Conventional, Speed Sintering and High-Speed Sintering of Zirconia: A Systematic Review of the Current Status of Applications in Dentistry with a Focus on Precision, Mechanical and Optical Parameters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Search Strategy

2.2. Information Sources

2.3. Study Selection and Eligibility Criteria

2.4. Data Extraction and Collection

3. Results

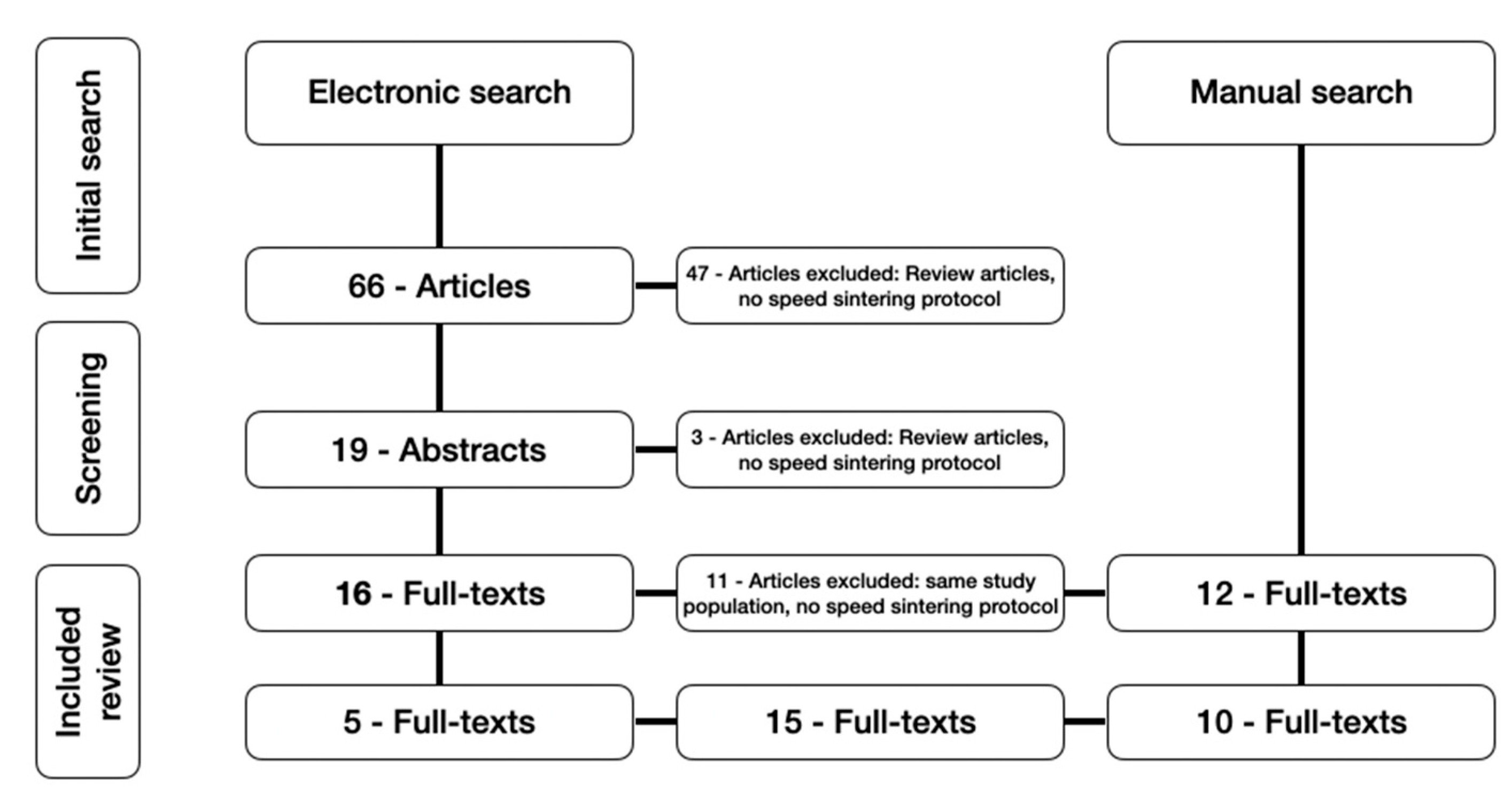

3.1. Study Selection

3.2. Study Characteristics

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kinane, D.F.; Stathopoulou, P.G.; Paapanou, P.N. Periodontal diseases. Nat. Rev. Dis. Primers. 2017, 22, 17038. [Google Scholar] [CrossRef]

