The Impact of Mechanically-Imposed Shear on Clogging, Fouling and Energy Demand for an Immersed Membrane Bioreactor

Abstract

:1. Introduction

2. Materials and Methods

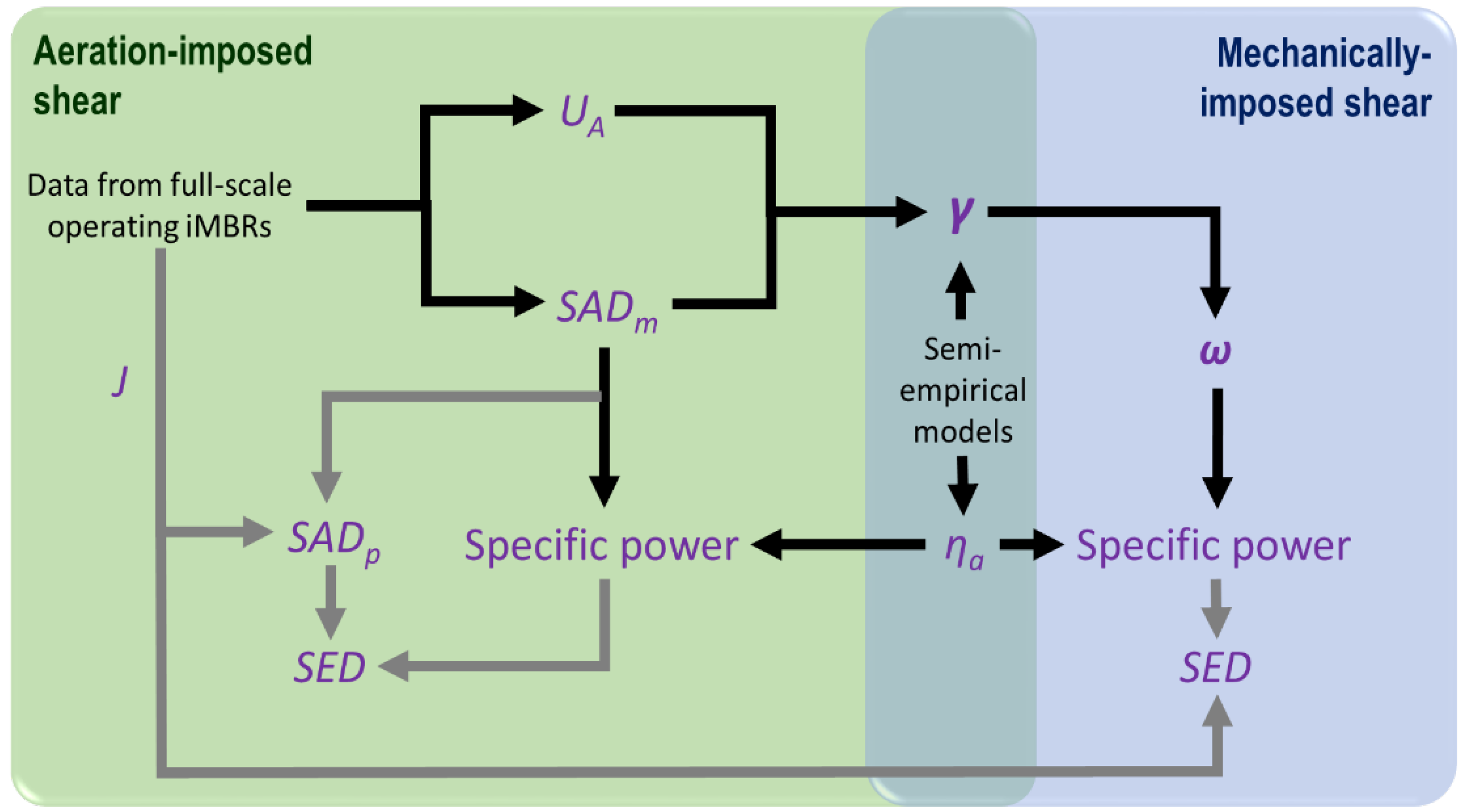

- Determining the cycle-averaged shear rate γ in s−1 associated with the reciprocation rate of 20 RPM applied in the study;

