A Review of Maricultural Wastewater Treatment Using an MBR: Insights into the Mechanism of Membrane Fouling Mitigation Through a Microalgal–Bacterial Symbiotic and Microbial Ecological Network

Abstract

1. Introduction

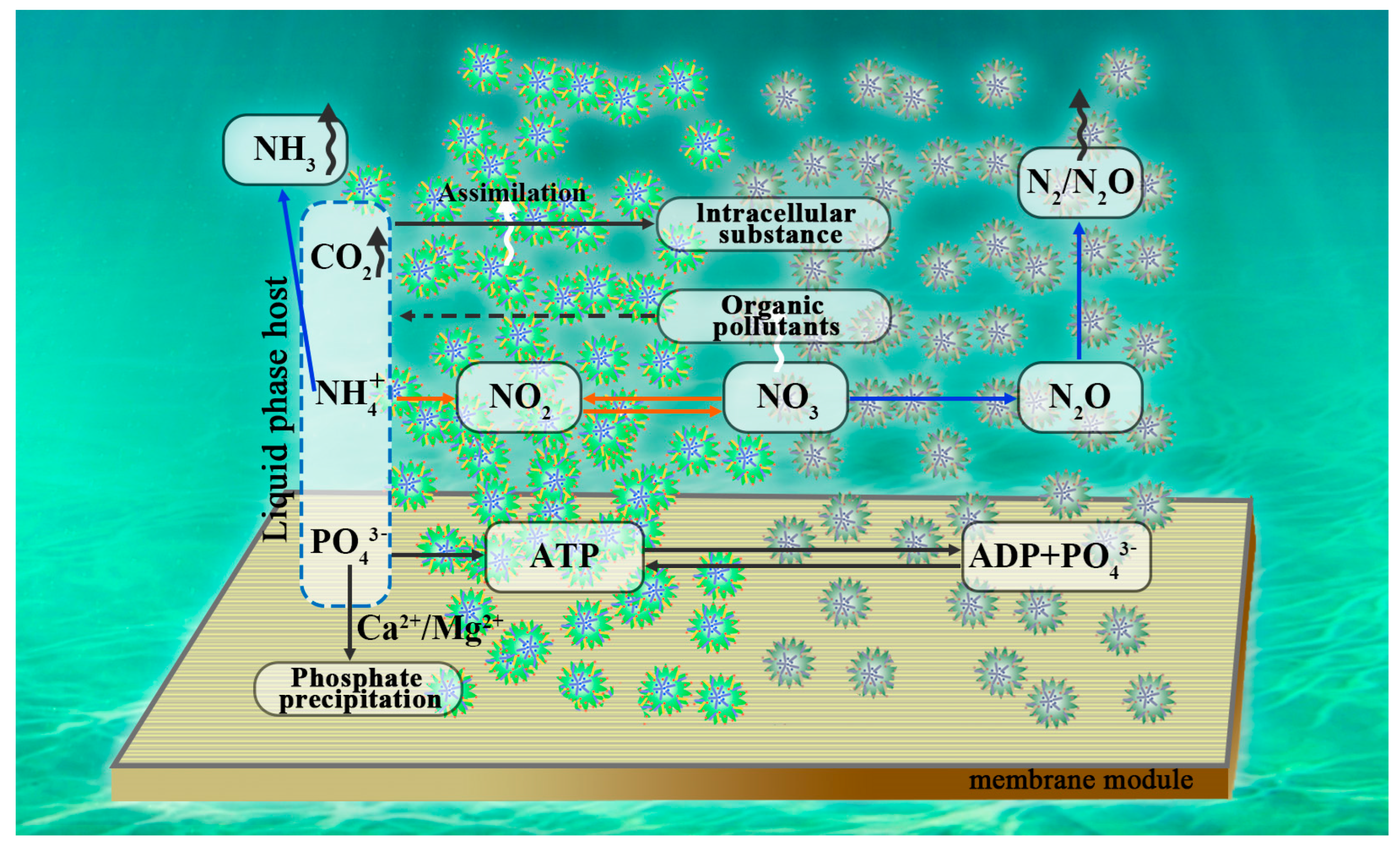

2. Membrane Fouling Mitigation Through Microalgal–Bacterial Interaction

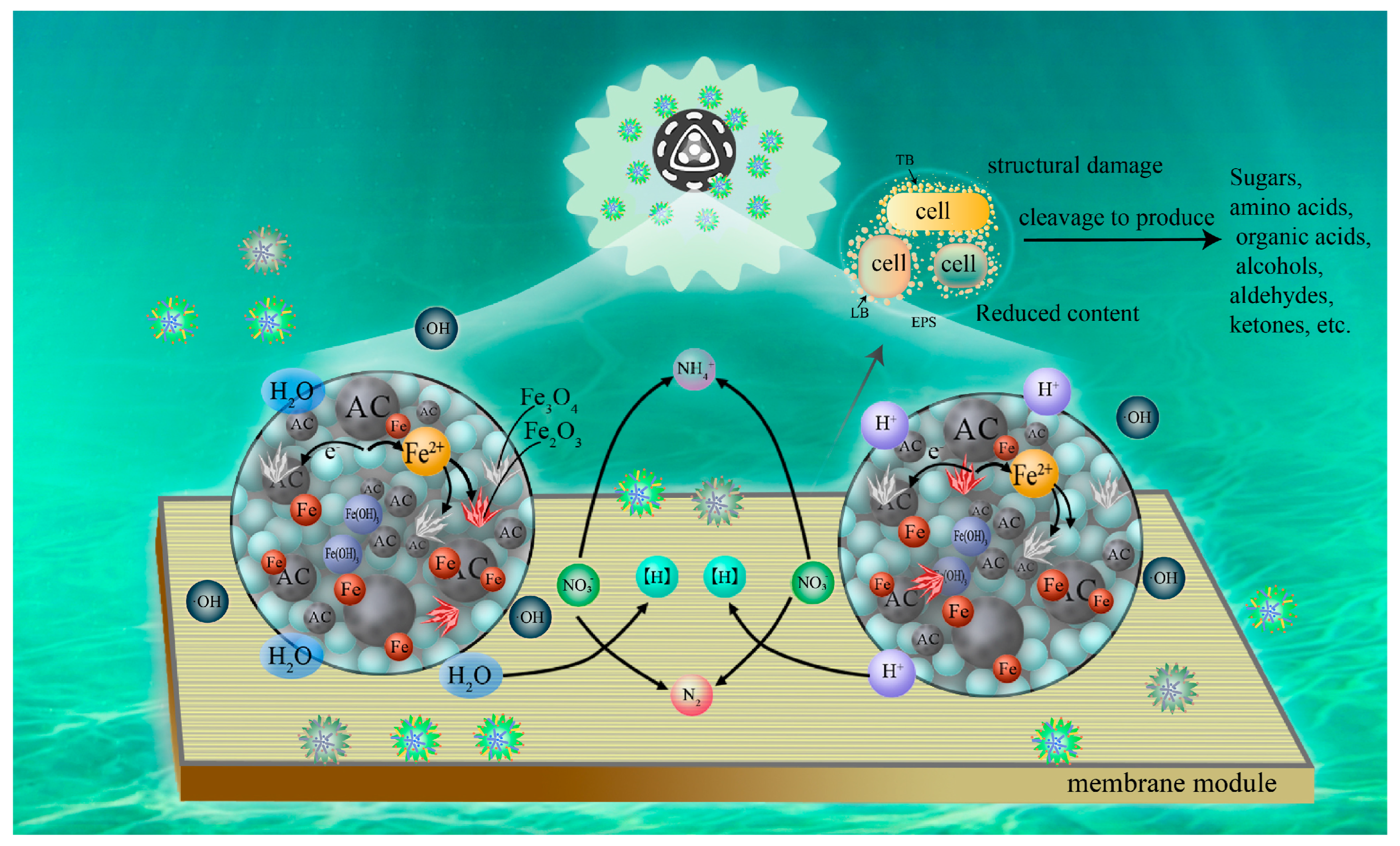

3. The Dual Advantages of Electrochemical Technology in the MBSS MBR

4. Microbial Community Analysis Based on Metagenomic Technology

4.1. Microbial Community Analysis in the MBR

4.2. Microbial Community Diversity in Actual Maricultural Wastewater

4.3. Distribution and Transmission of Antibiotic Resistance Genes

4.4. Functional Analysis of Microorganisms

4.5. Optimization of Wastewater Treatment Systems for Marine Aquaculture

4.6. Discovery and Application of Novel Microorganisms

5. Future Perspectives

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xu, J.; Han, L.M.; Yin, W. Research on the ecologicalization efficiency of mariculture industry in China and its influencing factors. Mar. Policy 2022, 137, 104935. [Google Scholar] [CrossRef]

- Lipp, M.; Bessy, C.; Cannavan, A.; Dupouy, E.; Fattori, V.; Kopko, C.; Lejeune, J.; Mukherjee, K.; Ferreira, J.P.; Schulz, D.; et al. Food and Agriculture Organization of the United Nations (FAO). In Encyclopedia of Food Safety, 2nd ed.; Smithers, G.W., Ed.; Academic Press: Oxford, UK, 2024; pp. 752–760. [Google Scholar] [CrossRef]

- Ji, J.Y.; Guo, X.; Zhang, Y. The study of symbiotic relationships between the economic and the ecological system of China’s mariculture industry-An empirical analysis of 10 coastal regions with Lokta-Volterra model. Reg. Stud. Mar. Sci. 2021, 48, 102051. [Google Scholar] [CrossRef]

