Fabrication and Evaluation of Filtration Membranes from Industrial Polymer Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

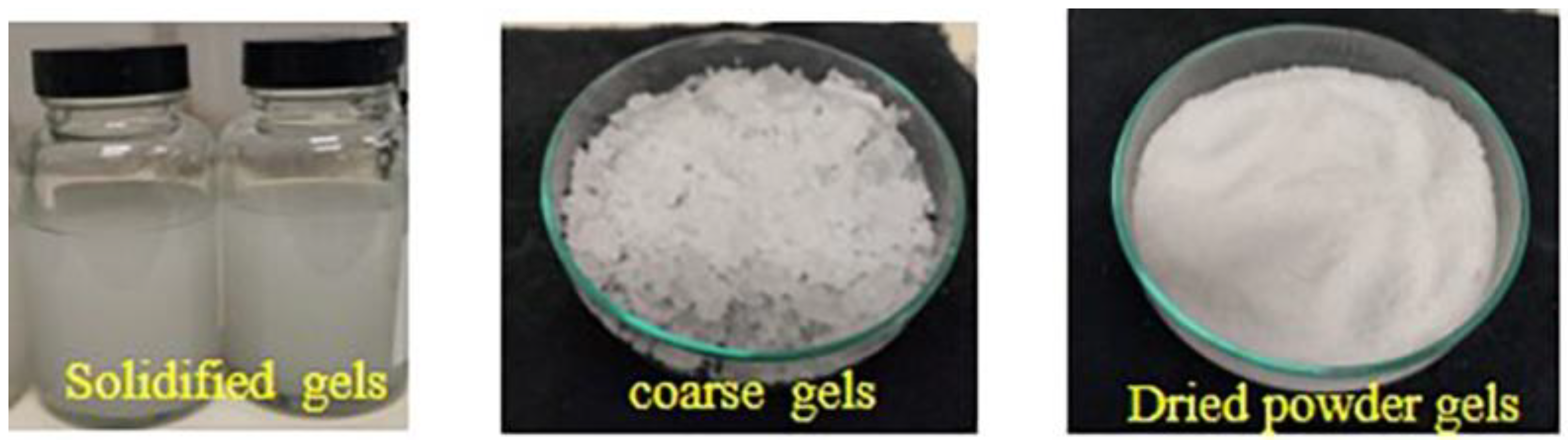

2.2. Production of Gels in PVDF Solutions

2.3. Fabrication of PVDF (Resin and Gel) Membranes

2.4. Characterization Methods

2.4.1. ATR—Fourier Transform Infrared (FTIR) Spectroscopy

2.4.2. Wide-Angle X-ray Diffraction (WAXD)

2.4.3. Viscosity Test

2.4.4. Rheological Test (Shear Viscosity)

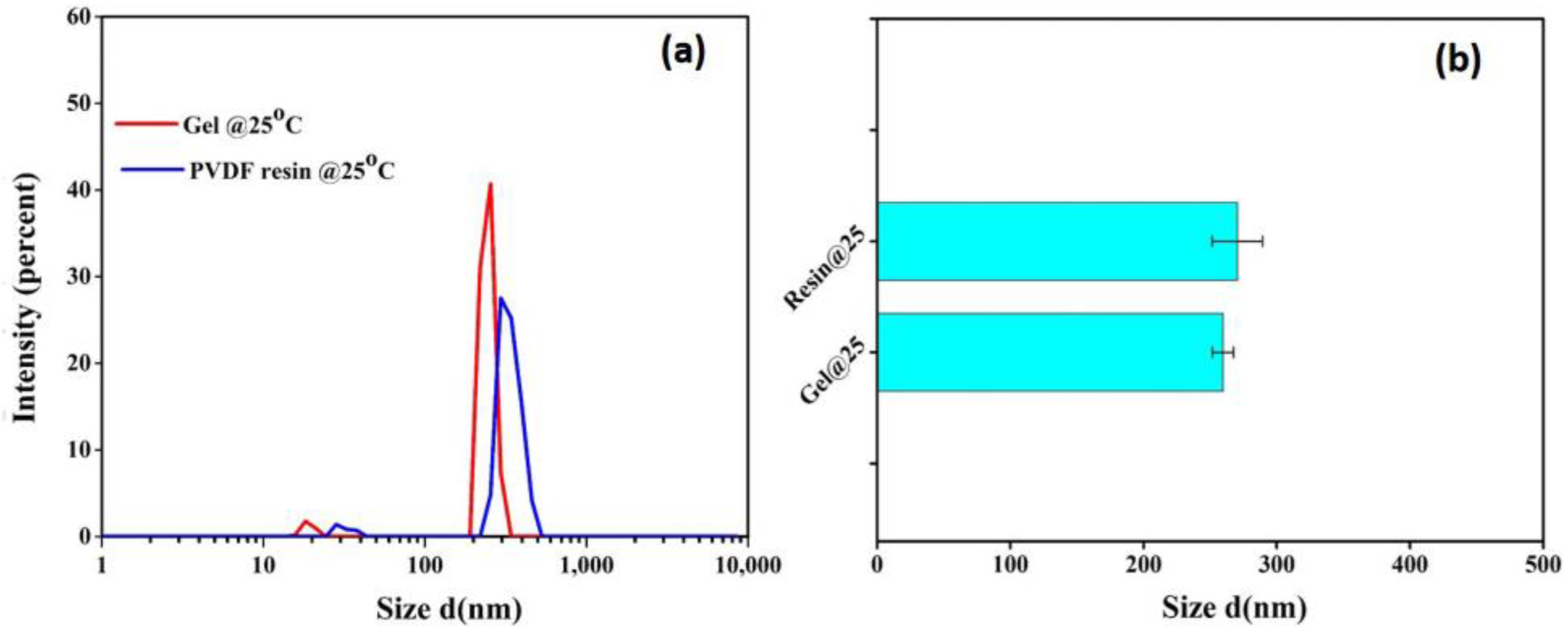

2.4.5. Light Scattering Analysis: Dynamic Light Scattering (DLS)

2.4.6. Turbidity Test

2.4.7. Molecular Weight Analysis

2.4.8. Differential Scanning Calorimetry (DSC) Analysis

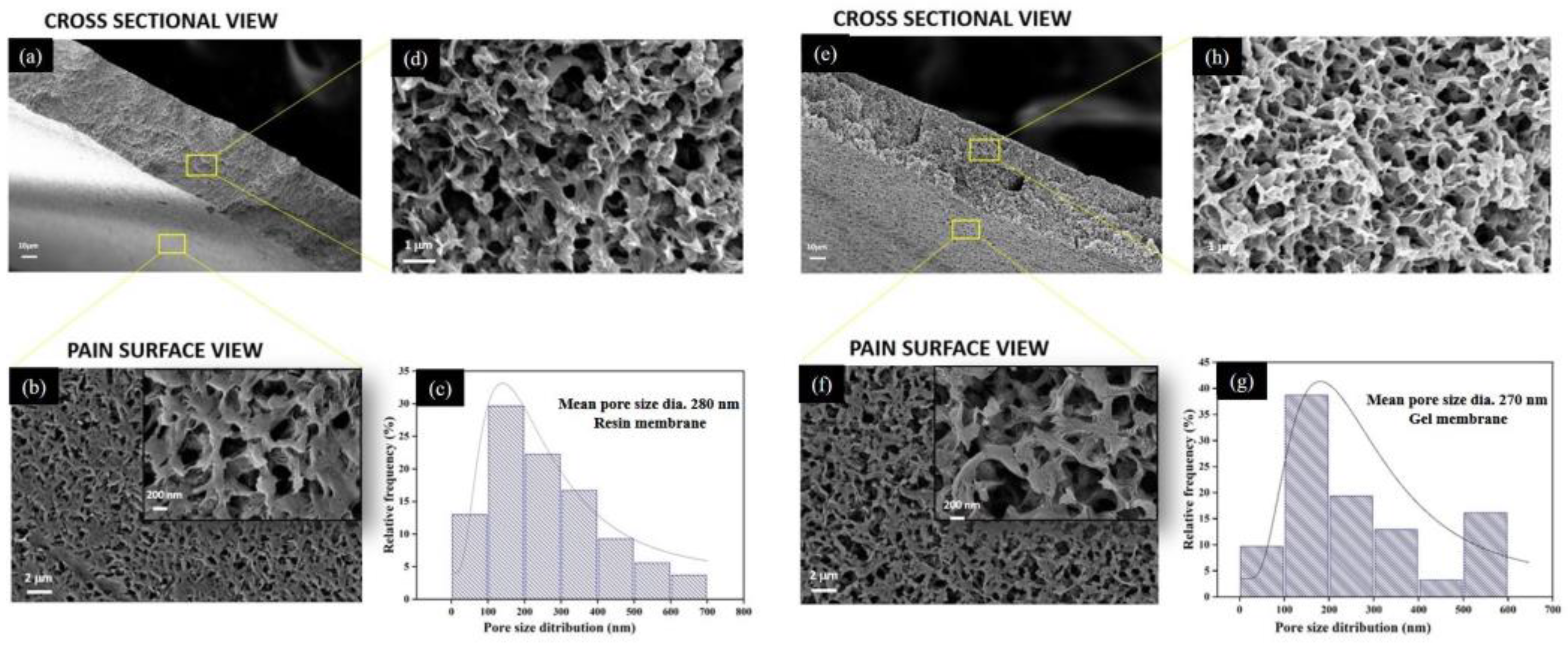

2.4.9. Field Emission Scanning Electron Microscopy (FE-SEM)

2.4.10. Pore Size Determination via Mercury Porosimetry

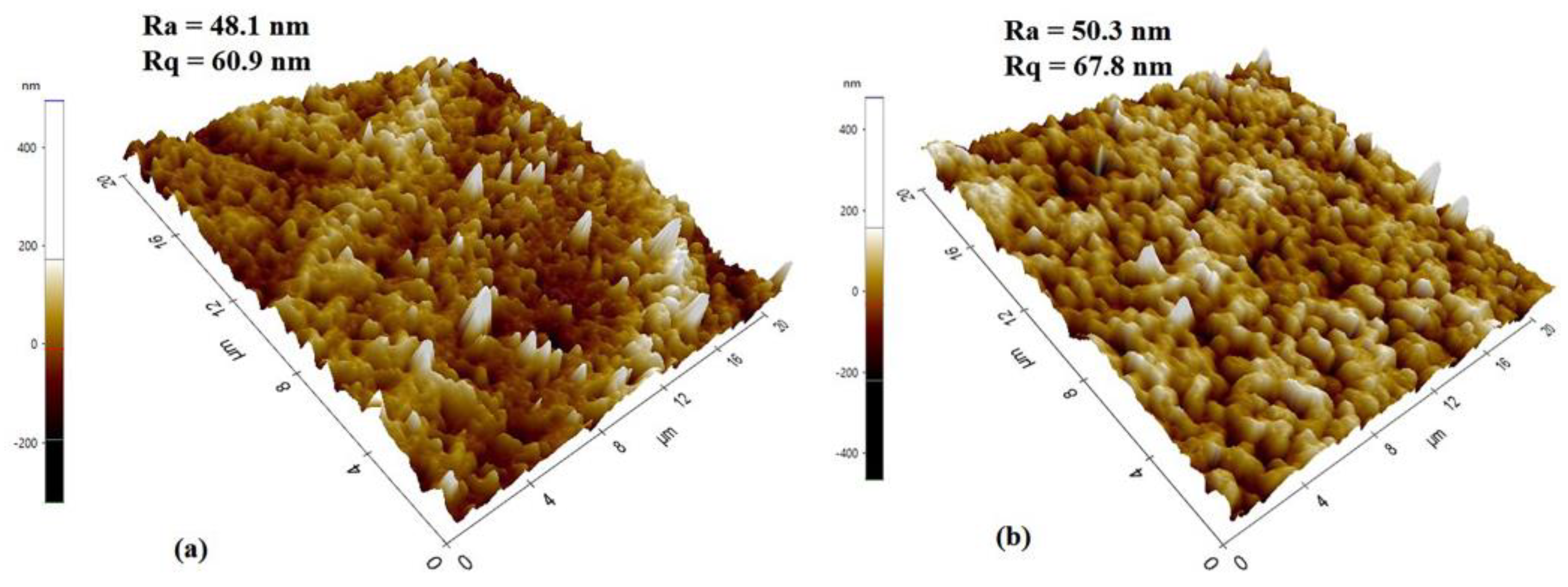

