The steady-state condition of the system was achieved using both distilled water and glucose syrup for about 1 h. The permeate fluxes were reported after this time. An

L9 orthogonal array (four variables in three levels) was offered by Taguchi design methodology.

Table 3 represents the experimental variables and their levels. Each row represents a specific experiment.

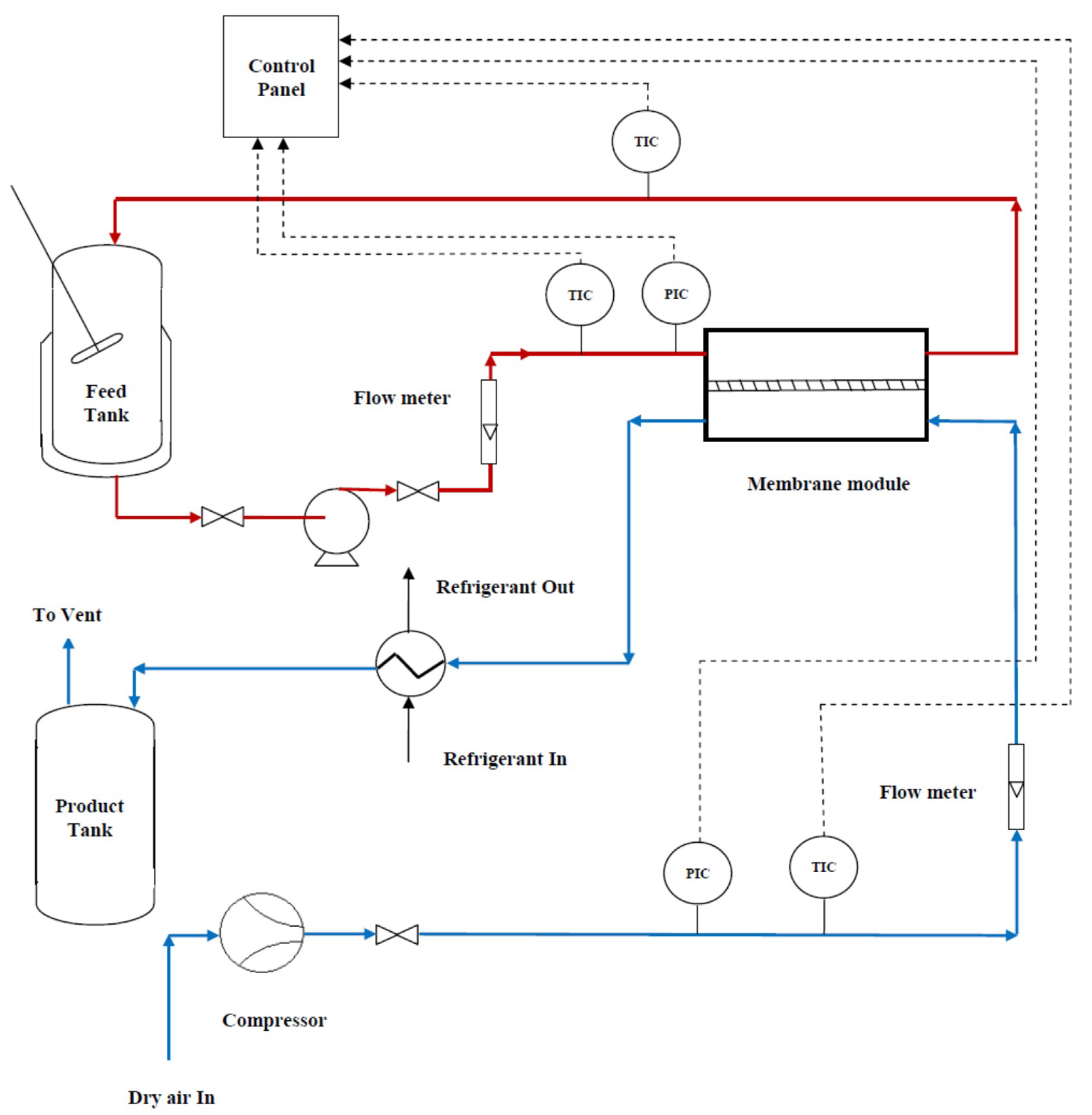

Figure 3a–d shows the main effect of the operating variables on the permeate flux.