- Gao, Y.D.; Guo, L.; Liao, Q.R.; Zhang, Z.S.; Zhao, Y.G.; Gao, M.C.; Jin, C.J.; She, Z.L.; Wang, G.C. Mariculture wastewater treatment with Bacterial-Algal Coupling System (BACS): Effect of light intensity on microalgal biomass production and nutrient removal. Environ. Res. 2021, 201, 111578. [Google Scholar] [CrossRef] [PubMed]

- Huang, F.; Pan, L.Q.; He, Z.Y.; Zhang, M.Y.; Zhang, M.Z. Heterotrophic nitrification-aerobic denitrification characteristics and antibiotic resistance of two bacterial consortia from Marinomonas and Halomonas with effective nitrogen removal in mariculture wastewater. J. Environ. Manag. 2021, 279, 111786. [Google Scholar] [CrossRef]

- Primavera, J.H. Overcoming the impacts of aquaculture on the coastal zone. Ocean Coast. Manag. 2006, 49, 531–545. [Google Scholar] [CrossRef]

- Li, J.; Wang, S.L.; Wang, Z.Z.; Zheng, Z.M.; Zhang, J. Assessing biomass activities, sludge characteristics and membrane fouling in the University of Cape Town membrane bioreactor under ferric chloride addition. Environ. Technol. Inno. 2021, 23, 101796. [Google Scholar] [CrossRef]

- Liu, C.C.; Yu, D.S.; Wang, Y.Y.; Chen, G.H.; Tang, P.; Huang, S. A novel control strategy for the partial nitrification and anammox process (PN/A) of immobilized particles: Using salinity as a factor. Bioresour. Technol. 2020, 302, 122864. [Google Scholar] [CrossRef]

- Osman, R.M.; Hodaifa, G. An overview of anaerobic membrane bioreactors: Current developments, fouling problems, and future prospects. J. Environ. Chem. Eng. 2023, 11, 111482. [Google Scholar] [CrossRef]

- Mannina, G.; Cosenza, A.; Rebouças, T.F. A plant-wide modelling comparison between membrane bioreactors and conventional activated sludge. Bioresour. Technol. 2020, 297, 122401. [Google Scholar] [CrossRef] [PubMed]

- Bis, M.; Montusiewicz, A.; Piotrowicz, A.; Łagód, G. Modeling of Wastewater Treatment Processes in Membrane Bioreactors Compared to Conventional Activated Sludge Systems. Processes 2019, 7, 285. [Google Scholar] [CrossRef]

- Zang, L.; Yang, X.L.; Xu, H.; Xia, Y.G.; Song, H.L. A novel integrated microbial fuel cell-membrane bioreactor (MFC-MBR) for controlling the spread of antibiotic and antibiotic resistance genes while simultaneously alleviating membrane fouling. Chem. Eng. J. 2024, 487, 150578. [Google Scholar] [CrossRef]

- Hu, P.; Shao, J.; Qian, G.; Adeleye, A.S.; Hao, T. Removal of tetracycline by aerobic granular sludge from marine aquaculture wastewater: A molecular dynamics investigation. Bioresour. Technol. 2022, 355, 127286. [Google Scholar] [CrossRef]

- Zhang, H.; Yuan, X.; Wang, H.; Ma, S.; Ji, B. Performance and Microbial Community of Different Biofilm Membrane Bioreactors Treating Antibiotic-Containing Synthetic Mariculture Wastewater. Membranes 2020, 10, 282. [Google Scholar] [CrossRef]

- Rahman, T.U.; Roy, H.; Islam, M.R.; Tahmid, M.; Fariha, A.; Mazumder, A.; Tasnim, N.; Pervez, M.N.; Cai, Y.; Naddeo, V.; et al. The Advancement in Membrane Bioreactor (MBR) Technology toward Sustainable Industrial Wastewater Management. Membranes 2023, 13, 181. [Google Scholar] [CrossRef]

- Li, L.; Qu, X.; Gong, W.; Guo, L.; Xie, B.; Li, W.; Zhang, G.; Tan, H.; Jia, Y.; Liang, J.; et al. The Impact of the Mechanism of Biocarriers on Bacterial–Microbial Symbiosis for Mariculture Wastewater Treatment: Performance and Microbial Community Evolution. Water 2025, 17, 1127. [Google Scholar] [CrossRef]

- Chen, S.; Wang, J.; Feng, X.; Zhao, F. Algal–Bacterial Symbiotic Granular Sludge Technology in Wastewater Treatment: A Review on Advances and Future Prospects. Water 2025, 17, 1647. [Google Scholar] [CrossRef]

- Yang, B.; Yan, Y.; Jia, Y.; Chen, B.; Khanal, S.K.; Shu, W.-S.; Lu, H. Optimizing formation of microalgal-bacterial granular sludge for aquaculture wastewater treatment. Chem. Eng. J. 2025, 504, 158884. [Google Scholar] [CrossRef]

- Alhajeri, N.S.; Tawfik, A.; Elsamadony, M.; Al-Fadhli, F.M.; Meng, F.G. Synergistic algal/bacterial interaction in membrane bioreactor for detoxification of 1,2-dichloroethane-rich petroleum wastewater. J. Hazard. Mater. 2024, 470, 134125. [Google Scholar] [CrossRef]

