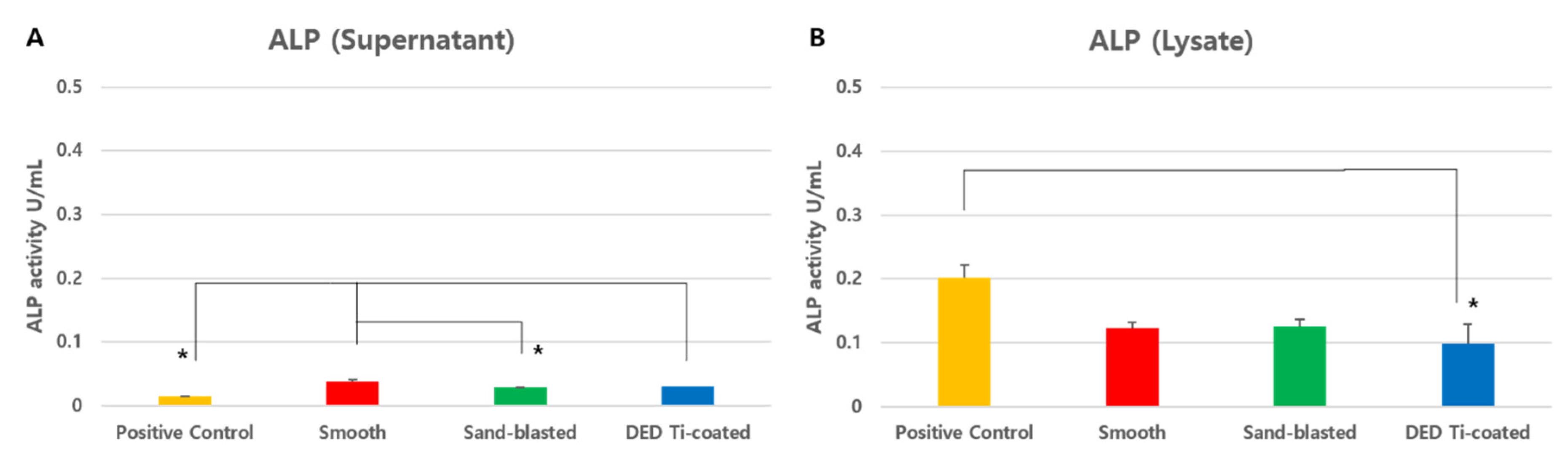

2.3.2. Alkaline Phosphatase (ALP) Activity Assay

2.3.3. BrdU Cell Proliferation Assay

2.3.4. Inflammatory Multiplex Cytokine Assay

2.4. In Vivo Preparation

2.4.1. Surgical Procedure

2.4.2. Postoperative Care and Sacrifice

2.4.3. X-ray

2.4.4. Histologic Slide Manufacturing and Staining

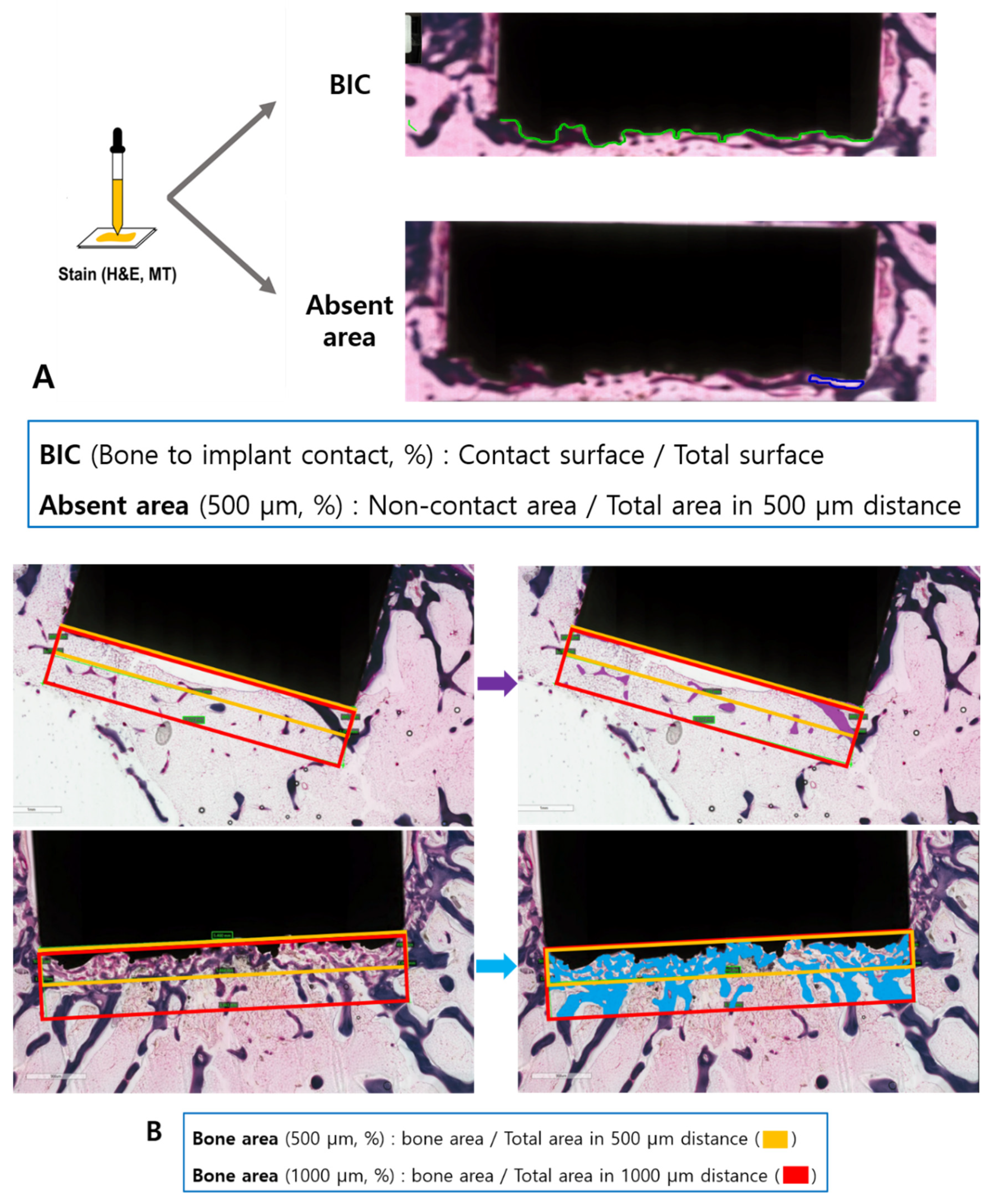

2.4.5. Bone Histomorphometry

2.5. Statistical Analysis

3. Result

3.1. In Vitro CCK-8 Assay

3.2. In Vitro ALP Assay

3.3. In Vitro BrdU Cell Proliferation Assay

