Performance Evaluation of a Thermophilic Anaerobic Membrane Bioreactor for Palm Oil Wastewater Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of POME

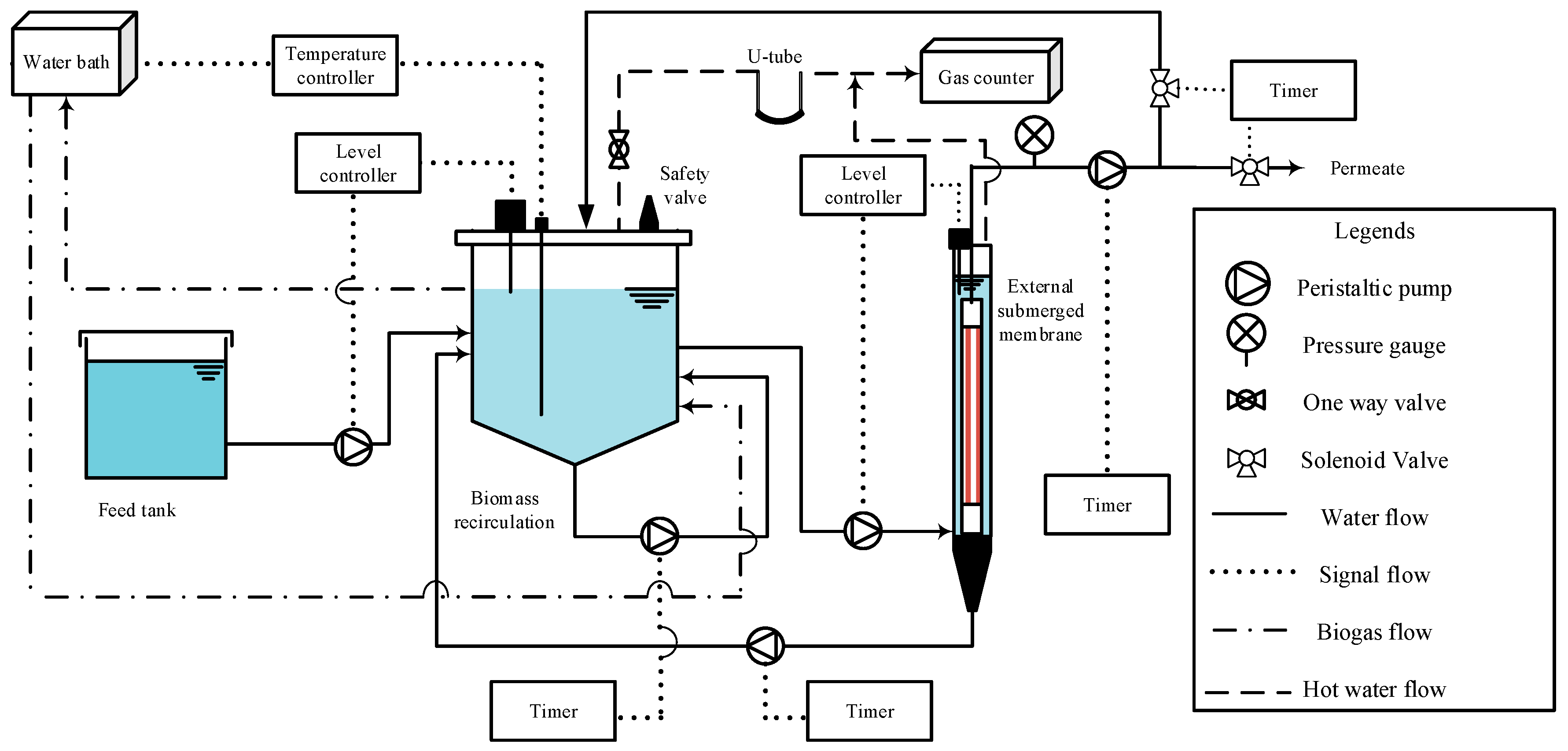

2.2. Reactor Configuration and Process Flow

2.3. Analytical Methods

3. Results and Discussion

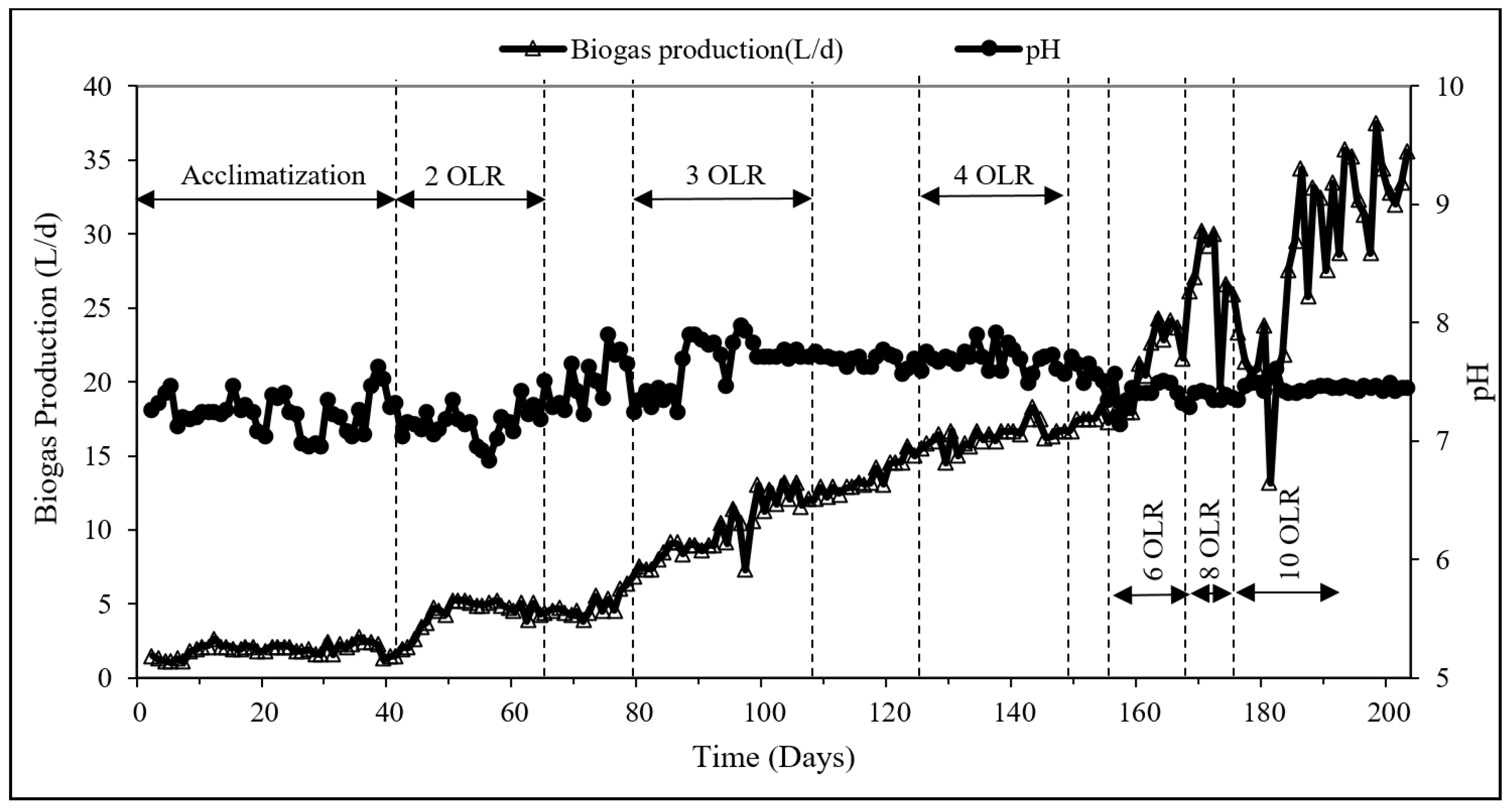

3.1. TAnMBR Start-up Phase

3.2. Performance Evaluation of the TAnMBR during Operational Period