- Yao, M.; Ladewig, B.; Zhang, K. Identification of the change of soluble microbial products on membrane fouling in membrane bioreactor (MBR). Desalination 2011, 278, 126–131. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, B.; Ji, C.; Zhou, M.; Wang, L. Effects of hydraulic retention time on adsorption behaviours of EPS in an A/O-MBR: Biofouling study with QCM-D. Sci. Rep. 2017, 7, 2895. [Google Scholar] [CrossRef]

- Sun, L.; Tian, Y.; Li, H.; Wang, Q. Fouling potentials and properties of foulants in an innovative algal-sludge membrane bioreactor. Environ. Int. 2021, 151, 106439. [Google Scholar] [CrossRef]

- Najm, Y.; Jeong, S.; Leiknes, T. Nutrient utilization and oxygen production by Chlorella vulgaris in a hybrid membrane bioreactor and algal membrane photobioreactor system. Bioresour. Technol. 2017, 237, 64–71. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Shen, J.; Mao, X.; Zhang, B.; Shen, Y.; Shi, W. A novel membrane bioreactor inoculated with algal-bacterial granular sludge for sewage reuse and membrane fouling mitigation: Performance and mechanism. Environ. Pollut. 2023, 334, 122194. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Tian, Y.; Zhang, J.; Cui, H.; Zuo, W.; Li, J.Z. A novel symbiotic system combining algae and sludge membrane bioreactor technology for wastewater treatment and membrane fouling mitigation: Performance and mechanism. Chem. Eng. J. 2018, 344, 246–253. [Google Scholar] [CrossRef]

- Zhang, M.; Leung, K.-T.; Lin, H.; Liao, B. Effects of solids retention time on the biological performance of a novel microalgal-bacterial membrane photobioreactor for industrial wastewater treatment. J. Environ. Chem. Eng. 2021, 9, 105500. [Google Scholar] [CrossRef]

- Zhang, M.; Leung, K.-T.; Lin, H.; Liao, B. Evaluation of membrane fouling in a microalgal-bacterial membrane photobioreactor: Effects of SRT. Sci. Total Environ. 2022, 839, 156414. [Google Scholar] [CrossRef]

- Radmehr, S.; Peltomaa, E.; Kallioinen-Mänttäri, M.; Mänttäri, M. Effects of monospecific and mixed-algae culture on performance of algae-sludge membrane bioreactors. Bioresour. Technol. 2023, 371, 128605. [Google Scholar] [CrossRef]

- Radmehr, S.; Kallioinen-Mänttäri, M.; Mänttäri, M. Interplay role of microalgae and bio-carriers in hybrid membrane bioreactors on wastewater treatment, membrane fouling, and microbial communities. Environ. Pollut. 2023, 339, 122764. [Google Scholar] [CrossRef]

- Rong, H.W.; Li, Y.Y.; Wang, J.Y.; Zhang, Q.; Cui, B.H.; Guo, D.B. Towards advanced mariculture wastewater treatment by bacterial-algal symbiosis system with different bacteria and algae inoculation ratios. J. Water Process Eng. 2023, 53, 103826. [Google Scholar] [CrossRef]

- Fan, G.Z.; Huang, J.; Jiang, X.; Meng, W.L.; Yang, R.; Guo, J.S.; Fang, F.; Yang, J.X. Microalgae biofilm photobioreactor and its combined process for long-term stable treatment of high-saline wastewater achieved high pollutant removal efficiency. J. Environ. Chem. Eng. 2023, 11, 111473. [Google Scholar] [CrossRef]

- Zhao, L.; Tang, J.; Xu, Y.; Zhang, Y.; Song, Z.; Fu, G.; Hu, Z. A vertical-flow constructed wetland–microalgal membrane photobioreactor integrated system for treating high-pollution-load marine aquaculture wastewater: A lab-scale study. Sci. Total Environ. 2024, 919, 170465. [Google Scholar] [CrossRef] [PubMed]

- Lin, B.; Lai, Y.; Ke, Y.; Huang, Y.; Tao, Y.; Han, X.; Ma, J. Recent advances in biofilm technologies for breeding wastewater treatment: Fundamentals, performance and impacts of antibiotics. J. Water Process Eng. 2024, 62, 105429. [Google Scholar] [CrossRef]

- Song, Q.; Fang, Y.; Liu, Z.; Li, L.; Wang, Y.; Liang, J.; Huang, Y.; Lin, J.; Hu, L.; Zhang, J.; et al. The performance of porous hexagonal BN in high adsorption capacity towards antibiotics pollutants from aqueous solution. Chem. Eng. J. 2017, 325, 71–79. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, J.; Shi, J.; Yang, Y.; Ji, J.; Chen, R. A review of electro-conductive membrane enabled electrochemical anaerobic membrane bioreactor process for low-carbon wastewater treatment. J. Environ. Chem. Eng. 2024, 12, 113494. [Google Scholar] [CrossRef]