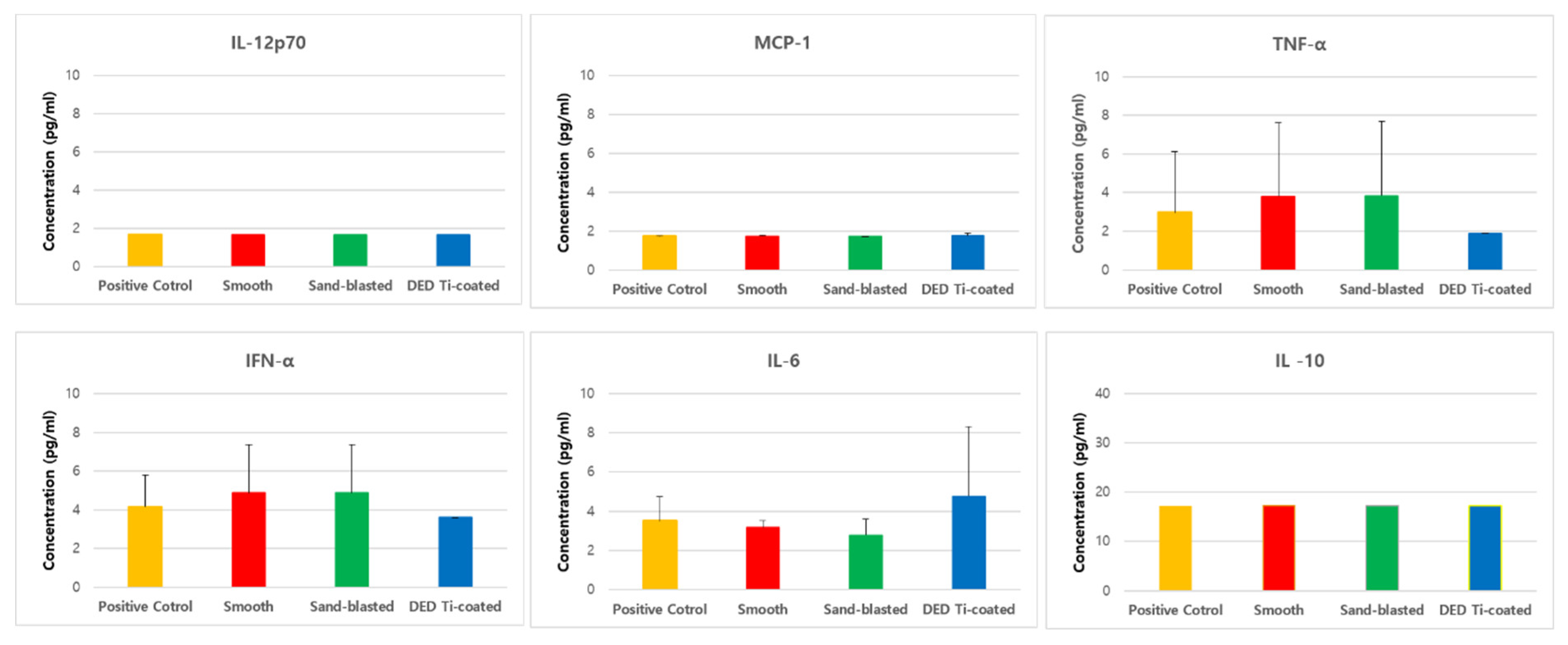

3.4. In Vitro Inflammatory Cytokine Assay

3.5. In Vivo X-ray

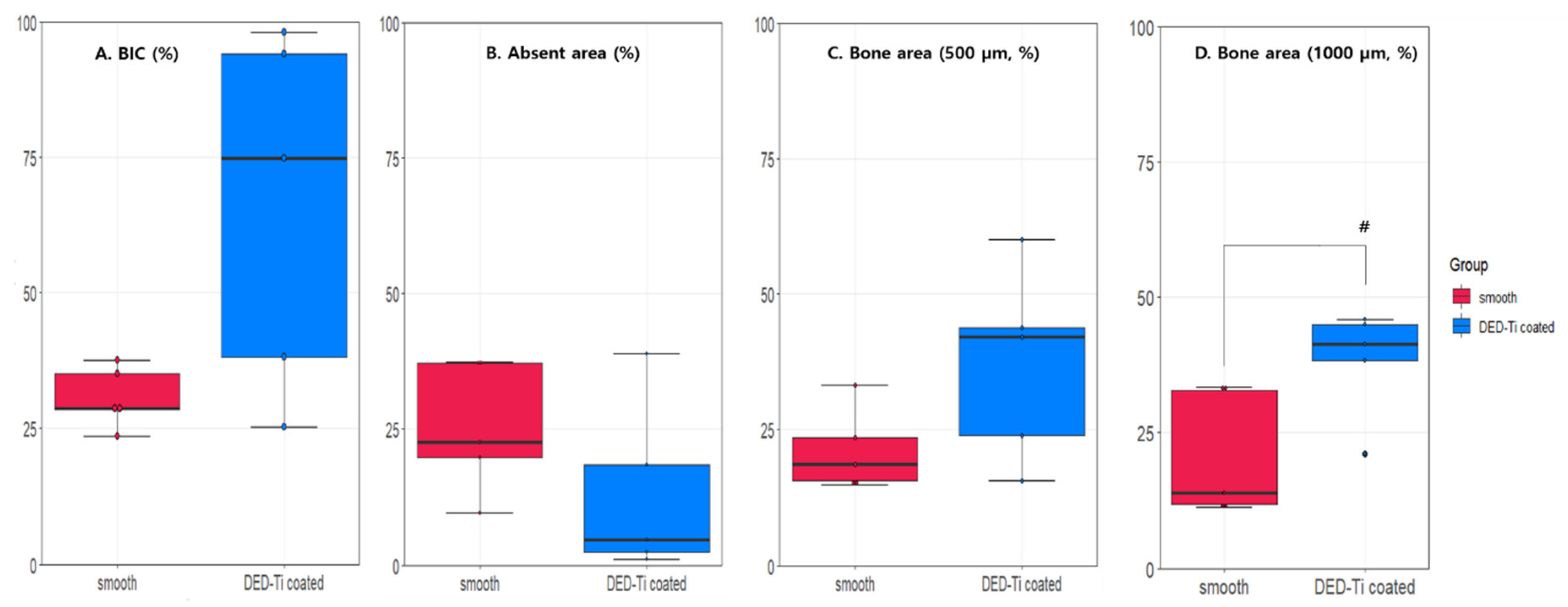

3.6. In Vivo Bone Histomorphometry

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Napier, R.J.; O’Neill, C.; O’Brien, S.; Doran, E.; Mockford, B.; Boldt, J.; Beverland, D.E. A prospective evaluation of a largely cementless total knee arthroplasty cohort without patellar resurfacing: 10-year outcomes and survivorship. BMC Musculoskelet. Disord. 