Mathematical and Statistical Evaluation of Reverse Osmosis in the Removal of Manganese as a Way to Achieve Sustainable Operating Parameters

Abstract

1. Introduction

1.1. Manganese and Health Risks

1.2. Removal of Manganese from Water

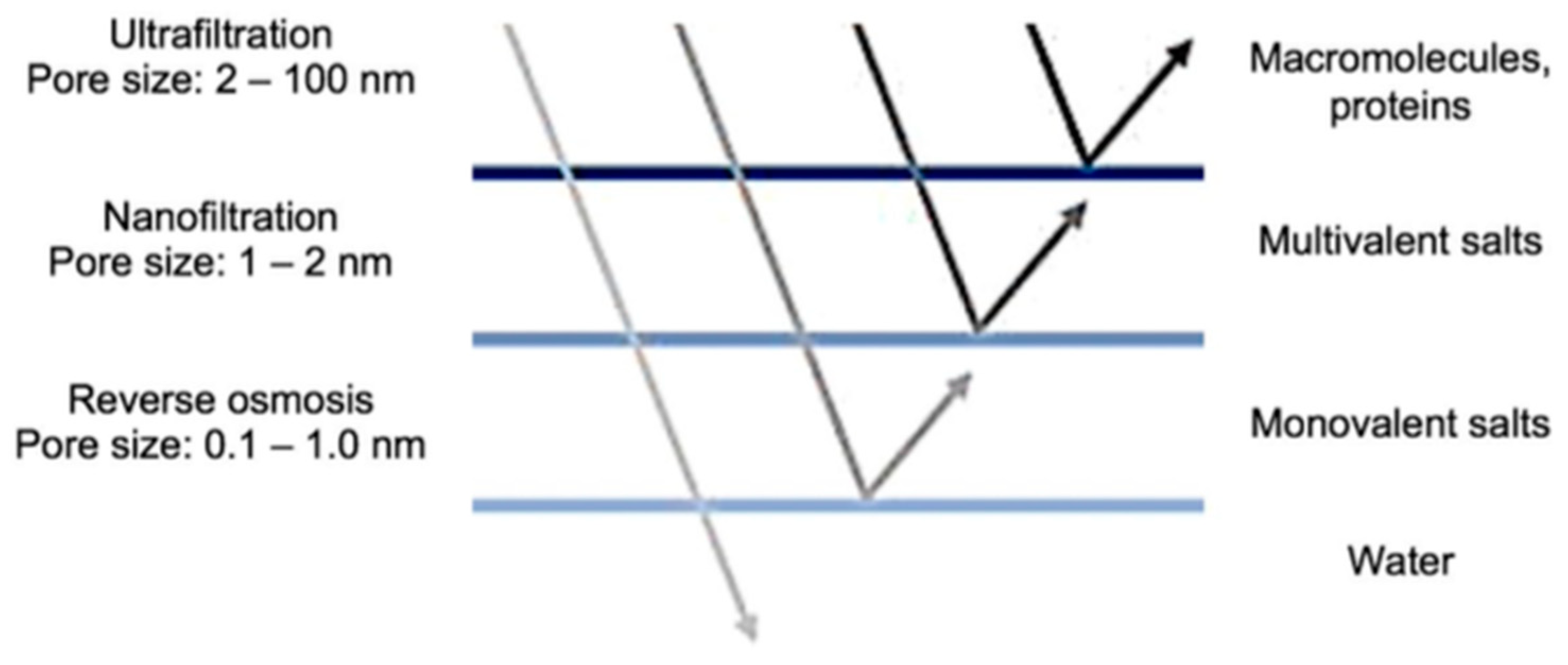

1.3. Reverse Osmosis

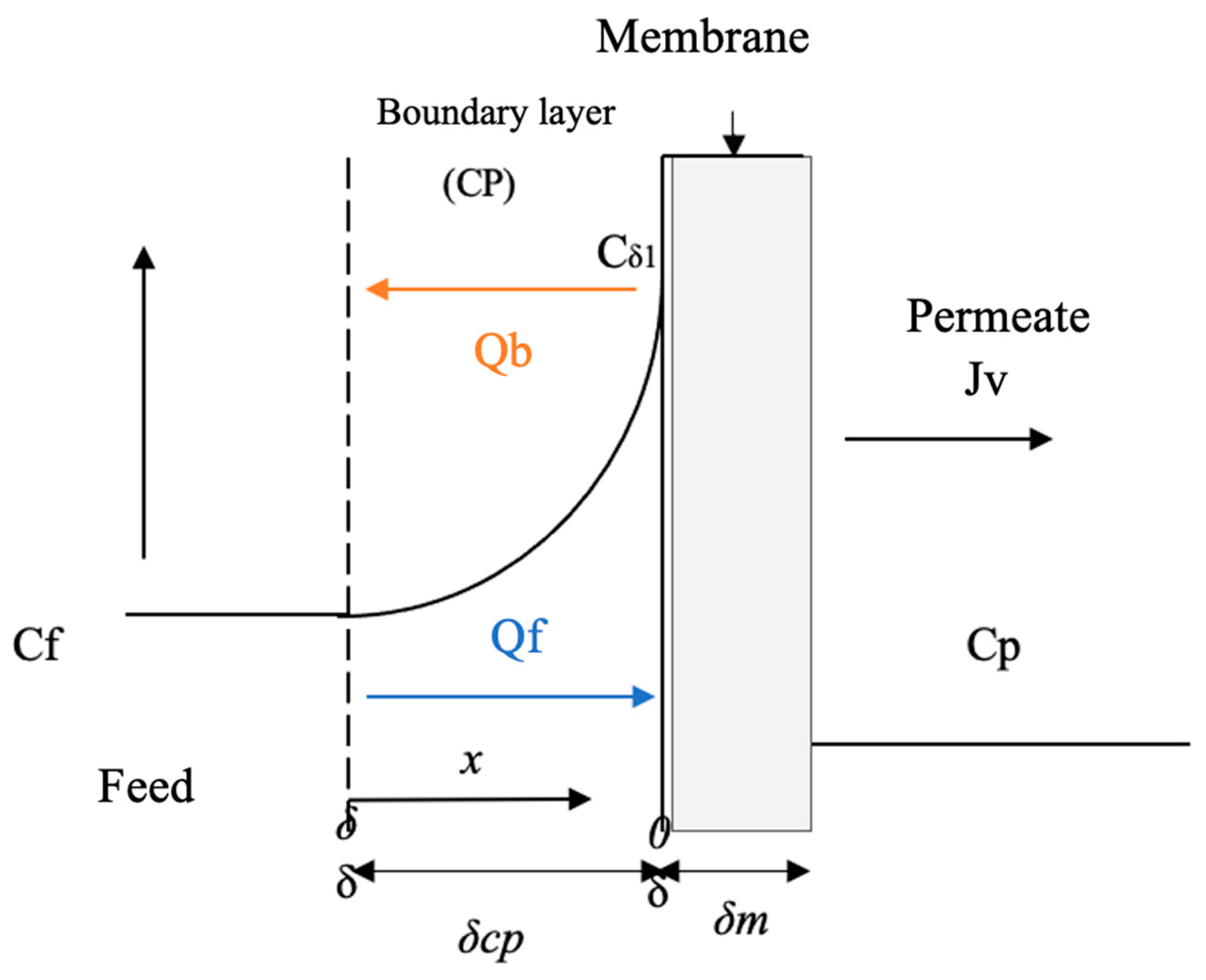

1.3.1. Concentration Polarization

1.3.2. Spiegler–Kedem Model

- Jv = flux of the solvent.

- Lp = permeability coefficient of the solvent (water permeability in the membrane).

- Δp = transmembrane pressure or system operating pressure.

- σ = reflection coefficient.

- Δπ = difference in osmotic pressure.

- Js = solute flow.

- Bs = solute transport coefficient.

- Cẟ1 = solute concentration at the membrane surface (feed side).

- Cp = concentration of the solute in the permeate.

- Cs = concentration of the solute inside the membrane.