- Suarez, M.J.; Perez, C.; Pelaez, J.; Lopez-Suarez, C.; Gonzalo, E. A randomized clinical trial comparing zirconia and metal-ceramic three-unit posterior fixed partial dentures: A 5-year follow-up. J. Prosthodont. 2018, 28, 750–756. [Google Scholar] [CrossRef]

- Bapat, R.A.; Yang, H.J.; Chaubal, T.C.; Dharmadhikari, S.; Abdulla, A.M.; Arora, S.; Rawal, S.; Kesharwani, P. Review on synthesis, properties and multifarious therapeutic applications of nanostructured zirconia in dentistry. RSC Adv. 2022, 27, 12773–12793. [Google Scholar] [CrossRef]

- Zhang, F.; Inokoshi, M.; Batuk, M.; Hadermann, J.; Naert, I.; Meerbeek, B.V.; Vleugels, J. Strength, toughness and aging stability of highly-translucent Y-TZP ceramics for dental restorations. Dent. Mater. 2016, 32, 327–337. [Google Scholar] [CrossRef]

- Alfawaz, Y. Zirconia crown as single unit tooth restoration: A literature review. JCPD 2016, 7, 418–422. [Google Scholar] [CrossRef]

- Sailer, I.; Balmer, M.; Husler, J.; Hammerle, C.H.F.; Kanel, S.; Thoma, D.S. 10-year randomized trial (RCT) of zirconia-ceramic and metal-ceramic fixed dental prostheses. J. Dent. 2018, 76, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Kern, M.; Passia, N.; Sasse, M.; Yazigi, C. Ten-year outcome of zirconia ceramic cantilever resin-bonded fixed dental prostheses and the influence of the reasons for missing incisors. J. Dent. 2017, 65, 51–55. [Google Scholar] [CrossRef]

- Baroudi, K.; Ibraheem, S.N. Assessment of chair-side computer-aided design and computer-aided manufacturing restorations: A review of the literature. J. Int. Oral. Health 2015, 7, 96–104. [Google Scholar]

- Roggendorf, M.J.; Kunzi, B.; Ebert, J.; Roggendorf, H.C.; Frankenberger, R.; Reich, S.M. Seven-year clinical performance of CEREC-2 all-ceramic CAD/CAM restorations placed within deeply destroyed teeth. Clin. Oral. Investig. 2012, 16, 1413–1424. [Google Scholar] [CrossRef]

- Alghazzawi, T.F. Advancements in CAD/CAM technology: Options for practical implementation. J. Prosthodont. Res. 2016, 60, 72–84. [Google Scholar] [CrossRef]

- Liu, L.Y.; Guo, J.J.; Du, X.Y.; Wang, Q.; Qiu, L.H. Comparison of mechanical properties of three machinable resin ceramic composite materials. Shanghai Kou Qiang Yi Xue 2019, 28, 25–29. [Google Scholar]

- Sulaiman, T.A.; Abdulmajeed, A.A.; Donovan, T.E.; Vallittu, P.K.; Nähri, T.O.; Lassila, L.V. The effect of staining and vacuum sintering on optical and mechanical properties of partially and fully stabilized monolithic zirconia. Dent. Mater. J. 2015, 34, 605–610. [Google Scholar] [CrossRef] [Green Version]

- Maginnis, S.; Carden, R.; Szeremeta, A.; Paskalov, G. Method of Rapid Sintering of Ceramics. US Patent US8845951B2, 2014. [Google Scholar]

- Kim, S.W.; Khalil, K.A.R. High-frequency induction heat sintering of mechanically alloyed alumina-yttria-stabilized zirconia nano-bioceramics. J. Am. Ceram. Soc. 2006, 89, 1280–1285. [Google Scholar] [CrossRef]

- Soult, M.D.; Lien, W.; Savett, D.A.; Gallardo, F.F.; Vandewalle, K.S. Effect of high-speed sintering on the properties of a zirconia material. Gen Dent. 2019, 67, 30–34. [Google Scholar]