2.4.11. Atomic Force Microscopy (AFM)

2.4.12. Porosity Measurement

2.4.13. Contact Angle (CA) Measurement

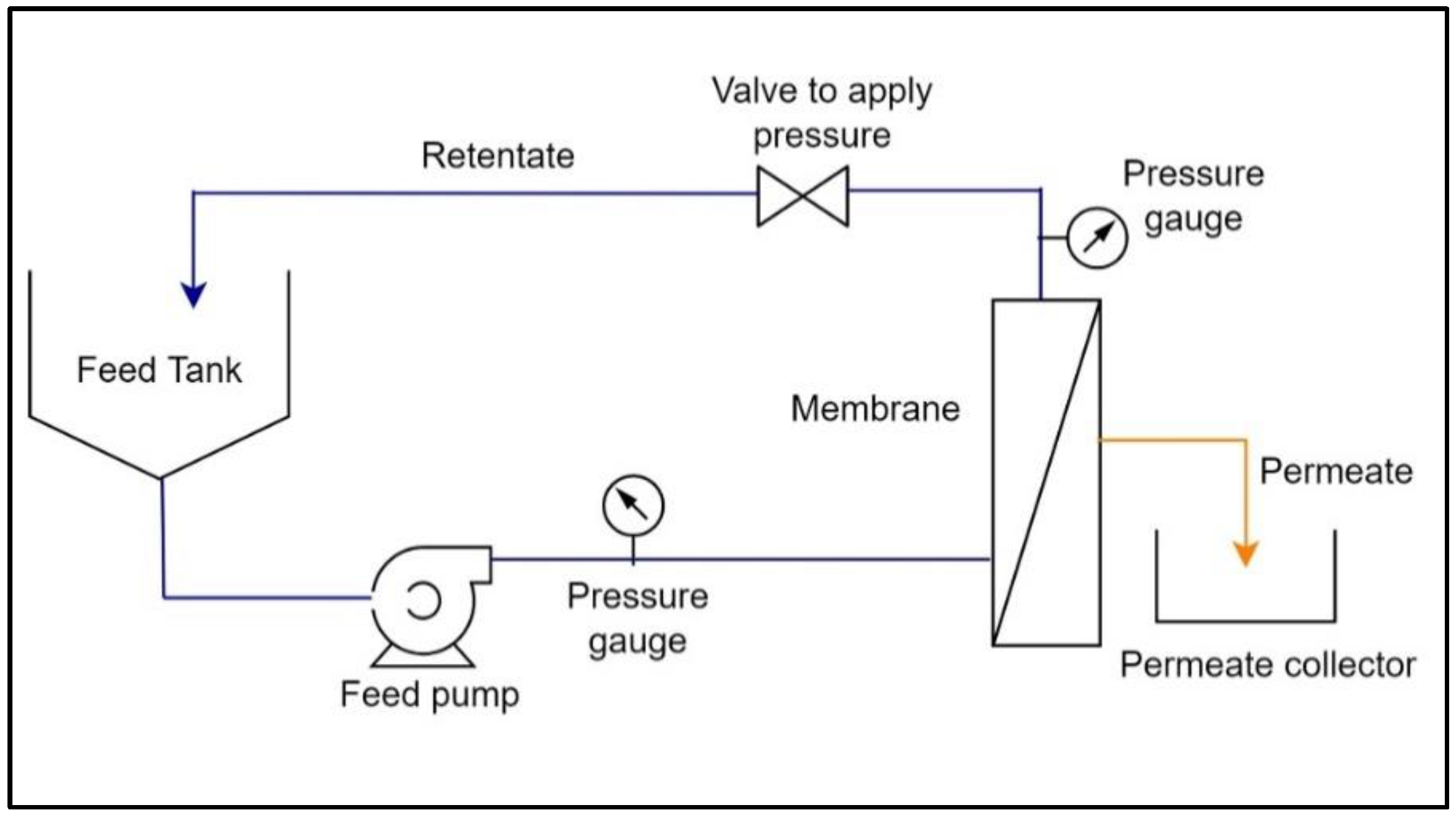

2.4.14. Membrane Performance Characterization

3. Results and Discussion

3.1. Analysis of Processed Dried Gels

3.1.1. Structural Analysis of Gels

3.1.2. Solution Properties

3.2. Analysis of Fabricated Gel Membrane

3.2.1. Physical Properties

3.2.2. Morphological Properties

3.2.3. Pore Size Analysis by Mercury Porosimetry

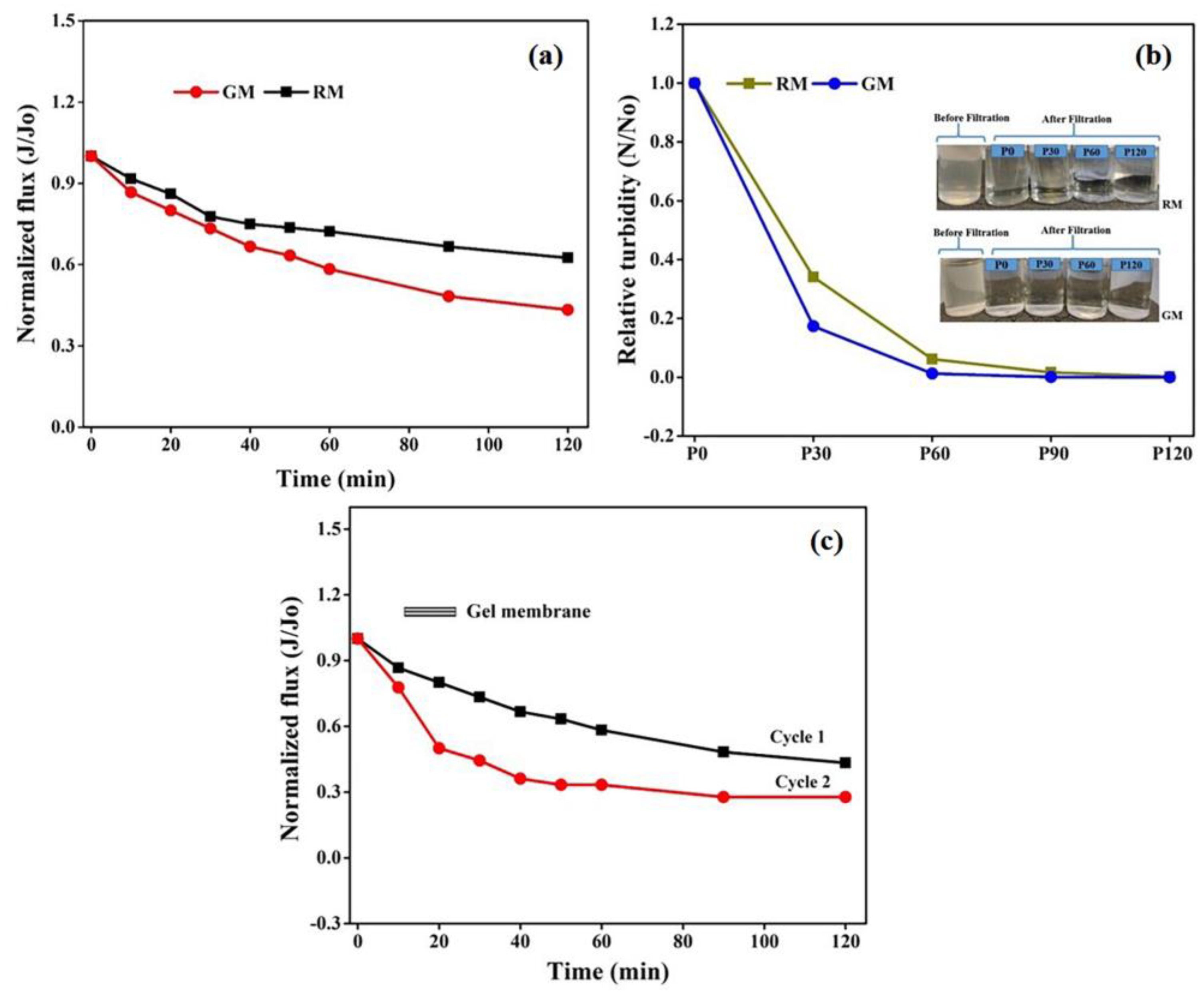

3.2.4. Filtration Properties

3.3. Wastewater Fouling and Recyclability of Gel Membranes

4. Conclusions and Future Outlook

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, W.; Cao, Y.; Gong, F.; Liu, C.; Tao, G.; Wang, X. Poly(vinylidene Fluoride) Membranes Prepared via Nonsolvent Induced Phase Separation Combined with the Gelation. Colloids Surf. A Physicochem. Eng. Asp. 2015, 479, 25–34. [Google Scholar] [CrossRef]

