Theoretical and Experimental Investigations of the Potential of Osmotic Energy for Power Production †

Abstract

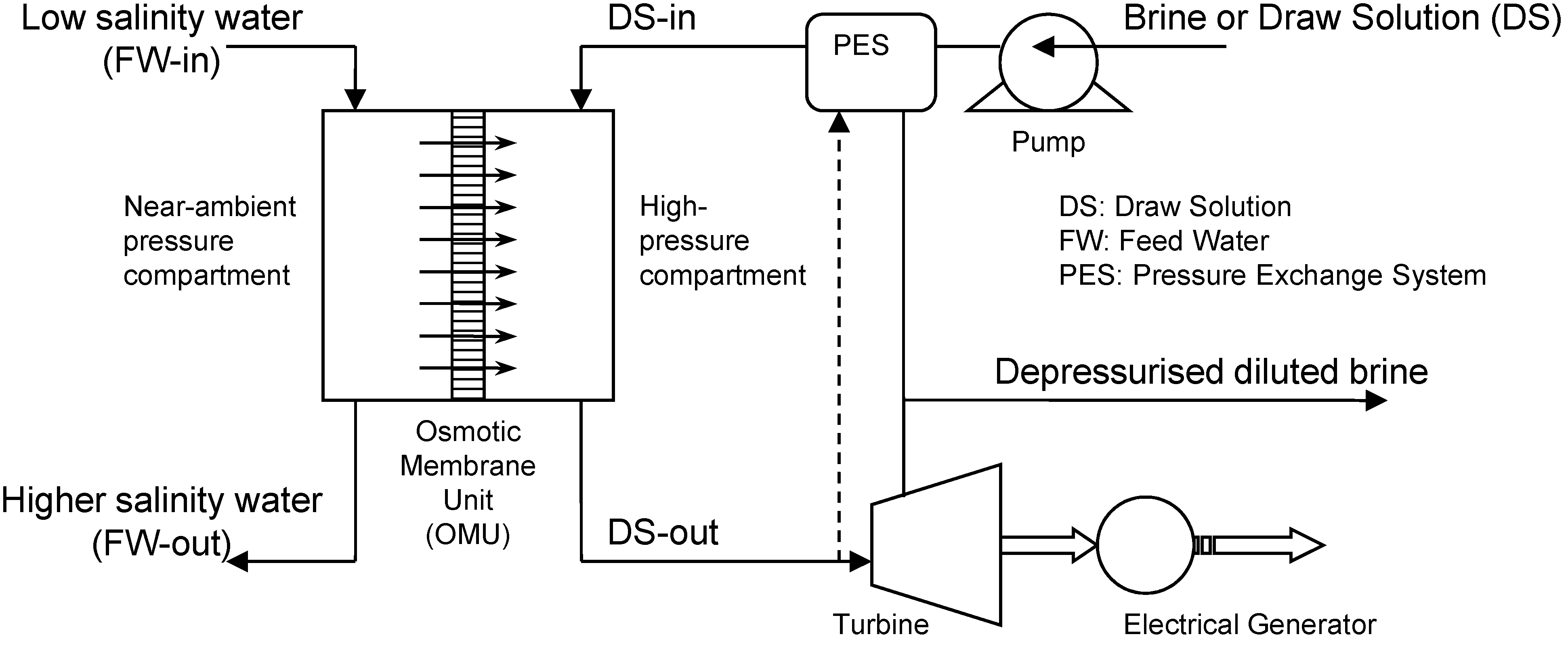

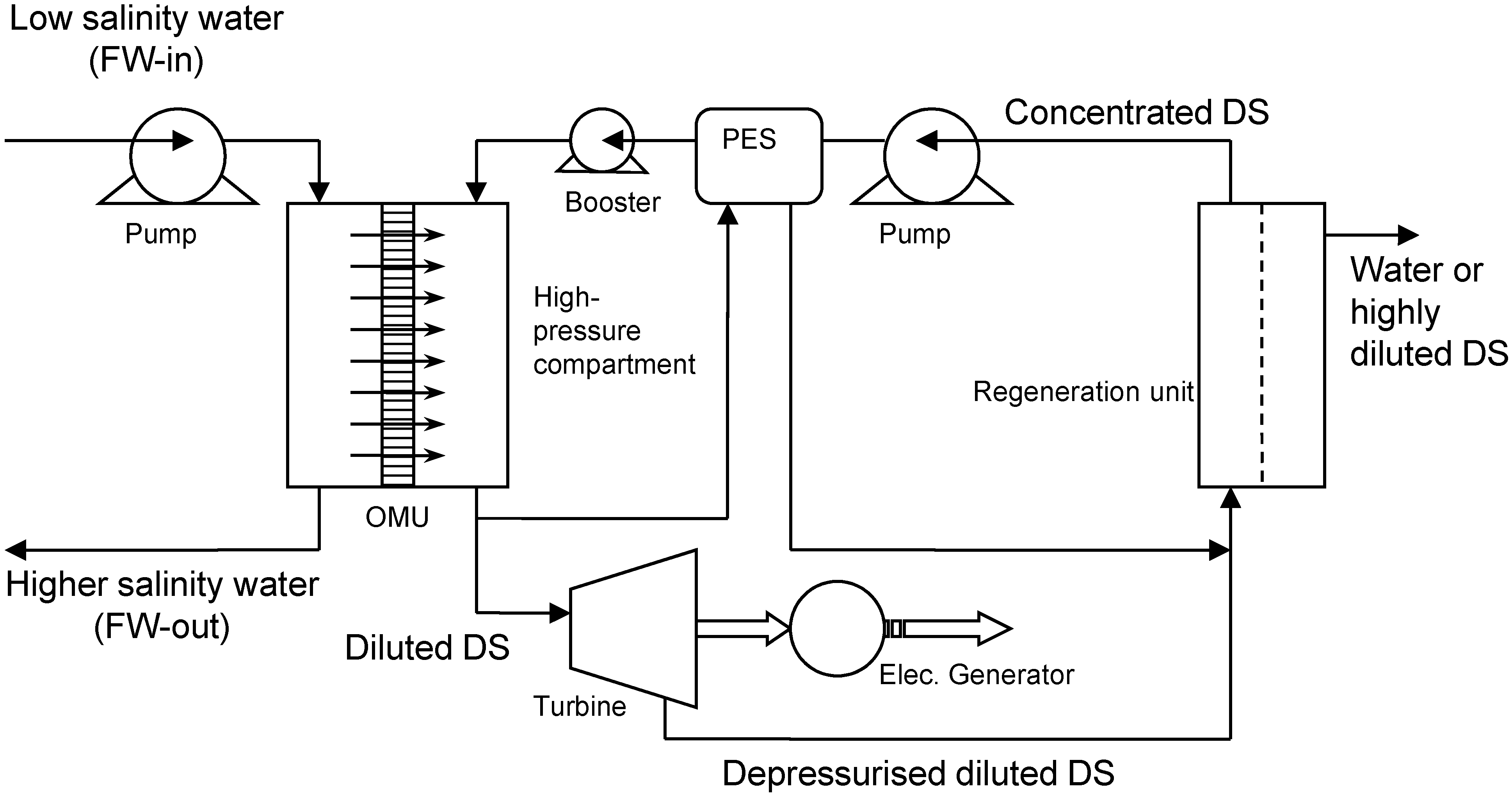

:1. Introduction

| Researcher (Year) | Feed/Draw Solution | Membrane | Hydraulic Pressure (bar) | Power Density (W/m2) | Ref. |

|---|---|---|---|---|---|

| Loeb et al. (1976) | Freshwater/Seawater | Hollow Fibre seawater RO | 12 | 0.35 | [11] |

| Mehta (1978) | Freshwater/Brine | Hollow Fibre seawater RO | 40 | 3.27 | [12] |