- Ahmed, W.M.; Abdallah, M.N.; McCullagh, A.P.; Wyatt, C.C.L.; Troczynski, T.; Carvalho, R.M. Marginal Discrepancies of Monolithic Zirconia Crowns: The Influence of Preparation Designs and Sintering Techniques. J. Prosthodont. 2019, 28, 288–298. [Google Scholar] [CrossRef]

- Nakamura, T.; Nakano, Y.; Usami, H.; Okamura, S.; Wakabayashi, K.; Yatani, H. In vitro investigation of fracture load and aging resistance of high-speed sintered monolithic tooth-borne zirconia crowns. J. Prosthodont. Res. 2020, 64, 182–187. [Google Scholar] [CrossRef]

- Edwards Rezende, C.E.; Sanches Borges, A.F.; Macedo, R.M.; Rubo, J.H.; Griggs, J.A. Dimensional changes from the sintering process and fit of Y-TZP copings: Micro-CT analysis. Dent. Mater. 2017, 33, e405–e413. [Google Scholar] [CrossRef]

- Wiedenmann, F.; Pfefferle, R.; Reichert, A.; Jerman, E.; Stawarczyk, B. Impact of high-speed sintering, layer thickness and artificial aging on the fracture load and two-body wear of zirconia crowns. Dent. Mater. 2020, 36, 846–853. [Google Scholar] [CrossRef]

- Kaizer, M.R.; Gierthmuehlen, P.C.; Dos Santos, M.B.; Cava, S.S.; Zhang, Y. Speed sintering translucent zirconia for chairside one-visit dental restorations: Optical, mechanical, and wear characteristics. Ceram. Int. 2017, 43, 10999–11005. [Google Scholar] [CrossRef]

- Cokic, S.M.; Vleugels, J.; Van Meerbeek, B.; Camargo, B.; Willems, E.; Li, M.; Zhang, F. Mechanical properties, aging stability and translucency of speed-sintered zirconia for chairside restorations. Dent. Mater. 2020, 36, 959–972. [Google Scholar] [CrossRef]

- Al-Zordk, W.; Saker, S. Impact of sintering procedure and clinical adjustment on color stability and translucency of translucent zirconia. J. Prosthet. Dent. 2020, 124, 788.e1–788.e9. [Google Scholar] [CrossRef]

- Lawson, N.C.; Maharishi, A. Strength and translucency of zirconia after high-speed sintering. J. Esthet. Restor. Dent. 2020, 32, 219–225. [Google Scholar] [CrossRef]

- Jansen, J.U.; Lümkemann, N.; Letz, I.; Pfefferle, R.; Sener, B.; Stawarczyk, B. Impact of high-speed sintering on translucency, phase content, grain sizes, and flexural strength of 3Y-TZP and 4Y-TZP zirconia materials. J. Prosthet. Dent. 2019, 122, 396–403. [Google Scholar] [CrossRef]

- Lümkemann, N.; Stawarczyk, B. Impact of hydrothermal aging on the light transmittance and flexural strength of colored yttria-stabilized zirconia materials of different formulations. J. Prosthet. Dent. 2021, 125, 518–526. [Google Scholar] [CrossRef]

- Jerman, E.; Wiedenmann, F.; Eichberger, M.; Reichert, A.; Stawarczyk, B. Effect of high-speed sintering on the flexural strength of hydrothermal and thermo-mechanically aged zirconia materials. Dent. Mater. 2020, 36, 1144–1150. [Google Scholar] [CrossRef]

- Elisa Kauling, A.; Güth, J.F.; Erdelt, K.; Edelhoff, D.; Keul, C. Influence of speed sintering on the fit and fracture strength of 3-unit monolithic zirconia fixed partial dentures. J. Prosthet. Dent. 2020, 124, 380–386. [Google Scholar] [CrossRef]

- Michailova, M.; Elsayed, A.; Fabel, G.; Edelhoff, D.; Zylla, I.M.; Stawarczyk, B. Comparison between novel strength-gradient and color-gradient multilayered zirconia using conventional and high-speed sintering. J. Mech. Behav. Biomed. Mater. 2020, 111, 103977. [Google Scholar] [CrossRef]