3.1. Main Effects of the Operating Parameters

In this work, the effect of investigated operating parameter of the SGMD process on the permeate flux at different levels (see

Table 3) were plotted, separately. This is due to the experimental design which was orthogonal.

Figure 3 shows the response value for each level.

Feed temperature (°C) was investigated as the first operating variable. This was due to the nature of the SGMD process which is a non-isothermal separation process. In the SGMD process, the driving force is a function of the temperature difference (Δ

T) between the two sides of the membrane pores [

19]. As can be observed in

Figure 3a, increasing the feed temperature increases the permeate flux, considerably. This can be attributed to the higher vapor pressure in the higher feed temperature. Due to the exponential behavior of the temperature versus the vapor pressure, increasing the feed temperature from 55 to 65 °C proved to have a greater effect than raising it from 45 to 55 °C (see

Table 4). It is worth noting that when further increasing the vapor pressure in higher operating temperatures, both the temperature and concentration polarizations increased [

20]. Moreover, higher feed temperature can lead to higher heat conduction through the membrane; however, this can be highlighted even more in the DCMD process. Hence, higher temperatures cannot necessarily lead to higher permeate fluxes. Moreover, the results presented in

Table 4 indicate that there are some interactions among investigated variables. Therefore, the response of each parameter versus the others should be constructed.

Furthermore, the Millard reaction, which is one the major draw-backs in sugar processing [

21], is more probable at higher temperatures; hence, the 65 °C was the maximum investigated value for the operating temperature. Moreover, it should be noted that the energy consumption needed to increase the temperature at lower feed temperatures (from 45 to 55 °C in this work) is higher [

22,

23]; therefore, based on the available energy resource, 65 °C was suggested as the most sufficient operating temperature for concentrating the glucose syrup.

As stated before, the SGMD process is a vapor pressure driven separation. The temperature difference imposes the driving force between the two sides of the membrane, including the feed channel (where the hot feed re-circulates in direct contact with the membrane active layer) and the permeate channel (where vaporization of liquid molecules were carried out when they crossed the membrane pores). Therefore, if the feed flow rate increases too much, the heat transfer between hot feed and cold air will also increase. This means the feed temperature decreases and the temperature of the sweeping air increases [

24]. Consequently, this can cause a reduction in the permeate flux [

25], and this is also experimentally confirmed in this work (see

Figure 3b). As most SGMD experiments carried out using hydrophobic porous membranes were specifically manufactured for microfiltration (MF) applications, designing and developing specific membranes for SGMD applications can solve this draw-back. Although less membrane fouling is expected by using higher feed flow rates, it may decrease the permeate flux, as is shown in

Figure 3. This also can be explained by the fact that higher feed flow rates under the constant feed channel depth needs higher inlet pressure. This higher inlet pressure can be translated to the fact of higher pore wetting risk, which consequently can lead to permeate flux decline.

In general, high concentration of solute in the feed stream has an almost negative effect on membrane separations due to the increase in the concentration polarization [

26] and vapor pressure reduction (due to the reduction of water activity in aqueous solutions [

27]) in MD process. Like other membrane separations, the SGMD process is also sensitive to the concentration polarization, as discussed in the literature [

19]. Although this sensitivity is less in the case of the SGMD process; however, the effect of feed concentration on the permeate flux should be studied. As observed in the results of the present work, with increasing the feed concentration, the permeate flux decreases, slightly. This can be attributed to the vapor pressure decline with increasing the glucose concentration in the feed stream. Moreover, higher feed concentration can highlight the effect of the concentration polarization layer (see

Figure 3c). It should be noted that one of the most important advantages of the SGMD process in comparison with other membrane separations, which use pressure difference for concentrating sugar syrups, such as the ultrafiltration (UF) and reverse osmosis (RO) process [

26], is that the MD process is not sensitive to osmotic pressure limitations. Even though the flux reduction at higher feed concentrations occurs, the MD process can be used for dewatering of the highly concentrated sugar syrups.

Figure 3c presents the effect of feed concentration of the target parameter, i.e., the permeate flux.