2. Materials and Methods

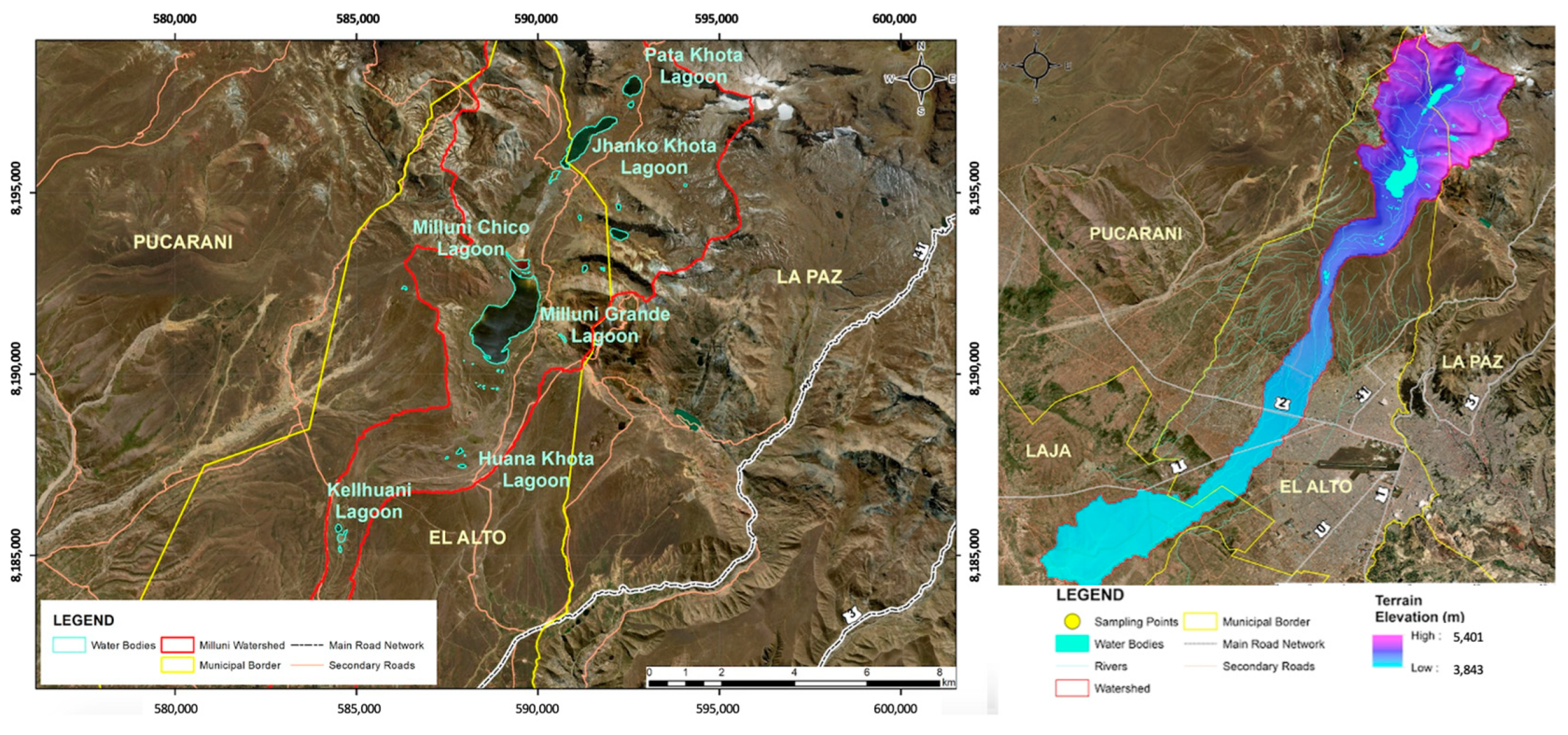

2.1. Study Area

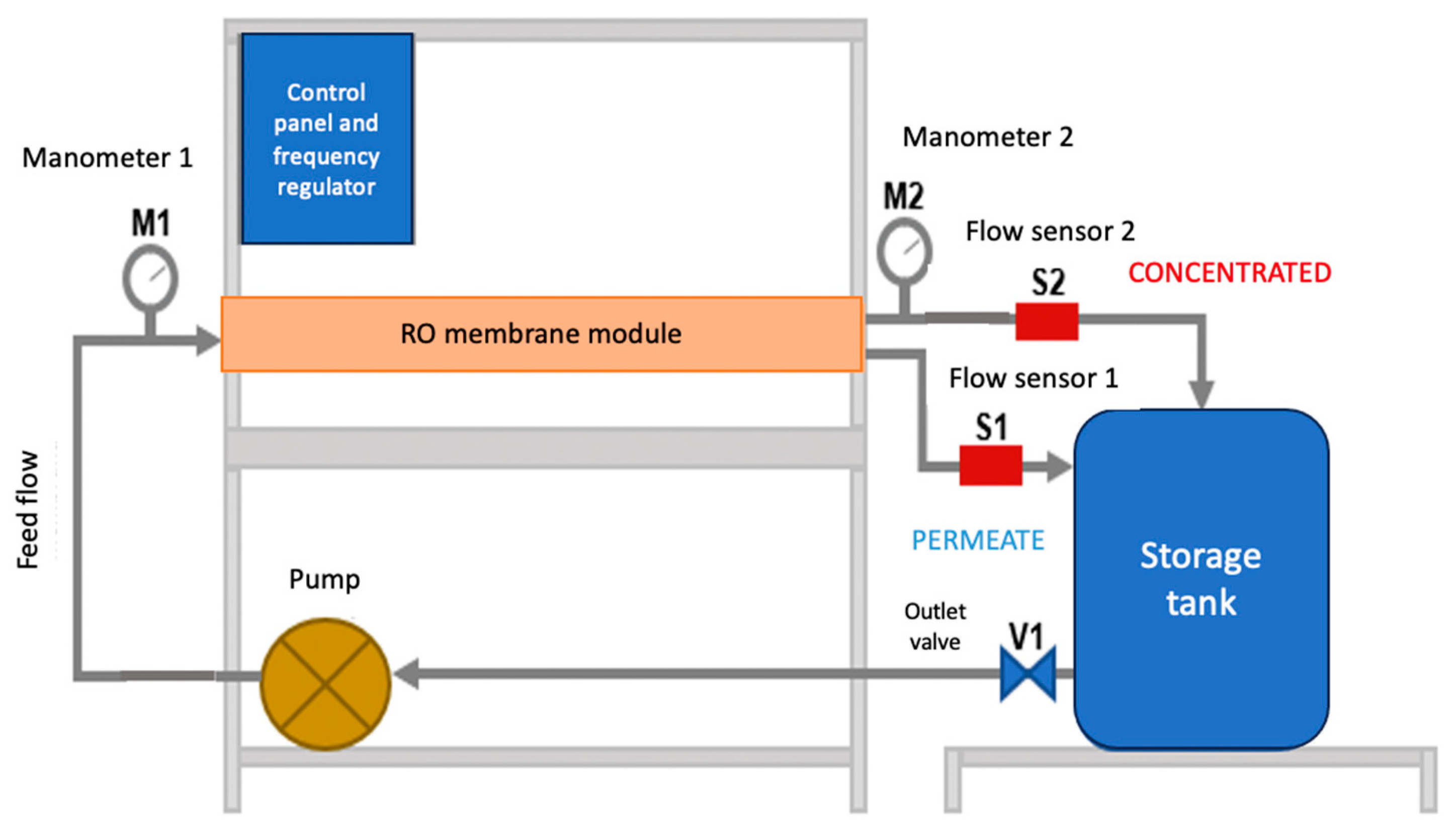

2.2. RO Pilot Plant

2.3. Design of Experiments

2.4. Synthetic Water Preparation

2.5. Mathematical and Statistical Evaluation

2.5.1. Mathematical Method

- C = concentration of the solute in the CP layer.

- D = diffusion coefficient.

- ẟcp = thickness of the CP layer.

- k = mass transfer coefficient in the CP.

- Qf = feed flow.

- Cf = feed concentration.

- Qb = concentrate flow.

- Cb = concentration of the concentrate flow.

- Qp = permeate flow.

- Cb = concentration of the permeate flow.

- S = effective area of the membrane.

- R = constant of the gas law.

- T = temperature.

- Cẟ2 = concentration of the solute on the surface of the membrane (permeate side).

