Integration of Ultra- and Nanofiltration for Potato Processing Water (PPW) Treatment in a Circular Water Recovery System

Abstract

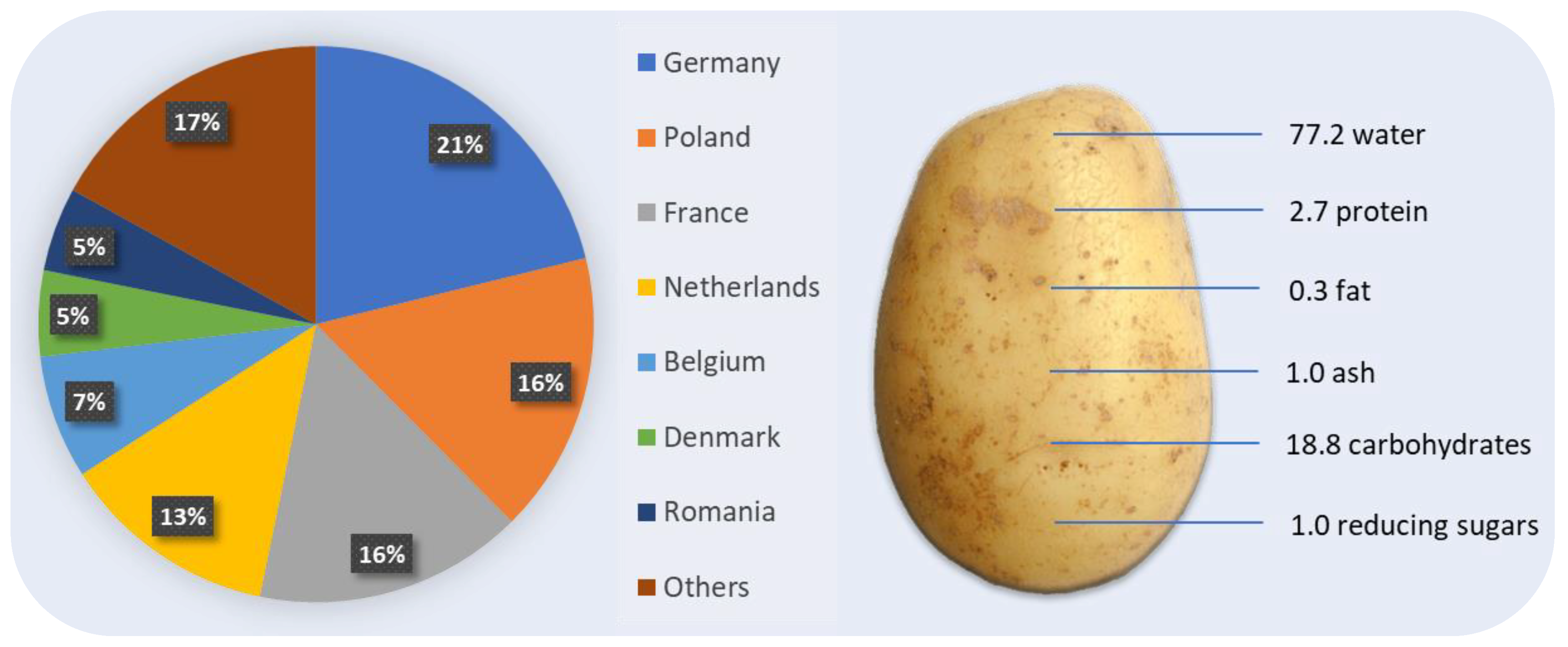

1. Introduction

2. Materials and Methods

2.1. Analytical Methods

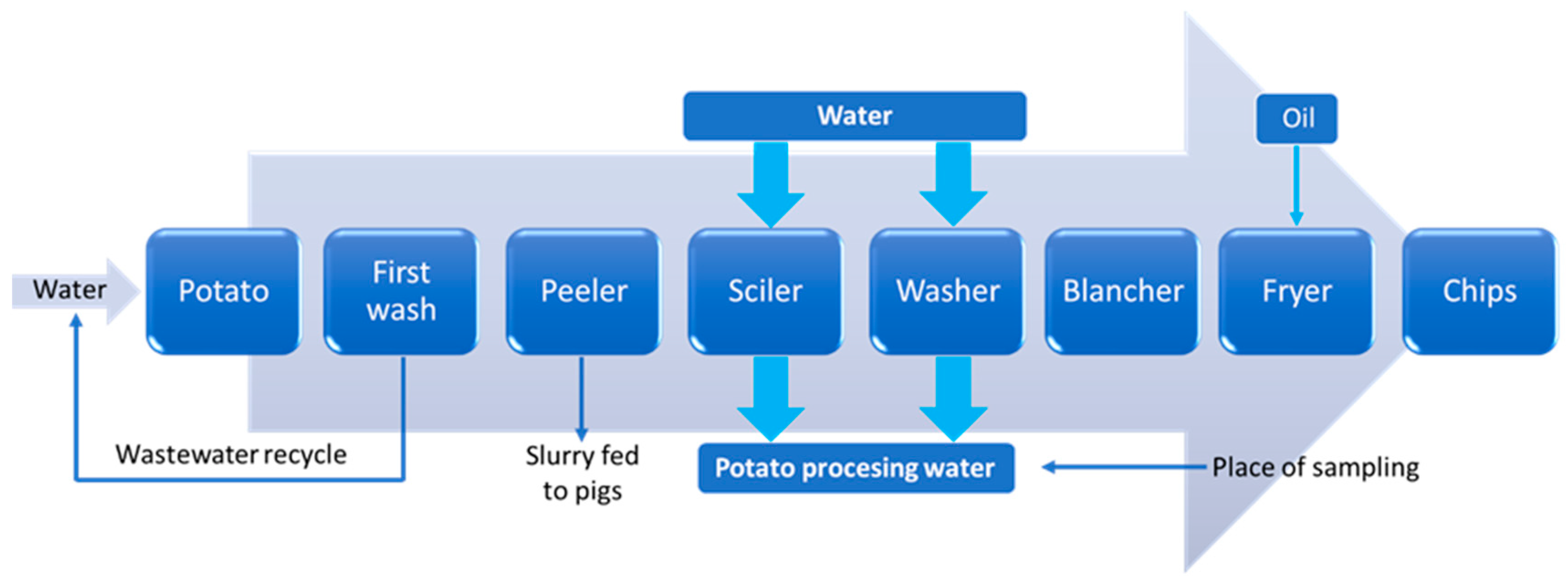

2.2. Characterization of the Potato Processing Wastewater (PPW)

