Marginal and Internal Fit of Ceramic Restorations Fabricated Using Digital Scanning and Conventional Impressions: A Clinical Study

Abstract

1. Introduction

2. Materials and Methods

- Group 1: Conventional impression (polyvinyl siloxane (PVS) (Aquasil Ultra; Dentsply Sirona, Bensheim, Germany) (PVS group)

- Group 2: Intraoral scanner (EZIS PO; DDS, Seoul, South Korea) (EZIS PO group)

- Group 3: Intraoral scanner (i500; MEDIT, Seoul, South Korea) (i500 group)

- Group 4: Intraoral scanner (CS3600; Carestream Dental, Atlanta USA) (CS3600 group)

3. Results

4. Discussion

5. Conclusions

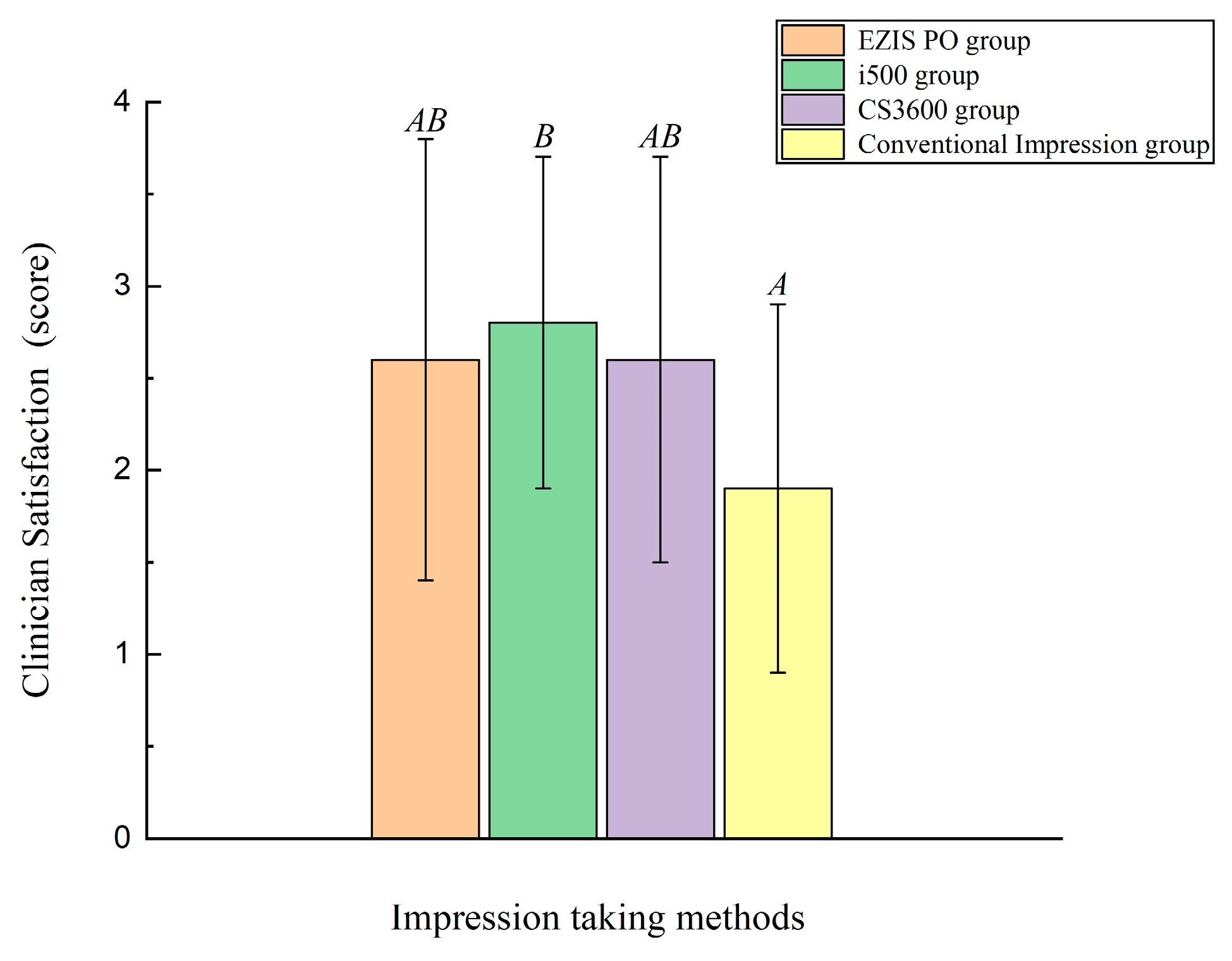

- There was an impact on the marginal and internal fit of the ceramic crowns based on the type of intraoral scanner that was used; however, there was no difference in the clinicians’ satisfaction with the prostheses.