Figure 3d shows the main effect of the sweeping gas (SG) flow rate on the permeate flux. As can be seen, the SG flow rate can affect the permeate flux, significantly. The higher the sweeping gas flow rates, the higher the fluxes achieved (see

Figure 3d). This could be explained as follow. Higher SG flow rate can lead to the vapor pressure reductions in the cold stream (permeate side), which can impose higher mass transfer (larger driving force). Moreover, increasing the SG flow rates can significantly decrease the temperature polarization effect in the cold stream of the MD module. As in the SGMD process, there is no pore wetting risk from the permeate side, the SG flow rate can be as high as possible. However, based on the obtained results it can be recommended that the gas inlet pressure should be lower than that of the hot stream inlet pressure.

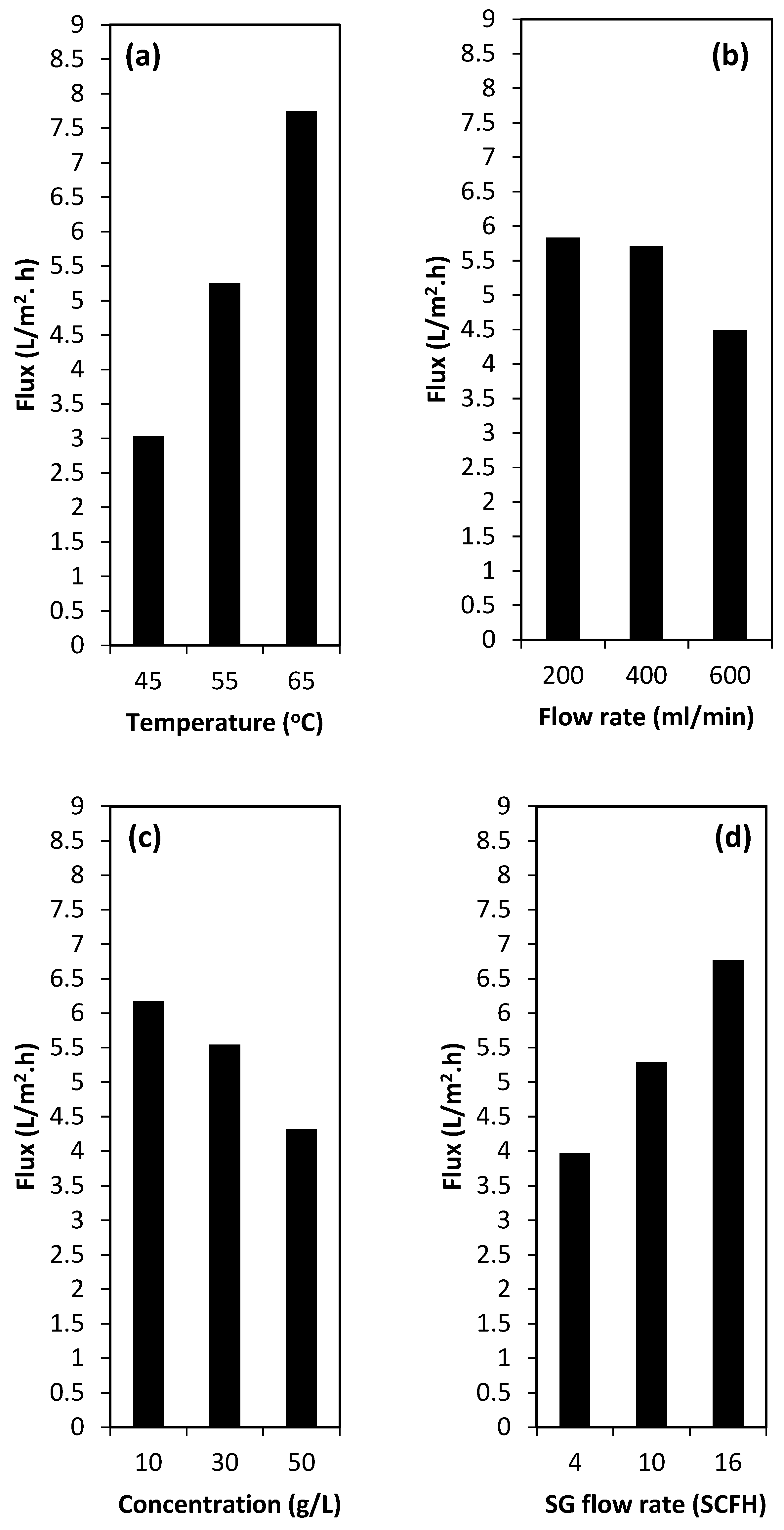

3.2. Interactions of Variables

The experimental results indicated that there are some interactions between the parameters. To identify the interaction between the parameters, the response of each parameter against the others should be plotted [