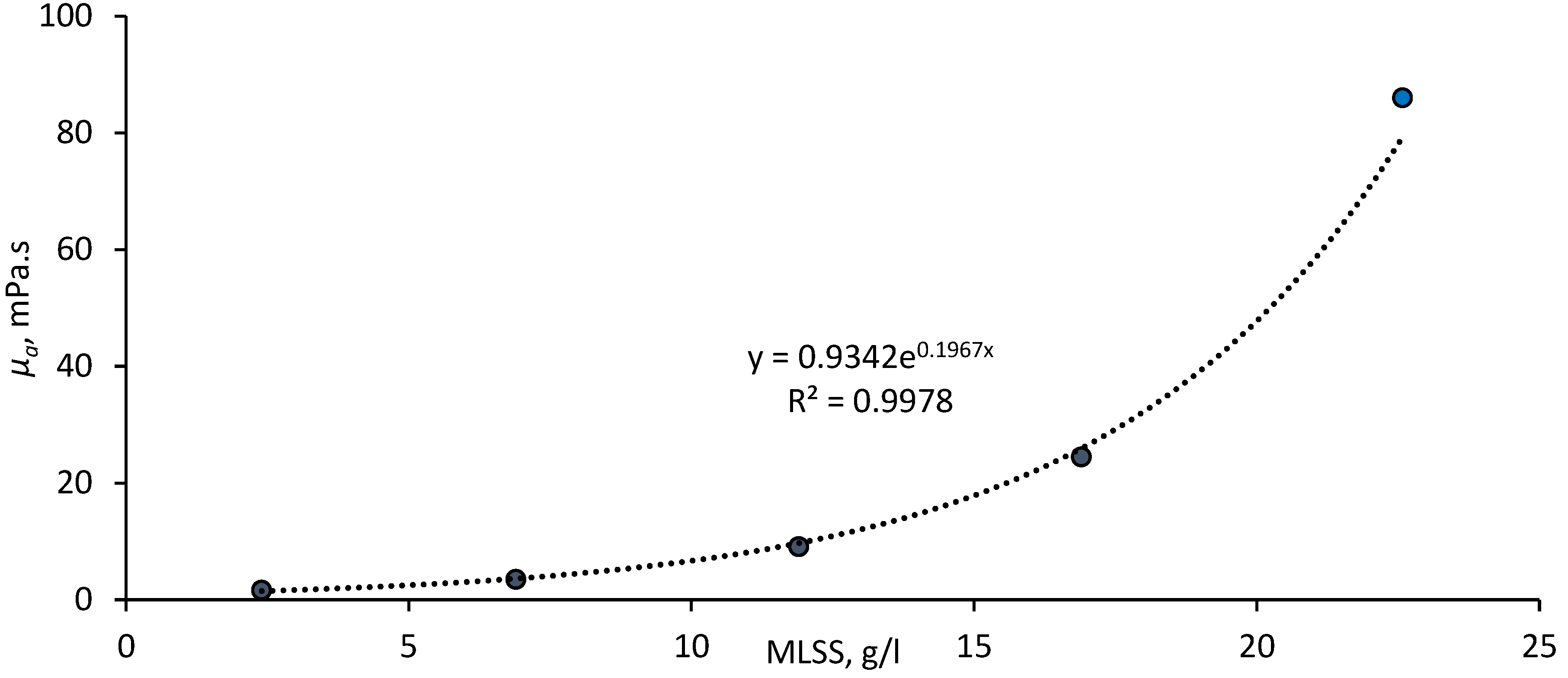

- Practical measurement of the apparent viscosity µa associated with this shear rate using the rheometer;

- Applying this viscosity to determine the specific power demand W·m−2, based on the approach of Buzatu et al. [8], as outlined below;

- Calculating the SED, given by the ratio of and the flux J.