3.2.1. Biogas Production Rate in TAnMBR

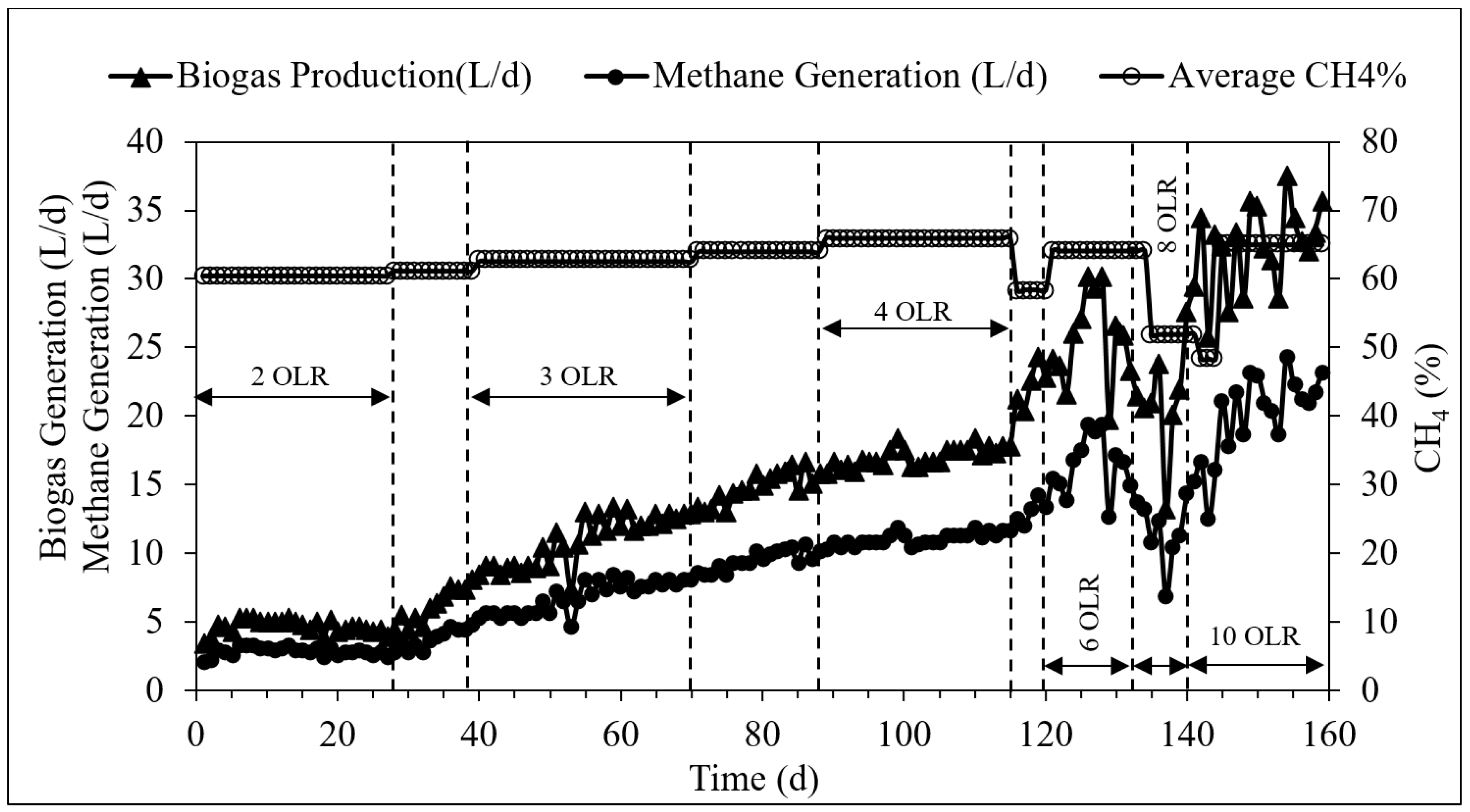

3.2.2. Biogas Composition

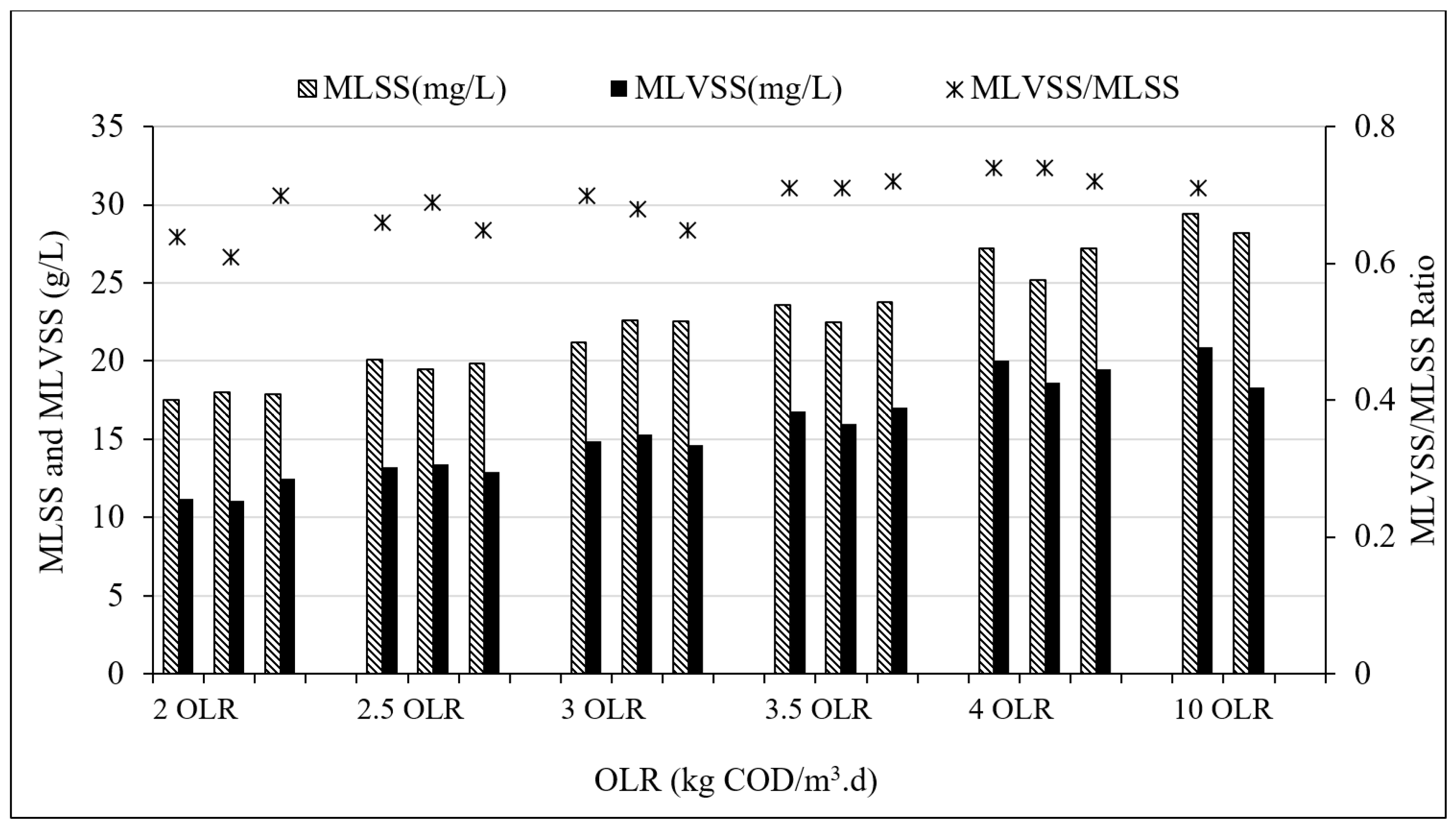

3.2.3. MLSS and MLVSS

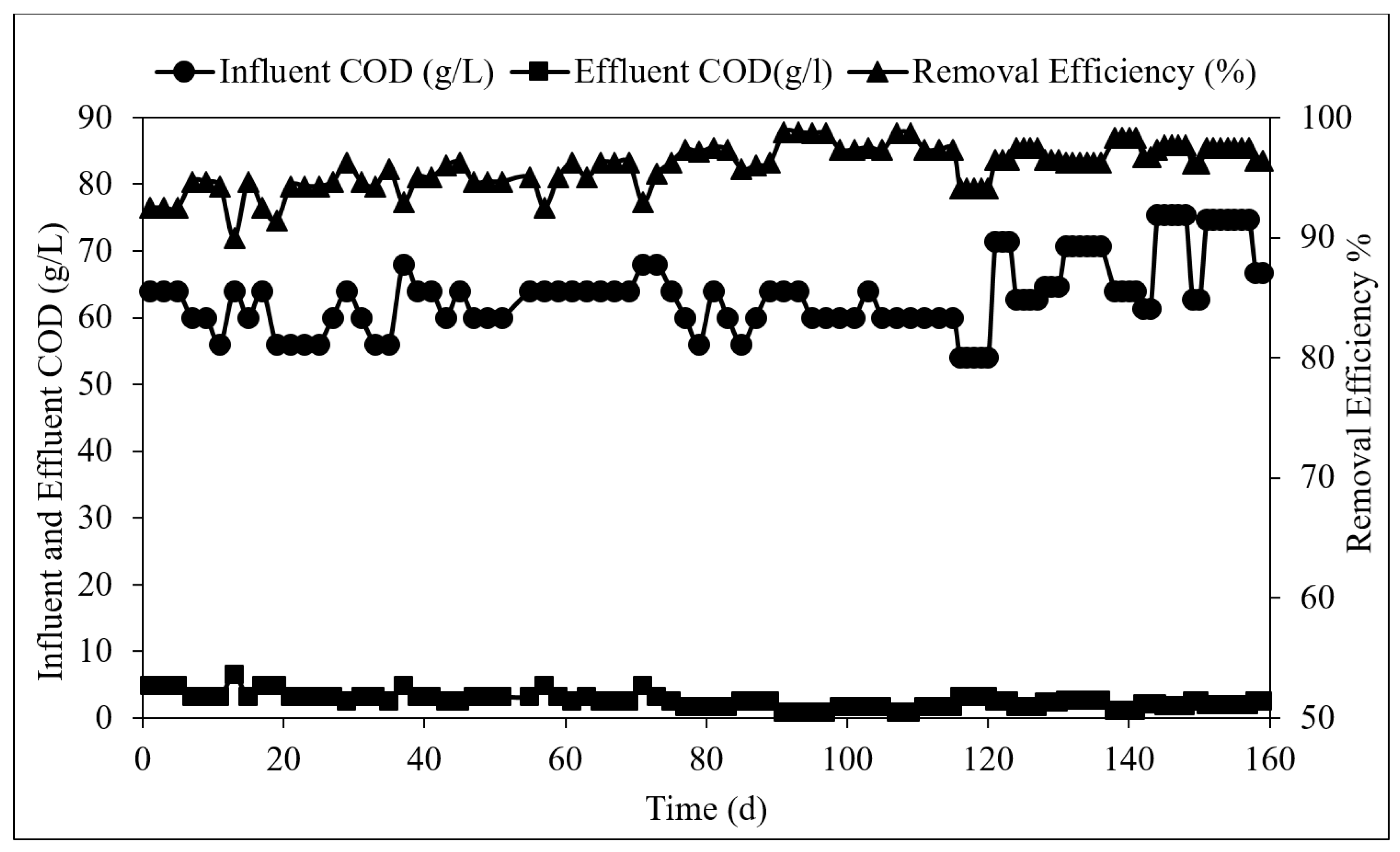

3.2.4. COD Removal and Methanogenic Activity

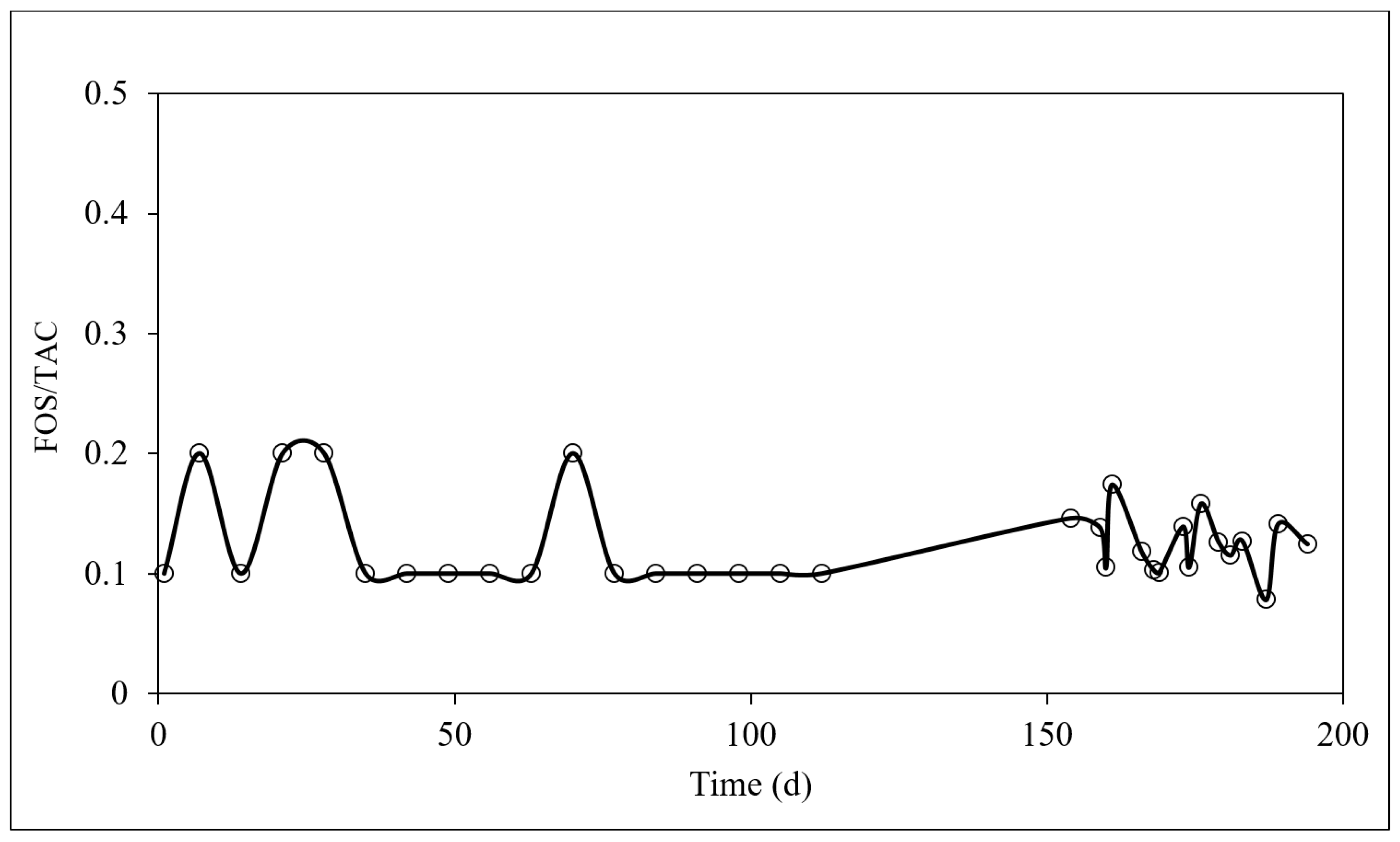

3.2.5. FOS/TAC and pH

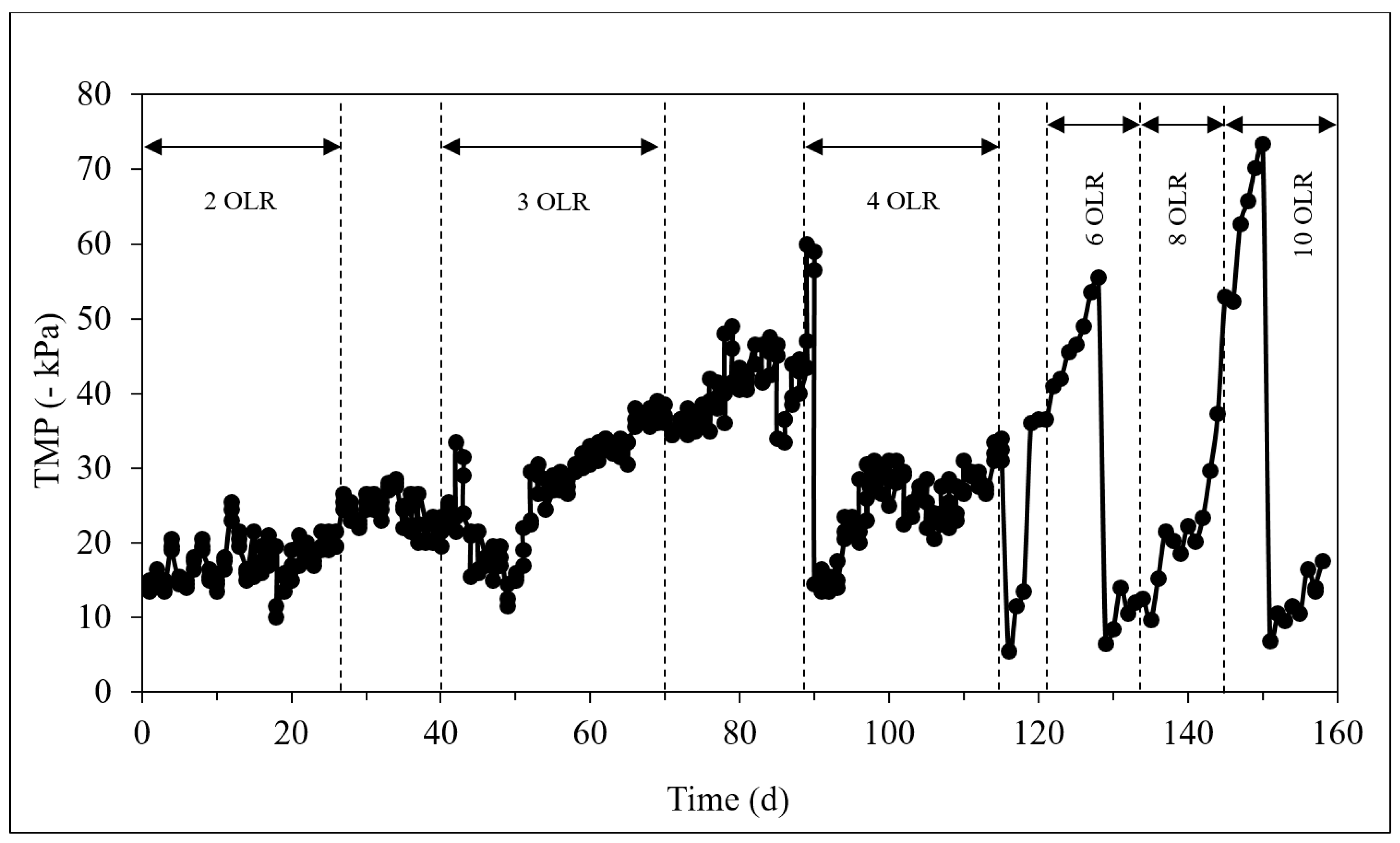

3.3. Membrane Performance and Fouling