2.5.2. Statistical Method

3. Results

3.1. Mathematical Evaluation

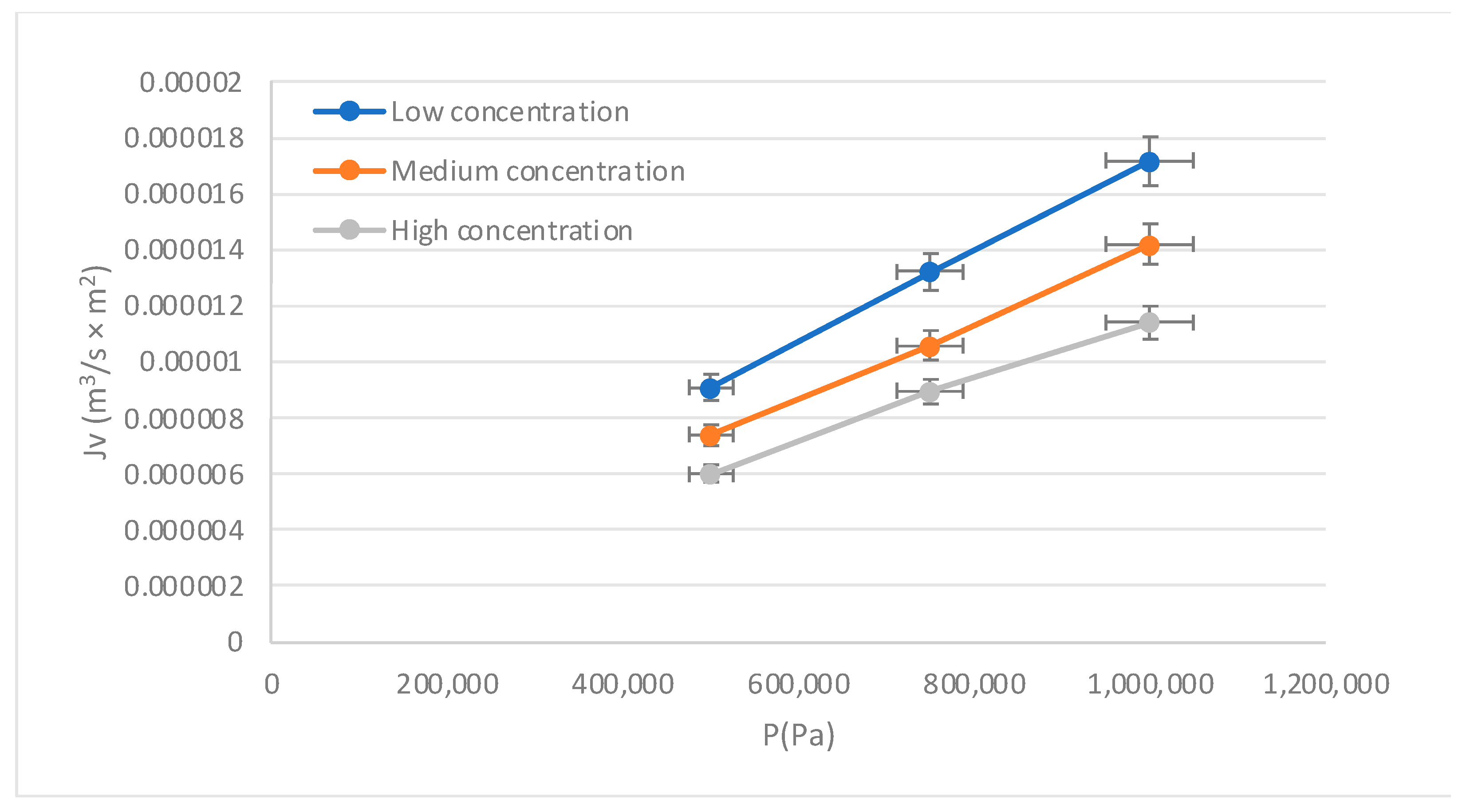

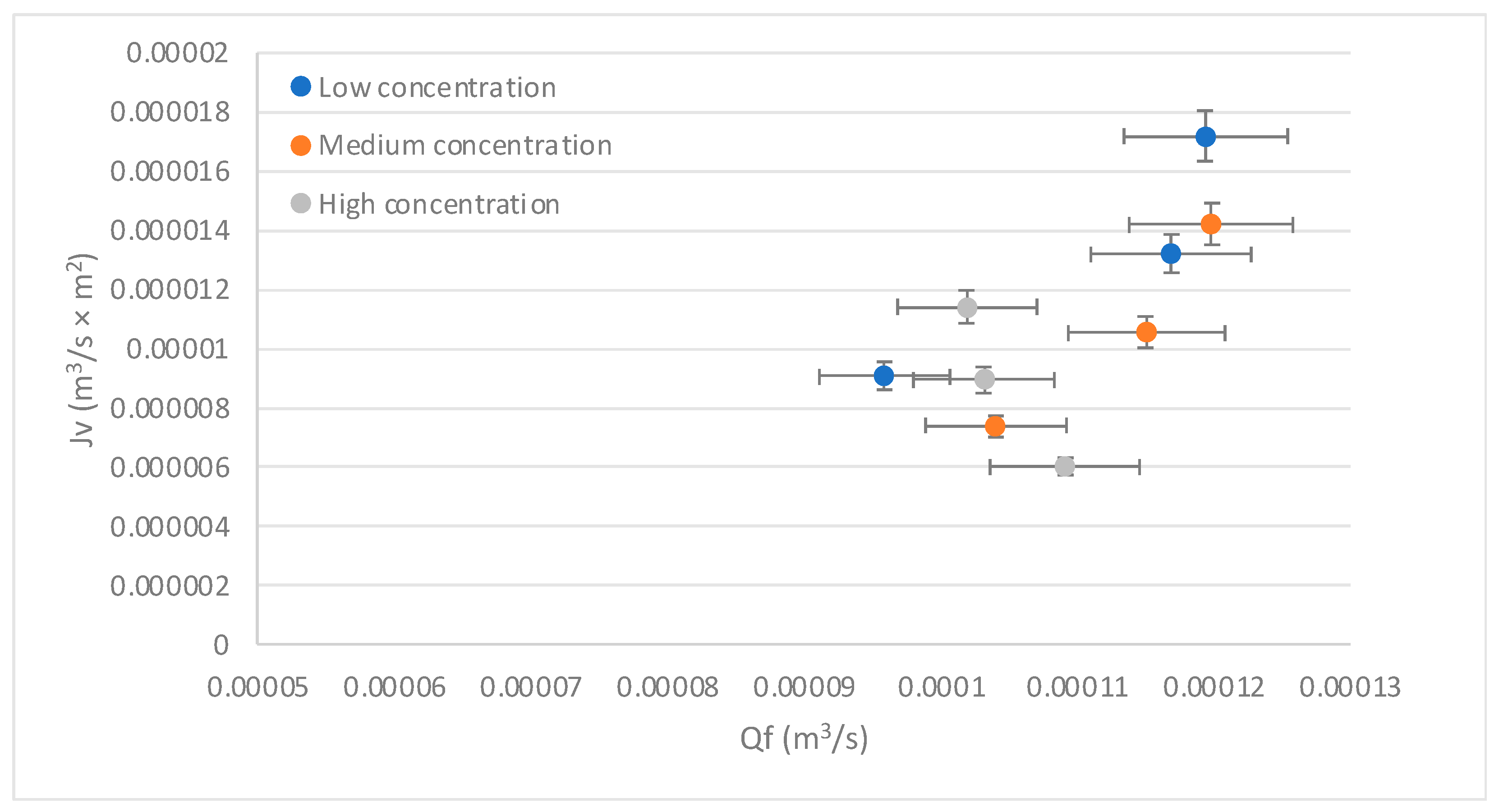

3.1.1. Effect of Feed Flow (Qf) on the flux (Jv)

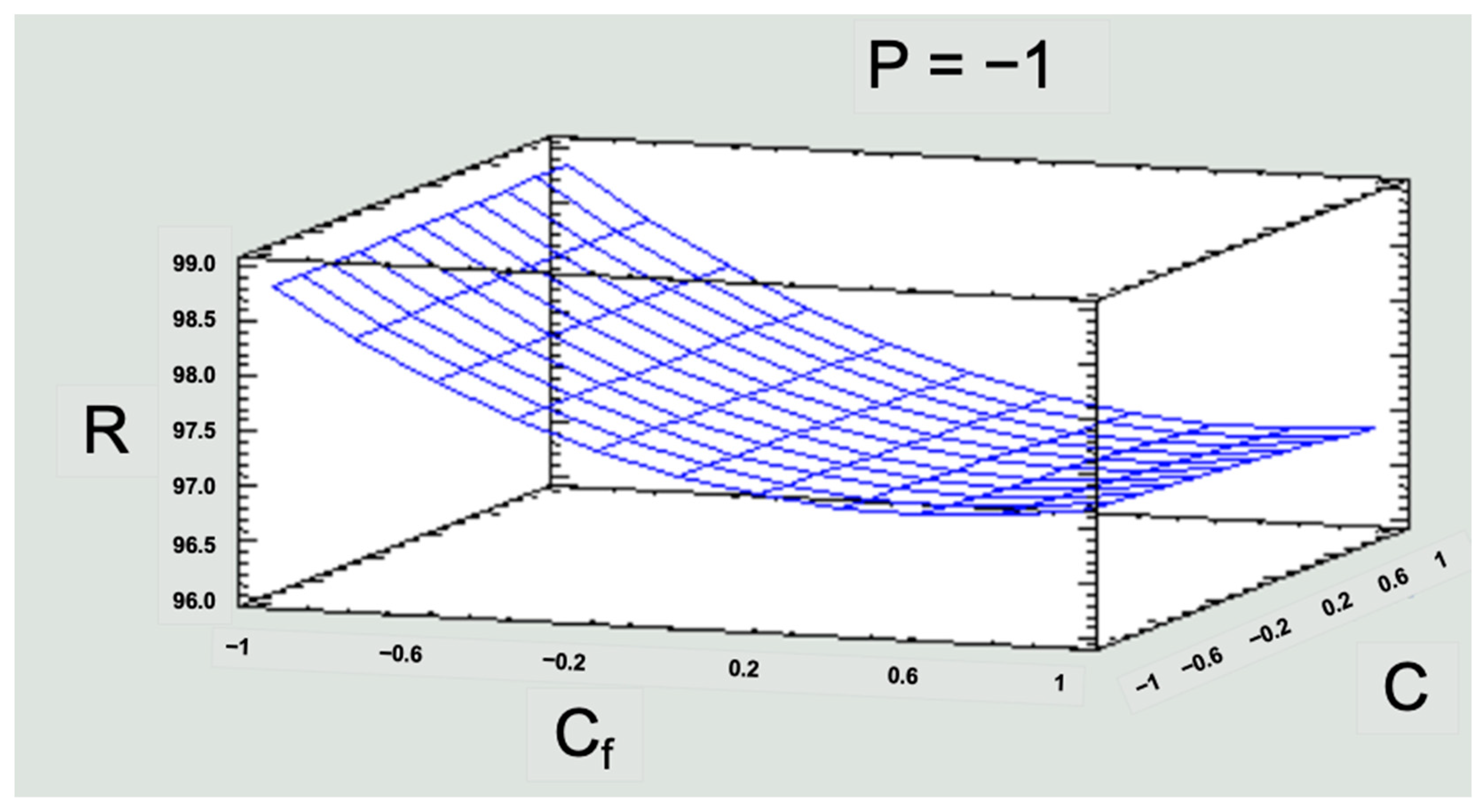

3.1.2. Effect of Pressure (P) on the Rejection Index (R)

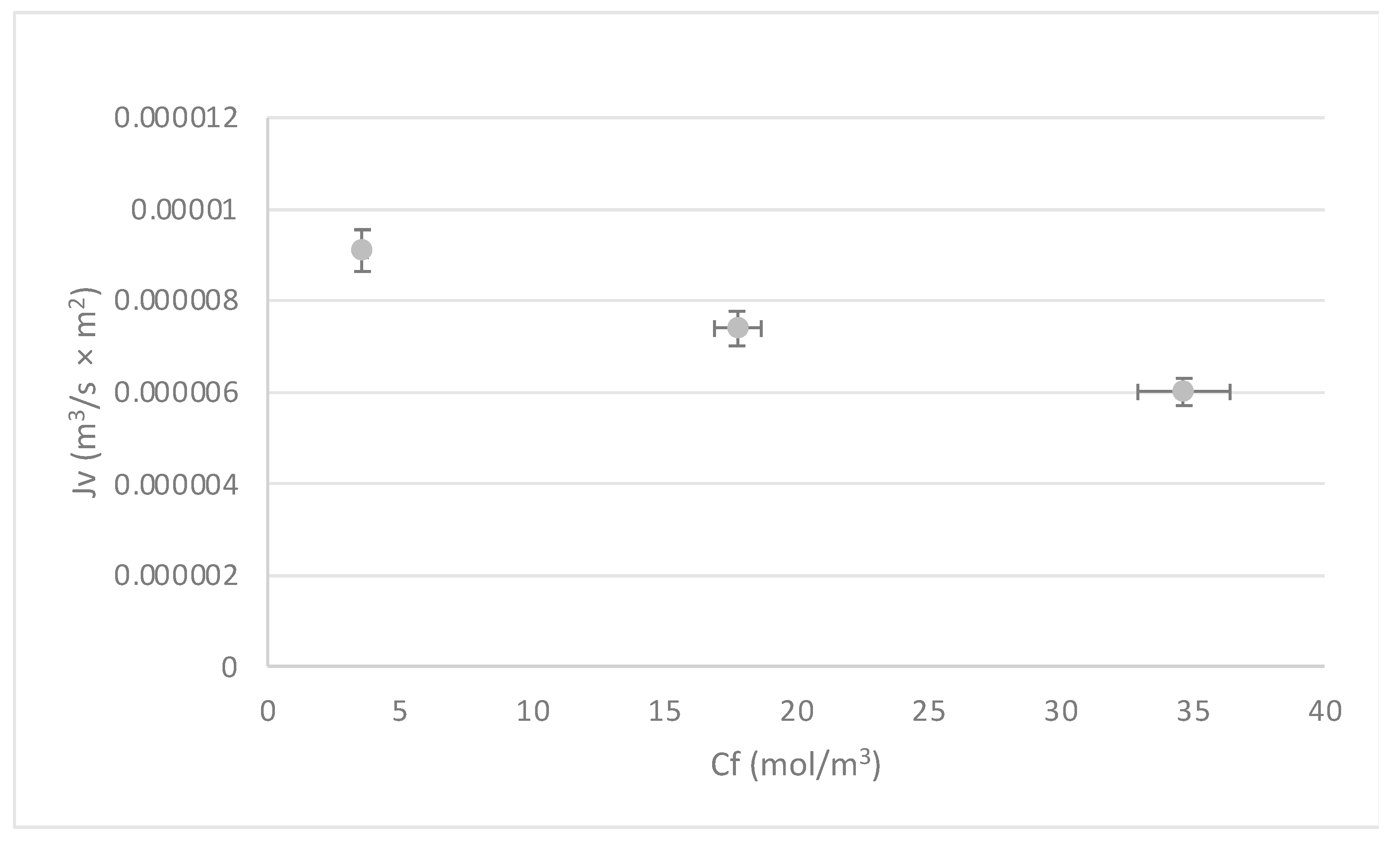

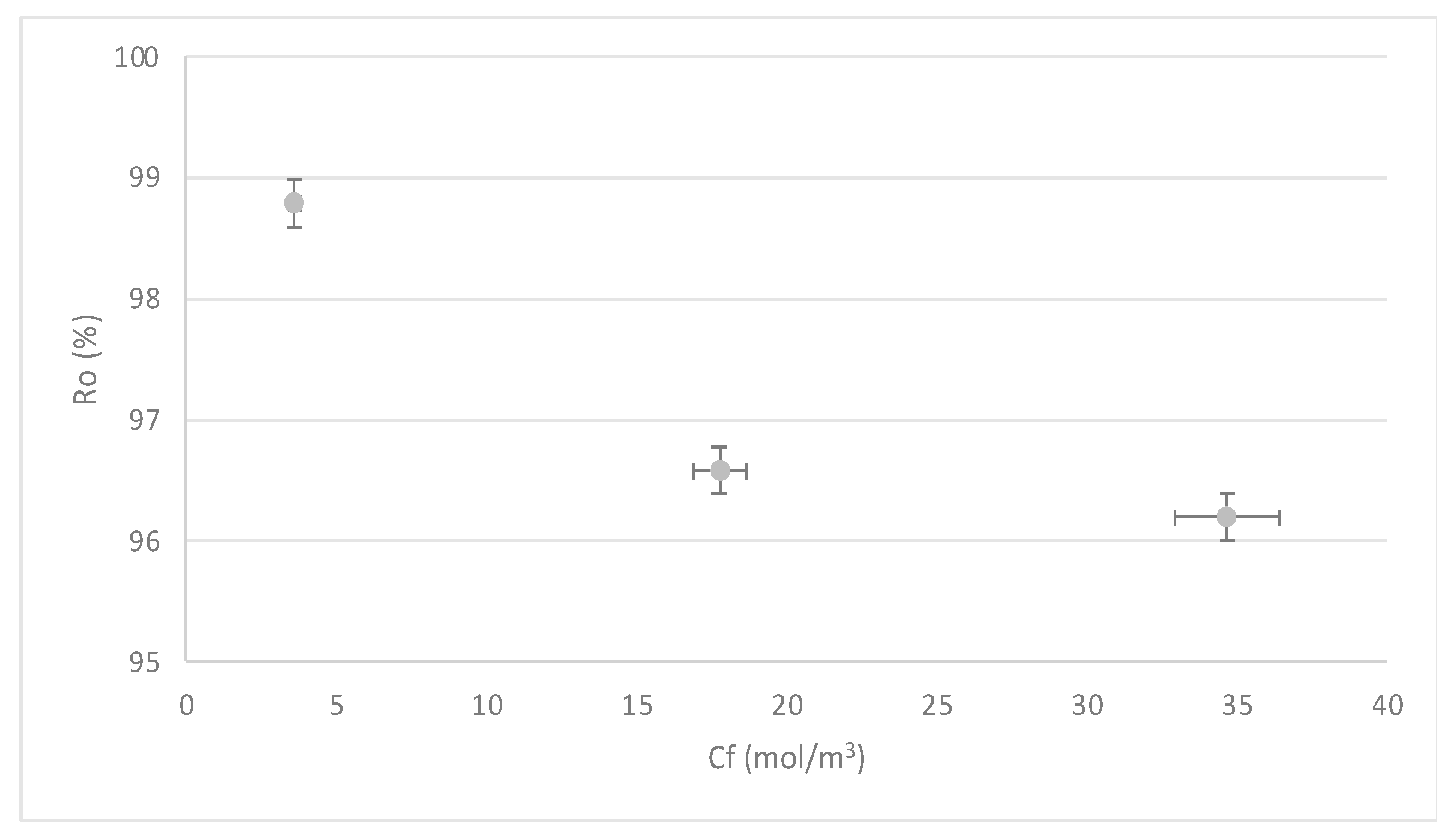

3.1.3. Effect of Solution Concentration (Cf) on the Flux (Jv) and the Rejection Index (R)

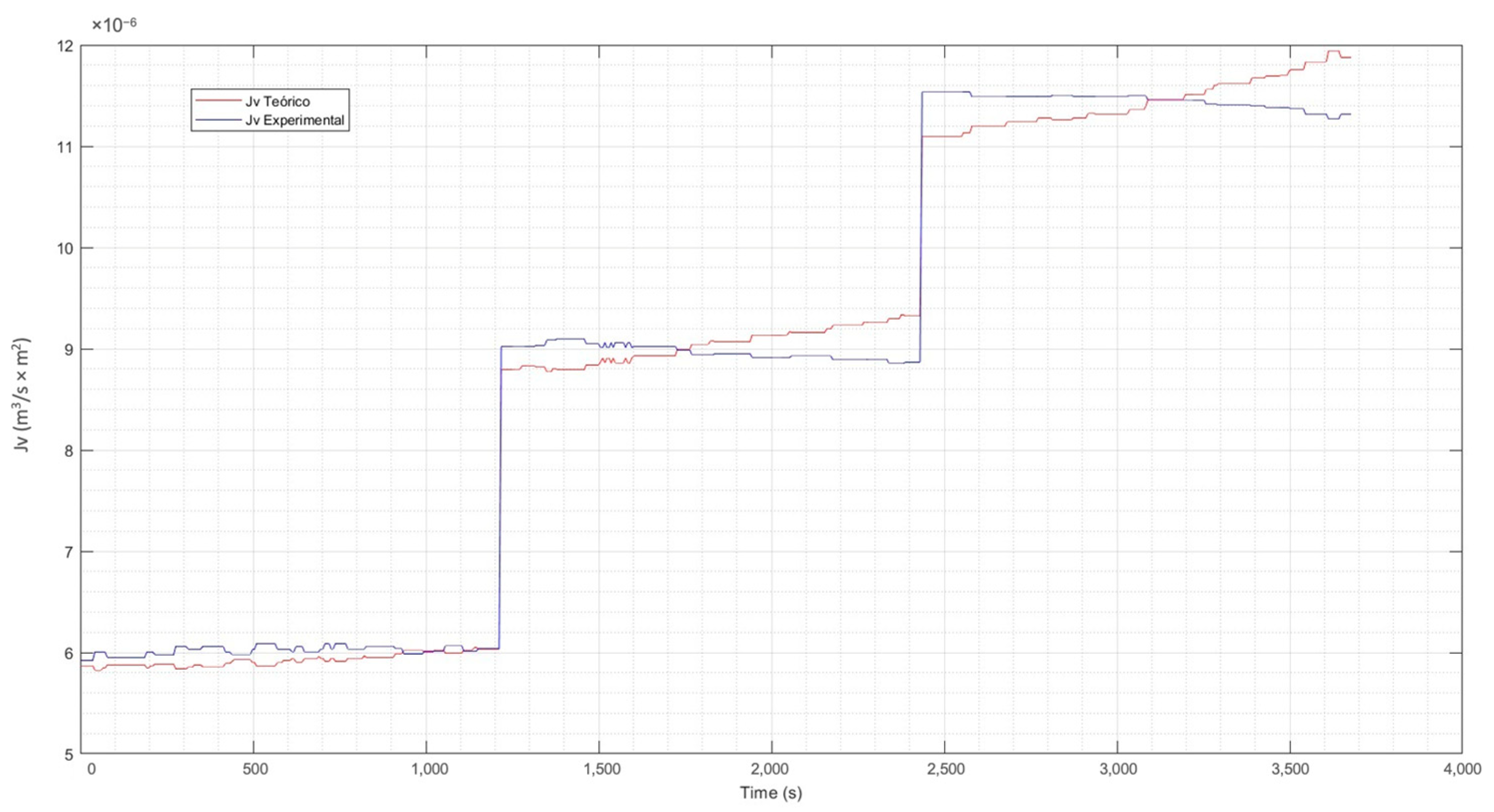

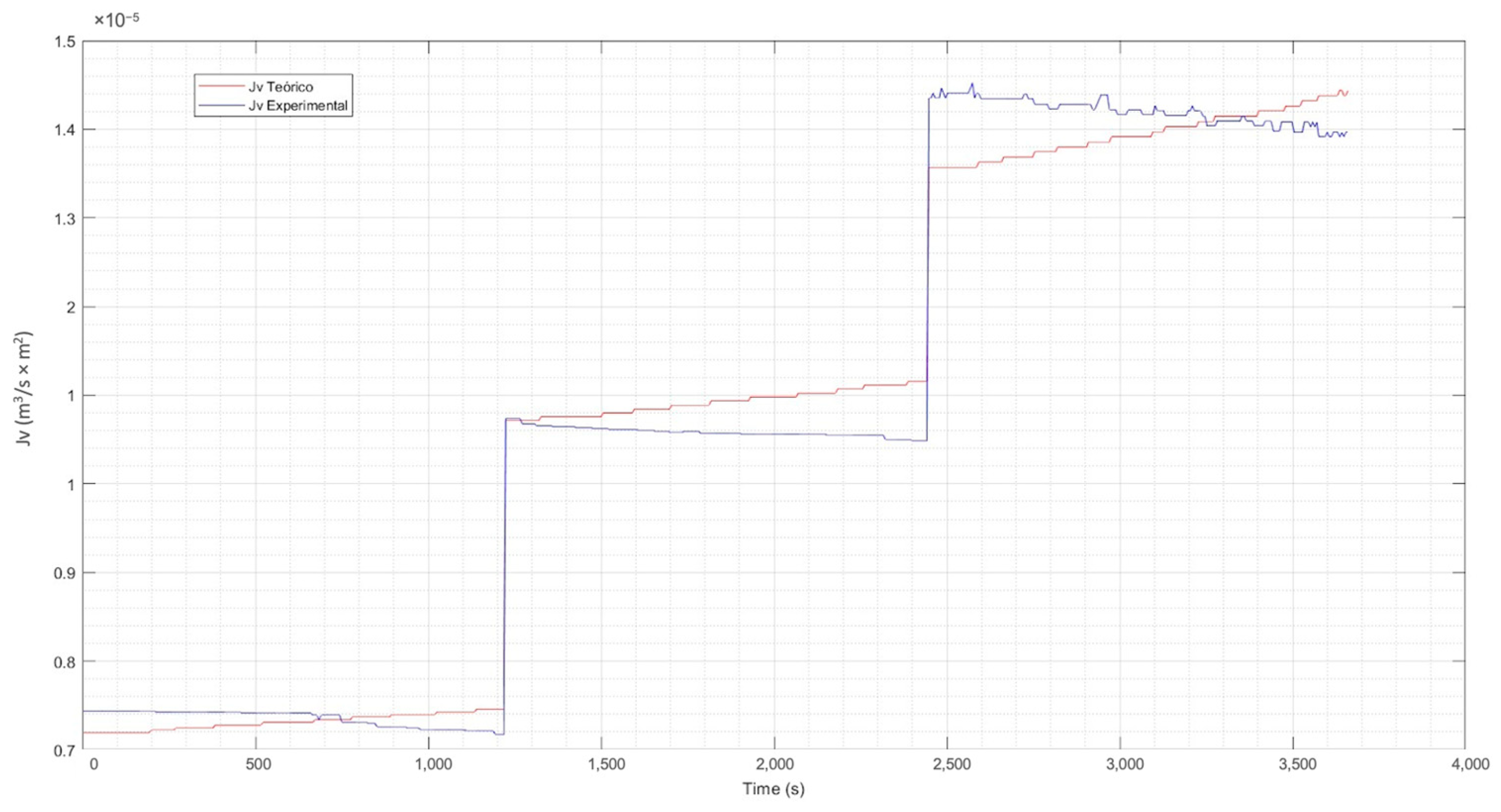

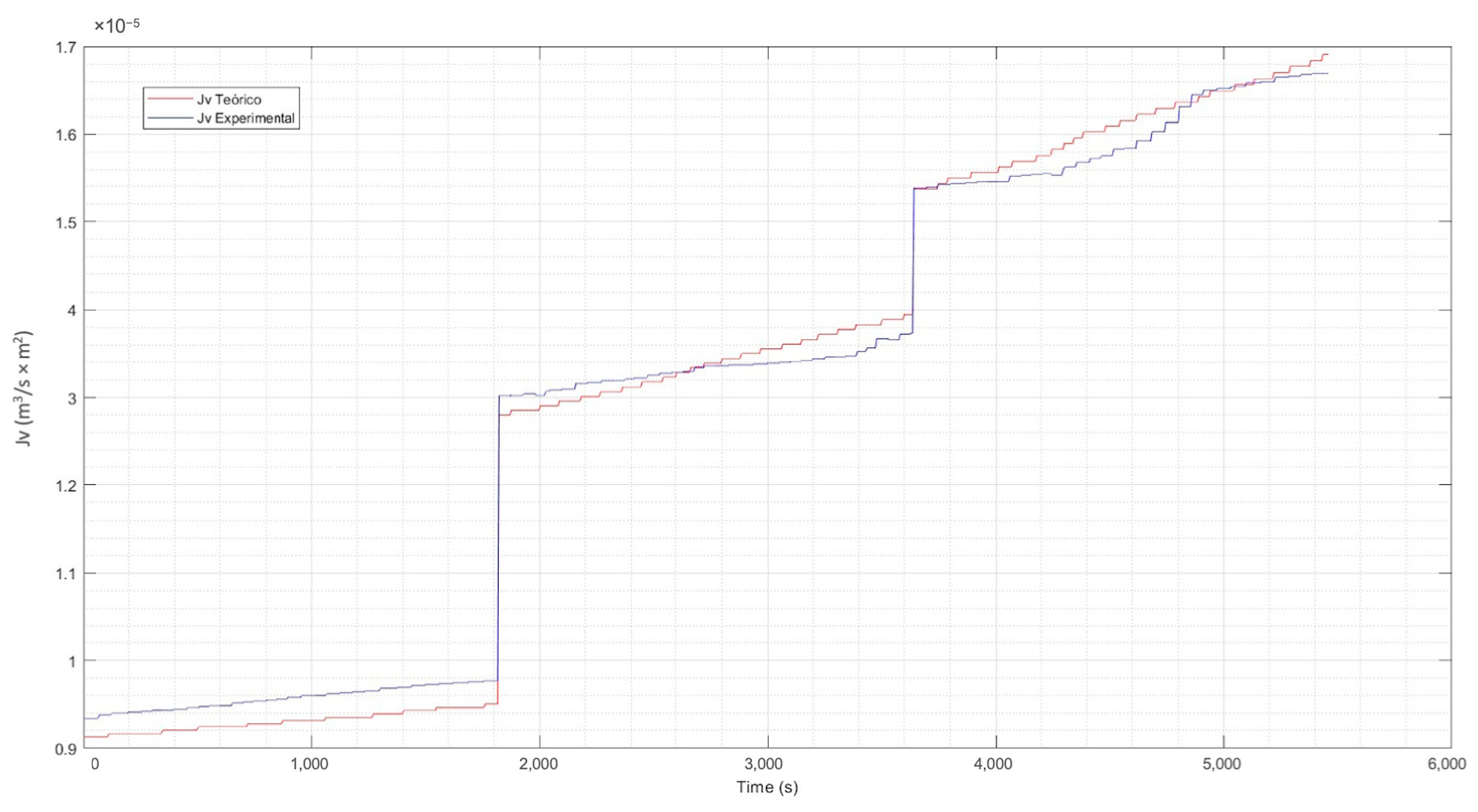

3.1.4. Contrast of Experimental Data vs. Theoretical

3.2. Statistical Evaluation

3.2.1. Rejection Index (R)

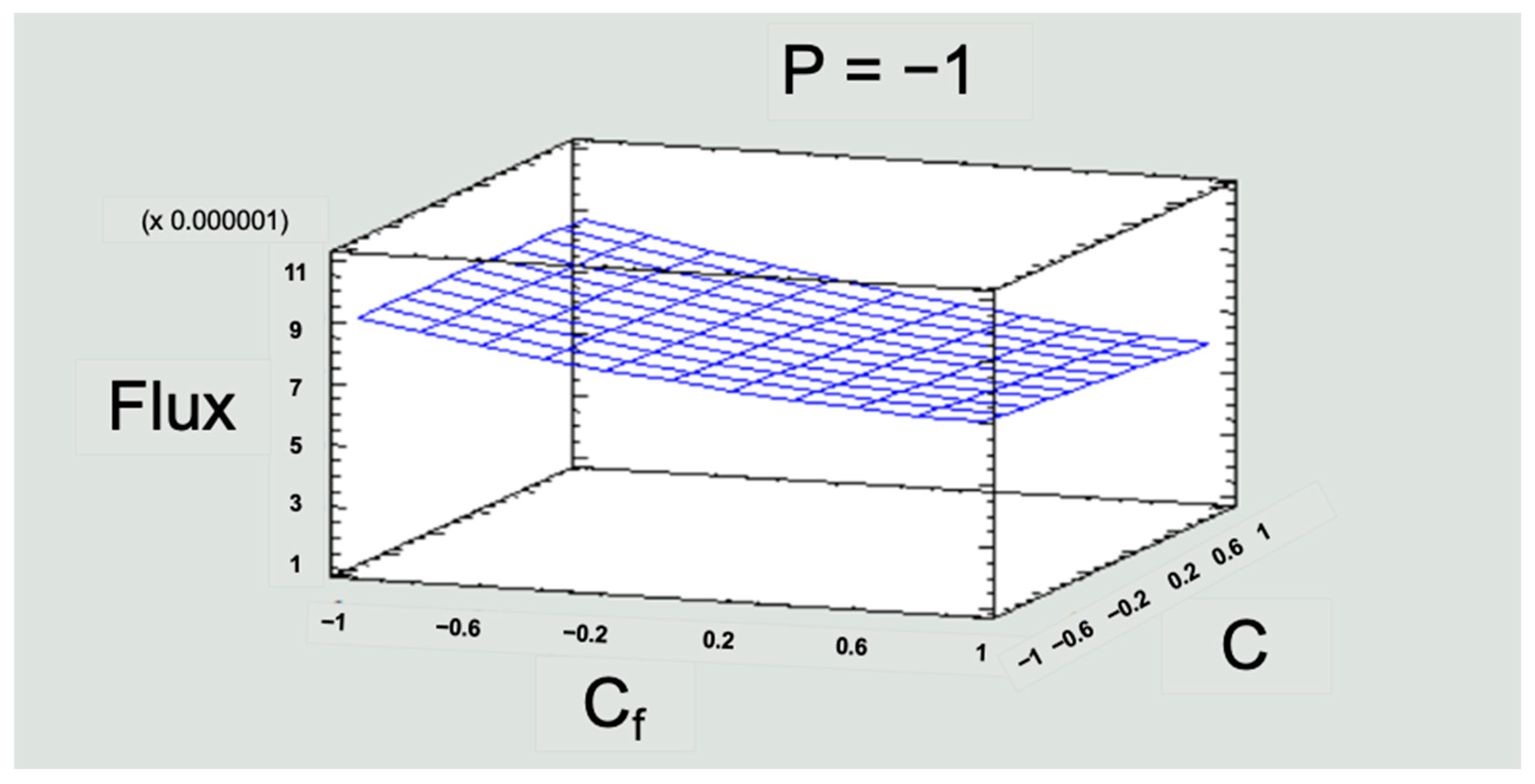

3.2.2. Flux (Jv)

- As already mentioned, operating with low pressures brings energy savings that would not decrease the removal efficiency of the membrane modules.

- The longer useful life of the equipment, since it will not work at full capacity, leading to an increased lifetime of the membranes.

- The periods between equipment maintenance will be longer, which implies not having as many problems with membrane fouling, which also means fewer chemical cleanups.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Herrera Melián, J.A. Sustainable wastewater treatment systems (2018–2019). Sustainability 2020, 12, 1940. [Google Scholar] [CrossRef]

- Duruibe, J.O.; Egwurugwu, M.O.C.; Ogwuegbu, J.N. Heavy Metal Pollution and Human Biotoxic Effects. Int. J. Phys. Sci. 2007, 2, 112–118. Available online: https://academicjournals.org/journal/IJPS/article-full-text-pdf/59CA35213127 (accessed on 18 June 2023).

- Khulbe, K.C.; Matsuura, T. Removal of heavy metals and pollutants by membrane adsorption techniques. Appl. Water Sci. 2018, 8, 19. [Google Scholar] [CrossRef]

