Long-Term Performance of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment: A Case Study

Abstract

1. Introduction

2. Materials and Methods

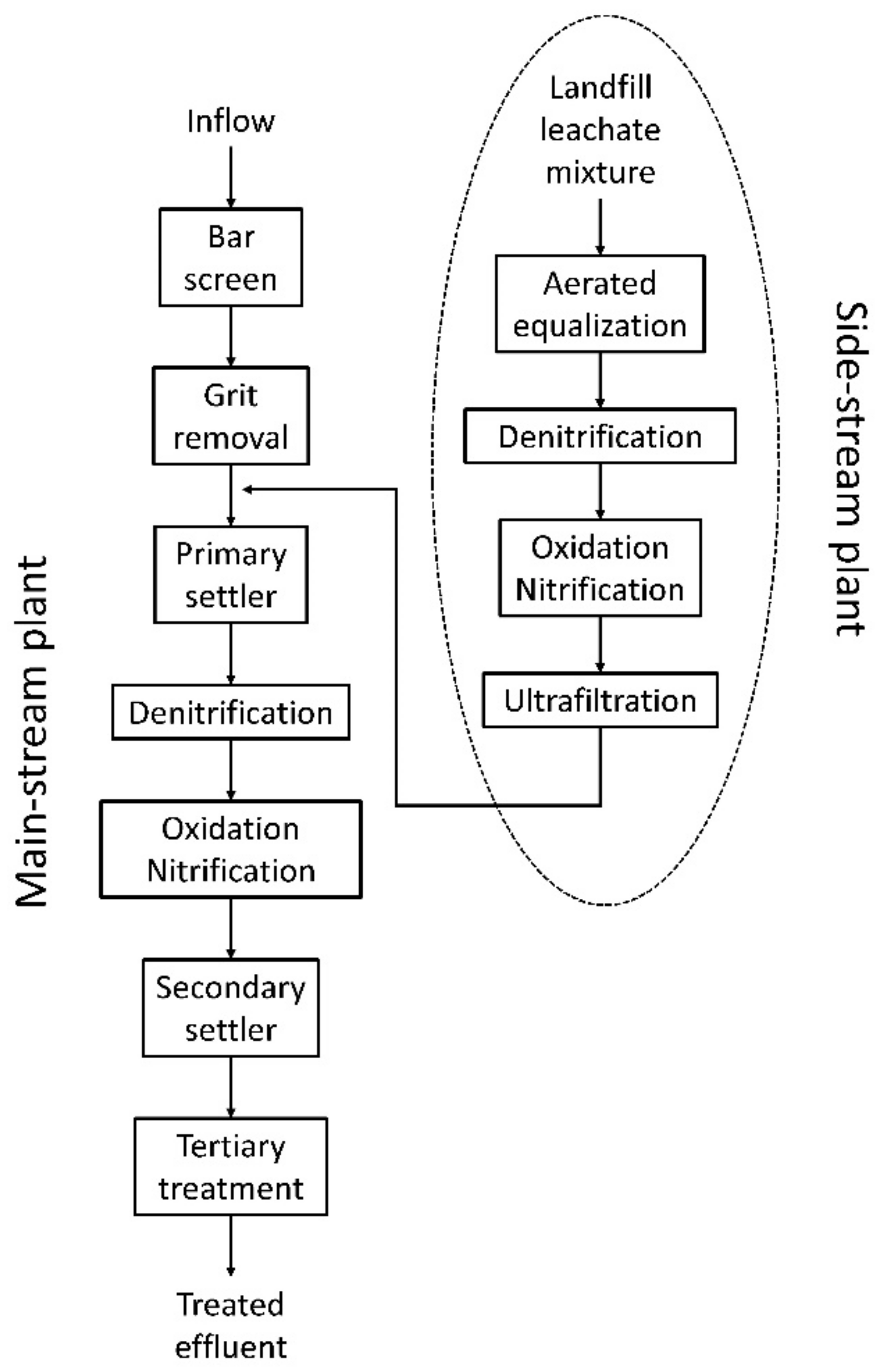

2.1. Plant Description

2.2. Membrane Filtration Unit

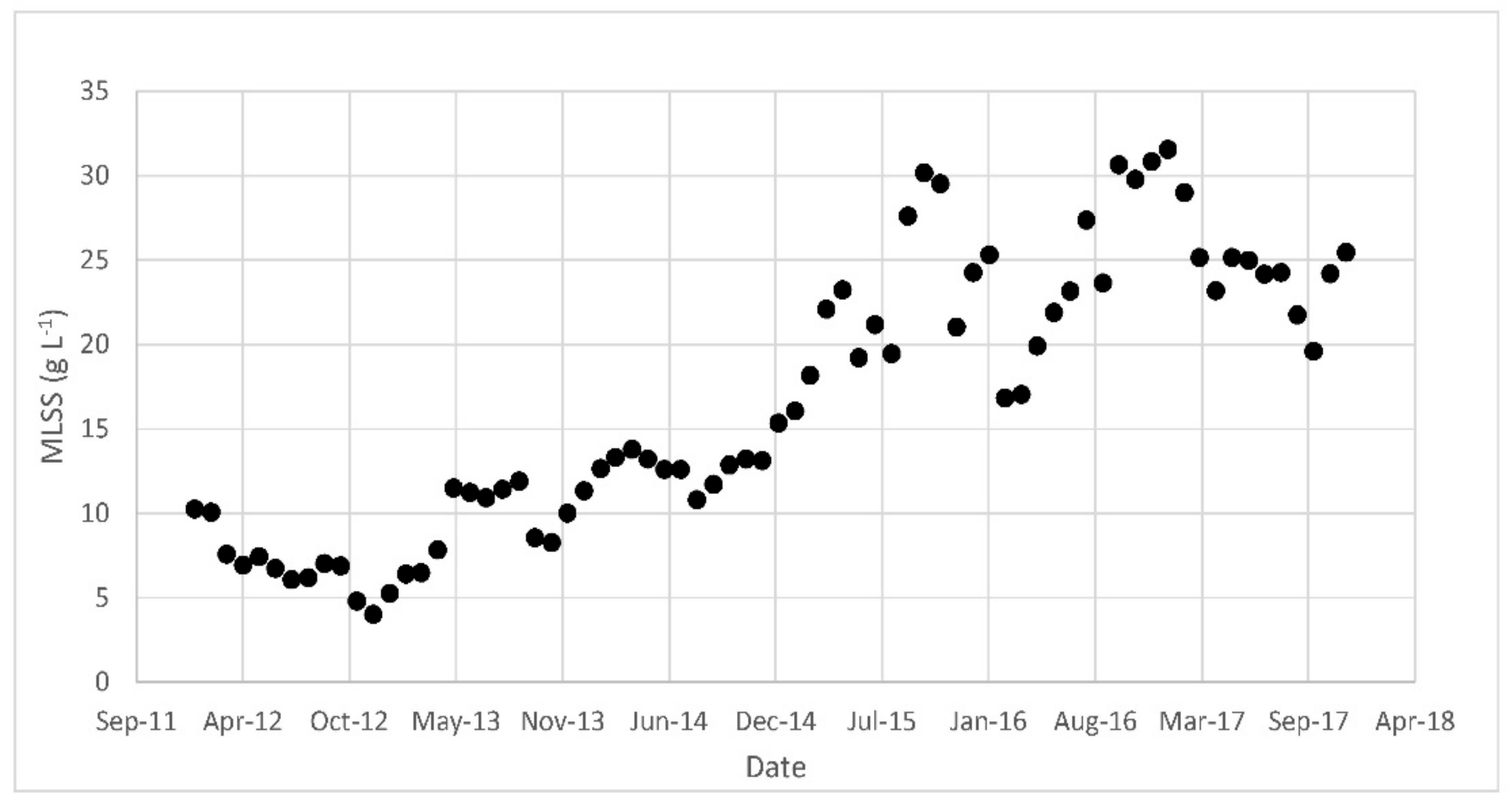

2.3. Operating Conditions

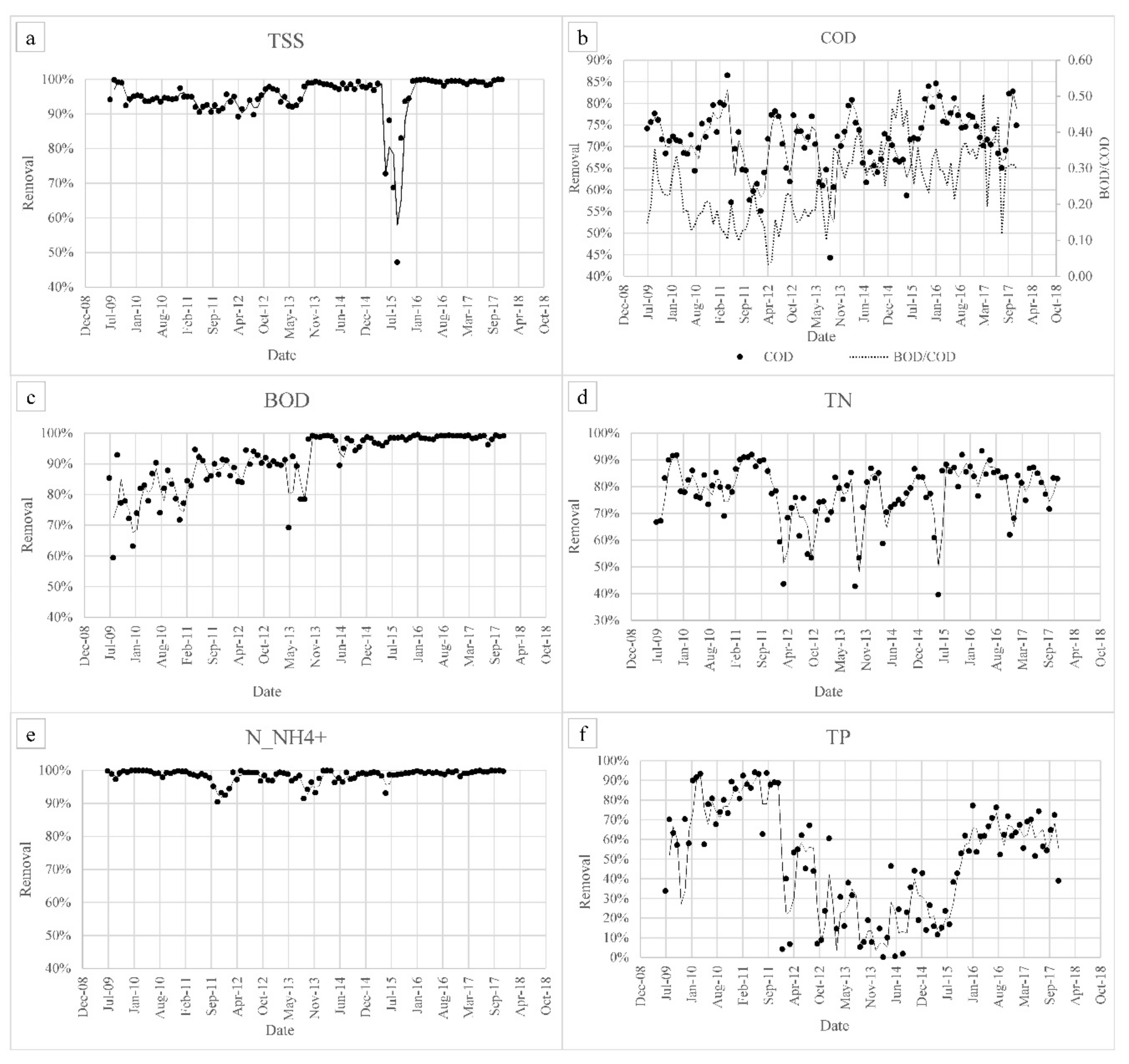

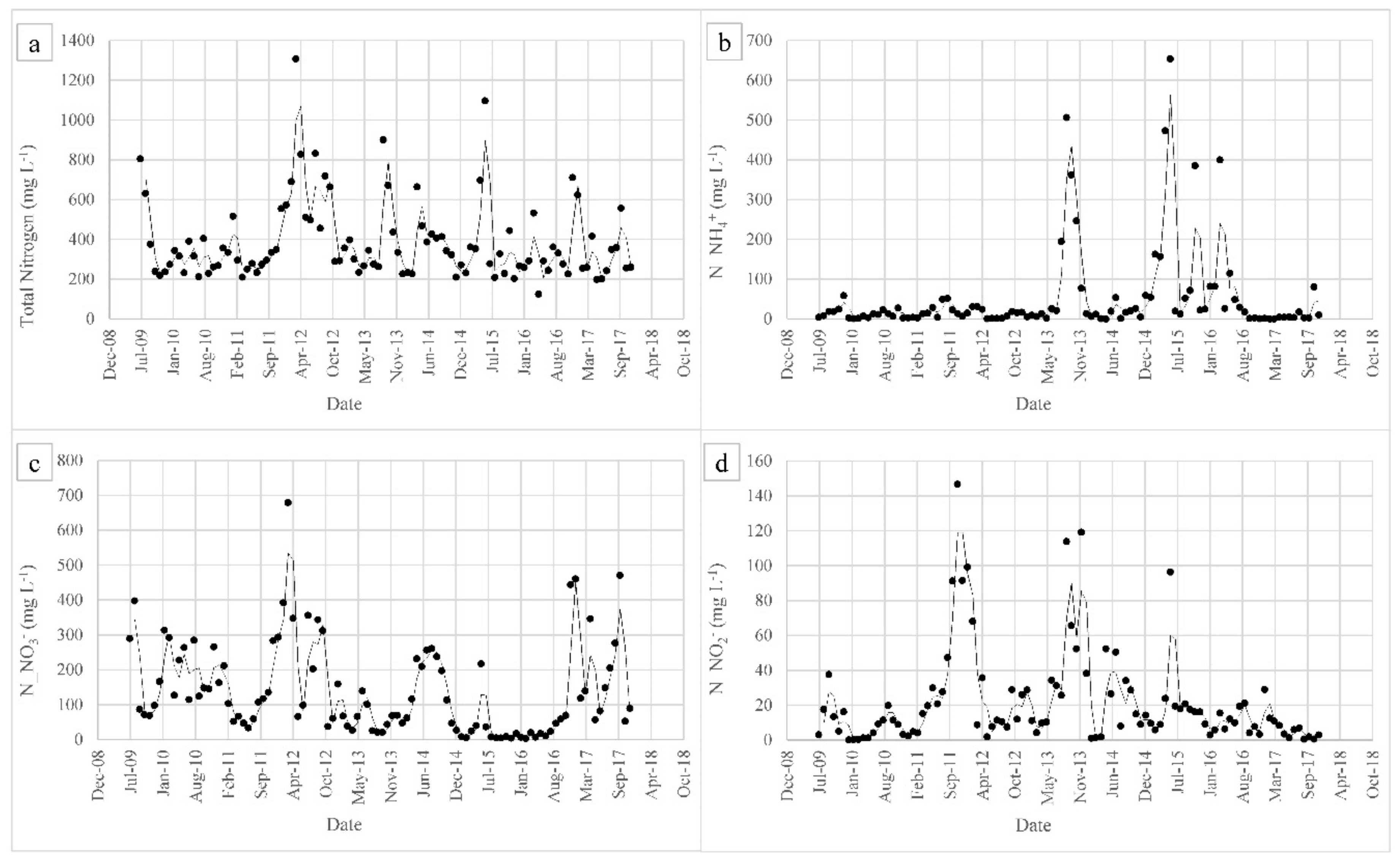

3. Results