- The ceramic crowns fabricated using an intraoral scanner showed superior marginal fit and internal fit as well as higher clinician satisfaction than those fabricated using the conventional method with PVS impression.

- The excellent marginal fit of the fabricated ceramic crowns can achieve high clinician satisfaction.

- Thus, clinicians should consider the use of the impression method for fabricating a ceramic crown with excellent goodness-of-fit and can realize high clinician satisfaction by reproducing excellent goodness-of-fit using the intraoral scanning method rather than the conventional method.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Falahchai, M.; Hemmati, Y.B.; Asli, H.N.; Emadi, I. Marginal gap of monolithic zirconia endocrowns fabricated by using digital scanning and conventional impressions. J. Prosthet. Dent. 2020. [Google Scholar] [CrossRef] [PubMed]

- Porrelli, D.; Berton, F.; Piloni, A.C.; Kobau, I.; Stacchi, C.; Di Lenarda, R.; Rizzo, R. Evaluating the stability of extended-pour alginate impression materials by using an optical scanning and digital method. J. Prosthet. Dent. 2020. [Google Scholar] [CrossRef] [PubMed]

- Sahin, V.; Jodati, H.; Evis, Z. Effect of storage time on mechanical properties of extended-pour irreversible hydrocolloid impression materials. J. Prosthet. Dent. 2020, 124, 69–74. [Google Scholar] [CrossRef] [PubMed]

- Bohner, L.O.L.; Canto, G.D.L.; Marció, B.S.; Laganá, D.C.; Sesma, N.; Neto, P.T. Computer-aided analysis of digital dental impressions obtained from intraoral and extraoral scanners. J. Prosthet. Dent. 2017, 118, 617–623. [Google Scholar] [CrossRef]

- Michelinakis, G.; Apostolakis, D.; Tsagarakis, A.; Kourakis, G.; Pavlakis, E. A comparison of accuracy of 3 intraoral scanners: A single-blinded in vitro study. J. Prosthet. Dent. 2019. [Google Scholar] [CrossRef]

- Park, J.M.; Kim, R.J.Y.; Lee, K.W. Comparative reproducibility analysis of 6 intraoral scanners used on complex intracoronal preparations. J. Prosthet. Dent. 2020, 123, 113–120. [Google Scholar] [CrossRef]

- Braian, M.; Wennerberg, A. Trueness and precision of 5 intraoral scanners for scanning edentulous and dentate complete-arch mandibular casts: A comparative in vitro study. J. Prosthet. Dent. 2019, 122, 129–136. [Google Scholar] [CrossRef]

- Stimmelmayr, M.; Groesser, J.; Beuer, F.; Erdelt, K.; Krennmair, G.; Sachs, C.; Güth, J.F. Accuracy and mechanical performance of passivated and conventional fabricated 3-unit fixed dental prosthesis on multi-unit abutments. J. Prosthodont. Res. 2017, 61, 403–411. [Google Scholar] [CrossRef]

- Hayama, H.; Fueki, K.; Wadachi, J.; Wakabayashi, N. Trueness and precision of digital impressions obtained using an intraoral scanner with different head size in the partially edentulous mandible. J. Prosthodont. Res. 2018, 62, 347–352. [Google Scholar] [CrossRef]

- Kihara, H.; Hatakeyama, W.; Komine, F.; Takafuji, K.; Takahashi, T.; Yokota, J.; Kondo, H. Accuracy and practicality of intraoral scanner in dentistry: A literature review. J. Prosthodont. Res. 2020, 64, 109–113. [Google Scholar] [CrossRef]

- Park, G.H.; Son, K.; Lee, K.B. Feasibility of using an intraoral scanner for a complete-arch digital scan. J. Prosthet. Dent. 2019, 121, 803–810. [Google Scholar] [CrossRef] [PubMed]

- Son, K.; Lee, K.B. Effect of Tooth Types on the Accuracy of Dental 3D Scanners: An In Vitro Study. Materials 2020, 13, 1744. [Google Scholar] [CrossRef] [PubMed]