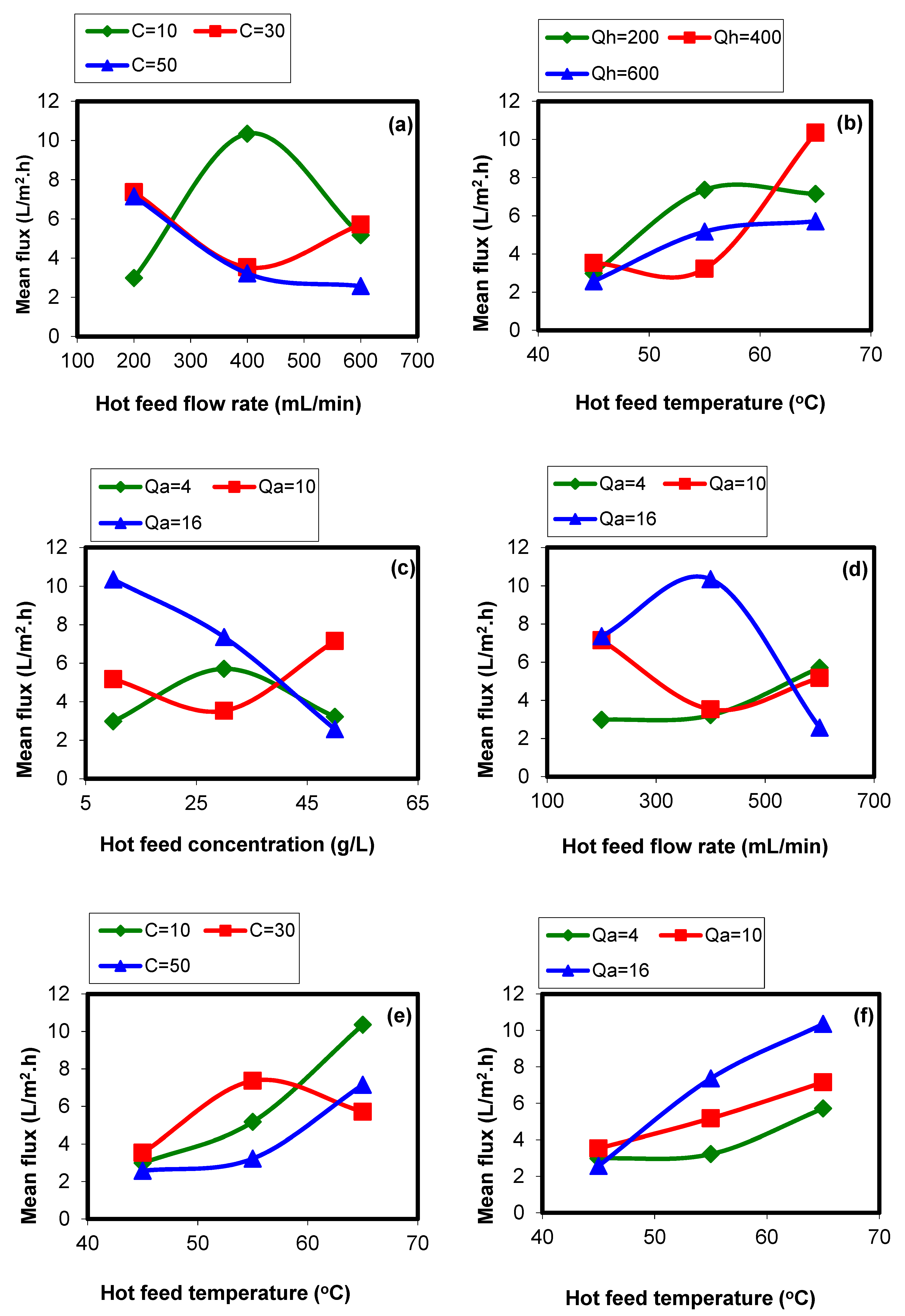

27]. The results of interactions are shown in

Figure 4. As could be observed, the regions in which there are interactions are illustrated. In each graph in which the lines with different colors (three level for each parameter) cross each other there is an interaction between the parameters.