| Loeb & Mehta (1979) | Freshwater/Brine | FRL Composite seawater RO | 19 | 1.56 | [13] |

| Mehta & Loeb (1979) | Freshwater/Brine | Hollow Fibre seawater RO | 40 | 3.12 | [14] |

| Lee et al. (1980) | Freshwater/Brine (3.5%) | CA& PA& PBIL flat sheet seawater RO | 12.5 | 1.55 | [15] |

| Jellinek & Masuda (1981) | Freshwater/Brine | seawater spiral wound RO | 11–16 | 1.6 | [16] |

| Gerstandt et al. (2008) | Freshwater/Seawater | Lab TFC (flat sheet/hollow fibre) and CA | 10–13 | 1.3–3.5 | [17] |

| Skilhagen et al. (2008) | Freshwater/Seawater | Modified TFC for PRO | 11–15 | 1.0 | [7] |

| Achilli et al. (2009) | DI water/Brine (3.5%–6%) | CTA flat sheet seawater FO (HTI) | 9.7 | 2.7–5.1 | [18] |

| Thorsen & Holt (2009) | Freshwater/Seawater | TFC & CTA commercial FO flat sheet seawater | 7–12 | 1.6–2.7 | [19] |

| Chou et al. (2011) | River water & waste water/Brine (3.5%–6%) | TFC Hollow Fibre seawater FO | 8–9.1 | 8.4–11 | [20] |

| Yip & Elimelech (2011) | River water/Seawater (3.5%) | Modified TFC membrane, Hollow Fibre | 10–15 | 6.1–10 | [21] |

| She et al. (2012) | Freshwater/Brine (2 M NaCl) | CTA commercial flat sheet seawater FO(HTI) | 13 | 6.7 | [22] |

| Kim & Elimelech (2012) | NaCl solution (0.5–1 M)/Brine (2 M) | CTA commercial FO flat sheet | 12.5 | 4.7 | [23] |

| Wang et al. (2012) | River & Wastewater (0.5 M)/Seawater | TFC hollow fibre commercial FO | 5–8.9 | 4.1–5.7 | [24] |

| Schiestel et al. (2012) | Freshwater/Seawater | CTA commercial FO flat sheet | 8 | 2.25 | [25] |

| Saito et al. (2012) | Waste water/RO Brine (2–2.5 M) | commercial FO hollow fibre | 25 | 7.7 | [26] |

| Efraty (2012) | Freshwater/Seawater | Modified TFC membrane | 9.6 | 7.4 | [27] |