- Son, K.; Lee, S.; Kang, S.H.; Park, J.; Lee, K.B.; Jeon, M.; Yun, B.J. A comparison study of marginal and internal fit assessment methods for fixed dental prostheses. J. Clin. Med. 2019, 8, 785. [Google Scholar] [CrossRef] [PubMed]

- Jang, D.; Son, K.; Lee, K.B. A Comparative study of the fitness and trueness of a three-unit fixed dental prosthesis fabricated using two digital workflows. Appl. Sci. 2019, 9, 2778. [Google Scholar] [CrossRef]

- Kang, B.H.; Son, K.; Lee, K.B. Accuracy of five intraoral scanners and two laboratory scanners for a complete arch: A comparative in vitro study. Appl. Sci. 2020, 10, 74. [Google Scholar] [CrossRef]

- Lee, K.; Son, K.; Lee, K.B. Effects of Trueness and Surface Microhardness on the Fitness of Ceramic Crowns. Appl. Sci. 2020, 10, 1858. [Google Scholar] [CrossRef]

- Alajaji, N.K.; Bardwell, D.; Finkelman, M.; Ali, A. Micro-CT Evaluation of Ceramic Inlays: Comparison of the Marginal and Internal Fit of Five and Three-Axis CAM Systems with a Heat Press Technique. J. Esthet. Restor. Dent. 2017, 29, 49–58. [Google Scholar] [CrossRef]

- Roperto, R.; Assaf, H.; Soares-Porto, T.; Lang, L.; Teich, S. Are different generations of CAD/CAM milling machines capable to fabricate restorations with similar quality? J. Clin. Exp. Dent. 2016, 8, e423. [Google Scholar]

- Sachs, C.; Groesser, J.; Stadelmann, M.; Schweiger, J.; Erdelt, K.; Beuer, F. Full-arch prostheses from translucent zirconia: Accuracy of fit. Dent. Mater. 2014, 30, 817–823. [Google Scholar] [CrossRef]

- Colpani, J.T.; Borba, M.; Della Bona, Á. Evaluation of marginal and internal fit of ceramic crown copings. Dent. Mater. 2013, 29, 174–180. [Google Scholar] [CrossRef]

- Mously, H.A.; Finkelman, M.; Zandparsa, R.; Hirayama, H. Marginal and internal adaptation of ceramic crown restorations fabricated with CAD/CAM technology and the heat-press technique. J. Prosthet. Dent. 2014, 112, 249–256. [Google Scholar] [CrossRef] [PubMed]

- Lins, L.; Bemfica, V.; Queiroz, C.; Canabarro, A. In vitro evaluation of the internal and marginal misfit of CAD/CAM zirconia copings. J. Prosthet. Dent. 2015, 113, 205–211. [Google Scholar] [CrossRef] [PubMed]

- Örtorp, A.; Jönsson, D.; Mouhsen, A.; von Steyern, P.V. The fit of cobalt–chromium three-unit fixed dental prostheses fabricated with four different techniques: A comparative in vitro study. Dent. Mater. 2011, 27, 356–363. [Google Scholar] [CrossRef] [PubMed]

- Varol, S.; Kulak-Özkan, Y. In Vitro Comparison of Marginal and Internal Fit of Press-on-Metal Ceramic (PoM) Restorations with Zirconium-Supported and Conventional Metal Ceramic Fixed Partial Dentures Before and After Veneering. J. Prosthodont. 2015, 24, 387–393. [Google Scholar] [CrossRef]

- Bayramoğlu, E.; Özkan, Y.K.; Yildiz, C. Comparison of marginal and internal fit of press-on-metal and conventional ceramic systems for three-and four-unit implant-supported partial fixed dental prostheses: An in vitro study. J. Prosthet. Dent. 2015, 114, 52–58. [Google Scholar] [CrossRef]

- Massignan Berejuk, H.; Hideo Shimizu, R.; Aparecida de Mattias Sartori, I.; Valgas, L.; Tiossi, R. Vertical microgap and passivity of fit of three-unit implant-supported frameworks fabricated using different techniques. Int. J. Oral Maxillofac. Implants 2014, 29, 1064–1070. [Google Scholar] [CrossRef]

- Rapone, B.; Palmisano, C.; Ferrara, E.; Di Venere, D.; Albanese, G.; Corsalini, M. The Accuracy of Three Intraoral Scanners in the Oral Environment with and without Saliva: A Comparative Study. Appl. Sci. 2020, 10, 7762. [Google Scholar] [CrossRef]

