Integration of Pre-Treatment with UF/RO Membrane Process for Waste Water Recovery and Reuse in Agro-Based Pulp and Paper Industry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Experiment Set Up

2.3. Operating Conditions

2.4. Sample Analysis

3. Results and Discussion

3.1. Characterization of Effluent Secondary Clarifier

3.2. Performance of Membrane Filtration Unit

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Water Resources, Government of India. Central Water Commission Annual Report, 2010; Ministry of Water Resources, Government of India: New Delhi, India, 2010. [Google Scholar]

- Ministry of Water Resources, Government of India. Public Information Bureau, 2013; Ministry of Water Resources, Government of India: New Delhi, India, 2013. [Google Scholar]

- Government of India. Infrastructural Statisctics-2010, A Report by Ministry of Statistics and Programme Implementation; Government of India: New Delhi, India, 2010. [Google Scholar]

- Gangwar, A.; Prakash, R.; Nagaraja, T.P. Applicability of Microbial Xylanases in Paper and Pulp Bleaching: A Review. Bioresources 2014, 9, 3733–3754. [Google Scholar] [CrossRef]

- Roy, T.K. Overview of Indian Paper Industry. In Proceedings of the Workshop on Adoption of Energy Efficient Process Technologies and Energy Management Practices in Pulp and Paper Sector under Energy Conservation Act, Saharanpur, India, 14 February 2007. [Google Scholar]

- Putatunda, S.; Bhattachrya, S.; Sen, D.; Bhattacharjee, C. A review on application of different treatment process for emulsified oily wastewater. Int. J. Environ. Sci. Technol. 2019, 16, 2525–2536. [Google Scholar] [CrossRef]

- He, Y.; Bagley, D.M.; Leung, K.T.; Liss, S.N.; Liao, B.A. Recent advances in membrane technologies for biorefining and bioenergy production. Bitechnol. Adv. 2012, 30, 817–858. [Google Scholar] [CrossRef]

- Asif, M.B.; Zhang, Z. Ceramic membrane technology for water and wastewater treatment: A critical review of performance, ful-scale applications, membrane fouling and prospects. Chem. Eng. J. 2021, 418, 129481. [Google Scholar] [CrossRef]

- Martini, S.; Haming, A. Hybrid TiO2/UV/PVDF ultrafiltation membrane for anola oil wastewater treatment. Desalination Water Treat. 2019, 148, 51–59. [Google Scholar] [CrossRef]

- Yadav, M.K.; Saidulu, D.; Gupta, A.K.; Ghosal, A.M. Status and management of arsenic pollution in groundwater: A comprehensive appraisal of recent global scenario, human health impacts, sustainable filed scale treatment technologies. J. Envion. Chem. Eng. 2021, 9, 105203. [Google Scholar] [CrossRef]

- Puro, L.; Kallioinen, M.; Mänttäri, M.; Nyström, M. Evaluation of behavior and fouling potential of wood extractives in ultrafiltration of pulp and paper mill process water. J. Memb. Sci. 2011, 368, 150–158. [Google Scholar] [CrossRef]

- Puro, L.; Tanninen, J.; Nyström, M. Analyses of organic foulants in membranes fouled by pulp and paper mill effluent using solid-liquid extraction. Desalination 2002, 143, 1–9. [Google Scholar] [CrossRef]

- Koivula, E.; Kallioinen, M.; Preis, S.; Testova, L.; Sixta, H.; Mänttäri, M. Evaluation of various pre-treatment methods to manage fouling in ultrafiltration of wood hydrolysates. Sep. Purif. Technol. 2011, 83, 50–56. [Google Scholar] [CrossRef]

- Maartens, A.; Jacobs, E.P.; Swart, P. UFof pulp and paper effluent: Membrane fouling-prevention and cleaning. J. Membr. Sci. 2002, 209, 81–92. [Google Scholar] [CrossRef]

- Li, J.; Sanderson, R.D.; Jacobs, E.P. Ultrasonic cleaning of nylon microfiltration membranes fouled by Kraft paper mill effluent. J. Membr. Sci. 2002, 205, 247–257. [Google Scholar] [CrossRef]

- Weis, A.; Bird, M.R.; Nystrom, M. The chemical cleaning of polymeric UF membrane fouled with spent sulphate liquor over multiple operational cycles. J. Membr. Sci. 2003, 216, 67–79. [Google Scholar] [CrossRef]

- Kamali, M.; Khodaparast, Z. Review on recent developments on pulp and paper mill wastewater treatment. Ecotoxicol. Environ. Saf. 2015, 114, 326–342. [Google Scholar] [CrossRef]

- Yordanov, D. Preliminary study of the efficiency of ultrafiltration treatment of poultry slaughterhouse wastewater. Bulgatian J. Agric. Sci. 2010, 16, 700–704. [Google Scholar]

- Oh, K.S.; Poh, P.E.; Chong, M.N.; Chan, E.S.; Lau, E.V.; Saint, C.P. Bathroom grey water recycling using polyelectrolyte-complex bilayer membrane: Advanced study of membrane structure and treatment efficiency. Carbohydate Polym. 2016, 148, 161–170. [Google Scholar] [CrossRef]

- Sun, X.; Wang, C.; Li, Y.; Wang, W.; Wei, J. Treatment of phenolic wastewater by combined UF and NF/RO processes. Desalination 2015, 355, 68–74. [Google Scholar] [CrossRef]

- Ellouze, E.; Tahri, N.; Amar, R.B. Enhancement of textile wastewater treatment process using Nanofiltration. Desalination 2012, 286, 16–23. [Google Scholar] [CrossRef]