2018, 19, 205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Harwin, S.F.; Patel, N.K.; Chughtai, M.; Khlopas, A.; Ramkumar, P.N.; Roche, M.; Mont, M.A. Outcomes of Newer Generation Cementless Total Knee Arthroplasty: Beaded Periapatite-Coated vs. Highly Porous Titanium-Coated Implants. J. Arthroplast. 2017, 32, 2156–2160. [Google Scholar] [CrossRef] [PubMed]

- Divya Rani, V.V.; Vinoth-Kumar, L.; Anitha, V.C.; Manzoor, K.; Deepthy, M.; Shantikumar, V.N. Osteointegration of titanium implant is sensitive to specific nanostructure morphology. Acta Biomater. 2012, 8, 1976–1989. [Google Scholar] [CrossRef] [PubMed]

- Robertsson, O.; Bizjajeva, S.; Fenstad, A.M.; Furnes, O.; Lidgren, L.; Mehnert, F.; Odgaard, A.; Pedersen, A.B.; Havelin, L.I. Knee arthroplasty in Denmark, Norway and Sweden. A pilot study from the Nordic Arthroplasty Register Association. Acta Orthop. 2010, 81, 82–89. [Google Scholar] [CrossRef] [PubMed]

- Drexler, M.; Dwyer, T.; Marmor, M.; Abolghasemian, M.; Sternheim, A.; Cameron, H.U. Cementless fixation in total knee arthroplasty: Down the boulevard of broken dreams–opposes. J. Bone Joint Surg. Br. 2012, 94, 85–89. [Google Scholar] [CrossRef]