- Lee, S.J.; Kim, S.W.; Lee, J.J.; Cheong, C.W. Comparison of Intraoral and Extraoral Digital Scanners: Evaluation of Surface Topography and Precision. Dent. J. 2020, 8, 52. [Google Scholar] [CrossRef]

- Russo, L.L.; Caradonna, G.; Biancardino, M.; De Lillo, A.; Troiano, G.; Guida, L. Digital versus conventional workflow for the fabrication of multiunit fixed prostheses: A systematic review and meta-analysis of vertical marginal fit in controlled in vitro studies. J. Prosthet. Dent. 2019, 122, 435–440. [Google Scholar] [CrossRef]

- Hasanzade, M.; Shirani, M.; Afrashtehfar, K.I.; Naseri, P.; Alikhasi, M. In Vivo and In Vitro Comparison of Internal and Marginal Fit of Digital and Conventional Impressions for Full-Coverage Fixed Restorations: A Systematic Review and Meta-analysis. J. Evid. Based Dent. Pract. 2019, 19, 236–254. [Google Scholar] [CrossRef]

- Hasanzade, M.; Aminikhah, M.; Afrashtehfar, K.I.; Alikhasi, M. Marginal and internal adaptation of single crowns and fixed dental prostheses by using digital and conventional workflows: A systematic review and meta-analysis. J. Prosthet. Dent. 2020, in press. [Google Scholar] [CrossRef] [PubMed]

- Goodacre, C.J.; Campagni, W.V.; Aquilino, S.A. Tooth preparations for complete crowns: An art form based on scientific principles. J. Prosthet. Dent. 2001, 85, 363–376. [Google Scholar] [CrossRef] [PubMed]

- Dancey, C.; Reidy, J. Statistics without Maths for Psychology: Pearson Higher; Pearson: London, UK, 2014. [Google Scholar]