2.3. Pretreatment

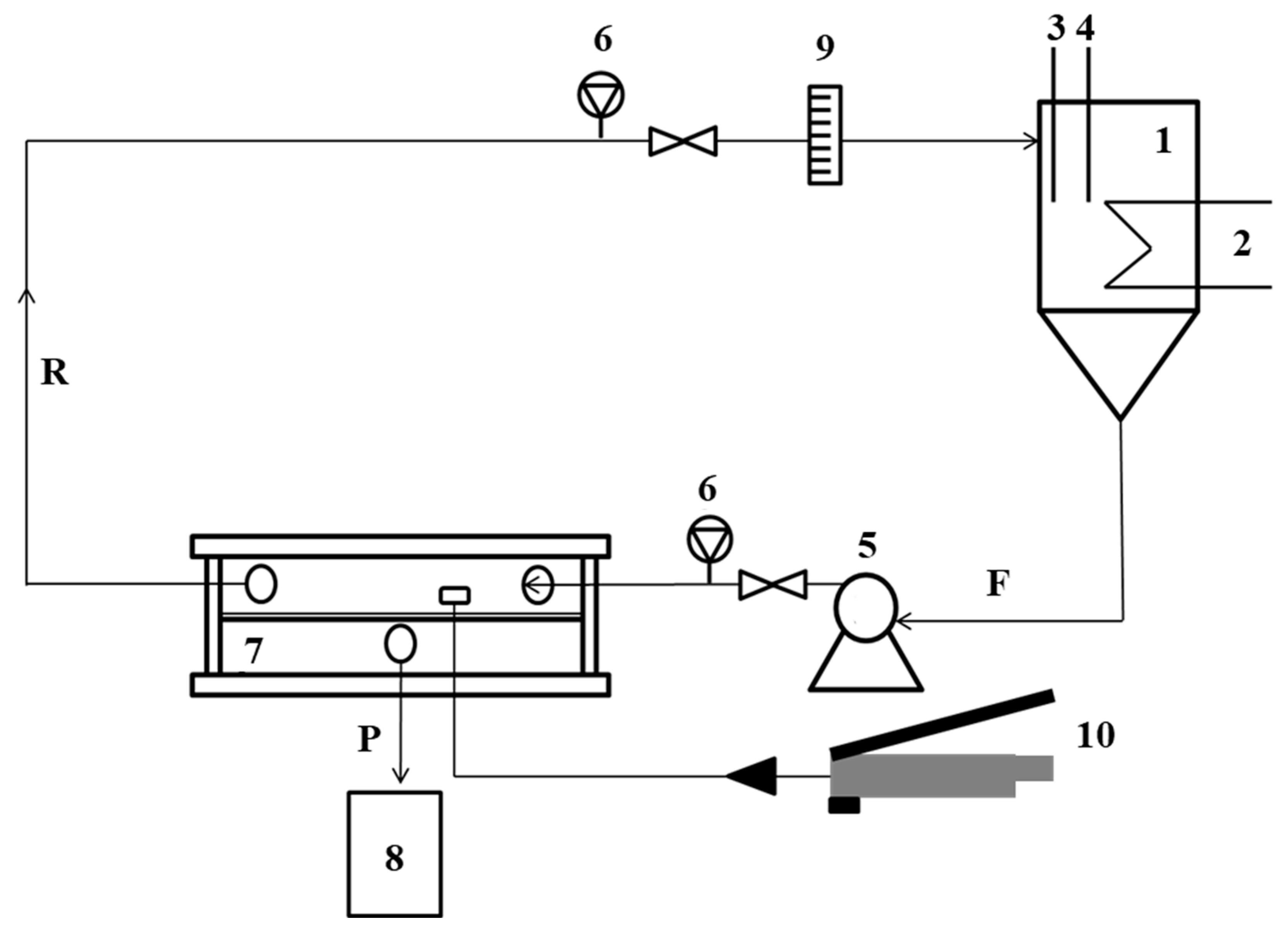

2.4. Membrane Filtration

2.5. UF Membrane Cleaning

- Deionized water (24 h),

- 0.5% sodium hydroxide solution (6.5 h),

- Deionized water (16 h),

- 0.03% hydrogen peroxide solution (6.5 h), and

- Deionized water (24 h).