- Lin, J.; Ye, W.; Baltaru, M.C.; Tang, Y.P.; Bernstein, N.J.; Gao, P.; Balta, S.; Vlad, M.; Volodin, A.; Sotto, A.; et al. Tight ultrafiltration membranes for enhanced separation of dyes and Na2SO during textile wastewater treatment. J. Membr. Sci. 2016, 514, 217–228. [Google Scholar] [CrossRef]

- Shukla, S.K.; Kumar, V.; Kim, T.; Bansal, M.C. Membrane filtration of chlorination and extraction stage bleach plant effluent in Indian paper Industry. Clean Technol. Environ. Policy 2013, 15, 235–243. [Google Scholar] [CrossRef]

- Shukla, S.K.; Kumar, V.; Bansal, M.C. Treatment of combined bleaching effluent by membrane filtration technology for system closure in paper industry. Desalination Water Treat. 2010, 13, 464–470. [Google Scholar] [CrossRef]

- Li, S.Z.; Li, X.Y.; Wang, D.Z. Membrane (RO-UF) filtration for antibiotic wastewater treatment and recovery of antibiotics. Sep. Purif. Technol. 2004, 34, 109–114. [Google Scholar] [CrossRef]

| S.No | Physico-Chemical Parameters | Method Used |

|---|---|---|

| 1 | pH | Potentiometer |

| 2 | Chemical oxygen demand (COD) | Open efflux (Potassium Dichromate Method) |