- Srivastava, N.K.; Majumder, C.B. Novel biofiltration methods for the treatment of heavy metals from industrial wastewater. J. Hazard. Mater. 2008, 151, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Zak, S. Treatment of the Processing Wastewaters Containing Heavy Metals with the Method Based on Flotation. Ecol. Chem. Eng. S 2012, 19, 433–438. [Google Scholar] [CrossRef][Green Version]

- Kamran, S.; Shafaqat, A.; Samra, H.; Sana, A.; Samar, F.; Muhammad, B.; Saima, A.; Tauqeer, H.M. Heavy Metals Contamination and what are the Impacts on Living Organisms. Greener J. Environ. Manag. Public Saf. 2013, 2, 172–179. [Google Scholar] [CrossRef]

- Jaishankar, M.; Tseten, T.; Anbalagan, N.; Mathew, B.; Beeregowda, K.N. Toxicity, mechanism and health effects of some heavy metals. Interdiscip. Toxicol. 2014, 7, 60–72. [Google Scholar] [CrossRef]

- Karaouzas, I.; Kapetanaki, N.; Mentzafou, A.; Kanellopoulos, T.D.; Skoulikidis, N. Heavy metal contamination status in Greek surface waters: A review with application and evaluation of pollution indices. Chemosphere 2021, 263, 128192. [Google Scholar] [CrossRef] [PubMed]

- Alvizuri Tintaya, P.A.; Torregrosa López, J.I.; Lo Iacono Ferreira, V.G.; Salinas Villafañe, O.R. Heavy metals problem in micro-basin that feeds a drinking water dam, Milluni—Bolivia case. In Proceedings of the XXIII International Congress on Project Management and Engineering, Málaga, Spain, 10–12 July 2019; Available online: http://dspace.aeipro.com/xmlui/handle/123456789/2396 (accessed on 20 June 2023).

- Wei, J.; Zheng, X.; Liu, J.; Zhang, G.; Zhang, Y.; Wang, C.; Liu, Y. The Levels, Sources, and Spatial Distribution of Heavy Metals in Soils from the Drinking Water Sources of Beijing, China. Sustainability 2021, 13, 3719. [Google Scholar] [CrossRef]

- Neculita, C.M.; Rosa, E. A review of the implications and challenges of manganese removal from mine drainage. Chemosphere 2019, 214, 491–510. [Google Scholar] [CrossRef]