These interactions are the result of the polarization phenomena in the system. Moreover, the module design can significantly affect the interaction among operating variables. In this work, a plate and frame module with 130 × 130 mm2 dimensions was used for the SGMD experiments. In some cases, the investigated geometry can make these interactions severer, especially when the DCMD configuration is used because the both sides are in direct contact with the process liquids (temperature polarization is probable in both feed and permeate sides). However, for the SGMD configuration, a lower temperature polarization effect is expected on the permeate side, while the negative effect on the feed side can still exist.

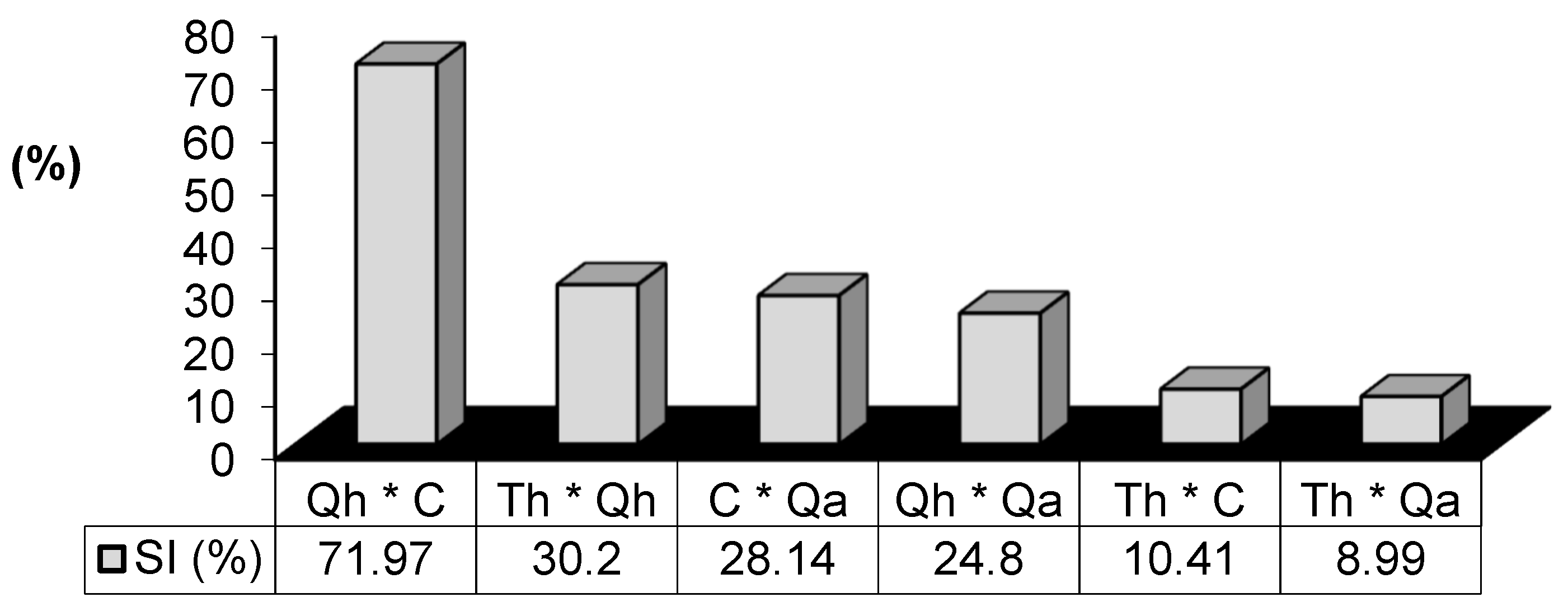

(Th: feed temperature, Qh: feed flow rate, C: feed concentration, and Qa: sweeping gas flow rate).

The results of the interaction study (see

Figure 4) show that the higher interaction level was observed for

Qh (feed flow rate) and

C (feed concentration) with the severity index (SI) of 71.97%. This can be attributed to the effects of concentration polarization, temperature polarization, and heat loss through the membrane body (the thermal conduction). It can be concluded that the

Qh and

C had almost the same effect on the system response (permeate flux). Based on the obtained results, low feed flow rate, and high feed concentration, both can intensify the effect of concentration and temperature polarizations, as well as conductive heat loss through the membrane’s body. The interaction between

Th (feed temperature) and

Qh with the severity index of 30.2% is also the result of the temperature polarization. This is true for the other interactions.

