The Effects of Scanning Speed and Standoff Distance of the Fiber on Dusting Efficiency during Short Pulse Holmium: YAG Laser Lithotripsy

Abstract

:1. Introduction

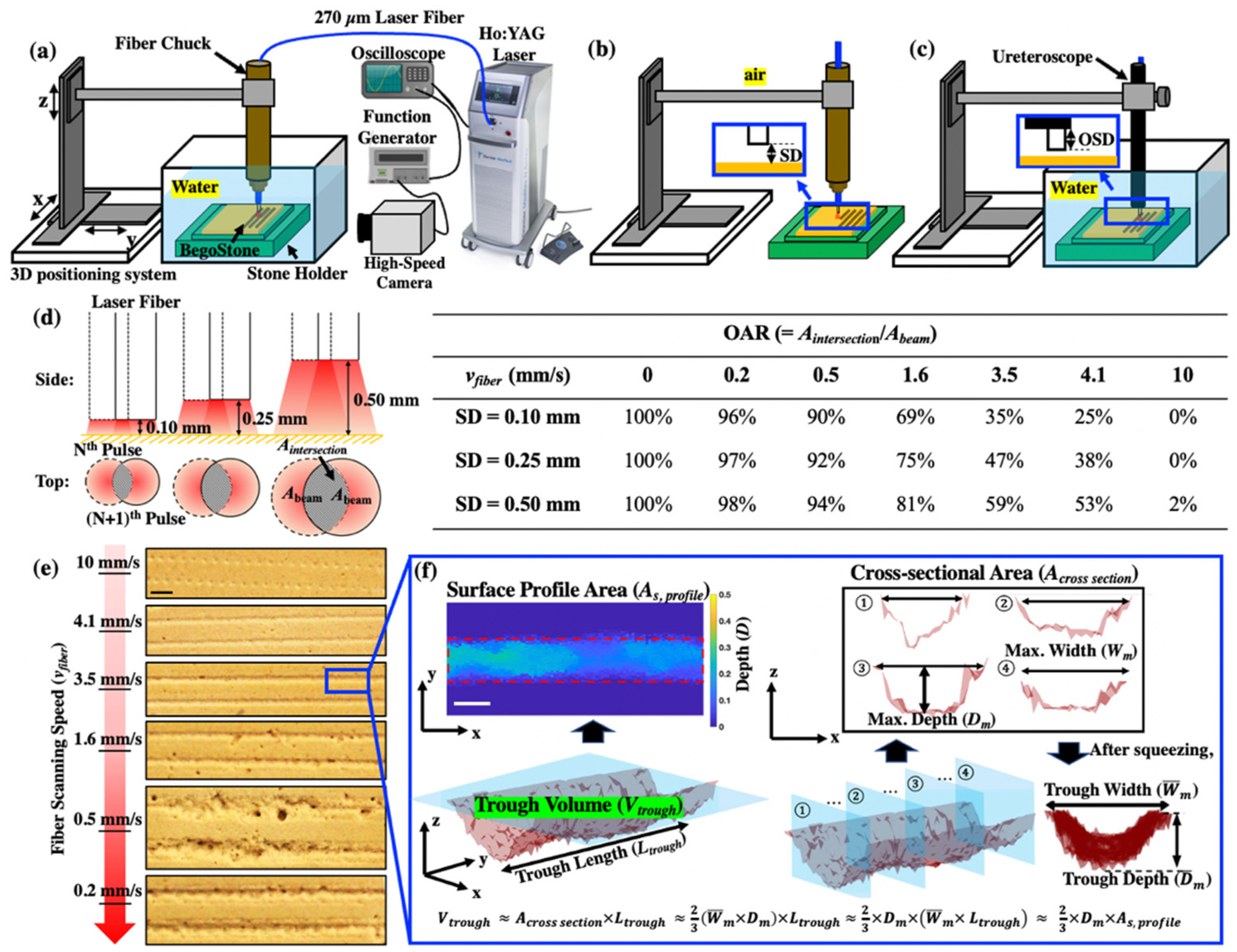

2. Materials and Methods

2.1. Sample Preparation Protocol