- Li, X.; Yang, H.; Wang, X.; Lu, S.; Wang, Y.; Liu, B.; Zhang, Y.; Zhao, H.; Tian, Z.; Zheng, X. Balancing sludge reduction and membrane fouling mitigation by tuning electrical voltages of a side-flow electrochemical oxidation system during MBR processing. J. Clean. Prod. 2023, 425, 138712. [Google Scholar] [CrossRef]

- Gharibian, S.; Hazrati, H. Towards practical integration of MBR with electrochemical AOP: Improved biodegradability of real pharmaceutical wastewater and fouling mitigation. Water Res. 2022, 218, 118478. [Google Scholar] [CrossRef]

- Mao, Z.; Liu, H.; Niu, B.; Bhagat, W.A.; Fan, W.; Liang, D.; Yang, L.; Zhao, Q.; Meng, S. Mitigation of fouling problem and optimization of treatment effect in the polyvinylidene fluoride (PVDF) based electrochemical membrane bioreactor (EMBR). Sep. Purif. Technol. 2024, 336, 126340. [Google Scholar] [CrossRef]

- Zhou, G.; Zhou, Y.; Zhou, G.; Lu, L.; Wan, X.; Shi, H. Assessment of a novel overflow-type electrochemical membrane bioreactor (EMBR) for wastewater treatment, energy recovery and membrane fouling mitigation. Bioresour. Technol. 2015, 196, 648–655. [Google Scholar] [CrossRef] [PubMed]

- Chung, C.M.; Tobino, T.; Cho, K.; Yamamoto, K. Alleviation of membrane fouling in a submerged membrane bioreactor with electrochemical oxidation mediated by in-situ free chlorine generation. Water Res. 2016, 96, 52–61. [Google Scholar] [CrossRef]

- Yang, Y.; Qiao, S.; Jin, R.; Zhou, J.; Quan, X. A novel aerobic electrochemical membrane bioreactor with CNTs hollow fiber membrane by electrochemical oxidation to improve water quality and mitigate membrane fouling. Water Res. 2019, 151, 54–63. [Google Scholar] [CrossRef] [PubMed]

- Cayetano, R.D.A.; Bae, S.; Oh, H.-S. Emerging biofouling control strategies in MBR systems: Quorum quenching, electrochemical methods, and mechanically imposed membrane shear. J. Water Process Eng. 2025, 73, 107684. [Google Scholar] [CrossRef]

- Chen, M.; Lei, Q.; Ren, L.; Li, J.; Li, X.; Wang, Z. Efficacy of electrochemical membrane bioreactor for virus removal from wastewater: Performance and mechanisms. Bioresour. Technol. 2021, 330, 124946. [Google Scholar] [CrossRef]

- Chen, M.; Ren, L.; Qi, K.; Li, Q.; Lai, M.; Li, Y.; Li, X.; Wang, Z. Enhanced removal of pharmaceuticals and personal care products from real municipal wastewater using an electrochemical membrane bioreactor. Bioresour. Technol. 2020, 311, 123579. [Google Scholar] [CrossRef]

- Chen, M.; Zheng, J.; Dai, R.; Wu, Z.; Wang, Z. Preferential removal of 2,4-dichlorophenoxyacetic acid from contaminated waters using an electrocatalytic ceramic membrane filtration system: Mechanisms and implications. Chem. Eng. J. 2020, 387, 124132. [Google Scholar] [CrossRef]

- Esteki, S.; Gharibian, S.; Hazrati, H.; Taheri, E. Application of an electrochemical filter-press flowcell in an electrocoagulation-MBR system: Efficient membrane fouling mitigation. J. Environ. Chem. Eng. 2024, 12, 111769. [Google Scholar] [CrossRef]

- Yang, Y.; Qiao, S.; Zheng, M.; Han, Q.; Wang, R.; Zhou, J.; Quan, X. Polyaniline derived carbon membrane and its in-situ membrane fouling mitigation performance in MBR based on metal-free electro-Fenton. Water Res. 2022, 219, 118564. [Google Scholar] [CrossRef]

- Karimi, L.; Hazrati, H.; Gharibian, S.; Shokrkar, H. Investigation of various anode and cathode materials in electrochemical membrane bioreactors for mitigation of membrane fouling. J. Environ. Chem. Eng. 2021, 9, 104857. [Google Scholar] [CrossRef]

- Chen, Q.; Wu, W.Q.; Guo, Y.F.; Li, J.T.; Wei, F. Environmental impact, treatment technology and monitoring system of ship domestic sewage: A review. Sci. Total Environ. 2022, 811, 151410. [Google Scholar] [CrossRef]

- Hong, J.; Li, W.; Lin, B.; Zhan, M.; Liu, C.; Chen, B.-Y. Deciphering the effect of salinity on the performance of submerged membrane bioreactor for aquaculture of bacterial community. Desalination 2013, 316, 23–30. [Google Scholar] [CrossRef]