- Cui, Z.; Drioli, E.; Lee, Y.M. Recent Progress in Fluoropolymers for Membranes. Prog. Polym. Sci. 2014, 39, 164–198. [Google Scholar] [CrossRef]

- Liu, F.; Hashim, N.A.; Liu, Y.; Abed, M.R.M.; Li, K. Progress in the Production and Modification of PVDF Membranes. J. Membr. Sci. 2011, 375, 1–27. [Google Scholar] [CrossRef]

- Younas, H.; Bai, H.; Shao, J.; Han, Q.; Ling, Y.; He, Y. Super-Hydrophilic and Fouling Resistant PVDF Ultrafiltration Membranes Based on a Facile Prefabricated Surface. J. Membr. Sci. 2017, 541, 529–540. [Google Scholar] [CrossRef]

- Kang, G.; Cao, Y. Application and Modification of Poly(vinylidene Fluoride) (PVDF) Membranes—A Review. J. Membr. Sci. 2014, 463, 145–165. [Google Scholar] [CrossRef]

- Kim, J.H.; Moon, S.J.; Park, S.H.; Cook, M.; Livingston, A.G.; Lee, Y.M. A Robust Thin Film Composite Membrane Incorporating Thermally Rearranged Polymer Support for Organic Solvent Nanofiltration and Pressure Retarded Osmosis. J. Membr. Sci. 2018, 550, 322–331. [Google Scholar] [CrossRef]

- Kim, J.H.; Park, S.H.; Lee, M.J.; Lee, S.M.; Lee, W.H.; Lee, K.H.; Kang, N.R.; Jo, H.J.; Kim, J.F.; Drioli, E.; et al. Thermally Rearranged Polymer Membranes for Desalination. Energy Environ. Sci. 2016, 9, 878–884. [Google Scholar] [CrossRef]

- Zhang, Y.; Sunarso, J.; Liu, S.; Wang, R. Current Status and Development of Membranes for CO2/CH4 Separation: A Review. Int. J. Greenh. Gas Control 2013, 12, 84–107. [Google Scholar] [CrossRef]

- Fasciani, C.; Panero, S.; Hassoun, J.; Scrosati, B. Novel Configuration of Poly(vinylidenedifluoride)-Based Gel Polymer Electrolyte for Application in Lithium-Ion Batteries. J. Power Sources 2015, 294, 180–186. [Google Scholar] [CrossRef]

- Jiao, B.; Cassano, A.; Drioli, E. Recent Advances on Membrane Processes for the Concentration of Fruit Juices: A Review. J. Food Eng. 2004, 63, 303–324. [Google Scholar] [CrossRef]

- Zaviska, F.; Drogui, P.; Grasmick, A.; Azais, A.; Héran, M. Nanofiltration Membrane Bioreactor for Removing Pharmaceutical Compounds. J. Membr. Sci. 2013, 429, 121–129. [Google Scholar] [CrossRef]

- Valtcheva, I.B.; Kumbharkar, S.C.; Kim, J.F.; Bhole, Y.; Livingston, A.G. Beyond Polyimide: Crosslinked Polybenzimidazole Membranes for Organic Solvent Nanofiltration (OSN) in Harsh Environments. J. Membr. Sci. 2014, 457, 62–72. [Google Scholar] [CrossRef]

- Buonomenna, M.G.; Macchi, P.; Davoli, M.; Drioli, E. Poly(vinylidene Fluoride) Membranes by Phase Inversion: The Role the Casting and Coagulation Conditions Play in Their Morphology, Crystalline Structure and Properties. Eur. Polym. J. 2007, 43, 1557–1572. [Google Scholar] [CrossRef]