2.2. Scanning Fiber Experiments

2.3. Quantitative Analysis of Stone Damage

2.4. Assessment of Different Damage Mechanisms

2.5. Effect of the Overlapping Area Ratio (OAR) on Dusting Efficiency

2.6. High-Speed Imaging and Pressure Transient of Bubble Dynamics

2.7. Statistical Analysis

3. Results

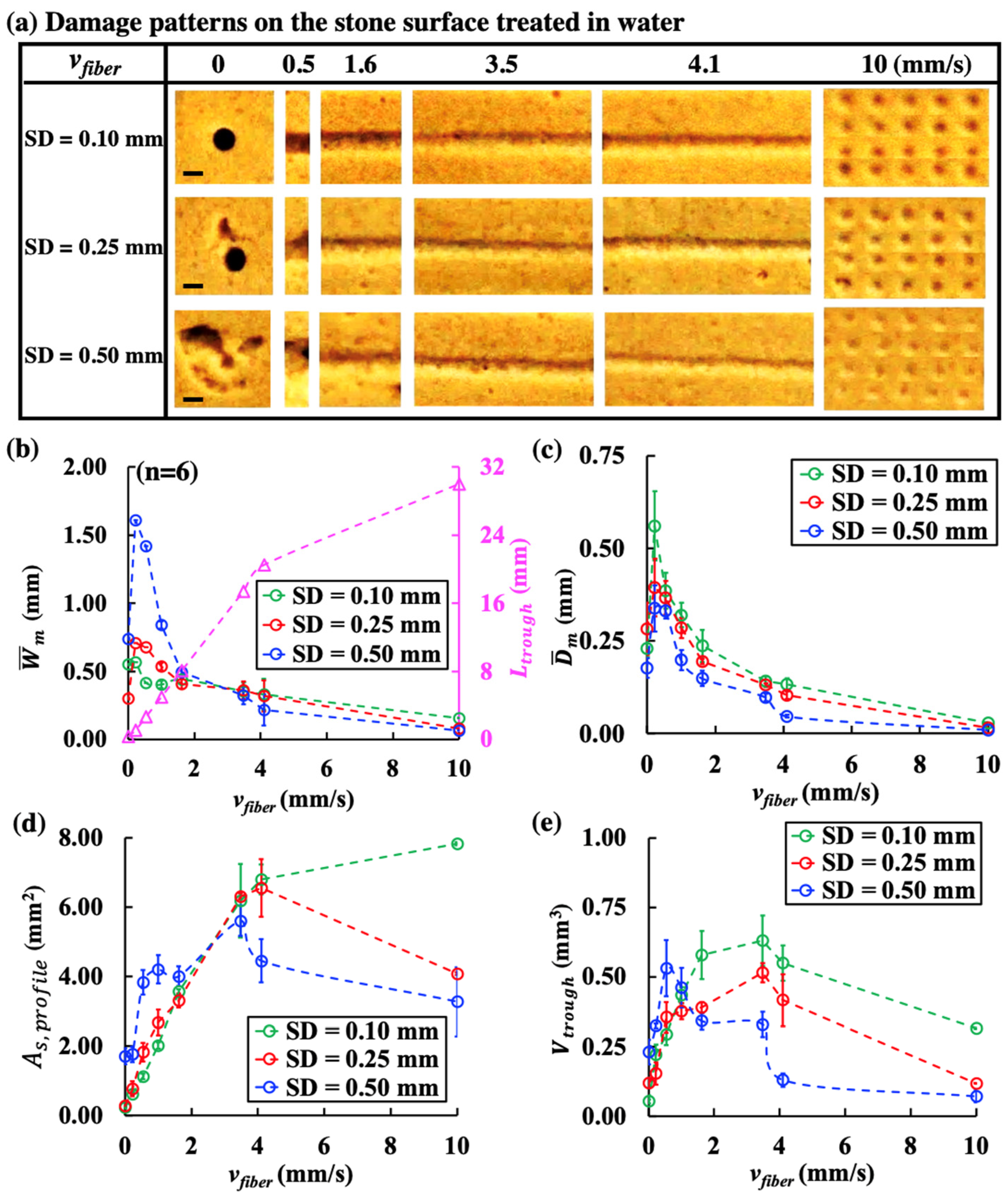

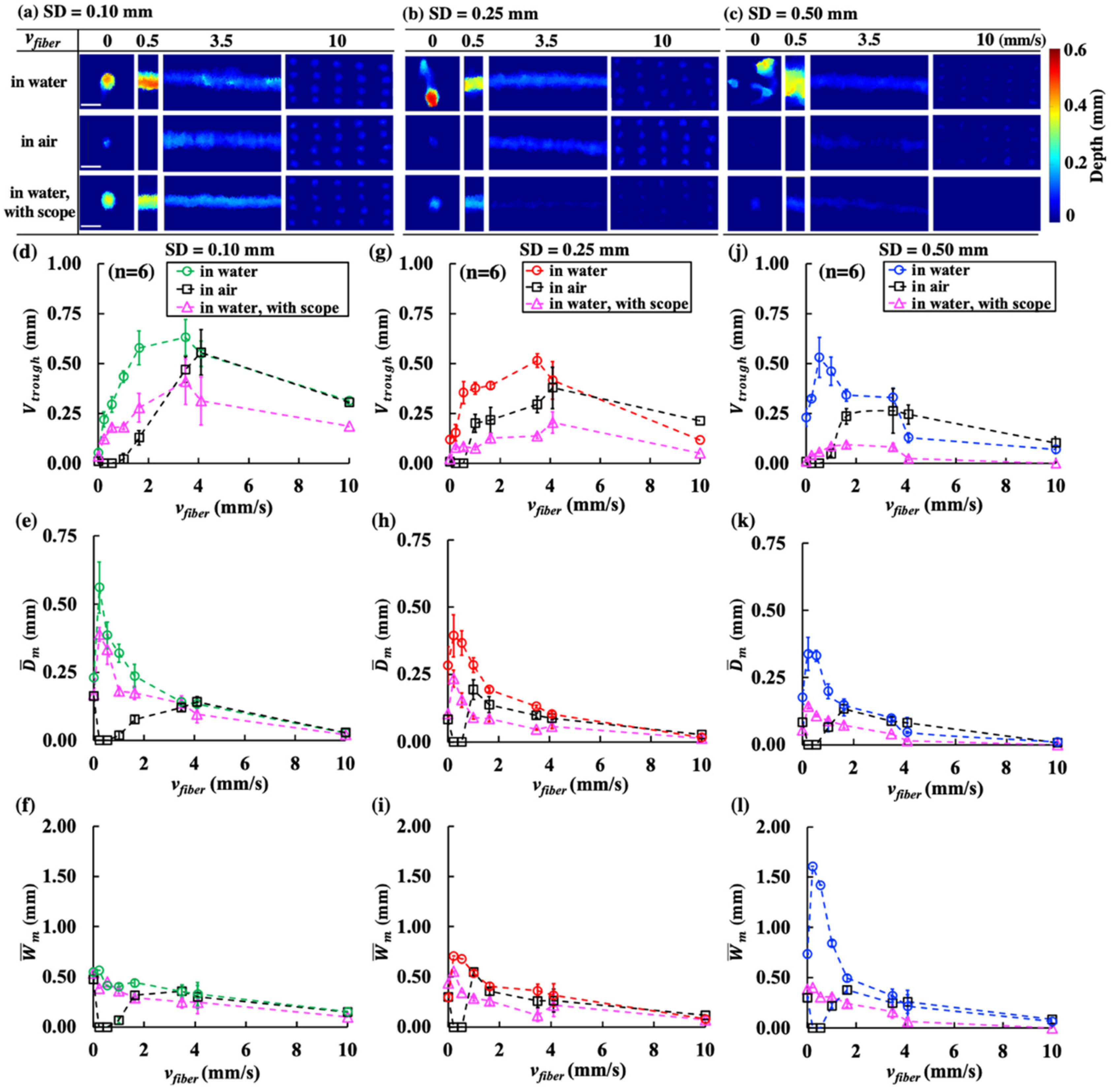

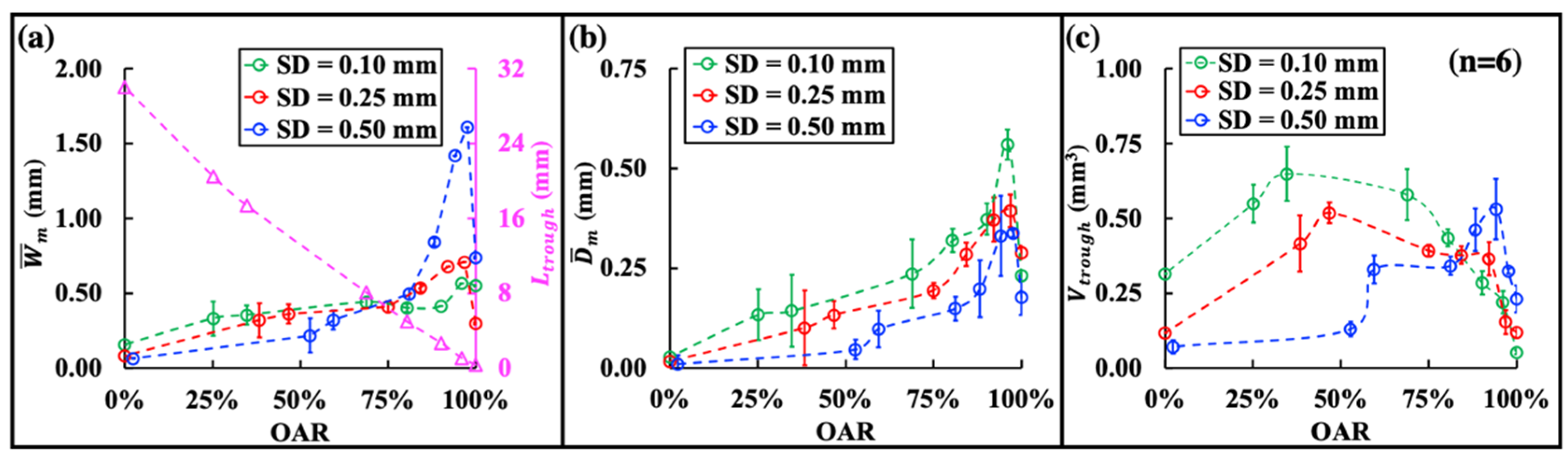

3.1. Stone Damage Produced in Water under Different vfiber and SDs

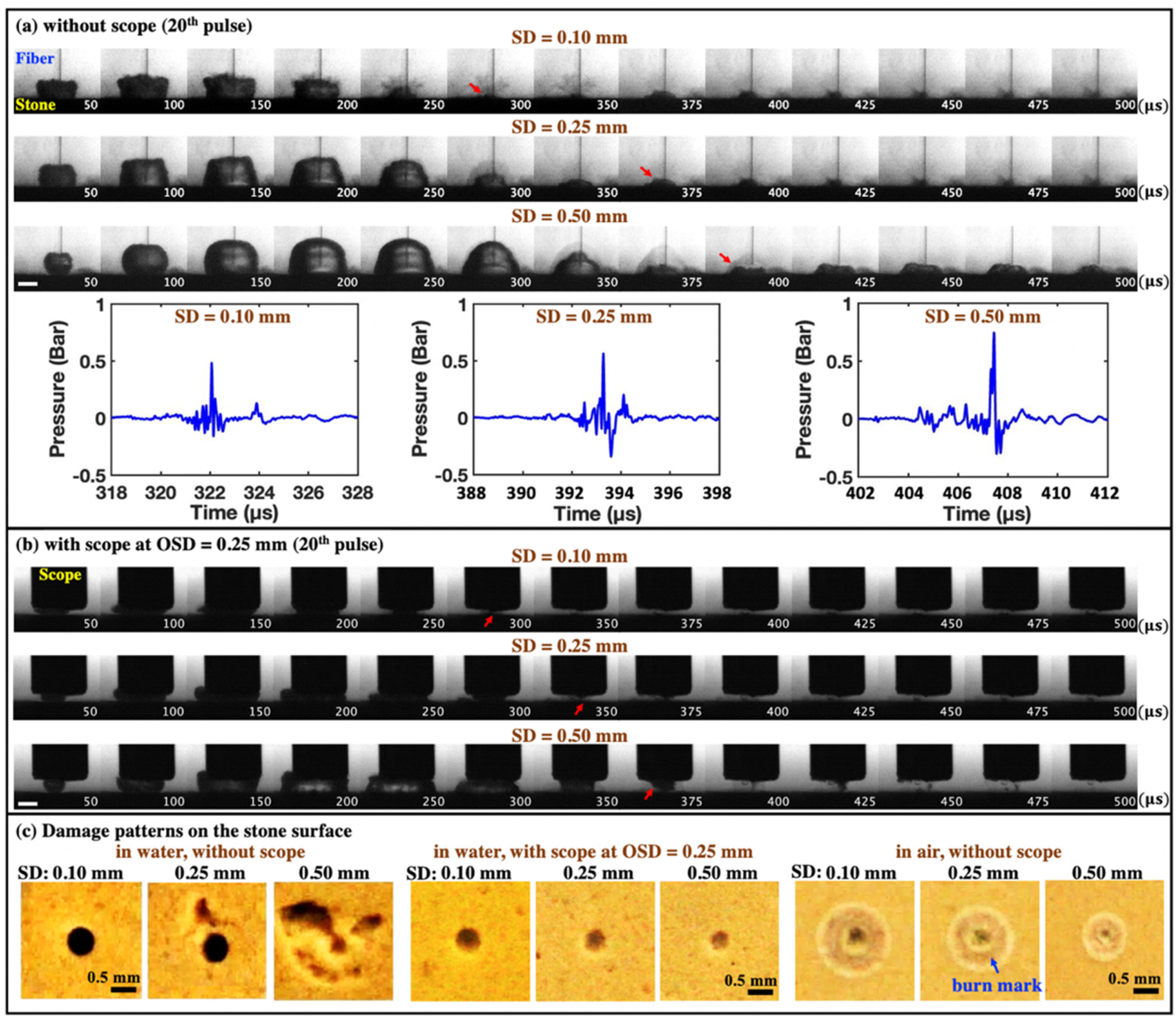