3. Results and Discussion

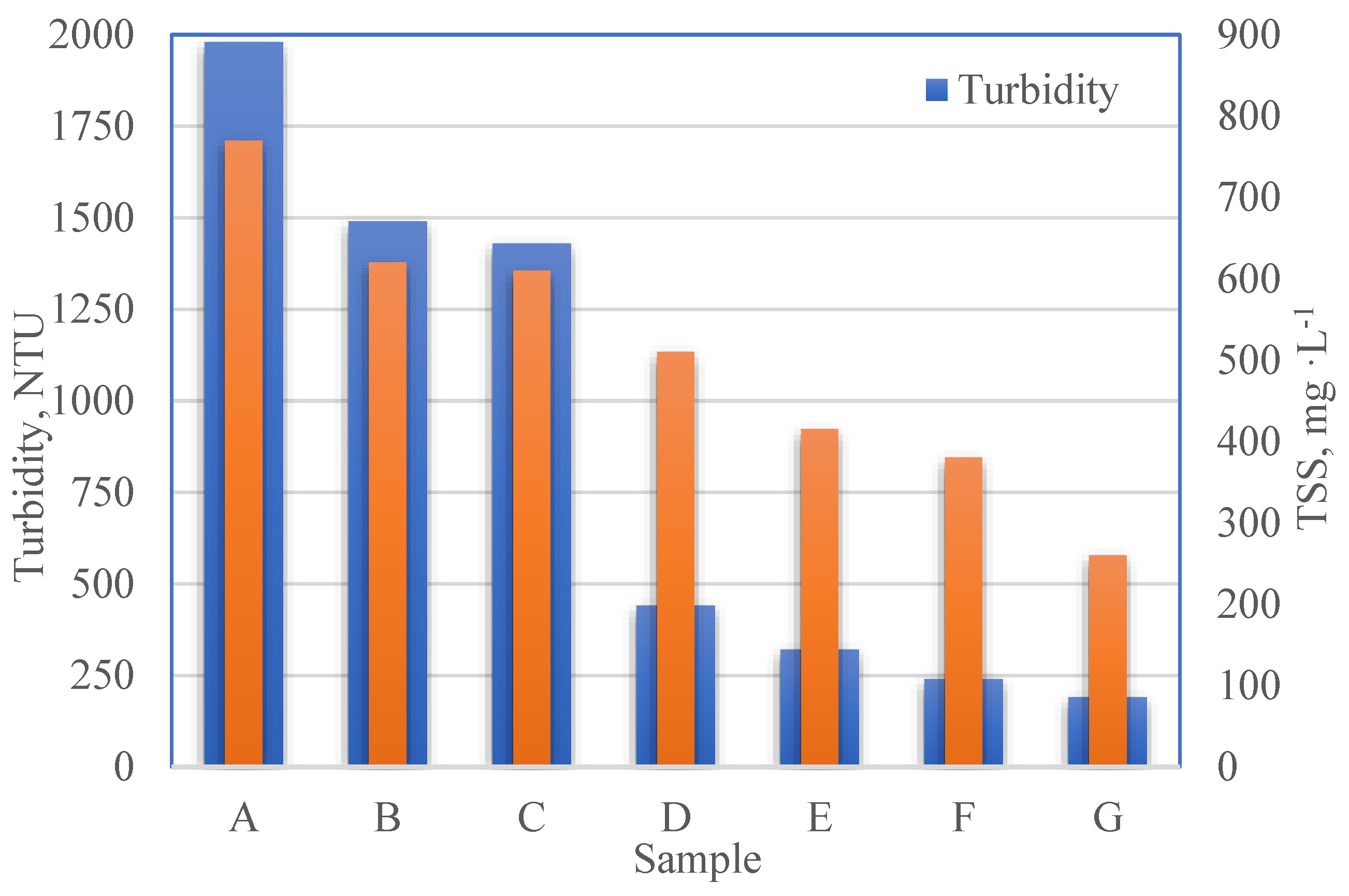

3.1. Pretreatment

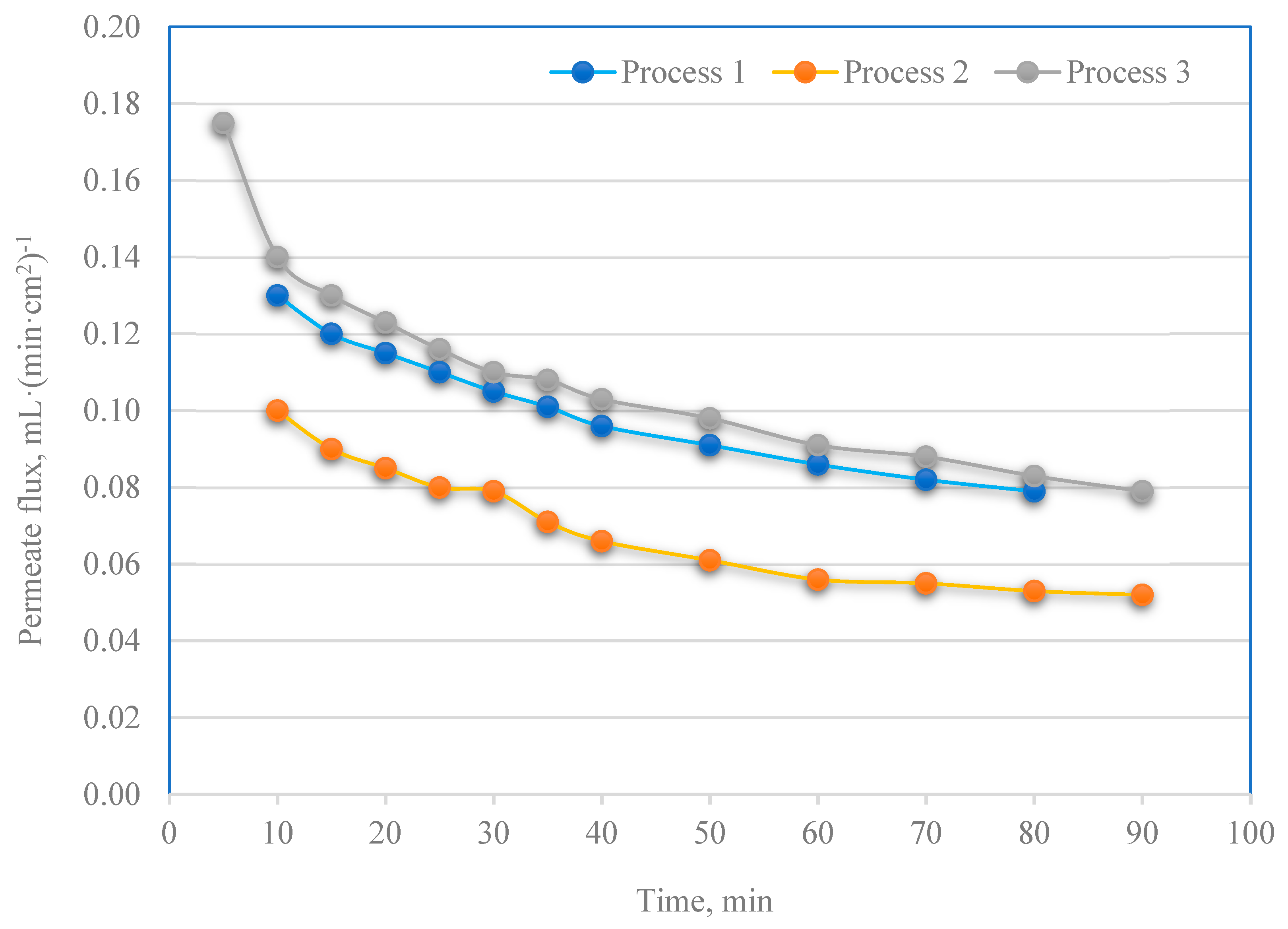

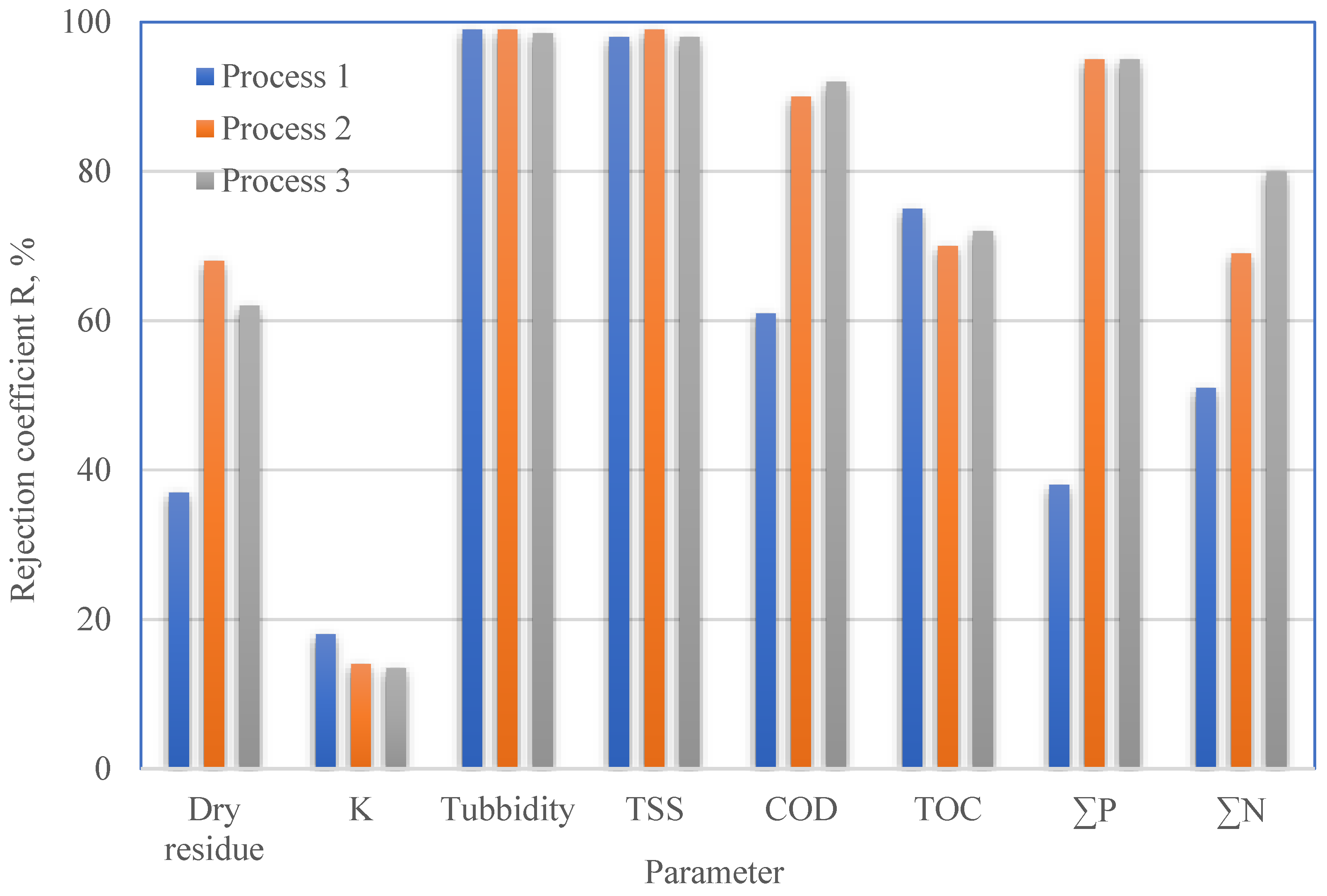

3.2. Ultrafiltration