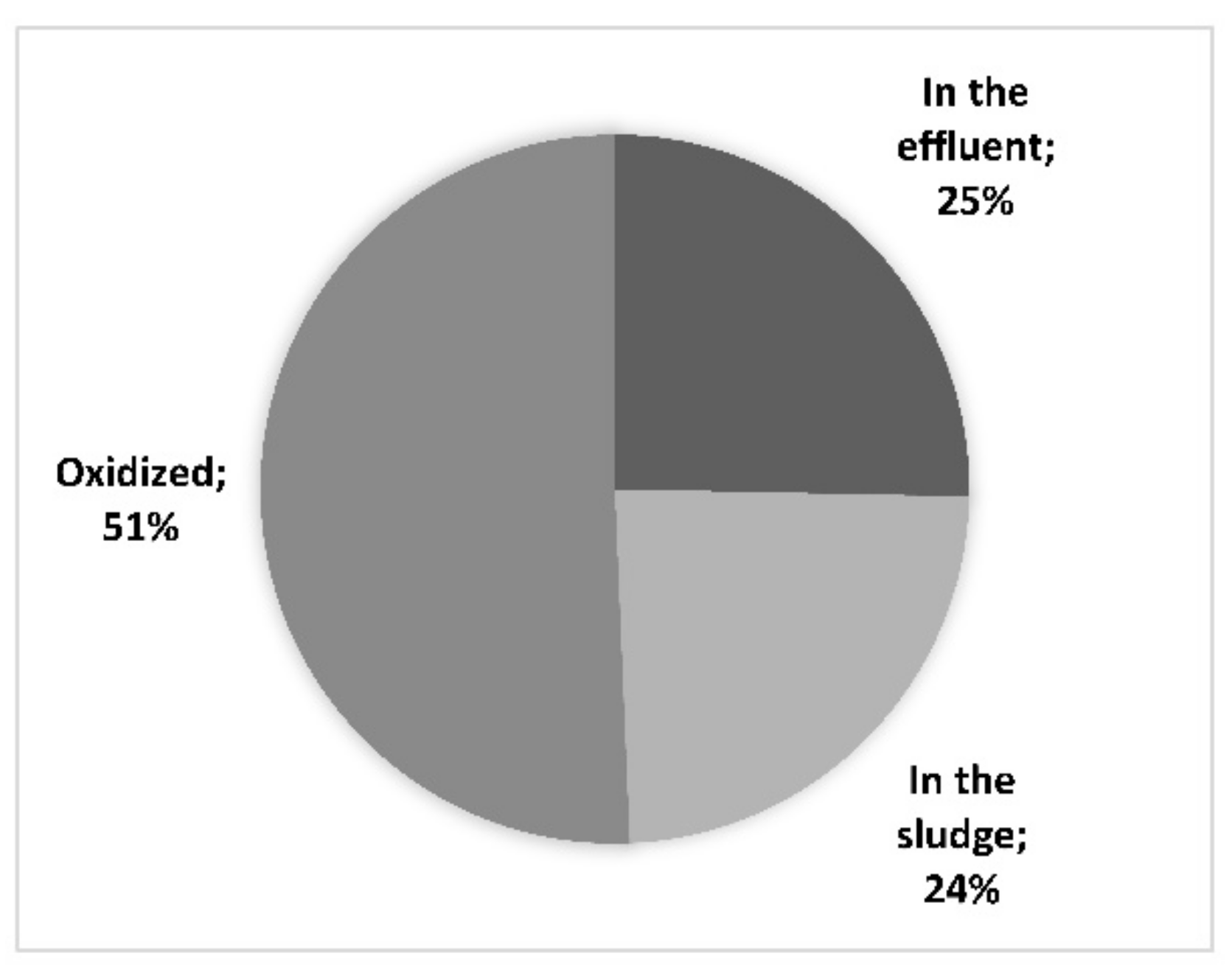

4. Discussion

4.1. Treatment Efficiency

4.2. Membrane Performance

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ahmed, F.N.; Lan, C.Q. Treatment of landfill leachate using membrane bioreactors: A review. Desalination 2012, 287, 41–54. [Google Scholar] [CrossRef]

- Alvarez-Vazquez, E.; Jefferson, B.; Judd, S.J. Review Membrane bioreactors vs conventional biological treatment