3.2. Contribution of Photothermal Ablation vs. Cavitation to Stone Dusting

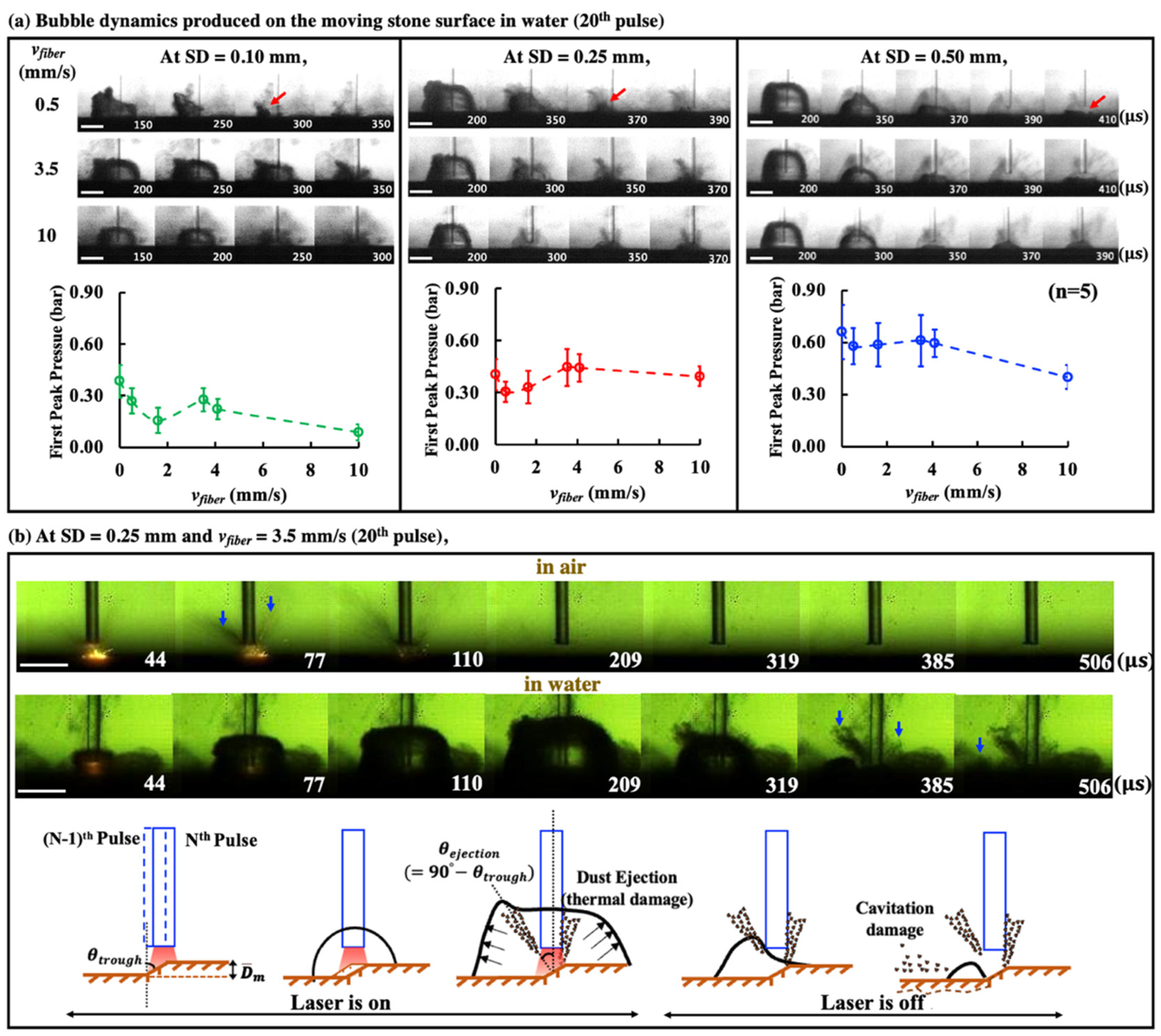

3.2.1. Different Bubble Dynamics and Stone Damage Characteristics Produced by Photothermal Ablation and Cavitation Bubble Collapse