- WHO. Guidelines for Drinking Water Quality Quality, 4th ed.; Incorporating the 1st addendum; WHO: Geneva, Switzerland, 2017; Available online: https://www.who.int/publications/i/item/9789241549950 (accessed on 10 May 2023).

- Gaillardet, J.; Viers, J.; Dupré, B. Trace elements in river waters. Treatise Geochem. 2003, 5, 605. [Google Scholar] [CrossRef]

- EPA. National Primary Drinking Water Regulations 2009. Available online: https://www.epa.gov/sites/default/files/2016-06/documents/npwdr_complete_table.pdf (accessed on 15 April 2023).

- Norma Boliviana NB 512; Agua Potable—Requisitos. Ibnorca: La Paz, Bolivia, 2004.

- Weiss, B. Endocrine disruptors as a threat to neurological function. J. Neurol. Sci. 2011, 305, 11. [Google Scholar] [CrossRef]

- Guilarte, T.R. Manganese and Parkinson’s disease: A critical review and new findings. Environ. Health Perspect. 2010, 118, 1071–1080. [Google Scholar] [CrossRef]

- O’Neal, S.L.; Zheng, W. Manganese Toxicity upon Overexposure: A Decade in Review. Curr. Environ. Health Rep. 2015, 2, 315–328. [Google Scholar] [CrossRef] [PubMed]

- Weiss, B. Lead, manganese, and methylmercury as risk factors for neurobehavioral impairment in advanced age. Int. J. Alzheimer’s Dis. 2011, 2011, 607543. [Google Scholar] [CrossRef]

- Bouchard, M.; Laforest, F.; Vandelac, L.; Bellinger, D.; Mergler, D. Hair manganese and hyperactive behaviors: Pilot study of school-age children exposed through tap water. Environ. Health Perspect. 2007, 115, 122–127. [Google Scholar] [CrossRef] [PubMed]

- Bouchard, M.F.; Sauvé, S.; Barbeau, B.; Legrand, M.; Brodeur, M.È.; Bouffard, T.; Limoges, E.; Bellinger, D.C.; Mergler, D. Intellectual impairment in school-age children exposed to manganese from drinking water. Environ. Health Perspect. 2011, 119, 138–143. [Google Scholar] [CrossRef]