| 3 | Biochemical Oxygen demand (BOD) | 5 Days Incubation at 25 °C |

| 4 | Total dissolved solids (TDS) | IS: 3025 (Part 16) |

| 5 | Total suspended solids (TSS) | Gravimetric Method |

| 6 | Color | Spectrophotometric Method |

| 7 | Lignin | APHA method 5550 B |

| 8 | Electrical Conductivity | Conductivity Meter |

| 9 | Sodium and Potassium | Flame Photometer |

| Parameter | Values | CPCB Limits |

|---|---|---|

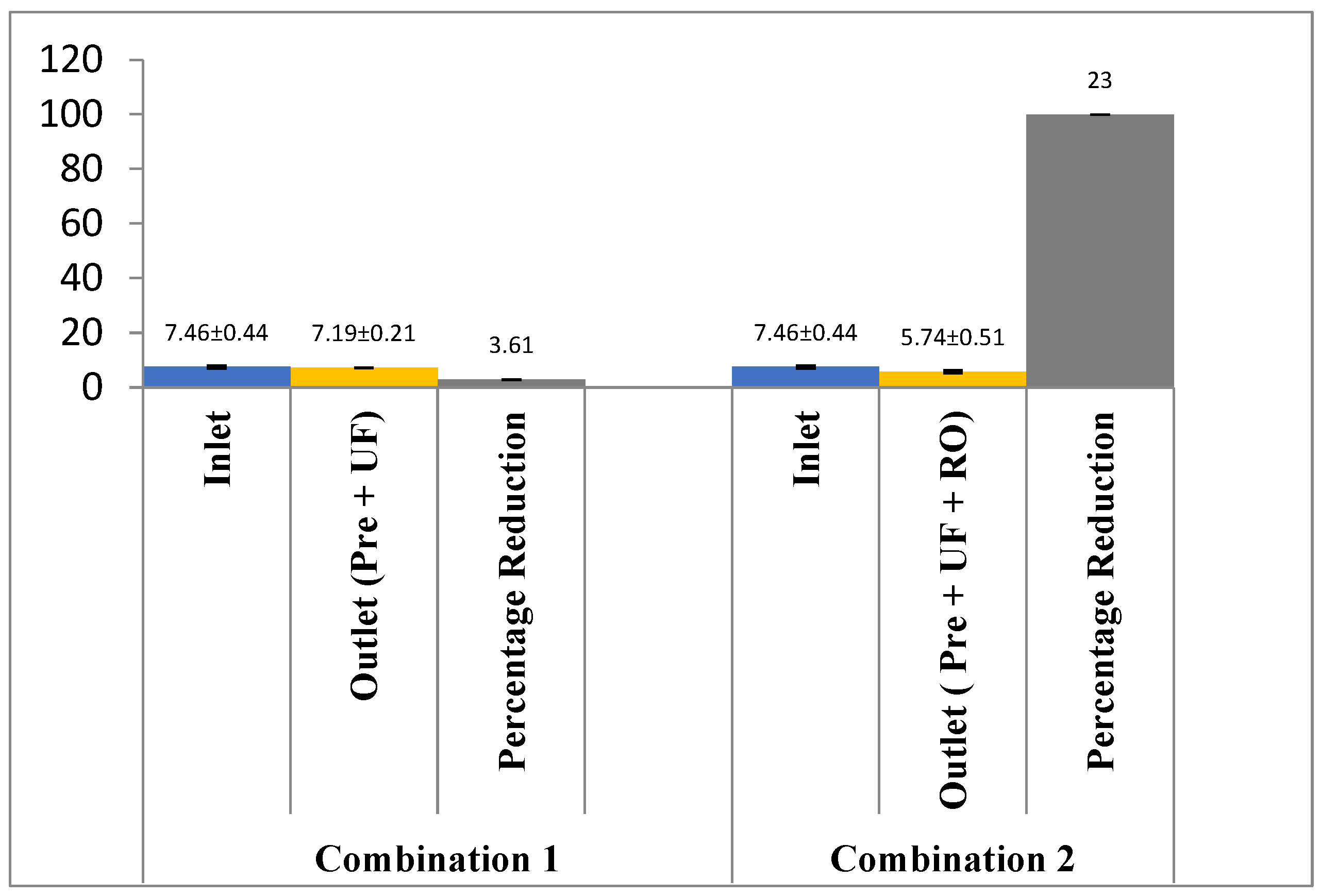

| pH | 7.46 ± 0.44 | 5.5–9.0 |

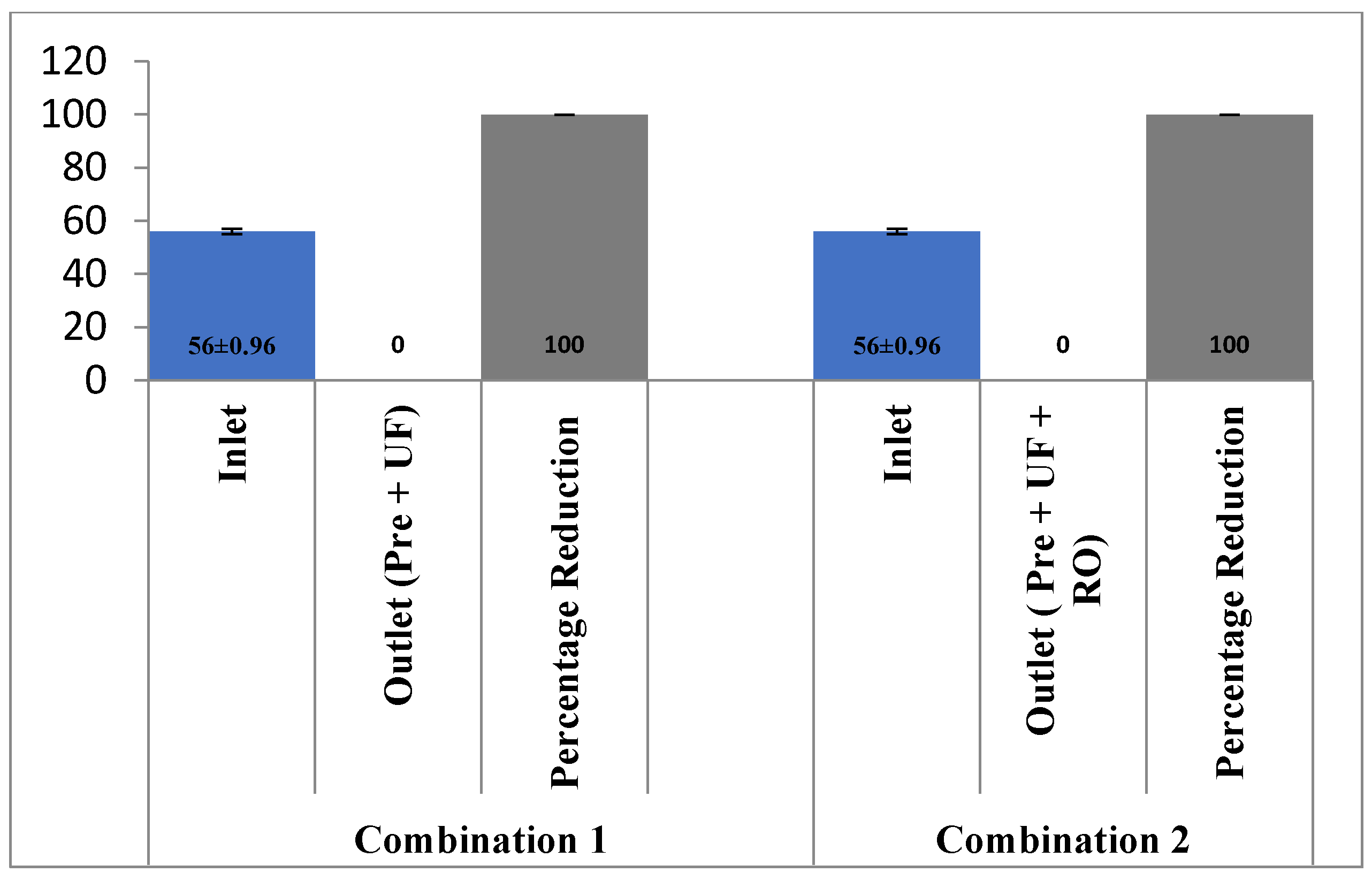

| TSS mg/L | 56 ± 0.96 | 100 |

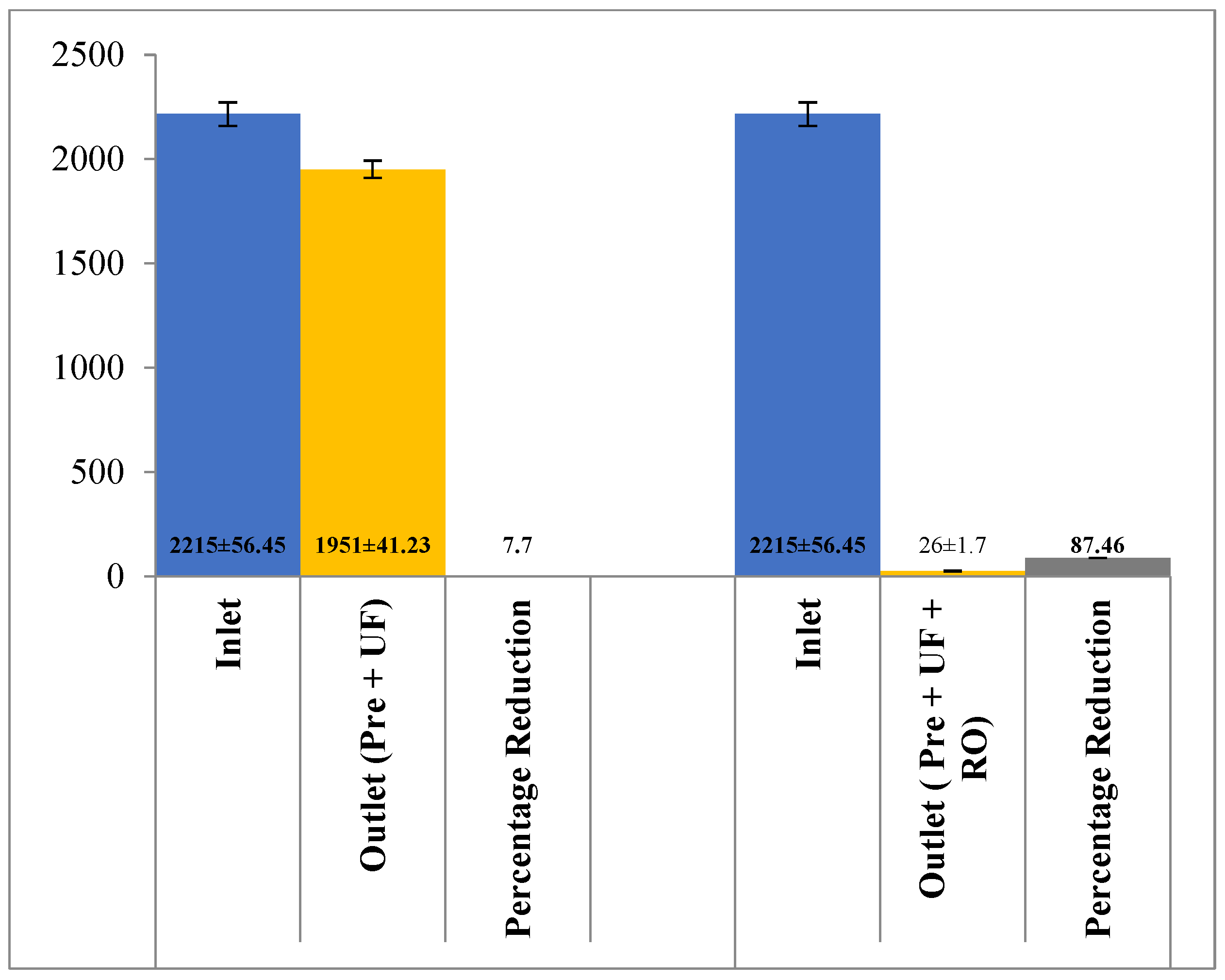