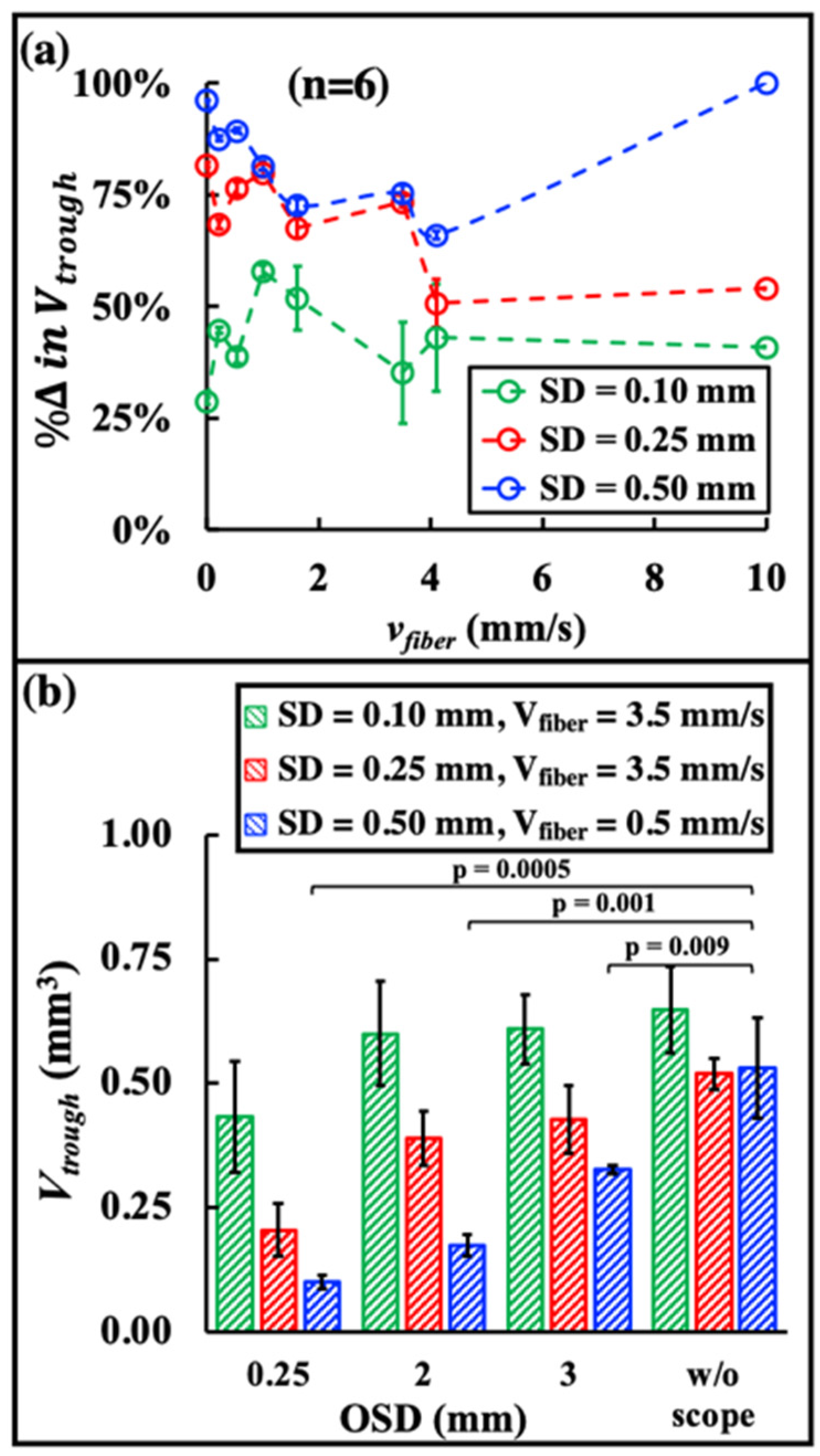

3.2.2. Cavitation Bubble Collapse toward the Stone Surface Is Indispensable in Stone Dusting

3.2.3. Effects of vfiber and SD on Bubble Dynamics and Resultant Acoustic Emission

3.2.4. Effect of Fiber Tip OSD from the Ureteroscope on Stone Dusting Efficiency

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bagley, D.H. Expanding role of ureteroscopy and laser lithotripsy for treatment of proximal ureteral and intrarenal calculi. Curr. Opin. Urol. 2002, 12, 277–280. [Google Scholar] [CrossRef] [PubMed]

- Aldoukhi, A.H.; Roberts, W.W.; Hall, T.L.; Ghani, K.R. Holmium Laser Lithotripsy in the New Stone Age: Dust or Bust? Front. Surg. 2017, 4, 57. [Google Scholar] [CrossRef] [PubMed]

- Dauw, C.A.; Simeon, L.; Alruwaily, A.F.; Sanguedolce, F.; Hollingsworth, J.M.; Roberts, W.W.; Faerber, G.J.; Wolf, J.S., Jr.; Ghani, K.R. Contemporary Practice Patterns of Flexible Ureteroscopy for Treating Renal Stones: Results of a Worldwide Survey. J. Endourol. 2015, 29, 1221–1230. [Google Scholar] [CrossRef] [PubMed]

- Tracey, J.; Gagin, G.; Morhardt, D.; Hollingsworth, J.; Ghani, K.R. Ureteroscopic High-Frequency Dusting Utilizing a 120-W Holmium Laser. J. Endourol. 2018, 32, 290–295. [Google Scholar] [CrossRef]