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, J.; Mahmood, Q.; Qiu, J.P.; Li, Y.S.; Chang, Y.S.; Li, X.D. Anaerobic treatment of palm oil mill effluent in pilot-scale anaerobic EGSB reactor. Biomed. Res. Int. 2015, 2015, 398028. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, K.T. Renewable and sustainable bioenergies production from palm oil mill effluent (POME): Win–win strategies toward better environmental protection. Biotechnol. Adv. 2011, 29, 124–141. [Google Scholar] [CrossRef] [PubMed]

- Ma, A.N. Environmental management for the palm oil industry. Palm Oil Dev. 2000, 30, 1–10. [Google Scholar]

- Choi, W.; Shin, C.; Son, S.; Ghorpade, P.A.; Kim, J.; Park, J. Anaerobic treatment of palm oil mill effluent using combined high-rate anaerobic reactors. Bioresour. Technol. 2013, 141, 138–144. [Google Scholar] [CrossRef] [PubMed]

- Khanal, S.K. Anaerobic Biotechnology for Bioenergy Production: Principles and Applications; Wiley & Sons, Inc.: New York, NY, USA, 2008. [Google Scholar]

- Jeong, J.Y.; Son, S.M.; Pyon, J.H.; Park, J.Y. Performance comparison between mesophilic and thermophilic anaerobic reactors for treatment of palm oil mill effluent. Bioresour. Technol. 2014, 165, 122–128. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Ahmad, A.; Ghufran, R.; Wahid, Z.A. Bioenergy from anaerobic degradation of lipids in palm oil mill effluent. Rev. Environ. Sci. Biotechnol. 2011, 10, 353–376. [Google Scholar] [CrossRef]

- Comte, I.; Colin, F.; Whalen, J.K.; Grünberger, O.; Caliman, J.P. Agricultural Practices in Oil Palm Plantations and Their Impact on Hydrological Changes, Nutrient Fluxes and Water Quality in Indonesia. A Review; Elsevier Ltd.: New York, NY, USA, 2012; Volume 116, ISBN 9780123942777. [Google Scholar]