- Xia, Z.; Ng, H.Y.; Bae, S. Synergistic microalgal-bacterial interactions enhance nitrogen removal in membrane-aerated biofilm photoreactors treating aquaculture wastewater under salt stress: Insights from metagenomic analysis. Water Res. 2025, 283, 123878. [Google Scholar] [CrossRef] [PubMed]

- Song, H.L.; Yang, X.L.; Xia, M.Q.; Chen, M. Co-metabolic degradation of steroid estrogens by heterotrophic bacteria and nitrifying bacteria in MBRs. J. Environ. Sci. Health Part A 2017, 52, 778–784. [Google Scholar] [CrossRef] [PubMed]

- Lagum, A.A.; Elektorowicz, M. Modification of nitrifying microbial community via DC electrical field application. J. Environ. Chem. Eng. 2022, 10, 107743. [Google Scholar] [CrossRef]

- Meng, Q.; Han, Y.; Zhu, H.; Yang, W.; Bello, A.; Deng, L.; Jiang, X.; Wu, X.; Sheng, S.; Xu, Y.; et al. Differences in distribution of functional microorganism at DNA and cDNA levels in cow manure composting. Ecotox Environ. Safe 2020, 191, 110161. [Google Scholar] [CrossRef]

- Li, S.; Guo, Y.; Zhang, X.; Feng, L.; Yong, X.; Xu, J.; Liu, Y.; Huang, X. Advanced nitrogen and phosphorus removal by the symbiosis of PAOs, DPAOs and DGAOs in a pilot-scale A2O/A+MBR process with a low C/N ratio of influent. Water Res. 2023, 229, 119459. [Google Scholar] [CrossRef]

- Sarioglu, M.; Sayi-Ucar, N.; Cokgor, E.; Orhon, D.; van Loosdrecht, M.C.M.; Insel, G. Dynamic modeling of nutrient removal by a MBR operated at elevated temperatures. Water Res. 2017, 123, 420–428. [Google Scholar] [CrossRef]

- Sahinkaya, E.; Yurtsever, A.; Isler, E.; Coban, I.; Aktaş, Ö. Sulfate reduction and filtration performances of an anaerobic membrane bioreactor (AnMBR). Chem. Eng. J. 2018, 349, 47–55. [Google Scholar] [CrossRef]

- Bertin, L.; Capodicasa, S.; Fedi, S.; Zannoni, D.; Marchetti, L.; Fava, F. Biotransformation of a highly chlorinated PCB mixture in an activated sludge collected from a Membrane Biological Reactor (MBR) subjected to anaerobic digestion. J. Hazard. Mater. 2011, 186, 2060–2067. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.; Gao, M.; Zhang, M.; Feng, L.; Liu, Q.; Zhang, G. Application of encapsulated algae into MBR for high-ammonia nitrogen wastewater treatment and biofouling control. Water Res. 2020, 187, 116430. [Google Scholar] [CrossRef] [PubMed]

- Maza-Márquez, P.; Vilchez-Vargas, R.; Kerckhof, F.M.; Aranda, E.; González-López, J.; Rodelas, B. Community structure, population dynamics and diversity of fungi in a full-scale membrane bioreactor (MBR) for urban wastewater treatment. Water Res. 2016, 105, 507–519. [Google Scholar] [CrossRef] [PubMed]

- Ramírez-Fernández, L.; Orellana, L.H.; Johnston, E.R.; Konstantinidis, K.T.; Orlando, J. Diversity of microbial communities and genes involved in nitrous oxide emissions in Antarctic soils impacted by marine animals as revealed by metagenomics and 100 metagenome-assembled genomes. Sci. Total Environ. 2021, 788, 147693. [Google Scholar] [CrossRef]

- Xiong, X.; Bond, T.; Saboor Siddique, M.; Yu, W. The stimulation of microbial activity by microplastic contributes to membrane fouling in ultrafiltration. J. Membrane Sci. 2021, 635, 119477. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, J.; Li, W.; Xie, B.; Zhang, G.; Ding, Y.; Liu, F.; Tan, H.; Jia, Y.; You, H.; et al. Mechanism of membrane fouling mitigation by microalgae biofilm formation for low C/N mariculture wastewater treatment: EPS characteristics, composition and interfacial interaction energy. J. Environ. Chem. Eng. 2024, 12, 114146. [Google Scholar] [CrossRef]

- Zhang, H.F.; Wu, J.H.; Li, R.F.; Kim, D.H.; Bi, X.J.; Zhang, G.L.; Jiang, B.; Ng, H.Y.; Shi, X.Q. Novel intertidal wetland sediment-inoculated moving bed biofilm reactor treating high-salinity wastewater: Metagenomic sequencing revealing key functional microorganisms. Bioresour. Technol. 2022, 348, 126817. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Jun, Y.; Zhao, C.; Zhou, C.; Zhu, T.; Shao, S. Using Fe(II)/Fe(VI) activated peracetic acid as pretreatment of ultrafiltration for secondary effluent treatment: Water quality improvement and membrane fouling mitigation. Water Res. 2023, 244, 120533. [Google Scholar] [CrossRef]