- Matlaga, B.R.; Chew, B.; Eisner, B.; Humphreys, M.; Knudsen, B.; Krambeck, A.; Lange, D.; Lipkin, M.; Miller, N.L.; Monga, M.; et al. Ureteroscopic Laser Lithotripsy: A Review of Dusting vs Fragmentation with Extraction. J. Endourol. 2018, 32, 1–6. [Google Scholar] [CrossRef]

- Kronenberg, P.; Somani, B. Advances in Lasers for the Treatment of Stones-a Systematic Review. Curr. Urol. Rep. 2018, 19, 45. [Google Scholar] [CrossRef]

- Reeves, T.; Griffin, S.; Pietropaolo, A.; Somani, B.K. Feasibility of dusting and pop-dusting using high-power (100W) Holmium YAG (Ho:YAG) laser in treatment of paediatric stones: Results of first worldwide clincial study. Cent. Eur. J. Urol. 2019, 72, 398–401. [Google Scholar] [CrossRef]

- Weiss, B.; Shah, O. Evaluation of dusting versus basketing—Can new technologies improve stone-free rates? Nat. Rev. Urol. 2016, 13, 726–733. [Google Scholar] [CrossRef]

- Chan, K.F.; Vassar, G.J.; Pfefer, T.J.; Teichman, J.M.; Glickman, R.D.; Weintraub, S.T.; Welch, A.J. Holmium:YAG laser lithotripsy: A dominant photothermal ablative mechanism with chemical decomposition of urinary calculi. Lasers Surg. Med. 1999, 25, 22–37. [Google Scholar] [CrossRef]

- Fried, N.M. Recent advances in infrared laser lithotripsy [Invited]. Biomed. Opt. Express 2018, 9, 4552–4568. [Google Scholar] [CrossRef]

- Aldoukhi, A.H.; Roberts, W.W.; Hall, T.L.; Ghani, K.R. Watch Your Distance: The Role of Laser Fiber Working Distance on Fragmentation When Altering Pulse Width or Modulation. J. Endourol. 2019, 33, 120–126. [Google Scholar] [CrossRef] [PubMed]

- Lü, T.; Xiao, Q.; Xia, D.; Ruan, K.; Li, Z. Cavitation effect of holmium laser pulse applied to ablation of hard tissue underwater. J. Biomed. Opt. 2010, 15, 048002. [Google Scholar] [CrossRef] [PubMed]

- Aldoukhi, A.H.; Black, K.M.; Hall, T.L.; Roberts, W.W.; Ghani, K.R. Frequency Threshold for Ablation During Holmium Laser Lithotripsy: How High Can You Go? J. Endourol. 2020, 34, 1075–1081. [Google Scholar] [CrossRef]

- Winship, B.; Wollin, D.; Carlos, E.; Li, J.; Peters, C.; Simmons, W.N.; Preminger, G.M.; Lipkin, M. Dusting Efficiency of the Moses Holmium Laser: An Automated In Vitro Assessment. J. Endourol. 2018, 32, 1131–1135. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.O.; Ryan R, T.; Teichman Joel, M.H.; Kim, J.; Choi, B.; Arakeri Navanit, V.; Welch, A.J. Stone Retropulsion during Holmium:Yag Lithotripsy. J. Urol. 2003, 169, 881–885. [Google Scholar] [CrossRef] [PubMed]

- Sea, J.; Jonat, L.M.; Chew, B.H.; Qiu, J.; Wang, B.; Hoopman, J.; Milner, T.; Teichman, J.M. Optimal power settings for Holmium:YAG lithotripsy. J. Urol. 2012, 187, 914–919. [Google Scholar] [CrossRef] [PubMed]

- Kronenberg, P.; Traxer, O. Update on lasers in urology 2014: Current assessment on holmium:yttrium-aluminum-garnet (Ho:YAG) laser lithotripter settings and laser fibers. World J. Urol. 2015, 33, 463–469. [Google Scholar] [CrossRef]

- Emiliani, E.; Talso, M.; Haddad, M.; Pouliquen, C.; Derman, J.; Côté, J.F.; Doizi, S.; Millán, F.; Berthe, L.; Audouin, M.; et al. The True Ablation Effect of Holmium YAG Laser on Soft Tissue. J. Endourol. 2018, 32, 230–235. [Google Scholar] [CrossRef]

- Chen, J.; Ho, D.S.; Xiang, G.; Sankin, G.; Preminger, G.M.; Lipkin, M.E.; Zhong, P. Cavitation Plays a Vital Role in Stone Dusting during Short Pulse Holmium: YAG Laser Lithotripsy. J. Endourol. 2022, 36, 674–683. [Google Scholar] [CrossRef]

- Ho, D.; Chen, J.; Xiang, G.; Whelan, P.; Preminger, G.; Lipkin, M.; Zhong, P. PD54-09 Siginificant Contribution of Cavitation to Dusting Stone Damage in Laser Lithotripsy. J. Urol. 2021, 206, e926. [Google Scholar] [CrossRef]

- Winship, B.; Wollin, D.; Carlos, E.; Peters, C.; Li, J.; Terry, R.; Boydston, K.; Preminger, G.M.; Lipkin, M.E. The Rise and Fall of High Temperatures During Ureteroscopic Holmium Laser Lithotripsy. J. Endourol. 2019, 33, 794–799. [Google Scholar] [CrossRef] [PubMed]

- Maxwell, A.D.; MacConaghy, B.; Harper, J.D.; Aldoukhi, A.H.; Hall, T.L.; Roberts, W.W. Simulation of Laser Lithotripsy-Induced Heating in the Urinary Tract. J. Endourol. 2019, 33, 113–119. [Google Scholar] [CrossRef] [PubMed]