- Bottino, A.; Camera-Roda, G.; Capannelli, G.; Munari, S. The Formation of Microporous Polyvinylidene Difluoride Membranes by Phase Separation. J. Membr. Sci. 1991, 57, 1–20. [Google Scholar] [CrossRef]

- Mal, S.; Nandi, A.K. On the Gelation Rate of Thermoreversible Poly(vinylidene Fluoride) Gels in Glyceryl Tributyrate. Macromol. Symp. 1997, 114, 251–256. [Google Scholar] [CrossRef]

- Wang, H.H.; Jung, J.T.; Kim, J.F.; Kim, S.; Drioli, E.; Lee, Y.M. A Novel Green Solvent Alternative for Polymeric Membrane Preparation via Nonsolvent-Induced Phase Separation (NIPS). J. Membr. Sci. 2019, 574, 44–54. [Google Scholar] [CrossRef]

- Figoli, A.; Marino, T.; Simone, S.; Di Nicolò, E.; Li, X.-M.; He, T.; Tornaghi, S.; Drioli, E. Towards Non-Toxic Solvents for Membrane Preparation: A Review. Green Chem. 2014, 16, 4034–4059. [Google Scholar] [CrossRef]

- Kim, D.; Salazar, O.R.; Nunes, S.P. Membrane Manufacture for Peptide Separation. Green Chem. 2016, 18, 5151–5159. [Google Scholar] [CrossRef]

- Razali, M.; Kim, J.F.; Attfield, M.; Budd, P.M.; Drioli, E.; Lee, Y.M.; Szekely, G. Sustainable Wastewater Treatment and Recycling in Membrane Manufacturing. Green Chem. 2015, 17, 5196–5205. [Google Scholar] [CrossRef]

- Yilmaz, E.; Soylak, M. Type of Green Solvents Used in Separation and Preconcentration Methods. In New Generation Green Solvents for Separation and Preconcentration of Organic and Inorganic Species; Elsevier: Amsterdam, The Netherlands, 2020; pp. 207–266. [Google Scholar] [CrossRef]

- Sifniades, S.; Levy, A.B.; Bahl, H. Acetone. In Ullmann’s Encyclopedia of Industrial Chemistry; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 257–275. [Google Scholar] [CrossRef]

- Joshi, D.R.; Adhikari, N. An Overview on Common Organic Solvents and Their Toxicity. J. Pharm. Res. Int. 2019, 28, 1–18. [Google Scholar] [CrossRef]

- Grandine, J.D. Processes of Making a Porous Membrane Material from Polyvinylidene Fluoride, and Products. U.S. Patent 4203848A, 20 May 1980. [Google Scholar]

- Tan, X.; Rodrigue, D. A Review on Porous Polymeric Membrane Preparation. Part I: Production Techniques with Polysulfone and Poly (Vinylidene Fluoride). Polymers 2019, 11, 1160. [Google Scholar] [CrossRef] [PubMed]

- Marshall, J.E.; Zhenova, A.; Roberts, S.; Petchey, T.; Zhu, P.; Dancer, C.E.J.; McElroy, C.R.; Kendrick, E.; Goodship, V. On the Solubility and Stability of Polyvinylidene Fluoride. Polymers 2021, 13, 1354. [Google Scholar] [CrossRef]

- Schwittay, C.; Mours, M.; Winter, H.H. Rheological Expression of Physical Gelation in Polymers. Faraday Discuss. 1995, 101, 93–104. [Google Scholar] [CrossRef]

- Tazaki, M.; Wada, R.; Abe, M.O.; Homma, T. Crystallization and Gelation of Poly(vinylidene Fluoride) in Organic Solvents. J. Appl. Polym. Sci. 1997, 65, 1517–1524. [Google Scholar] [CrossRef]

- Espinosa-Dzib, A.; Vyazovkin, S. Gelation of Poly(Vinylidene Fluoride) Solutions in Native and Organically Modified Silica Nanopores. Molecules 2018, 23, 3025. [Google Scholar] [CrossRef]

- Okabe, M.; Wada, R.; Tazaki, M.; Homma, T. The Flory-Huggins Interaction Parameter and Thermoreversible Gelation of Poly(vinylidene Fluoride) in Organic Solvents. Polym. J. 2003, 35, 798–803. [Google Scholar] [CrossRef]

- Arya, A.; Sharma, A.L. Polymer Electrolytes for Lithium Ion Batteries: A Critical Study. Ionics 2017, 23, 497–540. [Google Scholar] [CrossRef]

- Zhang, P.; Li, R.; Huang, J.; Liu, B.; Zhou, M.; Wen, B.; Xia, Y.; Okada, S. Flexible Poly(vinylidene Fluoride-Co-Hexafluoropropylene)-Based Gel Polymer Electrolyte for High-Performance Lithium-Ion Batteries. RSC Adv. 2021, 11, 11943–11951. [Google Scholar] [CrossRef] [PubMed]