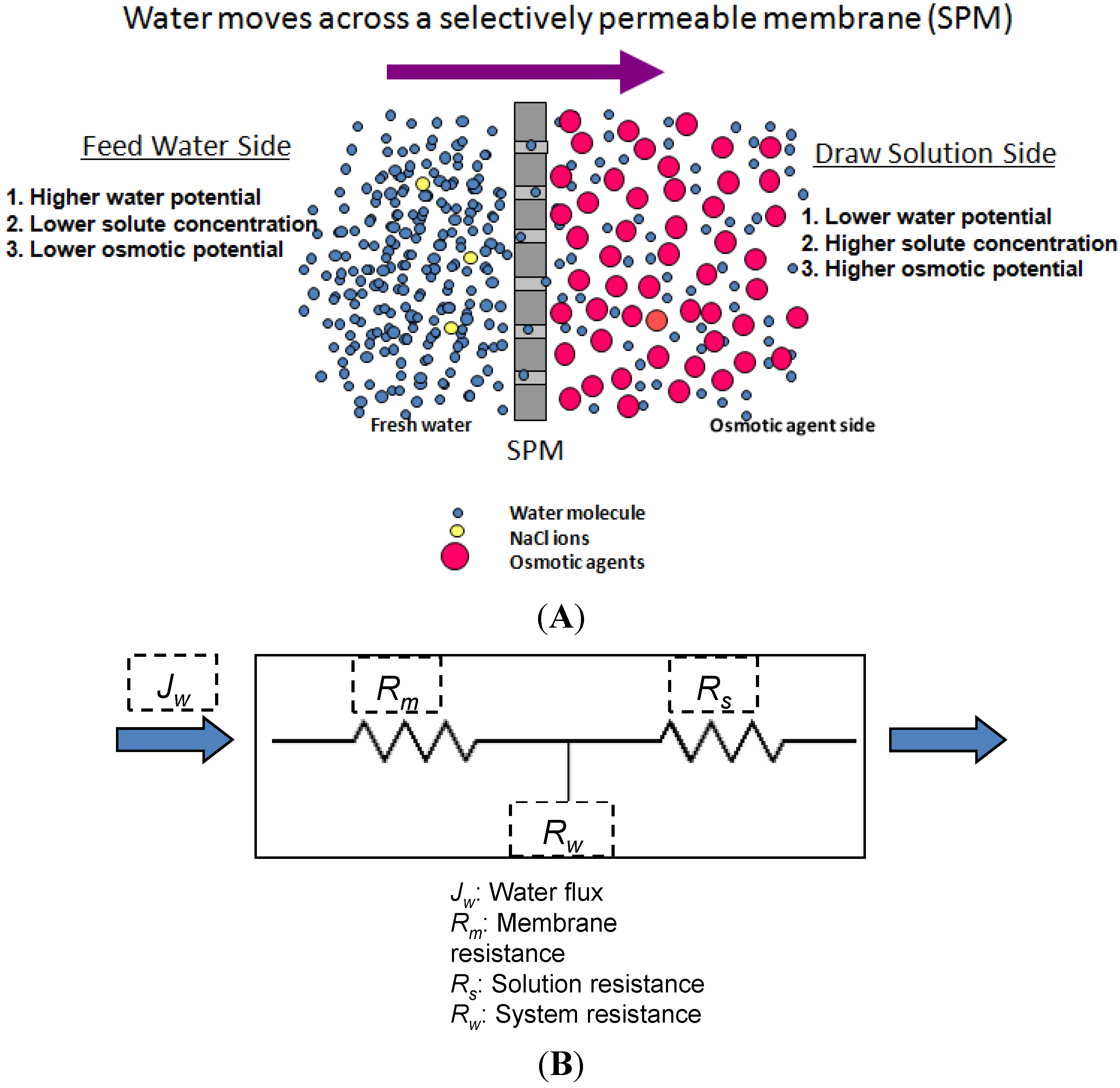

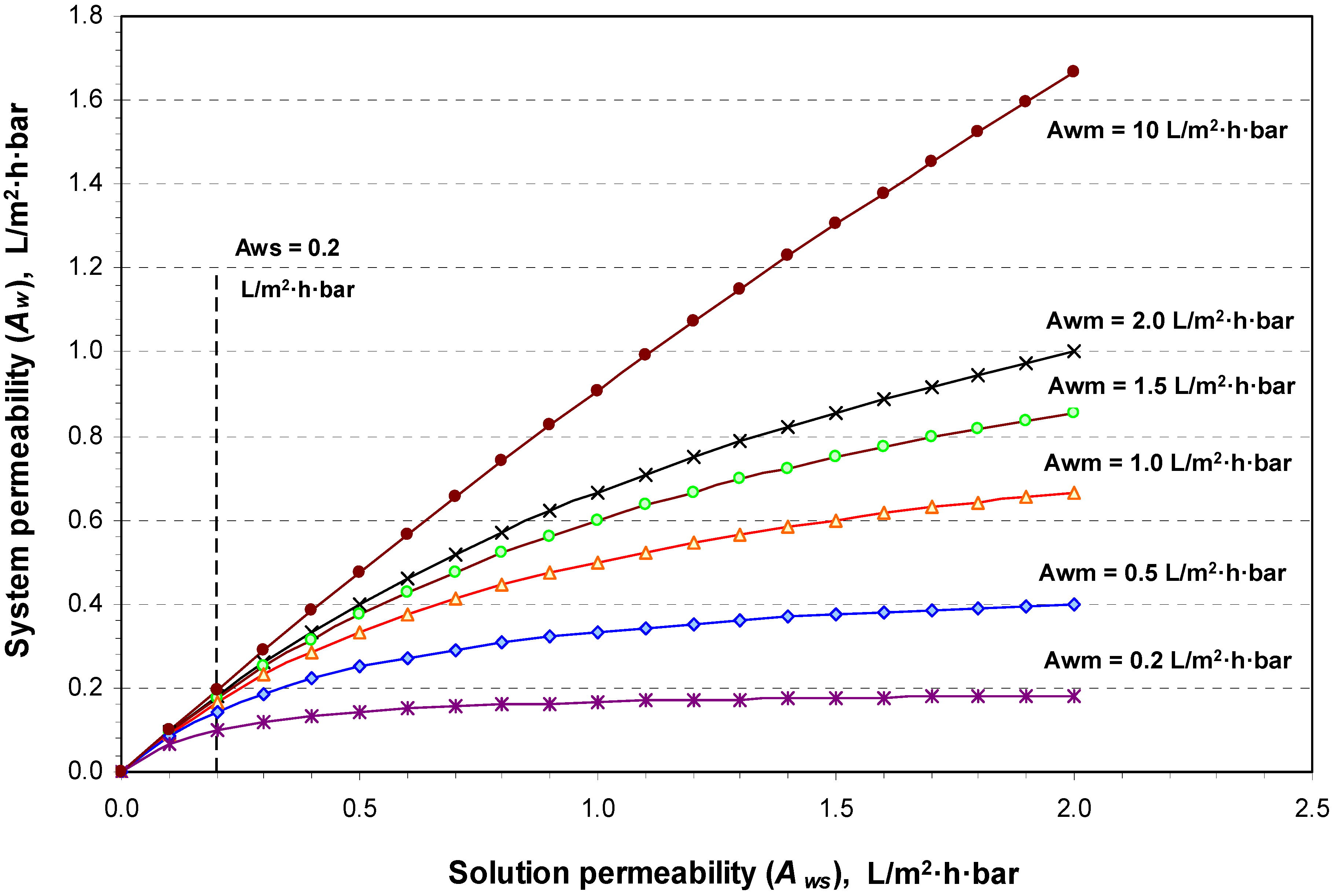

2. Basic Theory

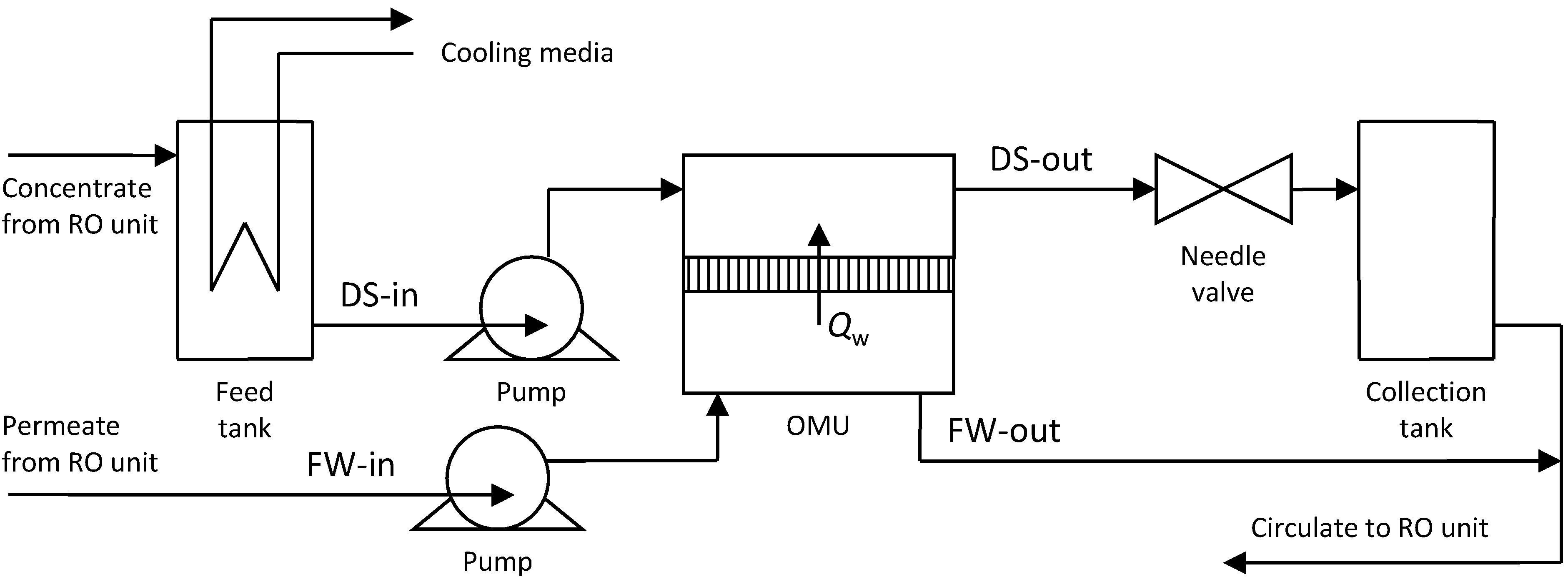

3. Experimental Setup

| Experiment No. | FW-in | DS-in | Osmotic pressure difference ∆Πf, bar | ||

|---|---|---|---|---|---|

| Concentration, ppm | Flow Rate, L/min | Concentration, ppm | Flow Rate, L/min | ||