| TDS, mg/L | 2215 ± 56.45 | 2100 |

| COD, mg/L | 216 ± 9.11 | 250 |

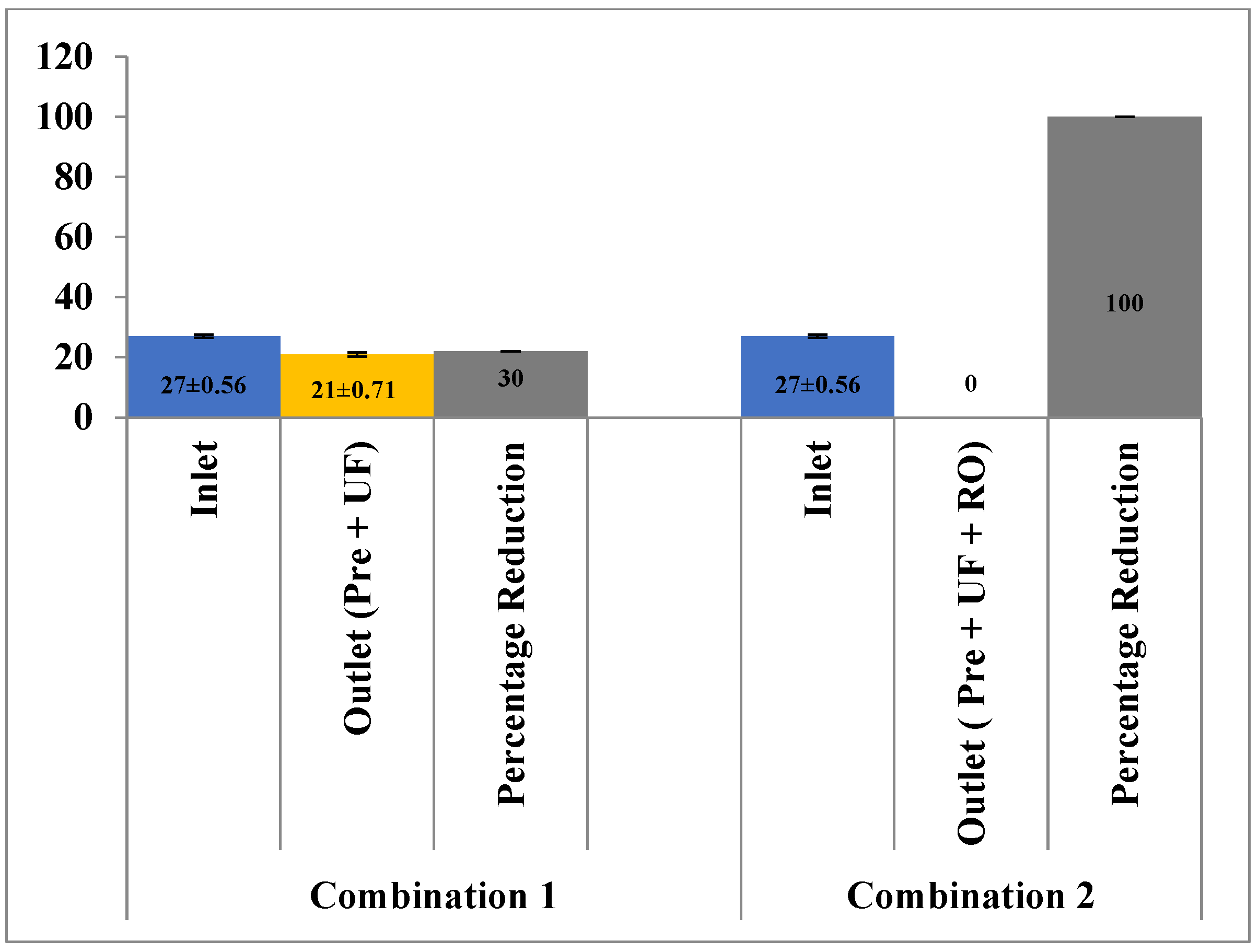

| BOD, mg/L | 27 ± 0.56 | 30 |

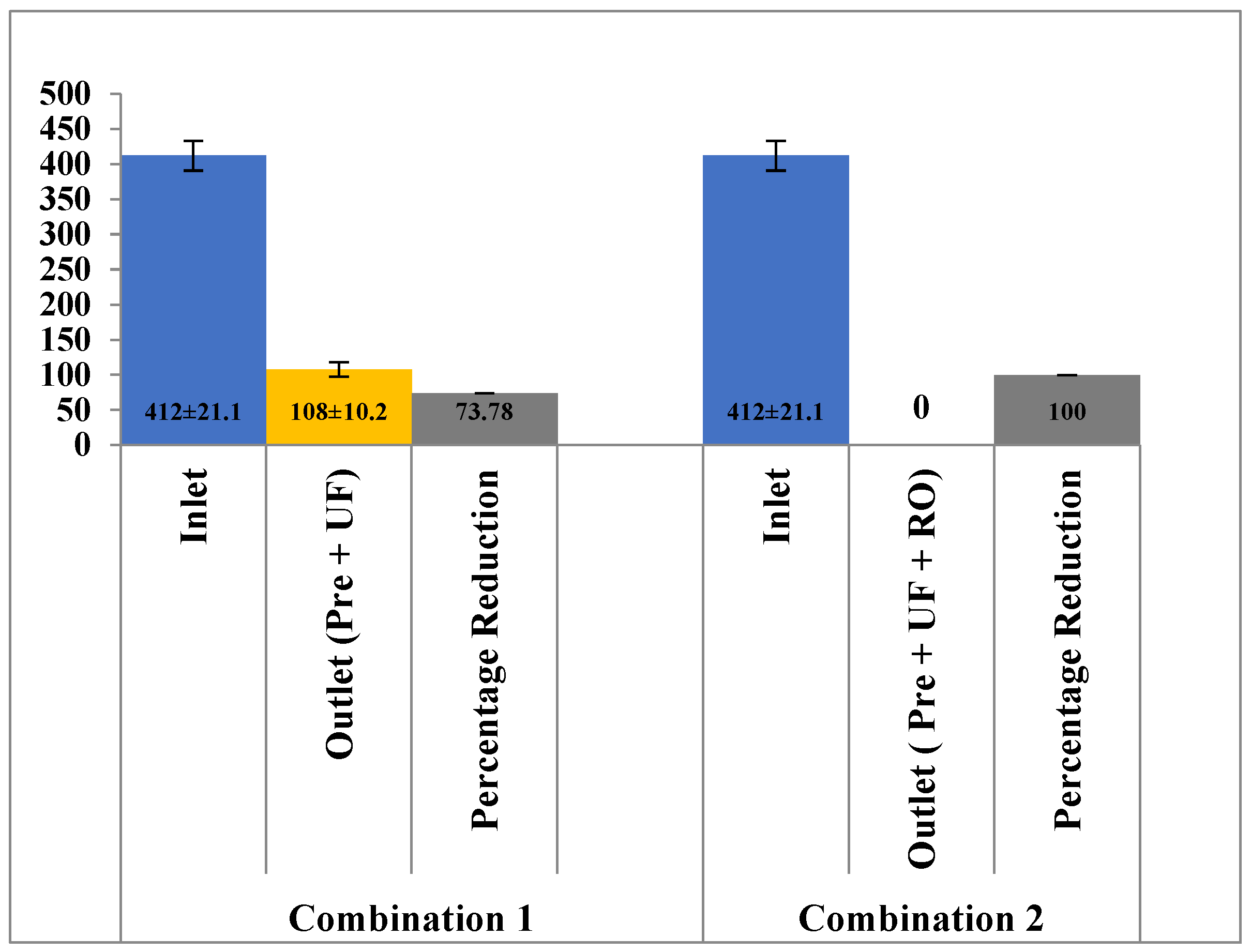

| Color, PCU | 412 ± 21.1 | 500 |

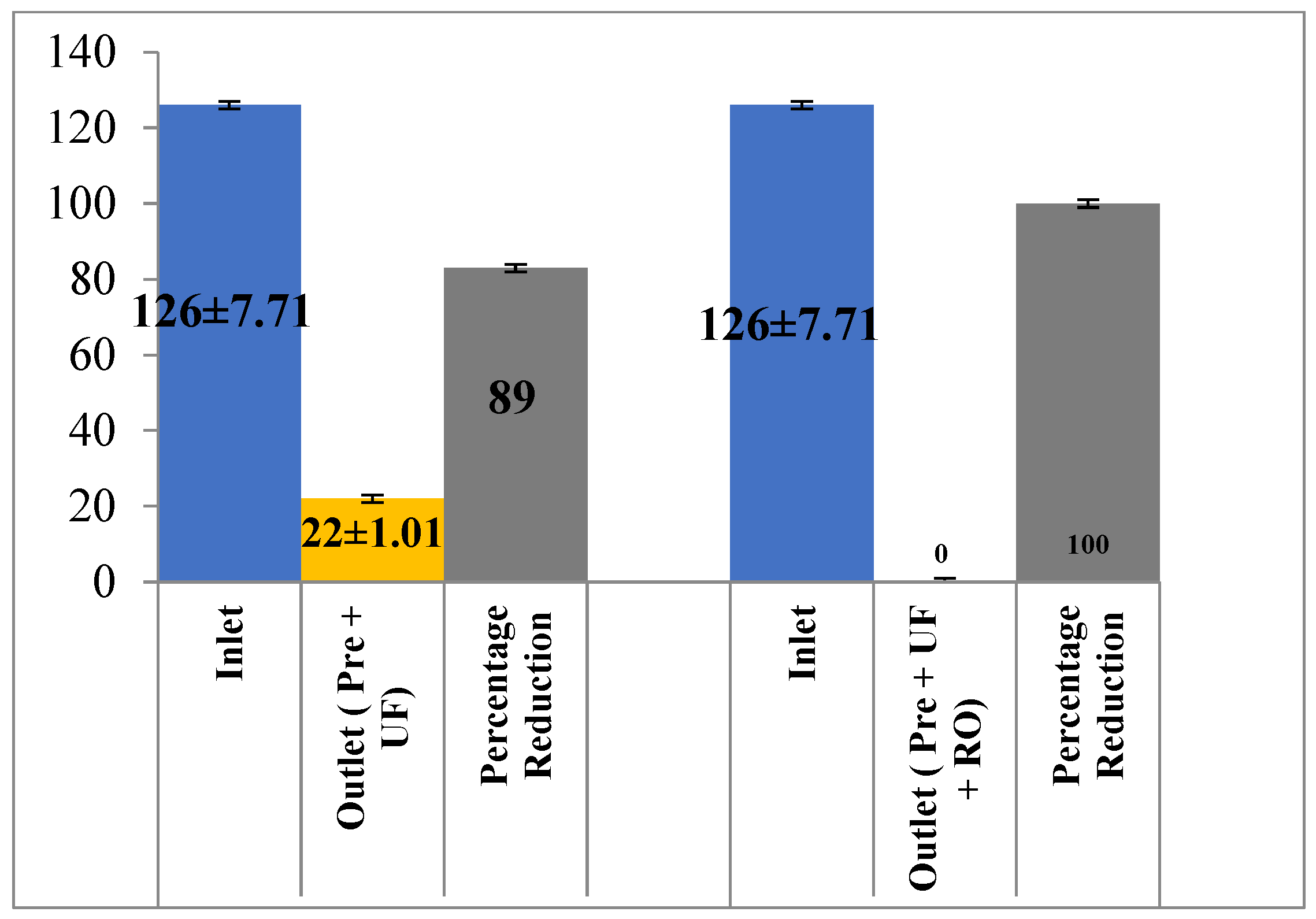

| Lignin, mg/L | 126 ± 7.71 | - |

| Conductivity, µS/cm | 2630 ± 81.21 | - |

| Sodium (Na), mg/L | 49 ± 2.1 | |

| Potassium (K), mg/L | 7.2 ± 0.17 | - |

| TSS (mg/L) | TDS (mg/L) | COD (mg/L) | BOD (mg/L) | Color (PCU) | Lignin (mg/L) | pH | Conductivity (µs) | Potassium (mg/L) | Na (mg/L) | |