On the other hand, the minimum interaction imposes between the feed temperature and the SG flow rate (SI = 8.99%). The feed temperature imposes its effect in the feed channel while the SG flow rate affects the permeate side and these regions are separated by the applied membrane. However, both of these parameters are effective on the permeate flux, separately.

3.3. Analysis of Variance (ANOVA)

Using the analysis of variance (ANOVA), the effect of operating parameters on the permeate flux can be investigated, significantly. This is followed up by separating the total variability of each level. This is measured by the sum of the squared (

S) deviations from the total mean of the responses, into contribution by each SGMD process parameter and the error [

28]. In addition, the importance of SGMD process parameters can be evaluated by the percentage contribution by each of the process parameters in the total sum of the squared deviations.

According to the ANOVA result for the operating parameters of the SGMD process the most significant operating variable(s) affecting the performance characteristic (i.e., the permeate flux as the target parameter in this work) can be investigated. The ANOVA results, which have been shown in

Table 5 indicate that the feed temperature and the feed flow rate are the most and the least significant operating variables due to their higher and lower percentages of contribution (62.14% and 6.11%, respectively). As could be observed, the degree of freedom (DOF) for all variables is 2 and

F-ratio is zero, based on the obtained results and experimental design in this study.

Moreover, based on the pool-factor analysis, all studied operating variables were effective. The error for these experiments was very low which indicates the accuracy of the performed tests and obtained experimental results.