| 1 | 240 | 11.1 | 34,560 | 9.8 | 27.4 |

| 2 | 6900 | 10.9 | 145,000 | 5.5 | 87.3 |

| 3 | 6900 | 9.5 | 34,690 | 5.5 | 22.1 |

4. Results and Discussion

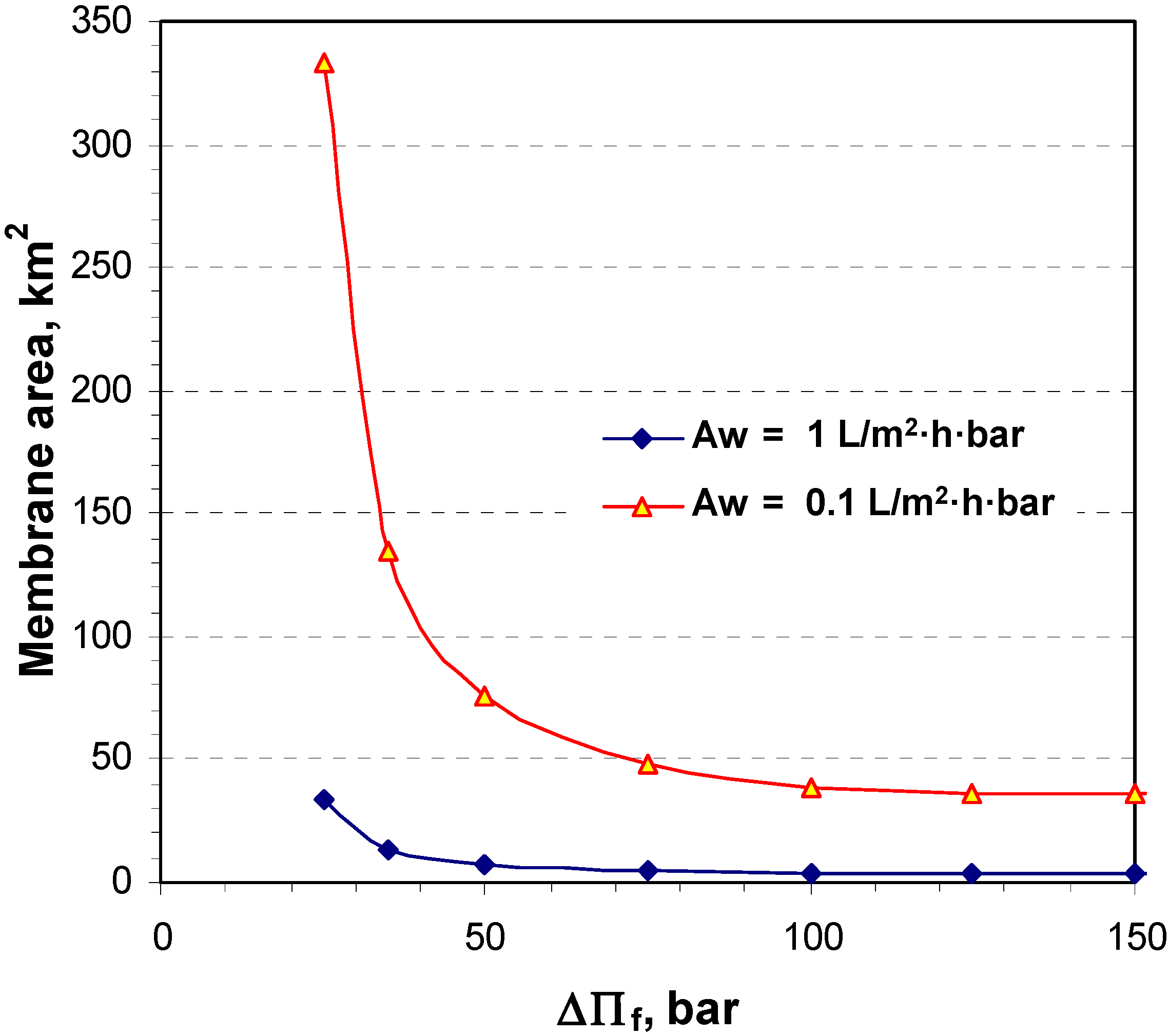

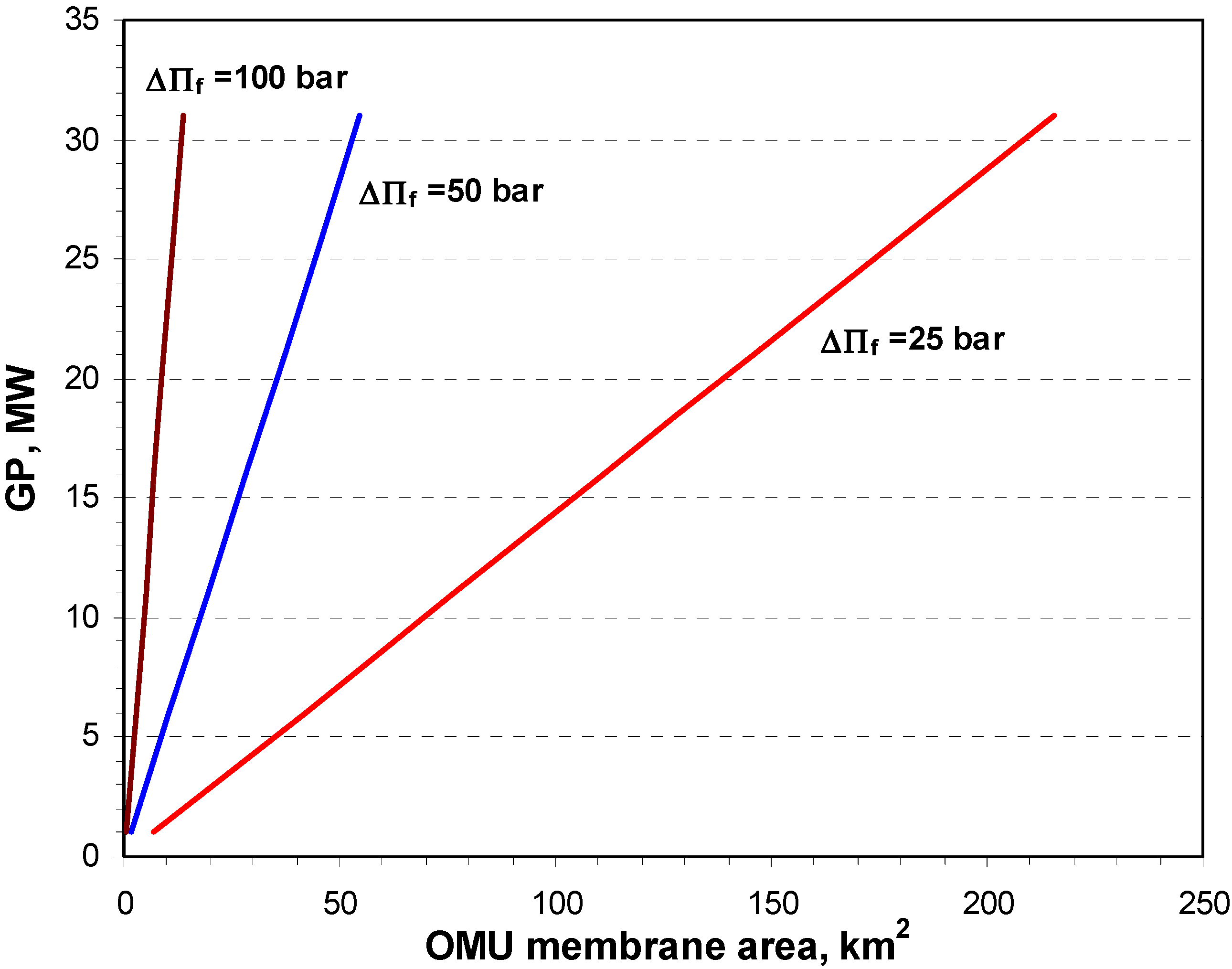

4.1. Theoretical Calculation Results

| Osmotic membrane unit (OMU) | Value |

| Inlet (concentrated) DS hydraulic pressure (bar) | 15.0 |

| DS side hydraulic pressure drop (%) | 10 |

| Membrane element area (m2) | 100.8 |

| DS dilution rate (%) | 100 |

| Freshwater inlet hydraulic pressure (bar) | 0.4 |

| Freshwater inlet osmotic pressure (bar) | 0.0 |

| Discharged freshwater hydraulic pressure (bar) | 0.1 |

| Freshwater recovery rate (%) | 95 |

| Regeneration unit (RU) (FO unit) | Value |

| Brine inlet maximum osmotic pressure (bar) | 250 |

| Brine inlet hydraulic pressure (bar) | 2.0 |

| Discharged (diluted) brine hydraulic pressure (bar) | 0.1 |

| DS side hydraulic pressure drop (%) | 30 |

| DS recovery rate (%) | 50 |

| Brine dilution rate (%) | 100 |

| Membrane element area (m2) | 100 |

| Efficiencies | Value |

| Pumps and booster (%) | 80 |

| Turbine and generator (%) | 80 |

| PES (%) | 95 |

| Diluted DS (PES/Turbine) input flowrate ratio | 1.5 |

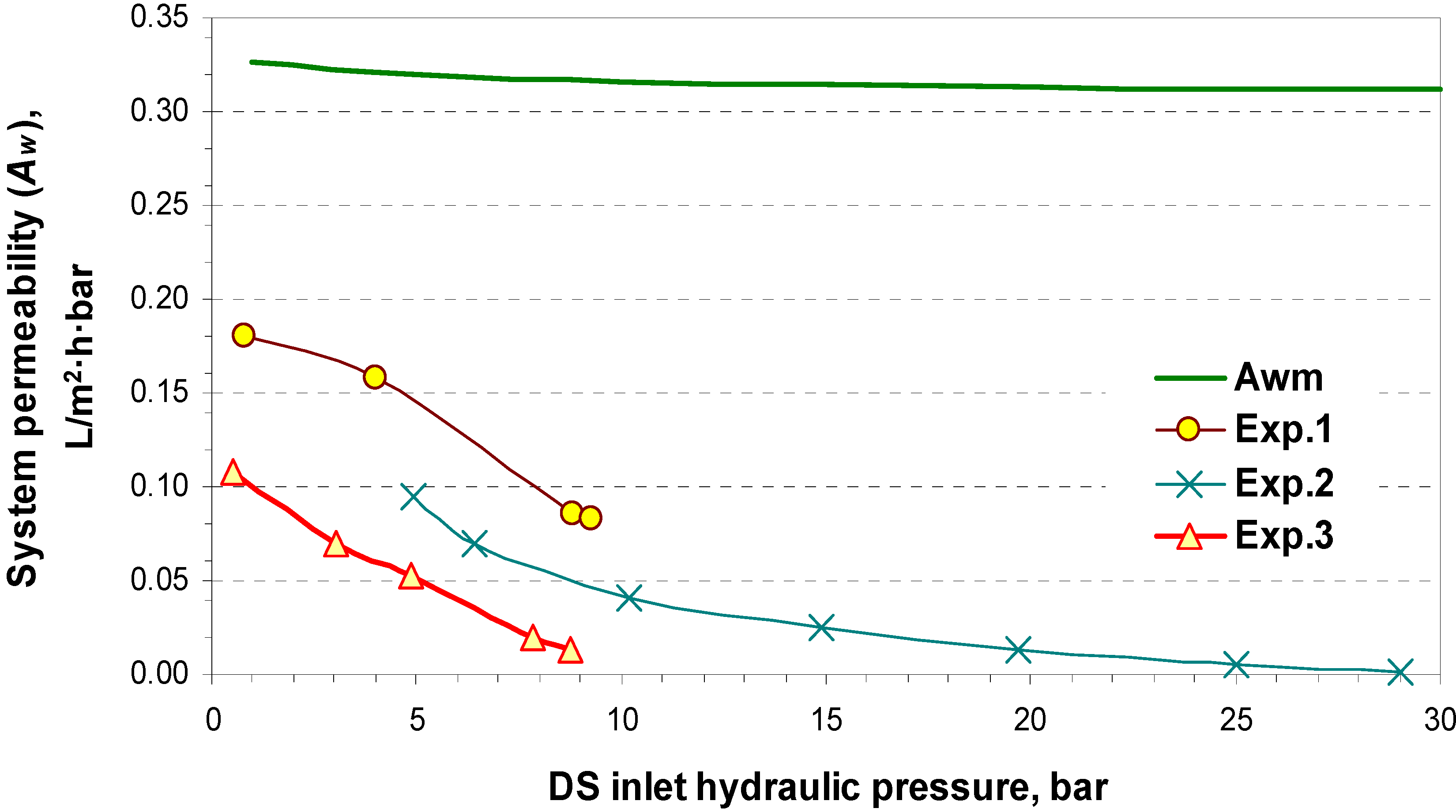