- Tobiason, J.E.; Bazilio, A.; Goodwill, J.; Mai, X.; Nguyen, C. Manganese removal from drinking water sources. Curr. Pollut. Rep. 2016, 2, 168–177. [Google Scholar] [CrossRef]

- Johnson, K.L. The importance of aeration in passive treatment schemes for manganese removal. Land Contam. Reclam. 2003, 11, 205–212. Available online: https://www.researchgate.net/profile/Karen-Johnson-30/publication/250162254_The_importance_of_aeration_in_passive_treatment_schemes_for_manganese_removal/links/00b4953baaaff5e82a000000/The-importance-of-aeration-in-passive-treatment-schemes-for-manganese-removal.pdf (accessed on 20 June 2023). [CrossRef]

- Rose, A.W.; Means, B.; Shah, P.J. Methods for passive removal of manganese from acid mine drainage. In Proceedings of the 24th West Virginia Surface Mine Drainage Task Force Symposium, Morgantown, WV, USA, 21–25 April 2003; pp. 71–82. Available online: https://n9.cl/wnm3t (accessed on 20 June 2023).

- Holkar, C.R.; Jadhav, A.J.; Pinjari, D.V.; Mahamuni, N.M.; Pandit, A.B. A critical review on textile wastewater treatments: Possible approaches. J. Environ. Manag. 2016, 182, 351–366. [Google Scholar] [CrossRef]

- Kelman Wieder, R. Metal cation binding to Sphagnum peat and sawdust: Relation to wetland treatment of metal-polluted waters. Water Air Soil Pollut. 1990, 53, 391–400. [Google Scholar] [CrossRef]

- Kessick, M.A.; Morgan, J.J. Mechanism of autoxidation of manganese in aqueous solution. Environ. Sci. Technol. 1975, 9, 157–159. [Google Scholar] [CrossRef]

- Burgos, W.D.; Senko, J.M.; Hansel, C.M. Improving Passive Mine Treatment through Better Understanding of Biogeochemistry and Mineralogy Associated with Mn (II) Oxidation; Final Report; Cooperative Agreement S07AP12478; US Office of Surface Mining: Washington, DC, USA, 2009; Available online: https://n9.cl/orzcq (accessed on 15 June 2023).