3.4. Taguchi Model Validation

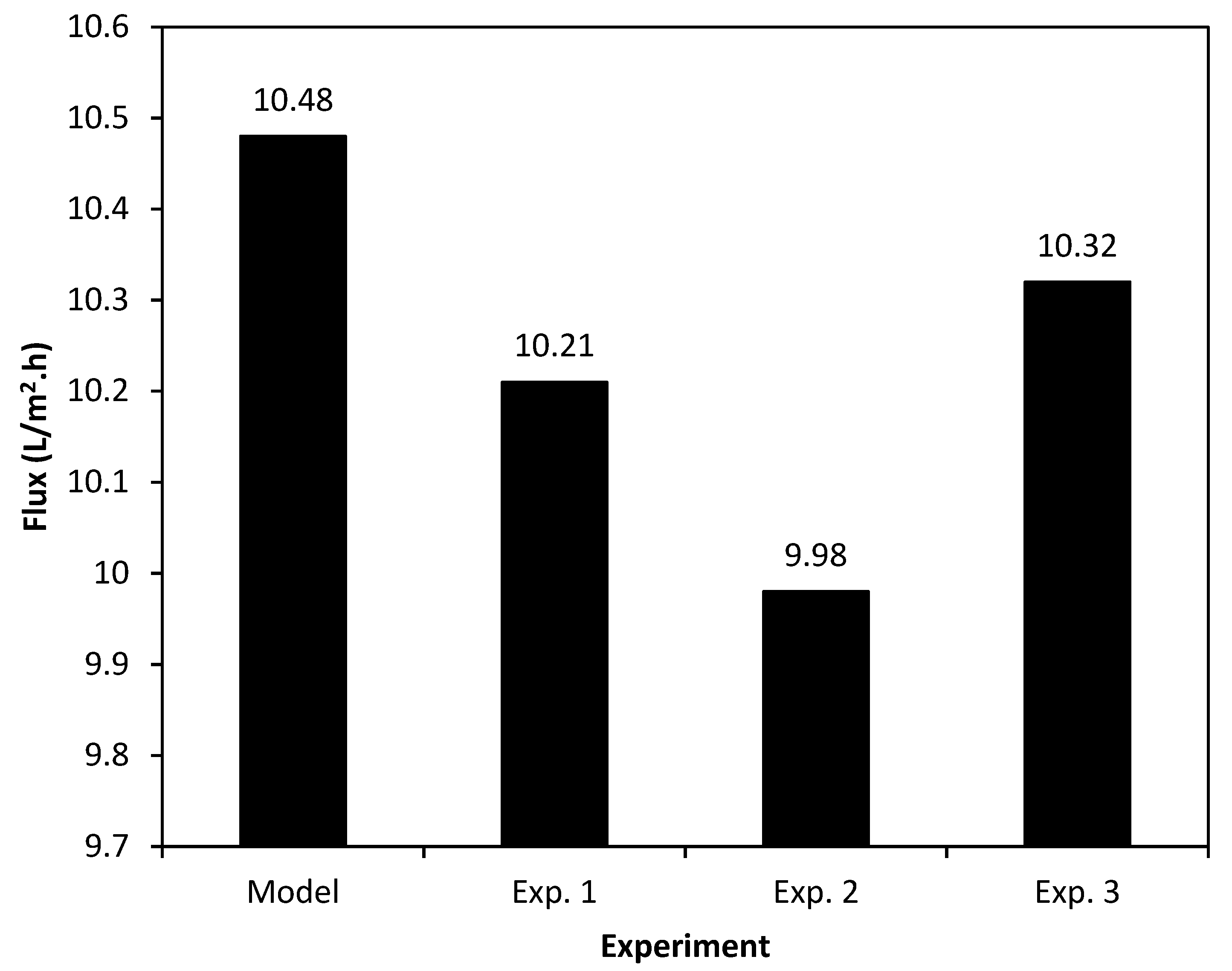

The optimum operating conditions can be predicted using the Taguchi method after analyzing the proposed experimental results. Moreover, it reports the expected target parameter, i.e., permeate flux, at the proposed optimum operating conditions.

Table 6 shows the results of this work. According to Taguchi method, the best combination of the SGMD process parameters is

A3B1C1D3. Using this combination of the operating parameters, the highest permeate flux will be attainable. The

A3B1C1D3 refers to feed temperature of 65 °C, feed flow rate of 200 ml/min, sugar concentration of 10 g/l, and SG flow rate of 16 SCFH, respectively. The predicted permeate flux under the proposed conditions was measured at 10.48 L/m

2·h. In order to assure the validity of the prediction of the Taguchi model, three individual experiments were carried out using the

A3B1C1D3 experimental conditions in different times.

Figure 5 shows the results of the Taguchi analysis prediction and the conducted experiments. Although a good agreement between the Taguchi prediction and the conducted experimental results can be observed (see

Figure 5), the obtained experimental permeate fluxes were slightly lower than that of the Taguchi prediction. Under the real operating conditions and at different test times there were some noises from the environment, such as humidity and temperature variation which can affect the permeate flux. These noses were investigated by the Taguchi method. That is why the predicted permeate flux was slightly higher than that of the test results.

Furthermore,

Table 7 shows the final concentrations and separation percentages for each experiment after 3 h of operations.

3.5. SGMD Performance Evaluation

The results of experiments including the separation factor (%

S) and the obtained flux (L·m

−2·h

−1) for each test are summarized in

Table 3. As can be observed, the lowest and the highest separation factors were achieved for the lowest glucose concentration in the feed (10 g/L), i.e., 25.25% (test 1) and 82.95% (test 8), respectively. The results confirm that the feed temperature was the most effective operating parameter. This is in good agreement with the literature [

29,

30,

31,

32]. The highest investigated operating temperature in this study was 65 °C. This temperature was not only in the safe range for processing the sugar syrup (due to thermal sensitivity of the glucose), but was also achieved by using the waste heat in the industrial sectors or by solar heating. The ability of coupling waste heat or solar energy is one of the most important advantages of all MD configurations. Moreover, the 99% solute rejection was achieved for experimental tests in this study.

Table 7 compares the results of this work and the results of the literature. It should be noted that the some of these studies have used the sucrose syrup as the feed sample. Among the MD configurations, the DCMD is the most investigated one for different applications, specifically desalination [

32]. However, due to the presence of process liquids in both the feed and permeate channels, the pore wetting risk is considerable [

33]. The same concern is attributed to the VMD process, while this configuration is more practical for removing volatile components. On the other hand, the obtained permeate flux using the AGMD process was not high enough for the concentration of the sugar syrup (see

Table 7). However, in the SGMD process, only one side of the applied membrane was in direct contact with the process liquid, i.e., in the feed channel. This can considerably lower the pore wetting risk, and consequently make the SGMD process a promising alternative for separations in which the permeance is not the target product. Comparing the results of published data from the literature for concentrating different sugar syrups can also confirm this conclusion. As can be observed in

Table 7, the permeate flux of the SGMD configuration was more affordable compared with the other MD configurations.