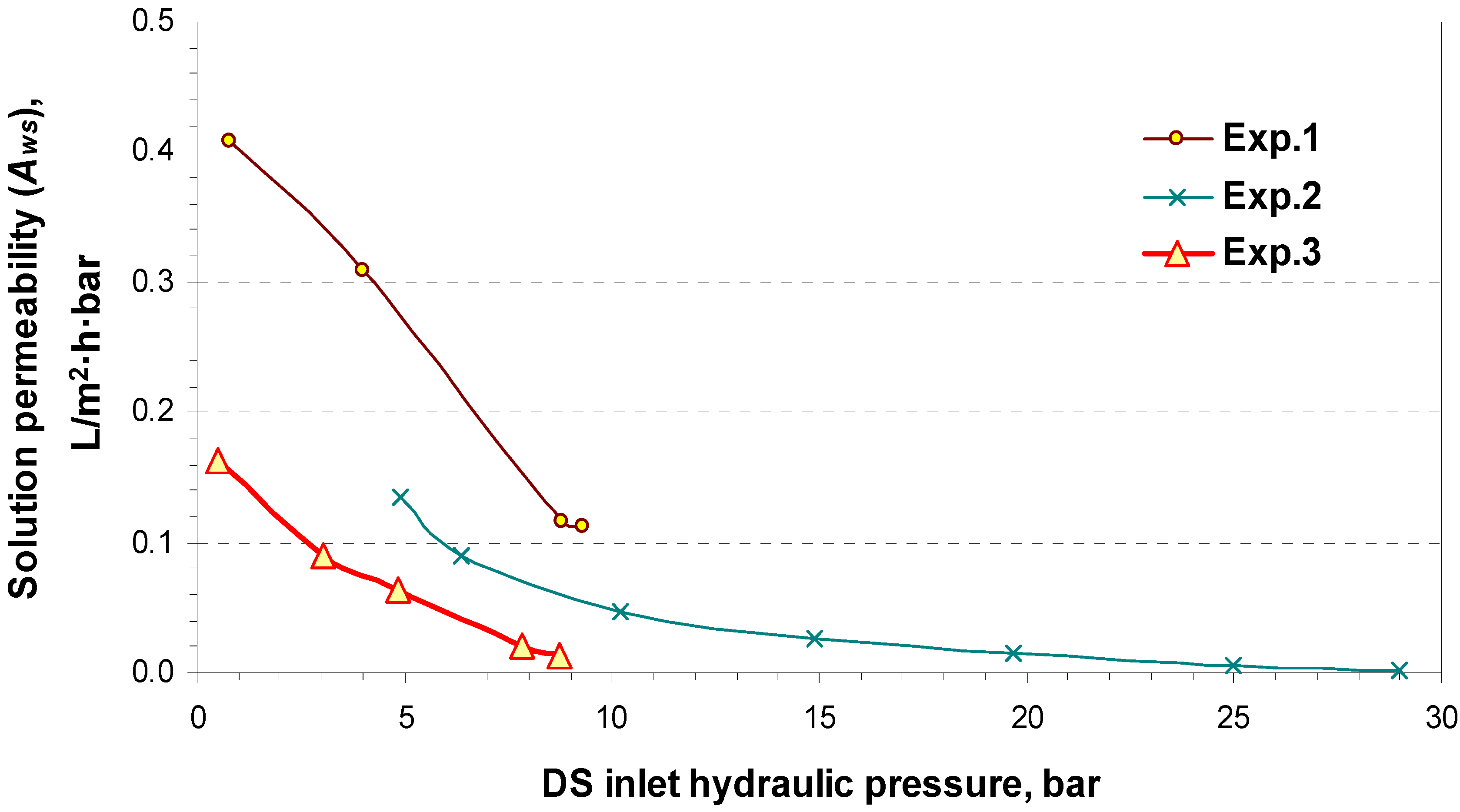

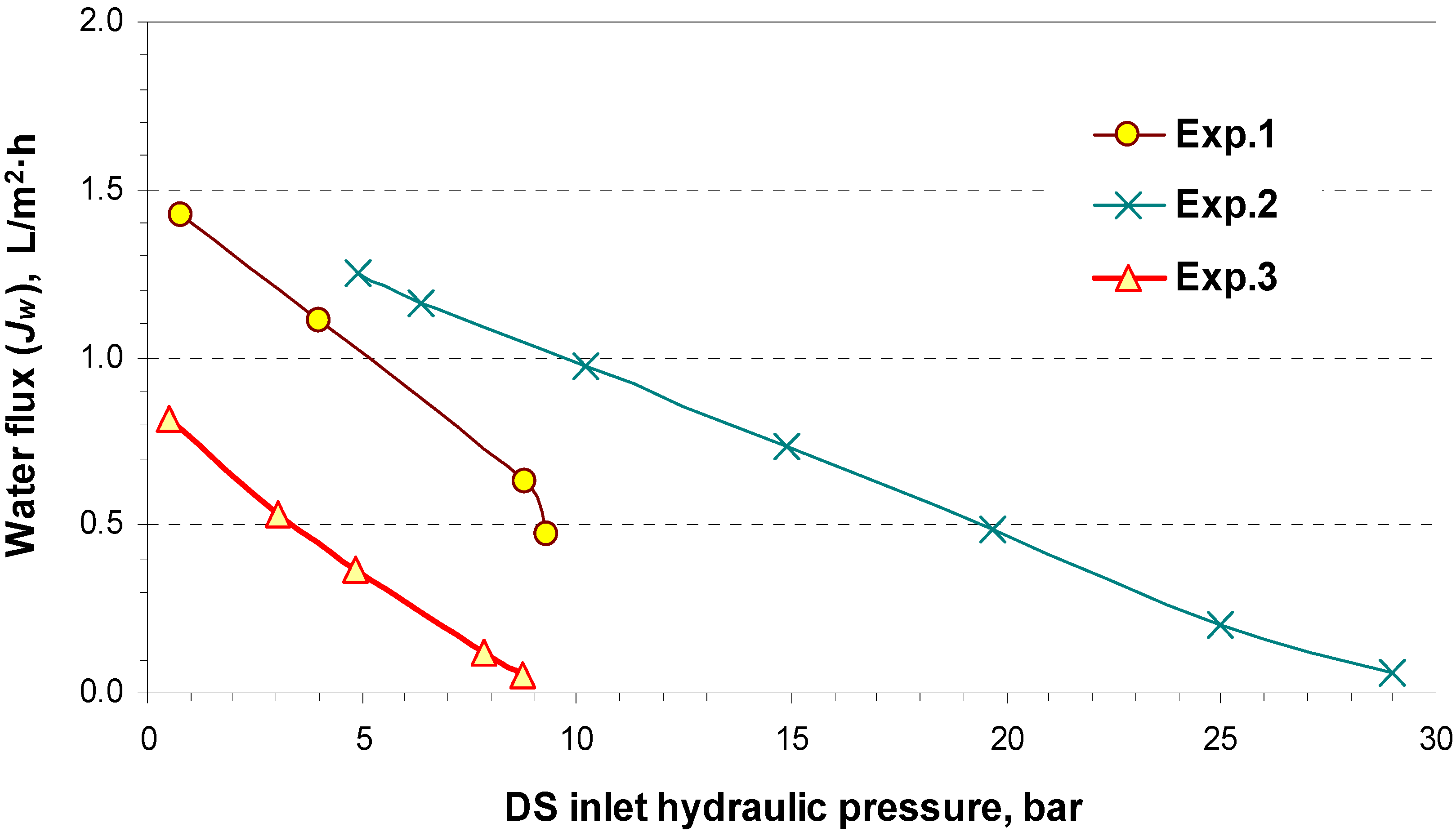

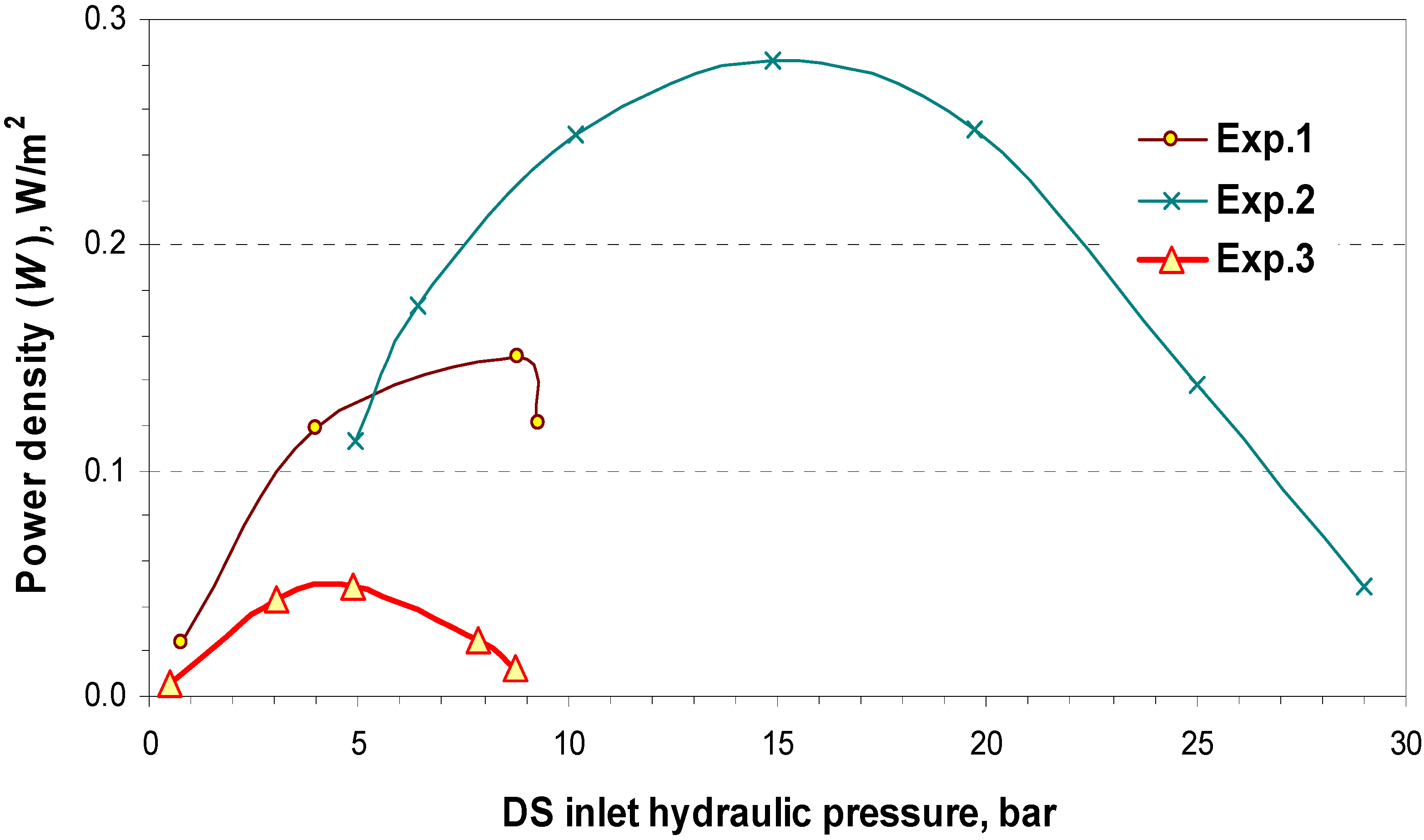

4.2. Pilot Plan Performance Test Results

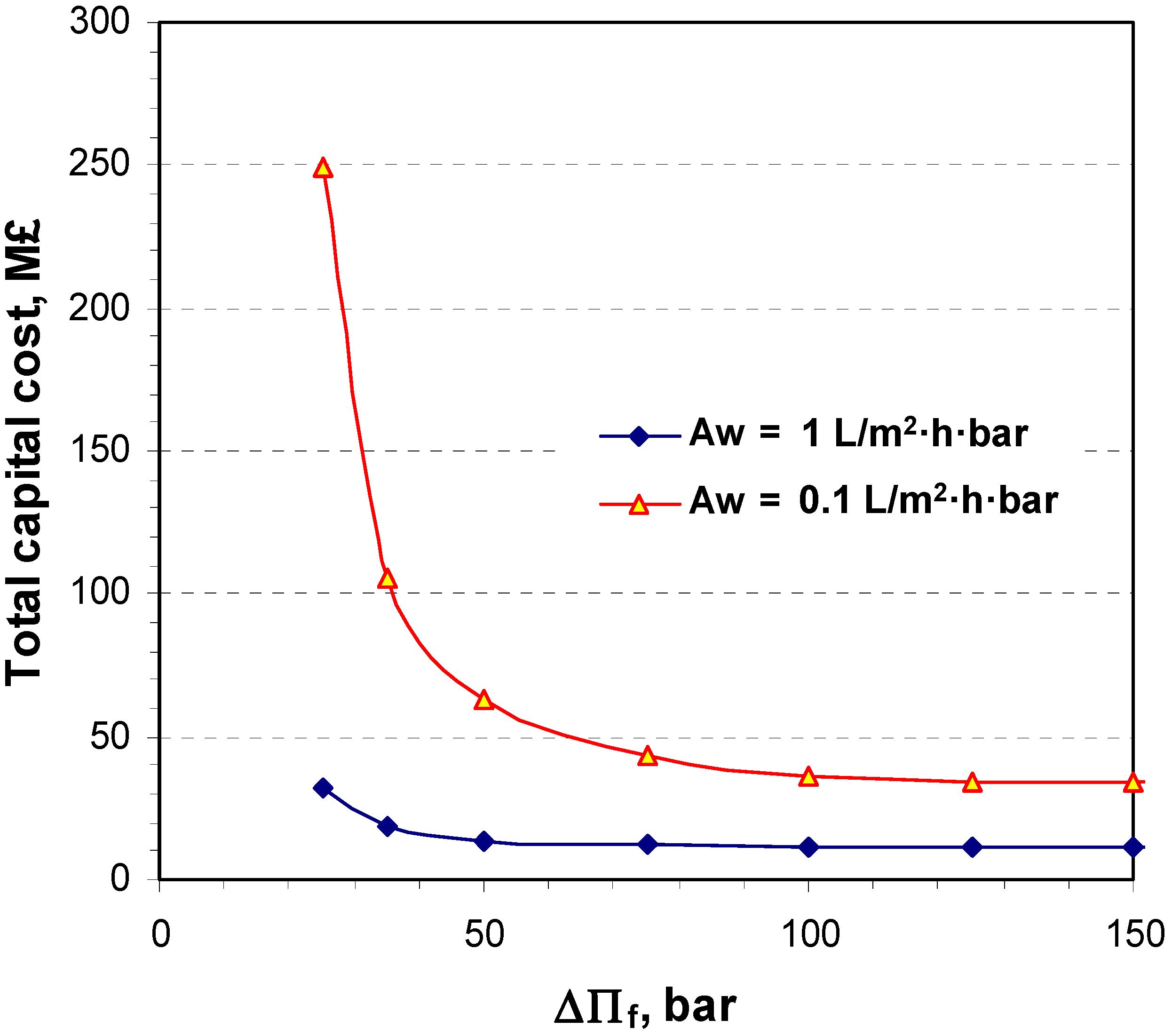

5. Commercial Potential and Cost Estimation

| Renewable/Non-Renewable Energy Sources | Estimated Energy Cost (€/MWh) Forecast 2030 |

|---|---|

| Nuclear | 45 |

| Gas CCGT | 85 |

| Oil CC | 125 |

| Coal PCC | 80 |

| Hydro dam | 85 |

| Hydro running | 48 |

| Biomass | 88 |

| Wind Offshore | 115 |

| Wind Onshore | 90 |

| Solar | 160 |

| Osmotic Energy | 50–100 |

| Plant Economic Performance | Value |

| Discount Rate (%) | 6 |

| Plant Lifetime (year) | 15 |

| Energy | Value |

| Industrial Electricity Price (£/kWh) | 0.05 |

| Turbine and Generator | Value |

| Specific Investment Cost (£/MWe) | 200,000 |

| O&M (% capital) | 3 |

| Life time (year) | 15 |

| Maximum Unit Capacity (MWe) | 100 |

| Low pressure pumps | Value |

| Specific Investment Cost (£/MWe) | 10,000 |

| Life time (year) | 15 |

| O & M (% capital) | 2.5 |

| Maximum Pump Unit Capacity (MWe) | 100 |

| Pressure exchanger system (PES) | Value |

| Specific Investment Cost (£/MW) | 50,000 |

| O&M costs (% capital) | 2.5 |

| Life time (year) | 15 |

| Maximum Unit Capacity (MWe) | 5 |