- Ersoy, N.M.; Aydogdu, H.M.; Degirmenci, B.Ü; Çökök, N.; Sevimay, M. The effects of sintering temperature and duration on the flexural strength and grain size of zirconia. Acta. Biomater. Odontol. Scand. 2015, 1, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Inokoshi, M.; Nozaki, K.; Shimizubata, M.; Nakai, H.; Cho Too, T.D.; Minakuchi, S. Influence of high-speed sintering protocols on translucency, mechanical properties, microstructure, crystallography, and low-temperature degradation of highly translucent zriconia. Dent. Mater. 2022, 38, 451–486. [Google Scholar] [CrossRef]

- Gintaute, A.; Weber, K.; Zitzmann, N.U.; Brägger, U.; Ferrari, M.; Joda, T. A Double-Blind Crossover RCT Analyzing Technical and Clinical Performance of Monolithic ZrO2Implant Fixed Dental Prostheses (iFDP) in Three Different Digital Workflows. J. Clin. Med. 2021, 10, 2661. [Google Scholar] [CrossRef]

| Focused Question (PICO) | For the Sintering of Zirconia, is Speed and High-Speed Sintering Comparable to Conventional Sintering in Terms of Mechanical Characteristics, Quality Fit and Volume Stability, Esthetics, Pre- and Post-Processing, and Economics Related to Time-/Cost-Efficiency? | |

|---|---|---|

| Search strategy | Population | Single-unit tooth-borne and/or implant-retained zirconia restorations: #1—((dental crowns [MeSH]) OR (full crown) OR (partial crown) OR (table top)) #2—((zirconia [MeSH]) OR (ZrO2) OR (zirconium dioxide)) |

| Intervention | Speed sintered zirconia restoration #3—((speed sintering) OR (high-speed sintering)) | |

| Comparison | Conventionally sintered zirconia restorations #4—((sintering) OR (firing)) | |

| Outcome | Mechanical, clinical and economic outcomes including pre- and postprocessing #5—((mechanical properties) OR (mechanical stability) OR (flexural strength) OR (microstructure) OR (grain size) OR (translucency)) #6—((volume stability) OR (internal fit) OR (marginal fit)) #7—((clinical behavior) OR (adverse event) OR (esthetics)) #8—((economics [MeSH Terms]) OR (time-efficiency) OR (cost effectiveness) OR (cost analysis)) | |

| Search combination(s) | (#1) AND (#2) AND (#3 or #4) AND (#5 or #6 or #7 or #8) | |

| Author/ Publication Year | Journal | Study Type | Restoration [n] | Material/ Brand | Grain | Manufacturing Technique | Sintering (Sintering, Holding Time, Cooling Time) | Test Method | Control Group | Test Group | Outcome |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Soult et al., 2019 [15] | Gen Dent | In vitro | 20 | CAD/CAM blocks (CEREC Zirconia, medi S, shade A2) | 3-YTZP 0.2 to 0.8 μm | Milling unit (CEREC MC XL) | (1) high-speed furnace (CEREC SpeedFire furnace) for 26.2 min with pre-drying and proprietary firing parameters (2) conventional furnace (Programat S1 1600, Ivoclar Vivadent) for 4.3 h, dwell time: 2 h at 1510 °C | Fracture strength and modulus (3-point bending) Translucency and opalescence (spectrophotometer) | Sintering protocol 2 | Sintering protocol 1 | (1) No difference in flexural strength, flexural modulus, translucency or opalescence. (2) Smaller grain size after high-speed sintering 0.3 μm compared to conventional sintering 0.5 μm |

| Ahmed et al., 2019 [16] | J Proshtodont | In vitro | 120 | IPS e.max ZirCAD LT zirconia blanks (Ivoclar Vivadent US, Amherst NY) | 3- YTZP | 5-axis milling machine (Wield Select; IvoclarVivadent, Schaan, Liechtenstein) | 1- Conventional sintering furnace (Programat S1 Furnace; Ivoclar Vivadent US). CS: 9 h 50 min2- S: 2 h 55 min | Marginal Discrepancy (Digital Microscope) | 1–6: sintering protocol 1, 7–12: sintering protocol 2 G1/G7 (0.5 mm chamfer, 0.8 mm thick); G2/G8 (0.5 mm chamfer, 1.5 mm thick); G3/G9 (1.0 mm chamfer, 0.8 mm thick); G4/10 (1.0 mm chamfer, 1.5 mm thick); G5/G11 (1.2 mm chamfer, 0.8 mm thick); G6/G12 (1.2 mm cham- fer, 1.5 mm thick). | Significant interaction between finish line widths, crown thickness and sintering protocol on the marginal gaps in both sintering protocols | |