- Dalby, M.J.; Gadegaard, N.; Tare, R.; Andar, A.; Riehle, M.O.; Herzyk, P.; Wilkinson, C.D.W.; Oreffo, R.O.C. The control of human mesenchymal cell differentiation using nanoscale symmetry and disorder. Nat. Mater. 2007, 6, 997–1003. [Google Scholar] [CrossRef] [PubMed]

- Catauro, M.; Bollino, F.; Papale, F. Biocompatibility improvement of titanium implants by coating with hybrid materials synthesized by sol-gel technique: Biocompatibility Improvement of Titanium Implants. J. Biomed. Mater. Res. A 2014, 102, 4473–4479. [Google Scholar] [CrossRef]

- Sidambe, A.T. Biocompatibility of Advanced Manufactured Titanium Implants—A Review. Materials 2014, 7, 8168–8188. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shah, F.A.; Omar, O.; Suska, F.; Snis, A.; Matic, A.; Emanuelsson, L.; Norlindh, B.; Lausmaa, J.; Thomsen, P.; Palmquist, A. Long-term osseointegration of 3D printed CoCr constructs with an interconnected open-pore architecture prepared by electron beam melting. Acta Biomater. 2016, 36, 296–309. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shin, T.; Kim, Y.-S.; Kim, J.; Lee, K.-Y.; Lee, S.-J.; Sun, D.; Lim, Y.-W.; Lim, D. Applicability evaluation of direct metal tooling-based additive manufacturing for reducing ceramic liner fracture in total hip arthroplasty. Surf. Coat. Tech. 2018, 347, 313–319. [Google Scholar] [CrossRef]

- Popov Jr, V.V.; Muller-Kamskii, G.; Kovalevsky, A.; Dzhenzhera, G.; Strokin, E.; Kolomiets, A.; Ramon, J. Design and 3D-printing of Titanium Bone Implants: Brief Review of Approach and Clinical Cases. Biomed. Eng. Lett. 2018, 8, 337–344. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.C.; Jo, W.L.; Kim, Y.S.; Kwon, S.Y.; Cho, Y.S.; Lim, Y.W. Titanium Powder Coating Using Metal 3D Printing: A Novel Coating Technology for Cobalt–Chromium Alloy Implants. Tissue Eng. Regen. Med. 2019, 16, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Bischoff, U.W.; Freeman, M.A.; Smith, D.; Tuke, M.A.; Gregson, P.J. Wear induced by motion between bone and titanium or cobalt-chrome alloys. J. Bone Joint Surg. Br. 1994, 76, 713–716. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sultan, A.A.; Mahmood, B.; Samuel, L.T.; Stearns, K.L.; Molloy, R.M.; Moskal, J.T.; Krebs, V.E.; Harwin, S.F.; Mont, M.A. Cementless 3D Printed Highly Porous Titanium-Coated Baseplate Total Knee Arthroplasty: Survivorship and Outcomes at 2-Year Minimum Follow-Up. J. Knee Surg. 2019. [Google Scholar] [CrossRef] [PubMed]

- Yoon, C.; Chang, M.J.; Chang, C.B.; Song, M.K.; Shin, J.H.; Kang, S.-B. Medial Tibial Periprosthetic Bone Resorption and Its Effect on Clinical Outcomes After Total Knee Arthroplasty: Cobalt-Chromium vs. Titanium Implants. J. Arthroplast. 2018, 33, 2835–2842. [Google Scholar] [CrossRef]

- Martin, J.R.; Watts, C.D.; Levy, D.L.; Kim, R.H. Medial Tibial Stress Shielding: A Limitation of Cobalt Chromium Tibial Baseplates. J. Arthroplast. 2017, 32, 558–562. [Google Scholar] [CrossRef]