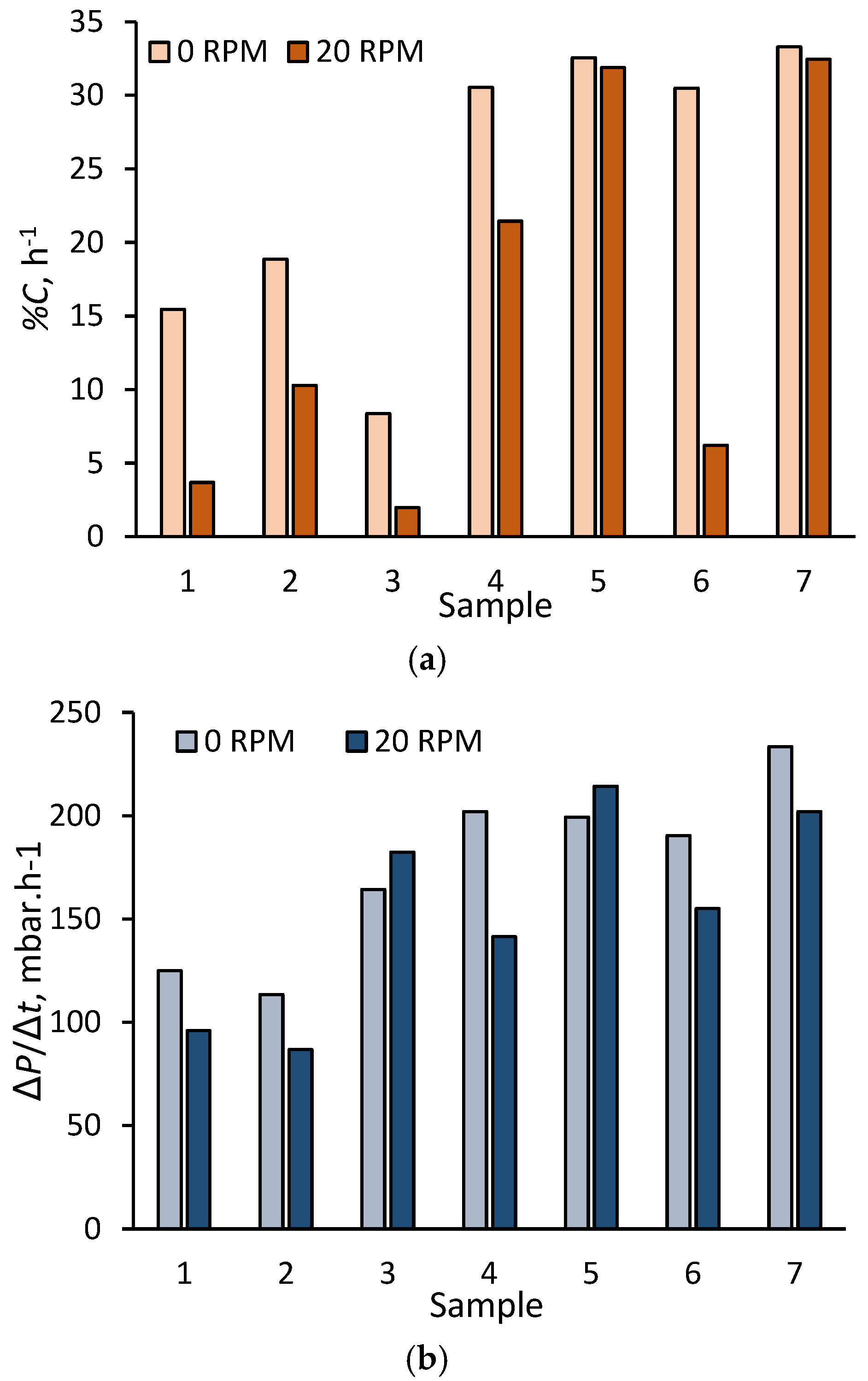

3. Results and Discussion

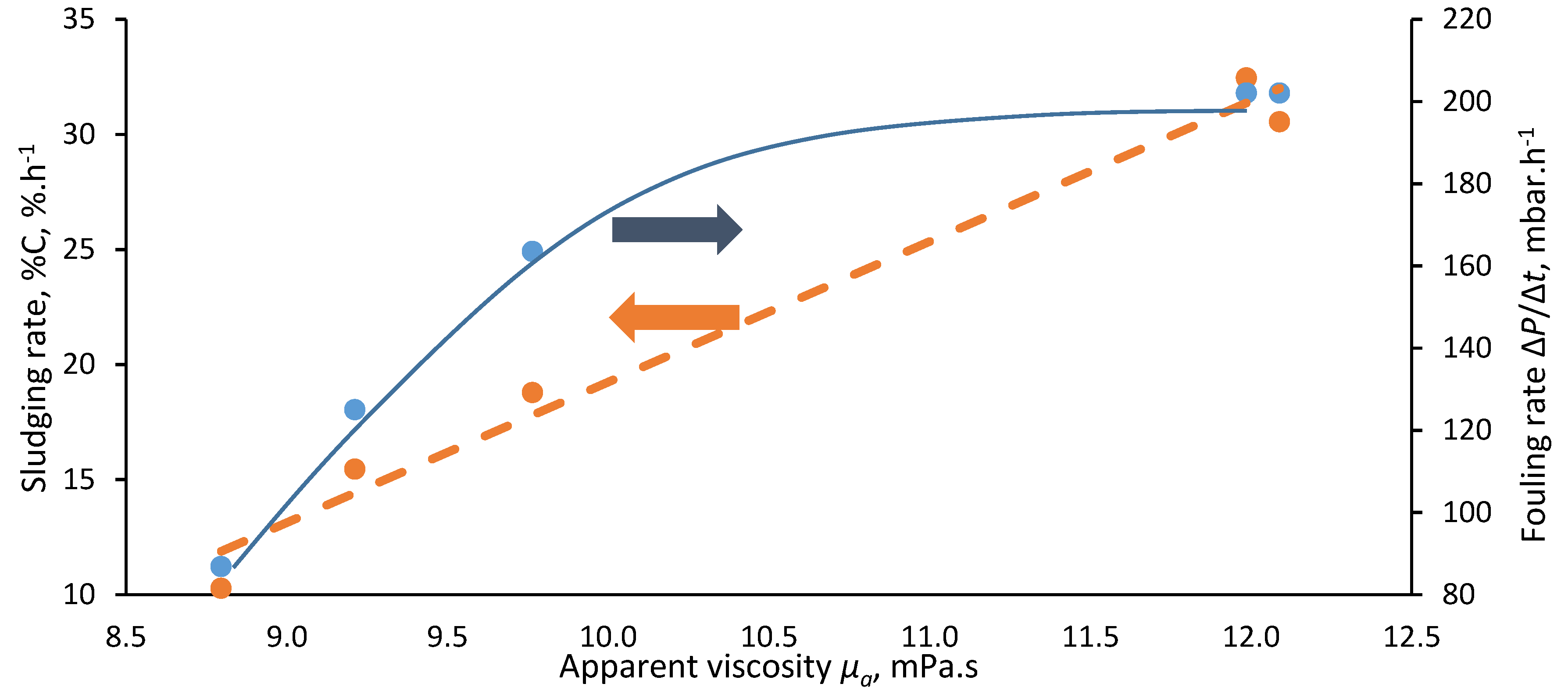

3.1. Practical Measurement

3.2. Determination of Energy Demand, Full-Scale Module

4. Conclusions

- Small but statistically significant beneficial effects recorded from the application of the mechanical shear, manifested by reduced pressure incline and sludging rates, and

- The calculated energy demand associated with this mechanical shear application to be significantly lower than that recently reported for a pilot-scale demonstration.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Beier, S.P.; Guerra, M.; Garde, A.; Jonsson, G. Dynamic microfiltration with a vibrating hollow fiber membrane module: Filtration of yeast suspensions. J. Membr. Sci. 2006, 281, 281–287. [Google Scholar] [CrossRef]

- Genkin, G.; Waite, T.D.; Fane, A.G.; Chang, S. The effect of vibration and coagulant addition on the filtration performance of submerged hollow fibre membranes. J. Membr. Sci. 2006, 281, 726–734. [Google Scholar] [CrossRef]