| Nakamura et al., 2020 [17] | J Proshtodont Res | In vitro | 28 | InCoris TZI, Dentsply Sirona and (CEREC inLab MC X5, Dentsply Sirona) | 3-YTZP | Milling machine (CEREC MC XL, Dentsply Sirona) | CS: at 1510 °C in laboratory furnace for 220 min (inFire HTC Speed, Dentsply Sirona) SS: at 1580 °C in laboratory furnace for 15 min (CEREC SpeedFire, Dentsply Sirona) | Fit (Digital microscope)Fracture load (Universal testing machine) Aging resistance (X-ray diffractometer) | Sintering protocol 1 | Sintering protocol 2 | Monolithic zirconia crowns produced by high-speed sintering showed no significant difference in the marginal gap and the fracture load after aging or occurrence of monoclinic crystals compared to conventional sintering. |

| Edwards Rezende et al., 2017 [18] | Dent Mater | In vitro | 36 | (1) Z-MAX, IPS e.max ZirCAD (Ivoclar Vivadent, Liechtenstein); (2) ZYZ, InCeram YZ (Vita Zahnfabrik, Germany); (3) ZK, Zirklein (Zirklein, Brazil)). | 3-YTZP | Milling procedure (MC XL milling machine; Sirona Dental Systems GmbH—Bensheim, Germany) | High-temperature furnace was used (Sintramat High Temperature Furnace; Ivoclar Vivadent; Liechtenstein) with a default cycle of 7 h and 52 min and a maximum temperature of 1500 °C. | Marginal and internal fit (micro-CT) Dimensional change, sintering shrinkage rate (micro-CT) | Before sintering | After sintering | No difference for marginal fit, with differences only for internal fit and between the different regions measured. The lack of uniformity of sintering shrinkage might lead to a non-uniform internal fit of Y-TZP copings. |

| Wiedenmann et al., 2020 [19] | Dent Mater | In vitro | 192 | Ceramill Zolid HT+, Amann Girrbach AG) | 3-YTZP 4-YTZP | Milling machine (Ceramill motion, Amann Girrbach AG) | Sintered at 1580 °C (high-speed sintering) or 1450 °C (control group | Fracture load with and without aging (Universal testing machine) Two body wear (3D laser scanner) | Sintering protocol 2 | Sintering protocol 1; 3 different groups with different layers (0.5, 1, 1.5 mm) | High-speed sintering resulted in less two-body wear of the zirconia and comparable or even higher fracture load results than the control group. |

| Kaizer et al., 2017 [20] | Ceram Int | In vitro | 30 | translucent Y-TZP (inCoris TZI, Sirona) | 3-YTZP | CAD/CAM-milled, sintered and glazed by Sirona | Super-speed (SS, 1580 °C, dwell time 10 min), Speed (S, 1510 °C, dwell time 25 min), and Long-term (LT, 1510 °C, dwell time 120 min). | - Microstructure (wear depth and volume loss for the steatite antagonists on 3D images of micro computed tomography scanner) - Wear (sliding wear testing using a chewing simulator) - Translucency (colorimeter (SpectroShadeTMMicro, MHT Optic Research AG, Switzerland) | 3 Sintering protocols | Micropits in the wear crater were less frequent for the LT group. Groups S and SS exhibited more surface pits, scratched steatite surface and a greater volume loss. Tetragonal to monoclinic phase transformation, resulting from the sliding wear process, was present in all three groups. | |