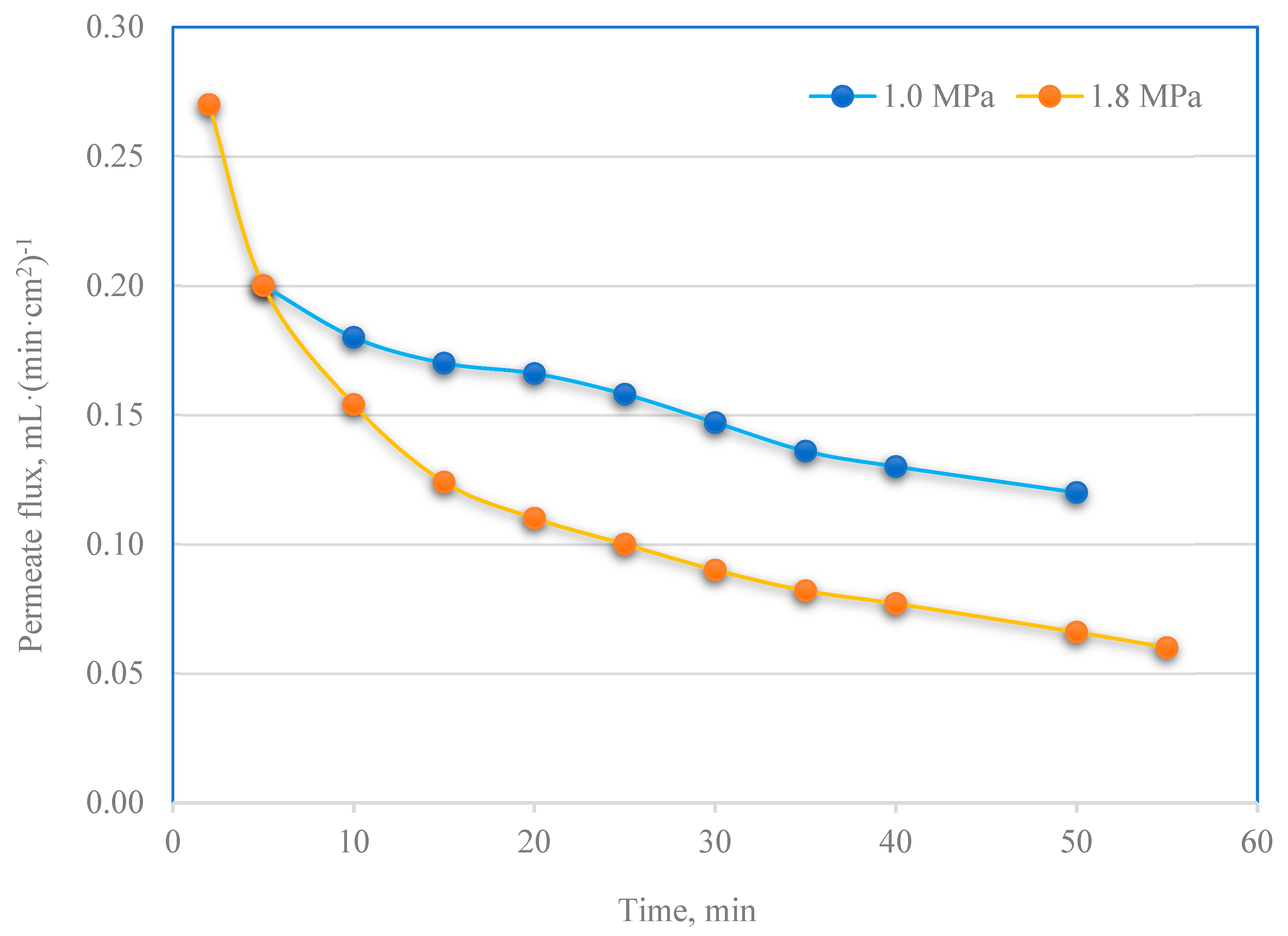

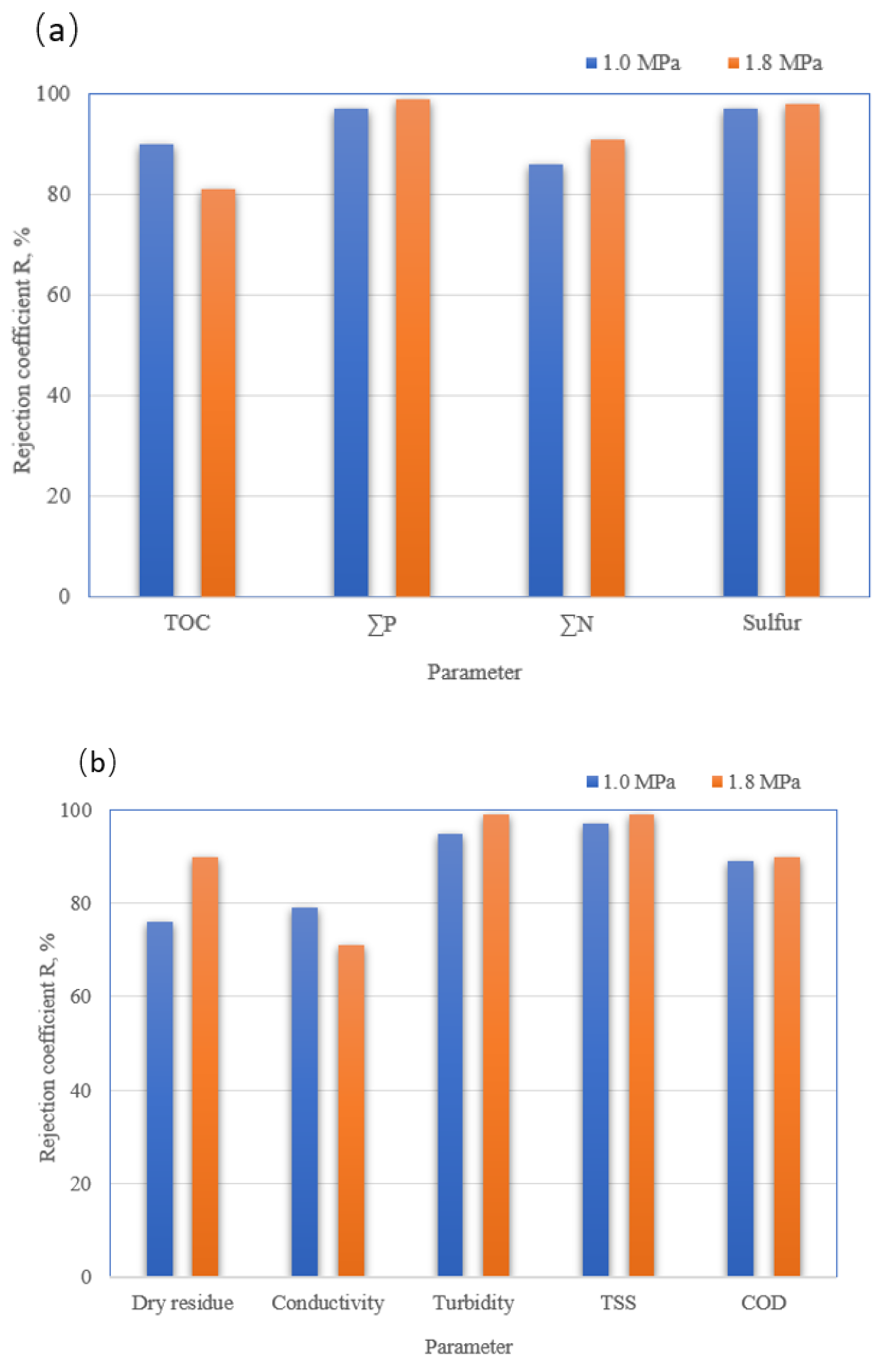

3.3. Nanofiltration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dabestani, S.; Arcot, J.; Chen, V. Protein recovery from potato processing water: Pre-treatment and membrane fouling minimization. J. Food Eng. 2017, 195, 85–96. [Google Scholar] [CrossRef]

- Bouchareb, R.; Bilici, Z.; Dizge, N. Potato Processing Wastewater Treatment Using a Combined Process of Chemical Coagulation and Membrane Filtration. Clean Soil Air Water 2021, 49, 2100017. [Google Scholar] [CrossRef]