- Xu, H.; Guo, C.-C.; Gao, Z.-Y.; Wang, C.-Y.; Zhang, H.-N.; Lv, C.-Y.; Yin, Z.-Y.; Wang, Y.-Z. Micrometer-Sized Titanium Particles Induce Aseptic Loosening in Rabbit Knee. Biomed. Res. Int. 2018, 2018, 5410875. [Google Scholar] [CrossRef] [Green Version]

- Bressan, E.; Ferroni, L.; Gardin, C.; Bellin, G.; Sbricoli, L.; Sivolella, S.; Brunello, G.; Schwartz-Arad, D.; Mijiritsky, E.; Penarrocha, M.; et al. Metal Nanoparticles Released from Dental Implant Surfaces: Potential Contribution to Chronic Inflammation and Peri-Implant Bone Loss. Materials (Basel) 2019, 12, 2036. [Google Scholar] [CrossRef] [Green Version]

- Shin, T.; Park, S.-J.; Kang, K.S.; Kim, J.S.; Kim, Y.; Lim, Y.; Lim, D. A laser-aided direct metal tooling technology for artificial joint surface coating. Int. J. Precis. Eng. Manuf. 2017, 18, 233–238. [Google Scholar] [CrossRef]

- Ryu, D.J.; Sonn, C.-H.; Hong, D.H.; Kwon, K.B.; Park, S.J.; Ban, H.Y.; Kwak, T.Y.; Lim, D.; Wang, J.H. Titanium Porous Coating Using 3D Direct Energy Deposition (DED) Printing for Cementless TKA Implants: Does It Induce Chronic Inflammation? Materials (Basel) 2020, 13, 472. [Google Scholar] [CrossRef] [Green Version]

- Faul, F.; Erdfelder, E.; Buchner, A.; Lang, A.-G. Statistical power analyses using G*Power 3.1: Tests for correlation and regression analyses. Behav. Res. Methods 2009, 41, 1149–1160. [Google Scholar] [CrossRef] [Green Version]

- Rothaeusler, K.; Baumgarth, N. Assessment of cell proliferation by 5-bromodeoxyuridine (BrdU) labeling for multicolor flow cytometry. Curr. Protoc. Cytom. 2007, 40, 7.31.1–7.31.13. [Google Scholar] [CrossRef] [PubMed]

- Staszkiewica, J.; Gimble, J.; Cain, C.; Dietrich, M.; Burk, D.; Kirk-Ballard, H.; Gawronska-Kozak, B. Flow Cytometric and Immunohistochemical Detection of in Vivo BrdU-labeled Cells in Mouse Fat Depots. Biochem. Biophys. Res. Commun. 2008, 378, 539–544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lehmann, J.S.; Zhao, A.; Sun, B.; Jiang, W.; Ji, S. Multiplex Cytokine Profiling of Stimulated Mouse Splenocytes Using a Cytometric Bead-based Immunoassay Platform. J. Vis. Exp. 2017. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, G.; Yang, P.; Guo, X.; Huang, N.; Shen, R. An in Vitro Evaluation of Inflammation Response of Titanium Functionalized with Heparin/Fibronectin Complex. Cytokine 2011, 56, 208–217. [Google Scholar] [CrossRef]

- Yoo, H.-S.; Bae, J.-H.; Kim, S.-E.; Bae, E.-B.; Kim, S.-Y.; Choi, K.-H.; Moon, K.-O.; Jeong, C.-M.; Huh, J.-B. The Effect of Bisphasic Calcium Phosphate Block Bone Graft Materials with Polysaccharides on Bone Regeneration. Materials (Basel) 2017, 10, 17. [Google Scholar] [CrossRef] [Green Version]

- Park, J.-W.; An, C.-H.; Jeong, S.-H.; Suh, J.-Y. Osseointegration of commercial microstructured titanium implants incorporating magnesium: A histomorphometric study in rabbit cancellous bone: Osseointegration of Mg-incorporated Ti implant. Clin. Oral Implants Res. 2012, 23, 294–300. [Google Scholar] [CrossRef]