| Membranes (for both OMU and RU) | Value |

| Specific Investment Cost (£/module) | 70 |

| Life time (year) | 7 |

| Max Module Area (m2) | 100.8 |

| Pipes and valves | Value |

| Specific Cost (£/km) | 100,000 |

| Life time (year) | 15 |

| O&M costs (% capital) | 2.5 |

| Specific inv. Cost of Brine pre-treatment (% plant capital) | 4 |

| control system (£/MWe) | 10,000 |

| Specific cost of Draw Solution(£/m3) | 10 |

| Plant Availability (%) | 90 |

| Yearly Salary of Personnel (£/year) | 25,000 |

| No. of Personnel | 66 |

6. Conclusions

Nomenclature

Abbreviations

| HOP | Hydro-Osmotic Power |

| RE | Renewable Energy |

| RO | Reverse Osmosis |

| SEC | Specific Energy Consumption |

| ERS | Energy Recovery System |

| PRO | Pressure Retarded Osmosis |

| PES | Pressure Exchange System |

| OE | osmotic energy |

| FO | Forward Osmosis |

| DS | Draw Solution |

| CTA | Cellulose Triacetate |

| R&D | Research & Development |

| MW | Modern Water |

| CORA | Centre for Osmosis Research and Applications |

| OMU | Osmotic Membrane Unit |

| FW | Feed Water |

| RU | Regeneration Unit |

| OHE | Osmotic Heat Engine |

| SDPFFR | Solution-Diffusion Pore-Flow Fluid-Resistance |

| ASDPF | Analytical Solution-Diffusion Pore-Flow |

Symbols