- Panthier, F.; Germain, T.; Gorny, C.; Berthe, L.; Doizi, S.; Traxer, O. Laser Fiber Displacement Velocity during Tm-Fiber and Ho:YAG Laser Lithotripsy: Introducing the Concept of Optimal Displacement Velocity. J. Clin. Med. 2022, 11, 181. [Google Scholar] [CrossRef] [PubMed]

- Petzold, R.; Miernik, A.; Suarez-Ibarrola, R. In Vitro Dusting Performance of a New Solid State Thulium Laser Compared to Holmium Laser Lithotripsy. J. Endourol. 2021, 35, 221–225. [Google Scholar] [CrossRef] [PubMed]

- Terry, R.S.; Ho, D.S.; Scialabba, D.M.; Whelan, P.S.; Qi, R.; Ketterman, B.T.; Preminger, G.M.; Zhong, P.; Lipkin, M.E. Comparison of Different Pulse Modulation Modes for Holmium:Yttrium-Aluminum-Garnet Laser Lithotripsy Ablation in a Benchtop Model. J. Endourol. 2022, 36, 29–37. [Google Scholar] [CrossRef]

- Esch, E.; Simmons, W.N.; Sankin, G.; Cocks, H.F.; Preminger, G.M.; Zhong, P. A simple method for fabricating artificial kidney stones of different physical properties. Urol. Res. 2010, 38, 315–319. [Google Scholar] [CrossRef]

- Simmons, W.N.; Cocks, F.H.; Zhong, P.; Preminger, G. A composite kidney stone phantom with mechanical properties controllable over the range of human kidney stones. J. Mech. Behav. Biomed. Mater. 2010, 3, 130–133. [Google Scholar] [CrossRef]

- Ho, D.S.; Scialabba, D.; Terry, R.S.; Ma, X.; Chen, J.; Sankin, G.N.; Xiang, G.; Qi, R.; Preminger, G.M.; Lipkin, M.E.; et al. The Role of Cavitation in Energy Delivery and Stone Damage During Laser Lithotripsy. J. Endourol. 2021, 35, 860–870. [Google Scholar] [CrossRef]

- Grasso, M.; Chalik, Y. Principles and Applications of Laser Lithotripsy: Experience with the Holmium Laser Lithotrite. J. Clin. Laser Med. Surg. 1998, 16, 3–7. [Google Scholar] [CrossRef]

- Khoder, W.Y.; Bader, M.; Sroka, R.; Stief, C.; Waidelich, R. Efficacy and safety of Ho:YAG Laser Lithotripsy for ureteroscopic removal of proximal and distal ureteral calculi. BMC Urol. 2014, 14, 62. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Ryan, R.T.; Teichman, J.M.H.; Landman, J.; Clayman, R.V.; Milner, T.E.; Welch, A.J. Effect of Lithotripsy on Holmium:YAG Optical Beam Profile. J. Endourol. 2003, 17, 63–67. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Avila, S.R.; Klaseboer, E.; Khoo, B.C.; Ohl, C.-D. Cavitation bubble dynamics in a liquid gap of variable height. J. Fluid Mech. 2011, 682, 241–260. [Google Scholar] [CrossRef]

- Talso, M.; Emiliani, E.; Haddad, M.; Berthe, L.; Baghdadi, M.; Montanari, E.; Traxer, O. Laser Fiber and Flexible Ureterorenoscopy: The Safety Distance Concept. J. Endourol. 2016, 30, 1269–1274. [Google Scholar] [CrossRef] [PubMed]

- Žemaitis, A.; Gaidys, M.; Brikas, M.; Gečys, P.; Račiukaitis, G.; Gedvilas, M. Advanced laser scanning for highly-efficient ablation and ultrafast surface structuring: Experiment and model. Sci. Rep. 2018, 8, 17376. [Google Scholar] [CrossRef]

- Weisstein, E.W. Circle-Circle Intersection. Available online: https://mathworld.wolfram.com/Circle-CircleIntersection.html (accessed on 4 July 2022).

- Schmidlin, F.R.; Beghuin, D.; Delacretaz, G.P.; Venzi, G.; Jichlinski, P.; Rink, K.; Leisinger, H.J.; Graber, P. Laser lithotripsy with the Ho:YAG laser: Fragmentation process revealed by time-resolved imaging. In Lasers in Surgery: Advanced Characterization, Therapeutics, and Systems VIII; SPIE: Bellingham, WA, USA, 1998. [Google Scholar]

- Mekayten, M.; Lorber, A.; Katafigiotis, I.; Sfoungaristos, S.; Leotsakos, I.; Heifetz, E.; Yutkin, V.; Gofrit, O.; Duvdevani, M. Will Stone Density Stop Being a Key Factor in Endourology? The Impact of Stone Density on Laser Time Using Lumenis Laser p120w and Standard 20 W Laser: A Comparative Study. J. Endourol. 2019, 33, 585–589. [Google Scholar] [CrossRef]

- Ventimiglia, E.; Pauchard, F.; Quadrini, F.; Sindhubodee, S.; Kamkoum, H.; Jiménez Godínez, A.; Doizi, S.; Traxer, O. High- and Low-Power Laser Lithotripsy Achieves Similar Results: A Systematic Review and Meta-Analysis of Available Clinical Series. J. Endourol. 2021, 35, 1146–1152. [Google Scholar] [CrossRef]

- De Coninck, V.; Hente, R.; Claessens, M.; Duchateau, A.; Doizi, S.; Keller, E.X. High-power, High-frequency Ho:YAG Lasers Are Not Essential for Retrograde Intrarenal Surgery. Eur. Urol. Focus 2021, 7, 5–6. [Google Scholar] [CrossRef]