- Pedreschi, F.; Cocio, C.; Moyano, P.; Troncoso, E. Oil distribution potato slices during frying. J. Food Eng. 2008, 87, 200–212. [Google Scholar] [CrossRef]

- Wang, L.K.; Hung, Y.; Lo, H.H.; Yapijakis, C. Potato Wastewater Treatment Waste Treatment. In The Food Processing Industry, 1st ed.; Taylor & Francis Group: Abingdon, UK, 2004; ISBN 9780429191091. [Google Scholar]

- Kobya, M.; Hiz, H.; Senturk, E.; Aydiner, C.; Demirbas, E. Treatment of potato chips manufacturing wastewater by electrocoagulation. Desalination 2006, 190, 201–211. [Google Scholar] [CrossRef]

- Zoutberg, G.R.; Eker, Z. Anaerobic treatment of potato processing wastewater. Water Sci. Technol. 1999, 40, 297–304. [Google Scholar] [CrossRef]

- Mishra, B.K.; Arora, A. Optimization of a biological process for treating potato chips industry wastewater using a mixed culture of Aspergillus foetidus and Aspergillus niger. Bioresour. Technol. 2004, 94, 9–12. [Google Scholar] [CrossRef]

- Wang, R.M.; Wang, Y.; Ma, G.P.; He, Y.F.; Zhao, Y.Q. Efficiency of porous burnt-coke carrier on treatment of potato starch wastewater with an anaerobic-aerobic bioreactor. Chem. Eng. J. 2009, 148, 35–40. [Google Scholar] [CrossRef]

- Kowalik-Klimczak, A. The possibilities of using membrane filtration in the dairy industry. J. Mach. Constr. Maint. 2017, 2, 99–108. [Google Scholar]

- Kowalik-Klimczak, A.; Stanisławek, E.; Grądkowski, M. Possibility of dairy wastewater regeneration in nanofiltration process. Chem. Eng. Equip. 2017, 56, 76–77. [Google Scholar]

- Chiang, H.; Pan, W.D. Ultrafiltration and Reverse Osmosis of the Waste Water from Sweet Potato Starch Process. J. Food Sci. 1986, 51, 971–974. [Google Scholar] [CrossRef]

- Chien-Hwa, Y.; Lung-Chen, F.; Shaik Khaja, L.; Chung-Hsin, W.; Cheng-Fang, L. Enzymatic treatment for controlling irreversible membrane fouling in cross-flow humic acid-fed ultrafiltration. J. Hazard Mater. 2010, 177, 1153–1158. [Google Scholar] [CrossRef]

- Ying, P.L.; Abdul, W.M. Effect of solution chemistry on flux decline during high concentration protein ultrafiltration through a hydrophilic membrane. Chem. Eng. J. 2010, 159, 91–97. [Google Scholar]

- Regula, C.; Carretier, E.; Wyart, Y.; Gésan-Guiziou, G.; Vincent, A.; Boudot, D.; Moulin, P. Chemical cleaning/disinfection and ageing of organic UF membranes: A review. Water Res. 2014, 56, 325–365. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Tal, G.; Hankins, N.P.; Gitis, V. Fouling and cleaning of ultrafiltration membranes: A review. J. Water Process. Eng. 2014, 1, 121–138. [Google Scholar] [CrossRef]

- European Commission Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Closing the Loop—An EU Action Plan for the Circular Economy, COM/2015/0614; European Commission Communication: Brussels, Belgium, 2015. [Google Scholar]

- Devereux, S.; Shuttleworth, P.S.; Macquarrie, D.J.; Paradisi, F. Isolation and Characterization of Recovered Starch from Industrial Wastewater. J. Polym. Environ. 2011, 19, 971–979. [Google Scholar] [CrossRef]

- Catarino, J.; Mendonça, E.; Picado, A.; Anselmo, A.; Costa, J.N.; Partidário, P. Getting value from wastewater: By-products recovery in a potato chips industry. J. Clean. Prod. 2007, 15, 927–931. [Google Scholar] [CrossRef]

- Chang, S. Anaerobic Membrane Bioreactors (AnMBR) for Wastewater Treatment. Adv. Chem. Eng. Sci. 2014, 4, 56–61. [Google Scholar] [CrossRef]

- Arogundade, L.A.; Mu, T. Influence of oxidative browning inhibitors and isolation techniques on sweet potato protein recovery and composition. Food Chem. 2012, 134, 1374–1384. [Google Scholar] [CrossRef]

- Schoenbeck, I.; Graf, A.M.; Leuthold, M.; Pastor, A. Purification of high-value proteins from particle containing potato fruit juice via direct capture membrane adsorption chromatography. J. Biotechnol. 2013, 168, 693–700. [Google Scholar] [CrossRef]

- Zhu, Z.; Yuan, F.; Xu, Z.; Wang, W.; Di, X. Stirring-assisted dead-end ultrafiltration for protein and polyphenol recovery from purple sweet potato juices: Filtration behavior investigation and HPLC-DAD-ESI-MS2 profiling. Sep. Purif. Technol. 2016, 169, 25–32. [Google Scholar] [CrossRef]