- Ong, J.L.; Carnes, D.L.; Bessho, K. Evaluation of Titanium Plasma-Sprayed and Plasma-Sprayed hydroxyapatite Implants in Vivo. Biomaterials 2004, 25, 4601–4606. [Google Scholar] [CrossRef]

- Gehrke, S.A.; Eliers Treichel, T.L.; Pérez-Díaz, L.; Calvo-Guirado, J.L.; AramburúJúnior, J.; Mazón, P.; de Aza, P.N. Impact of Different Titanium Implant Thread Designs on Bone Healing: A Biomechanical and Histometric Study with an Animal Model. J. Clin. Med. 2019, 8, 777. [Google Scholar] [CrossRef] [Green Version]

- Benjamini, Y.; Hochberg, Y. Controlling the False Discovery Rate: A Practical and Powerful Approach to Multiple Testing. J. R. Stat. Soc. B (Methodological) 1995, 57, 289–300. [Google Scholar] [CrossRef]

- Fu, D.-L.; Jiang, Q.-H.; He, F.-M.; Fu, B.-P. Adhesion of bone marrow mesenchymal stem cells on porous titanium surfaces with strontium-doped hydroxyapatite coating. J. Zhejiang Univ.-SCI. B 2017, 18, 778–788. [Google Scholar] [CrossRef] [Green Version]

- Khalili, A.; Ahmad, M. A Review of Cell Adhesion Studies for Biomedical and Biological Applications. Int. J. Mol. Sci. 2015, 16, 18149–18184. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pieuchot, L.; Marteau, J.; Guignandon, A.; Dos Santos, T.; Brigaud, I.; Chauvy, P.-F.; Cloatre, T.; Ponche, A.; Petithory, T.; Rougerie, P.; et al. Curvotaxis directs cell migration through cell-scale curvature landscapes. Nat. Commun. 2018, 9, 3995. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Werner, M.; Blanquer, S.B.G.; Haimi, S.P.; Korus, G.; Dunlop, J.W.C.; Duda, G.N.; Grijpma, D.W.; Petersen, A. Surface Curvature Differentially Regulates Stem Cell Migration and Differentiation via Altered Attachment Morphology and Nuclear Deformation. Adv. Sci. 2017, 4, 1600347. [Google Scholar] [CrossRef] [PubMed]

- Tavakoli, J.; Khosroshahi, M.E. Surface morphology characterization of laser-induced titanium implants: Lesson to enhance osseointegration process. Biomed. Eng. Lett. 2018, 8, 249–257. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Wang, C.; Yan, J.; Zhang, Q.; Dang, B.; Wang, Z.; Yao, Y.; Lin, K.; Guo, Z.; Bi, L.; et al. Evaluation of the osteogenesis and osseointegration of titanium alloys coated with graphene: An in vivo study. Sci. Rep. 2018, 8, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Lohmann, C.H.; Rampal, S.; Lohrengel, M.; Singh, G. Imaging in peri-prosthetic assessment: An orthopaedic perspective. EFORT Open Rev. 2017, 2, 117–125. [Google Scholar] [CrossRef]

- Kienapfel, H.; Sprey, C.; Wilke, A.; Griss, P. Implant fixation by bone ingrowth. J. Arthroplast. 1999, 14, 355–368. [Google Scholar] [CrossRef]

- Xue, W.; Krishna, B.V.; Bandyopadhyay, A.; Bose, S. Processing and biocompatibility evaluation of laser processed porous titanium. Acta Biomater. 2007, 3, 1007–1018. [Google Scholar] [CrossRef]

- Karageorgiou, V.; Kaplan, D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials 2005, 26, 5474–5491. [Google Scholar] [CrossRef]