- Lin, K.-Y.; Wang, D.-M.; Lai, J.-Y. Nonsolvent-Induced Gelation and Its Effect on Membrane Morphology. Macromolecules 2002, 35, 6697–6706. [Google Scholar] [CrossRef]

- Lin, D.J.; Beltsios, K.; Young, T.H.; Jeng, Y.S.; Cheng, L.P. Strong Effect of Precursor Preparation on the Morphology of Semicrystalline Phase Inversion Poly(vinylidene Fluoride) Membranes. J. Membr. Sci. 2006, 274, 64–72. [Google Scholar] [CrossRef]

- Pagliero, M.; Bottino, A.; Comite, A.; Costa, C. Novel Hydrophobic PVDF Membranes Prepared by Nonsolvent Induced Phase Separation for Membrane Distillation. J. Membr. Sci. 2020, 596, 117575. [Google Scholar] [CrossRef]

- Madaeni, S.S.; Taheri, A.H. Effect of Casting Solution on Morphology and Performance of PVDF Microfiltration Membranes. Chem. Eng. Technol. 2011, 34, 1328–1334. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Zhang, L.; An, Q.; Chen, H. Morphology and Formation Mechanism of Poly(Vinylidene Fluoride) Membranes Prepared with Immerse Precipitation: Effect of Dissolving Temperature. J. Macromol. Sci. Part B 2009, 48, 696–709. [Google Scholar] [CrossRef]

- Nawi, N.I.M.; Bilad, M.R.; Nordin, N.A.H.M. Effect of Dope Solution Temperature on the Membrane Structure and Membrane Distillation Performance. IOP Conference Series: Earth and Environmental Science. In Proceedings of the 4th International Conference on Civil and Environmental Engineering for Sustainability, Langkawi, Malaysia, 4–5 December 2017; Volume 140, p. 12032. [Google Scholar] [CrossRef]

- Arahman, N.; Maimun, T.; Mukramah; Syawaliah. The Study of Membrane Formation via Phase Inversion Method by Cloud Point and Light Scattering Experiment. AIP Conf. Proc. 2017, 1788, 30018. [Google Scholar] [CrossRef]

- Lin, D.-J.; Chang, H.-H.; Chen, T.-C.; Lee, Y.-C.; Cheng, L.-P. Formation of Porous Poly(vinylidene Fluoride) Membranes with Symmetric or Asymmetric Morphology by Immersion Precipitation in the water/TEP/PVDF System. Eur. Polym. J. 2006, 42, 1581–1594. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.C.; Lanceros-Mendez, S. Electroactive Phases of Poly(vinylidene Fluoride): Determination, Processing and Applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Wu, L.; Sun, J. An Improved Process for Polyvinylidene Fluoride Membrane Preparation by Using a Water Soluble Diluent via Thermally Induced Phase Separation Technique. Mater. Des. 2015, 86, 204–214. [Google Scholar] [CrossRef]

- Nishiyama, T.; Sumihara, T.; Sato, E.; Horibe, H. Effect of Solvents on the Crystal Formation of Poly(vinylidene Fluoride) Film Prepared by a Spin-Coating Process. Polym. J. 2017, 49, 319–325. [Google Scholar] [CrossRef]

- Li, C.-L.; Wang, D.-M.; Deratani, A.; Quémener, D.; Bouyer, D.; Lai, J.-Y. Insight into the Preparation of Poly(vinylidene Fluoride) Membranes by Vapor-Induced Phase Separation. J. Membr. Sci. 2010, 361, 154–166. [Google Scholar] [CrossRef]

- Liu, F.; Tao, M.; Xue, L. PVDF Membranes with Inter-Connected Pores Prepared via a Nat-Ips Process. Desalination 2012, 298, 99–105. [Google Scholar] [CrossRef]

- Tian, M.; Yuan, S.; Decaesstecker, F.; Zhu, J.; Volodine, A.; Van der Bruggen, B. One-Step Fabrication of Isotropic Poly(vinylidene Fluoride) Membranes for Direct Contact Membrane Distillation (DCMD). Desalination 2020, 477, 114265. [Google Scholar] [CrossRef]

- Marino, T.; Russo, F.; Figoli, A. The Formation of Polyvinylidene Fluoride Membranes with Tailored Properties via Vapour/Non-Solvent Induced Phase Separation. Membranes 2018, 8, 71. [Google Scholar] [CrossRef]

- Ariono, D.; Aryanti, P.T.P.; Subagjo, S.; Wenten, I.G. The Effect of Polymer Concentration on Flux Stability of Polysulfone Membrane. AIP Conf. Proc. 2017, 1788, 30048. [Google Scholar] [CrossRef]