| Jw | Water flux (L/m2·h) |

| AW | System permeability to water (L/m2·h·bar) |

| ∆П | Net osmotic pressure difference across membrane |

| ∆P | Net hydraulic pressure difference |

| W | Density of power (W/m2) |

| Awm | The membrane phase permeability (L/m2·h·bar) |

| Aws | The solution phase, the DS and the FW, permeability (L/m2·h·bar) |

| δmo | Membrane thickness |

| εo | Membrane porosity |

| τo | Membrane tortuosity |

| dmo | Membrane mean pore diameter |

| Dwo | Self-diffusivity |

| ρwo | Density |

| μo | Viscosity |

| Mw | Molecular weight of pure water at the reference temperature (To = 298.15 K) |

| Rg | Universal gas constant |

| T, Y, K, H | Constant values |

| П | Osmotic pressure (bar) |

| P | Hydraulic pressure (bar) |

| Q | The volumetric flow rate (m3/s) |

| Qw | The permeated water flow rate across the membrane (m3/s) |

| PG | The gross power production (MW) |

| ρE | The energy density (kWh/m3) |

| ES | The specific energy production (kWh/m3) |

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Herzog, A.V.; Lipman, T.E.; Kammen, D.M. Renewable Energy Sources. Available online: https://rael.berkeley.edu/sites/default/files/old-site-files/2001/Herzog-Lipman-Kammen-RenewableEnergy-2001.pdf (accessed on 28 July 2001).