|---|---|---|---|---|---|---|---|---|---|---|

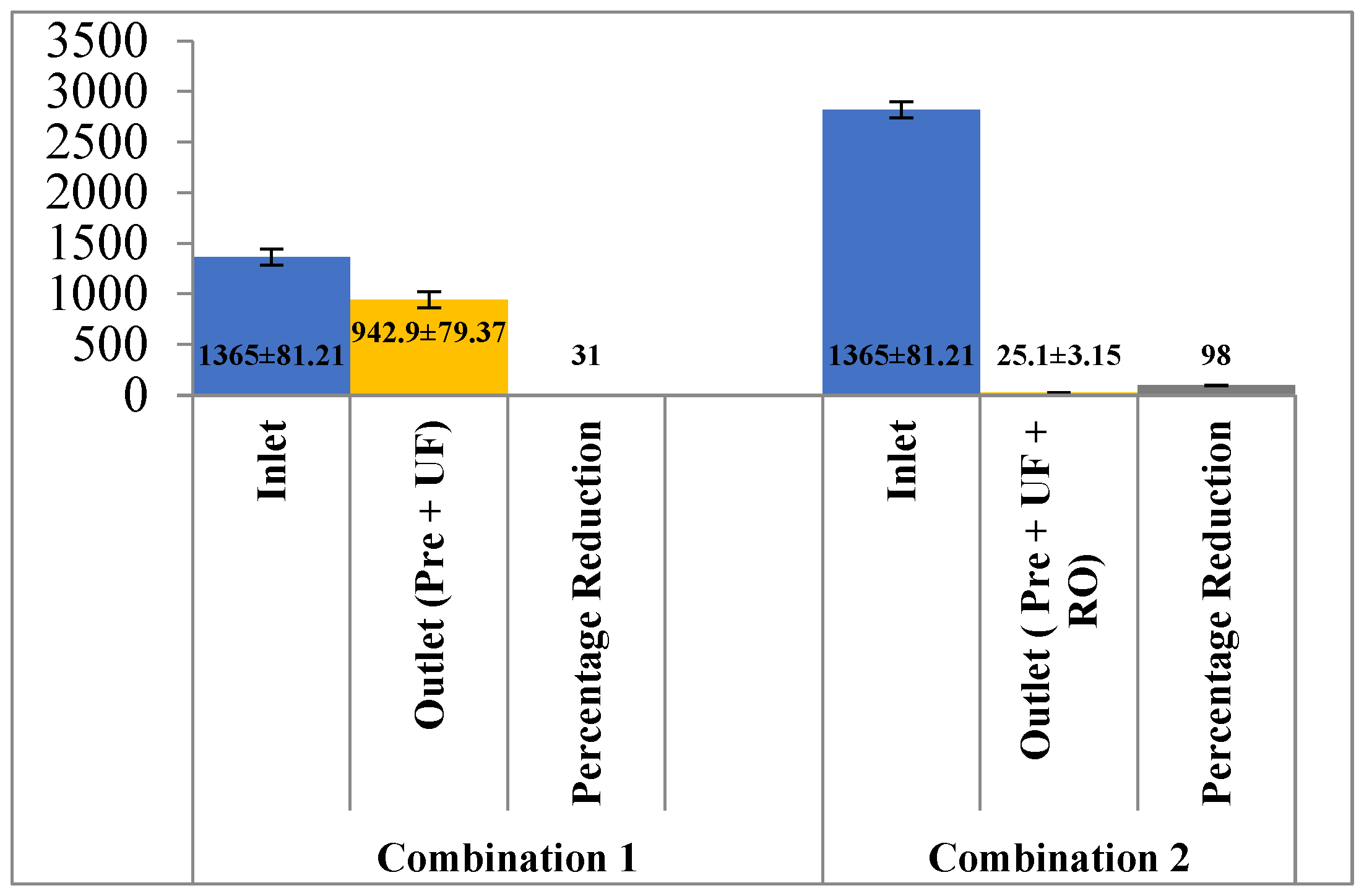

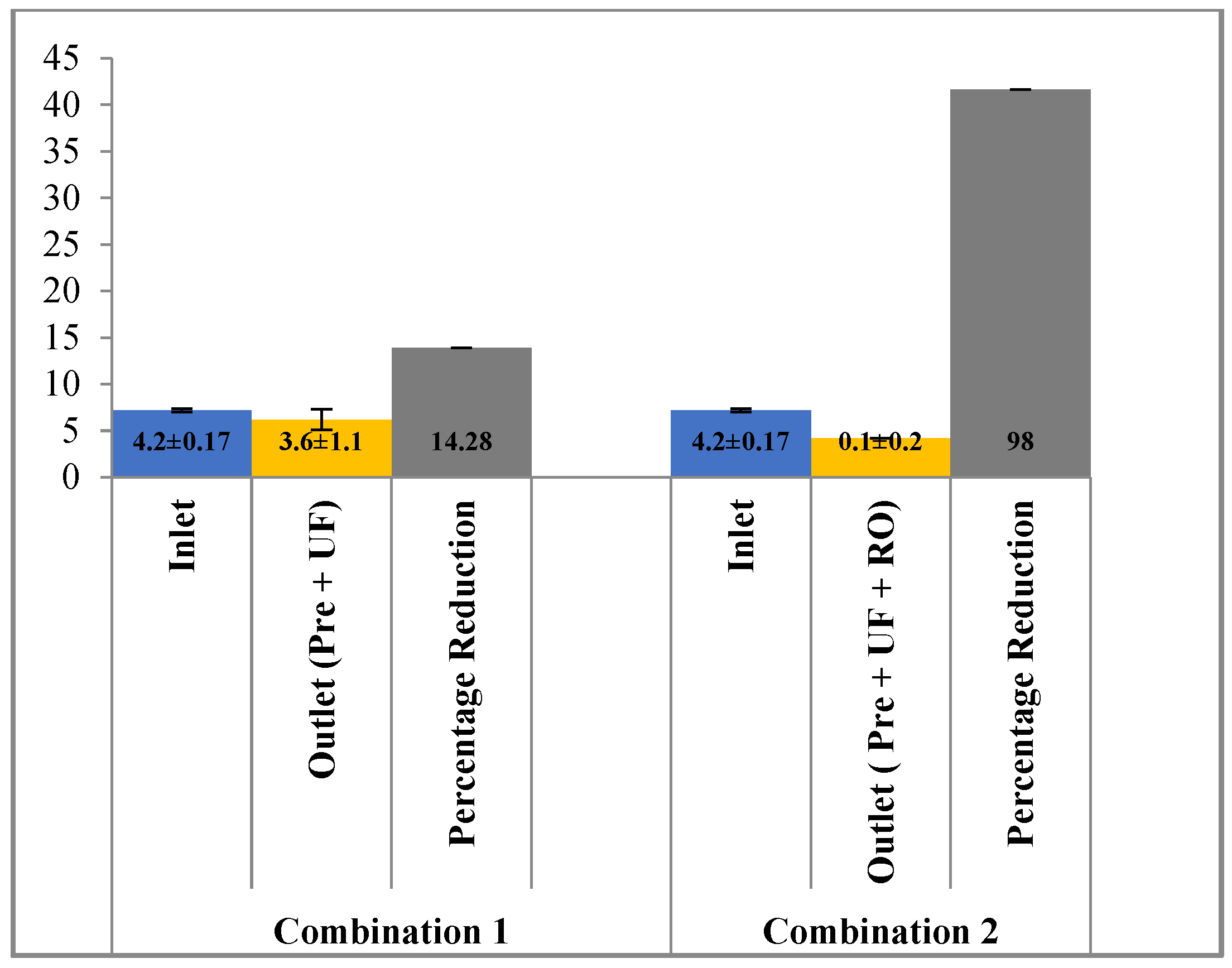

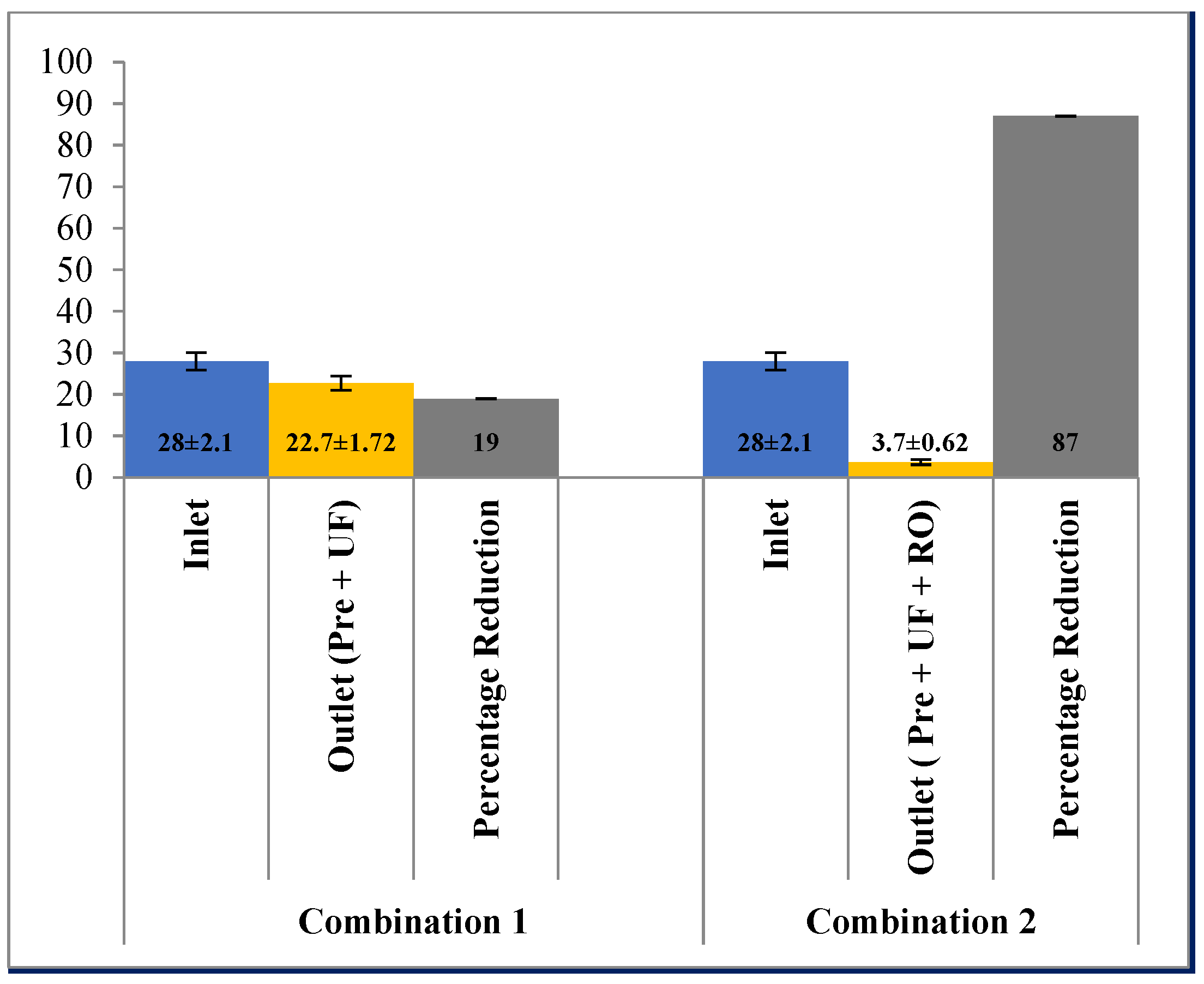

| Inlet (Secondary Clarifier) | 56 ± 0.96 | 2215 ± 88.26 | 216 ± 9.11 | 27 ± 0.56 | 412 ± 21.1 | 126 ± 7.71 | 7.46 ± 0.44 | 1365 ± 81.21 | 4.2 ± 0.17 | 28 ± 2.1 |

| Outlet (Pre-treatment+ UF) | 0 * | 1951 ± 56.45 * | 179 ± 10.76 * | 21 ± 0.71 * | 108 ± 10.2 * | 22 ± 1.01 * | 7.19 ± 0.12 * | 942.9 ± 79.37 * | 3.6 ± 1.1 * | 22.7 ± 1.72 * |

| Outlet (Pre-treatment+ UF + RO) | 0 * | 26 ± 1.70 * | 0 * | 0 * | 0 * | 0 * | 5.74 ± 0 * | 25.1 ± 3.15 * | 0.1 ± 0 * | 3.7 ± 0.62 * |

| Effluent from Different Processes | Tolerance for Water for Pulp and Paper Industry (BIS) | ||||||