| Cokic et al., 2020 [21] | Dent Mater | In vitro | 64 | Katana STMLCS, STMLSS (Kuraray Noritake) CEREC Zirconia (CEREC ZrS) (Dentsply Sirona) inCoris TZICS | 5-YTZP 3-YTZP 3-YTZP | Plates with dimensions of approximate 15 × 15 × 3.5 mm | Katana STMLSS (Kuraray Noritake) (total thermal cycle/sintering time/dwell temperature: 30 min/16 min/1560 °C) and CEREC Zirconia (CEREC ZrSS) (Dentsply Sirona) (15 min/2 min/1578 °C) were compared to conventionally sintered (CS) Katana STMLCS (6.8 h/2 h/1550 °C) and inCoris TZICS (4 h/2 h/1510 °C). | Translucency parameter and contrast ratio (spectrophotometer) Chemical composition (X-ray fluorescence spectroscopy) and phase composition (X-ray diffraction). Hydrothermal aging behavior (XRD) The indentation fracture toughness, Vickers hardness and biaxial strength of the sintered ceramics were assessed (Vickers micro-hardness tester, Universal testing machine). | 2 Groups (CS) | 2 Groups (S) | SS and CS zirconia revealed similar density, microstructure, average strength and hydrothermal aging stability. Both Katana STMLSS/CS 5Y-PSZ ceramics were characterized with a higher content of cubic phase (≈53 wt%), resulting in higher amount of Y2O3 in the remaining tetragonal ZrO2 phases compared to the 3Y-TZP CEREC ZrSS and inCoris TZICS (8 and 20 wt%, respectively). The sintering program did not affect the hydrothermal aging behavior of Katana STMLSS and CEREC ZrSS. TP of Katana STMLSS (TP ≈ 32) was not affected by speed sintering, while the translucency of CEREC ZrSS (TP = 14) was significantly reduced. Hardness, fracture toughness and Weibull characteristic strength of Katana STMLSS and CEREC ZrSS also reached the optimal level, but speed sintering substantially lowered their mechanical reliability. |

| Al-Zordk et al., 2020 [22] | J Prosthet Dent | In vitro | 80 | 4 zirconia brands (Zolid FX Preshaded, Zolid FX White, DD Cubex2, and DD Bio ZX2) | 3-Y-TZP | Milled from A2 pre-shaded blanks except for Zolid FX White disks which were milled from white blanks with subsequent immersion in A2 coloring liquid | Sintering time/dwell temperature: Zolid FX (120 min/1450 °C)Zolid FX White (120 min/1450 °C) DD Cubex2 (60 min/1450 °C)DD Bio ZX2 (50 min/1450 °C) | Color stability, contrast ratio and the translucency parameter after coffee thermocycling (reflectance spectrophotometer) | 4 Groups (CS) | 4 Groups (S) | The color and the translucency of the translucent zirconia can be affected by the type of the zirconia brand and the sintering protocol. Furthermore, the color and the translucency were affected by both the clinical adjustment procedure and the coffee thermocycling, but not beyond the clinically acceptable limit of the color difference. |

| Lawson et al., 2020 [23] | J Esthet Restor Dent | In vitro | 40 | (Katana STML Block, Prettau Ante- rior, and Zpex Smile) lithium disilicate material (IPS e.max CAD) | 3-YTZP 5-YTZP 5-YTZP | Katana STML Block and Prettau Anterior (dry sectioned and dry polished). Specimens of Zpex Smile were fabricated by obtaining pure powders and pressing into molds. IPS e.max CAD (wet sectioned and wet polished) | Conventional (7 h) or high-speed (18 or 30 min in a SpeedFire furnace) sintering | - Translucency (Color-i7spectrophotometer); - Flexural strength (3-point bending test) - Grain structure (SEM) | lithium disilicate material | Katana STML, Prettau Anterior, and Zpex Smile | - Significant differences between materials for flexural strength, translucency parameter and grain size (p < 0.001). Grains became significantly larger, and pores were present when two of the zirconia materials (Prettau Anterior and Zpex Smile) were sintered with a high-speed sintering program. - Two of the zirconia materials (Prettau Anterior and Zpex Smile) became less translucent and less strong using a high-speed sintering program, whereas another (Katana STML Block) was unaffected. |