- Gong, W.; Guo, L.; Huang, C.; Xie, B.; Jiang, M.; Zhao, Y.; Zhang, H.; Wu, Y.; Liang, H. A systematic review of antibiotics and antibiotic resistance genes (ARGs) in mariculture wastewater: Antibiotics removal by microalgal-bacterial symbiotic system (MBSS), ARGs characterization on the metagenomic. Sci. Total Environ. 2024, 930, 172601. [Google Scholar] [CrossRef]

- Zhou, S.; Zhu, Y.J.; Yan, Y.; Wang, W.G.; Wang, Y.Y. Deciphering extracellular antibiotic resistance genes (eARGs) in activated sludge by metagenome. Water Res. 2019, 161, 610–620. [Google Scholar] [CrossRef]

- Cai, C.; Huang, X.; Dai, X. Differential variations of intracellular and extracellular antibiotic resistance genes between treatment units in centralized sewage sludge treatment plants. Water Res. 2022, 222, 118893. [Google Scholar] [CrossRef] [PubMed]

- Man, Y.; Zhang, H.; Huang, J.; Xi, S.; Wang, J.; Tao, H.; Zhou, Y. Combined effect of tetracycline and copper ion on catalase activity of microorganisms during the biological phosphorus removal. J. Environ. Manag. 2022, 304, 114218. [Google Scholar] [CrossRef]

- Cao, Y.; Huang, R.H.; Li, T.H.; Pan, D.D.; Shao, S.C.; Wu, X.W. Effect of antibiotics on the performance of moving bed biofilm reactor for simultaneous removal of nitrogen, phosphorus and copper(II) from aquaculture wastewater. Ecotox Environ. Safe 2023, 266, 115590. [Google Scholar] [CrossRef]

- Wang, L.; Lin, Y.; Ye, L.; Qian, Y.; Shi, Y.; Xu, K.; Ren, H.; Geng, J. Microbial Roles in Dissolved Organic Matter Transformation in Full-Scale Wastewater Treatment Processes Revealed by Reactomics and Comparative Genomics. Environ. Sci. Technol. 2021, 55, 11294–11307. [Google Scholar] [CrossRef]

- Lin, H.; Du, Y.; Yu, M.; Zhang, W.; Cai, W. Unveiling the impacts of salts on halotolerant bacteria during filtration: A new perspective on membrane biofouling formation in MBR treating high-saline organic wastewater. Chemosphere 2024, 364, 143258. [Google Scholar] [CrossRef]

- Feng, Y.; Sun, J.-W.; Shi, W.-W.; Duan, J.-L.; Sun, X.-D.; Feng, L.-J.; Wang, Q.; Gan, Y.-D.; Yuan, X.-Z. Microplastics exhibit accumulation and horizontal transfer of antibiotic resistance genes. J. Environ. Manag. 2023, 336, 117632. [Google Scholar] [CrossRef]

- Zhao, Z.; Wei, Y.; Wang, Y.; Peng, G.; Zeng, E.Y.; Yu, K.; Xu, X.-R.; Li, R. Fate and drivers of mariculture-derived microplastics from ponds to mangrove forests. Environ. Pollut. 2024, 361, 124790. [Google Scholar] [CrossRef]

- Li, H.K.; Shen, M.C.; Li, M.Y.; Tao, S.Y.; Li, T.H.; Yang, Z.X. Removal of microplastics and resistance genes in livestock and aquaculture wastewater: Current knowledge and future directions. J. Environ. Chem. Eng. 2024, 12, 113384. [Google Scholar] [CrossRef]

- Rodríguez, E.; García-Encina, P.A.; Stams, A.J.M.; Maphosa, F.; Sousa, D.Z. Meta-omics approaches to understand and improve wastewater treatment systems. Rev. Environ. Sci. Bio/Technol. 2015, 14, 385–406. [Google Scholar] [CrossRef]

- Tikariha, H.; Purohit, H.J. Unfolding microbial community intelligence in aerobic and anaerobic biodegradation processes using metagenomics. Arch. Microbiol. 2020, 202, 1269–1274. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.-H.; Lu, J.; Zhang, Y.-X.; Wu, J.; Luo, Y.; Liu, H. Metagenomic analysis of antibiotic resistance genes in coastal industrial mariculture systems. Bioresour. Technol. 2018, 253, 235–243. [Google Scholar] [CrossRef]

- Pratap, V.; Kumar, R.; Kumar, S.; Yadav, B.R. Optimization of moving bed biofilm reactors for the treatment of municipal wastewater. Environ. Res. 2024, 241, 117560. [Google Scholar] [CrossRef]