| Measurement Position | Discrepancy (Mean ± SD) | F | p | |||

|---|---|---|---|---|---|---|

| Intraoral Scanner Group | Conventional Impression Technique | |||||

| EZIS PO | i500 | CS3600 | ||||

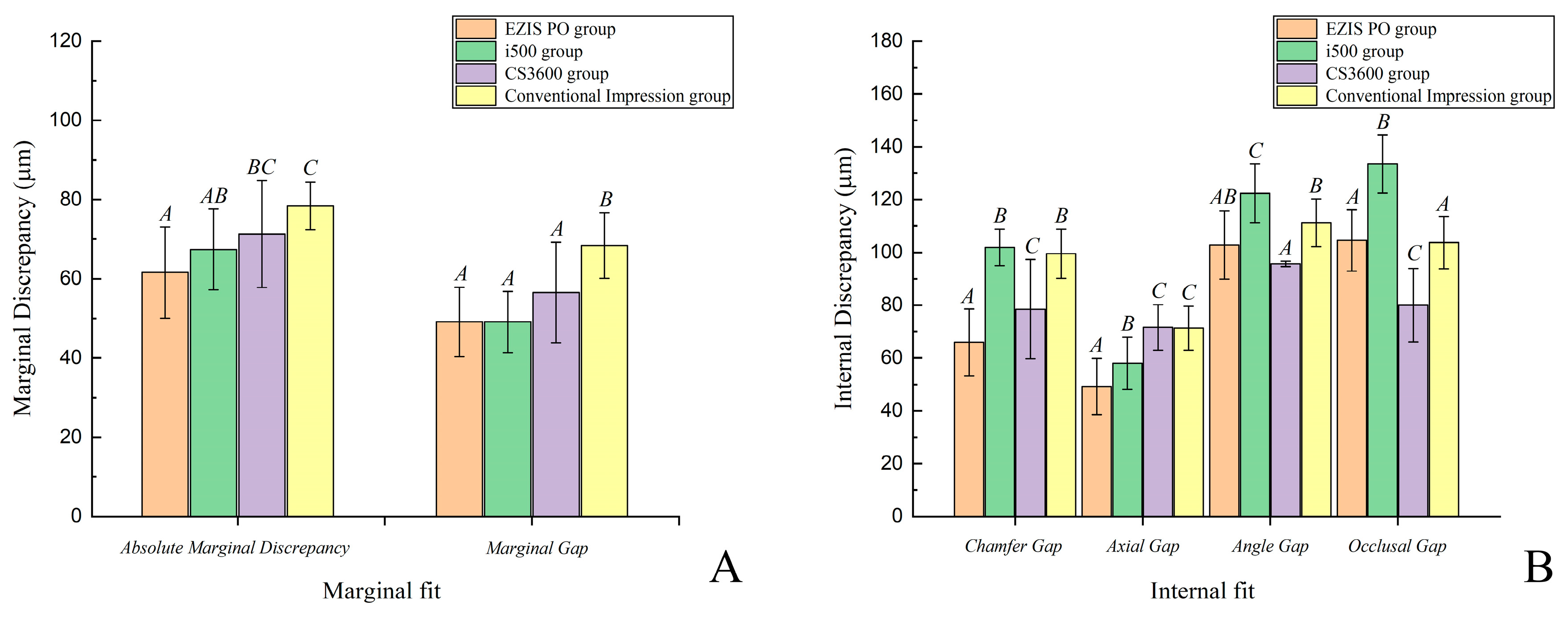

| Absolute Marginal Discrepancy | 61.6 ± 11.5 A | 67.4 ± 10.2 A,B | 71.3 ± 13.5 B,C | 78.4 ± 6 C | 8.758 | <0.001 * |

| Marginal Gap | 49.1 ± 8.8 A | 49.1 ± 7.7 A | 56.5 ± 12.7 A | 68.4 ± 8.3 B | 17.771 | <0.001 * |

| Chamfer Gap | 65.9 ± 12.7 A | 101.9 ± 6.9 B | 78.5 ± 18.8 C | 99.5 ± 9.3 B | 36.483 | <0.001 * |

| Axial Gap | 49.2 ± 10.6 A | 58 ± 10 B | 71.6 ± 8.6 C | 71.3 ± 8.3 C | 26.547 | <0.001 * |

| Angle Gap | 102.8 ± 12.9 A,B | 122.4 ± 11.2 C | 95.7 ± 12.8 A | 111.2 ± 9 B | 19.505 | <0.001 * |

| Occlusal Gap | 104.5 ± 11.6 A | 133.5 ± 11 B | 80 ± 13.9 C | 103.7 ± 9.9 A | 69.547 | <0.001 * |

| Intraoral Scanner Group | Conventional Impression Technique | F | p | |||

|---|---|---|---|---|---|---|

| EZIS PO | i500 | CS3600 | ||||

| Clinician satisfaction (Mean ± SD, Score) | 2.6 ± 1.2 A,B | 2.8 ± 0.9 B | 2.6 ± 1.1 A,B | 1.9 ± 1 A | 2.909 | 0.04 * |

| Clinician Satisfaction | Absolute Marginal Discrepancy | Marginal Gap | Chamfer Gap | |||

| p | PCC | p | PCC | p | PCC | |

| 0.015 | −0.271 | <0.001 | −0.403 | 0.207 | - | |

| Axial Gap | Angle Gap | Occlusal Gap | ||||

| p | PCC | p | PCC | p | PCC | |

| 0.166 | - | 0.526 | - | 0.457 | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-H.; Son, K.; Lee, K.-B. Marginal and Internal Fit of Ceramic Restorations Fabricated Using Digital Scanning and Conventional Impressions: A Clinical Study. J. Clin. Med. 2020, 9, 4035. https://doi.org/10.3390/jcm9124035

Lee J-H, Son K, Lee K-B. Marginal and Internal Fit of Ceramic Restorations Fabricated Using Digital Scanning and Conventional Impressions: A Clinical Study. Journal of Clinical Medicine. 2020; 9(12):4035. https://doi.org/10.3390/jcm9124035

Chicago/Turabian StyleLee, Jeong-Hyeon, Keunbada Son, and Kyu-Bok Lee. 2020. "Marginal and Internal Fit of Ceramic Restorations Fabricated Using Digital Scanning and Conventional Impressions: A Clinical Study" Journal of Clinical Medicine 9, no. 12: 4035. https://doi.org/10.3390/jcm9124035

APA StyleLee, J.-H., Son, K., & Lee, K.-B. (2020). Marginal and Internal Fit of Ceramic Restorations Fabricated Using Digital Scanning and Conventional Impressions: A Clinical Study. Journal of Clinical Medicine, 9(12), 4035. https://doi.org/10.3390/jcm9124035