of landfill leachate: A brief review. J. Chem. Technol. Biotechnol. 2004, 79, 1043–1049. [Google Scholar] [CrossRef]

- Al-Wabel, M.I.; Al Yehya, W.S.; AL-Farraj, A.S.; El-Maghraby, S.E. Characteristics of landfill leachates and bio-solids of municipal solid waste (MSW) in Riyadh City, Saudi Arabia. J. Saudi Soc. Agric. Sci. 2011, 10, 65–70. [Google Scholar] [CrossRef]

- Foo, K.Y.; Hameed, B.H. An overview of landfill leachate treatment via activated carbon adsorption process. J. Hazard. Mater. 2009, 171, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Renou, S.; Givaudan, J.G.; Poulain, S.; Dirassouyan, F.; Moulin, P. Landfill leachate treatment: Review and opportunity. J. Hazard. Mater. 2008, 150, 468–493. [Google Scholar] [CrossRef] [PubMed]

- Fudala-Ksiazek, S.; Pierpaoli, M.; Luczkiewicz, A. Efficiency of landfill leachate treatment in a MBR/UF system combined with NF, with a special focus on phthalates and bisphenol A removal. Waste Manag. 2018, 78, 94–103. [Google Scholar] [CrossRef]

- El-Fadel, M.; Sleem, F.; Hashisho, J.; Saikaly, P.E.; Alameddine, I.; Ghanimeh, S. Impact of SRT on the performance of MBRs for the treatment of high strength landfill leachate. Waste Manag. 2018, 73, 165–180. [Google Scholar] [CrossRef] [PubMed]