|---|---|---|---|---|---|---|---|

| Water Quality Parameter | Effluent from Secondary Clarifier | Permeate from Pre-Filtration and Ultra- Filtration Unit | Permeate from Pre-Filtration, Ultra-Filtration and RO Unit | Ground Wood Paper | Kraft Paper Bleached | Soda and Sulfite Paper | High Grade Paper |

| Color | 615 | 176 | 0 | 20 | 15 | 10 | 5 |

| TDS | 1933 | 1784 | 0 | 500 | 300 | 300 | 300 |

| TSS | 36 | 0 | 0 | 25 | 25 | 25 | 10 |

| COD | 183 | 146 | 0 | NS | NS | NS | NS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dagar, S.; Singh, S.K.; Gupta, M.K. Integration of Pre-Treatment with UF/RO Membrane Process for Waste Water Recovery and Reuse in Agro-Based Pulp and Paper Industry. Membranes 2023, 13, 199. https://doi.org/10.3390/membranes13020199

Dagar S, Singh SK, Gupta MK. Integration of Pre-Treatment with UF/RO Membrane Process for Waste Water Recovery and Reuse in Agro-Based Pulp and Paper Industry. Membranes. 2023; 13(2):199. https://doi.org/10.3390/membranes13020199

Chicago/Turabian StyleDagar, Sumit, Santosh Kumar Singh, and Manoj Kumar Gupta. 2023. "Integration of Pre-Treatment with UF/RO Membrane Process for Waste Water Recovery and Reuse in Agro-Based Pulp and Paper Industry" Membranes 13, no. 2: 199. https://doi.org/10.3390/membranes13020199

APA StyleDagar, S., Singh, S. K., & Gupta, M. K. (2023). Integration of Pre-Treatment with UF/RO Membrane Process for Waste Water Recovery and Reuse in Agro-Based Pulp and Paper Industry. Membranes, 13(2), 199. https://doi.org/10.3390/membranes13020199