- Akpor, O.B.; Muchie, M. Remediation of Heavy Metals in Drinking Water and Wastewater Treatment Systems: Processes and Applications. Int. J. Phys. Sci. 2010, 5, 1807–1817. Available online: https://www.researchgate.net/publication/277775724_Remediation_of_heavy_metals_in_drinking_water_and_wastewater_treatment_systems_Processes_and_applications (accessed on 15 June 2023).

- Fu, F.L.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef] [PubMed]

- Barakat, M.A. New trends in removing heavy metals from industrial wastewater. Arab. J. Chem. 2011, 4, 361–377. [Google Scholar] [CrossRef]

- Hua, M.; Zhang, S.; Pan, B.; Zhang, W.; Lv, L.; Zhang, Q. Heavy metal removal from water/wastewater by nanosized metal oxides: A review. J. Hazard. Mater. 2012, 211–212, 317–331. [Google Scholar] [CrossRef]

- Alvizuri Tintaya, P.A.; Torregrosa López, J.I.; Lo Iacono Ferreira, V.G.; Salinas Villafañe, O.R. Review of treatment technologies for heavy metals from acid mine drainage. In Proceedings of the XXIII International Congress on Project Management and Engineering, Málaga, Spain, 10–12 July 2019; Available online: http://dspace.aeipro.com/xmlui/handle/123456789/2315 (accessed on 20 June 2023).

- Khedr, M.G. Membrane methods in tailoring simpler, more efficient, and cost-effective wastewater treatment alternatives. Desalination 2008, 222, 135–145. [Google Scholar] [CrossRef]

- Bodzek, M.; Konieczny, K.; Kwiecińska, A. Application of membrane processes in drinking water treatment–state of art. Desalination Water Treat. 2011, 35, 164–184. [Google Scholar] [CrossRef]

- Abdullah, N.; Yusof, N.; Lau, W.J.; Jaafar, J.; Ismail, A.F. Recent trends of heavy metal removal from water/wastewater by membrane technologies. J. Ind. Eng. Chem. 2019, 76, 17–38. [Google Scholar] [CrossRef]

- Alvizuri Tintaya, P.A.; Villena Martínez, E.M.; Torregrosa López, J.I.; Lo Iacono Ferreira, V.G.; Lora, J. Review of membrane technologies in the removal of heavy metals in surface waters for human consumption. In Proceedings of the XXIV International Congress on Project Management and Engineering, Alcoy, Spain, 7–9 July 2020; Available online: http://dspace.aeipro.com/xmlui/bitstream/handle/123456789/2498/AT04-019_20.pdf?sequence=1&isAllowed=y (accessed on 20 June 2023).

- Yang, Z.; Zhou, Y.; Feng, Z.; Rui, X.; Zhang, T.; Zhang, Z. A Review on Reverse Osmosis and Nanofiltration Membranes for Water Purification. Polymers 2019, 11, 1252. [Google Scholar] [CrossRef]

- Chang, F.F.; Liu, W.J.; Wang, X.M. Comparison of polyamide nanofiltration and low-pressure reverse osmosis membranes on As(III) rejection under various operational conditions. Desalination 2014, 334, 10–16. [Google Scholar] [CrossRef]

- Figoli, A.; Cassano, A.; Criscuoli, A.; Mozumder, M.S.I.; Uddin, M.T.; Islam, M.A.; Drioli, E. Influence of operating parameters on the arsenic removal by nanofiltration. Water Res. 2010, 44, 97–104. [Google Scholar] [CrossRef]

- Zhu, W.-P.; Sun, S.-P.; Gao, J.; Fu, F.-J.; Chung, T.-S. Dual-layer polybenzimidazole/polyethersulfone (PBI/PES) nanofiltration (NF) hollow fiber membranes for heavy metals removal from wastewater. J. Membr. Sci. 2014, 456, 117–127. [Google Scholar] [CrossRef]

- Vera, L.; García, N.; Uguña, M.F.; Flores, M.; González, E.; Brazales, D. Biosorption technologies and membranes in the removal of heavy metals. Tecnol. Y Cienc. Del Agua 2018, 9, 91–102. [Google Scholar] [CrossRef]

- Huang, J.H.; Zeng, G.M.; Zhou, C.F.; Li, X.; Shi, L.J.; He, S.B. Adsorption of surfactant micelles and Cd+2/Zn+2 in micellar-enhanced ultrafiltration. J. Hazard. Mater. 2010, 183, 287–293. [Google Scholar] [CrossRef]

- Nasir, S.; Ibrahim, E.; Arief, A.T. Design and experimental testing of small-scaleacid mine drainage treatment plant. J. Mater. Environ. Sci. 2016, 7, 2912–2918, ISSN: 2028-2508. Available online: https://www.jmaterenvironsci.com/Document/vol7/vol7_N8/303-JMES-1791-Nasir.pdf (accessed on 18 February 2020).

- Barakat, M.A.; Schmidt, E. Polymer-enhanced ultrafiltration process for heavy metals removal from industrial wastewater. Desalination 2010, 256, 90–93. [Google Scholar] [CrossRef]

- Cimen, A.; Kılıcel, F.; Arslan, G. Removal of chromium ions from waste waters using reverse osmosis AG and SWHR membranes. Russ. J. Phys. Chem. A 2014, 88, 845–850. [Google Scholar] [CrossRef]

- GreenIee, L.F.; Lawler, D.F.; Freeman, B.D.; Marrot, B.; Moulin, P. Reverse osmosis desalination: Water sources, technology, and today’s challenges. Water Res. 2009, 43, 2317–2348. [Google Scholar] [CrossRef]

- Feria-Díaz, J.J.; Correa-Mahecha, F.; López-Méndez, M.C.; Rodríguez-Miranda, J.P.; Barrera-Rojas, J. Recent Desalination Technologies by Hybridization and Integration with Reverse Osmosis: A Review. Water 2021, 13, e1369. [Google Scholar] [CrossRef]

- Sablani, S.S.; Goosen, M.F.A.; Al-Belushi, R.; Wilf, M. Concentration polarization in ultrafiltration and reverse osmosis: A critical review. Desalination 2001, 141, 269–289. [Google Scholar] [CrossRef]

- Chenghan, C.; Han, Q. A Mathematical Modeling of the Reverse Osmosis Concentration Process of a Glucose Solution. Processes 2019, 7, 2–12. [Google Scholar] [CrossRef]

- Aramijo, C.; Condorhuaman, C. Simulación dinámica de sistemas de ósmosis inversa. Revista Peruana de Química e Ingeniería Química 2012, 15, 21–34. Available online: https://revistasinvestigacion.unmsm.edu.pe/index.php/quim/article/view/4758/3831 (accessed on 14 April 2023).

- García, C. Aplicación de Ósmosis Inversa y Nanofiltración en Acondicionamiento de Agua Para Calderas. Ph.D. Thesis, Universidad de Oviedo, Oviedo, España, 2002. Available online: https://www.tesisenred.net/handle/10803/11146 (accessed on 20 May 2023).

- Salcedo-Díaz, R. Aplicación de la Interferometría Holográfica al Estudio de la Capa de Polarización en Ósmosis Inversa. Efecto de la Convección Natural. Ph.D. Thesis, Universidad de Alicante, Alicante, España, 2006. Available online: https://dialnet.unirioja.es/servlet/tesis?codigo=6870 (accessed on 25 June 2023).

- Lora, J.; López, M.; Cardona, S.; Fombuena, V.; Carbonell, A. Análisis del consumo Energético como factor clave en proyectos de desalación de agua de mar. In Proceedings of the XXIV International Congress on Project Management and Engineering, Alcoy, Spain, 7–9 July 2020; Available online: http://dspace.aeipro.com/xmlui/handle/123456789/2486 (accessed on 16 May 2023).

- Mulder, M. Basic Principles of Membrane Technology; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1996; pp. 281–304, 246–248. Available online: https://ebookcentral.proquest.com/lib/bibliotecaupves-ebooks/reader.action?docID=3102158&ppg=1 (accessed on 15 June 2023).

- Pontié, M.; Dach, H.; Leparc, J.; Hafsi, M.; Lhassani, A. Novel approach combining physico-chemical characterizations and mass transfer modelling of nanofiltration and low-pressure reverse osmosis membranes for brackish water desalination intensification. Desalination 2008, 221, 174–191. [Google Scholar] [CrossRef]

- Hidalgo, A.M.; Gómez, M.; Murcia, M.D.; Serrano, J.; Otón, J. Caracterización de la membrana NF-97 mediante disoluciones salinas. Aplicación del modelo de Spiegler- Kedem-Kachalsky. Afinida 2013, 70, 48–53, 561. Available online: https://raco.cat/index.php/afinidad/article/view/268539 (accessed on 24 May 2023).

- Villena-Martínez, E.M.; Alvizuri-Tintaya, P.A.; Lora-García, J.; Torregrosa-López, J.I.; Lo-Iacono-Ferreira, V.G. Reverse osmosis modeling study of lead and arsenic removal from drinking water in tarija and La paz, Bolivia. Processes 2022, 10, 1889. [Google Scholar] [CrossRef]

- Sundaramoorthy, S.; Srinivasan, G.; Murthy, D.V.R. An analytical model for spiral wound reverse osmosis membrane modules: Part I—Model development and parameter estimation. Desalination 2011, 280, 403–411. [Google Scholar] [CrossRef]

- Organización de las Naciones Unidas. Resolución 64/292. El Derecho Humano al Agua y el Saneamiento. 2010. Available online: https://www.refworld.org/cgi-bin/texis/vtx/rwmain/opendocpdf.pdf?reldoc=y&docid=4cc9270b2 (accessed on 20 March 2023).