- Ventimiglia, E.; Pauchard, F.; Gorgen, A.R.H.; Panthier, F.; Doizi, S.; Traxer, O. How do we assess the efficacy of Ho:YAG low-power laser lithotripsy for the treatment of upper tract urinary stones? Introducing the Joules/mm3 and laser activity concepts. World J. Urol. 2021, 39, 891–896. [Google Scholar] [CrossRef]

- Teichman, J.M.H.; Jansen, E.D.; Milner, T.E. Editorial Comment on “Cavitation Plays a Vital Role in Stone Dusting During Short Pulse Holmium:YAG Laser Lithotripsy” by Chen et al. J. Endourol. 2022, 36, 684–685. [Google Scholar] [CrossRef]

- Zhong, P.; Lipkin, M.E.; Preminger, G.M. Editorial Comment:Elucidating the Mechanism of Stone Dusting Requires a Fresh and Rigorous Approach in the New Era of Laser Lithotripsy. J. Endourol. 2022, 36, 686–687. [Google Scholar] [CrossRef]

- Wezel, F.; Häcker, A.; Gross, A.J.; Michel, M.S.; Bach, T. Effect of pulse energy, frequency and length on holmium:yttrium-aluminum-garnet laser fragmentation efficiency in non-floating artificial urinary calculi. J. Endourol. 2010, 24, 1135–1140. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Ruckle, D.; Keheila, M.; Maldonado, J.; Lightfoot, M.; Alsyouf, M.; Yeo, A.; Abourbih, S.R.; Olgin, G.; Arenas, J.L.; et al. High-Frequency Dusting Versus Conventional Holmium Laser Lithotripsy for Intrarenal and Ureteral Calculi. J. Endourol. 2016, 31, 272–277. [Google Scholar] [CrossRef] [PubMed]

- Kadihasanoglu, M.; Yucetas, U.; Culha, M.G.; Erkan, E.; Toktas, M.G. Effect of Stone Composition on the Outcomes of Semi-Rigid Ureteroscopy Using Holmium: Yttrium-Aluminum-Garnet Laser or Pneumatic Lithotripsy. JCPSP J. Coll. Physicians Surg. Pak. 2017, 27, 227–231. [Google Scholar] [PubMed]

- King, J.B.; Katta, N.; Teichman, J.M.H.; Tunnell, J.W.; Milner, T.E. Mechanisms of Pulse Modulated Holmium:YAG Lithotripsy. J. Endourol. 2021, 35, S29–S36. [Google Scholar] [CrossRef]

- Hall, L.A.; Gonzalez, D.A.; Fried, N.M. Thulium fiber laser ablation of kidney stones using an automated, vibrating fiber. J. Biomed. Opt. 2019, 24, 038001. [Google Scholar] [CrossRef]

- Glickman, L.; Munver, R. PD42-08 Comparison of Low Power/High Frequency Holmium Laser Settings with Conventional Settings on Ureteral and Renal Stone Fragmentation Efficiency. J. Urol. 2015, 193, e888–e889. [Google Scholar] [CrossRef]

- Frank, D.S.; Aldoukhi, A.H.; Roberts, W.W.; Ghani, K.R.; Matzger, A.J. Polymer–Mineral Composites Mimic Human Kidney Stones in Laser Lithotripsy Experiments. ACS Biomater. Sci. Eng. 2019, 5, 4970–4975. [Google Scholar] [CrossRef]

| SD = 0.10 mm (Contact Mode) | |||

| Optimal at F = 20 Hz | Optimal F at Different | ||

| 1 mm/s | 2 mm/s | 3 mm/s | |

| 6 Hz | 11 Hz | 17 Hz | |

| Time required for 100 pulses, tcontact | 17.5 s | 8.7 s | 5.8 s |

| SD = 0.50 mm (non-contact mode) | |||

| 40 Hz | 80 Hz | 120 Hz | |

| Time required for 100 pulses, tnon-contact | 2.5 s | 1.3 s | 0.8 s |

| Ratio of treatment time, tcontact:tnon-contact | 7:1 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Li, D.; Yu, W.; Ma, Z.; Li, C.; Xiang, G.; Wu, Y.; Yao, J.; Zhong, P. The Effects of Scanning Speed and Standoff Distance of the Fiber on Dusting Efficiency during Short Pulse Holmium: YAG Laser Lithotripsy. J. Clin. Med. 2022, 11, 5048. https://doi.org/10.3390/jcm11175048

Chen J, Li D, Yu W, Ma Z, Li C, Xiang G, Wu Y, Yao J, Zhong P. The Effects of Scanning Speed and Standoff Distance of the Fiber on Dusting Efficiency during Short Pulse Holmium: YAG Laser Lithotripsy. Journal of Clinical Medicine. 2022; 11(17):5048. https://doi.org/10.3390/jcm11175048

Chicago/Turabian StyleChen, Junqin, Daiwei Li, Wenjun Yu, Zhiteng Ma, Chenhang Li, Gaoming Xiang, Yuan Wu, Junjie Yao, and Pei Zhong. 2022. "The Effects of Scanning Speed and Standoff Distance of the Fiber on Dusting Efficiency during Short Pulse Holmium: YAG Laser Lithotripsy" Journal of Clinical Medicine 11, no. 17: 5048. https://doi.org/10.3390/jcm11175048

APA StyleChen, J., Li, D., Yu, W., Ma, Z., Li, C., Xiang, G., Wu, Y., Yao, J., & Zhong, P. (2022). The Effects of Scanning Speed and Standoff Distance of the Fiber on Dusting Efficiency during Short Pulse Holmium: YAG Laser Lithotripsy. Journal of Clinical Medicine, 11(17), 5048. https://doi.org/10.3390/jcm11175048