- Leaper, S.; Abdel-Karim, A.; Faki, B.; Luque-Alled, J.M.; Alberto, M.; Vijayaraghavan, A.; Holmes, S.M.; Szekely, G.; Badawy, M.I.; Shokri, N.; et al. Flux-Enhanced PVDF Mixed Matrix Membranes Incorporating APTS-Functionalized Graphene Oxide for Membrane Distillation. J. Membr. Sci. 2018, 554, 309–323. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Sun, D.; An, Q.; Chen, H. Formation Mechanism and Crystallization of Poly(vinylidene Fluoride) Membrane via Immersion Precipitation Method. Desalination 2009, 236, 170–178. [Google Scholar] [CrossRef]

- Nagrath, M.; Rahimnejad Yazdi, A.; Rafferty, A.; Daly, D.; Rahman, S.U.; Gallant, R.C.; Ni, H.; Arany, P.R.; Towler, M.R. Tantalum-Containing Meso-Porous Glass Fibres for Hemostatic Applications. Mater. Today Commun. 2021, 27, 102260. [Google Scholar] [CrossRef]

- Kahrs, C.; Schwellenbach, J. Membrane Formation via Non-Solvent Induced Phase Separation Using Sustainable Solvents: A Comparative Study. Polymer 2020, 186, 122071. [Google Scholar] [CrossRef]

- Hong, J.; He, Y. Effects of Nano Sized Zinc Oxide on the Performance of PVDF Microfiltration Membranes. Desalination 2012, 302, 71–79. [Google Scholar] [CrossRef]

- Yu, L.-Y.; Xu, Z.-L.; Shen, H.-M.; Yang, H. Preparation and Characterization of PVDF–SiO2 Composite Hollow Fiber UF Membrane by Sol–gel Method. J. Membr. Sci. 2009, 337, 257–265. [Google Scholar] [CrossRef]

- Wang, X.; Xiao, C.; Liu, H.; Huang, Q.; Fu, H. Fabrication and Properties of PVDF and PVDF-HFP Microfiltration Membranes. J. Appl. Polym. Sci. 2018, 135, 46711. [Google Scholar] [CrossRef]

- Zin, G.; Wu, J.; Rezzadori, K.; Petrus, J.C.C.; Di Luccio, M.; Li, Q. Modification of Hydrophobic Commercial PVDF Microfiltration Membranes into Superhydrophilic Membranes by the Mussel-Inspired Method with Dopamine and Polyethyleneimine. Sep. Purif. Technol. 2019, 212, 641–649. [Google Scholar] [CrossRef]

| Sample | % Crystallinity | Average Molecular Weight (Mw) Daltons | Polydispersity Index (PDI) | Average Viscosity (cP) @25 °C @10 rpm |

|---|---|---|---|---|

| PVDF resin | 33.36 ± 0.004 | 664,000 | 3.06 | 984 ± 1.43 |

| Gel powder | 35.02 ± 0.001 | 684,000 | 3.58 | 1008 ± 2.22 |

| Sample | Melting Temperature (Tm) (°C) | Melting Enthalpy (ΔHm) (J/g) | % Crystallinity |

|---|---|---|---|

| PVDF resin | 159.49 | 33.04 | 31.55 |

| Gel powder | 159.83 | 33.21 | 31.72 |

| RM | 159.46 | 37.34 | 35.67 |

| GM | 158.64 | 37.91 | 36.21 |

| Sample | Mean Pore Size (μm) | Porosity (%) | Contact Angle (°) | Average Flux (LMH) | Retention (%) | FRR (%) |

|---|---|---|---|---|---|---|

| RM | 0.23 ± 0.11 | 69.18 ± 4.09 | 110 ± 3.33 | 591.43 ± 15.18 | 25.41 ± 2.32 | 82.5 |

| GM | 0.19 ± 0.08 | 66.78 ± 6.12 | 105 ± 3.17 | 478.92 ± 12.30 | 26.88 ± 5.03 | 83.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bano, S.; Pednekar, M.; Rameshkumar, S.; Borah, D.; Morris, M.A.; Padamati, R.B.; Cronly, N. Fabrication and Evaluation of Filtration Membranes from Industrial Polymer Waste. Membranes 2023, 13, 445. https://doi.org/10.3390/membranes13040445

Bano S, Pednekar M, Rameshkumar S, Borah D, Morris MA, Padamati RB, Cronly N. Fabrication and Evaluation of Filtration Membranes from Industrial Polymer Waste. Membranes. 2023; 13(4):445. https://doi.org/10.3390/membranes13040445

Chicago/Turabian StyleBano, Saleheen, Mukesh Pednekar, Saranya Rameshkumar, Dipu Borah, Michael A. Morris, Ramesh Babu Padamati, and Niamh Cronly. 2023. "Fabrication and Evaluation of Filtration Membranes from Industrial Polymer Waste" Membranes 13, no. 4: 445. https://doi.org/10.3390/membranes13040445

APA StyleBano, S., Pednekar, M., Rameshkumar, S., Borah, D., Morris, M. A., Padamati, R. B., & Cronly, N. (2023). Fabrication and Evaluation of Filtration Membranes from Industrial Polymer Waste. Membranes, 13(4), 445. https://doi.org/10.3390/membranes13040445