- Cairns, M.R. Metering water: Analyzing the concurrent pressures of conservation, sustainability, health impact, and equity in use. World Dev. 2018, 110, 411–421. [Google Scholar] [CrossRef]

- Iltis, A. Datos Sobre las Lagunas de Altura de la Región de la Paz (Bolivia). La Paz: ORSTOM, (14), 50 p. multigr. (Informe-ORSTOM; 14). 1988. Available online: http://horizon.documentation.ird.fr/exl-doc/pleins_textes/doc34-05/26148.pdf (accessed on 15 February 2023).

- Ahlfeld, F.; Schneider-Scherbina, A. Los Yacimientos Minerales y de Hidrocarburos de Bolivia; Departamento Nacional de Geología, Ministerio de Minas y Petróleo: La Paz, Bolivia, 1964. [Google Scholar]

- Raffailac, E. Estudio de la contaminación de la Cuenca de Milluni. In Mémoire de stage en Aguas del Illimani; Inédito: La Paz, Bolivia, 2002; 96p. [Google Scholar]

- Salvarredy-Aranguren, M.M.; Probst, A.; Roulet, M.; Isaure, M.P. Contamination of surface waters by mining wastes in the Milluni Valley (Cordillera Real, Bolivia). Mineralogical and hydrological influences. Appl. Geochem. 2008, 23, 1299–1324. [Google Scholar] [CrossRef]

- Instituto Nacional de Estadística (INE). Estimaciones y Proyecciones de Población de Bolivia, Departamentos y Municipios. Revisión. 2020. Available online: https://www.ine.gob.bo/index.php/estimaciones-y-proyecciones-de-poblacion-de-bolivia-departamentos-y-municipios-revision-2020/ (accessed on 21 June 2023).

- Saavedra, C. Riego, Viceministerio. Plan Nacional de Cuencas de Bolivia. 2015. Available online: https://www.researchgate.net/publication/281244646_Plan_Nacional_de_Cuencas_de_Bolivia/references (accessed on 12 May 2023).

- Alvizuri Tintaya, P.A.; Villena Martínez, E.M.; Micó Vicent, B.; Lora Garcia, J.; Torregrosa-López, J.I.; Lo-Iacono-Ferreira, V.G. On the Road to Sustainable Water Supply: Reducing Public Health Risks and Preserving Surface Water Resources in the Milluni Micro-Basin, Bolivia. Environments 2022, 9, 4. [Google Scholar] [CrossRef]

- Alvizuri-Tintaya, P.A.; Rios-Ruiz, M.; Lora-Garcia, J.; Torregrosa-López, J.I.; Lo-Iacono-Ferreira, V.G. Study and Evaluation of Surface Water Resources Affected by Ancient and Illegal Mining in the Upper Part of the Milluni Micro-Basin, Bolivia. Resources 2022, 11, 36. [Google Scholar] [CrossRef]

- Alvizuri-Tintaya, P.A.; Villena-Martínez, E.M.; Avendaño-Acosta, N.; Lo-Iacono-Ferreira, V.G.; Torregrosa-López, J.I.; Lora-García, J. Contamination of Water Supply Sources by Heavy Metals: The Price of Development in Bolivia, a Latin American Reality. Water 2022, 14, 3470. [Google Scholar] [CrossRef]

- Villena-Martínez, E.M.; Alvizuri-Tintaya, P.A.; Torregrosa-López, J.I.; Lo Iacono Ferreira, V.G.; Lora, J. Design and assembly of a reverse osmosis pilot experimental plant for the removal of heavy metal Pb, Fe, As, Zn and Mn in consumption waters in Bolivia. In Proceedings of the XXIV International Congress on Project Management and Engineering, Alcoy, Spain, 7–9 July 2020; Available online: http://dspace.aeipro.com/xmlui/handle/123456789/250 (accessed on 14 June 2023).

- Keensen. 2020. Available online: http://www.keensen.com/Products/ultralowpressur.html (accessed on 13 April 2023).

- Statgraphics. Statgraphics Centurion XVIII. 2018. Available online: https://statgraphics.net/ (accessed on 7 November 2021).

- Norma Boliviana NB 496; Agua Potable—Toma de Muestras. Ibnorca: La Paz, Bolivia, 2016.

- Huang, R.Y.; Lin, V.J. Separation of liquid mixtures through the use of polymeric membranes. I. Permeability of binary organic liquid mixtures through polyethylene. J. Appl. Polym. Sci. 1968, 12, 2615–2631. Available online: https://onlinelibrary.wiley.com/doi/epdf/10.1002/app.1968.070121204 (accessed on 15 June 2023). [CrossRef]

- Matlab. Available online: https://www.mathworks.com/products/matlab.html (accessed on 15 May 2023).

- Alanood, A.; Al-Obajdib, M.A.; Al-Hroubc, A.M.; Patela, R.; Mujtaba, I.M. Evaluation and minimization of energy consumption in a medium scale reverse osmosis brackish water desalination plant. J. Clean. Prod. 2020, 248, e119220. [Google Scholar] [CrossRef]

- Patil, D.S.; Chavan, S.M.; Oubagaranadin, J.U.K. A review of technologies for manganese removal from wastewaters. J. Environ. Chem. Eng. 2016, 4, 468–487. [Google Scholar] [CrossRef]

- Villena-Martínez, E.M.; Alvizuri-Tintaya, P.A.; Lora-Garcia, J.; Torregrosa-López, J.I.; Lo-Iacono-Ferreira, V.G. A Comparative Analysis of Statistical Models and Mathematics in Reverse Osmosis Evaluation Processes as a Search Path to Achieve Better Efficiency. Water 2022, 14, 2485. [Google Scholar] [CrossRef]

- Karabelas, A.J.; Mitrouli, S.T.; Kostoglou, M. Treating reverse osmosis concentrate to address scaling and fouling problems in zero-liquid discharge systems: A scientometric review of global trends. Desalinización 2020, 474, 114193. [Google Scholar] [CrossRef]

| Solution Concentration | Mn (mol/m3) | NaCl (mol/m3) | Solution Concentration Cf (mol/m3) |

|---|---|---|---|

| Low | 1.08 × 10−2 | 3.59 × 100 | 3.60 × 100 |

| Medium | 5.38 × 10−2 | 1.77 × 101 | 1.78 × 101 |

| High | 1.04 × 10−1 | 3.46 × 101 | 3.47 × 101 |

| No | Input Variables | Output Variables | |||

|---|---|---|---|---|---|

| Solution Concentration Cf (mol/m3) | Pressure P (Pa) | Income Flow C (m3/s) | Flux Jv (m3/s m2) | Global Rejection Rate R (%) | |

| 1 | 3.60 × 100 | 5.00 × 105 | 9.57 × 105 | 9.09 × 10−6 | 98.79 |

| 2 | 3.60 × 100 | 7.50 × 105 | 1.17 × 10−4 | 1.32 × 10−5 | 98.72 |

| 3 | 3.60 × 100 | 1.00 × 106 | 1.13 × 10−4 | 1.72 × 10−5 | 98.54 |

| 4 | 1.78 × 101 | 5.00 × 105 | 1.04 × 10−4 | 7.39 × 10−6 | 97.22 |

| 5 | 1.78 × 101 | 7.50 × 105 | 9.95 × 10−5 | 1.06 × 10−5 | 96.96 |

| 6 | 1.78 × 101 | 1.00 × 106 | 1.20 × 10−4 | 1.42 × 10−5 | 96.58 |

| 7 | 3.47 × 101 | 5.00 × 105 | 1.09 × 10−4 | 6.01 × 10−6 | 96.80 |

| 8 | 3.47 × 101 | 7.50 × 105 | 1.03 × 10−4 | 8.95 × 10−6 | 96.69 |

| 9 | 3.47 × 101 | 1.00 × 106 | 1.02 × 10−4 | 1.14 × 10−5 | 96.19 |

| Solution Concentration | σ | Lp (m3/s × m2 Pa) | K (m/s) |

|---|---|---|---|

| Low | 0.9850 | 1.5822 × 10−11 | 5.6 × 10−6 |

| Medium | 0.9908 | 1.4160 × 10−11 | 5.83 × 10−6 |

| High | 0.9893 | 1.9043 × 10−11 | 7.49 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alvizuri-Tintaya, P.A.; Villena-Martínez, E.M.; Lo-Iacono-Ferreira, V.G.; Torregrosa-López, J.I.; Lora-García, J.; d’Abzac, P. Mathematical and Statistical Evaluation of Reverse Osmosis in the Removal of Manganese as a Way to Achieve Sustainable Operating Parameters. Membranes 2023, 13, 724. https://doi.org/10.3390/membranes13080724

Alvizuri-Tintaya PA, Villena-Martínez EM, Lo-Iacono-Ferreira VG, Torregrosa-López JI, Lora-García J, d’Abzac P. Mathematical and Statistical Evaluation of Reverse Osmosis in the Removal of Manganese as a Way to Achieve Sustainable Operating Parameters. Membranes. 2023; 13(8):724. https://doi.org/10.3390/membranes13080724

Chicago/Turabian StyleAlvizuri-Tintaya, Paola Andrea, Esteban Manuel Villena-Martínez, Vanesa G. Lo-Iacono-Ferreira, Juan Ignacio Torregrosa-López, Jaime Lora-García, and Paul d’Abzac. 2023. "Mathematical and Statistical Evaluation of Reverse Osmosis in the Removal of Manganese as a Way to Achieve Sustainable Operating Parameters" Membranes 13, no. 8: 724. https://doi.org/10.3390/membranes13080724

APA StyleAlvizuri-Tintaya, P. A., Villena-Martínez, E. M., Lo-Iacono-Ferreira, V. G., Torregrosa-López, J. I., Lora-García, J., & d’Abzac, P. (2023). Mathematical and Statistical Evaluation of Reverse Osmosis in the Removal of Manganese as a Way to Achieve Sustainable Operating Parameters. Membranes, 13(8), 724. https://doi.org/10.3390/membranes13080724