- Dérand, P.; Rännar, L.-E.; Hirsch, J.-M. Imaging, virtual planning, design, and production of patient-specific implants and clinical validation in craniomaxillofacial surgery. Craniomaxillofac. Trauma Reconstr. 2012, 5, 137–144. [Google Scholar] [CrossRef] [Green Version]

- Kulkarni Aranya, A.; Pushalkar, S.; Zhao, M.; LeGeros, R.Z.; Zhang, Y.; Saxena, D. Antibacterial and bioactive coatings on titanium implant surfaces: ANTIBACTERIAL AND BIOACTIVE COATINGS ON TITANIUM IMPLANT SURFACES. J. Biomed. Mater. Res. A 2017, 105, 2218–2227. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Jarsha, M.; Moulisova, V.; Leal-Egana, A.; Connell, A.; Naudi, K.B.; Ayoub, A.; Dalby, M.J.; Salmerón-Sánchez, M. Engineered coatings for titanium implants to present ultra-low doses of BMP-7. ACS Biomater. Sci. Eng. 2018, 4, 1812–1819. [Google Scholar] [CrossRef] [PubMed]

- Popov, V.V.; Muller-Kamskii, G.; Katz-Demyanetz, A.; Kovalevsky, A.; Usov, S.; Trofimcow, D.; Dzhenzhera, G.; Koptyug, A. Additive Manufacturing to Veterinary Practice: Recovery of Bony Defects After the Osteosarcoma Resection in Canines. Biomed. Eng. Lett. 2019, 9, 97–108. [Google Scholar] [CrossRef]

- Shen, J.; Velasco, O.; Khadarian, K.; Asatrian, G.; Hwang, A.; Zhang, Y.; Kwak, J.; Chawan, C.; Khalilinejad, K.; Ajalat, M.; et al. A mouse femoral defect model demonstrates the clinically relevant side effects of BMP-2. Int. J. Orthop. 2015, 2, 468–475. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, D.J.; Ban, H.Y.; Jung, E.Y.; Sonn, C.-H.; Hong, D.H.; Ahmad, S.; Gweon, B.; Lim, D.; Wang, J.H. Osteo-Compatibility of 3D Titanium Porous Coating Applied by Direct Energy Deposition (DED) for a Cementless Total Knee Arthroplasty Implant: In Vitro and In Vivo Study. J. Clin. Med. 2020, 9, 478. https://doi.org/10.3390/jcm9020478

Ryu DJ, Ban HY, Jung EY, Sonn C-H, Hong DH, Ahmad S, Gweon B, Lim D, Wang JH. Osteo-Compatibility of 3D Titanium Porous Coating Applied by Direct Energy Deposition (DED) for a Cementless Total Knee Arthroplasty Implant: In Vitro and In Vivo Study. Journal of Clinical Medicine. 2020; 9(2):478. https://doi.org/10.3390/jcm9020478

Chicago/Turabian StyleRyu, Dong Jin, Hun Yeong Ban, Eui Yub Jung, Chung-Hee Sonn, Da Hee Hong, Shakra Ahmad, Bomi Gweon, Dohyung Lim, and Joon Ho Wang. 2020. "Osteo-Compatibility of 3D Titanium Porous Coating Applied by Direct Energy Deposition (DED) for a Cementless Total Knee Arthroplasty Implant: In Vitro and In Vivo Study" Journal of Clinical Medicine 9, no. 2: 478. https://doi.org/10.3390/jcm9020478

APA StyleRyu, D. J., Ban, H. Y., Jung, E. Y., Sonn, C.-H., Hong, D. H., Ahmad, S., Gweon, B., Lim, D., & Wang, J. H. (2020). Osteo-Compatibility of 3D Titanium Porous Coating Applied by Direct Energy Deposition (DED) for a Cementless Total Knee Arthroplasty Implant: In Vitro and In Vivo Study. Journal of Clinical Medicine, 9(2), 478. https://doi.org/10.3390/jcm9020478