- Chan, Y.J.; Chong, M.F.; Law, C.L. An integrated anaerobic-aerobic bioreactor (IAAB) for the treatment of palm oil mill effluent (POME): Start-up and steady state performance. Process. Biochem. 2012, 47, 485–495. [Google Scholar] [CrossRef]

- Usack, J.G.; Spirito, C.M.; Angenent, L.T. Continuously-stirred anaerobic digester to convert organic wastes into biogas: System setup and basic operation. J. Vis. Exp. 2012, 65, e3978. [Google Scholar] [CrossRef] [PubMed]

- Achilli, A.; Marchand, E.A.; Childress, A.E. A performance evaluation of three membrane bioreactor systems: Aerobic, anaerobic, and attached-growth. Water Sci. Technol. 2011, 63, 2999–3005. [Google Scholar] [CrossRef]

- Xia, T.; Gao, X.; Wang, C.; Xu, X.; Zhu, L. An enhanced anaerobic membrane bioreactor treating bamboo industry wastewater by bamboo charcoal addition: Performance and microbial community analysis. Bioresour. Technol. 2016, 220, 26–33. [Google Scholar] [CrossRef]

- Iorhemen, O.; Hamza, R.; Tay, J. Membrane bioreactor (MBR) technology for wastewater treatment and reclamation: Membrane fouling. Membranes 2016, 6, 33. [Google Scholar] [CrossRef] [PubMed]

- Stuckey, D.C. Recent developments in anaerobic membrane reactors. Bioresour. Technol. 2012, 122, 137–148. [Google Scholar] [CrossRef] [PubMed]

- Abdurahman, N.H.; Rosli, Y.M.; Azhari, N.H. Development of a membrane anaerobic system (MAS) for palm oil mill effluent (POME) treatment. Desalination 2011, 266, 208–212. [Google Scholar] [CrossRef]

- Fakhru’l-Razi, A.; Noor, M. Treatment of palm oil mill effluent (POME) with the membrane anaerobic system (MAS). Water Sci. Technol. 1999, 39, 159–163. [Google Scholar] [CrossRef]

- Damayanti, A.; Ujang, Z.; Salim, M.R. The influenced of PAC, zeolite, and Moringa oleifera as biofouling reducer (BFR) on hybrid membrane bioreactor of palm oil mill effluent (POME). Bioresour. Technol. 2011, 102, 4341–4346. [Google Scholar] [CrossRef] [PubMed]

- Ng, C.A.; Wong, L.Y.; Chai, H.Y.; Bashir, M.J.; Ho, C.D.; Nisar, H.; Lo, P.K. Investigation on the performance of hybrid anaerobic membrane bioreactors for fouling control and biogas production in palm oil mill effluent treatment. Water Sci. Technol. 2017, 76, 1389–1398. [Google Scholar] [CrossRef]

- Borja, R.; Banks, C.J.; Sánchez, E. Anaerobic treatment of palm oil mill effluent in a two-stage up-flow anaerobic sludge blanket (UASB) system. J. Biotechnol. 1996, 45, 125–135. [Google Scholar] [CrossRef]

- Yacob, S.; Hassan, M.A.; Shirai, Y.; Wakisaka, M.; Subash, S. Baseline study of methane emission from anaerobic ponds of palm oil mill effluent treatment. Sci. Total Environ. 2006, 366, 187–196. [Google Scholar] [CrossRef] [PubMed]

- Yacob, S.; Hassan, M.A.; Shirai, Y.; Wakisaka, M.; Subash, S. Baseline study of methane emission from open digesting tanks of palm oil mill effluent treatment. Chemosphere 2005, 59, 1575–1581. [Google Scholar] [CrossRef]

- Borja, R.; Banks, C.J. Treatment of palm oil mill effluent by upflow anaerobic filtration. J. Chem. Technol. Biotechnol. 1994, 61, 103–109. [Google Scholar] [CrossRef]

- Tong, S.L.; Jaafar, A.B. POME Biogas capture, upgrading and utilization. Palm Oil Eng. Bull. 2006, 78, 11–17. [Google Scholar]

- Ibrahim, A.; Yeoh, B.G.; Cheah, S.C.; Ma, A.N.; Ahmad, S.; Chew, T.Y.; Raj, R.; Wahid, M.J.A. Thermophilic anaerobic contact digestion of palm oil mill effluent. Water Sci. Technol. 1984, 17, 155–165. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Di Perta, E.S.; Panico, A.; Frunzo, L.; Esposito, G.; Lens, P.N.; Pirozzi, F. Effect of ammoniacal nitrogen on one-stage and two-stage anaerobic digestion of food waste. Waste Manag. 2015, 38, 388–398. [Google Scholar] [CrossRef] [PubMed]

- Dvořák, L.; Gómez, M.; Dolina, J.; Černín, A. Desalination and Water Treatment. Anaerobic membrane bioreactors—A mini review with emphasis on industrial wastewater treatment: Applications, limitations and perspectives. Desalination Water Treat. 2016, 57, 19062–19076. [Google Scholar] [CrossRef]