- Loeb, S. Large-scale power production by pressure-retarded osmosis using river water and seawater passing through spiral modules. Desalination 2002, 143, 115–122. [Google Scholar] [CrossRef]

- Loeb, S. Method and Apparatus for Generating Power Utilizing Pressure-Retarded-Osmosis. U.S. Patent US4193267 A, 18 March 1980. [Google Scholar]

- Reali, M. Submarine hydro-electro-osmotic power plants for an efficient exploitation of salinity gradients. Energy 1981, 6, 227–231. [Google Scholar] [CrossRef]

- Sharif, A.O.; Rahal, Z.; Merdaw, A.A. Power from salt water- is water going to be the World’s new oil? Arab Water World XXXIV 2010, 2, 6–9. [Google Scholar]

- Logan, B.E.; Elimelech, M. Membrane-based processes for sustainable power generation using water. Nature 2012, 488, 313–319. [Google Scholar] [CrossRef]

- Skilhagen, S.E.; Dugstad, J.E.; Aaberg, R.J. Osmotic power-Power production based on the osmotic pressure difference between waters with varying salt gradients. Desalination 2008, 220, 476–482. [Google Scholar] [CrossRef]

- Al-Mayahi, A.; Sharif, A.O. Energy Generation Method (Osmotic Energy). European Patent 1660772, 27 June 2007. [Google Scholar]

- McGinnis, R.L.; McCutcheon, J.R.; Elimelech, M. A novel ammonia-carbon dioxide osmotic heat engine for power generation. J. Membr. Sci. 2007, 305, 13–19. [Google Scholar] [CrossRef]

- Helfer, F.; Lemckert, Ch.; Anissimov, Y.G. Osmotic power with Pressure Retarded Osmosis: Theory, performance and trends—A review. J. Membr. Sci. 2014, 453, 337–358. [Google Scholar] [CrossRef]

- Loeb, S.; Hessen, F.V.; Shahaf, D. Production of energy from concentrated brines by pressure-retarded osmosis II Experimental results and projected energy costs. J. Membr. Sci. 1976, 1, 249–269. [Google Scholar] [CrossRef]

- Mehta, G.D. Further results on the performance of present-day osmotic membranes in various osmotic regions. J. Membr. Sci. 1982, 10, 3–19. [Google Scholar] [CrossRef]

- Loeb, S.; Mehta, G.D. A two coefficient water transport equation for pressure retarded osmosis. J. Membr. Sci. 1979, 4, 351–362. [Google Scholar] [CrossRef]

- Mehta, G.D.; Loeb, S. Performance of permasep B-9 and B-10 membranes in various osmotic regions and at high osmotic pressures. J. Membr. Sci. 1979, 4, 335–349. [Google Scholar] [CrossRef]

- Lee, K.L.; Baker, R.W.; Lonsdale, H.K. Membrane for power generation by pressure retarded osmosis. J. Membr. Sci. 1981, 8, 141–171. [Google Scholar] [CrossRef]

- Jellinek, H.H.; Masuda, H. Osmo-power, theory and performance of an osmo-power pilot plant. Ocean Eng. 1981, 8, 103–128. [Google Scholar] [CrossRef]

- Gerstandt, K.; Peinemann, K.V.; Skilhagen, S.E.; Thorsen, T.; Holt, T. Membrane processes in energy supply for an osmotic power plant. Desalination 2008, 224, 64–70. [Google Scholar] [CrossRef]

- Achilli, A.; Cath, T.; Childress, A. Power generation with pressure retarded osmosis: An experimental and theoretical investigation. J. Membr. Sci. 2009, 343, 42–52. [Google Scholar] [CrossRef]

- Thorsen, T.; Holt, T. The potential for power production from salinity gradients by pressure retarded osmosis. J. Membr. Sci. 2009, 335, 103–110. [Google Scholar] [CrossRef]

- Chou, S.; Wang, R.; Shi, L.; She, Q.; Tang, C.; Fane, A.G. Thin-film composite hollow fibre membranes for pressure retarded osmosis (PRO) process with high power density. J. Membr. Sci. 2012, 389, 25–33. [Google Scholar] [CrossRef]

- Yip, N.; Elimelech, M. Thermodynamic and energy efficiency analysis of power generation from natural salinity gradients by pressure retarded osmosis. Energy Environ. Sci. 2012, 46, 5230–5239. [Google Scholar]

- She, Q.; Jin, X.; Tang, C. Osmotic power production from salinity gradient resource by pressure retarded osmosis: Effect of operating conditions and reverse solute diffusion. J. Membr. Sci. 2012, 401–402, 262–273. [Google Scholar] [CrossRef]

- Kim, Y.; Elimelech, M. Potential of osmotic power generation by pressure retarded osmosis using seawater as feed solution: Analysis and experiments. J. Membr. Sci. 2013, 429, 330–337. [Google Scholar] [CrossRef]

- Wang, R.; Tang, C.; Fane, A.G. Development of pressure retarded osmosis (PRO) membranes with high power density for osmotic power harvesting. In Proceedings of the 3rd Osmosis Membrane Summit, Statkraft, Barcelona, Spain, 26–27 April 2012.

- Schiestel, T.; Hänel, C.; Öxler, L.; Roelofs, K.; Walitza, E. Cellulose acetate membranes with an optimized internal structure for pressure retarded osmosis. In Proceedings of the 3rd Osmosis Membrane Summit, Statkraft, Barcelona, Spain, 26–27 April 2012.

- Saito, K.; Irie, M.; Zaitsu, S.; Sakai, H.; Hayashi, H.; Tanioka, A. Power generation with salinity gradient by pressure retarded osmosis using concentrated brine from SWRO system and treated sewage as pure water. Desalin. Water Treat. 2012, 41, 114–121. [Google Scholar] [CrossRef]

- Efraty, A. Pressure retarded osmosis in closed circuit without need of energy recovery. In Proceedings of the 3rd Osmosis Membrane Summit, Statkraft, Barcelona, Spain, 26–27 April 2012.

- Spiegler, K.S.; E1-Sayed, Y.M. The energetics of desalination processes. Desalination 2001, 134, 109–128. [Google Scholar] [CrossRef]

- Loeb, S. Energy production at the Dead Sea by pressure-retarded osmosis: Challenge or chimera? Desalination 1998, 120, 247–262. [Google Scholar] [CrossRef]

- Lachish, U. Osmosis and thermodynamics. Am. J. Phys. 2007, 75, 997–998. [Google Scholar] [CrossRef]

- Merdaw, A.A.; Sharif, A.O.; Derwish, G.A.W. Water permeability in polymeric membranes, Part II. Desalination 2010, 257, 184–194. [Google Scholar] [CrossRef]

- Toffoletto, M.; Merdaw, A.A.; Sharif, A.O.; Bertucco, A. Experimental approaches to feed solution permeability in pressure-driven membrane separation processes. J. Membr. Sci. 2010, 364, 27–33. [Google Scholar] [CrossRef]

- Merdaw, A.A.; Sharif, A.O.; Derwish, G.A.W. Mass transfer in pressure-driven membrane separation processes, Part I. Chem. Eng. J. 2011, 168, 215–228. [Google Scholar] [CrossRef]

- Merdaw, A.A.; Sharif, A.O.; Derwish, G.A.W. Water permeability in polymeric membranes, Part I. Desalination 2010, 260, 180–192. [Google Scholar] [CrossRef]

- Skilhagen, S. Osmotic power a new renewable energy source. Desalination 2010, 15, 271–278. [Google Scholar] [CrossRef]

- Sharif, A.O. Separation Process. UK Patent Application No. WO 2008/050087, September 2008. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Sharif, A.O.; Merdaw, A.A.; Aryafar, M.; Nicoll, P. Theoretical and Experimental Investigations of the Potential of Osmotic Energy for Power Production. Membranes 2014, 4, 447-468. https://doi.org/10.3390/membranes4030447

Sharif AO, Merdaw AA, Aryafar M, Nicoll P. Theoretical and Experimental Investigations of the Potential of Osmotic Energy for Power Production. Membranes. 2014; 4(3):447-468. https://doi.org/10.3390/membranes4030447

Chicago/Turabian StyleSharif, Adel O., Ali A. Merdaw, Maryam Aryafar, and Peter Nicoll. 2014. "Theoretical and Experimental Investigations of the Potential of Osmotic Energy for Power Production" Membranes 4, no. 3: 447-468. https://doi.org/10.3390/membranes4030447

APA StyleSharif, A. O., Merdaw, A. A., Aryafar, M., & Nicoll, P. (2014). Theoretical and Experimental Investigations of the Potential of Osmotic Energy for Power Production. Membranes, 4(3), 447-468. https://doi.org/10.3390/membranes4030447