| Jansen et al., 2019 [24] | J Prosthet Dent | In vitro | 450 | Ceramill ZI Zolid (ZD) Zolid HT+ | 3-YTZP3-YTZP4-YTZP | 5 thicknesses (1.0, 1.5, 2.0, 2.5, and 3.0 mm); milled (Ceramill Motion 2; Amann Girrbach AG) | Final temperature 1570 °C and 1590 °C and a reference sintering protocol (1450 °C) | monoclinic phase content (Raman spectrometry) translucency (UV-Vis spectrophotometer) Biaxial flexural strength (Universal testing machine) | Conventional sintering protocol | Speed sintering protocol | For ZI, the sintering protocols did not affect the translucency or biaxial flexural strength. ZD and HT+ showed significantly lower translucency for high-speed sintering protocols (p 0.001), but the biaxial flexural strength remained the same after the high-speed sintering protocol at 1590 °C. Grain sizes increased with increasing final sintering temperature for ZI and HT+, whereas translucency generally decreased with increasing material thickness. No monoclinic phase was detected in any group. The flexural strength was maintained with high-speed sintering but led to a decrease in translucency for ZD and HT+. |

| Lümkemann et al., 2021 [25] | J Prosthet Dent | In vitro | 210 | 3Y-TZP0.25 (n = 30), 3Y-TZP0.05 (n = 30), 5Y-TZP (n = 30), 4Y-TZP (n = 60), pre4Y-TZP (preshaded, n = 30), and LiSi2 (n = 30) | 3Y-TZP 3Y-TZP 5Y-TZP 4Y-TZP 4Y-TZP | Milled (Ceramill Match 2/Ceramill Motion 2; Amann Girrbach AG) | Conventionally sintered at 1450 °C (3Y-TZP0.25, 3Y-TZP0.05, 5Y-TZP, and half of 4Y-TZP) or high-speed sintered at 1580 °C (the other half of 4Y-TZP and pre4Y-TZP) | Translucency (UV/Vis spectrophotometer) flexural strength (Universal testing machine) | Conventional sintering protocol | Speed sintering protocol | The decrease in translucency related to aging hours was higher for LiS2 and conventional sintered zirconia materials than for 4Y-TZPspeed and pre4Y-TZPspeed. Initially, 3Y-TZP0.25 had the highest flexural strength, followed by 3Y-TZP0.05, 4Y-TZP and pre4Y-TZPspeed. pre4Y-TZPspeed was comparable with 4Y-TZPspeed but significantly higher than 5Y-TZP. LiSi2 had the lowest biaxial flexural strength. Hydrothermal aging increased biaxial flexural strength for 3Y-TZP0.25 and 3Y-TZP0.05 but decreased it for 5Y-TZP and pre4Y-TZPspeed. After aging, 4Y-TZPspeed showed comparable values of flexural strength with 4Y-TZP and higher values than pre4Y-TZPspeed after aging. Manually colored, conventionally sintered 4Y-TZP was resistant to hydrothermal aging regarding flexural strength. High-speed sintering inhibited color development for manually colored 4Y-TZP but did not affect the resistance to hydrothermal aging. The findings were reversed for industrially pre-shaded 4Y-TZP. |

| Jerman et al., 2020 [26] | Dent Mater | In vitro | 288 | (ZI Zolid; Zolid HT+; Amann Girrbach AG) | 3-YTZP4-YTZP | Milled using a five-axis milling machine (Ceramill Motion 2, Amann Girrbach, Koblach, Austria) | High-speed sintering protocol (final temperature 1580 °C) or a conventional sintering protocol (control group, final temperature 1450 °C) | flexural strength (Universal testing machine) | Conventional sintering protocol | Speed sintering protocol | ZI showed the highest and HT+ the lowest FS, regardless of the sintering protocols and aging regimens. High-speed sintered HT+ showed higher initial FS than the control group. ZI and Zolid showed higher FS after thermo-mechanical aging. High-speed sintered HT+ showed higher FS in the initial stage. |

| Elisa Kauling et al., 2020 [27] | J Prosthet Dent | In vitro | 48 | zirconia blocks (CEREC Zirconia Medi S A2, Lot 2016219456; Dentsply Sirona), | 3-YTZP | 3-unit FDPSs milled (MCXL Premium; CEREC Zirconia; Dentsply Sirona) | Speed sintering (group S) by using the SpeedFire (Dentsply Sirona) for 25 min and the conventional sintering (group C) by using the inFire HTC speed (Dentsply Sirona) for 4 h | Fit (image analysis software pro- gram (Optimas 6.5 version 6.51–1999; Media Cybernetics) Fracture load (Universal testing machine) | Conventional sintering protocol | Speed sintering protocol | - Group S showed a better marginal and occlusal fit than group C. For the fracture load values, no significant difference was found because of the sintering procedure or the interaction of the sintering procedure and artificial aging. - Speed-sintered FPDs had equal and better values for the fit and fracture load than conventional sintering. |