- Li, H.; Zeng, X.; Shi, W.; Zhang, H.; Huang, S.; Zhou, R.; Qin, X. Recovery and purification of potato proteins from potato starch wastewater by hollow fiber separation membrane integrated process. Innov. Food Sci. Emerg. Technol. 2020, 63, 1466–8564. [Google Scholar] [CrossRef]

- Janiszewska, J.; Rajewska, P. The possibility for the use of ultrafiltration for the treatment of potato processing water. J. Mach. Constr. Maint. 2017, 4, 131–139. [Google Scholar]

- Bosak, V.K.; VanderZaag, A.C.; Crolla, A.; Kinsley, C.; Miller, S.S.; Chabot, D.; Gordon, R.J. Treatment of farm potato wastewater with coagulation. Appl. Eng. Agric. 2017, 33, 95–101. [Google Scholar]

- Lee, J.; Jeong, S.; Ye, Y.; Chen, V.; Vigneswaran, S.; Leiknes, T.; Liu, Z. Protein fouling in carbon nanotubes enhanced ultrafiltration membrane: Fouling mechanism as a function of pH and ionic strength. Sep. Purif. Technol. 2017, 176, 323–334. [Google Scholar] [CrossRef]

- Chen, V.; Li, h.; Li, D.; Tan, S.; Petrus, H.B. Cleaning strategies for membrane fouled with protein mixtures. Desalination 2006, 200, 98–200. [Google Scholar] [CrossRef]

| Parameter/Analyte | Unit | Range of Determining Value | |

|---|---|---|---|

| Dry residue | % | 0.8–1.5 | |

| Conductivity | μS·cm−1 | 1187–1451 | |

| Turbidity | NTU | 496–2599 | |

| Total suspended solids | mg·L−1 | 1027–1584.7 | |

| COD | mg·L−1 | 3864–9275 | |

| TOC | mg·L−1 | 846–2243 | |

| ∑P (as PO43−) | mg·L−1 | 4.0–9.17 | |

| ∑N | mg·L−1 | 160.7–263.2 | |

| Microbiology | Total | pcs. mL−1 | 0.54–1.25 × 106 |

| including G− | 0.08–0.5 × 106 | ||

| Designation of the Sample | Preparation Method | Conditions |

|---|---|---|

| A | Raw wastewater | |

| B | Sedimentation | 2 h |

| C | Filtration through the bag filter | Pore diameter 5 µm |

| D | Centrifugation | 5 min |

| E | 10 min | |

| F | 20 min | |

| G | 30 min |

| UF | NF | |

|---|---|---|

| Membrane type | “Thin film” | “Thin film” |

| Polymer | polysulfone | polypiperazine amide |

| Cut-off [Da] | 10,000 | 150–300 |

| Pressure | 0.2; 0.4 MPa | 1.0; 1.8 MPa |

| Parameter/Analyte | UF Permeate | NF Permeate | Legal Standards | ||

|---|---|---|---|---|---|

| Water Intended for Human Consumption | Wastewater Discharged into Water or Soil | Wastewater Introduced into Sewage Equipment | |||

| Dry residue/% | 0.11–0.16 | <DL-0.03 | - | - | - |

| pH | 6.9–7.5 | 6.9–7.5 | 6.5-9.5 | 6.5–9.0 | 6.5–9.5 |

| Conductivity/μS cm−1 | 1008–1075 | 291–468 | 2500 | - | - |

| Turbidity/NTU | 2.7–5.3 | 0.1–0.6 | 1 | - | - |

| TSS/mgL−1 | 10.5–11.5 | 0 | - | 35 | * |

| CODCr/mgL−1 | 790–955 | 66.9–80.1 | - | 125 | * |

| TOC/mg L−1 | 188–192 | 35.2–98.9 | without abnormal change | 30 | * |

| ∑P/mg L−1 | 5.7–7.8 | 0.1–0.2 | - | 3 | * |

| ∑N/mg L−1 | 71.6–94.2 | 5.9–11.0 | - | 30 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajewska, P.; Janiszewska, J.; Rajewski, J. Integration of Ultra- and Nanofiltration for Potato Processing Water (PPW) Treatment in a Circular Water Recovery System. Membranes 2023, 13, 59. https://doi.org/10.3390/membranes13010059

Rajewska P, Janiszewska J, Rajewski J. Integration of Ultra- and Nanofiltration for Potato Processing Water (PPW) Treatment in a Circular Water Recovery System. Membranes. 2023; 13(1):59. https://doi.org/10.3390/membranes13010059

Chicago/Turabian StyleRajewska, Paulina, Jolanta Janiszewska, and Jakub Rajewski. 2023. "Integration of Ultra- and Nanofiltration for Potato Processing Water (PPW) Treatment in a Circular Water Recovery System" Membranes 13, no. 1: 59. https://doi.org/10.3390/membranes13010059

APA StyleRajewska, P., Janiszewska, J., & Rajewski, J. (2023). Integration of Ultra- and Nanofiltration for Potato Processing Water (PPW) Treatment in a Circular Water Recovery System. Membranes, 13(1), 59. https://doi.org/10.3390/membranes13010059