- Gao, Y.; Guo, L.; Jin, C.; Zhao, Y.; Gao, M.; She, Z.; Wang, G. Metagenomics and network analysis elucidating the coordination between fermentative bacteria and microalgae in a novel bacterial-algal coupling reactor (BACR) for mariculture wastewater treatment. Water Res. 2022, 215, 118256. [Google Scholar] [CrossRef]

- Neshat, S.A.; Santillan, E.; Seshan, H.; Wuertz, S. Non-redundant metagenome-assembled genomes of activated sludge reactors at different disturbances and scales. Sci. Data 2024, 11, 855. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Park, H.; Jang, J.U.; Kim, H.; Park, H.; Iqbal, T.; Oh, H.S.; Choo, K.H.; Lee, K. Benefits of fungal-to-bacterial quorum quenching as anti-biofouling strategy in membrane bioreactors for wastewater treatment and water reuse. Bioresour. Technol. 2024, 403, 130848. [Google Scholar] [CrossRef] [PubMed]

| Microbial Community | Functions and Roles | Major Wastewater Types |

|---|---|---|

| Heterotrophic bacteria (e.g., Pseudomonas spp.) | Decompose organic matter, reducing BOD and COD [52] | Domestic wastewater, food processing wastewater, aquaculture wastewater |

| Nitrifying bacteria (e.g., Nitrosomonas spp., Nitrobacter spp.) | Convert ammonia into nitrite and nitrate, facilitating nitrification [53] | Domestic wastewater, aquaculture wastewater, nitrogen-rich industrial wastewater |

| Denitrifying bacteria (e.g., Paracoccus spp., Pseudomonas spp.) | Reduce nitrate and nitrite to nitrogen gas under anoxic conditions [54] | Domestic wastewater, industrial wastewater, aquaculture wastewater |

| Polyphosphate-accumulating organisms (PAOs, e.g., Candidatus Accumulibacter spp.) | Uptake and store phosphorus, removing total phosphorus [55] | Phosphorus-containing industrial wastewater, domestic wastewater |

| Phosphate-releasing bacteria (e.g., certain Pseudomonas spp.) | Release phosphate for denitrifying and PAOs’ utilization [56] | Domestic wastewater, aquaculture wastewater |

| Sulfate-reducing bacteria (SRB, e.g., Desulfovibrio spp.) | Reduce sulfate to sulfide, aiding in heavy metal precipitation [57] | Industrial wastewater (e.g., mining wastewater, petrochemical wastewater) |

| Methanogens (e.g., Methanosarcina spp.) | Convert organic matter into methane and carbon dioxide [58] | High-strength organic wastewater (e.g., slaughterhouse, food processing wastewater) |

| Algae (e.g., Chlorella, Spirulina) | Absorb nitrogen and phosphorus, purify water, and provide oxygen [59] | Aquaculture wastewater, domestic wastewater |

| Fungi (e.g., yeasts, molds) | Degrade complex organic matter and recalcitrant pollutants [60] | Industrial wastewater (e.g., pharmaceutical, textile wastewater) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, Y.; Zhao, S.; Xie, B.; Li, Z.; Gong, W.; Zhang, G.; Li, Q.; Zhao, X.; Xin, Z.; Wu, J.; et al. A Review of Maricultural Wastewater Treatment Using an MBR: Insights into the Mechanism of Membrane Fouling Mitigation Through a Microalgal–Bacterial Symbiotic and Microbial Ecological Network. Membranes 2025, 15, 234. https://doi.org/10.3390/membranes15080234

You Y, Zhao S, Xie B, Li Z, Gong W, Zhang G, Li Q, Zhao X, Xin Z, Wu J, et al. A Review of Maricultural Wastewater Treatment Using an MBR: Insights into the Mechanism of Membrane Fouling Mitigation Through a Microalgal–Bacterial Symbiotic and Microbial Ecological Network. Membranes. 2025; 15(8):234. https://doi.org/10.3390/membranes15080234

Chicago/Turabian StyleYou, Yijun, Shuyu Zhao, Binghan Xie, Zhipeng Li, Weijia Gong, Guoyu Zhang, Qinghao Li, Xiangqian Zhao, Zhaofeng Xin, Jinkang Wu, and et al. 2025. "A Review of Maricultural Wastewater Treatment Using an MBR: Insights into the Mechanism of Membrane Fouling Mitigation Through a Microalgal–Bacterial Symbiotic and Microbial Ecological Network" Membranes 15, no. 8: 234. https://doi.org/10.3390/membranes15080234

APA StyleYou, Y., Zhao, S., Xie, B., Li, Z., Gong, W., Zhang, G., Li, Q., Zhao, X., Xin, Z., Wu, J., Gao, Y., & Xiang, H. (2025). A Review of Maricultural Wastewater Treatment Using an MBR: Insights into the Mechanism of Membrane Fouling Mitigation Through a Microalgal–Bacterial Symbiotic and Microbial Ecological Network. Membranes, 15(8), 234. https://doi.org/10.3390/membranes15080234