| Michailova et al., 2020 [28] | J Mech Behav Biomed Mater | In vitro | 96 | Katana Zirconia STML Block (KZC), Katana Zirconia STML Disc (KZL) and IPS e. max ZirCAD Prime (EZL). Lithium disilicate ceramic (IPS e. max Press, ELC) | KZC and KZL: 4Y-TZP EZL: 3&5Y-TZP | Milled (Ceramill Motion2, Amann Girrbach, Koblach, Austria) milled (CEREC MCXL, Dentsply Sirona) | Sintered according to the manufacturer’s instructions (Nabertherm, Lilienthal, Germany) at 1550 °C (KZL) and 1500 °C (EZL). KZC crowns were high-speed sintered at 1560 °C for 19 min (CEREC SpeedFire, Dentsply Sirona). ELC crowns were crystallized according to the manufacturer instructions at 840 °C (Programat EP 5000, Ivoclar Vivadent, Schaan, Liechtenstein). | Translucency (UV/Vis spectrophotometer) Fracture load (Universal testing machine) | (ELC). | KZL, KZC, EZL | The high-speed sintering of zirconia showed neither a negative impact on the fracture load nor on the two-body wear. However, the optical properties and the reliability of zirconia is lower than those of highly translucent lithium disilicate ceramic. |

| Ersoy et al., 2015 [29] | Acta Biomater Odontol Scand | In vitro | 120 | (In-Coris ZI, In-Coris TZI) | 3 Y-TZP | Cut using a low-speed diamond saw | Three groups and sintered at different final sintering temperatures and for various durations: CS) 1510 ° C for 120 min, S) 1540 °C for 25 min and SS) 1580 °C for 10 min. | Grain sizes (scanning electron microscopy (SEM)) phase transitions (X-ray diffraction (XRD)) Flexural strength (Universal testing machine) | Conventional sintering protocol | Speed sintering protocol | The highest flexural strength was observed in ZI and TZI samples sintered (SS). The differences between the ZI samples sintered at CS and those sintered at S were statistically insignificant. Also, TZI samples sintered at CS and those sintered at S also did not show any statistically significant differences. There were no visible differences in the grain sizes between the ZI and TZI specimens. The XRD patterns indicated similar crystalline structure for both materials subjected to the three different procedures. The results of this study showed that experimented high sintering temperature and short sintering time combination increases the flexural strength of zirconia. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Haj Husain, N.; Özcan, M.; Dydyk, N.; Joda, T. Conventional, Speed Sintering and High-Speed Sintering of Zirconia: A Systematic Review of the Current Status of Applications in Dentistry with a Focus on Precision, Mechanical and Optical Parameters. J. Clin. Med. 2022, 11, 4892. https://doi.org/10.3390/jcm11164892

Al-Haj Husain N, Özcan M, Dydyk N, Joda T. Conventional, Speed Sintering and High-Speed Sintering of Zirconia: A Systematic Review of the Current Status of Applications in Dentistry with a Focus on Precision, Mechanical and Optical Parameters. Journal of Clinical Medicine. 2022; 11(16):4892. https://doi.org/10.3390/jcm11164892

Chicago/Turabian StyleAl-Haj Husain, Nadin, Mutlu Özcan, Nataliya Dydyk, and Tim Joda. 2022. "Conventional, Speed Sintering and High-Speed Sintering of Zirconia: A Systematic Review of the Current Status of Applications in Dentistry with a Focus on Precision, Mechanical and Optical Parameters" Journal of Clinical Medicine 11, no. 16: 4892. https://doi.org/10.3390/jcm11164892

APA StyleAl-Haj Husain, N., Özcan, M., Dydyk, N., & Joda, T. (2022). Conventional, Speed Sintering and High-Speed Sintering of Zirconia: A Systematic Review of the Current Status of Applications in Dentistry with a Focus on Precision, Mechanical and Optical Parameters. Journal of Clinical Medicine, 11(16), 4892. https://doi.org/10.3390/jcm11164892