- Jaffrin, M.Y. Dynamic filtration with rotating disks, and rotating and vibrating membranes: An update. Curr. Opin. Chem. Eng. 2012, 1, 171–177. [Google Scholar] [CrossRef]

- Zsirai, T.; Qiblawey, H.; A-Marri, M.J.; Judd, S. The impact of mechanical shear on membrane flux and energy demand. J. Membr. Sci. 2016, 516, 56–63. [Google Scholar] [CrossRef]

- Buzatu, P.; Qiblawey, H.; Nasser, M.S.; Judd, S. Comparative power demand of mechanical and aeration imposed shear in an immersed membrane bioreactor. Water Res. 2017, 126, 208–215. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, R.; Cui, Z.F. Mass transfer in gas-sparged ultrafiltration: Upward slug flow in tubular membranes. J. Membr. Sci. 1999, 162, 91–102. [Google Scholar] [CrossRef]

- Delgado, S.; Villarroel, R.; Gonzalez, E. Effect of the shear intensity on fouling in submerged membrane bioreactor for wastewater treatment. J. Membr. Sci. 2008, 311, 173–181. [Google Scholar] [CrossRef]

- Ho, J.; Smith, S.; Kim, G.D.; Roh, H.K. Performance evaluation of a novel reciprocation membrane bioreactor (rMBR) for enhanced nutrient removal in wastewater treatment: A comparative study. Water Sci. Technol. 2015, 72, 917–927. [Google Scholar] [CrossRef] [PubMed]

- Ho, J.; Smith, S.; Patamasank, J.; Tontcheva, P.; Kim, G.D.; Roh, H.K. Pilot demonstration of energy-efficient membrane bioreactor (MBR) using reciprocating submerged membrane. Water Environ. Res. 2015, 87, 266–273. [Google Scholar] [CrossRef] [PubMed]

- Buzatu, P.; Qiblawey, H.; Odai, A.; Jamaleddin, J.; Nasser, M.S.; Judd, S. Clogging vs. fouling in immersed membrane bioreactors. Water Res. 2018, 144, 46–54. [Google Scholar] [CrossRef] [PubMed]

- American Public Health Association (APHA). American Water Works Association (AWWA) and Water Environment Federation (WEF): Standard Methods for the Examination of Water and Wastewater, 22 nd ed; APHA: Washington, DC, USA, 2012. [Google Scholar]

- Yang, M.; Yu, D.; Liu, M.; Zheng, L.; Zheng, X.; Wei, Y.; Wang, F.; Fan, Y. Optimization of MBR hydrodynamics for cake layer fouling control through CFD simulation and RSM design. Bioresour. Technol. 2017, 227, 102–111. [Google Scholar] [CrossRef] [PubMed]

- Rosenberger, S.; Kubin, K.; Kraume, M. Rheology of activated sludge in membrane bioreactors. Eng. Life Sci. 2002, 2, 269–275. [Google Scholar] [CrossRef]

- Khalili Garakani, A.H.; Mostoufi, N.; Sadeghi, G.; Hosseinzadeh, M.; Fatourechi, M.; Sarrafzadeh, M.H.; Mehrnia, M.R. Comparison between different models for rheological characterisation of activated sludge. Iran. J. Environ. Health Sci. Eng. 2011, 8, 255–264. [Google Scholar]

- Eshtiaghi, N.; Markis, F.; Yap, S.D.; Baudez, J.-C.; Slatter, P. Rheological characterisation of municipal sludge: A review. Water Res. 2013, 47, 5493–5510. [Google Scholar] [CrossRef] [PubMed]

- Krzeminski, P.; Van Der Graaf, J.H.J.M.; Van Lier, J.B. Specific energy consumption of membrane bioreactor (MBR) for sewage treatment. Water Sci. Technol. 2012, 65, 380–392. [Google Scholar] [CrossRef] [PubMed]

- Krzeminski, P.; Leverette, L.; Malamis, S.; Katsou, E. Membrane bioreactors—A review on recent developments in energy reduction, fouling control, novel configurations, LCA and market prospects. J. Membr. Sci. 2017, 527, 207–227. [Google Scholar] [CrossRef]