- Lin, H.; Peng, W.; Zhang, M.; Chen, J.; Hong, H.; Zhang, Y. A review on anaerobic membrane bioreactors: Applications, membrane fouling and future perspectives. Desalination 2013, 314, 169–188. [Google Scholar] [CrossRef]

- Dereli, R.K.; Ersahin, M.E.; Ozgun, H.; Ozturk, I.; Jeison, D.; van der Zee, F.; van Lier, J.B. Potentials of anaerobic membrane bioreactors to overcome treatment limitations induced by industrial wastewaters. Bioresour. Technol. 2012, 122, 160–170. [Google Scholar] [CrossRef]

| Parameters | Unit | Current Study | Palm Oil Wastewater | ||||

|---|---|---|---|---|---|---|---|

| [4] | [2] | [8] | [9] | [10] | |||

| pH | - | 4.7 ± 0.1 | 4–5 | 3.4–5.2 | 4.75 | 4.5 | 4.5 |

| Temperature | °C | 55 | - | 80–90 | - | 55.5 | - |

| BOD5 | mg/L | 42,670 ± 2894 | 25,000–65,714 | 25,000–65,714 | 30,000 ± 10,391 | 40,000 | 45,357 |

| COD | mg/L | 60,000 ± 3002 | 44,300–102,694 | 15,000–100,000 | 70,000 ± 7612 | 65,000 | 73,498 |

| Oil & Grease | mg/L | 7102 ± 1740 | 4000–9341 | 130–18,000 | 10,540 ± 1000 | 1500 | 6670.5 |

| TS | mg/L | 44,980 ± 336 | 40,500–72,058 | 11,500–79,000 | - | 45,000 | 56,279 |

| TSS | mg/L | 25,009 ± 4142 | 18,000–46,011 | 5000–54,000 | 28,900 ± 3065 | 20,000 | 32005.5 |

| TVS | mg/L | 37,666 ± 383 | - | 9000–72,000 | - | 26,300 | 41,650 |

| Ammonia-N | mg/L | 85 ± 6 | 35–103 | 4–80 | - | 90 | 69 |

| Wastewater | Reactor Configuration | OLR (kg COD/m3·d) | MLSS (g/L) | MLVSS (g/L) | MLVSS/MLSS | Reference |

|---|---|---|---|---|---|---|

| Palm Oil Mill Effluent (POME) | AnMBR | 1–11 | 11.76–20.8 | 8.9–17.68 | 0.76–0.85 | [16] |

| AnMBR | 14.2–21.7 | 50–57 | - | 0.74–0.82 | [17] | |

| Hybrid Membrane Bioreactor | 10.1–11.9 | 15 | 12 | 0.8 | [18] | |

| AnMBR | 10.9 ± 1.2 | 9.2 ± 1.2 | 0.85 ± 0.01 | [19] | ||

| TAnMBR | 2–10 | 17.5–29.4 | 11.1–20.9 | 0.61–0.74 | This study |

| Different Treatment Configurations | OLR (kg COD/m3·d) | COD Removal (%) | Methane Yield (m3 CH4/kg CODr) | Methane Composition (%) | Reference |

|---|---|---|---|---|---|

| Anaerobic pond | 1.4 | 97.8 | - | 54.4 | [21] |

| Anaerobic digester | 2.16 | 80.7 | - | 36 | [22] |

| Anaerobic filtration | 4.5 | 94 | - | 63 | [23] |

| Continuously Stirred Tank Reactor | 3.33 | 80 | - | 62.5 | [24] |

| Anaerobic contact process | 3.44 | 93.3 | - | 63 | [25] |

| AnMBR | 1–11 | 96–99 | 0.25–0.57 | - | [16] |

| AnMBR | 14.2–21.7 | 91.7–94.2 | 0.24–0.28 | - | [17] |

| TAnMBR | 2–10 | 90–98.75 | 0.19–0.56 | 65.1 ± 2.2 | This study |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yee, T.L.; Rathnayake, T.; Visvanathan, C. Performance Evaluation of a Thermophilic Anaerobic Membrane Bioreactor for Palm Oil Wastewater Treatment. Membranes 2019, 9, 55. https://doi.org/10.3390/membranes9040055

Yee TL, Rathnayake T, Visvanathan C. Performance Evaluation of a Thermophilic Anaerobic Membrane Bioreactor for Palm Oil Wastewater Treatment. Membranes. 2019; 9(4):55. https://doi.org/10.3390/membranes9040055

Chicago/Turabian StyleYee, Thet Lei, Thusitha Rathnayake, and Chettiyappan Visvanathan. 2019. "Performance Evaluation of a Thermophilic Anaerobic Membrane Bioreactor for Palm Oil Wastewater Treatment" Membranes 9, no. 4: 55. https://doi.org/10.3390/membranes9040055

APA StyleYee, T. L., Rathnayake, T., & Visvanathan, C. (2019). Performance Evaluation of a Thermophilic Anaerobic Membrane Bioreactor for Palm Oil Wastewater Treatment. Membranes, 9(4), 55. https://doi.org/10.3390/membranes9040055