- Zolfaghari, M.; Jardak, K.; Drogui, P.; Brar, S.K.; Buelna, G.; Dubé, R. Landfill leachate treatment by sequential membrane bioreactor and electro-oxidation processes. J. Environ. Manag. 2016, 184, 318–326. [Google Scholar] [CrossRef] [PubMed]

- Barreto, C.M.; Garcia, H.A.; Hooijmans, C.M.; Herrera, A.; Brdjanovic, D. Assessing the performance of an MBR operated at high biomass concentrations. Int. Biodeterior. Biodegrad. 2017, 119, 528–537. [Google Scholar] [CrossRef]

- Boonyaroj, V.; Chiemchaisri, C.; Chiemchaisri, W.; Yamamoto, K. Enhanced biodegradation of phenolic compounds in landfill leachate by enriched nitrifying membrane bioreactor sludge. J. Hazard. Mater. 2017, 323, 311–318. [Google Scholar] [CrossRef] [PubMed]

- Reis, B.G.; Silveira, A.L.; Tostes Teixeira, L.P.; Okuma, A.A.; Lange, L.C.; Amaral, M.C.S. Organic compounds removal and toxicity reduction of landfill leachate by commercial bakers’ yeast and conventional bacteria based membrane bioreactor integrated with nanofiltration. Waste Manag. 2017, 70, 170–180. [Google Scholar] [CrossRef] [PubMed]

- Buzatu, P.; Qiblawey, H.; Nasser, M.S.; Judd, S. Comparative power demand of mechanical and aeration imposed shear in an immersed membrane bioreactor. Water Res. 2017, 126, 208–215. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, P.; Li, H.; Tian, Y.; Wang, S.; Song, Y.; Zeng, G.; Sun, C.; Tian, Z. Denitrification of landfill leachate under different hydraulic retention time in a two-stage anoxic/oxic combined membrane bioreactor process: Performances and bacterial community. Bioresour. Technol. 2018, 250, 110–116. [Google Scholar] [CrossRef] [PubMed]

- Palli, L.; Gullotto, A.; Tilli, S.; Caniani, D.; Gori, R.; Scozzafava, A. Biodegradation of 2-naphthalensulfonic acid polymers by white-rot fungi: Scale-up into non-sterile packed bed bioreactors. Chemosphere 2016, 164, 120–127. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Mean Value ± SD * | Minimum | Maximum |

|---|---|---|---|

| pH | 8.2 ± 0.15 | 7.98 | 8.36 |

| SST (mg·L−1) | 174 ± 150 | 42 | 441 |

| COD (mg·L−1) | 8050 ± 1911 | 6010 | 10,900 |

| BOD5 (mg·L−1) | 2280 ± 1002 | 960 | 3360 |

| TN (mg·L−1) | 1730 ± 209 | 1450 | 1990 |

| N_NH4+ (mg·L−1) | 1325 ± 127 | 1190 | 1515 |

| N_NO3− (mg·L−1) | 8 ± 10.5 | 1.1 | 28 |

| N_NO2− (mg·L−1) | 1.9 ± 1.2 | 0.1 | 3.4 |

| TP (mg·L−1) | 57 ± 14 | 36 | 75 |

| Parameter | Mean Value | Minimum | Maximum |

|---|---|---|---|

| MLSS (g·L−1) | 17 | 4 | 31 |

| Monthly waste flow rate (t SS) | 34 | 0 | 154 |

| SRT (d) | 144 | 23 | 450 |

| pH | 8.3 | 6.1 | 8.9 |

| DO * (mg·L−1) | 1.4 | 0.3 | 3.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coppini, E.; Palli, L.; Fibbi, D.; Gori, R. Long-Term Performance of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment: A Case Study. Membranes 2018, 8, 52. https://doi.org/10.3390/membranes8030052

Coppini E, Palli L, Fibbi D, Gori R. Long-Term Performance of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment: A Case Study. Membranes. 2018; 8(3):52. https://doi.org/10.3390/membranes8030052

Chicago/Turabian StyleCoppini, Ester, Laura Palli, Donatella Fibbi, and Riccardo Gori. 2018. "Long-Term Performance of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment: A Case Study" Membranes 8, no. 3: 52. https://doi.org/10.3390/membranes8030052

APA StyleCoppini, E., Palli, L., Fibbi, D., & Gori, R. (2018). Long-Term Performance of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment: A Case Study. Membranes, 8(3), 52. https://doi.org/10.3390/membranes8030052