- Judd, S. Industrial MBRs; Judd & Judd: Cranfield, UK, 2014. [Google Scholar]

- Ginzburg, B. LEAPmbr Process Design. In Proceedings of the MEA UFMBR Workshop for ITPs, Abu Dhabi, UAE, 4–7 November 2013. [Google Scholar]

- Tao, G.; Htoo, C.; Phua, K.M.; Chua, S.C.; Wah, Y.L.; Ooi, K.E.; Seah, H. Biosorption and low energy step-feed membrane bioreactor for water and resource recovery. Presented at the IWA Congress 2018, Tokyo, Japan, 16–21 September 2018. [Google Scholar]

| Parameter | Sludging Rate Data | Fouling Rate Data | ||

|---|---|---|---|---|

| 20 RPM | 0 RPM | 20 RPM | 0 RPM | |

| Mean | 12.6 | 22.1 | 146.0 | 165.4 |

| Variance | 138 | 84.2 | 2418 | 1243 |

| Observations | 6 | 7 | 6 | 7 |

| Pooled variance | 109 | 1777 | ||

| Hypothesized mean difference | 0 | 0 | ||

| Degrees of freedom | 11 | 11 | ||

| t Stat | −1.65 | −0.829 | ||

| P(T <= t) one-tail | 0.063 | 0.212 | ||

| t Critical one-tail | 1.80 | 1.80 | ||

| P(T <= t) two-tail | 0.127 | 0.425 | ||

| t Critical two-tail | 2.20 | 2.20 | ||

| Parameter | Units | Bench-Scale | Full-Scale |

|---|---|---|---|

| Frequency | RPM | 20 | 20 |

| γ | s−1 | 4.9 | 22.2 |

| Amplitude | m | 0.022 | 0.1 |

| ηa | mPa·s | 153 | 56.4 |

| P | W·m−2 | 0.00839 | 0.07263 |

| J | LMH | 15 | 15 |

| Motor efficiency | % | 60% | 60% |

| SED | kWh·m−3 | 0.00093 | 0.00807 |

| Parameter | Unit | Ho et al. [8,9] | This Study |

|---|---|---|---|

| Design and operation | |||

| Membrane area | m2 | 45 | 0.1 |

| Membrane length | m | 1.3 | 0.316 |

| TMP | kPa | <20 | <60 |

| Amplitude | mm | 38 to 57 | 100 |

| Reciprocation frequency | Hz | 0.38 to 0.53 | 0.33 |

| RPM | 23 to 32 | 20 | |

| Specific power demand | W·m−2 | 1.55 | 0.073 a |

| Experimental outputs | |||

| Flux (J) range | L·m−2·h−1 or LMH | 20 to 40 | 15 |

| Permeability | LMH·bar−1 | 200 to 300 | 25 to 180 |

| SED (/J) | kWh·m−3 | 0.04 to 0.09 | 0.0081 b |

| Motor efficiency | - | 71% | 60% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Judd, S.; Odai, A.; Buzatu, P.; Qiblawey, H. The Impact of Mechanically-Imposed Shear on Clogging, Fouling and Energy Demand for an Immersed Membrane Bioreactor. Membranes 2018, 8, 104. https://doi.org/10.3390/membranes8040104

Judd S, Odai A, Buzatu P, Qiblawey H. The Impact of Mechanically-Imposed Shear on Clogging, Fouling and Energy Demand for an Immersed Membrane Bioreactor. Membranes. 2018; 8(4):104. https://doi.org/10.3390/membranes8040104

Chicago/Turabian StyleJudd, Simon, Albert Odai, Pompilia Buzatu, and Hazim Qiblawey. 2018. "The Impact of Mechanically-Imposed Shear on Clogging, Fouling and Energy Demand for an Immersed Membrane Bioreactor" Membranes 8, no. 4: 104. https://doi.org/10.3390/membranes8040104

APA StyleJudd, S., Odai, A., Buzatu, P., & Qiblawey, H. (2018). The Impact of Mechanically-Imposed Shear on Clogging, Fouling and Energy Demand for an Immersed Membrane Bioreactor. Membranes, 8(4), 104. https://doi.org/10.3390/membranes8040104